Deposits: miners need to dig deeper

• Shaft sinking can extend the life span of a mine, writes

Pedro van Gaalen

Global demand for metals and minerals will experience a six-fold increase by 2050 as the world transitions towards a carbonfree economy, according to the International Energy Agency. As such, mines risk their long-term sustainability if they do not take decisive action today to access additional orebody reserves.

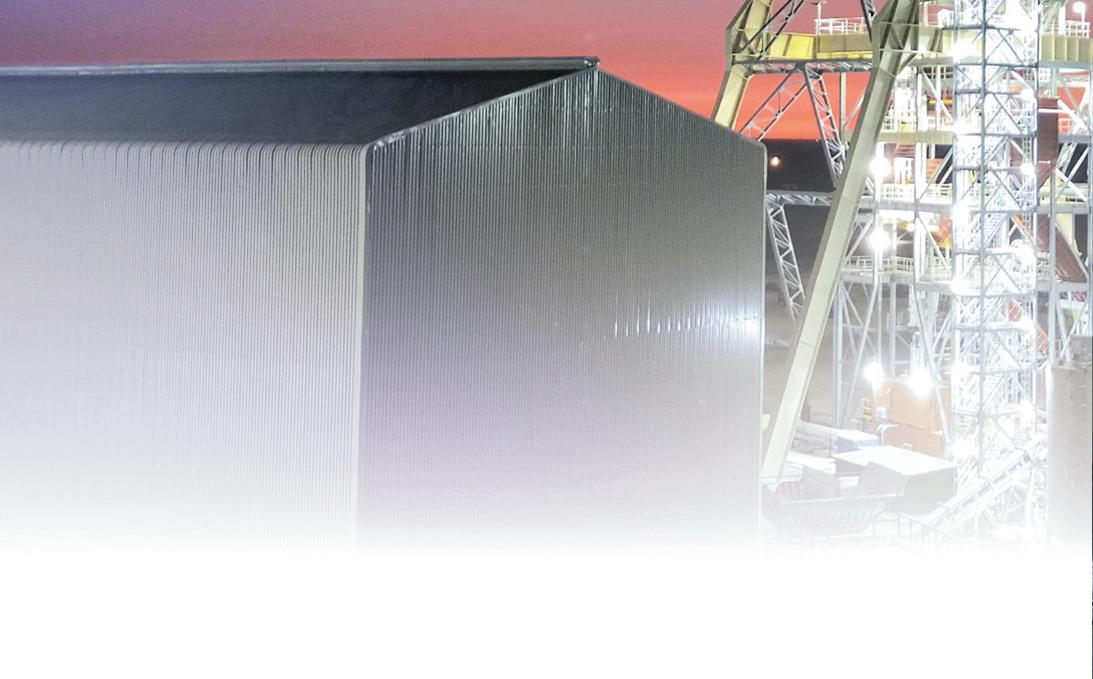

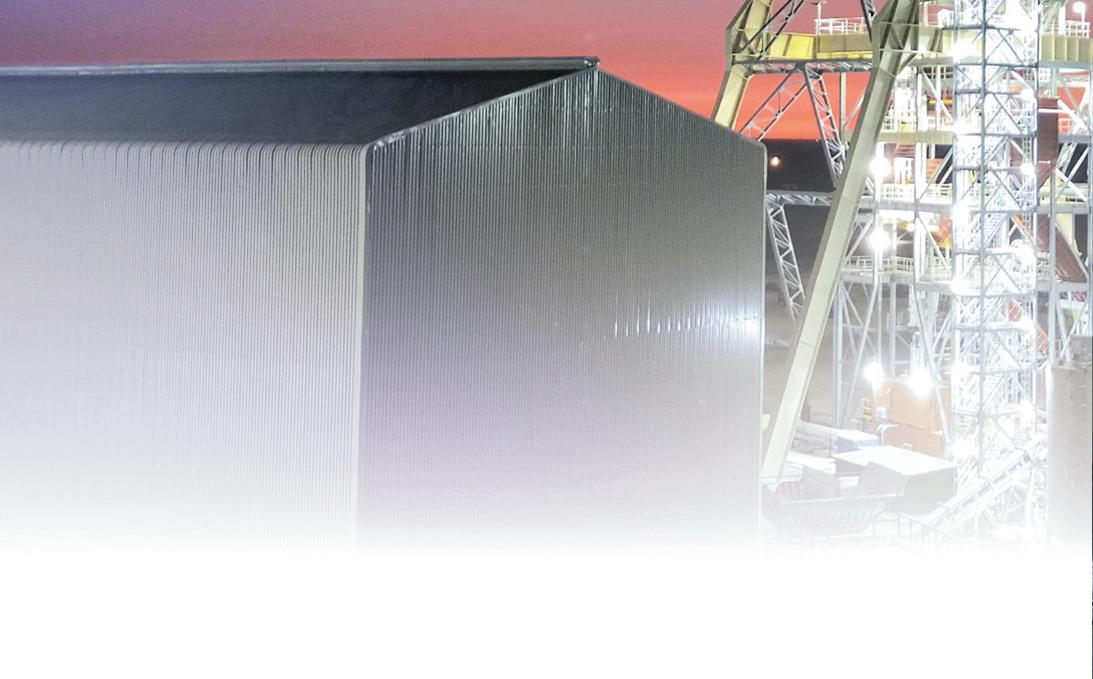

Due to the cost-efficiencies and shorter time to production, miners typically start with bulk surface mining operations,” says Digby Glover, CEO at United Mining Services (UMS) Group.

In this regard, spiral ramps and declines are popular, but these options only get miners so far. When surface-level reserves run out, miners generally seek other orebodies close to the surface rather than invest in shaft sinking due to the associated costs and lengthy times to completion.

Miners will often choose to venture into remote areas as shafts are considered a grudge purchase. However, establishing

remote operations can prove costly and complex, and if the miner cannot find another reserve, the company risks going bust.

Glover asserts that sinking a shaft is becoming increasingly necessary and can often make financial sense by extending the life span of amine by decades.

For example, UMS is sinking two shafts at an open pit mine in Botswana. This underground mine expansion project will extend the mine s operational life span from 2026 to 2040.

When miners realise they need to look deeper to access embedded orebody deposits, the decision to go underground often comes too late. The process should start as soon as possible as shaft sinking can take up to 10 years to progress from concept to ore extraction.

