Chaos and uncertainty is buffeting retailers and manufacturers, forcing organisations to innovate their way to profit.

Sportswear giant Nike is running a global fire-sale, because it is facing a glut of inventory, caused by –among other things – earlier-than-expected ordering by retailers, delivery problems (both too quick and too slow) and cash-strapped customers reigning in spending.

Nike is not alone; many major retailers are facing the same set of issues. This has left retailers facing the perilously difficult task of managing inventory in a world of turmoil, while extending reach to customers.

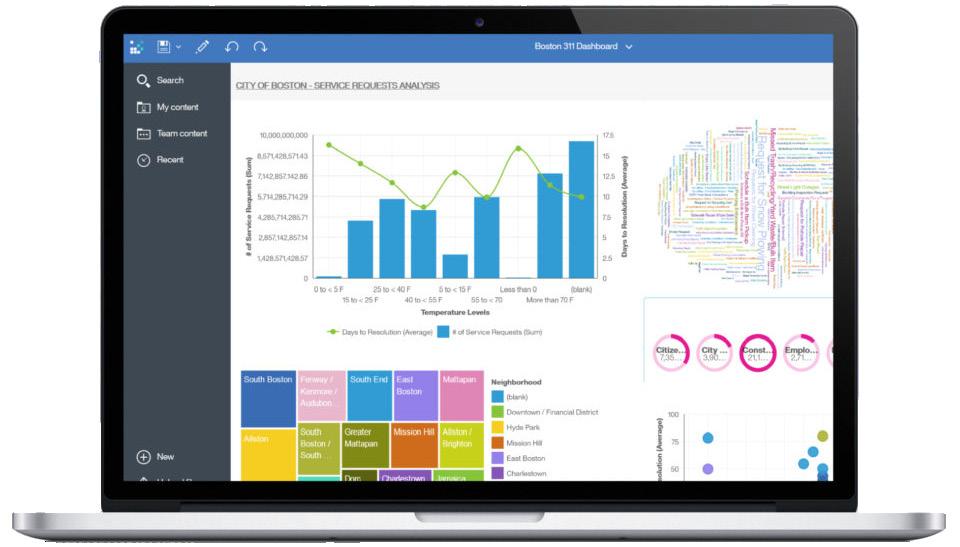

While the digitalisation of inventory management can help here, we learn in this issue of Supply Chain that it is by no means a panacea.

Technology rarely is. In this instance, retailers-cummanufacturers such as Nike need to look beyond technology, to reimagine the traditional retail supply chain as far more network-based, more dynamic, and more customer-focused.

This is no small order, and is indicative of the complex problems facing many organisations in today’s uncertain world.

That space – where problems meet solutions – is where you will find Supply Chain magazine, asking questions and seeking answers.

SEAN ASHCROFT sean.ashcroft@bizclikmedia.com

“Retailers face the difficult task of managing inventory in a world of turmoil, while extending customer reach”

It’s no coincidence that the orange is a Christmas stocking staple: around this time, oranges – as well as tangerines, mandarins, and satsumas – are bang in season. And January is the month that sees citrus fruits at their most sweet and succulent.

In terms of growing, China (it always seems to be China) is the world’s top citrus fruit producer, growing 44.6 million tonnes in 2020, which was roughly 28% of the world's total. Guangdong Province is the country’s top producing region. The next top producers are Brazil, India, Mexico, and the US, who together account for 59.15% of the total.

Heathrow Airport

By 2050, clean hydrogen could help save seven gigatonnes (GT) of CO2 emissions annually, which is about 20% of current global emissions. Below are the areas that will offer the greatest C02 savings, in descending order of importance

Source: McKinsey

“What drives the overall culture at Rivian is a multigenerational purpose that goes beyond any one of us”

Brad Hood Director of Indirect Purchasing Rivian

“In the Middle East & Africa we have the sun to thank for the region’s access to renewable energy”

Ako Djaf VP Contract Logistics ME&A DB Schenker

“An airport is a city of services and the diversity of what we do is on a huge scale”

Amazon's plans to lay off around 10,000 corporate and technology jobs – 3% of its workforce – has sparked concerns it is set to begin axing roles in logistics.

The cuts include Amazon’s retail division, which is responsible for online shopping, physical retail and a chunk of the firm’s logistics operations.

Amazon has scaled back its logistics operations in recent months. The company has delayed, or is closing, 60 warehouses, as well as scrapping services like free Whole Foods delivery, and its Scout home delivery robot as it contends with slowing e-commerce growth.

Like many businesses, Amazon is struggling in the face of soaring inflation and rising interest rates.

There is concern in the wider logistics sector that Amazon’s shrinking retail operation might have a knock-on effect on Amazon Freight, a third-party logistics operation that in the UK and Europe alone, runs a network of 6,500 trailers and 13,000 carrier partners.

Ports worldwide are clogged with empty shipping containers as the readjusts to economic slowdown and a post-pandemic change in customer behaviours, says a company whose digital platform helps match container supply with demand.

The first rail bridge connecting Russia and China is finally up and running, having been first mooted in 2008. The Nizhneleninskoye-Tongjiang Bridge means the route to reach northern Chinese provinces from Russia will be cut by 700km.

DHL’s latest Airfreight State of the Industry report suggests soaring inflation is likely to see reduced purchasing power and demand for air freight going into 2023. It shows lower sales and high inventory are common across most sectors, with retail and manufacturing most affected.

Most organisations are failing to measure the environmental impact of their supply chains, a new report by CIPS and Deloitte has found. Just 26% of public and private sector organisations are monitoring greenhouse gas emissions in their supply chain.

The chip shortage is an ongoing global crisis that has seen integrated circuit demand massively outstip supply - a problem that continues to affect 169 industries

The COVID-19 pandemic caused massive disruptions in supply chains and logistics. This was coupled with a 13% increase in global demand for PCs as people worked from home. Chips were suddenly unavailable for the manufacture of a broad range of products, including vehicles.

As part of the economic conflict between China and the United States, the US Department of Commerce imposed restrictions on China's largest chip manufacturer, Semiconductor Manufacturing International Corporation (SMIC), which made it harder for them to sell to companies with American ties

Severe weather in Taiwan

Taiwan is the leading producer of chips, and severe droughts in the summer of 2021 affected output. The droughts affected production due to the lack of available ultrapure water that is needed to clean the silicon wafers used in microprocessors.

The increased use of cryptocurrencies requires a huge amount of data mining, all done with specialised computers. The high demand for cryptocurrency mining machines reduced the availability of chips for other uses.

Russia invades Ukraine

Neon is critical for the lasers used to make chips, and Ukraine's two leading suppliers of neon produce about half the world's supply . Both halted operations when Russia invaded, causing further disruptions to supplies of chips

Robert Martichenko is a supply chain business leader who has turned his attention to improving the very nature of work

Robert Martichenko is a business leader, author, speaker, educator, and strategic advisor who was founder of the LeanCor Supply Chain Group, spending 15 years as its CEO.

Martichenko has spent 25 years learning and implementing lean operational excellence, with a focus on end-to-end supply chain management across a wide array of industries.

LeanCor was acquired by Uber Freight in 2020, triggering Martichenko to transition to advisory work early in 2022.

These days, his mission is to embrace the role of the “Human CEO”.

He defines this as being someone “who believes that respect, empathy, relationships, education, courage, and critical thinking matter to remain both relevant and competitive”.

To this end, he created TrailPaths, an online venture to promote workforce development and “promote advances in workplace dynamics”.

Martichenko says of TrailPaths: “Technology, the pandemic and disruptive business models are fundamentally changing the nature of work as well as the relationships between people and the work we perform.”

North America, he says, “is struggling with workforce issues relative to workforce engagement at many levels”. He adds that the key issues “are with all the people that actually get stuff done – the people that add true value and are a critical part of the team”.

“Yet, do organisations even see these people as an important part of the team? Blue Collar workers? Front line workers? Now, the tables have turned and such people have decided to take things into their own hands – and we’ve learned that this isn’t simply an issue of compensation. This is about people not being part of a meaningful work environment.”

Martichenko says people “need to see meaning in what they do and who they do it for”, and that this goes to the heart of what TrailPaths is about. “It’s a community that

wants to help develop these meaningful environments,” he explains.

In this way, Martichenko’s thought leadership has seen his influence spread beyond the sphere of supply chain.

As a professional speaker, he addresses topics as diverse as: building cultures of continuous improvement; the power of narrative leadership; discovering hidden profit; and making work meaningful.

Martichenko also volunteers on multiple advisory boards and educational institutions, including the American Logistics Aid Network and the Association for Manufacturing Excellence.

