MARCH / APRIL 2024 R39.90 (incl VAT) International R44.50 (excl tax) AECI Limited Group CEO Holger Riemensperger 100 years: AECI’s track record in SA 5 000: Delayed SAMRAD applications in 2022 100 NOT OUT AECI LOOKS TO THE FUTURE MIN NG READ WHAT REALLY GOES DOWN IN SADC SA www.samining.co.za INSIDE: Energy management standards boost productivity CONFLICT RESOLUTION IN CIVIL ENGINEERING CENTRALISE DATA AND SAVE LIVES JUNIOR MINERS The new cadastre system

PROVEN PERFORMANCE Polyurethane Coatings and Repair Technologies A unique plural component cartridge spray system for our LVHS series sprayable coating products. U-Spray is a simple application technique with minimal component involvement. The cartridge system is excellent for small project coating applications the perfect solution for field coating repair jobs. NORMAC U-Repair Polyurethane products are designed for quick accurate mixing with long lasting results for conveyor belting and supporting parts. Packaged for easy-on ratio mixing using either our dual cartridge dispensing system or hand mixing can kits. Contact our Local Agent: Tel. 074.143.7870, admin@rdtengineering.co.ca Innovative Solutions for Exceptional Protection and Versatility Learn more at normacadhesives.com

of long steel plants in SA likely to reduce demand for zinc

FEATURES

18 Energy

Internationally accredited energy management standards can reduce production downtime, share price reduction of production targets, and drive up ESG achievements.

24 Minerals Processing

In theory, the new mining cadastre system should significantly improve licence applications for junior miners, but for these players, many of the underlying challenges of SAMRAD remain.

28 Materials Handling & Logistics

The Ctrack Transport and Freight Index recorded a notable decline in the logistics sector at the start of 2024 – but thanks to the transport industry, it is not all doom and gloom.

32 Green Mining

The key focus of the recent Mining Indaba was on sustainability and the JET. We look at some of the key issues around these subjects raised by the delegates.

34 The Digital Mine

The importance of centralised data management in the mining sector, and how this drives both competitive advantage and improved safety. NEWS IN NUMBERS

8 100 years: AECI’s track record in SA 24 5 000: Delayed SAMRAD applications in 2022

REGULARS

4 Out of Africa

VIEW OUR 2024 CALENDAR https://issuu.com/sundaytimesza/docs/2024_calendar_a2

CONTENTS MARCH / APRIL 2024 MARCH APRIL 2024 R39.90 (incl VAT) International R44.50 (excl tax) AECI Limited Group CEO Holger Riemensperger 100 years: AECI’s track record in SA 5 000: Delayed SAMRAD applications in 2022 100 NOT OUT AECI LOOKS TO THE FUTURE MIN NG READ WHAT REALLY GOES DOWN IN SADC SA www.samining.co.za INSIDE: Energy management standards boost productivity CONFLICT RESOLUTION IN CIVIL ENGINEERING CENTRALISE DATA AND SAVE LIVES JUNIOR MINERS The new cadastre system COVER STORY: PAGE 8 In business for more than a century, AECI’s latest plans are to expand its international footprint further, transform digitally, and drive important net zero goals. www.linkedin.com/company/samining/ businessmediamags.co.za/mining/sa-mining/subscribe/ www.samining.co.za or www.businessmediamags.co.za www.facebook.com/businessmediaMAGS/company/samining/ twitter.com/BMMagazines www.instagram.com/business_media_mags/ 18 24 Will the new cadastre system work for the junior mining industry? How energy management standards can impact load shedding. COMPETITION WINNER! Maxene Gene Daly Page 11 Your Partner in Coal Mining IN BRIEF

Closure

6

WCENTRALISE YOUR DATA AND MINE IT EFFECTIVELY

Effectively leveraging data can boost safety, productivity and smoother operations. The key for mines lies in centralising their data management.

Rodney Weidemann

e live in a digitally transforming world, and mining – like most other industries – should be doing its utmost to leverage the benefits such transformation can bring.

Ask any technologist and they will tell you that “data is the new oil”, meaning it is the single most valuable resource a business has.

By placing data at the heart of modern mining, this resource can be utilised to ensure smoother operations, safer working conditions, and significantly improve productivity. However, thanks to the disparate nature of their operations, mines face numerous challenges in centralising their data, a central requirement to e ective management and use of this information.

In this issue, we consider these challenges, as well as the impact on the mine when flawed data is used, and the massive benefits that can be derived from the e ective centralising of data management.

implemented as soon as possible, as an e ective system that provides access to the right prospecting, licensing and other critical data in one place will be a crucial step forward. It will help juniors reduce both the costs and costly delays that currently make it extremely tough for them to properly compete in the South African mining industry.

The announcement that SA will implement a new cadastre system was received with joy by the industry, especially the junior mining sector, as in theory, the new mining cadastre system should significantly improve licence applications for these players.

However, it is vital that this solution be

We also consider how internationally accredited energy management standards can reduce production downtime, share price reduction of production targets, and drive up environmental, social and governance (ESG) achievements. Essentially, energy management allows organisations to understand their significant energy uses – those assets that consume the most amount of energy. Standards, meanwhile, provide guidelines, requirements and calculations to help them understand the current energy baseline.

EDITOR

Rodney Weidemann

Tel: 062 447 7803

Email: rodneyw@samining.co.za

ONLINE EDITOR

Stacey Visser

Email: vissers@businessmediamags.co.za

ART DIRECTOR

Shailendra Bhagwandin

Tel: 011 280 5946

Email: bhagwandinsh@arena.africa

ADVERTISING CONSULTANTS

Ilonka Moolman

Tel: 011 280 3120

Email: moolmani@samining.co.za

Tshepo Monyamane

Tel: 011 280 3110

Email: tshepom@samining.co.za

PRODUCTION COORDINATOR

Neesha Klaaste

Tel: 011 280 5063

Email: neeshak@sahomeowner.co.za

SUB-EDITOR

Andrea Bryce

In the field of civil engineering, it is vital to uphold equity and stability. To accomplish this goal, e icient conflict resolution is essential, and we look at the crucial role played here by the Bargaining Council for the Civil Engineering Industry.

On the environmental side, a columnist suggests that in order to safeguard Africa’s financial future, it is critical that regulators take an approach that – while recognising the massive potential of Africa’s natural environment and resources – also takes nature-related environmental risks into account.

Recognising the importance of shi ing from a carbon-based economy, the recent Mining Indaba placed a strong focus on the Just Energy Transition (JET). We take a look at some of the issues raised by the various delegates around the di erent concerns regarding both the JET and the closely related matter of sustainability.

Finally, in our cover story, AECI celebrates its centenary in South Africa, looking back on 100 years of success, and outlines its vision of where it aims to go in the next century of its existence. This future path includes expanding its international footprint further, focusing strongly on digital transformation, and driving its critically important net zero goals.

BUSINESS MANAGER

Claire Morgan

Tel: 011 280 5783

Email: morganc@sahomeowner.co.za

GENERAL MANAGER MAGAZINES

Jocelyne Bayer

SWITCHBOARD

Tel: 011 280 3000

SUBSCRIPTIONS

Neesha Klaaste

Tel: 011 280 5063

Email: neeshak@sahomeowner.co.za

PRINTING

CTP Printers, Cape Town

PUBLISHER

Arena Holdings (Pty) Ltd, PO Box 1746, Saxonwold, 2132

Copyright Arena Holdings (Pty) Ltd. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic or mechanical, without prior written permission. Arena Holdings (Pty) Ltd is not responsible for the views of its contributors.

FROM THE EDITOR

MIN NG READ WHAT REALLY GOES DOWN IN SADC SA www.samining.co.za

We offer the following affordable quality services and products:

Motor engineering (Deutz, Perkins, Cummins, Detroit and all other engine types)

Parts Engine Re-manufacturing

Car, LDV, truck, bus and heavy duty vehicle service & repairs

Diesel fuel injection services (Bosch accredited)

Field services (mining and other onsite services)

SOUTH AFRICA PRODUCES ANOTHER INTERNATIONAL ENGINEERING WINNER

South African engineer Neo Hutiri was recently selected as the best of the best out of 10 years of the Africa Prize for Engineering Innovation. He initially won the Africa Prize in 2019, and was recently awarded the Royal Academy of Engineering’s 10th anniversary medal, beating nine previous Africa Prize alumni from Nigeria, Kenya, Uganda, Ghana and Cameroon.

The medal comes with more than R1-million (UK £50 000) to boost his business, Technovera, which makes Pelebox smart lockers to improve access to medication for chronic diseases, including tuberculosis and HIV.

He says these lockers work in African countries where national health ministries need to reach more people, but are limited by the number of traditional healthcare facilities, sta shortages, and higher patient volumes.

“Pelebox smart lockers o er convenient collection points and are now operational across South Africa, Botswana, and Namibia. We have shown that we can take a patient from three hours in a queue and get them to collect their medication in under 30 minutes. Pelebox smart lockers are now operational across 123 communities and are impacting the lives of 32 000 patients per month,” says Hutiri.

AFRICA’S LARGEST GOLD MINE IS NOW ALSO ONE OF ITS GREENEST

Kibali, the largest gold mine in Africa, is now also one of the greenest mines on the continent, according to Barrick president and chief executive Mark Bristow. He notes that much of the electricity that drives Kibali is already supplied by its three hydropower stations.

Once the mine’s new 16 megawatt solar plant and additional battery energy storage infrastructure, designed to back up the hydropower supply during the region’s dry season, are commissioned, it’s expected the mine’s overall renewable electricity supply will increase from 81% to 85%. And for six months of the year its electricity demand will be met entirely by renewable energy.

“Bearing in mind that Kibali is also a leader in automation, the mine is a real role model for mining in Africa. As a long-standing partner of the Democratic Republic of the Congo (DRC), we built Kibali in the remote north-east of the country, opening up a new mining frontier and, in the process, also promoted the development of a flourishing local economy,” Bristow says.

“This partnership has been particularly beneficial for the DRC. Our total in-country investment to date in the form of royalties, taxes, dividends and payments to local suppliers amounts to $4.7-billion.

“The implementation of community development projects supported by Kibali’s community development fund, which contributes 0.3% of revenue to such projects, continues with 44 new projects launched in 2023.”

He says the mine’s new Cahier des Charges scheme, funded by Kibali to the tune of $8.9-million over five years, has also launched 11 projects, with seven nearing completion. Furthermore, Barrick is also continuing its support for biodiversity, with plans underway to introduce additional white rhinos to the Garamba National Park.

Operationally, Kibali achieved its production guidance for 2023, and set a new annual throughput record in the process. It is also well on track to again successfully replace the reserves mined during the year.