Focus on investment at indaba

Stakeholders in the African mining industry will gather at the Cape Town International Convention Centre (CTICC) from February 6-9 2023 to facilitate greater investment in the continent across the mining value chain.

power, continues Ford.

Yet miners often shelve capital expenditure on mine expansion projects in response to boom and bust cycles in the mining sector.

“These cycles usually play out over 10-year periods and typically result in a dearth of capital expenditure when commodity prices dip. While the sector recently experienced some reinvestment as the commodities supercycle gathered momentum, mines should always consider going underground independent of market sentiment, says Glover.

While there are complex factors at play across various commodities, miners need to start implementing plans to access additional high-grade orebody deposits now to ensure their long-term sustainability.

Faced with this reality, shaft sinking is gathering momentum globally, with Glover pointing out many projects, including multiple in the notoriously conservative Australian mining sector, as examples.

We also see opportunities in Europe, North and South America and Africa, he adds.

In certain circumstances, the sector is seeing a shift in the technology used in vertical boring, with various machines developed that can bore down directly to the orebody in suitable ground.

Anglo American is sinking

production and service shafts at its Woodsmith polyhalite project in the UK, using Herrenknecht s Shaft Boring Roadheader technology to reach depths of about 1,600m.

Applying technology to traditional shaft sinking methodologies also helps to significantly improve safety for mine workers.