He has also received many prominent industry awards, most notably the Distinguished Service Award by the Council of Supply Chain Management Professionals – the highest recognition available for supply chain professionals.

Writing is another of Martichenko’s accomplishments. He is the author of several business books, most recently of Discovering Hidden Profit, which he says is for CEOs and executives “who are dealing with continuous industry disruption and increased complexity”.

He adds: “It offers an actionable methodology to extract hidden profit by removing organisational masks while connecting people and business processes in order to maximise customer value at the lowest possible total cost”.

His other books include Everything I Know About Lean I Learned in First Grade, written to educate the entire organisation on the fundamentals of lean thinking, and in which he shows how to identify and eliminate waste.

» 1NCE is an IoT company – the only one to offer IoT connectivity and software service at a lifetime flat-rate across the globe. I’ve worked in IoT and the mobile industry for 20 years. Previously, I was SVP at T-Mobile and CEO of IoT at Vodafone. I suppose you could say I’ve been in IoT since its infancy. In my current role, I lead the company operationally and oversee its expansion into the Americas and Asia.

» An IoT telecoms network handles the communication and management of a device with its software environment in the cloud. There are sensors on one side that want to communicate with software on the other side, providing intelligence that helps companies decide how to adjust resources and optimise their supply chain, smart city utilities or any one of a million uses the IoT can offer.

The sensors collect data via integrated sensors on things like temperature and position, and the software then processes it.

In between them is 1NCE: we connect the sensor with the local telecom network via cellular technologies and forward the data to the cloud. We also handle security and authentication processes, protocol conversion, device management and much more.

The plumbing of the IoT has nothing directly to do with what a supply chain manager is using IoT for, yet 75% of IoT projects fail largely due to these complex requirements.

» Supply is dependent on synchronisation across borders, currencies, measurement systems and time zones. Billions of IoT devices keep it all together, which is why 80% of IoT projects are international in nature. But there aren’t global mobile operators that can bring IoT together.

For supply chain managers, it’s a pain – to put it very lightly – to deal with devices that use different operators in every country.

We have strategic relationships across the globe to provide seamless, easy connectivity everywhere.

.

» 1NCE is very fortunate to have some large investors like Deutsche Telekom, with whom we have a unique partnership to deliver connectivity to every type of IoT network. Deutsche Telekom's global networks are designed for the requirements of global communication between humans and devices – driving the evolution of IoT in Europe and the USA with state-of-the-art networks.

The Internet of Things (IoT) underpins much supply chain connectivity, but holding IoT together is an unseen telecoms network managed by 1NCE

1NCE helps Deutsche Telekom and others like it meet the full spectrum of IoT network needs.

» There’s limitless potential for 1NCE to be that behind-the-scenes company you’ve never heard of – the backbone that keeps every part of the supply chain’s IoT network running smoothly.

We are already building the network of the future. It will have lifetime connectivity for low-data sensors and unlimited data for highbandwidth sensors.

Simply put, we’ll make connectivity electricity-ready for consumption, so you can focus on what you want sensors to capture.

» If you want you to scale, be conscious of your limitations and hire the best possible team, and then give them the freedom to act with confidence. Confidence can only have two sources: expertise and experience. Every other form of confidence is just cockiness.

» The person I admire I will not name, for the very good reason that his philosophy is that business is not about yourself.

This person was once the CEO of an airline that, for several years in a row, was recognised as the most customer friendly. When asked why customers rated his company so highly, his answer was brilliant: “Because we realise that people don’t want to fly.”

This is deeply insightful. He realised that it was not about the flight, the plane or even the journey, but about making people forget they were travelling and making them enjoy the moment with whatever they were doing.

“IF

Brutally honest. That’s a phrase that springs to mind when talking procurement transformation with Sue Spence – Vice President, Global Sourcing & Procurementat FedEx Corporation.

Drafted in by the shipping and transportation giant a little over nine years ago to build a centralised sourcing and procurement operation from scratch, straight-talking Spence wasted little time in making a big impression.

“One of my favourite phrases is ‘begin with the end in mind’,” she says. “My approach to designing the future state of sourcing and procurement at FedEx was to first define what world-class looked like for our function. We came up with seven characteristics of a bestin-class organisation and then gave ourselves a brutally honest assessment (red, yellow, green) on how close or far apart we were from those characteristics. There was a whole lot of red back in 2013, but by 2018, it was a whole lot of green.”

Let’s just put the scale of the task Spence faced into perspective. In fiscal year 2022, FedEx delivered 3.1 billion packages. That is almost 8.5 million packages per day, delivered globally, by plane, train and truck. Over 550,000 people work for FedEx, literally juggling billions of moving parts, schedules and itineraries.

FedEx Corporation, on driving the organisation’s procurement

SUE SPENCE VICE PRESIDENT, GLOBAL

SUE SPENCE VICE PRESIDENT, GLOBAL

A great deal of that US$17bn annual Spence spend goes on fuel, and when there is disruption in the supply chain, like during the Colonial Pipeline cyber attack, it would be easy for FedEx operations to slowly run out of gas – were it not for robust risk assessment in the organisation’s supply chain. This is where Spence – and the sourcing and procurement team she has shaped – really shows her value.

Prior to joining FedEx, Spence had a 28-year career with United Technologies Corporation, in positions of increasing responsibility at the aerospace divisions of Pratt & Whitney, Hamilton Sundstrand and Sikorsky Aircraft as well as a key leadership role in Sourcing at the UTC Corporate office. She had multiple roles of traditional procurement, strategic sourcing as well as managing continuous improvement for both the assembly and maintenance and repair operations at Pratt & Whitney – experience that has proved invaluable in her FedEx role.

“Take a leap of faith and be more confident in your abilities. There is never a perfect time to go for the big job or challenge”

SOURCING & PROCUREMENT, FEDEX CORPORATION

“My time managing continuous improvement taught me the criticality of the measurement system as well as ‘learning to see’ through process mapping, root cause and corrective action, and especially in business processes where there is so much opportunity to streamline,” she says. Spence brought that methodology to FedEx, which proved an extra challenge as she was an ’outsider’, but also gave her the distance from the company to see a clearer route forward. But when you are tasked with building a world-class procurement team, what are you looking for? Spence is quick to list: demonstrating category expertise; managing effective stakeholder relationships; making decisions based on data, not emotion, and monitored by a robust measurement system; focusing on process improvement to increase productivity; raising the bar on performance for both suppliers and employees; and leveraging spend across the entire book of business you have with your suppliers. Recognising that this is a Herculean task for an organisation as complex and vast as FedEx, it’s also essential to proactively develop and manage the existing talent on your team. And that’s just for starters.

TITLE: VICE PRESIDENT, GLOBAL SOURCING & PROCUREMENT AT FEDEX CORPORATION

INDUSTRY: FINANCIAL PACKAGE FREIGHT DELIVERY

LOCATION: UNITED STATES US$17bn

Joining FedEx in October 2013, Sue leads a team managing US$17bn of spend, systems and policies governing the global sourcing and procurement process. Sue serves as a member of several Supply Chain Industry and University councils and advisory boards, and in 2020 was honored with the Institute of Supply Management’s J. Shipman Gold Medal Award, a recognition of individuals whose career accomplishments have advanced the supply chain management profession. Prior to FedEx, Sue spent 28 years at UTC in positions of increasing responsibility in Supply Management and Operations Transformation at Pratt & Whitney, UTC Headquarters, Hamilton Sundstrand and Sikorsky Aircraft.

Company

“In order to drive such a large transformation, you need to understand what you are getting into and do not underestimate the level of energy it will take,” says Spence. “This isn’t just referring to hours in the day, but mental energy to drive toward something new, especially in an organisation where outside executives are unusual.

“Be an evangelist about the mission and transparent with your team as much as possible; give frequent feedback and always explain what the accomplishment of the team’s goals can mean to their career. Be decisive, once you have allowed for multiple points of view to be heard. Don’t be afraid of the stretch goal and ensure when you ask for resources (both people and budget) you have a solid business case for your request.”

So just how did Spence achieve the sourcing and procurement transformation FedEx was hoping for? She says it was down to a number of what she calls guiding principles – five pillars that delivered the desired results. Lucky for us, she is happy to share:

• INCLUSION – include every one of our managers and their teams in creating the enabling initiatives that would help us accomplish the best-in-class characteristics, and allow those ‘future state teams’ to lead the execution of these projects.

• ALIGNMENT – socialise and gain alignment with our key stakeholders inside the company so they understand WHY we were undertaking the journey, HOW we would measure success, and WHAT service levels they could expect from us. In the first six months I was there, I met with 100 of the top

SUE SPENCE VICE PRESIDENT, GLOBAL SOURCING & PROCUREMENT, FEDEX CORPORATION“Don’t be afraid of the stretch goal and ensure when you ask for resources (both people and budget) you have a solid business case for your request”

executives of the company personally to explain the mission and gain their support for it.