“Kibali is a standout example of what can be achieved through our commitment to partnering with our host countries and local communities, and we stand ready to work with the government to grow our investments and development projects in the DRC,” says Bristow.

www.samining.co.za 4 SA MINING MARCH / APRIL 2024 OUT OF AFRICA

© ISTOCK –Kumer © ISTOCK –PeopleImages

THE NEW LAND CRUISER 70 SERIES

STILL THE MASTER

Introducing the new Land Cruiser 70 Series. Equipped with a new rugged grille and bumper with a black finish, refined styling, improved safety* and convenience features* and LED fog lamps, the new Land Cruiser 70 Series has been upgraded to suit the present-day, while retaining the durability and reliability that have made it the master of Africa for so many years.

When it comes to performance, the new Land Cruiser 70 Series delivers incredible power throughout the range, which now has a more fuel-efficient, 2.8 ℓ turbo-diesel model added to the line-up.

No matter the task or the terrain, the new Land Cruiser 70 Series is Still the Master.

*Available on selected models

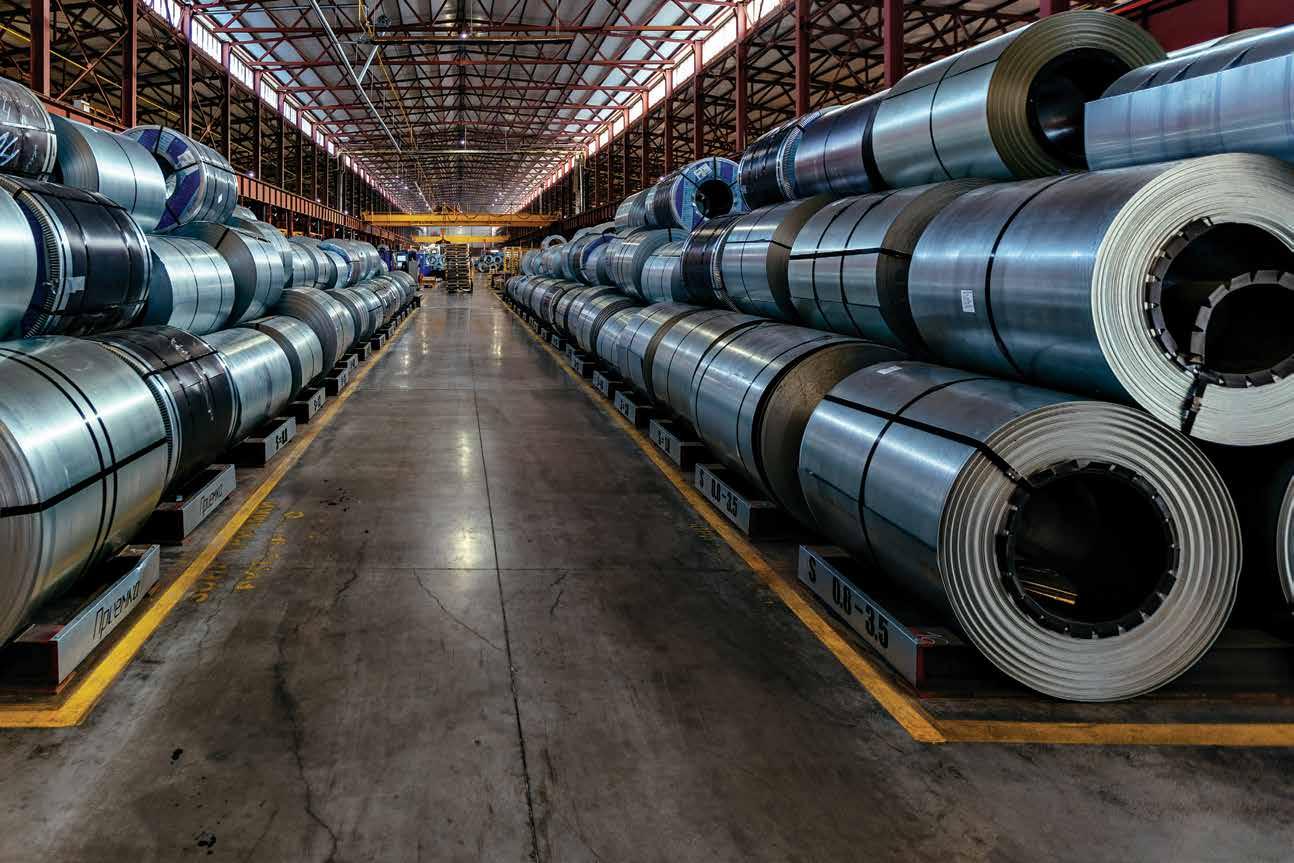

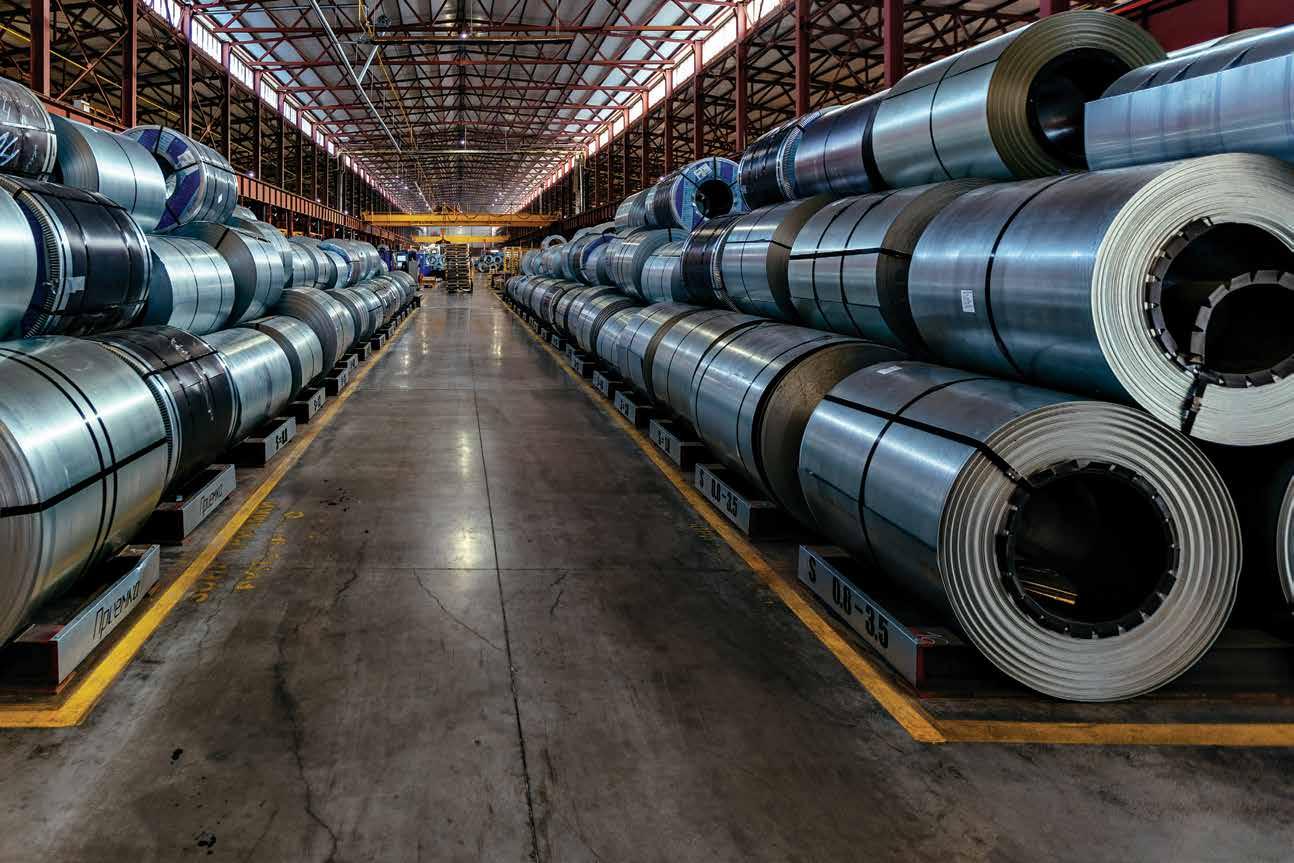

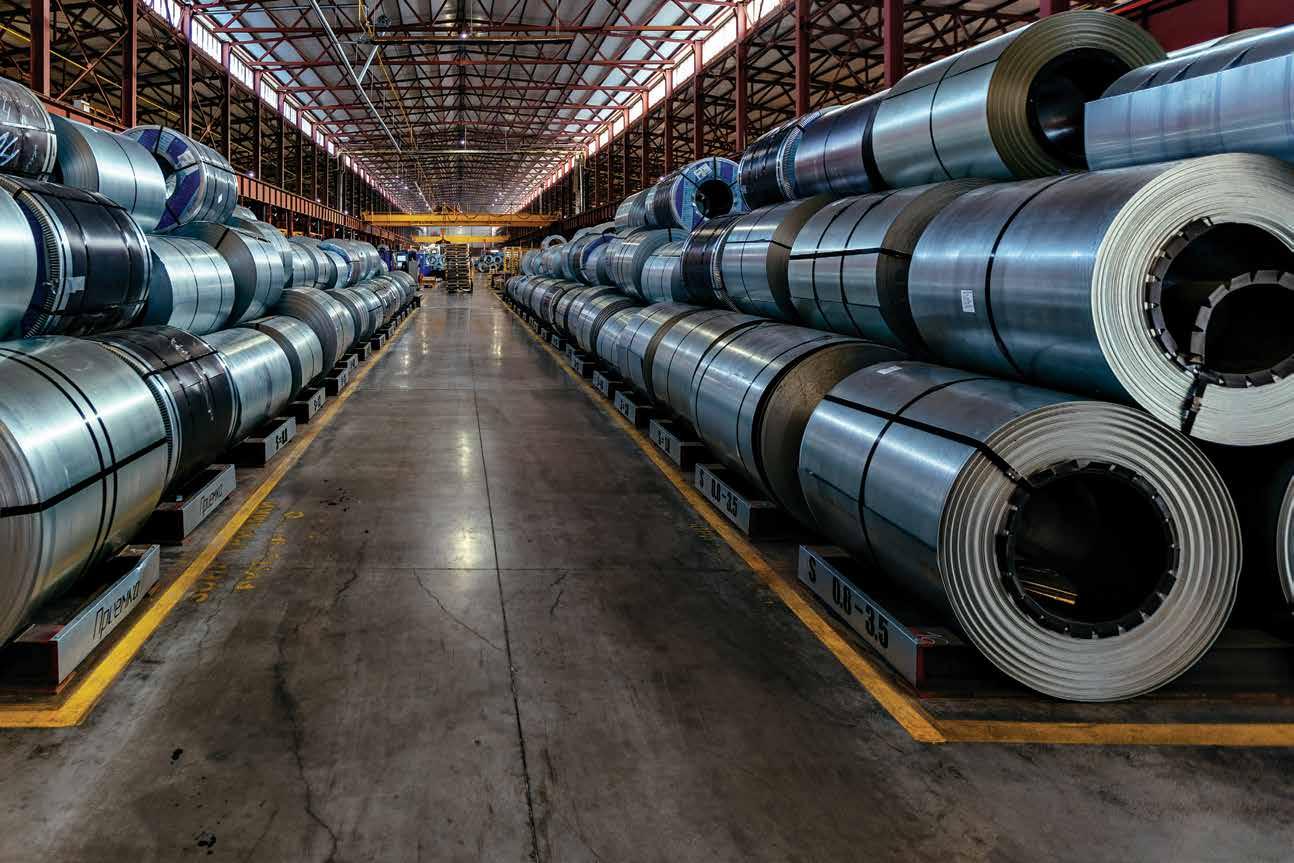

CLOSURE OF LONG STEEL PLANTS IN SA

LIKELY TO REDUCE DEMAND FOR ZINC

The closure of long steel plants in South Africa, which use zinc extensively in galvanising, could have a notable impact on local zinc usage.

