Dairy products

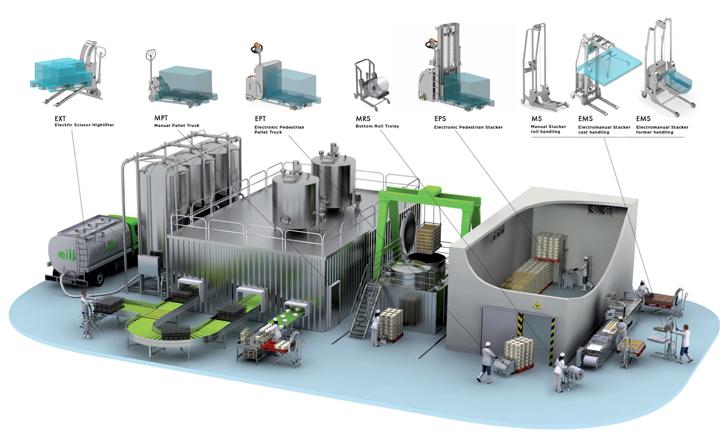

Load Handling Solutions for Production Areas

ULMA Inoxtruck equipment offers an innovative and sanitisable design that minimises the accumulation of food debris in the equipment and allows easy access to all areas of the forklift to facilitate cleaning, minimising the risk of microbiological contamination.

In addition, we have taken into account in our designs those critical points that suffer greater wear and tear due to the aggressiveness of the environment, incorporating improvements that allow less and better maintenance of the equipment.

The best stainless steel materials to resist the worst salinity conditions and the incorporation of electronic components with high resistance to humidity provide our equipment with a robust behaviour and high resistance to corrosion.

The objective pursued by ULMA Inoxtruck with its innovative, robust and sanitisable designs is to minimise the cost of using the equipment, allowing a rapid return on investment.

DESIGN HYGIENIQUE

• Sans chaînes de levage

• Sans graisseurs

• Batteries de dernière géneration

100% stainless steel 100% inoxidable

100% inoxydable

100% Edelstahl

Open frame Estructura abierta Structure ouverte O ene Struktur

No gr Sin lubricación

Pas de graissage

Keine Schmiernippel

Quiet Silencioso Silencieux Leise

Sealed bearings

Rodamientos estancos

Routements étanches

Abgedichtete Lager

Without emissions

Sin emisiones Sans émissions

Emissionfrei

Without chains

Sin cadenas

Pas de chaines

Ohne Hubketten

Hygienic design

Diseño higienizable Design hygiénique

Hygienisches Design

M inimum maintenance

M ínimo mantenimiento

Entretien minimum Geringer War tungsaufwand

EX-PROOF,Protectionagainst explosive atmospheres

ATEX, Protección contra atmosferas explosívas

EX-PROOF, Protection contre les atmosphères explosives

Hygienic design Solutions for dairy plants

- Sans émissions

-Charge permanente

• 100% inoxydable

• Suivant les normes ISO et GMP

Ergonomic design

• Protection IP 65 pour les composants électriques

EX-PROOF, Protection contre les atmosphères explosives

Transport in production areas

Standard and bespoken solutions to transport plastic or stainless steel racks full of cheese portions. Very often cheese portions are laid on trays which are supported in racks with different dimensions. From manual to fully powered trucks can transport several racks with/without side support arms

Feeding in cutting lines

Very often big cheese blocks piled on a pallet need to be loaded to the slicers/cutting machines. Our scissor higlifters are the most ergonomic solution to keep the blocks on an ergonomic position so the operator does not need to bend his/her back to pick and load the them on to the production line. Automatic heights adjustment is an option in this lifter which will allow being more efficient in this process.

Handling in drying/curing areas

Transport and lifting piles of cheese into/from crying/curing room is very common in most cheese production factories. Our range of stackers, from manual to full electronic models will help do the job in a safe and efficient way.

Feeding in packaging lines

Once the cheese portions are ready for packaging the process to load/unload each cheese portion from the packaging line will represent thousands of picking movements from a pallet. Even though the weight of the cheese portions may not be heavy these repeated movements bending the back to pick them can be ‘relieved’ if the height of the crates can be always kept at an ergonomic height. Our scissor highlifters will

be a perfect ergonomic solution to undesirable backaches.

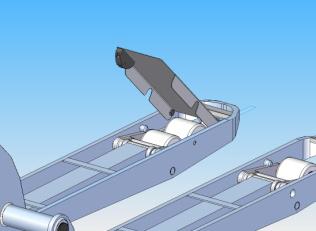

Handling of packaging machine reels

Before we leave the packaging area beware of the ergonomic problems when Loading film réels and/or thermoforming dies into the packaging lines. Light to heavy film reels/dies have to be picked from a pallet and loaded to a height above the waist which you are not allowed to do from a Health & Safety point of view. A range of reel/die lifters to take the reels in different positions/layouts from a pallet are also included in our catalogue and can always be adapted to meet your requirements.

Cage handling in cleaning machines

Very often the trays and racks used to transport and cure/dry the cheese portions need to be cleaned/desinfected before you use them again. We have a range of solutions based on our stackers/lifters to load them into/from the washing machines

Options

Splash proof system

Options

Cage fastening system

ULMA Inoxtruck

Paseo Otadui, 10

20560 OÑATI (Gipuzkoa) SPAIN

Tlf +34 943 848 943

info@ulmainoxtruck.com www.ulmainoxtruck.com