The huge advances realised in terms of safety relate to how we sequence activities, and the ability to remove people from dangerous situations through remote operating capabilities, modern equipment and machine automation, For example, in the past, equipment such as the cactus grab proved dangerous when operated by people. Now, miners use remotely-operated grabbers to scoop material, but no workers are allowed on the shaft floor during the mucking cycle, which improves safety and productivity. Similarly, miners can also operate mechanised drilling remotely, thereby minimising the need for workers in the shaft bottom during the drilling cycle.

These technological advancements have drastically improved safety and productivity on conventional shaft sinking projects over the past 10 years, which remain the leading considerations on all projects, says Glover.

Held under the theme of Unlocking African Mining Investment: Stability, Security and Supply conference organisers plan to cover myriad topics affecting the industry in the year ahead.

The Mining Indaba is the only place where the community comes together to share perspectives and learnings that can spark change and, ultimately, drive investment, says Simon Ford, Portfolio Director for Investing

in African Mining Indaba. While ESG remains an investment imperative and the social licence to operate continues to underpin the Mining Indaba values, Ford believes that the new chapter unfolding in pan-African and global economies necessitates important dialogue between influential industry stakeholders

“The theme for 2023 captures the geopolitical shifts and economic disruptions creating pressure points and opportunities within African mining as global economies seek security of supply, especially for their own energy transitions, as well as raw materials and precious metals to bolster their economic

This year s programme will delve into integral economic empowerment strategies, ways to support supply chain security for the energy transition and seizing opportunities to capitalise on the commodities supercycle.

Numerous new initiatives and programmes will also debut this year. These include the Explorers Showcase, which will profile early-stage explorers to help stimulate conversations with investors, as well as the Junior MINE and the Official Government Leaders programmes.

We are also delighted to launch our new InfraTech @ Indaba content programme, which combines our previous

Mining 2050 and Infrastructure & Supply Chain streams into one platform,” adds Tom Quinn, Head of Content at the Investing in Mining Indaba. This conference track will showcase leading suppliers and experts involved with technology convergence, critical supply chains and infrastructure in the mining sector. Delegates can also attend mainstay content streams, including the Ministerial Symposium, Intergovernmental Summit, Green Metals Day, Sustainable Development Day, the General Counsel Forum and the Innovation & Research Battlefield, a unique platform for academic institutions and start-ups to showcase their latest ideas.

Companies act to secure long-term growth

The numerous global supplyside constraints fuelling the current commodities super cycle will likely persist for years, creating significant opportunities for South African mining companies to benefit from higher prices. However, multiple areas require focused investment over the coming decade to support continued sector growth, including access to reliable energy, transport and water infrastructure.

According to Arnold van Graan, Head: Markets Research at Nedbank CIB, miners have multiple avenues to fund these growth-supporting initiatives.

Unlock sustainable growth for mining Ļ Ħ ăĬĖ ēĖăĺ

The commodities boom that has run since 2017 has shored up balance sheets, and miners used this windfall to bring down debt and gearing levels and pay dividends to shareholders.

However, the sector has recently witnessed a shift in this capital allocation framework, with cash flush mining companies, especially those in the PGM universe, investing to continue generating strong cash flows and sustain growth into the future. We have subsequently seen an increase in capital expenditure on initiatives that add growth to portfolios.

According to Van Graan, these investments primarily focus on two areas. These include developing new projects and mergers and acquisitions (M&A).

We have already seen a rise

in capital expenditure to replace existing reserves and M&A activity as mining companies look to secure longer-term growth opportunities. Mining companies are also investing in embedded renewable energy generation capacity to help achieve their net-zero and ESG targets and decouple their reliance on Eskom for power. Mine operators will continue spending substantial amounts to diversify their existing energy mix, with many considering green funding mechanisms to realise these ESG-linked outcomes, concludes Van Graan.