• COMMUNICATION – frequent updates to my entire team about the progress of each of the initiatives and over communicate why they were important, how they contributed to the mission and how our value would connect and contribute to FedEx’s overall value for our stakeholders (employees, customers, and shareholders).

• ACCOUNTABILITY – commit to the team to train and coach them as much as possible so they could become worldclass sourcing and procurement members but hold them to a very high level of accountability.

• TRANSPARENCY – create measurement systems for our team, both qualitative and quantitative; act with data and drive relentlessly to root cause and corrective actions for issues we uncover as we perform our work and deliver our value.

“Take a leap of faith and be more confident in your abilities. There is never a perfect time to go for the big job or challenge. Read all the time, research anything that seems interesting whether it is business related or not (satisfy the curious mind). Never, ever think you have to choose between your family and your job.

“Family/kids, if you are lucky enough to have them, always come first. Providing for them by working hard and accelerating your career is not choosing the job first. You are providing a role model for them and having your own professional satisfaction, wherever you are in your career, is important to them because you will be happier.”

In 2020, Spence won the coveted Institute of Supply Management’s J. Shipman Gold Medal – recognition of her advancement of the procurement and supply chain management profession. She is suitably modest about her achievement, saying her grown daughters now believe “mom may have a good idea or two every now and again” while also saying it has helped boost her LinkedIn connections. But don’t be fooled for a second – Spence appreciates the gravitas of the award, and her position as a role model both within procurement and in general.

“I attribute that to a diversity of experience within procurement – from the beginner level all the way up to the Chief Procurement Officer role, both on the direct as well as indirect side in very different industries,” she says.

“In business generally, I attribute that to working for my first 29 years in a very male-oriented environment that was also engineering focused. I am an economics and political science major with an MBA, and learning the technical side of the business presented quite the challenge.

As you can probably tell by now, as you would within five minutes of sitting face to face with Spence, her leadership style is inclusive, transparent, decisive and what she calls “biased for action”.

“My team will tell you I push like hell and am always digging for more info, more achievement, what’s next,” she says. “I love the debate and will switch sides of the debate to hear how they will defend their positions; I want them to be confident and anticipate as many questions as possible. I’ve often said if you can get by me, you are ready for anyone!”

“A non-technical female in a maleoriented engineering-focused industry…. success took grit, resilience and asking a whole lot of questions. Being curious was/ is a critical skill that has helped propel my career.”

Speaking at Procurement & Supply Chain LIVE London in October, Spence had the audience riveted both in her keynote session and the closing panel discussion. Respected and revered by her peers and the next generation of procurement professionals alike, she is a warm, honest, and supremely talented leader that other leaders can learn from. Which is just one reason why we expect Spence to continue

“My team will tell you I push like hell and am always digging for more info, more achievement, what’s next”

“A non-technical female in a male-oriented engineering-focused industry….success took grit, resilience and asking a whole lot of questions”

to drive the shape of procurement in the foreseeable future. So what does she think that looks like?

“The transactional, repeatable work that we did 30 years ago will and should be automated and as touchless as possible,” she says. “The focus of our talented teams has to be strategic, market-savvy, innovative, and value-driven so that we are

seen less as the back-office support group and more as the partners for the business.”

You can imagine procurement professionals around the world nodding in agreement with that.

In the early stages of the pandemic, sportswear manufacturer and retailer Nike deployed radio frequency identification (RFID) technology to track products flowing through outsourced manufacturing operations. It also used predictive-demand analytics to minimise the impact of store closures across China. By rerouting inventory from in-store to digital-sales channels – and acting

early to minimise excess inventory buildup across its network – the company was able to limit sales decline in the region to just 5%.

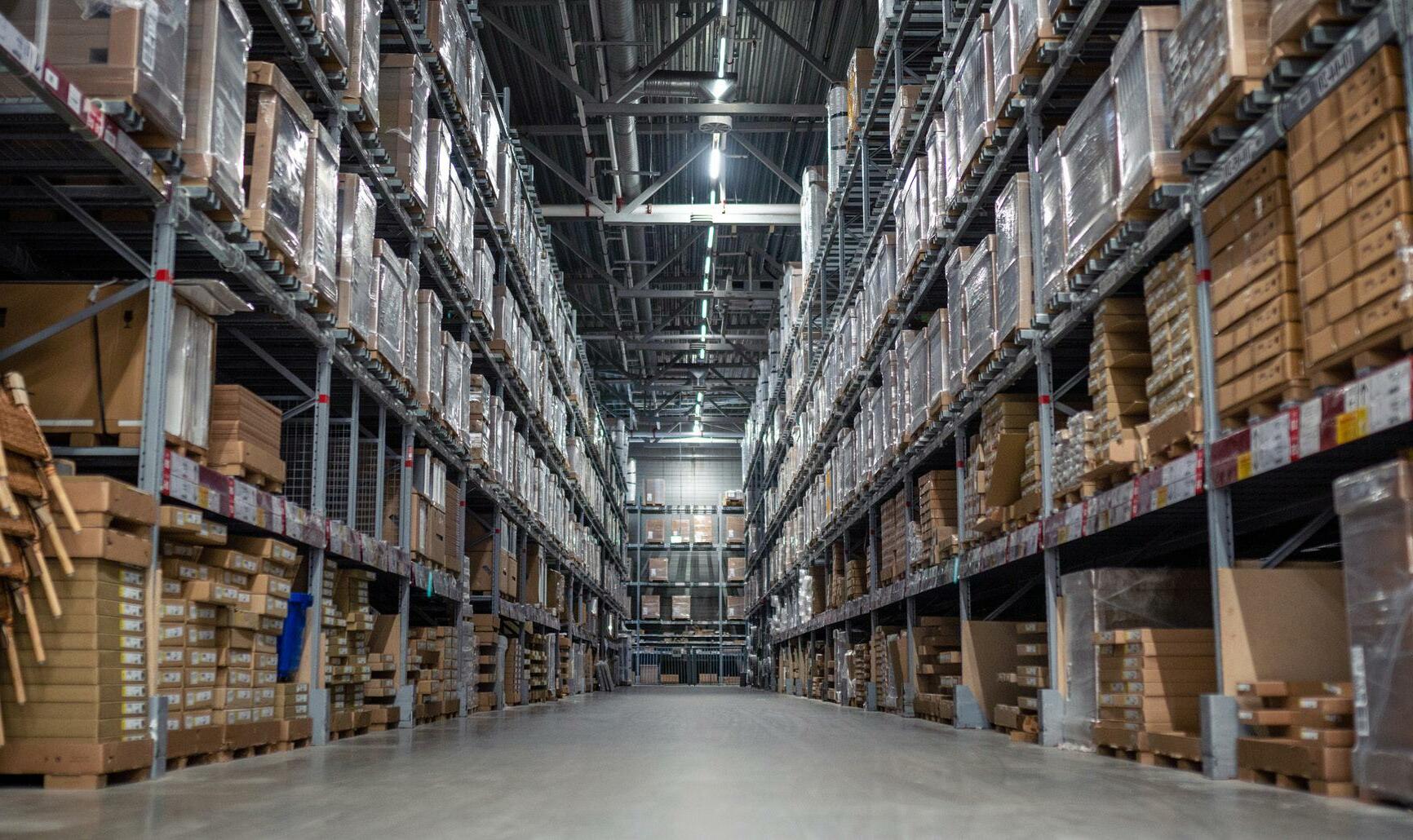

But fast-forward two years, and Nike is in the midst of a global fire sale as it bids to clear an epic inventory glut that the company blames on late deliveries over the past two seasons, compounded by earlier ordering by retailers and faster-than-usual deliveries.

The company has admitted that, despite strong demand, it will follow a policy of “aggressive markdowns” to clear inventories, though this will likely impact margins this fiscal year.

Nike CFO Matt Friend said on the company’s quarterly call that inventory was

up 44% company-wide, driven largely by a 65% hike in North America, its largest market. Friend said Nike plans to “tighten buys in the second half of the financial year and liquidate excess inventory more aggressively beginning in the current quarter”, in the hope it better balances inventory in 2023.

Many clothes retailers are experiencing something similar, watching inventory pile up as inflation-hit consumers rein-in their spending.

“I hesitate to call it a bloodbath, but it’s going to be ugly in terms of the amount of discounting and markdowns,” Urban Outfitters CEO Richard Hayne said during a Q3 earnings.