ArcelorMittal South Africa recently announced it is placing its major Newcastle and Vereeniging long steel operations in care and maintenance, due to a lack of demand. The company cited high logistical and transportation costs, energy prices, and load shedding as the main reasons for the decision. In addition, South Africa’s steel consumption has declined by 20% over the past seven years. Over 3 500 employees will be a ected by the decision.

A decline in steel production due to plant closures would directly translate into reduced demand for zinc by galvanisers, notes Simon Norton, executive director, International Zinc Association (IZA) Africa.

However, Norton notes that since the COVID-19 lockdown in 2020, the tonnage of refined zinc imported into South Africa increased to 77 000 tonnes in 2023. “So, steel must be coming into South Africa via imports and not via ArcelorMittal,” he points out.

“South Africa, if it aims to restore its position as an African industrial giant, must grow its employment base and rebuild its decaying waterworks, wastewater works and infrastructure, and it must have steel mills to convert its rich iron ore into high-quality finished steel products. This is followed by the use of zinc galvanising to protect the steel against corrosion,” he says.

“The blame for our current economic position and the state of the steel industry in SA lies fairly and squarely with the

government, which has ruined many parastatals and collapsed numerous municipalities. We in the industry hope that the upcoming national election will result in employment and industry-friendly policy changes.”

Zinc galvanising is an indispensable process in the construction industry. The loss of long steel plants could potentially disrupt the construction market, impacting steel usage. “As South Africa grapples with infrastructure challenges and the need for sustainable solutions, zinc galvanising remains a vital tool to protect and extend the life of critical steel structures,” says Norton.

Corrosion, the deterioration of steel due to its interaction with the environment, poses a significant threat to the longevity and safety of steel structures. Zinc galvanising e ectively combats corrosion by creating a protective barrier between the steel and the surrounding environment. Composed of iron-zinc alloys, this barrier acts as a sacrificial anode, preferentially corroding in place of the steel.

In the realm of rail infrastructure, zinc galvanising safeguards steel components from the corrosive e ects of moisture, salt, and other contaminants. Such protection is particularly essential in regions with harsh weather conditions or in coastal areas, where exposure to salt spray can accelerate corrosion. Railway lines are metallised as opposed to being galvanised, which involves applying a protective zinc coating in addition to galvanising.

Power infrastructure, including transmission towers, substations, and other steel structures, also relies heavily on zinc galvanising to maintain its integrity. Corrosion of these components can lead to power outages, disruptions in electricity supply, and even catastrophic failures. Zinc galvanising safeguards these critical structures, ensuring the reliable delivery of electricity.

“However, underlying all zinc galvanising lies steel. If South Africa can no longer manufacture its own steel, then our industrial, mining and civil engineering sectors will all be the poorer for it and have to battle to import steel products,” he says.

www.samining.co.za 6 SA MINING MARCH / APRIL 2024 IN BRIEF

Simon Norton.

–

© ISTOCK

Zapletin

WE CAN HANDLE THE PRESSURE. GUARANTEED.

AECI’S CEO SHARES FRESH STRATEGY AT 100-YEAR MILESTONE

With a 100-year track record in South Africa, AECI already has a strong vision of where it aims to go in the next century of its existence, expanding its international footprint further, while transforming digitally, and driving important net zero goals.

As the company celebrates its centenary, AECI Limited Group CEO Holger Riemensperger claims that international expansion is high on the group’s agenda for the next stage of its business journey.

While the JSE-listed business commemorates a century of shaping industries and ground-breaking solutions in 2024, Riemensperger is already focused on what lies ahead, including digitisation, its net zero goals, and ensuring mining is its primary growth focus.

CELEBRATING 100 NOT OUT

Established as African Explosives and Industries (AE&I) on 20 March 1924, AECI Limited has evolved from its origins as an explosives provider for South Africa’s growing mining sector into a global leader in the chemicals and mining industries.

The company’s influence now extends across Africa, Europe, South East Asia, North America, South America, and Australia, and he says the aim is to continue its internationalisation drive, as 80% of its business currently lies outside of South Africa.

“We have 100 years of being a registered business, but 128 years of operational and industry experience,” he says. “I firmly believe that the enduring success of AECI lies

in our unwavering solution-focused value proposition and the dedication from our workforce.

“Our business is built on unique customer relationships and an exceptional ability to adapt to evolving global landscapes. We’re

“

Our business is built on unique customer relationships and an exceptional ability to adapt to evolving global landscapes. – Riemensperger

“

recognised in the industry as a training ground for the best people, in terms of technical capabilities and on-bench support, which is why our customers refer to us as the industry university.”

Riemensperger notes further that the

recent agreement with Newcrest Lihir not only enhances AECI’s presence in the broader Asia Pacific region, but also marks a noteworthy achievement in its pursuit of sustainable international business expansion. The contract encompasses the establishment of a modular emulsion plant on Lihir Island in Papa New Guinea.

“This strategic move positions us to provide comprehensive blasting services, utilising our specially cra ed hot and reactive ground bulk products, along with our purpose-built delivery systems and initiation systems. Our research and development team successfully developed a new product, the S300 Volcano, tailored to meet the unique requirements of this customer.”

The Lihir mine sits on volcanic ground, he says, presenting challenges of extreme hot ground conditions. “Through a collaborative approach, the AECI team delivered a product that is safe, suitable, and e ective for application in such an environment.”

Riemensperger adds that AECI’s customer relationships and technical expertise are backed by the company’s consistent production of safe, reliable, and quality products. “We will continue to rely on these strengths as we concentrate our e orts on a more focused AECI moving towards the next 100 years.”

www.samining.co.za 8 SA MINING MARCH / APRIL 2024

EXPLOSIVES COVER STORY

SUSTAINABLE EXPLOSIVES

BETTER BLASTING

Our suite of Surface and Underground Explosives is meticulously researched to ensure sustainable blasting outcomes in the most challenging conditions.

INITIATING SYSTEMS AND ELECTRONICS

Our experience has enabled us to perfect robust electronic initiation systems and electronics technology which provides significant advances in safety and operational e ciencies.

SMART DELIVERY SYSTEMS

Providing smart delivery systems that enables the customer to utilise new mining methods and blasting techniques to ensure e ciency, increase productivity and reduce blasting costs.

Through o ering the latest digital technology like Virtual Reality, Digital Twin, Advanced Blast Design and Smart MMU’s, we assist customers to continuously improve their blasting processes and outcomes.

AECI Mining globally assists the mining industry to achieve optimal blasting processes and outcomes. Our sustainable approach enables e ciencies and best practice through the application of experience and advanced blasting technology.

aecimining.com GLOBALLY PROVIDING

SMART MMU SUPPLY CHAIN DIGITAL CLASSROOM SECURITY & SAFETY PLANT AUTOMATION VIRTUAL REALITY BLAST HUB

AECI MINING E mining.marketing@aeciworld.com T +27 11 606 00001 | Platinum Drive, Longmeadow Business Estate North, Modderfontein, 1645, South Africa

TECHNOLOGIES

By integrating digital solutions into our product and service applications, we’ve achieved tighter value chains, precision blasting and consistent results. – Riemensperger

MAXIMISING INTERNATIONAL EXPANSION

“AECI is dominant in Africa, however global expansion will require a di erent approach. Decarbonisation within mining companies is a critical priority, along with the shi from CO2 to Nature Positive, and a fundamental move towards energy transition metals and sustainable water management.”

He adds that zero harm and sustainability remain a key part of AECI’s growth strategy, with a vision of delivering sustainable solutions for a better world through innovation and excellence.

“Key to this is our commitment at group level to net zero emissions by 2050,” he says. “AECI has committed to reducing its Scope 1 and Scope 2 emissions (direct emissions from owned or controlled sources and indirect emissions from electricity, steam, heating and cooling) in pursuit of this target, and we have implemented a system to track our Scope 3 emissions for raw materials produced through leveraging digitisation.”

AMBITIOUS TARGETS

Ultimately, he says, AECI’s aim is to become a global top-three integrated mining explosives and chemicals solutions provider by 2030, a leader in profitability, safety and operational excellence.

“On the mining explosives side, we will pursue this goal by protecting our core markets, building value-added capabilities, leveraging existing client relationships and leaning on our underground mining expertise and di erentiated capabilities,” says Riemensperger.

AECI, he says, has a longstanding tradition of innovation, evident in its range of explosive products and associated services tailored for its customer. The company has continuously sought to enhance its operations through digital solutions, spanning from manufacturing to storage and use of these o erings.

“By integrating digital solutions into our product and service applications, we’ve achieved tighter value chains, precision

AECI: OVER 100 YEARS OF MAKING HISTORY

■ 1896 – Opening of the Modderfontein Dynamite Factory.

■ 1924 – Formation of African Explosives and Industries Limited (AE&I).

■ 1966 – The company lists on the Johannesburg Stock Exchange (JSE).

■ 1976 – Name changed to African Explosives and Chemical Industries Limited (AECI).

■ 1978 – AECI files first emulsion patent.

■ 2001 – First single blast using 1 500 electronic detonators at Damang Gold Mine in Ghana.

■ 2007 – AECI’s first capital investment outside Africa in Indonesia.

■ 2019 – Powergel X2, an industry first, is developed for customers who experience reactive ground and hot hole conditions.

■ 2021 – AECI successfully commissions the world’s deepest emulsion vertical drop system with a depth of 1 000m.

■ 2022 – The CyberDet smart wireless detonator is available for remote and autonomous charging and blasting.

blasting and consistent results. Our range of solutions includes smart delivery systems, digital blast so ware, and the groundwork for transitioning towards an AI-driven future.

