Master 2025

UNITING MATERIALS, TECHNOLOGY AND DESIGN

• PRODUCT LEADERSHIP •

MOMENTUM POWERFUL MOMENTUM

As the most comprehensive laminate panel and component supplier in the U.S., Genesis is the single source for your next door, drawer or panel program. We never stop moving forward to meet our customers’ needs. BECAUSE PROGRESS ISN’T JUST WHAT WE MAKE – IT’S WHO WE ARE.

UNITING MATERIALS, TECHNOLOGY AND DESIGN

PRODUCTS/MANUFACTURERS

6 PLYWOOD PRODUCTS

• Softwood Plywood

• Hardwood Plywood

• Aircraft Plywood

• Marine Plywood

10 FIBERBOARD PRODUCTS

• Hardboard (HDF)

• Medium Density Fiberboard (MDF)

• Particleboard (LDF)

14 ENGINEERED WOOD SIDING & TRIM

16 LAMINATES

• Thermally Fused Laminate (TFL)

• High Pressure Laminate (HPL)

• Specialty Laminates (2D & 3D Laminates & Films)

20 LIQUID & POWDER COATINGS

23 DECORATIVE FOILS & LIGHTWEIGHT PAPERS

25 VENEERS

27 EDGE TREATMENTS

29 ADHESIVES

• Hot Melt

• Solvent-Based

• Water-Based

• Heat Seal Coatings

• Primers

31 TECHNOLOGY

• Software

• Digital Printing & Screening

• Processing Technology

34 HARDWARE & FASTENERS

36 TOOLS & MACHINERY

SPECIAL SECTION

143 DISTRIBUTION MATTERS

Highlighting NBMDA (North American Building Material Distribution Association).

144 Making Its Mark in the Big Easy

The 2024 convention was one of the largest in the association's history

147 Why Distribution Matters

NBMDA Executive Vice President Michael Wilbur celebrates the industry and strives to make it even better

150 Charting the Future

New NBMDA President Jon Minnaert shares his vision and direction for the association

152 Protecting Your Business

Experts weigh in on how to best prepare for and manage geopolitical strife

154 Engaging Emerging Leaders

A look at NBMDA's Emerging Distribution Leaders Program and opportunities

156 2025 NBMDA Member Director y

MASTERS OF THE INDUSTRY 2025

38 A comprehensive listing and directory of the providers of materials and services in the panel processing industry. 142 AD INDEX

ON THE COVER: OneSkin's eco-friendly MDF Carb P2 panels, free of solvents and PVC, feature UV Lacquered Melamine with matching backsides in High Gloss or Super Matte, and are available in many finishes, including this striking Clay Red.

APPRECIATION: 526 Media Group and Surface & Panel magazine thank the following companies & organizations who contributed images for the publication of this issue: Arauco, Besse Forest Products, Canon, Chemetal, Columbia Forest Products, Designs of Distinction, EGGER, Funder, Georgia Pacific, Grass America, Greenline Industries, HOMAG, IFS Coatings, KCD Software, Kronospan, LP Building Solutions, MachMotion, NBMDA, OneSkin, Richelieu, Riken, Roseburg, Schattdecor, swissQprint, Tafisa, Timber Products, Toppan, Treefrog Veneers, Ultrapan, USPly, Vizsolution and Wilsonart.

PRESIDENT/PUBLISHER

Patrick Adams

PH: 714-486-2735 padams@526mediagroup.com

VICE PRESIDENT Shelly Adams

EDITORIAL

Jennifer Williams, MANAGING EDITOR

PH: 714-486-2735 jwilliams@526mediagroup.com

David Koenig, DIRECTOR OF EDITORIAL

Sara Graves, SENIOR EDITOR

GUEST COLUMNISTS

Michael Wilbur, Denise Williams

SALES

Nick Kosan

PH: 714-486-2735 nkosan@526mediagroup.com

Chuck Casey

PH: 714-486-2735 ccasey@526mediagroup.com

John Haugh

PH: 714-486-2735 jhaugh@526mediagroup.com

GRAPHIC DESIGN

Greg A. Lane

DIGITAL SUPPORT

Katherine Williams kwilliams@526mediagroup.com

CIRCULATION/SUPPORT

PH: 714-486-2735 info@526mediagroup.com

526 MEDIA GROUP

151 Kalmus Drive, Ste. J3 Costa Mesa, CA 92626

PH: 714-486-2735

Master

MASTER

Plywood Products

Fiberboard Products

Engineered Wood

Siding & Trim

Laminates

Coatings

Decorative Foils &

Lightweight Papers

Veneers

Edge Treatments

Adhesives

Technology

Hardware & Fasteners

Tools & Machinery

Plywood Products

■ SOFTWOOD PLYWOOD

■ HARDWOOD PLYWOOD

■ AIRCRAFT PLYWOOD

■ MARINE PLYWOOD

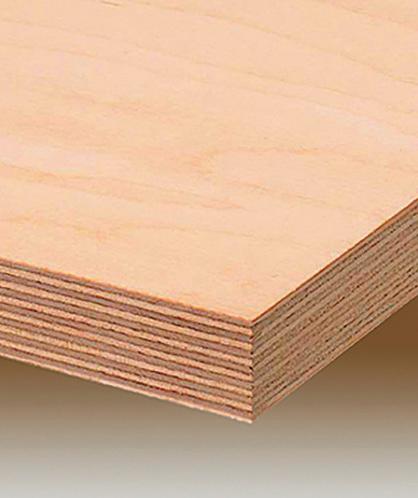

The grandaddy of the surfaced panel industry, plywood continues to be a cornerstone of engineered wood products in 2025, celebrated for its strength, versatility, and sustainability. With roots stretching back millennia to ancient Egypt and China, plywood’s evolution has transformed it into a modern essential for construction, design, and specialized applications.

Plywood Through the Ages

Pioneered as a way to maximize dwindling wood resources, plywood’s ingenuity took hold in the 20th century. Early milestones include Gustav Carlson’s Pacific Northwest softwood panels, the introduction of waterproof adhesives in 1934, and the post-World War II building boom that cemented plywood’s role in construction. These developments, coupled with the emergence and evolution

of industry associations — the Douglas Fir Plywood Association in 1933, which became the American Plywood Association in 1964, which then transformed into today's APA as the Engineered Wood Association — have sustained plywood’s enduring appeal through their efforts to standardize quality across the industry.

Modern-Day Plywood Varieties

Today’s plywood combines thin wood layers bonded with advanced adhesives, with grains rotated to enhance strength and stability. Its applications span construction, furniture, packaging, and specialty uses like boats and airplanes. Key varieties include:

• Softwood Plywood: Lightweight, cost-effective, and sustainable; ideal for construction and DIY projects

• Hardwood Plywood: Durable and wear-resistant; prized for furniture, cabinetry, and millwork

• Baltic Birch Plywood: Renowned for its stability; crafted from cross-banded birch and exterior-grade adhesives. Global events in recent years have affected the supply of this species, and many companies have found alternative woods to use

• Aircraft and Marine Plywood: Designed for extreme conditions; offering high strength and extreme moisture resistance

Innovation and Sustainability

Plywood production minimizes waste by repurposing wood scraps, aligning with ecoconscious practices. Specialty plywood, including formaldehyde-free and pressuretreated options, meets growing demands for sustainable and high-performance materials. In 2025, plywood remains a testament to adaptability, serving as a reliable solution across industries. ■

DIRECTORY

These companies are recognized for their production and distribution of plywood products. Please note that this list might not be exhaustive and the availability of plywood manufacturers can vary based on geographical locations and specific market demands.