In a post on LinkedIn, Brandon Rael – Business Transformation Leader with Capgemini Invent – said of the Nike situation: “It’s continuing its aggressive push with its direct-to-consumer (DTC) strategies, and, at the same time, is in an overinventoried situation where it has to review its wholesale partnership model.

“Nike is re-evaluating its wholesale partnership model while growing its DTC retail space. Its partnerships with Foot Locker, JD Sports, and others offer Nike an opportunity to manage its inventory challenges while extending its reach to customers, via well-established retail and wholesale models.

“Foot Locker and others have done an outstanding job of adding value to the Nike brand by providing a shop-within-a-shop customer experience.”

This ‘tale of two Nikes’ shows just how perilously difficult it is for businesses to manage inventory in a world in which market chaos is … groan … the ‘new normal’.

While the digitalisation of inventory management can be seen as a salve to such problems, it is no panacea. Here, Supply

Chain Digital speaks to Will Lovatt, General Manager and Vice President Europe with Deposco, an inventory visibility platform whose customer profiles range from rapidly growing small ecommerce operators through to global consumer packaged goods brands and leading-edge 3PL fulfilment operators.

Lovatt shares insights into the inventory management challenges facing today’s businesses and how some of these challenges can be met.

Nike is drowning in inventory. How can digitalisation help? Our proposition enables organisations to use inventory to satisfy customer demand, no matter where that inventory is located. The net effect is that, for the same inventory

“ WITH OMNICHANNEL, BRANDS ARE HELPLESS WITHOUT A WAY TO RECEIVE ORDERS AND PROACTIVELY IDENTIFY THE BEST INVENTORY TO SATISFY THAT DEMAND”

WILL LOVATT VP & GENERAL MANAGER, DEPOSCO EUROPE

investment, we are able to extend the reach and responsiveness of the network.

Nike’s consumer-facing ecommerce operations send stock via retail partners to satisfy its end customers. Digital solutions such as ours help organisations match customer demand to available inventory across the business, minimising overstocking.

How has inventory management changed since COVID-19?

When the bricks-and-mortar retail world initially closed for Covid, online sales grew explosively, so having an omnichannel fulfilment capability became a necessity for every retailer, consumer brand, or marketplace operation.

IBM’s 2022 Chief Supply Chain Officer study shows that CSCOs are embracing AI and automation technologies “to provide ecosystem interconnectivity, sustainable operations and operational predictability”. Almost half (47%) of surveyed CSCOs said they have introduced new automation technologies in the past two years to add predictability, flexibility and intelligence to their operations.

IBM found that innovating businesses are outperforming their peers on KPIs, enjoying 11% more revenue growth on average.

Sustainability has become a higher priority: The study focuses on how CSCOs are navigating significant supply chain disruption brought about by inflation, instability in the financial markets, recent geopolitical events, a global pandemic, climate change and more – and how they plan to future-proof their supply chains.

It is based on interviews with 1,500 CSCOs and COOs in 35 countries and across 25 industries.

With omnichannel, brands are largely helpless. They lack a way to receive orders from whichever channels and locations orders are placed and then proactively identify the best inventory across the network to satisfy that demand, As the pandemic grew, many businesses were left with excess pockets of inventory originally intended to serve now-closed retail operations, as well as customer orders left unsatisfied in channels where no inventory was available.

How do you make an omnichannel supply chain work well?

For an omnichannel supply network to operate effectively, it needs to fulfil three key requirements.

First, it must be sufficiently flexible to evolve as new channels open and sources dry up. Plus, new selling platforms – marketplaces and ecommerce frontends, for example – need to be integrated and served.

Second, it has to be connected in realtime to all viable sources of inventory – something that can only be achieved with the help of web-based IT services.

Finally, the company’s supply network must have deep knowledge of both the product and the sources of supply, so that the most suitable option is offered to customers based on location, timing, and local legislative requirements.

How can businesses best meet these challenges?

Primarily, organisations need to break away from the constraints of traditional retailserving supply chains to accommodate supply networks. They can do so through dynamic, customer-focused, demandsatisfaction solutions; these need to

WILL LOVATT VP & GENERAL MANAGER, DEPOSCO EUROPEdeliver a real-time interface that embraces every commerce touchpoint while also considering all inventory sources.

Is legacy software in omnichannel fulfilment a problem?

Yes, it’s a major issue. Batch updates and overnight refreshes between domains may have been adequate for a supply chain where customer interaction was limited to retail locations only. But the dynamic world of omnichannel fulfilment has to execute in sub-seconds across all customer-serving locations. Mismatches can lead either to heavy overstocking or the risk of double selling.

What role do strategies such as dark warehouses, micro-fulfilment and in-store inventory warehousing have to play?

Our solutions were born on the web and are architected to work in mixed omnichannel IT environments to serve our rapidly growing ecommerce direct-to-consumer customers.

We offer visibility across the inventory landscape, including traditional warehousing, retail stores, and various forms of fulfilment centres. Our customers also have the realtime ability to match source with demand.

It’s all about working at scale and complexity but delivering simplicity and rapid time-to-value

PRODUCED BY: CRAIG KILLINGBACK

PRODUCED BY: CRAIG KILLINGBACK

From empty terminals in 2020, to serving over 50 million passengers in 2022, Heathrow Airport has weathered some mighty turbulence in recent years. Now the UK’s hub airport is building back, Heathrow’s procurement team stands ready to ensure the airport’s growth is efficient, responsible and meets the needs of every passenger

From the outside, running a procurement operation with the size and variety of London Heathrow airport is an incredibly complex challenge. For Paul Doherty – the Procurement Director at Heathrow Airport –and his team, their job becomes clearer when they focus on the most important person in the building.

“The passenger is central to everything we do, every decision that we make and every project that we launch. Every operational change or operating procedure that we do has the passenger at the centre of those decisions,” he says.

With passenger numbers steadily climbing back higher, a hundred thousand priorities are walking through the terminal doors every day, each of whom need to be given the best possible travelling experience.

‘It is really important to us that, from the moment the passenger enters the airport, their holiday starts. So we want them to be comfortable, we want them to be enjoying the experience that they have,” he says.

Paul speaks passionately about customer care, about how every member of staff at the airport should support a passenger if

they see them in any form of confusion or discomfort. That mantra permeates right from the very top of the executive team down to all of Heathrow’s colleagues - including the airport's operators via their service signatureswhich provide a framework for the passenger service proposition, to notice and care, share what they know and ensure the passenger’s problem is resolved before they leave.

This is just an example of the variety of tasks that present themselves daily in what Doherty describes as a ‘city of services’, which features an enormous range of diversity regarding what they have to deliver on a huge scale.

“I've just come off of a call talking to someone who is at the party conferences, understanding the political landscape. Later on, I'm going to go and talk about cleaning performance in one of our terminals. This afternoon I'm going to talk about algorithm development and security products.”

Because of the incredible breadth of the services he speaks about, becoming a “specialist at being a generalist” is a given –there are few jobs where you can start your day dealing with politics and end with cleaning regimes, successfully able to pivot between the two as well as engage with everything else within that. It also necessitates having experienced people in post who can cope with operating under the pressures of one of the busiest airports in the world.

PAUL DOHERTY PROCUREMENT DIRECTOR , HEATHROW

“ The passenger is central to everything we do, every decision that we make and every project that we launch”

A world class player in the mobility market, committed to empowering the freedom to move everyday thanks to safe, reliable, sustainable and innovative solutions that serve the common good.

Contact us

Rebecca Mupita, MD of Transdev Airport Services, says the future for the company will be green, and connected to local Heathrow communities

Rebecca Mupita is Managing Director of Transdev Airport Services and CCH Aviation Logistics, both of which are part of the Transdev Group, whose core function is delivering multimodal transportation services.

Mupita and her colleagues are based a stone’s throw away from Heathrow Airport, and provide innovative, sustainable passenger transport and fleet maintenance solutions for the aviation sector. “We deliver solutions that are aimed at providing clients and customers with complete transparency, so that they better understand their operational demands,” she explains. “With this insight, we can identify and tailor the right solutions to support.”

As well as managing and maintaining complex airport fleet and equipment, Mupita and her team provide scheduled and on-demand transportation services and manage airport bus and coach stations. Tailoring its services and solutions is just part of the company’s transformation journey,

as it continues its recovery from a brutally tough pandemic. “Covid hit Transdev very hard,” says Mupita. “It decimated the aviation industry.” In the post-pandemic era Transdev is not just rebuilding, but is “rebuilding green”, says Mupita.

“Reducing emissions is at the heart of our sustainability measures,” Mupita adds. “We are currently planning to deploy a new electric fleet at Heathrow Airport, and through our new technologies we are also designing passenger services that reduce unnecessary transfers, while enhancing the passenger experience.” And, she adds, the company will also continue to extend its outreach initiatives, working with local schools, colleges, and universities, looking to find the next generation of ‘journey makers’.