“With a legacy built on innovation and a vision focused on shaping the next century of progress, AECI is well positioned to inspire and drive digital innovations that will redefine the landscape of its industry for generations to come,” says Riemensperger.

www.samining.co.za 10 SA MINING MARCH / APRIL 2024 EXPLOSIVES COVER STORY

“ “

www.samining.co.za SA MINING MARCH / APRIL 2024 11 COMPETITION Two lucky readers will win a La Motte gift set AND WIN FIND THE ADVERT YOU COULD WIN … A La Motte gi set that includes a 2021 La Motte Sauvignon and a 2018 La Motte Cabernet Sauvignon. To stand a chance to win and be included in our Business Media Mags newsletter database, simply SMS the letters and page numbers (for example, A15) of the adverts as they appear in the magazine, followed by your full name, email address and physical address to 41892. SMSs costs R1.50 each. Terms and conditions apply. SMS errors are billed; free SMSs do not apply. For full terms and conditions visit https://businessmediamags.co.za/ Competition ends 29 May 2024. BETTER BLASTING aecimining.com GLOBALLY PROVIDING SUSTAINABLE EXPLOSIVES Our suite of Surface and Underground Explosives is meticulously researched to ensure sustainable blasting outcomes in the most challenging conditions. INITIATING SYSTEMS AND ELECTRONICS Our experience has enabled us to perfect robust electronic initiation systems and electronics technology which provides significant advances in safety and operational e ciencies. SMART DELIVERY SYSTEMS Providing smart delivery systems that enables the customer to utilise new mining methods and blasting techniques to ensure e ciency, increase productivity and reduce blasting costs. Through o ering the latest digital technology like Virtual Reality, Digital Twin, Advanced Blast Design and Smart MMU’s, we assist customers to continuously improve their blasting processes and outcomes. TECHNOLOGIES mining.marketing@aeciworld.com +27 11 606 00001 Platinum Drive, Longmeadow Business Estate North, Modderfontein, 1645, South Africa AECI Mining globally assists the mining industry to achieve optimal blasting processes and outcomes. Our sustainable approach enables e ciencies and best practice through the application of experience and advanced blasting technology. CONTACT US TODAY • www.mineral-loy.co.za • 011 802 4050 • info@mineral-loy.co.za PRODUCT AND SERVICE BEYOND EXPECTATION KINETIC BREAKER Your guaranteed solution for eliminating secondary blasting, oxygen lancing, rock breaking and Iron skulls. • High impact energy • Zero injuries • Eliminates noise pollution, dust, toxic emissions, and chemical contamination. • Minimal ground vibrations • Improved productivity • Zero fly rock www.manitou.com Represented throughout the African continent through our network of dealers. Tel: +27 11 601 3000 Email: info.msa@manitou-group.com MHT-X RANGE The Manitou Heavy Telescopic MHT machines are designed to safely handle bulky, heavy loads on all types of terrain. Combining performance and versatility, the MHT will increase productivity on any mining site. Equipped with an attachment recognition system, which provides an adapted load chart on the in-cab display to ensure that the machine is always operated within safe working envelope, the MHT range offers greater safety on the site! HEAVY DUTY TASKS NEED HEAVY DUTY SOLUTIONS End-to-End Solutions: Sales Services Training Parts 25 T CAPACITY UP TO WE CAN HANDLE THE PRESSURE. GUARANTEED. Introducing the new Land Cruiser 70 Series. Equipped with a new rugged grille and bumper with black finish, refined styling, improved safety* and convenience features* and LED fog lamps, the new Land Cruiser 70 Series has been upgraded to suit the present-day, while retaining the durability and reliability that have made the master of Africa for so many years. When it comes to performance, the new Land Cruiser 70 Series delivers incredible power throughout the range, which now has more fuel-efficient, 2.8 turbo-diesel model added to the line-up. No matter the task or the terrain, the new Land Cruiser 70 Series is Still the Master. STILL THE MASTER THE NEW LAND CRUISER 70 SERIES A D C F B E HOW TO ENTER All you have to do is let us know on which page each advert appears.

ENERGY INFRASTRUCTURE: A COMPETITIVE ADVANTAGE TO RESOURCES COMPANIES

Mining companies need to proactively invest in renewable energy infrastructure, to help support their operational needs, while aligning with sustainability goals.

African-based mining and resource companies that have invested in renewable energy infrastructure over the past few years are now reaping the benefits. Not only do they have access to cheaper power, but they’re also achieving sustainability goals identified by stakeholders, including lenders looking to fund expansion.

Sustainable financing is becoming an increasingly topical issue for both bank and nonbank financing institutions, and mining companies will feel the pinch at the balance sheet level if they are not embracing a shi towards clean energy projects. This could be encapsulated in possibly lower funding costs for clean energy projects.

Due to “traceability” considerations by certain markets – for example pending European Union legislation, or possible London Metal Exchange requirements – the price paid for certain commodities like green copper and green steel could be higher. At the same time, the demand for commodities that do not meet this threshold could wane as the price becomes more expensive, due to additional carbon and other taxes or restrictions imposed by such legislation or guidelines.

Some of South Africa’s largest mining and resource businesses have recognised this, and have proactively invested in energy infrastructure that not only supports their operational needs through energy access, but also aligns with sustainability goals and growth strategies.

BATTERY STORAGE

By Theuns Ehlers

By Theuns Ehlers

Head: Resources & Project Finance and

Bhavtik Vallabhjee

Head: Power and Renewables, at Absa CIB

A key development in 2023 was the recognition that generation was only part of the equation when it comes to energy infrastructure, and that storage, transmission, and distribution will be the focus areas in the foreseeable future.

The November announcement of the first four bidders for phase 1 of the Battery Energy Storage Independent Power Producers Procurement Programme is an important milestone, one that will provide a catalyst for further energy storage projects in Africa. Traditionally, electricity is a commodity that cannot be stored a ordably, with very limited storage capacity existing mainly in the form of pumped storage.

BESS (Battery Energy Storage Systems) would allow for electricity storage and dispatchability on an “as-needed” basis, and will help unlock grid capacity in congested areas where surplus generation – for example from the Northern Cape – can be stored during the day, and then released during peak demand periods.

The investment into transmission grid capacity would thus help unlock the bottlenecks that currently exist, and allow for more generation capacity, including decentralised generation capacity, to be built.

While South African businesses have made significant progress in the rollout of renewable energy projects to support the mining sector

EGYPT

and drive sustainability, most of the rest of Africa has not kept pace with SA.

Notwithstanding this, there has been some very notable activity on the continent. Here are some examples:

ZAMBIA

Zambia has been an interesting country to watch as it is undergoing a significant shi in its energy infrastructure. The country has a relatively low generation base – roughly 2 800MW – of which 85% is via hydroelectric power. Climate change has severely impacted rainfall patterns in the country, and the state-owned power utility ZESCO has been forced to implement load shedding as a result of lower-than-expected hydro-generation capacity. This has curtailed investment in key sectors, including agriculture and mining.

Considering that Zambia is one of the top 10 copper producers in the world, home to one of the largest nickel mines in Africa, a leader in gemstones, and is considered a key supplier in the electric vehicle battery supply chain for battery minerals, these crippling power issues will impact the ability of the country to unlock its economic potential.

Increased investment in its clean energy sector will help diversify its generation base and provide stability to the mining sector, while it is also worth noting that mining companies are turning to captive power initiatives to augment grid power supply.

Egypt is another country that’s worth watching closely – particularly with its ties to the Middle East, and its proximity to Europe.

As a country that’s rich in resources including oil, gas, gold, phosphate, tantalum, and other minerals, developments in its energy sector are of paramount importance to support these energy-intensive industries.

The country enjoys a combination of flat terrain, glorious levels of sunlight, and wind, which makes it a destination of choice for renewable energy projects and capital-intensive green hydrogen projects.

Despite this, less than 10% of its nearly 60GW of installed capacity is delivered via non-fossil fuel sources. The country has set itself a goal of securing $1-billion in new mining project investment by 2030, and through its abundance of clean energy sources – wind, solar and hydro – it has the potential to be a destination of choice for mining houses.

Clearly, investment in power is the precursor to any energyintensive business. Mining and resource companies that have recognised that investments in distributed, a ordable clean energy infrastructure will be a comparative advantage are likely to find themselves better positioned, relative to peers who have underinvested in this area.

www.samining.co.za 12 SA MINING MARCH / APRIL 2024 The views expressed are the author’s own and do not necessarily reflect SA Mining’s editorial policy. © ISTOCK –Bilanol COLUMN ENERGY

Engineering solutions for the Global Mining Industry

Mining Geotechnical Ventilation Mechanical Electrical Metallurgical

SOUTH AFRICA OFFICE: +27 11 476-7091

Etienne de Villiers: +27 83 327 6517 / etiennedv@baraconsulting.co.za

Jim Pooley: +27 82 373 0796 / jim@baraconsulting.co.za

Clive Brown: +27 82 557 5373 / clive@baraconsulting.co.za

www.baraconsulting.co.za

UNITED KINGDOM OFFICE

Andrew Bamber: +44 744 486 4046 / bamber@baraconsulting.co.uk

www.baraconsulting.co.uk

MITIGATING CO² EMISSIONS

WHILE ENABLING THE JET

The Council for Geoscience suggests that Carbon Capture, Utilisation and Storage is a scientifi c intervention that can reduce emissions, while assisting the Just Energy Transition.

The economic impact of coal across local communities should not be underestimated, particularly in light of the fact that close to a quarter of a million workers are employed in the coal industry. Thus, any discontinuation of this fossil fuel cannot be spoken of without considering its socio-economic impact.

Nonetheless, South Africa – like the rest of the world – is eager to find lasting solutions that protect its environment and reduce greenhouse carbon emissions.

The Council for Geoscience (CGS), with over 111 years of geoscience knowledge and experience, remains fully committed to finding new technologies that will enhance environmentally friendly energy sources. Sustainable solutions are needed though. One of these, currently considered globally as a key solution, is Carbon Capture, Utilisation and Storage (CCUS).

Globally, hydrocarbons like coal and oil have been largely depended on for more than a century, and South Africa is no exception. It’s nearly 30 years since the United Nations Framework Convention on Climate Change (UNFCCC) was initiated, and most member states are signatories.

The UNFCCC calls on members to act in the interest of their citizenry and humanity at large.

Advances in CCUS technology globally, including in countries like the United States (US), Norway and Canada, have proven that the technology is a feasible alternative to reducing CO2 emissions through utilisation and underground storage in suitable geological formations. Once underground, the CO2 interacts with the geological environment and mineralises, which reduces the risks associated with leakage.

CCUS’s intention is to capture CO2 from the source, such as the fired power plants, and transport it to carefully selected geological sites for permanent storage, which is supported by an extensive monitoring of the process, from the start to post injection and storage.

The CGS has recently commenced with geological characterisation of an identified potential site in Leandra, Govan Mbeki Local Municipality, in Mpumalanga. Here, consultations with myriad stakeholders from three government spheres, along with local traditional leaders, communities, environmental non-governmental organisations, and farmers and local

businesses, have borne fruit. This is due to the long-term goal, which is to see the community benefit from this development.

Govan Mbeki Local Municipality, meanwhile, has contributed a piece of land for this research to be implemented. The identified site has taken into consideration all factors such as location, geology, socioeconomic and technological aspects to make a pilot feasible, thus a site proximal to CO2 emitters.