SOFTWOOD PLYWOOD

Aspen Planers www.aspenplaners.ca

Boise Cascade www.bc.com

Canoe Forest Products www.canoefp.com

Eagle Plywood Specialties www.eagleplywood.com

Freres Lumber www.frereswood.com

GP Wood Products www.buildgp.com

Hardel Mutual Plywood www.hardel.com

Hood Industries www.hoodindustries.com

Hunt Forest Products www.huntforpro.com

LP Building Solutions www.lpcorp.com

Murphy www.murphyplywood.com

Pacific Wood Laminates www.socomi.com

PotlatchDeltic www.potlatchdeltic.com

Richmond Plywood Corp. www.richply.com

Roseburg www.roseburg.com

RoyOMartin www.royomartin.com

Scotch Plywood www.scotchplywood.com

SDS Lumber www.sdslumber.com

Southern Veneer Products www.southernveneerproducts.com

Swanson Group www.swansongroup.biz

Timber Products Co. www.timberproducts.com

Tolko www.tolko.com

Westlam Industries www.westlam.com

Weyerhaeuser www.weyerhaeuser.com

HARDWOOD PLYWOOD

Besse Forest Products Group www.bessegroup.com

Buffalo Veneer & Plywood www.buffaloveneerandplywood.com

Columbia Forest Products www.columbiaforestproducts.com

Commonwealth Plywood Inc. www.cpiwhitehall.com

Darlington Veneer www.dvcplywood.com

Eastern Panel Manufacturing www.easternpanel.com

Formwood Industries www.formwood.com

Genesis Products www.genesisproductsinc.com

GL Veneer www.glveneer.com

Husky Plywood www.huskyplywood.com

Manthei Wood Products www.mantheiwoodproducts.com

Murphy www.murphyplywood.com

Premwood www.premwoodllc.com

Roseburg www.roseburg.com

S.J. Morse Co. www.sjmorse.com

States Industries www.statesind.com

Swanson Group www.swansongroup.biz

TIMBER PRODUCTS

Timber Products Co.

www.timberproducts.com

The Wood Gallery Inc. www.woodgallery.biz

AIRCRAFT PLYWOOD

Aircraft Plywood Manufacturing www.aircraftplywood.com

Aircraft Spruce & Specialty Company www.aircraftspruce.com

Thomas Canada LTD www.thomescanada.com

Wicks Aircraft

www.wicksaircraft.com

MARINE PLYWOOD

Anderson Plywood www.andersonplywood.com

Chesapeake Plywood, LLC www. chesapeakeplywood.com

Homestead Hardwoods www.marine-plywood.us

J. Gibson McIlvain www.mcilvain.com

Plywood Logistics www. plywoodlogistics.com

Seacoast Hardwood www.seacoasthardwood.com

Toledo Plywood www.toledoplywood.com

Weber Plywood https://weber-plywood.com/

2O25 TRENDS

2025 Trends in the Plywood Industry

1. Sustainability as a Priority

The push for eco-conscious materials is driving innovations in plywood production. Manufacturers are increasingly utilizing formaldehydefree adhesives, recycled wood fibers, and sustainable sourcing practices. Certification programs, such as FSC (Forest Stewardship Council), are gaining prominence as consumers and builders prioritize environmentally friendly products.

2. Specialty Plywood Growth

Demand for high-performance plywood is on the rise. Marinegrade plywood is gaining traction for outdoor applications, offering superior moisture resistance, while aircraft plywood continues to evolve for both hobbyist and industrial uses. Pressure-treated and fire-rated variants cater to specific construction needs, further expanding the specialty plywood market.

3. Lightweight and High-Strength Panels

Technological advancements are enabling the production of lighter, stronger plywood panels. These innovations cater to applications where weight and durability are critical, such as furniture,

transportation, and modular construction.

4. Enhanced Aesthetic Options

Plywood is no longer just a structural material; it’s becoming a design element. Improved face veneers, precision-cut patterns, and textured finishes allow plywood to double as a decorative surface, appealing to modern interior and furniture designers.

5. Digital and Automated Production

The adoption of digital manufacturing technologies is streamlining plywood production. Automated processes improve consistency, reduce waste, and enable customizable options for thickness, size, and finish. ■

Fiberboard Products

As solid wood becomes increasingly scarce and expensive, fiberboard has emerged as a sustainable, versatile, and cost-effective alternative for modern construction and design. Derived from wood byproducts, fiberboard — in its many iterations — is a foundational material across industries, providing a flexible canvas for diverse coatings, patterns, and finishes.

Hardboard / High-Density Fiberboard (HDF)

Renowned for its strength and density, hardboard has a storied history dating back to 1898 in England. Today’s HDF is a staple in furniture, construction, automotive applications, and even artistic uses including painter’s canvases. Technological advancements have enhanced its durability, water resistance, and environmental credentials, with manufacturers now focusing on no-added formaldehyde (NAF) products to reduce VOC emissions.

Medium-Density Fiberboard (MDF)

MDF remains a favorite for its smooth finish, easy machinability, and versatility. Often used as a cost-effective alternative to solid timber, it’s widely applied in cabinetry, furniture, closets and decorative surfaces. In 2025, MDF production emphasizes sustainability, incorporating recycled

fibers, waste paper, and eco-friendly resins. Variable density options and improved moisture-resistant formulations expand its use across a broader range of environments.

Particleboard / Low-Density Fiberboard (LDF)

Particleboard, the budget-friendly member of the fiberboard family, continues to evolve. Used extensively in Ready-to-Assemble furniture, kitchen cabinetry, and even countertop bases, modern LDF integrates advanced binding technologies to improve moisture resistance and structural integrity. Its smooth surface is ideal for veneers and other finishes, allowing it to mimic higher-end materials. Driven by sustainability and innovation, fiberboard products in 2025 are more durable, eco-conscious, and versatile, making them indispensable in shaping the future of construction and manufacturing. ■

TAFISA

DIRECTORY

These companies are recognized for their production and distribution of Fiberboard products. Please note that this list might not be exhaustive and the availability of fiberboard manufacturers can vary based on geographical locations and specific market demands.

HDF

CalPlant 1, LLC

www.eurekamdf.com

D&M Lumber Products www.dmlumber.com

Kronospan LLC www.kronospan.com

Premwood www.premwoodllc.com

Uniboard www.uniboard.com

West Wood Products www.west-wood.net

MDF

Arauco North America

www. na.arauco.com

Buffalo Veneer & Plywood www.buffaloveneerandplywood.com

CalPlant 1, LLC

www.eurekamdf.com

D&M Lumber Products www.dmlumber.com

Duraplay de Parral SAPI www.duraplay.com.mx

Egger Wood Products www.egger.com

Genesis Products www.genesisproductsinc.com

GP Wood Products www.buildgp.com

Great Plains MDF www.greatplainsmdf.com

Kronospan LLC www. kronospan.com

Langboard www.langboard.com

Maderas Conglomeradas SA www.macosa.com.mx

Pan Pacific Products www.panpacificproducts.com

Premwood www.premwoodllc.com

Roseburg www.roseburg.com

Swiss Krono USA www.swisskronousa.com

Timber Products Co. www.timberproducts.com

Ultrapan www.ultrapan.net

Uniboard www.uniboard.com

Unilin MDF www.unilin.com

West Fraser www.westfraser.com

West Wood Products www.west-wood.net

Weyerhaeuser MDF www.weyerhaeuser.com

PARTICLEBOARD

Arauco North America www. na.arauco.com

BestBoard Impulsora SA www.bestboard1.com

Buffalo Veneer & Plywood

www.buffaloveneerandplywood.com

Collins Products www.collinswood.com

D&M Lumber Products www.dmlumber.com

Duraplay de Parral SAPI www.duraplay.com.mx

Egger Wood Products www.egger.com

Florida Plywoods www.fply.com

Forestal Terranova Mexico SA www.masisa.com

Genesis Products www.genesisproductsinc.com

GP Wood Products www.buildgp.com

Kronospan LLC www. kronospan.com

Maderas Conglomeradas SA www.macosa.com.mx

Masonite Corp.