“We’re increasing our apprenticeship schemes to develop young talent,” says Mupita. “Typically, logistics isn’t a career young people think about going into. But we are looking to change that.”

Doherty speaks on the transformational challenges – caused in part by the pandemic – that Heathrow have undergone while continuously modernising and embracing new security technologies. “Our new security solution means you won't have to take your laptop out of your bag,” he says. “You can go through security and just put your bags through a scanner. It’s a much less intrusive journey.”

“We talk about a frictionless passenger journey, and it's just like a good doctor in the NHS: when you need us, we're there.”

Doherty’s route to being Director of Procurement started in a very different, but also incredibly demanding form of transport.

He worked in operations at the London Underground for seven years, but says he always found getting into the capital space appealing and, ultimately, took on a more junior role at Heathrow to expand his personal skill-set. From there, he progressed through different projects, including the airport's role in hosting London 2012 Olympics arrivals, baggage categories, heading up terminals and, when the pandemic arrived, closing down aspects of the capital portfolio before moving into the operational environment to focus on cost reductions and supplier management.

“We did that as caringly and as responsibly as we could with our capital supply chain partners, many of whom are still with us and working. Following that, I went over

Paul Doherty is the Procurement Director at Heathrow Airport, responsible for Operational, Infrastructure and Technology procurement.

Paul’s accountabilities centre around meeting the airport’s current and future business needs. His teams are focused on delivering value for money, data-driven insights and trusted advice to both internal and external stakeholders. Paul is passionate about empowering his teams to target continuous improvement and delivering results to advance the talent of the procurement team.

A constant focus for Paul is working with our supply chain partners and local community to ensure Heathrow’s strategic sustainability goals and targets are achieved to maintain the airport's licence to operate.

Where our data experts pinpoint where you can make the biggest carbon savings to accelerate your path to net zero.

This is the Science of Service

This is just the star t

mitie.com/scienceofservice

The exceptional, every day

Mitie prioritises decarbonisation and takes a flexible approach to sustainability through its Plan Zero, which supports its partner Heathrow Airport

As the UK’s leading facilities management and professional services company, Mitie is determinedly working on not only its own decarbonisation journey, but also supporting partners including Heathrow Airport. As Mike Sewell, Mitie’s Plan Zero Director, says, “if an organisation wants to drive real change in decarbonisation, it absolutely should be front and centre for their facilities management providers to be the party that’s helping them on that journey”. For partners like Heathrow Airport, Scope 3 includes their supply chain, which includes Mitie. Sewell’s approach to partner support is simple: “Just by operating better ourselves, we’re already helping reduce their Scope 3 emissions— and that applies to every single customer that we work with”.

Mitie has “committed to having net zero, from a Scope 1 and Scope 2 perspective, by 2025 and Scope 3 by 2035”. Mitie’s industry-leading Plan Zero initiative has three key focuses: eliminate carbon emissions from power and transport; eradicate non-sustainable waste; and enhance inefficient buildings.

For example, Sewell says that within Mitie’s operations the majority of emissions sits in our use of vehicles: “We’ve focused our efforts on decarbonisation of our fleet together with connected workplaces where we’re actually looking at better data connectivity, where we can actually monitor sites, understand sites and deal with things remotely.”

Mitie’s latest ESG report highlights its progress, centred around five pillars: Environment, People, Community, Responsible Supply Chain and Innovation. Among its sustainability successes Mitie reports a 33.4% reduction in emissions since the FY19/20 baseline year and how it has cut 11,445 tonnes of CO2 by investing in electric vehicles (EVs).

By prioritising its own decarbonisation journey, Mitie put itself in the best position to support partners and proactively work to reduce its impact.

As Sewell states: “Decarbonisation: it’s not a challenge for one organisation, one customer. It affects us all.”

1944 - Construction of London Airport's runways begins 1946 - London Airport Officially Opens

1955 - Her Majesty The Queen opens the Central Terminal Area and Control Tower 1966 - London Airport renamed ‘Heathrow’ 1969 - Terminal 1 opened 1976 - Concorde makes its first passenger flight 1986 - His Royal Highness Prince Charles and Princess Diana inaugurate Terminal 4 1987 - The British Airports Authority is privatised as BAA plc 2003 - Three Concordes make their final touchdown at Heathrow 2007 - A new air traffic control tower is operational – the tallest in the UK 2008 - Terminal 5 officially opened by Her Majesty The Queen 2009 - Major refurbishment of Terminal 4 2014 - New Terminal 2 re-opens 2015 - Terminal 1 closed 2016 - Heathrow celebrates 70th anniversary

to our operations teams to support them in removing the costs that we needed to be able to continue operating through the pandemic,” he says.

It resulted in him being offered the Director of Procurement in 2021, a role for which Doherty thinks the breadth of his experience across both the capital and operational sides of transportation has positioned him well, as having both pillars of experience gives a better, more holistic outlook on the role.

“I always knew the benefit of broadening my portfolio. I had relative success at quite a young age in the operational space and knew that to actually really understand the business, you need to understand both the capital and the operational side of the company,” he says.

The pandemic presented all sectors with genuinely unprecedented challenges, and Doherty believes that the legacy of that time is the biggest single challenge facing all airports: passenger numbers at Heathrow had consistently climbed in the decade leading up to the pandemic, before dropping to 22.1 million in 2020. This created a situation when scale had to be quickly changed to cope with a 73% decrease compared to 2019, while still keeping planes in the sky and passengers happy.

“Speaking as a Procurement Director, the pandemic is the primary challenge. Aviation took a substantive knock during the pandemic period that we have to take care of over the coming three to four years. It’s not just the debt in terms of commerce, it’s the debt in terms of having had to make difficult decisions around assets, services, our service proposition, our security proposition; having had to slow down pieces of work to make them affordable means that we now need to speed them up to make them deliver.”

“The playbook for the pandemic didn't exist. The thing that makes the UK proud

PAUL DOHERTY PROCUREMENT DIRECTOR , HEATHROW

PAUL DOHERTY PROCUREMENT DIRECTOR , HEATHROW

about Heathrow as a piece of national infrastructure is that we run at a capacity that no other airport, globally, runs at. We run at 98% across our two runways, we have more air traffic movements during the day, we move and turn aircraft around quickly. We have operating procedures for if we have a busy day, we have an operating procedure for if something goes wrong during a day –we have an operating procedure for most things. Yet this isn't operating procedure, this is managing demand in a different way.”

Strategic partners and pillars to posts With demand fluctuating rapidly during the most acute months of the pandemic –followed by a gradual return to more familiar capacity levels – there has been pressure to scale engagement with suppliers and service providers around the Heathrow

“ We talk about a frictionless passenger journey, and it's just like a good doctor in the NHS: when you need us, we're there”

environment. This operates alongside a project called the Heathrow Partner Balanced Scorecard, which helps the procurement team choose the best strategic partners and convey the strategic aims of the business for prioritisation.

“It focuses on five main pillars: carbon reduction, social value inclusive of accessibility, inclusion and diversity, opportunities for local business, innovative solutions and behaviours. And that’s not just behaviours

“ The thing that makes the UK proud about Heathrow as a piece of national infrastructure is that we run at a capacity that no other airport, globally, runs at”

in terms of business-to-business behaviours, but also the behaviours between our supply chain and our passengers, should they encounter them, and also behaviours towards sustainability. So Heathrow’s role is incredibly influential and important in the supply chain, persuading them to contribute towards our aims.”

He describes the intention of creating a ripple effect with their partner organisations and the supply chains that support them, but making sure that that whole ecosystem is made up of organisations with sustainable practices built into their DNA as a service

provider, rather than simply raising their game to be part of the Heathrow environment.

“We are really keen that companies bring to bear, here at the airport, the best of what they're doing centrally. An account director reporting here at Heathrow, for example, will contribute towards their central numbers as a business.“

Doherty speaks about how the needle has moved rapidly on the subject of sustainability, due to matters such as the London living wage that are now built into contracts, yet wouldn’t even have been a discussion point a decade ago. He describes how sustainability is now a ‘licence to operate’ at an airport and how, if you do not have those strategies in place, it’s difficult to be part of the operation.

“It’s quite exciting how sustainability has kicked on and matured. It's absolutely the case that it is going to grow, not diminish. As an airport, we have to accept that we are historically polluters, so we have to take a responsible view of that. And we have an executive right now passionate about being responsible.”