TWO-PRONGED APPROACH

The two-pronged approach then sees the CGS being on the drive to make South Africans aware of the CCUS technology. There is no doubt this technology is encouraging, though we need to be mindful that it may take time before we see the commercial benefits and return on investment, notes the CGS.

The models that have worked in countries such as the US cannot be readily assumed to also work in South Africa. Hence, the CGS and other scientists are investing time and e ort in extensive techno feasibility studies and technological disruptions, particularly adaptable to sites in South Africa, both on- and o -shore. This

www.samining.co.za 14 SA MINING MARCH / APRIL 2024 GREEN MINING ADVERTORIAL

The identified site has taken into consideration all factors such as location, geology, socio-economic and technological aspects to make a pilot feasible, thus a site proximal to CO2 emitters.

is in line with the fact that the country has already pledged to cut CO2 emissions by 50% by 2030, which is eight years from now.

The truth about coal is that it is a ordable. There are enough coal companies in South Africa, employing tens of thousands of citizens, although today, financing development of coal projects has become increasingly challenging, with financing institutions investigating how best to contribute towards the reduction of greenhouse emissions. Technologies need to be applied on how best to use coal, as we transition towards a low-carbon economy. The big question is whether this just transition can be done sustainably, justly and justifiably.

Once we have figured out the nature of this reduction intervention, such a breakthrough will not only benefit Eskom, communities, and business, but will also go a long way in the commitment we have made when it comes to CO2 emissions. As Eskom unbundles into three divisions, it is hoped these would be synced to address this long-standing problem, as Eskom continues to operationally rely on coal.

The technology associated with CCUS is centrally developed as an economic

contributor that aims to do better and contribute generously towards the country’s gross domestic product. In this regard, the South African government assigned the CGS as an implementing agent for the CCUS research in partnership with the World Bank.

The CGS has further developed a network of private business partnerships that span the Development Bank of Southern Africa, Sasol and Exxaro, while others are still in the pipeline for finalisation. With such partners, this intervention is guaranteed to benefit from collective wisdom, resource crowding and accelerated implementation of ideas and technological applications.

The CCUS project has underlined how pivotal South Africa’s commitment to reducing greenhouse gas emissions is. The project directly responds to government’s call that innovative solutions are sought for a transition to a low-carbon economy.

It’s a question that cannot be brushed aside, and one that a project such as CCUS aims to answer as it undertakes to be part of a solution that will ultimately benefit the entire country. Moreover, it has been proven from other parts of the world that CCUS could be a viable option.

The CGS’s aim, though, is to not only

WHAT IS THE JET?

The Just Energy Transition (JET) is a $497-million project approved by the World Bank Group in November 2022 at the request of the SA government. It will support its public energy utility, Eskom, to decommission the 56-year-old Komati coal-fired power plant, repurpose the project area with renewable energy and batteries, and create opportunities for workers and communities. Beyond improving supply and grid stability, the technical solutions tested at Komati can demonstrate how South Africa can integrate renewables and batteries in the national energy grid, leading to employment creation opportunities through the installation of those new technologies.

copy from the work that’s already begun in other parts of the world, but endeavour to deliver a project that takes into account our diverse geology, unique environment, and overall technical excellence of our South African institutions.

www.samining.co.za SA MINING MARCH / APRIL 2024 15

–

“ “ © ISTOCK –rui_noronha

CGS

KINETIC BREAKER

OFFERS MINES A SMASHING TIME

Designed to crush a wide range of different materials, Mineral-Loy’s Kinetic Breaker offers an environmentally friendly and safe breaking solution.

Mining companies often struggle with the secondary blasting of rocks, boulders, crop rocks, slag, iron skulls and other large materials. The answer to this challenge can be found in the new Kinetic Breaker solution.

The Kinetic Breaker is a 15-tonne machine equipped with a five-tonne guided hammer, something that generates a remarkable 290 000 joules of energy. This makes it capable of crushing a wide range of different materials.

According to Mineral-Loy, the Kinetic Breaker offers an environmentally friendly and safe breaking solution, when compared to traditional methods like blasting or oxygen lancing. Essentially, this specialised solution works by repeatedly dropping a large, weighted hammer through a guided tube, onto the material in order to fracture it through a high level of precision.

The breaker is designed to be used in the mining, construction, quarry and steel-making industries. The range of materials that can be processed is significant as the Kinetic Breaker can smash the toughest of materials. This is why the solution is ideal for eliminating scenarios such as secondary blasting, crop-rock breaking, and slag and iron skulls breaking. It is equally effective at breaking down sizable boulders and other materials into more manageable fragments.

The Kinetic Breaker is affixed to an excavator, which thus provides it with mobility, allowing it to operate in remote locations and to more easily be moved to operate where required.

Among the key benefits offered by the Mineral-Loy solution is that mines can rest assured that it will help in reducing operating

expenses and enhancing productivity, while complying with safety and environmental requirements. By offering an all-in-one solution, the Kinetic Breaker caters to all a mine’s breaking requirements.

Furthermore, Mineral-Loy boasts an in-house team of mechanical engineers, chemical engineers and metallurgists, who are adept at furnishing technical assistance and specialised project management expertise.

“With more than seven years of expertise operating this unique equipment at several mining and industrial sites around South Africa, we have consistently upheld a 70% uptime productivity rate,” notes company managing director Philip Steenkamp.

“This has been achieved through zero safety incidents, implementing essential design modifications through constant research and development, provision of

adequate training and upskilling for employees, the establishment of rigorous maintenance programmes, and the leveraging of a welldeveloped, reliable local supplier network for all spares.”

Mineral-Loy was founded in 1975 to meet the needs of the South African steel and foundry industry, through the supply of various raw materials. Over the years, the company has expanded its operations to encompass diverse markets while enhancing its material processing capabilities.

These include turnkey projects, crushing, screening, briquetting and cutting. Mineral-Loy has been the local agent and/or distributor of certain products for entities such as Richards Bay Minerals and Samancor Chrome, among others, for over 20 years – which speaks volumes about the organisation’s established track record.

www.samining.co.za 16 SA MINING MARCH / APRIL 2024 CRUSHING, SCREENING & MILLING CORPORATE PROFILE

CONTACT US TODAY • www.mineral-loy.co.za • 011 802 4050 • info@mineral-loy.co.za PRODUCT AND SERVICE BEYOND EXPECTATION KINETIC BREAKER Your guaranteed solution for eliminating secondary blasting, oxygen lancing, rock breaking and Iron skulls. • High impact energy • Zero injuries • Eliminates noise pollution, dust, toxic emissions, and chemical contamination • Minimal ground vibrations • Improved productivity • Zero fly rock

HOW ENERGY MANAGEMENT STANDARDS CAN IMPACT LOAD SHEDDING

Energy management standards provide guidelines, requirements and calculations for understanding the energy baseline.

By Rodney Weidemann

There is little doubt that the impact of load shedding on South Africa’s mining sector has been considerable. In fact, according to Statistics South Africa, mining output slowed almost 2% in September 2023, compared to the same period in 2022, largely due to the country’s power crisis. Moreover, this was the third month in a row that output dropped o .

It is clear, notes Muhammad Ali, MD of International Organization for Standardization (ISO) specialist World Wide Industrial & Systems Engineers (WWISE), that mining operations cannot rely on Eskom’s power supply and scheduled downtime.

“Power outages impact production targets, market share price and shareholder confidence. This in turn has a huge impact on the economy. Mining companies have therefore invested heavily in diesel generators or alternative energy, such as solar plants – but all these expenses make the cost of mining higher in SA, and investors are losing confidence and looking to put their money elsewhere,” he says.

The situation is such that top management have had to come up with

innovative and impactful mitigation strategies. One of the keys ways they are doing this is by turning to standardisation.

The ISO comprises over 160 national standards bodies, and develops and publishes a wide range of proprietary, industrial and commercial standards. In 2022 alone, it published almost 25 000 international standards and standards-type documents, and SA is a major contributor to standardisation processes in Africa.

“Energy management allows organisations like mining houses to understand their significant energy uses –assets that consume the most amount of energy. The standards, meanwhile, provide guidelines, requirements and calculations to help you understand the current energy baseline,” he says.

“Once these are established, alternative measures can be calculated using a risk-based approach, based on capital expenditure for alternative energy solutions, as a phased approach.”

Load shedding as a whole could actually have been avoided, continues Ali, if standards were followed by Eskom from the beginning, with accountability

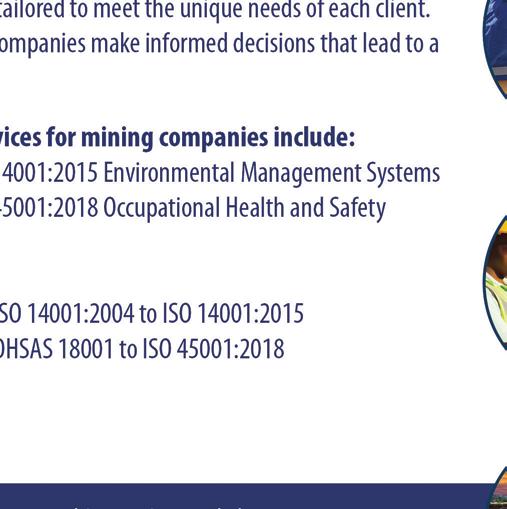

INTERNATIONAL BEST PRACTICE STANDARDS SA MINES SHOULD IMPLEMENT:

■ ISO 14001:2015 Environmental Management

■ ISO 45001:2018 Occupational Health and Safety

■ ISO 9001:2015 Quality Management

■ ISO 50 0001:2018 Energy Management

■ ISO/IEC 27001:2022 Information Security

These standards create a level of governance with systems to be able to create a level of consistency and auditable documents/records to justify compliance and conformance. This not only enhances the performance by creating structure in-house, but creates shareholder confidence.

and consequence management, as promulgated by the standards. Although the standards cannot prevent an incident, a cyber-attack or load shedding for that matter, it does allow mines to both reduce the probability and better manage the impact.

www.samining.co.za 18 SA MINING MARCH / APRIL 2024 ENERGY

© ISTOCK –kamilpetran

“

DIGITALISATION TRANSFORMS THE GRID

As the world decarbonises its energy system, electricity will remain the backbone. There is an accelerated shi from fossil-based to renewable power generation, with growing electrification of the transportation, industrial and building sectors.

To manage this, says Malvin Naicker, MD for Hitachi Energy, Sub-Saharan Africa, digital and energy platforms are needed for the enormous power system energy transition challenges related to increased complexity and additional capacity requirements.

“These platforms will enable greater grid resilience, and help manage the shi to a more complex power generation landscape, by matching fluctuations in power supply and demand dynamically,” he says.

Sophisticated so ware solutions are available to manage such trading, allowing real-time exchange of power between users, and settlement of the resultant commercial transactions.

“As the power generation landscape evolves in South Africa, the demand for grid connection solutions is increasing rapidly. There is simply not enough time to meet the demand for new o take and grid integration solutions, unless new solutions such as prefabricated substations are considered as a way to speed up the deployment of such grid connections.”