www.masonite.com

Panel Processing, Inc. www.panel.com

Panolam Industries www.panolam.com

Plummer Forest Products www.plummerforest.com

Premwood www.premwoodllc.com

Roseburg www.roseburg.com

Tafisa Canada www.tafisa.ca

Timber Products Co. www.timberproducts.com

Uniboard www.uniboard.com

West Wood Products www.west-wood.net

Woodgrain Composites www.woodgraincomposites.com

2O25 TRENDS

2025 Trends in the Fiberboard Industry

1. Sustainability and Green Manufacturing

Eco-conscious consumers and stricter regulations are pushing manufacturers to adopt more sustainable practices. The ban on formaldehyde (NAF) has accelerated the shift towards lowVOC products, with recycled wood fibers, agricultural residues, and waste paper becoming integral to fiberboard production. Circular manufacturing processes and reduced carbon footprints are top priorities for leading companies.

2. Enhanced Durability

Innovation in resin technologies is enabling the production of more durable fiberboards. New formulations improve resistance to moisture, pests, and fire, expanding the use of Medium-Density Fiberboard (MDF) and Low-Density Fiberboard (LDF) into environments previously unsuitable for these materials, such as outdoor settings or high-humidity areas.

3. Variable Density Products

Demand for specialized applications is driving the development of fiberboard

products with tailored densities. Highdensity fiberboards (HDF) are evolving to include lightweight, yet equally durable, versions for niche uses in furniture, automotive interiors, and portable structures.

4. Design and Surface Innovations

Fiberboard panels are increasingly being used as decorative surfaces, thanks to advanced digital printing and veneer applications. These technologies mimic natural materials like wood and stone with stunning realism, meeting consumer demand for high-end aesthetics at affordable prices.

5. Automation in Production

Automated manufacturing and quality control systems are enhancing production efficiency and consistency, making fiberboard an even more competitive choice. ■

TAFISA

Engineered Wood Siding & Trim

Engineered wood siding and trim continue to lead the way in providing durable, versatile, and cost-effective alternatives to traditional wood. These composite panels are crafted by bonding wood fiber strands — such as plywood, particleboard, MDF, or OSB — with advanced resins under heat and pressure, creating a product that combines the strength and durability of engineered materials with the aesthetic appeal of natural wood.

Modern advancements have further enhanced their resilience. Treated with water-resistant waxes and zinc borate, these panels offer exceptional resistance to moisture, fungal decay, and termite damage. This makes them ideal for both interior and exterior applications, from cabinetry and accent walls to outdoor siding and trim.

In 2025, the range of finishes, textures, and colors available for engineered wood panels is more extensive than ever. Embossed textures and ultra-realistic wood grains allow them to replicate the look of premium natural wood at a fraction of the cost. This aesthetic adaptability makes them a preferred choice for a wide array of commercial and residential projects, seamlessly complementing both modern and traditional design schemes.

Beyond aesthetics, engineered wood panels excel in practicality. Their lightweight yet durable composition makes them easy to handle and install, reducing labor costs and speeding up construction timelines. With their combination of affordability, sustainability, and versatility, engineered wood siding and trim remain a top choice for designers, builders, and homeowners in 2025. ■

DIRECTORY

These companies are recognized for their production and distribution of engineered wood siding & trim. Please note that this list might not be exhaustive and the availability of manufacturers can vary based on geographical locations and specific market demands.

Collins Products www.truwoodsiding.com

Georgia Pacific www.buildgp.com

Kaycan www.kaycan.com

KWP www.kwpproducts.com

LP Building Solutions www.lpcorp.com

Maibec Canexel www.maibec.com

Trespa www.trespa.com

2O25 TRENDS

2025 Trends in the Engineered Wood Siding & Trim Industry

1. Sustainability at the Forefront

Environmental concerns are steering the market toward sustainable solutions. Engineered wood products are now manufactured with renewable raw materials and eco-friendly resins. Many manufacturers are prioritizing the use of postconsumer recycled wood fibers, reducing waste and lowering the carbon footprint of production.

2. Enhanced Durability Treatments

Advancements in protective treatments, such as waterresistant coatings and zinc borate applications, have further improved resistance to moisture, fungal decay, and termites. These developments make engineered wood siding and trim increasingly viable for exterior applications in challenging climates.

3. Aesthetic Advancements

Design innovation is enabling engineered wood products to mimic high-end natural materials with greater realism. From embossed wood grains to customizable finishes, these products now offer more sophisticated options, appealing to architects and homeowners seeking premium aesthetics without the associated costs.

4. Easy Installation Solutions

Builders and contractors are embracing engineered wood panels for their lightweight, user-friendly properties. Modern designs now feature pre-finished panels and snap-together systems, which simplify installation and reduce labor costs.

5. Smart Integration

The integration of smart coatings and sensors, such as weather-resistant finishes that change color or repel dirt, is emerging as a futuristic trend in siding and trim. ■

Laminates

Laminates have come a long way from their origins in the early 20th century as plastic insulators for electronics. Today, they are essential decorative and functional surfaces in residential, commercial, and industrial spaces. Their appeal lies in versatility, affordability, and enhanced properties such as sound insulation, fire resistance, UV resilience, and antibacterial features.

Lamination fuses multiple layers of materials, using heat, pressure, and adhesives to create durable surfaces. Initially developed by the Formica Insulation Company in 1927, the first decorative laminates introduced a palette of vibrant colors, sparking their use in interiors. The invention of melamine in 1938 added stain resistance and durability, catapulting laminates into prominence during the post-war housing boom.

2025: Advanced and Versatile Laminates

High-Pressure Laminate (HPL):

A durable favorite, HPL excels in high-traffic environments including countertops and flooring. Enhanced by digital printing and pressing techniques, HPL offers realistic textures and custom designs, making it a cost-effective alternative to stone and veneer. Its strength and on-site flexibility cater to diverse commercial and residential needs.

Thermally Fused Laminate (TFL):

TFL, or melamine panels, fuse decorative layers to substrates under heat, mimicking natural materials like wood and stone. Once limited in design, today’s TFL offers seamless finishes, durability, and cost-efficiency for cabinetry, furniture,

■ HIGH PRESSURE LAMINATE

■ THERMALLY FUSED LAMINATE

■ SPECIALTY LAMINATES (2D & 3D LAMINATES & FILMS)

RIKEN

ARAUCO

and wall panels. And TFL is by far the most popular material used in custom closets, according to experts.

Specialty Laminates

• 3D Laminates (3DL): Wrap seamlessly around panel edges, ideal for furniture and cabinetry. Their scratch resistance and varied designs make them a standout in custom applications.

• 2D Laminates (2DL): Offer protection and decorative options for flat surfaces, with a focus on scratch resistance and customization.

• Advanced Films: PVC-free laminates, UV-resistant options, and antibacterial finishes meet niche needs in healthcare, outdoor spaces, and eco-conscious projects.

With modern innovations, laminates in 2025 are more sustainable, durable, and design-forward than ever, revolutionizing surface solutions for a wide range of applications. ■

2O25 TRENDS

2025 Trends in the Laminates Industry

1. Sustainable Materials

Sustainability is a major driver of innovation. Manufacturers are prioritizing eco-friendly practices, with an emphasis on PVC-free laminates, recyclable materials, and low-emission production processes. Cast polypropylene laminating films, known for their recyclability and high clarity, are gaining traction as a sustainable alternative.