These advancements in sustainability, and how it is inextricably linked to the supply

At Vanderlande, we’re committed to delivering sustainable solutions in every aspect of our operations. We do not want to do this alone, which is why we seek collaboration with our suppliers and customers like Heathrow Airport to maximise the impact of our efforts throughout the value chain.

When it comes to sustainability, there’s no doubt that close collaboration enriches discussions and allows all partners to learn from each other and align activities that support each other’s sustainability goals.

Want to know more? Read the blog about our partnership for sustainability with Heathrow Airport.

Learn more:

chain and procurement operation, play a pivotal role in Heathrow’s sustainability strategy. Heathrow 2.0 is their plan to connect ‘people and planet’ and to work to build a better, more sustainable airport. The broad strategy includes net-zero aviation, creating a great place to live and work, and having responsible business foundations. It’s a piece of work that shows how far the airport has come since they took the step to publish their first environmental policy back in 1992.

There is a raft of commitments from Heathrow to make them a better neighbour to both their locality and the wider environment. They are committed to cutting carbon in the air by 15% compared to 2019, their ground level emissions by an even more ambitious 45% and an air-side ultra-low emission zone by 2025 for all operational vehicles. The targets also include doing even more for the region in which they operate, providing 10,000 external jobs, apprenticeships and career opportunities for local people, as well as 15,000 workplace experiences.

This strategy also aims to have a positive impact throughout the sprawling sphere of influence the airport achieves via its strategic partners, being part of the London Living Wage Foundation and a good neighbour to other local businesses.

“I also personally have an objective to grow our small to medium-size enterprises from

2019 levels,” he says. “There are a number of initiatives and schemes we are doing both in the local chambers of commerce and through business summits to help us achieve those aims.” A statement that demonstrates Heathrow and its procurement team's passion passion to deliver on the commitments it has made.

Lessons to carry into the future and beyond It is this culture of collaboration that Doherty feels is the best route to building mutuallybeneficial relationships between Heathrow and their strategic partners. If they are working with other organisations who can innovate and deliver more than would normally be expected, they can produce better and wider outcomes than the ceiling setting a defined target could engender. He believes the biggest piece of learning for the whole management team was for them not to mandate but to collaborate, as they do not just want their partners to deliver up to a set limit, but instead to bring the best of what they can deliver to the airport, with a level of quality that is centrally ingrained within the business.

“We go back to the mantra: ‘if you can make it work at Heathrow, you can make it work anywhere’.”

Ultimately, Paul Doherty returns to the key purpose of every operational decision the airport makes, which is the experience of every person who walks through the terminal door with a suitcase in hand.

“The way in which we work with our supply chain is to always make sure that we are listening, collaborating and challenging ourselves to make sure that we don't miss the opportunity to get something even better for ourselves, for our passengers and for our airport community and stakeholders.”

The logistics industry has had to move quickly with the inexorable rise of omnichannel. So what have been the main challenges and how well are these being met?

WRITTEN BY: SEAN ASHCROFTThe supply chain landscape has changed more in the past three years than in the previous 30. Not only is digital transformation altering the fabric of supply but, thanks to the pandemic, omnichannel is now people’s preferred means of shopping.

In lockdown, consumers flooded online to find the goods they needed; online sales saw an estimated four years’ growth in just 12 months. This seismic shift in purchasing patterns has meant that the logistics industry has had to adapt quickly to help businesses meet the exacting last-mile demands of omnichannel delivery.

Here, we speak to two last-mile logistics experts for their take on how omnichannel has changed the logistics industry, and how well it

has done in meeting the unique challenges of our new-look world. Mahmoud Ghulman (MG) is Co-Founder and CEO of Nash, an online platform for businesses to manage, track, and integrate local, same-day deliveries into their operations. Rory O’Connor (RO) is CEO of delivery management platform provider, Scurri.

MG: Before Covid, running to the store to pick up what you needed was a daily task that we never really questioned. It was ingrained. But when the pandemic hit, that was no longer an option, and, suddenly, there was an acute need for omnichannel distribution – especially around last-mile.

Mahmoud Ghulman (MG) Co-Founder and CEO of Nash

Mahmoud Ghulman (MG) Co-Founder and CEO of Nash

The best logistics technologies will help any business take advantage of such a shift and implement omnichannel distribution without operational burden. Logistics tech is the bridge between businesses and consumer expectation.

RO: Pre-pandemic, omnichannel operations were still focused on a variety of distinct channels to engage customers. With the growing popularity of ecommerce, mobile, and social-media buying, the industry needs to unite customer experience across all channels.

The use of legacy fulfilment systems with segregated interfaces and inadequate visibility is slowing down the growth of fullyintegrated supply chains. The pandemic will have a lasting impact on consumer expectations and behaviours, as well as how businesses and logistics function.

How are logistics firms helping make omnichannel work?

MG: By building flexibility and customisation into solutions. There is no one-size-fits-all logistics model, and the tech to make logistics run smoothly needs to be as diverse as the industries and consumers who use them.

“IN FIVE YEARS, OMNICHANNEL LASTMILE LOGISTICS WILL BE THE BACKBONE OF EVERY BUSINESS”

MAHMOUD GHULMAN CO-FOUNDER AND CEO, NASH

To build for flexibility, you need to understand the behaviour of businesses and customers, for which you need AI and machine learning, and through which you can learn delivery and transport patterns, as well as begin parsing-out verticals.

Then you need to build customisation to legislate for the differences. For example, if you’re serving grocery stores your technology needs a blend of on-demand, same-day, long-term scheduled delivery or pick-up. If you’re fulfilling restaurant deliveries, you should recognise that catering

is an entirely different logistics model.

It’s scheduled more in advance than your average food delivery, and requires larger vehicles, power to keep the food warm for long periods, or even refrigerated trucks.

RO: Logistics companies are taking steps to adapt and onboard omnichannel practices by improving delivery experience. We’re seeing innovation that improves navigation for more efficient routing, crowdsourced drivers, and advanced capabilities that improve the tracking and management of deliveries, for example.

Conventional warehousing strategy, based on fragmented systems, is no longer as effective. That’s why many are opting to build high-tech omnichannel warehouses with improved capabilities to help create a more seamless process. The main benefits derive from managing data from multiple sources in one centralised platform to prevent issues with order fulfilment.

What are omnichannel’s biggest logistics challenges?

MG: Balancing logistics with reliability. For example, it’s one thing to offer on-demand or same-day delivery, but it’s another challenge to follow through on consumer expectation that the delivery arrives quickly and reliably.

Businesses offering these options can get stuck in two ways. Either their delivery

Decades-old RFID technology has emerged as a powerful driver of omnichannel retail offerings, Lindsey Mazza – Global Retail Lead, Capgemini Invent – told Supply Chain magazine recently.

RFID technology sprang from WWII radar tech, used by the British, American and German militaries to identify whether aircraft were friend or foe.

Today, RFID is helping retail companies shape omnichannel supply chain strategies, explains Mazza: “RFID has become so important to retail because in manufacturing, logistics and delivery networks, tracking and monitoring product location is critical.

“The pandemic forced businesses to rapidly adjust their priorities to meet new customer preferences, particularly the switch from in-store to online shopping. And the new retail experience is channelless, meaning commerce is everywhere, and consumers expect it anywhere.

“A reduction in the cost of sensors, as well as improvements in both range and readability, make RFID a renewed option for supporting retailers in creating data-driven, omnichannel experiences for consumers.”

RORY O’CONNOR CEO, SCURRI

services are in-house, which means they’re dependent on a handful of expensive drivers who aren’t always available or can only go so far. Or they use a large gig-fleet service, with great coverage and availability but with a level of customer service that might not reflect the business’s brand image.

The solution is to balance having a delivery service that reflects the brand's value with the availability and coverage of a giant on-demand fleet.

RO: One of the main challenges facing the logistics’ sector is responding to heightened customer expectations of delivery.

With diverse channels and customer touchpoints, all stakeholders are tasked with ensuring post-purchase customer experience is as seamless as possible.

Customers expect to choose from a range of delivery services and speeds. One of the single biggest disruptors of online customer experience is not being able to fulfil your delivery promise.

Taking control of delivery management allows you to switch between carriers quickly and in a frictionless way, avoiding loss of service and ensuring that customer support in the last-mile works by tracking orders through the full order journey. It puts you in control of exactly how you want to notify customers about the status of their orders.

What’s the future for omnichannel logistics?

MG: Omnichannel last-mile logistics will become the backbone of every business. Getting products from storefronts (digital and actual) to the doorstep was once a painstaking process, but not anymore. Fintech has made payments easy, and logistics tech will make the transfer of goods seamless.

Plus, we’ll see demand for omnichannel logistics grow as consumers want demand met wherever they are – at home, at the office or pick up in-store. Businesses that don’t adopt an omnichannel approach will be left behind.