Decarbonisation, too, is transforming the energy system. It is driving an accelerated shi from fossilbased to renewable power generation, along with electrification of the transportation, industry and buildings sectors, he says. This is creating the need to optimise energy both locally and system-wide, leading to a complex “system of systems” that must be integrated and managed.

“ Load shedding as a whole could actually have been avoided if energy management standards were followed by Eskom from the beginning.

– Ali

REDUCING THE RISK OF INJURIES

Ali says ISO 45001 is a standard that focuses on the following: awareness, consultation, communication, participation and embedding a culture of safety, before every activity that can result in injury, illhealth, or fatality. Following the processes to avoid these risks is what the standards require. This reduces the probability of impact, as each control is focused within a hierarchy that includes elimination, substitution, engineering, administrative controls and personal protective equipment.

“ISO implementation, along with an accredited certification, helps to validate the numbers on the environmental, social and governance (ESG) reports. This, in turn, increases shareholder confidence and share prices, and reduces insurance premiums.”

The standards provide a set of requirements for achieving the goals,

“A significant aspect of resilience is in cyber-security. The world needs a cyber-secure ecosystem for a resilient electric future. Energy is among the top three target sectors for cyber-attacks globally, and as energy grids become more resilient through the application of digitalisation, attention must be paid to the design and implementation of cybersecurity.”

Through changes in regulation and technology, large power users are now able to generate and use their own electrical energy. Naicker notes that as this self-generation becomes more prevalent, users will start to trade power with each other, with the grid being the trading platform for such exchanges.

“Digitalisation is the only way to manage this complexity, by simplifying the contextualisation of massive amounts of data. However, this must be balanced with managing and optimising today’s operations.

“In the end, if we want to solve real-world challenges and add real value, what is required is the right combination of connected products, so ware-based solutions, and digitally enabled services,” says Naicker.

objectives and targets set out in the ESG framework, with an e ective management system comprising policies, processes, procedures, work instructions, and systems/ applications aligned with the standard requirements. These provide a structured, methodical way for any organisation to achieve ESG commitments, he says.

Ali points out that standards like ISO 45001:2018, along with regular audits of companies in terms of the Mine Health and Safety Act, are vital.

“Organisations tend to be fearful of

audits when these systems are aligned to international standards and local legislation. In South Africa audit findings are generally perceived as negative, given they a ect key performance indicators.

“However, audit findings should instead be encouraged. Once an expert is appointed to assist the organisation to improve, they will make top management accountable for poor maintenance plans and budget reductions that may put lives at risk. This will ultimately leave the company better o , all round,” says Ali.

www.samining.co.za SA MINING MARCH / APRIL 2024 19

© ISTOCK –cozyta

NATURE IS KEY TO AFRICA’S FINANCIAL FUTURE

Africa’s natural resources will remain its greatest economic assets for some time. Those assets need to be protected, and regulation is an important part of that.

By Sandra Villars, Partner, Financial Services at Oliver Wyman

The COP28 conference has resulted in a variety of new climaterelated financial, environmental and infrastructure pledges from leaders across the world. Discussions around nature-based solutions for Africa featured prominently at the event. But how should regulators turn those proposed solutions into concrete regulations?

Africa has a long and complex history with nature and finance. For much of that history, the continent’s abundant, extractable natural resources have been touted as an engine for wealth generation and development. While some countries, most notably Botswana, have used their natural resources successfully, others have suffered from the “resource curse”, whereby they underperform economically, despite abundant natural resources.

“

More recently, however, it’s become apparent that the picture is far more complicated than that. On the plus side, it’s clear that Africa’s renewable natural resources have immense potential for wealth creation. According to a 2022 report by the International Energy Agency, for instance, the continent has 60% of the world’s best solar energy resources.

That’s without mentioning the immense scientific and tourism value to be found in Africa’s flora and fauna. But the natural world also represents economic risks. For example, a 2023 Emergency Event Database (EM-DAT) report found that droughts affected 88.9 million people across the continent in 2022, and floods in Nigeria cost US$4.2-billion.

When it comes to safeguarding Africa’s financial future, it’s therefore critical that regulators take an approach that recognises the massive potential of Africa’s natural

When it comes to safeguarding Africa’s financial future, it’s therefore critical that regulators take an approach that recognises the massive potential of Africa’s natural resources, but also takes all nature-related risks into account.

“

resources, but also takes nature-related risks – both man-made and naturally occurring –into account.

UNDERSTANDING THE GRAVITY OF NATURE-RELATED RISKS

Before examining steps regulators can take, it’s worth digging a little deeper into why nature is so key to Africa’s financial future.

There are prominent examples, such as biodiversity. For example, South Africa alone is home to 10% of all plant species found on Earth (per Fauna and Flora International). Meanwhile, the continent as a whole (per the Intergovernmental Science-Policy Platform on Biodiversity and Ecosystem Services) is home to a quarter of the world’s mammal species and a fifth of its bird species.

Anything that threatens that biodiversity has massive potential knock-on effects.

According to the World Wildlife Fund, reduced biodiversity means more vulnerable food supplies, increased vulnerability to pests and diseases, and less regular supplies of safe drinking water.

But it’s also worth bearing in mind that, according to the United Nations Environment Programme, some 70% of people in Sub-Saharan Africa depend on the region’s forests and woodlands for their livelihoods. Any disruption to those ecosystems could therefore have a significant negative economic impact.

www.samining.co.za 20 SA MINING MARCH / APRIL 2024

SAFETY, HEALTH & ENVIRONMENT

There are dozens of other examples that could be used, all of which underline how important it is for regulators to protect the continent’s natural assets, while safeguarding against nature-related risks. One of the best ways to achieve this is by fostering transparency from both themselves and the financial institutions they oversee.

COLLABORATION, ASSESSMENT, AND GLOBAL ENGAGEMENT

One important way regulators can do so is by engaging proactively with state ministries (such as finance and environmental affairs) as well as policymakers within government. This comes with a couple of advantages.

First off, it means that regulators are much more likely to get government backing for any proposed regulations. It also means that any interventions put in place by regulators are in line with the political context of the country, helping to ensure that

everyone is working towards the same goal.

Continuous assessment is also important. That’s true both for the regulators themselves and for financial institutions. Internally, regulators need to ensure that they understand whether they have the capacity needed to respond to the call for nature-related disclosure transparency, by integrating nature risks into financial sector regulation.

This is a complex undertaking and regulators need to ensure they have the resources needed before starting. But regulators also need to assess whether the financial institutions they’re charged with overseeing have the capacity to take action too. Such an exercise is especially useful in identifying capacity gaps, and how to address them in the short-, medium-, and long-term horizons.

Finally, regulators should ensure they engage regularly with voluntary networks

Continuous assessment is also important. That’s true both for the regulators themselves and for financial institutions.

such as the Sustainable Insurance Forum, the Network for Greening the Financial System, African Natural Capital Alliance, and the Task Force on Nature-related Financial Disclosures.

These networks have set up frameworks that can easily be adapted by regulators. It also means they have a voice in how emerging regulatory frameworks are conceptualised, meaning that they’re suited to African contexts from the start, rather than having to be adapted later on.

Ultimately, Africa’s natural resources (both extractable and renewable) are likely to remain its greatest economic assets for some time. Those assets need to be protected, and regulation is an important part of that. But regulators also need to understand nature-related risks, and how an approach that treats those risks in a way that’s open and transparent can help mitigate them, and secure the continent’s economic future.

www.samining.co.za SA MINING MARCH / APRIL 2024 21

“

“

© ISTOCK –Alfio Manciagli © ISTOCK –Red Stock

LEVERAGING ISO 45001 FOR CONTINUOUS IMPROVEMENT

Effectively leveraging this standard for occupational health and safety management systems should lead to operational excellence and employee wellbeing.

Mining, with its complex operations and inherent risks, demands a steadfast commitment to safety, according to environmental consultancy ENVASS. In the pursuit of a secure working environment, the role of a robust safety culture cannot be overstated, it says, as this is the heart of any mining operation’s success.

This goes beyond mere compliance with regulations; it involves fostering a mindset where safety is ingrained in every aspect of the organisation. A positive safety culture is synonymous with operational excellence and employee wellbeing.

ISO 45001:2018 is the international standard for occupational health and safety management systems, and provides a structured framework for organisations to address occupational health and safety risks. Adopting ISO 45001 is not merely about compliance, but rather it’s a strategic move to embed safety into the organisational DNA.

The ISO 45001 standard serves as the cornerstone for fostering a robust safety culture in mining operations, by providing a structured framework and guidance. This international standard creates an environment conducive to safety consciousness through:

Leadership commitment: Defining roles, responsibilities, and accountability, compelling leaders to actively champion safety initiatives.

Employee involvement: Placing a strong emphasis on engaging workers in safetyrelated decisions, and making safety a collective responsibility.

Adopting ISO 45001 is not merely about compliance, but rather it’s a strategic move to embed safety into the organisational DNA. “ “

Communication strategies: Aligning with e ective communication channels to ensure seamless flow of safety-related information.

Learning and development: Encouraging continuous learning through investment in training programmes and competency assessments.

Measurement and evaluation:

Promoting a data-driven approach to safety, using metrics and indicators specified in the standard for accurate performance assessment.

Continuous improvement: Instilling a culture of continuous improvement by emphasising a cycle of planning, doing, checking, and acting, thereby encouraging organisations to view safety as an evolving process.

It’s worth noting that ISO 45001 serves as a catalyst for building and sustaining a strong safety culture in mining organisations. By aligning with the principles of ISO 45001, mining companies can create safer workplaces, enhance employee wellbeing, and contribute to the overall success and sustainability of their operations. It’s not just a standard; it’s a commitment to excellence in safety, ensuring that every worker returns home safely at the end of the day.

Ultimately, ENVASS is equipped with a team of experienced ISO auditors and implementation sta – o ering expertise and support to enhance safety practices and ensure compliance with international standards – who can play a vital role in guiding mining organisations through the implementation and continual improvement of ISO 45001.

www.samining.co.za 22 SA MINING MARCH / APRIL 2024 SAFETY, HEALTH & ENVIRONMENT CORPORATE PROFILE

WILL THE NEW CADASTRE SYSTEM WORK FOR THE JUNIOR MINING INDUSTRY?

While in theory the new mining cadastre system should signifi cantly improve licence applications for junior miners, many of the underlying challenges of SAMRAD remain.

Dr Andries van der Linde, Executive Head of Renewable Energy at SSC Energy

The objective of mineral processing is to produce maximum value from a given raw material, and to derive value from unexplored and sterile resources. As with anything in life, there must be a starting point, and in this case, it is the knowledge of where the minerals are. For this, there are numerous tools to assist the prospector, starting with researching geological features.