2. Enhanced Realism and Customization

Digital printing and advanced pressing techniques have elevated the realism of laminate surfaces, enabling designs that closely mimic wood, stone, and even textiles. Customization is a growing trend, with manufacturers offering digitally printed designs tailored to specific projects, expanding creative possibilities.

3. High-Performance Laminates

Demand for specialty laminates is on the rise.

Fire-rated, antibacterial and UV- water- and fingerprintresistant laminates are now standard offerings, addressing needs in healthcare, hospitality, and outdoor applications. These high-performance products combine functionality with durability and aesthetic appeal.

4. Seamless Integration

3D laminates (3DL) are becoming increasingly popular for their ability to wrap seamlessly around edges, eliminating the need for additional finishing. This innovation supports clean, modern designs in cabinetry, furniture, and architectural applications.

5. Multifunctional Applications

Laminates are finding broader uses beyond decorative surfaces. Thermally Fused Laminates (TFL) and High-Pressure Laminates (HPL) are now integral to modular furniture, wall systems, and even flooring, expanding their utility across industries. ■

DIRECTORY

These companies are recognized for their production and distribution of laminate products. Please note that this list might not be exhaustive and the availability of laminate manufacturers can vary based on geographical locations and specific market demands.

HIGH PRESSURE LAMINATES

AICA Group www.aica-al.com/aica_group

CEI Materials www.ceimaterials.com

Dackor www.dackor.com

Formatop www. formatop.com

Formica Corp. www.formica.com

Jiangsu TRSK New Material Co., Ltd. www.js-trsk.com

Lamitech www.lamitech.co

Merino Laminates www.merinolaminates.com

Panolam Industries International, Inc. www.panolam.com

Stevens Advantage www.stevensadvantage.com

Tafisa Canada, Inc. www.tafisa.ca

Uniboard www.uniboard.com

Wilsonart www.wilsonart.com

LOW-PRESSURE LAMINATES/ THERMALLY FUSED LAMINATES

AICA Kogyo www.aica.co.jp/english

American Laminates, Inc. www.americanlaminates.com

Arauco North America www. na.arauco.com

Arclin www.arclin.com

Dalbac Manufacturing Co., Inc. www. dalbac.com

Dongwha Malaysia www.dongwha.com/myen/main/main.asp

Egger Wood Products LLC. www.egger.com

Fiberesin Industries www. fiberesin.com

Formatop www. formatop.com

Funder by Genesis Products www.funderamerica.com

KML Corp. www.kmldesignerfinishes.com

Kronospan, LLC. www. kronospan.com

MJB Wood Group www.mjbwood.com

Panel Processing, Inc. www.panel.com

Panolam Industries International, Inc. www.panolam.com

Premier Eurocase www.premiereurocase.com

Purbanchal Laminates Pvt. Ltd. www.purbanchallaminates.com

Roseburg www.roseburg.com

Specialty Laminates www.specialtylaminates.com

Stevens Industries, Inc. www.stevens-wood.com

Swiss Krono Group www.swisskrono.com

Tafisa Canada, Inc. www.tafisa.ca

Texas Wooden Solutions, Corp. www.melaminetex.com

Timber Products Co. (Value Added Division) www.timberproducts.com

Uniboard www.uniboard.com

Wilsonart www.wilsonart.com

SPECIALTY LAMINATES & FILMS

Dackor www.dackor.com

Decotone Surfaces www.decotonesurfaces.com

DNP America, LLC www. dnpamerica.com

Interprint, Inc. www.interprint.com

Klockner Pentaplast www.kpfilms.com/en Omnova www.omnova.com/laminates

Paladin Ind., Inc. www. paladinind.com

Premier Eurocase www.premiereurocase.com

Profol www.profol.com

Renolit Corp. www.renolit.com

Riken U.S.A. Corp. www.riken-usa.com

Sekisui Kydex LLC www. kydex.com

SSI North America www.ssinorthamerica.com

Synergy Thermal Foils www. synergythermofoils.com

Tafisa Canada, Inc. www.tafisa.ca

Taghleef Industries www.syndecor.com

Toppan Interamerica, Inc. www.toppaninteramerica.com

UFP Industrial www.inbound.ufpindustrial.com

Vekaplan www.vekaplan.co.uk

UV CURED POWDER COATING ON WOOD

Liquid & CoatingsPowder

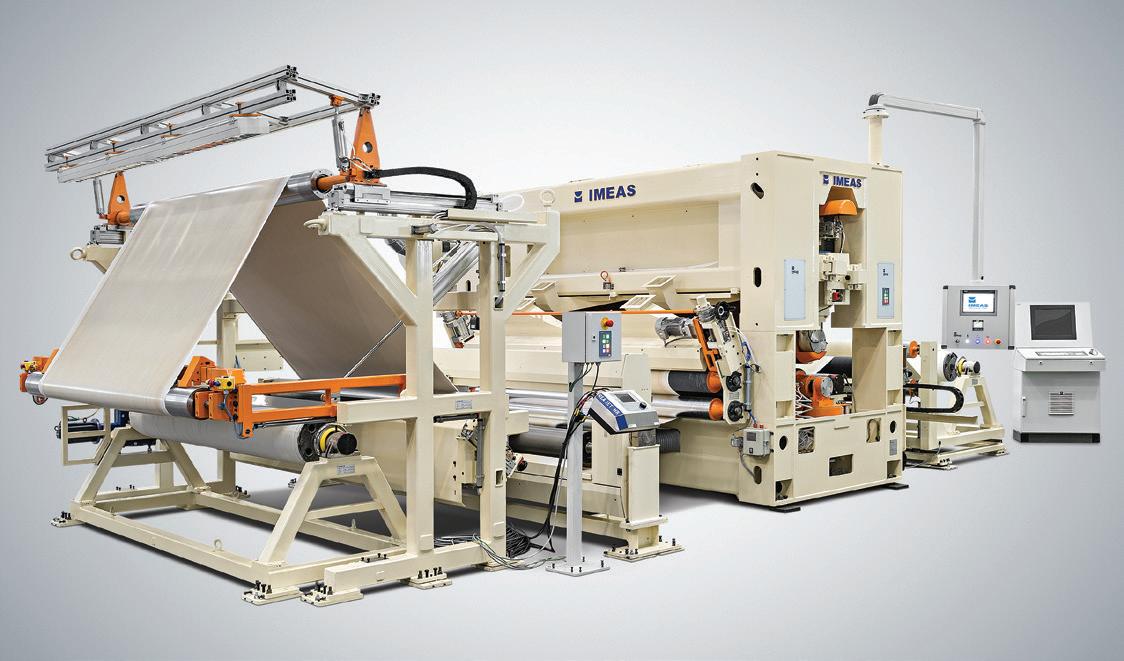

The surface coating industry in 2025 offers an everexpanding array of advanced solutions, addressing both functional and aesthetic demands. Coatings, applied as protective or decorative layers, are available in liquid, solid, and powder forms, each tailored to specific applications and substrates.

Modern industrial coating processes often employ methods like roll-to-roll or web-based coating, where substrates are spooled and coated in continuous sheets. This approach, alongside other innovations, enhances efficiency while maintaining precision.

Multi-purposes

• Protective Coatings: Paints and lacquers safeguard surfaces while enhancing their appearance.

• Functional Coatings: Improve properties like durability, adhesion, or water resistance and can impart entirely new capabilities such as magnetism or conductivity.