INSIGHTS 5 BusinessDay www.businessday.co.zaFriday3February2023 36B 34B 32B 30B 28B 20222023202420252026202720282029 see money differently Ħ ă ŕŝřŕƠŔŔŔŔŔŝƠŔŚ ĝ Ō ĝ Ėĺ ĝ Ė ĝĦ Ė Ė Ħ ēĖăĺ Ė ঠLeader in large sustainability-linked loans for the mining sector by a South African bank. ĝ ĝē ĝĦ Ħ ēĖăĺ Ħ ĖăĬ Ħ Ł Ĭ ĝē ĦĖĬ ĝă ĬĦ ă ĝ ă ē ĝĝ Ħ ĺ ĝăĖŁ ĝ Ėĺ ĝ Ė Ħ ōăĻĝ Łă ĝ Ħ ēĖăĺ Ō ŀē ĖĦ ĝ Ħă ē Ĭ ă ĝĬĝĦ ĖăĻĦ ĦĖ ĦăĖŁ ăĖ Ħ ĬĦĬĖ ă Ė nedbank.co.za/cib-mining 32617

Sponsored content INVESTING IN AFRICAN

INDABA

ŀē ĖĦ ĝ

MINING

Digby Glover complex factors.

Arnold van Graan energy mix.

BusinessDay www.businessday.co.zaFriday3February2023 cib.absa.africa

Africa to capitalise on trends

Digitalisation helps improve margins

• Operators look to technology to reduce costs and boost productivity

Shirley Webber potential

Multiple global factors have aligned to create significant opportunities for mining companies in Africa.

Research by the African Development Bank highlights the significance of the sector for the continent, says Shirley Webber, Coverage Head of Resources & Energy at Absa CIB.

“The organisation estimates Africa’s extractive resources could contribute more than $30bn per annum in government revenue for the next 20 years and that revenues from recent hydrocarbon and mineral discoveries could contribute from 9% to 31% of additional revenues over the first 10 years of production for countries such as Ghana, Liberia, Mozambique, Sierra Leone, Tanzania and Uganda.

The abundance of green metals in Africa, such as lithium, nickel, graphite and cobalt, offers a prolific opportunity for the continent amid the growing urgency around achieving decarbonisation targets.

“These potentially gamechanging economic contributions for African countries will assist in driving development, but it is important we create an enabling environment that allows Africa to realise this potential, she says. Capitalising on the opportunities created by trends such as the just energy transition, decarbonisation and the resultant commodities super cycle will require focused investment by stakeholders in the private and public sectors, with capital set to follow sustainability. In this regard, investments that improve infrastructure to enhance export volumes have become a strategic imperative for African countries to maximise miningderived revenue.

According to the World Bank Container Port Performance report, which reviews 370 port operations globally, 10 African ports rank in the bottom 15. As a frontier market, it is perhaps unsurprising African countries are at the tail-end of this ranking. However, it is vital to get these ports working to realise the economic multiplier effect, says Webber.

According to the Axora Innovation Forecast 2022/23: Digital Transformation in Mining report, only 53% of mining organisations surveyed described their progress towards deploying a digital/ technology transformation strategy as advanced , which is 6% up on the 2021 figure.

However, the challenging global economic environment is sparking renewed impetus among mine operators to focus on margins, with many opting to invest in technological solutions to reduce costs, improve efficiencies and boost productivity and output.

“Investments need to pivot and miners must prepare to change how they think about generating value, says Anton Fester, Director at Sedna Industrial IT Solutions. Those who are patient and

play the long game will unlock extensive benefits if they find the right use cases to build value going forward.

In this regard, mine operators are increasingly considering how they can integrate technical expertise, industry experience and cutting-edge digital technologies to transform mining processes across the value chain to enhance performance and create more profitable operations.