In this regard resources from the Council for Geoscience, which makes data, information, and knowledge available to the mining and exploration industry, comes to mind. The sources of such data can come from surface exploration, aerial surveys or satellite sensor technology. Other sources include compare-and-contrast methods, based on magnetic and electromagnetic data, regional gravity data, topographic mapping, ground penetrating radar, infrared spectroscopy, and photogrammetry. Of course, such methods only provide indicators, and eventual confirmation is only established by means of test holes.

This creates a major challenge for the junior mining industry, from the perspective of turnover, because a er expending what for them could be significant resources, the prospecting entity must ensure that the area of interest is available and hasn’t already been applied for or had a mining licence granted. Environmental considerations are also important – something that can stop any future mining activity in its tracks.

Theoretically, the South African Mineral Resources Administration System (SAMRAD) should facilitate the answers required by junior miners. However, as it stands, the SAMRAD system is totally unreliable, being consistently impacted by what is either permanent paralysis or intermittent issues combined with bad timing. However, it appears for starters to be virtually impossible to establish whether selected areas are available for registering a prospect right.

“ “

As it stands, the SAMRAD system is totally unreliable, being consistently impacted by what is either permanent paralysis or intermittent issues combined with bad timing.

STRONG EXAMPLES FROM AFRICA

For comparative purposes, the author had a look at the Namibia Mines and Energy Cadastre Map Portal, and the surprising and interesting di erence immediately shows itself.

The first aspect one notices is the mining cadastre map, combined with a legend of

the Active-Mining Rights and Applications –Mining Rights and an Administrative section listing Withdrawn Areas, Geology, Mineral Occurrence, Heritage Sites and Satellite Imagery. Areas are colour-coded, with tools to interrogate the map in more depth and which provide detailed information of an area of interest.

Clicking on an area the following information is provided: type of licence (mining, prospecting or reconnaissance); company name; relevant dates; commodities to be found on the site; and magnitude. For anybody in the junior mining industry, this would be an incredible tool to easily find out which areas to avoid.

Talking about avoiding, one of the banes of exploration and establishment of a mine is the environmental impact assessment, with heritage sites o en becoming a contentious issue. The heritage function identifies what is possibly all the heritage sites in Namibia. The Botswana portal is even more impressive and detailed, and any description that would give it the justice it deserves, would take up most of this article.

Should South Africa adopt a similar approach to Namibia or Botswana, it would already be a major step forward. However, although the information provided by these interactive maps would be a significant step forward, this is only the start for the junior miner. The next step, a er having done their homework to ensure the prospecting right area is available, is to make sure there are

www.samining.co.za 24 SA MINING MARCH / APRIL 2024

–TomasSereda

© ISTOCK

MINERALS PROCESSING

no obvious environmental issues, and that the geological indicators are positive, before applying for a prospecting right.

A NEW SOLUTION

However, registration is a tedious process requiring a certain level of competence, which is not helped by the inadequate SAMRAD system. Based on numerous complaints, some of the faults here lie with the people behind the system, which results in delays, confusion, and sometimes, outright manipulation.

As in all problem areas, these issues will not suddenly disappear unless there is a total overhaul. This must include another look at the people behind the scenes, because although it is an online portal, delayed applications already peaked at 5 000 in November 2022, and must be labelled an obstacle to mining investment in South Africa.

The good news is that South Africa will

It would be overly optimistic to believe that the new mining cadastre system would suddenly solve all the problems and eliminate all the obstacles facing the junior miner sector. “ “

replace SAMRAD with a new mining licensing system and online database, known as a cadastre system. This, according to Minerals Council South Africa CEO Mzila Mthenjane, will speed up applications for prospecting and mining rights. However, it has already taken four years to announce the service provider, while the implementation date has also come and gone. Despite these apparent delays, Minister Gwede Mantashe has said the country won’t rush the implementation of the new cadastre system.

The term “time is money” comes to mind. Considering the time and money it takes to get any mining operation going, and adding to this the financial issues faced by most junior miners, any delay can become a major problem – while extended delays can be catastrophic.

At the same time, it would be overly optimistic to believe the new mining cadastre system would suddenly solve all the problems and eliminate all the obstacles

facing the junior miner sector. Therefore, to blame it all on the SAMRAD system is simplistic.

To start with, the expertise required to complete the documentation process, which includes a prospecting works programme, as well as the final rehabilitation, decommissioning and closure of the mining plan, would require expert input. The environmental impact assessment can be equally expensive and contentious, while there are further costs in the form of a test hole programme to collect geologic information, which requires further expert input to analyse.

When asked which is the most significant hurdle the junior miner faces, the invariable answer is finances – which really is the main di erence between the junior mining industry and the majors when it comes to success and failure. This is because junior miners typically do not have the cash in hand, and they find it di icult to attract investors.

Therefore, despite the fact that the new cadastre system will not eliminate all the challenges faced by these players, it is vital that this solution be implemented as soon as possible. A er all, having access to the right prospecting, licensing and other critical data in one place is a crucial step forward in helping such businesses reduce both the costs and costly delays that currently make it extremely tough for juniors to properly compete in the South African mining industry.

www.samining.co.za SA MINING MARCH / APRIL 2024 25

© ISTOCK –

Chulov

THE CRUCIAL ROLE OF DISPUTE RESOLUTION IN THE CIVIL ENGINEERING SECTOR

In the fi eld of civil engineering, it’s vital to uphold equity and stability. To accomplish this goal, effi cient confl ict resolution is essential, and this is where the Bargaining Council for the Civil Engineering Industry (BCCEI) plays a crucial part in this industry.

In the civil engineering arena, maintaining fairness and stability is of paramount importance. To achieve this, e ective dispute resolution is indispensable, and this is where

the Bargaining Council for the Civil Engineering Industry (BCCEI) plays a vital role in this sector.

The BCCEI’s Dispute Resolution Centre is central to the handling of disputes specific to the industry, and is accredited by the Commission for Conciliation, Mediation and Arbitration (CCMA).

It must be stressed that dispute resolution is not only a means to solve conflicts, but also a vital aspect of good business management. For one thing, it prevents conflicts from escalating, saving both time and money, while o ering an alternative to costly court proceedings.

By Merle Denson Dispute Resolution Centre Manager at the BCCEI

By Merle Denson Dispute Resolution Centre Manager at the BCCEI

As far as the Dispute Resolution Centre goes, its accreditation from the CCMA ensures that disputes are e iciently resolved within legal parameters. Moreover, the Dispute Resolution Centre leverages the skills of a panel of commissioners,

all of whom bring deep industry knowledge and experience to the table, thereby guaranteeing expert handling of complex civil engineering issues. Its function is also to prioritise accessibility, by scheduling cases regionally – this helps to minimise financial burdens and time constraints for parties. Furthermore, and in response to the challenges posed by COVID-19, the Dispute Resolution Centre also o ers online dispute resolution services, enhancing e iciency and reducing costs.

It is important to note that the accessibility of the Dispute Resolution Centre’s services is ensured through a specific funding mechanism, one where both employers and employees contribute to the cost of dispute resolution, via a monthly levy.

In dismissal cases that are referred to the BCCEI, the process adopted by the Dispute Resolution Centre is one that involves referral, notice of hearing, conciliation, arbitration, and potential settlement agreements. Commissioners and arbitrators, appointed by the BCCEI, are crucial in ensuring fair and e icient resolution.

Dispute resolution is vital in preventing conflicts from escalating – saving both time and money, while additionally o ering an alternative to costly court proceedings.

– Merle Denson “ “

Ultimately, e ective dispute resolution is a vital component in the civil engineering industry’s drive to achieve stability and fairness.

www.samining.co.za 26 SA MINING MARCH / APRIL 2024 COLUMN ENGINEERING

views expressed are the author’s own and do not necessarily reflect SA Mining’s editorial policy. © ISTOCK –Phonsawat

The

And the BCCEI and its Dispute Resolution Centre are the ideal tools to provide genuinely accessible, expert and e icient mechanisms for resolving industry-specific disputes – thereby fostering a more e ective and harmonious work environment.

YOUR 24/7 SERVICE PARTNER

Repairs, maintenance and customised manufacture of all electrical and mechanical rotating machines.

ELECTRICAL SERVICES

Medium and low voltage, Ex certified, AC and DC motors, transformers, generators, alternators and ancillary power generation equipment up to 373 MVA.

MECHANICAL SERVICES

Full range of rotating machinery mechanical services. Machine shop capabilities including dynamic balancing up to 32 tons, large machining up to 40 tons, micro welding and hydraulic presses up to 1000 tons.

24 HOUR ON-SITE SERVICES

Breakdown repairs, removal, re-installation, on-site testing, dynamic balancing, alignment, vibration analysis, root cause analysis, condition monitoring, preventative and predictive maintenance, motor management programmes and maintenance contracts.

CUSTOMISED ELECTRICAL AND MECHANICAL DESIGN

Reliability improvements/enhancements, efficiency improvements, performance upgrades and root cause analyses.

+27 (0) 11 607 1700 | support@mandc.co.za

53 Hospital Street, Cleveland 2094, JHB

PRIMARY GOALS AND OBJECTIVES

The BCCEI’s primary goals and objectives extend beyond dispute resolution as a bargaining council. Its responsibilities encompass concluding and enforcing collective agreements; preventing and resolving labour disputes; administering dispute resolution functions; establishing and managing funds for dispute resolution; promoting and initiating training and education schemes; developing proposals for labour policies and legislation; providing industrial support services; and extending services to non-parties in the industry.