Liquid Coatings

Liquid coatings remain a cornerstone of the industry, with advancements in automated air gun spray systems ensuring uniform application. These systems accommodate waterand solvent-based coatings, offering quick, even coverage and efficient material reuse. For thicker coatings, thermal spraying applies heated materials over large surfaces at high deposition rates.

Powder Coatings

Powder coatings, applied electrostatically as dry powder and cured through heat or UV light, offer superior toughness compared to traditional paints. Innovations in 2025 have further reduced heat and dwell-time requirements, enabling use on a wider range of materials.

Powder coatings:

• Produce thick, sag-free layers.

• Emit minimal VOCs, supporting environmental compliance.

• Enable color blending and specialty effects in a single application.

Despite challenges in applying ultra-thin layers, technological advancements continue to expand powder coatings' versatility, making them a top choice for highperformance, eco-friendly finishes in the modern industry. ■

2O25 TRENDS

2025 Trends in the Coatings Industry

1. Sustainability and Low-Emission Solutions

Environmental regulations continue to push the adoption of low-VOC and VOC-free coatings. Powder coatings, with their minimal emissions, are gaining wider acceptance. Water-based liquid coatings, which eliminate solventrelated emissions, are also being enhanced to match the performance of solvent-based alternatives.

2. Hybrid Coating Systems

Hybrid liquid and powder coating

systems are emerging, combining the best attributes of both technologies. These systems enable manufacturers to achieve specialized finishes with greater efficiency, reduced waste, and improved durability.

3. Ultra-Fast Curing Technology

Advancements in UV-curable coatings and low-temperature curing processes are revolutionizing the industry. These innovations reduce energy consumption and make it possible to apply coatings on heat-sensitive substrates, expanding material versatility.

4. Advanced Functional Coatings

Coatings that enhance functionality, such as anti-microbial, anti-scratch, or self-healing properties, are in high demand. The development of smart coatings, which react to environmental changes, is also gaining momentum.

5. Automation and Digital Integration

Automated application systems paired with digital monitoring tools ensure precise coating thickness, reduced waste, and consistent quality. AI and IoT are driving predictive maintenance and realtime adjustments, streamlining production.

In 2025, the coatings market is set to offer more sustainable, efficient, and innovative solutions, catering to the evolving needs of the surface and panel industry. ■

DIRECTORY

These companies are recognized for their production and distribution of coatings and veneer products. Please note that this list might not be exhaustive and the availability of these product manufacturers can vary based on geographical locations and specific market demands.

COATINGS

AKZO Nobel Coatings, Inc. www.akzonobel.com

Arauco North America www. na.arauco.com

Arkema www.arkema.com

Asian Paints PPG PVt. Ltd. www.asianpaintsppg.com

Axalta Coating Systems www.axaltawoodcoatings.com

BASF (North America) www.basf.com

Benjamin Moore & Co. Inc. www.benjaminmoore.com

DVUV, LLC www.dvuv.com

Eastman Chemical Co. www.eastman.com

Funder by Genesis Products www.funderamerica.com

Hempel, Inc. (North America) www.hempel.com

Indigo Paints www.indigopaints.com

IVM Chemicals/Milesi Wood Coatings www.milesi.us

Jotun www.jotun.com

Kwality Paints and Coatings Pvt. Ltd. www. kwalitypaints.co.in

PPG Industries, Inc. www.ppg.com

RPM International Inc. www.rpminc.com

Sherwin-Williams www.sherwin-williams.com

Stahl www.wendelgroup.com

Tafisa Canada, Inc. www.tafisa.ca

Teknos www.teknos.com

Tiger Drylac U.S.A., Inc. www.Tiger-coatings.com

Worthen Industries www.worthenind.com/adhesives

24_012952_Surface_Panel_Annual Mod: November 1, 2024 4:39 PM Print: 11/12/24 11:19:08 AM page 1 v7

Uline

We provide over 42,000 shipping, packaging and office furniture products to businesses across North America. From crates and tubes to tables and chairs, everything is in stock. Order by 6 PM for same day shipping. Best service and selection. Please call 1-800-295-5510 or visit uline.com

Decorative Foils & Lightweight Papers

Decorative foils and lightweight papers remain at the forefront of surface design innovation, offering versatile and costeffective solutions for modern interiors.

These thin, paper-based materials are bonded to substrates like MDF, creating surfaced panels that achieve high levels of realism while maintaining affordability.

Favored for their flexibility and economic appeal, decorative foils and papers are staples in Ready-to-Assemble furniture, cabinet interiors, and other vertical surfaces. Their extensive range of printed designs replicates natural materials such as wood grains, stone textures, and other intricate patterns, making them ideal for achieving premium aesthetics on a budget.

These materials excel in wrapping contoured edges and shapes, complementing Thermally Fused Laminate (TFL) panels in cohesive design schemes. Decorative foils, often impregnated with resins, and lightweight papers with resin top coatings, deliver striking optical texture effects that rival the appearance of natural materials.

Key applications include decorative wall panels, architectural trims, and other vertical surfaces where embossing isn’t required. While their thinness limits certain textural enhancements, modern ink-resistant coatings allow for visually appealing variations that mimic finished wood and other designs with precision.

In 2025, decorative foils and lightweight papers continue to evolve in tandem with TFL, HPL, and 3DL technologies. This ensures seamless design integration across diverse applications, offering reproducible patterns and consistent quality, making them indispensable in creating sophisticated and cost-effective interiors.

2O25 TRENDS

2025 Trends in the Decorative Foils

& Lightweight Papers Industry

1. Ultra-Realistic Designs

Thanks to advancements in digital printing, decorative foils and papers now achieve hyper-realistic designs that closely mimic natural materials like wood, stone, and textiles. Optical texture effects, such as synchronized grain patterns, create an authentic look and feel, elevating their appeal in high-end applications.

2. Sustainable Materials

The push for sustainability is reshaping the industry. Recyclable papers, water-based resins, and reduced reliance on synthetic additives are becoming standard. Manufacturers are also adopting more energy-efficient production processes and promoting circular economy initiatives.

3. Increased Customization

Demand for unique and personalized interiors is driving innovation in customizable designs. Flexible production techniques now enable manufacturers to produce smallbatch or bespoke decorative foils and papers tailored to specific client needs without sacrificing cost-efficiency.

4. Compatibility with New Substrate Technologies

With the rise of ultra-lightweight MDF and other advanced substrates, decorative foils and papers are being optimized for seamless application on a wider range of materials. Enhanced adhesion technologies ensure durability even on complex shapes and edges.

5. Integrated Design Solutions

To meet market demands for cohesive interiors, decorative foils are increasingly paired with TFL, HPL, and 3DL materials. This integration ensures consistent aesthetics across surfaces and simplifies project execution. ■

DIRECTORY

These companies are recognized for their production and distribution of coatings and decorative foils and lightweight papers. Please note that this list might not be exhaustive and the availability of these product manufacturers can vary based on geographical locations and specific market demands.

DECORATIVE FOILS & LIGHTWEIGHT PAPERS

Ahlstrom-Munksjö www.munksjo.com

American Adhesive Coatings LLC www.aacchotmelts.com

Dawei Decorative www.dawei-decor.com

Decorative Panels Group www. decorativepanels.co.uk

Interprint, Inc. www.interprint.com

LamiGraf www.lamigraf.com

Olon Industries www.olon.ca

Omnova www.omnova.com/laminates

Panel Processing Inc. www.panel.com

Schattdecor, Inc. www.schattdecor.com

Surteco North America www.surteco.com

Toppan Interamerica Inc. www.toppaninteramericainc.com

Yodean Décor ww.yodean-decor.com/product

Veneers

Veneer, a thin hardwood layer typically less than 1/8 inch, continues to be a staple in modern design, offering an eco-friendly, cost-effective way to enhance surfaces with the beauty of natural wood. By applying this slender layer to substrates, manufacturers achieve not only aesthetic elegance but also structural reinforcement, maximizing the utility of every piece of wood.