RO: As consumers embrace omnichannel in growing numbers the lines between digital and physical touchpoints are becoming even more blurred. The challenge is to create a consistent, on-brand experience from start to finish. That’s why the last mile is absolutely crucial to the future of omnichannel logistics. It’s a key battleground for all stakeholders, and one beset by the greatest number of challenges.

Last-mile is still the most inefficient and expensive link in the fulfilment chain, so the future will see all market players embrace innovative solutions to improve it.

Ultimately, those that invest in a highly connected, cohesive omnichannel presence and create reliable, cost-effective delivery outcomes for customers will succeed.

WRITTEN BY: TOM SWALLOW

PRODUCED BY: MIKE SADR

WRITTEN BY: TOM SWALLOW

PRODUCED BY: MIKE SADR

Anyone harbouring a passion for adventure and sustainability will no doubt have heard of the company leading the market for electrified pickup trucks.

Not only does Rivian boast sustainability credentials across its entire business, it’s also a business built with the planet at the forefront of all its activities. Yet, while there are many exciting aspects to highlight, the critical element of Rivian’s story is the “design and development of categorydefining electric vehicles”, in the words of the company’s Director of Indirect Purchasing, Brad Hood.

We often see the company through the consumer lens. Thousands evangelise the clean, robust, unique style of the Rivian R1T and R1S—its pioneering EVs, the pinnacle of the environmentally and socially responsible business.

Founded in 2009, the Rivian story began with a vision for sustainable mobility. As an automotive enthusiast himself, the company’s founder, RJ Scaringe, saw that the two things he lived for—cars and nature— were not compatible in the long-term. This conclusion formed the very basis of the company, which holds an integral place in the electrification of automotive.

Brad Hood, Director of Indirect Purchasing at Rivian, on the benefits of a ‘blank canvas’ and how the EV manufacturer implements sustainable procurement

“He created a product that was a more sustainable alternative to the fossil-fuelburning carried out by internal combustion engine vehicles. He really wanted to facilitate a transition to more neutral energy transportation, not only for our generation, but for our kids', kids’, kids,” says Hood.

“It's a multi-generational purpose that goes beyond any one of us, which is what drives the overall culture at Rivian: we're here for something bigger than ourselves.”

Of course, there’s more to Rivian vehicles than the fact they run on electric propulsion. The company prides itself on sustainable sourcing and leveraging a circular system, right from the design stage. Its batteries can be easily removed for either recycling or ‘second life’ applications. When it comes to the interiors, vegan leather and other animal-free materials are used, with mid-life repairability in mind.

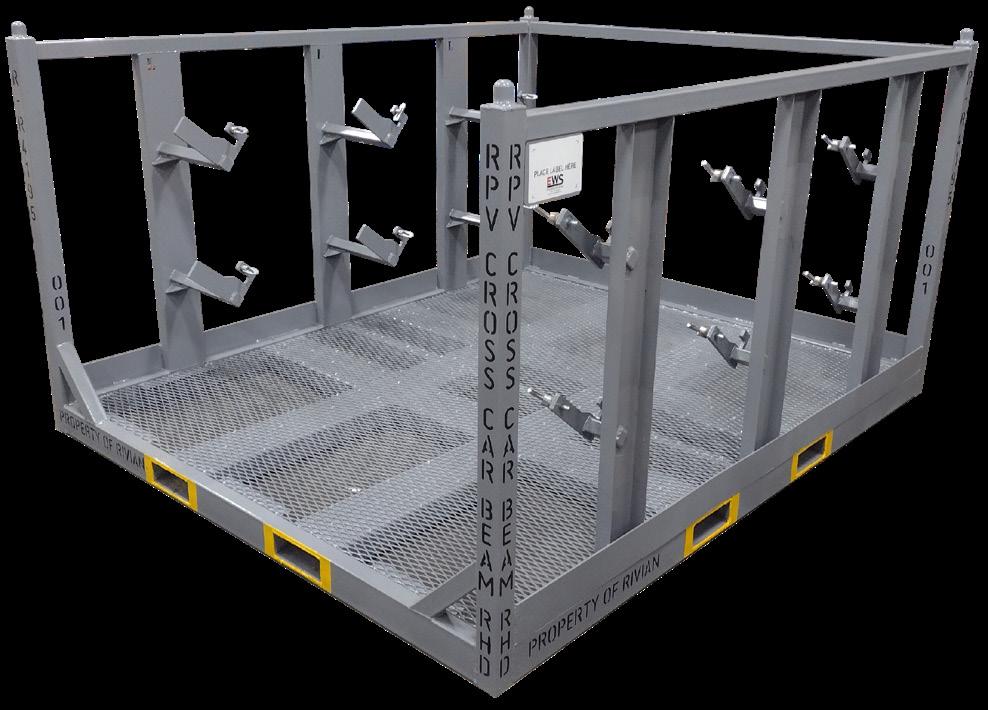

Beyond the product itself, sourcing also involves the unique procurement of oceanharvested plastics for its dunnage containers and other packaging solutions. Such actions earned the company the 2022 Excellence and Reusable Packaging award from the Reusable Packaging Association.

“If we are working on an e-sourcing event or an auction, we can leverage these templates”

“We use the most sustainable products we can and when we went public, 1% of the company went to the Rivian Forever Fund,” says Hood.

“We think about how to operate responsibly within the plant. When we began the conversion of the old Mitsubishi plant to the new Rivian plant, we used some of the old steel to make tables, a mezzanine—and we even repurposed old robots as a door holder for the conference room.

“We reused things, and maybe went above and beyond. Instead of scrapping it, instead of getting rid of those materials, we thought, ‘how can we repurpose that and reuse them?’.”

As a new entrant to the automotive industry in 2009, Rivian was built with sustainability in mind. And being a new business gave the company a competitive edge to not only grow, but advance the use of new technologies and lean processes.

Hood explains that when he joined the organisation in 2018, the procurement function was significantly smaller than it is today, but this has allowed the company to take an approach that is driven by technology.

“When I joined, there were 500, 600 employees. There were about three people within our department,” Hood says. “Now, the total company size is more than 20 times that.”

“At the beginning, we had a shell of a manufacturing plant. Now, we're fully operational, building three different vehicles with multiple different variations in Normal, Illinois.”

TITLE: DIRECTOR OF INDIRECT PURCHASING

INDUSTRY: OIL & ENERGY LOCATION: DETROIT, USA

Brad shifted careers from manufacturing and production planning to procurement after graduating from Western Michigan University with a major in Integrated Supply Chain Management. After spending most of his procurement career in consulting, he joined Rivian at the tail-end of their stealth mode in 2018 to help build their procurement department. Rivian has experienced tremendous growth since then, which includes the indirect procurement team that Brad leads. This has proved both Rivian and Brad the opportunity to grow the procurement organisation in the same manner as Rivian talks about designing the vehicles, from a blank

Essex Weld Solutions is a global company servicing customers across North America.

Our focus is the development and global supply of custom and standard automotive racking products. Essex Weld Solutions is a “Full Service Manufacturer” of custom automotive containers from bins to racks. We offer Designs, Prototypes, and high-volume production. This ensures superior quality control, something our customers expect and deserve.

LEARN MORE

Essex Weld Solutions began with a handful of customers and a production plant in Essex, Ontario. From the start, people were our strength. We have selected a team with a focus on integrity and trust, which is the foundation that we have built our reputation on. Keeping our customers’ needs at the center of every decision is what has led us to strive for excellence in everything we do. These values have been instilled in all our team members ensuring we all work together towards these goals.

Twenty years later, we have expanded to multiple locations across three countries. Our Canadian plants include Leamington and Essex, Ontario. We also have American plants in Laurens, South Carolina and Warren, Michigan as well as one plant in Durango, Mexico. All locations boast on-site engineering and full production capabilities so that we can provide in-house concepting, designing, prototyping, and large-scale production allowing us to be a one stop shop for our customers’ projects.

Over one-hundred years of combined experience has taught us that investing in the latest manufacturing technology is necessary to provide top quality products. Our plate and tube lasers, break presses, robotic welders, and full powder coat system allow us to maintain high standards across all locations. Our manufacturing process is monitored from concept to delivery using

our own ERP system, Edata+, with real time inventory levels, production status, and barcode tracking labels. This enables us to maintain inventory of common materials at all locations and efficiently control quality and delivery timing.

Our innovative approach to the everevolving world of manufacturing means we never stop improving the service we provide our customers. As manufacturing shifts to a greater integration of robotic production lines, we have developed a Metrology team that exclusively handles the precise quality control required for those projects. These continuous improvement efforts allow us to expand our capabilities so that we can better serve our existing customers, and reach out to new ones, as their needs change, especially as the shift to Electric Vehicles continues.