In every scenario, cloudbased data is the foundational platform layer needed to build the solutions that can take mine operations from hindsight to insight and, eventually, to foresight through predictive intelligence” explains Willie Ackerman, chief sales and marketing officer at 4Sight Holdings. By converging operational technology and information

technology, miners can send all data to an extraction layer for visualisation across their full environment. A hosted application layer can then provide real-time analytics from systems and IoT-enabled machines and vehicles. Miners can then build predictive intelligence capabilities that deliver foresight through advanced technologies such as artificial intelligence and machine learning. At this stage in the digital transformation journey, mine

Core set of values act as a miner’s ‘north star metric’

While environmental, social, and governance (ESG) issues currently dominate boardroom discussions within the mining sector, energy efficiency, climate change and the journey to net-zero typically top the agenda

However, broader issues that pertain to social impact and the need for greater transparency in related disclosures are gaining importance.

As the relevance and necessity to address the social dimension of ESG-related issues grows, miners need to reframe their licence-tooperate (LTO) approach to create long-term value and positively impact the communities within which they operate.

“Overall, miners should move beyond LTOs as pure compliance issues and view them as a strategic advantage to enhance the security of supply by preventing unplanned work stoppages at facilities, says Hans Kuipers, MD and Partner at Boston Consulting Group Johannesburg.

Graeme Wilkinson, Senior Social Investment Specialist at impact management and advisory firm Tshikululu Social Investments, explains that a mine operator can strengthen

its position and create shareholder and stakeholder value by focusing on valuesbased leadership, partnerships and collaboration to grow the local economy.

“Establishing a core set of context-relevant values as a mining company is key to maximising impact for all stakeholders while extracting full value from the resources in the ground.

According to Wilkinson, these values act as the miner s north star metric and litmus test and frame the mine’s LTO. These values serve to rally all parts of the business around the creation and equitable sharing of value to all stakeholders says Wilkinson.

If the company s governing body ensures that it always remains true to its values statement and vision, this is half the battle won. From this, the miner will find it easier to remain agile, especially in stakeholder engagements, without losing focus on the long-term objectives. To this end, Kuipers believes that miners must provide input on how to maximise the impact of the capital allocated to community trusts to support mining communities. Better co-ordination between what is needed and enabling broader community engagement in the formulation of the social plan will help to positively impact communities by serving their holistic interests, he says. And, perhaps most importantly, mine operators should place as much emphasis on setting social impact targets that extend beyond the life of the mine as they do in setting production targets during the mine s life cycle, suggests Wilkinson The mine should immediately set about working with environmental, social and business partners to achieve all targets and, in so doing, ensure the relevance and sustainability of its LTO.

operators start using data to pre-empt issues, reduce unplanned downtime, inform decision-making and realise faster times to value for a better return on investment.

According to Wilhelm Swart, chief operations technology officer at 4Sight, data-driven predictive and prescriptive maintenance can create more efficient operations and improve mine safety.

Maintenance planning and task prioritisation support is vital to utilise allocate resources better and reduces reliance on people to monitor assets. This proactive maintenance response looks upstream and downstream to key assets for early detection to predict maintenance requirements with significant lead times and guide operators to the causes, he says.

For example, a predictive data solution implemented by 4Sight at a customer site detected a potential failure on an HPRC fixed roller bearing using various operational data inputs. Empowered with component and process

information, the maintenance team had about 20 days to intervene. After an inspection confirmed the bearing issue, the team performed regular greasing and scheduled a replacement.

“And it is also at the foresight stage that mine operators can take strategic decisions to work faster and smarter, adds Ackerman.

For example, a digital twin simulation conducted by 4Sight for a gold miner used a Demand Chain Management analysis to address transport bottlenecks and plan how to move material from the mine to the port more efficiently.

By analysing multiple factors, the solution determined that a combination of greater capacity with additional wagons for double-span trips, with longer shifts and an increase in travel

INVESTMENTS INTO AUTOMATION WILL DRIVE BOTTOM-LINE

VALUE

speed of 5km/hour, would reduce transit times and help maximise profits. Fester highlights additional technology-driven use cases in autonomous technology, connected worker solutions and private LTE networks within the mining sector.