A Legacy in Woodworking

The roots of veneering trace back to ancient Egyptian and Roman times when luxurious wood layers adorned common materials to craft furniture and decor. Today’s advanced slicing techniques minimize waste and deliver incredibly thin, precise veneer sheets.

Modern veneers are crafted from tree trunks using three primary methods, each yielding unique grain patterns:

• Rotary Peeling: Produces continuous strips, ideal for plywood.

• Slicing Machines: Create crown-cut patterns resembling sawn wood.

• Half-Round Lathes: Generate visually striking riftcut grains. Hardwood species like maple, cherry, oak, and walnut, as well as softwoods like pine and fir, dominate North American veneer production.

Veneer Types and Faces

Veneers are available in various types:

• Raw Veneer: Usable on either side.

• Paper-Backed Veneer: Offered in multiple sizes for ease of application.

• Phenolic-Backed Veneer: Engineered for composite materials.

• Reconstituted Veneer: Made from dyed, laminated fast-growing woods.

GREENLINE INDUSTRIES

TOPPAN

2O25 TRENDS

2025 Trends in the Veneers Market

1. Sustainable Veneer Practices

Eco-conscious consumers are prompting manufacturers to adopt greener practices. Reconstituted veneers, made from fast-growing, sustainably harvested woods, are gaining popularity for their minimal environmental impact. Additionally, enhanced slicing techniques are reducing waste while maximizing yield from each log.

2. Digital Customization

Digital printing and advanced imaging technologies are revolutionizing veneer design. These tools enable precise replication of unique wood grains or the creation of entirely custom patterns, offering manufacturers unparalleled design flexibility. Digitally designed veneers can mimic rare or endangered woods, reducing the need for harvesting precious species.

3. Enhanced Durability and Functionality

Innovations in backing materials, like phenolic and paperbacked veneers, are improving durability and workability. These advancements make veneers suitable for a wider range of substrates, including flexible applications like curved surfaces,

and enhance resistance to wear and moisture.

4. Multifunctional Veneers

Veneers are increasingly being engineered to offer additional functionality. From antimicrobial finishes to UV-resistant coatings, these enhancements are catering to specialized markets such as healthcare and outdoor applications.

5. Natural Aesthetics with a Modern Twist

Consumers are drawn to veneers that balance traditional craftsmanship with contemporary design. Techniques like slipmatching and splicing allow for bold, repetitive patterns, while raw veneers highlight the raw beauty of natural wood. ■

Grain alignment techniques include book-matched, slip-matched, and spliced designs, offering diverse aesthetic options.

Grades and Applications

Select, uniform, natural, and paintgrade veneers cater to varied design needs, while their adaptability for curved surfaces and eco-friendly production solidify veneer as a timeless material in contemporary projects. ■

DIRECTORY

These companies are recognized for their production and distribution of veneers. Please note that this list might not be exhaustive and the availability of these product manufacturers can vary based on geographical locations and specific market demands.

VENEERS

Atlantic Veneer Corp. www.moehring-group.com

Besse Forest Group www.bessegroup.com

Cahaba Veneer www.cahabaveneer.com

Columbia Forest Products www.columbiaforestproducts.com

Commonwealth Plywood www.commonwealthplywood.com

Danzer www.danzer.com

Formwood Industries www.formwood.com

Freeman Corp. www.freemancorp.com

Great Lakes Veneer www.greatlakesveneer.com

Manthei Veneer www.mantheiveneer.com

Oakwood Veneer www.oakwoodveneer.com

Timber Products Co. www.timberproducts.com

Treefrog Veneer www.treefrogveneer.com

Veneer Technologies www.veneertech.com

Edge Treatments

Exposed edges of manufactured wood cores such as MDF, plywood, and particleboard remain a design and durability challenge. Untreated edges not only disrupt visual harmony but are also vulnerable to moisture absorption, compromising the longevity of finished products. Edge treatments continue to be the go-to solution for achieving seamless, polished surfaces while enhancing protection and functionality.

Modern edge treatments offer unparalleled versatility, with materials ranging from polyvinyl chloride (PVC) to natural wood, advanced resins, and even eco-friendly alternatives. This diversity ensures compatibility with various substrates and aligns with the industry's growing emphasis on sustainability.

The 2025 market offers an impressive selection of colors, designs, and textures in edge treatments, empowering manufacturers and designers to achieve perfect aesthetic matches for laminates and veneers. Thickness options cater to specific applications, with thinner bands suited for sleek furniture designs and thicker profiles ideal for high-traffic, heavy-duty products like cabinetry and countertops.

Edge treatment styles have also expanded to include:

• T-mold and straight-line banding for clean, modern finishes.

• Contour edges for wrapping complex shapes.

• Painted finishes and custom detailing for a personalized touch.

• Aluminum channels and tongue-and-groove options for structural and decorative needs.

Advanced technologies in edge bonding and application now deliver improved durability, precision, and efficiency, ensuring treatments not only meet but exceed aesthetic and functional requirements. In 2025, edge treatments remain essential for creating refined, high-quality finished surfaces in furniture, cabinetry, and architectural designs. ■

EGGER

TOPPAN

DIRECTORY

These companies are recognized for their production and distribution of edge treatments. Please note that this list might not be exhaustive and the availability of these product manufacturers can vary based on geographical locations and specific market demands.

EDGE TREATMENT PRODUCTS

■ ABS

■ ACRYLIC/PMMA

■ HIGH PRESSURE LAMINATE (HPL)

■ CPL

■ MELAMINE

■ PP

■ PVC

■ WOOD VENEER (EDGEBANDING)

Arborite ■ www.arborite.com

Cefla North America ■ www.ceflafinishing.com

Crown Laminates ■ www.crownlam.com

Edgeband USA ■ www.edgebandusa.com

Edgemate ■ www.edgemate.com

Egger Wood Product ■ ■ ■ ■ www.egger.com

Emco Industrial Plastics ■ www.emcoplastics.com

Finixia ■ ■ www.finixia.com

Formica Corp. ■ www.formica.com

Formwood Industries ■ www.formwood.com

Hopewell ■ www.hopewellplastics.com

Olon Industries ■ www.olon.ca

Panolam Industries ■ www.panolam.com

PRI Edgebanding ■ ■ ■ www.priedgebanding.com

Rehau ■ ■ ■ www.rehau.com

2O25 TRENDS

2025 Trends in the Edge Treatment Market

1. Sustainable Materials

Eco-friendly options are on the rise, with manufacturers offering edge treatments made from recycled or biobased materials. Innovations in waterbased adhesives and low-VOC bonding agents further align edge treatments with sustainability goals.

2. Seamless Integration with Laminates

Advances in color-matching technology and precision application ensure edge treatments blend seamlessly with laminates and veneers. Techniques like

digitally printed edge banding replicate complex textures and patterns, providing a unified design aesthetic.

3. Functional Enhancements

Edge treatments now offer more than just aesthetics. Moisture-resistant and anti-microbial finishes are gaining popularity in applications like kitchen cabinets and healthcare furniture. Impact-resistant options are being developed for heavy-duty environments to enhance product durability.