The story behind sustainability Rivian entered the automotive industry at an interesting period. The company was very much undergoing its formation when major carmakers first started thinking about EVs, which, at the time, were seen as a ‘nice-to-have’.

With a passion for automotive and a desire to protect nature in all its glory, Rivian’s CEO, RJ Scaringe, set about building his dream: a vehicle with no limits and an adventurous edge that would allow drivers to explore harmlessly, reinvigorating their love for the environment.

The company first piqued interest with its two EV models. The R1T, its pickup truck model, and the R1S, which leverages the same great technology in an SUV body. In 2022, the company reached a major milestone with the announcement of it supplying electric delivery vans to Amazon—the initial quantity being 10,000, with potential for the e-commerce giant to expand this to 100,000.

Rivian cultivating a business on what was seemingly a blank canvas meant that the company worked through many challenges in its indirect procurement function to ensure that it remained true to its roots.

The solutions adopted by the company were pivotal. They allowed the team to focus on more hands-on tasks, alleviating the need for human input in the day-to-day processes.

“We had the opportunity to build an organisation that is truly best-in-class, from the ground up. We don't have to change any old behaviours; we can create new ones, and in the right manner, too. Balancing the two of those meant knowing

what we needed to do daily versus what was required to build a foundation for the future.

“This was the biggest challenge, balancing the short-term and long-term needs. There are so many day-to-day requirements, but we must be able to balance the day-to-day work, while building the foundation of the organisation we desire to build.”

Another major challenge that wreaked havoc on all supply chains—and inevitably affected Rivian—was the COVID-19 pandemic, which meant navigating a remote-working environment while scaling and taking on new team members across the globe.

BRAD HOOD DIRECTOR OF INDIRECT PURCHASING, RIVIAN

BRAD HOOD DIRECTOR OF INDIRECT PURCHASING, RIVIAN

“We're fully operational, building three different vehicles with multiple different variations down in Normal, Illinois”

With data, automation, and AI, we help organizations transform and build value across the board. Explore how people and companies are reimagining supply chain networks at accenture.com

These trying times meant the company had to adapt to onboarding and training the team online, without knowing when new starters would come into contact with their colleagues.

As a result of these challenges, the company adopted ‘category cards’ to create ease in the purchasing process. This is just one of the ways in which the company streamlines the onboarding process, automating indirect procurement processes to allow a smaller team to manage more purchases.

“When you log in, you see the category, you select that category, and it gives you a brief description to tell you if you can buy it from a catalogue—so we can drive more spend to a catalogue—or it gives you a direction to reach out to a purchasing manager or supplier,” Hood explains.

“That way, we can touch more spend with a smaller team, increasing the addressability of the spend and continuing to educate the rest of the organisation to drive spend to our preferred buying channels.”

Further sourcing platforms used by the company provide further standardisation of indirect procurement processes. This includes supplier negotiation preparation, which can largely be templated—as Hood explains.

“If we are working on an e-sourcing event or an auction,

we can leverage these templates. “Automatically, a quantitative proposal comes in and we can analyse that based on our previous price paid, other proposals, market intelligence,” says Hood.

“We can look at that pretty quickly and find any outliers, identify where the best quantitative values are and work with our stakeholders as we incorporate the qualitative aspects. These tools really allow us to work faster.”

While businesses would often apply the term ‘digital transformation’ to their operations, it seems Rivian is beyond this, ensuring that technology is embedded into all processes from the earliest possible stage as part of its strategic approach to growth.

“It's a multi-generational purpose that goes beyond any one of us, which is what drives the overall culture at Rivian”

“It can standardise things and reduce errors but, for us, it allows us to actually promote and enrich the daily operations of those working in data-entry roles. They've now gone into more category management roles and supporting student sourcing, as well as those roles where we can marry technology and experience,” Hood explains.

As the company looks to ramp up the production of EVs, technology will become an integral component in allowing the organisation to scale its operations and meet demand.

The company will continue to add value to its services sustainably, with

“We use the most sustainable products we can and try to be more sustainable with the materials of the vehicles”

sourcing playing an integral role in reducing emissions down the supply chain. As the company expands its own charging network, technology will allow personnel more time to explore renewable energy sourcing, making sure that Rivian customers are charging up with clean energy.

Meeting its strategy for success hinges on its use of data in the procurement functions to standardise processes and focus on saving costs, time, and limiting negative

climate impact—with the overarching aim of eliminating it. As such, the procurement team will look at supplier spend and consider whether its dollars are going towards the desired suppliers.

While much of the technology adoption and integration is carried out in-house, Hood explains that technology partners will be leveraged by Rivian to meet demands unique to its processes.

Hood says: “We understand what we want to do in theory—on a whiteboard—but how do we integrate that into the actual software that’s more commonplace?”

In trying to answer this question, the company has been able to push technologies to their absolute limits, which is a benefit to Rivian, but also the partner that supplies that solution—making Rivian a testbed ripe for procurement solutions.

Claims of Greenwashing can be hugely damaging for any brand, which is why it’s vital businesses are meticulous about their sustainability claims.

WRITTEN BY: SEAN ASHCROFTGreenwashing is a phrase that was coined by environmentalist Jay Westerveld in a 1980's essay in which he explored the practices of the hotel industry. He claimed the hotel industry was falsely promoting the reuse of towels as part of a broader environmental strategy when, in truth, it was a cost-saving measure.

Back then, greenwashing was a rarely mentioned phenomenon but, in recent years, the term has taken on huge significance, as organisations worldwide have set ambitious and very public net-zero carbon goals.

Sometimes – knowingly or unknowingly – businesses make claims around their sustainability credentials that fail to stand up under close scrutiny, and the accusations of greenwashing that arise from this can result in huge reputational brand damage.

The e2open connected supply chain platform provides the end-to-end visibility and collaboration you need to tackle unpredictability. Build trust and confidence with your channel, supply, logistics, and global trade partners. Take control of supply constraints through direct procurement and meet customer commitments in the face of disruptions and scarcity.

The connected supply chain. Moving as one™. www.e2open.com

E2open and the e2open logo are registered trademarks of e2open, LLC, or its affiliates.

CAMILLAOrganisations with large supply chains are more prone than most to falling foul of this. With value-chain vendors for large companies often numbering in their thousands, running the ESG rule over all of them is devilishly difficult.

But, with sustainability, the devil is very much in the details. This is why end-to-end transparency is so important in the supply chain, not just as a way to ensure operational resilience, but so organisations can exercise control over ESG compliance – especially in the deepest recesses of their supply chain, where non-compliance is most likely to be found.

There can be little doubt that greenwashing is a real problem. A recent report from global spend management specialist Ivalua suggests that 90% of organisations fail to drive green initiatives across the supply chain, with just 10% saying they always include sustainable practices in contracts and agreements.

The Ivalua Supplier Relationships Report surveyed suppliers across the UK, France, Germany and Switzerland, with a view to examining how collaboration can boost environmental initiatives.

Ivalua Chief Marketing Officer Alex Saric said of the report’s findings: “Firms need to ensure environmental efforts to cut carbon

emissions extend beyond their own four walls. Anything else is greenwashing.”

Working with suppliers crucial on sustainability

“For most organisations, emissions from their supply chain are several times greater than their own direct emissions. This means it’s critical they work with immediate and sub-tier suppliers to drive improvements in environmental practices.”

Saric then stresses that suppliers have a vital role to play in reducing environmental impact but that organisations have a responsibility to give them the right tools to boost green initiatives.

“This means regularly communicating with suppliers, assessing their efforts, and

“Avoid generic claims about your products and business that are not supported by data”

MJELDE COMPLIANCE & SUSTAINABILITY DIRECTOR, TRIMCO

Olivia Montgomery is Associate Principal Supply Chain Analyst at Software Advice, a subsidiary of Gartner. Montgomery produces reports and insights on smallbusiness project management, supply chain trends and technology strategies.

She recently told the Supply Chain Digital Show on LinkedIn that a Software Advice report showed a number of supply chain managers say their employer’s communication around sustainability “doesn't align with what is actually happening”.

Montgomery added: “Such messages must be accurate because accusations of greenwashing can severely impact a brand’s reputation, especially if they are trying to attract the newer or younger customers that are exceptionally engaged with sustainability. Often, you only get one shot to make sure messaging is honest and transparent.”

The report also suggests that many businesses are not disposing of returned products responsibly. “There’s room for improvement there,” Montgomery says. “Especially when you're focusing on not just cost savings and operational efficiency, but also sustainability, which is now super-important to consumers.”

providing them with flexibility to offer innovative solutions.”