Investing in a private LTE network instead of Wi-Fi can give miners an extra two hours of drilling time a day due to the resultant efficiencies. For instance, an autonomous haulage system deployment with 50% of production sites on private LTE reduced communication errors per truck by about 85%.

According to Fester, one site that undertook this deployment recorded a production increase of 255,013 tonnes annually. And an open-pit iron mine in Australia with more than 50 autonomous connected trucks reported a €10m saving from replacing about 150 Wi-Fi trailers with six radio cell LTE trailers on wheels. This resulted in a productivity increase of 75

hours a year per truck and 1.5million tonnes a year, resulting in top-line growth of more than €50m. Other benefits included lower operational costs thanks to fewer disruptions, lower fuel consumption and less downtime.”

In terms of automation and connected workers, Fester explains that these solutions can add value to mine operations by removing humans from dangerous environments while increasing productivity, enabling 24/7 operations and providing predictability.

“Investments into automation that focus on drilling and hauling and connected worker communication solutions to improve location services and biometric monitoring will drive bottomline value.

However, miners should not expect to realise all the value in one chunk, cautions Fester. Start with use cases with a neutral value and then create a roadmap that builds value going forward. Do not fixate on huge returns on investment upfront.

Tech, drones make mines safer

According to the Minerals Council South Africa, the number of fatalities in the local mining sector declined by 75% overall between 1995 and 2021, with fall-of-ground fatalities declining by 85%. Over the same period, total injuries decreased by 66%.

However, the mining industry s safety performance deteriorated in 2021 for the second consecutive year, with the number of fatalities and injuries increasing year on year.

The August 2022 Safety in Mining fact sheet released by the Minerals Council shows that fatalities regressed by 23%, increasing from 60 in 2020 to 74 in 2021. Injuries also increased by 11%, from 1,814 in 2020 to 2,014 in 2021.

In response, industry stakeholders have sought ways to improve safety performance on mine sites, with many miners turning to technology for solutions.

Open and underground mine operations pose various safety risks as workers may operate while activity continues above and around them. These circumstances create the potential for injuries and fatalities from ground fall or contact with equipment. In these environments, automating machinery offers an intelligent risk reduction approach that balances safety

without compromising output.

Murray Macnab, Group Technical Director at UMS Group, explains that the greatest risks arise when heavy machinery operates while workers are in close proximity.

When mines operate machines remotely, with no human activities undertaken in parallel, they can effectively elevate productivity without compromising safety, he says.

Kevin Naicker, Partner at Boston Consulting Group, Johannesburg, highlights additional ways that technological innovations are

75% the overall decline in the number of fatalities in the local mining sector between 1995 and 2021, with fall-ofground fatalities declining by 85%

ESG initiatives must ‘deliver real impact’

Mining executives continue to grapple with environmental, social and governance (ESG) issues, including decarbonisation, their social licence-to-operate (LTO) and compliance with everincreasing regulatory and reporting requirements.

In the White & Case 2022 Mining & Metals market sentiment survey, 40% of respondents viewed ESG issues, including climaterelated activism and regulations, as the most significant business risk.

Notwithstanding these challenges, three-quarters of businesses surveyed in the 2022 Mazars C-suite barometer planned to boost their ESG focus by investing in sustainability initiatives.

However, these ESG commitments must extend beyond environmental compliance and regulatory boxticking to deliver real impact.

According to the Deloitte Tracking the Trends 2022 Redefining Mining report, mining companies should apply an ESG lens for smart capital allocation and think holistically to ensure their capitalallocation decisions reflect their ESG commitments.

In relation to the mining

sector s environmental impact, a recent review by WSP of public ESG commitments made by 12 of the top international mining companies revealed various trends.