Sonae Industria ■ ■ www.surforma.com

Surteco North America ■

www.surteco.com

Tafisa Canada ■ www.tafisa.ca

Tece ■ ■ ■ ■ ■ ■ www.tece.com.tr

Toppan ■ ■ www.toppan.com

Ultrapan ■ ■ ■ www.ultrapan.net

Uniboard ■ www.uniboard.com

Veneer Technologies ■ www.veneertech.com

West Wood Products ■ ■ ■ www.west-wood.net

Wilsonart ■ ■ ■ ■ www.wilsonartengineeredsurfaces.com 222

4. Thinner, More Flexible Options

As minimalist designs gain traction, thinner edge banding materials that deliver clean, streamlined edges are in high demand. Flexible options are also evolving to wrap seamlessly around curved or contoured surfaces.

5. Automation and Smart Bonding

Automated edge application systems integrated with real-time quality monitoring tools are becoming standard, ensuring precision and reducing waste. Smart adhesives enhance bonding strength while allowing for faster production cycles. ■

Adhesives

Adhesives are indispensable in the surfaced panel industry, ensuring seamless bonding of veneers, decorative papers, foils, and edgebanding to composite and plywood panels. With advancements in adhesive technology, solutions are now available for projects of all scales and complexities, each offering unique benefits to meet specific needs.

Hot Melt Adhesives (HMA)

Hot Melt Adhesives are celebrated for their high performance and rapid application. These thermoplastic resins provide:

• Exceptional strength: With shear strength often exceeding 100 psi.

• Instant drying: Enhancing production speed by eliminating the need for clamps or extended drying times.

• Invisibility upon setting: Contributing to a clean and polished aesthetic finish.

HMAs liquefy under heat and harden within seconds, achieving full bond strength almost immediately. Their versatile application methods boost productivity and minimize waste. Furthermore, HMAs are an eco-friendly option, producing low VOC emissions and requiring no curing. However, they can be sensitive to heat after drying and may offer less resistance to long-term weathering compared to other adhesive types.

Solvent-Based Adhesives

Solvent-based adhesives are formulated with polymers, pigments, and curatives dissolved in a solvent solution, delivering:

• Durability: Exceptional resistance to high temperatures, UV exposure, and harsh environmental conditions.

• Precise application control: Film thickness can be adjusted through viscosity measurements.

• Superior bond strength: Outperforming water-based adhesives in demanding environments.

These adhesives excel in challenging applications but are not VOC-compliant, making them less suitable for projects with strict environmental regulations.

■ HOT MELT

■ SOLVENT-BASED

■ WATER-BASED

■ HEAT SEAL COATINGS

■ PRIMERS

Water-Based Adhesives

Water-based adhesives combine high molecular weight polymer emulsions with pigments and curatives in a water-based medium. Their key features include:

• Environmental compliance: Fully VOC-compliant, supporting sustainability goals.

• Ease of use: Typically ready for application without dilution.

• Film thickness control: Achieved through density measurements for consistent application.

Water-based adhesives are a reliable choice for projects prioritizing environmental considerations without compromising on performance.

Heat Seal Coatings

These thermoplastic coatings function as adhesives to bond flexible substrates like film, foil, or paper to other materials. Key characteristics include:

• Non-tacky drying: Remaining smooth and non-sticky at room temperature.

• Heat activation: Creating a strong seal when exposed to heat, enabling efficient and durable bonding.

Heat seal coatings are versatile and efficient for sealing projects requiring flexible and adaptable adhesive solutions.

Primers

Though not adhesives in the traditional sense, primers are essential for enhancing the adhesion of topcoats to various base materials. Available in both water- and solvent-based formulations, primers:

• Improve bond strength: Between substrates and topcoatings.

• Expand versatility: By enabling adhesion to a wide variety of materials.

Primers are an invaluable step for achieving optimal adhesion and longlasting results in complex bonding applications.

The continued evolution of adhesive technologies for 2025 ensures that manufacturers can select solutions tailored to their specific project requirements, enhancing efficiency, sustainability, and performance. ■

DIRECTORY

These companies are recognized for their production and distribution of adhesive products.

Please note that this list might not be exhaustive and the availability of manufacturers can vary based on geographical locations and specific market demands.

3M Co. www.3M.com

Akzo Nobel www.akzonobel.com

American Adhesive Coatings LLC

www.aacchotmelts.com

Chemique Adhesives www.chemiqueadhesives.com

Covestro www.solutions.covestro.com

Daubert Chemical Co. www.daubertchemical.com

Dow/ChemPoint www.laminatingadhesiveproducts.com

Dupont www.dupont.com

Fielco Adhesives www.fielco.com

Franklin Adhesives & Polymers www.franklinadhesivesandpolymers.com

H.B. Fuller www.hbfuller.com

Henkel www.henkel-adhesives.com

2O25 TRENDS

2025

Trends in the Adhesives Industry

1. Eco-Friendly Formulations

Sustainability remains a driving force in adhesive development. Manufacturers are increasingly adopting water-based and low-VOC adhesives to meet stringent environmental regulations. Bio-based adhesives, utilizing renewable resources, are gaining traction as companies prioritize ecofriendly production processes.

2. Enhanced Heat and Weather Resistance

As applications diversify, adhesives with improved heat and weather

resistance are in demand. Solventbased adhesives and advanced hybrid formulations are evolving to provide durability in extreme conditions, catering to both interior and exterior applications.

3. Rapid Application and Cure Times

Efficiency is paramount. Hot Melt Adhesives (HMAs) and fastcuring systems are dominating as manufacturers look to reduce production bottlenecks. Innovations in heat-activated adhesives and UV-curable systems are further streamlining processes.

Mitsubishi Chemical Group www.mcgc.com

Panacol-USA www.panacol-usa.com

Sika AG

www. usa.sika.com

Solvay www.solvay.com

Surteco North America www.surteco.com

Toppan Interamerica Inc. www.toppaninteramericainc.com

Transcendia www.transcendia.com/industrial Weiss www.usa-weiss.com

Wilsonart www.wilsonart.com

Worthen Industries www.worthenind.com/adhesives

4. Adhesion Versatility

The need for adhesives that bond dissimilar materials, such as metals, composites, and flexible substrates, is growing. Multi-surface compatibility is becoming a standard requirement, driving research into advanced formulations that enhance bond strength without additional primers.

5. Digitalization and Automation

The rise of smart manufacturing is influencing adhesive application. Automated dispensing systems, paired with digital monitoring tools, ensure precision, reduce waste, and improve quality control. ■

Technology

Technology in 2025: Transforming Design and Manufacturing

Digital Printing & Scanning

Advances in digital scanning and printing continue to revolutionize design and manufacturing across industries, from artisanal furniture to large-scale panel fabrication. Modern scanners now capture not only colors but also intricate 3D textures with stunning realism, enabling faithful replication of natural materials like wood grains and stone. Leveraging advanced inkjet technology, printers can reproduce these textures with remarkable precision, creating surfaces that are nearly indistinguishable from their real-world counterparts.

2D printing has also made significant strides. By using multiple scanning passes and diverse lighting angles, printers now capture and reproduce elevation data alongside image details. This data is seamlessly translated into print files, ensuring perfect registration and flawless results. Matching colors and patterns across edge finishes and flat surfaces has never been more accurate, contributing to cohesive, highquality final products.

Software

Software advancements are reshaping the design-toproduction pipeline. Cutting-edge programs enable realistic 3D rendering of spaces, allowing consumers to visualize products within their environments. This enhanced visualization builds confidence and streamlines the decision-making process. Simultaneously, software-generated cut lists, material orders, and production plans integrate directly with automated machinery, enhancing accuracy and efficiency.