© ISTOCK –goncharovaia

© ISTOCK –sorn340

www.mandc.co.za

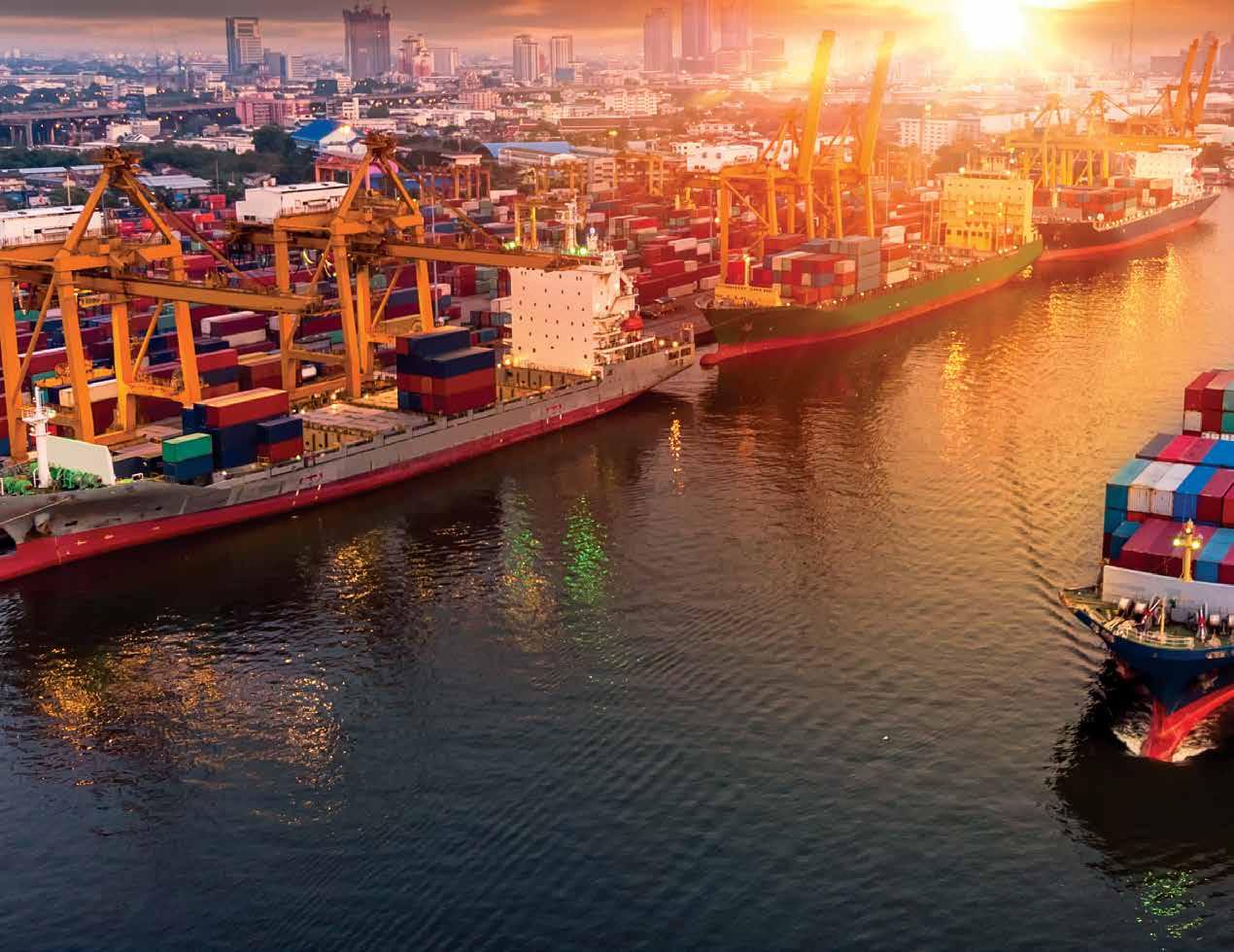

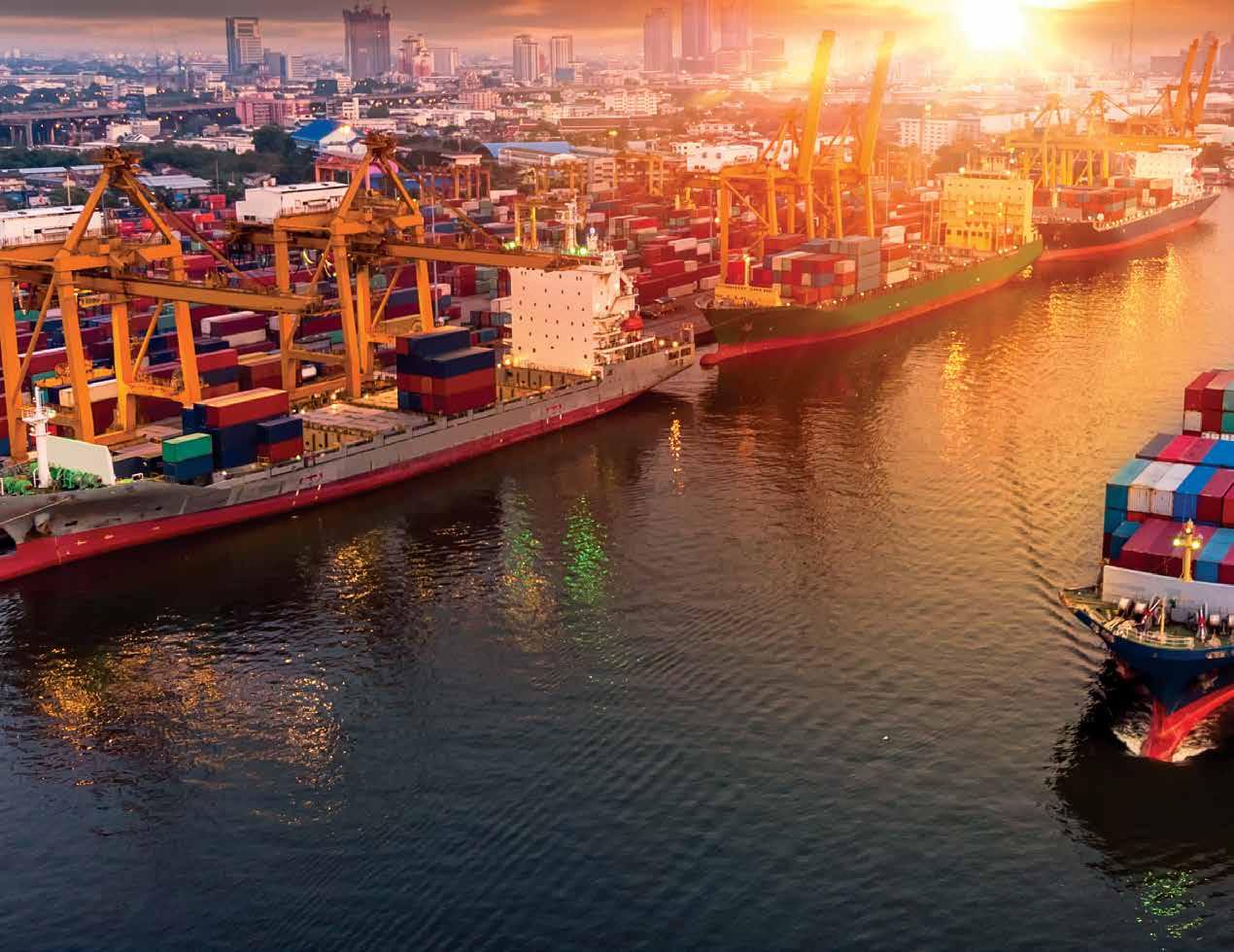

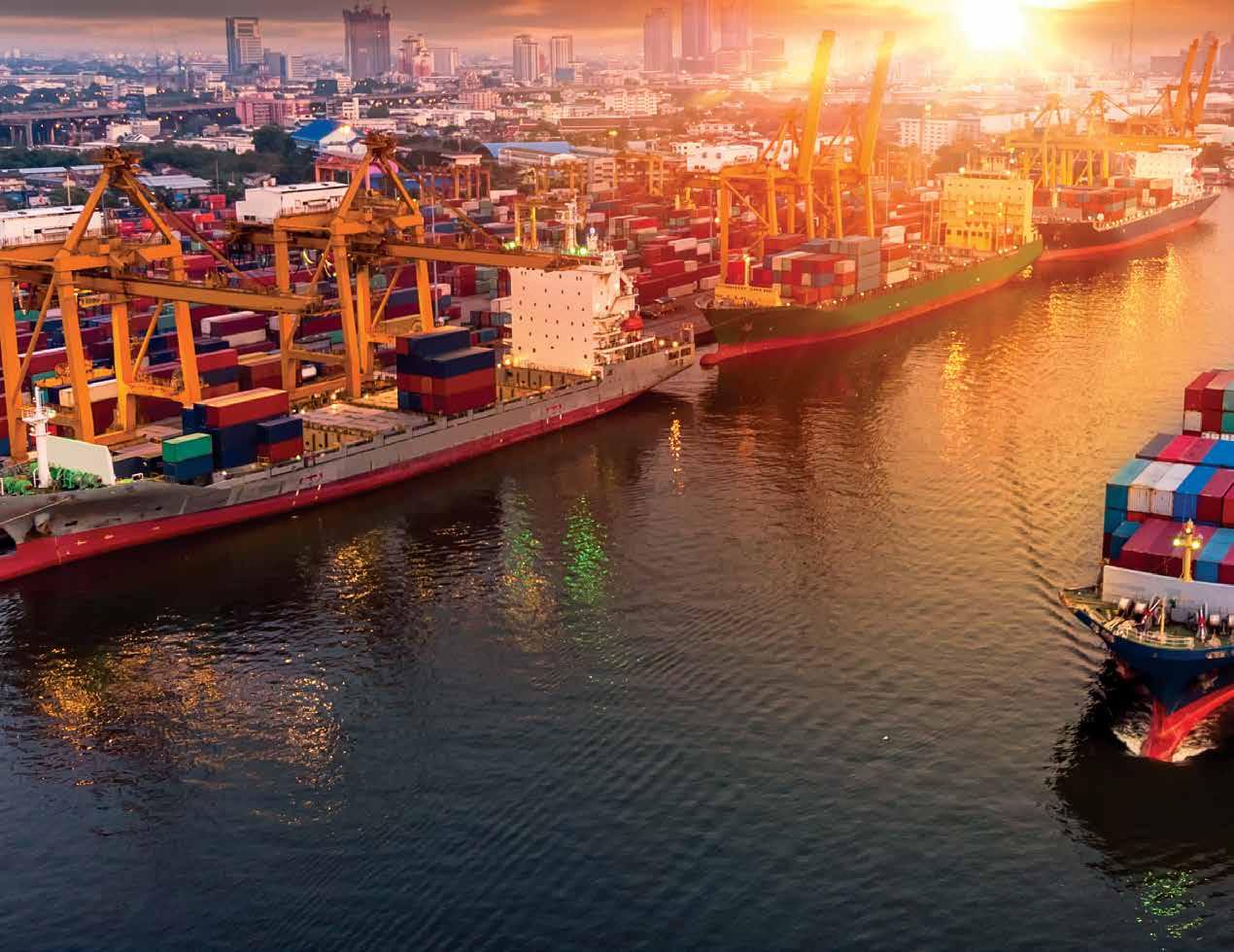

BROAD-BASED WEAKNESS EVIDENT IN THE LOGISTICS SECTOR

The Ctrack Transport and Freight Index recorded a notable decline at the start of 2024 – but thanks to the transport sector, it is not all doom and gloom.

Aer increasing somewhat in December 2023, the Ctrack Transport and Freight Index (Ctrack TFI) declined notably at the start of 2024, to an index level of 119.3, a drop of 2.1% compared to December’s level of 121.9. This abrupt deterioration in January is indeed a stark reminder that the sector still faces many challenges at the beginning of 2024.

Although born out of crisis, some progress had been made towards the end of 2023 to address the sector’s challenges and urgent focus is needed to take these reforms to fruition. According to the latest report from Operation Vulindlela (Q3/Q4 2023), progress has been made in the following areas:

APPROVAL OF THE FREIGHT LOGISTICS ROADMAP

The appointment of a permanent board for Transnet National Ports Authority (TNPA).

The National Logistics Crisis Committee (NLCC) has been formally constituted with participation from relevant government departments, Transnet and business.