Notably, decarbonisation is one of the foremost commitments global mining companies are making. Even more encouraging is that addressing climate change, renewable energy and incorporating sustainability into decision-making rank in the top five says Ralph Heath, MD: Earth & Environment Africa at WSP. Mine operators are also increasingly required to integrate environmental

sustainability disciplines across the mine life cycle, including the planning, operating and mine closure phases, says Andrew van Zyl, incoming MD of SRK Consulting (SA).

“Project teams should pursue engineering solutions with early-stage input on pressing issues such as water stewardship, climate action and energy efficiency. Mining companies must not only pay attention to mitigating their own impacts by decarbonising operations, but must also adapt to the inevitable effects of climate change, he said.

According to Van Zyl, early gains in decarbonisation include the move by numerous South African mines to self-provision electricity by developing their own renewable energy generation solutions.

Alternatively, they are partnering with energy providers or broadening their corporate mandates to acquire businesses that specialise in renewable energy.

Growing social concerns relate to the impact mining and other industrial projects have on society. Many segments of society are increasingly mobilising around human rights, labour practice and anticorruption measures, says

Dr Vidette Bester, Senior Social Scientist at SRK Consulting.

This has raised the potential for stakeholder concerns to boil over into serious disruptions and delays, and even collapse projects,” adds Bester. Furthermore, financial institutions increasingly require details from borrowers regarding their social impact, along with other ESG measures.

helping to reduce risks in the mining industry.

There is increasing adoption of digital tools within the health, safety and environment (HSE) space. A specific example entails the use of realistic virtual reality simulations to onboard new employees, refresh returning employees and retrain underperforming employees on health and safety rules and regulations. Drones have also emerged as invaluable tools in the mining sector. Mine operators already integrate drones across on-site operations to perform various

tasks such as stockpile measurement, surveying, mapping and inspections. With regard to HSE, Naicker says drones can monitor air quality and working conditions within underground and surface mining operations. Applying this emerging technology in the underground mining environment can help protect workers while simultaneously reducing the time typically taken to conduct these checks in the traditional manner and thus positively impact productivity,” he concludes.

75% of businesses surveyed in the 2022 Mazars

C-suite barometer planned to boost their ESG focus by investing in sustainability initiatives

Financial institutions, regulators and investors are all aware of the risks posed by poor ESG performance, such as the reduced ability to finance and obtain operating permits, says Heath. The result is ESG factors are now viewed as a key part of investment due diligence and have begun to affect other financial areas, such as a company s eligibility for insurance, loans and securities, and the ability to attract and retain staff. Heath affirms a dedicated ESG programme will likely result in decreased operational risks alongside enhanced social value, as well as increased productivity through automation and digitalisation, and reduced water usage.

From a governance perspective, regulators in the European Union (EU) and North

America are looking to introduce stringent new rules on reporting with new standardised international metrics to measure ESG. South African miners will have to comply with the new EU Corporate Sustainability Reporting Directive (CSRD) if they wish to continue exporting to EU countries, says Bongiwe Mbunge, Partner for Sustainability Services at Mazars in SA.

As a major exporter of many minerals into Europe, these regulations will become critical, as noncompliance will impact business performance.

The CSRD mandates that disclosed information is proportionate to the scale of the risks and impacts related to sustainability matters of each sector, acknowledging that sectors such as mining are riskier than others.

The CSRD prioritises the development of specific disclosure standards for highrisk sectors including mineral, oil and gas extraction, which we welcome says Mbunge. Consequently, sustainable mining and the just energy transition will not be possible without full transparency from mining, oil and gas companies on their extraction projects.

7 BusinessDay www.businessday.co.zaFriday3February2023 UNITED MINING SERVICES GROUP UMS Call Center +27 (0)11 445 4300 E-mail Web S for all and for mining and projects. Solving and mineral processing challenges INSIGHTS: INVESTING IN AFRICAN MINING INDABA

Andrew van Zyl adapt.

Anton Fester build value.

Graeme Wilkinson litmus test.