AI and IoT in Manufacturing

Artificial intelligence (AI) and the Internet of Things (IoT) are revolutionizing manufacturing operations. AI-driven algorithms analyze real-time data from IoT-connected equipment, enabling

HOMAG

HOMAG

predictive maintenance to minimize downtime and improve efficiency. Smart sensors monitor machinery and materials, providing actionable insights that optimize production workflows. AI also powers design automation, generating custom patterns, textures, and configurations with unmatched speed and precision. These technologies together are fostering “smart factories,” where seamless integration of equipment, data, and processes ensures maximum productivity and flexibility.

Processing Technology

Automation continues to drive efficiency in panel processing. Sophisticated equipment like CNC machining centers, automated saws, and edgebanders reduce labor demands while boosting output. The rise of “lights-out” factories—where manufacturing runs autonomously—ushers in localized production that minimizes shipping costs and accelerates speed-to-market.

In 2025, technology empowers manufacturers to push boundaries, delivering custom, high-quality, efficient, and intelligent solutions that define the future of design and production. ■

SWISSQPRINT

DIRECTORY

These companies are recognized for their production and distribution of technology. Please note that this list might not be exhaustive and the availability of technology can vary based on geographical locations and specific market demands.

SOFTWARE

Autodesk www.autodesk.com

Cim-Tech.com www.cim-tech.com

DAK Engineering www.dakeng.com

Hexagon www.alphacam.com

Inventables www.inventables.com

KCD Software www.kcdsoftware.com

DIGITAL PRINTING & SCANNING

Canon

www.csa.canon.com

CGS-Oris www.cgs-oris.com/en SwissQPrint America www.swissqprint.com

PROCESSING TECHNOLOGY MANUFACTURERS

Cim-Tech.com www. cim-tech.com

DAK Engineering www.dakeng.com

Hexagon www.alphacam.com

Inventables www.inventables.com

KCD Software www.kcdsoftware.com

2O25 TRENDS

Technology Trends to Watch in 2025: AI, IoT, and Beyond

The surface and panel industry in 2025 is embracing cuttingedge technologies to enhance customization, efficiency, and sustainability. Here are the top trends shaping the industry:

1. AI-Powered Manufacturing

Artificial intelligence (AI) is transforming production processes. AI algorithms analyze real-time data to optimize workflows, predict maintenance needs, and improve quality control. For instance, AIdriven pattern recognition ensures flawless matching of designs across surfaces and edges, while predictive analytics reduce downtime by scheduling maintenance before issues arise. AI’s role in automating design customization is also growing, enabling manufacturers to offer bespoke patterns and textures with remarkable speed.

2. IoT-Connected Operations

The Internet of Things (IoT) is enabling smarter, more connected factories. IoT sensors monitor equipment performance and environmental conditions, providing actionable insights to improve operational efficiency. Smart systems track material usage, detect inconsistencies, and ensure seamless communication across machines, reducing waste and enhancing precision. This connectivity

supports the rise of “smart factories,” where automation and data-driven decisions drive production.

3. Advanced Digital Printing and Scanning

Digital printing and scanning technologies are achieving unprecedented levels of realism, with the ability to replicate textures and patterns that rival natural materials. Elevation data captured by 3D scanners is seamlessly integrated into digital print processes, ensuring precise, high-quality finishes.

4. Lights-Out Manufacturing

Fully automated “lights-out” factories are becoming a reality, where manufacturing runs without human intervention. These facilities enhance speed-to-market, reduce labor costs, and support localized production, cutting shipping times and emissions.

Together, AI, IoT, and automation are revolutionizing the surface and panel industry, creating smarter, more efficient, and highly customizable production processes. ■

Hardware & Fasteners

Modern hardware and fasteners have transformed beyond mere functionality or aesthetics into integral components of design and user experience. Innovations in hinge systems, drawer mechanisms, slide variations, lift systems, and fasteners are redefining what’s possible in residential and commercial spaces.

Seamless Motion and Smart Features

Imagine doors that glide silently closed or drawers that open with a gentle nudge when your hands are full. These are no longer futuristic concepts but standard offerings in 2025. Push-to-open and soft-close functionalities, integrated into hinges and slides, have become essential, streamlining daily tasks and elevating user convenience.

Personalized Style and Aesthetics

Hardware is now a key element in personalizing spaces. From sleek, modern finishes like matte black and brushed nickel to timeless options like polished gold or vintageinspired crystal and ceramic, the choices are endless. Designers are embracing mismatched hardware across rooms to create eclectic and personalized spaces, breaking

away from the outdated "uniformity rule."

Advanced Hinges and Concealed Designs

Hinges have taken on multifunctional roles, supporting thicker, heavier doors with T-type designs while offering concealed options that blend seamlessly into walls. Intricate cladding on concealed doors transforms them into design features rather than functional necessities.

Multifunctional Innovations

Hardware has evolved to maximize space. Brackets, hinges, and slides now enable hidden tables, extendable countertops, and electronically assisted mechanisms, merging utility with modern design.

Specialized Fasteners

Fasteners in 2025 are precision-engineered for specific materials, ensuring secure and durable installations. Whether for wood, metal, or composites, advanced fastener technology supports the seamless integration of today’s sophisticated hardware systems.

Hardware and fasteners have truly become the unsung heroes of transformative design. ■

GRASS RICHELIEU

DIRECTORY

These companies are recognized for their production and distribution of hardware & fasteners. Please note that this list might not be exhaustive and the availability of manufacturers can vary based on geographical locations and specific market demands.

HARDWARE

FGV America www.fgvamerica.com

Grass America www.grassusa.com

Hettich www.hettich.com

Lockdowel www.lockdowel.com

Richelieu www.richelieu.com

Salice

www.salice.com

Sugatsune www.sugatsune.com

Titus Group www.titusplus.com

Top Knobs www.topknobs.com

FASTENERS

AFT Fasteners & Industrial Supply www.aftfasteners.com

Grainger www.grainger.com

Leola www.leolafasteners.com

2O25 TRENDS

Trends in the Hardware and Fasteners Industry for 2025

The hardware and fasteners market is evolving rapidly in 2025, driven by technological advancements, changing design preferences, and a focus on functionality. Here are the key trends reshaping the industry:

1. Smart and Automated Hardware

The integration of smart technology into hardware is gaining momentum. Electronically assisted hinges, slides, and lift mechanisms enable automated movements for drawers, doors, and cabinets. These features enhance convenience, particularly in kitchens and workplaces, where efficiency is crucial.

2. Minimalist and Concealed Designs

Sleek, minimalist hardware continues to dominate design trends. Concealed hinges, push-toopen mechanisms, and integrated handles provide a clean, streamlined appearance. These elements seamlessly blend with surrounding surfaces, emphasizing functionality without compromising aesthetics.

3. Customization and Personalization

Consumers and designers alike are prioritizing individuality. Hardware now comes in an extensive range of finishes, from matte black and

brushed bronze to contemporary shades like champagne gold. The mix-and-match approach is gaining popularity, with unique hardware choices across different spaces in homes and offices.

4. Space-Saving Solutions

As spaces shrink, multifunctional hardware is becoming a necessity. Foldable brackets, hidden table systems, and extendable countertops are now widely available, allowing for greater adaptability and space optimization in small or modular environments.

5. Specialized Fasteners for Diverse Materials

Advances in fastener technology ensure compatibility with a variety of materials, including composites, lightweight panels, and high-strength surfaces. Fasteners designed for durability and precision are crucial for integrating modern hardware systems securely. ■

Tools & Machinery

Investing in advanced tools and machinery is essential for manufacturers looking to stay competitive and optimize operations. Efficiency in cutting times, streamlined setups, and enhanced operator productivity remain key pillars of success in the modern manufacturing landscape.

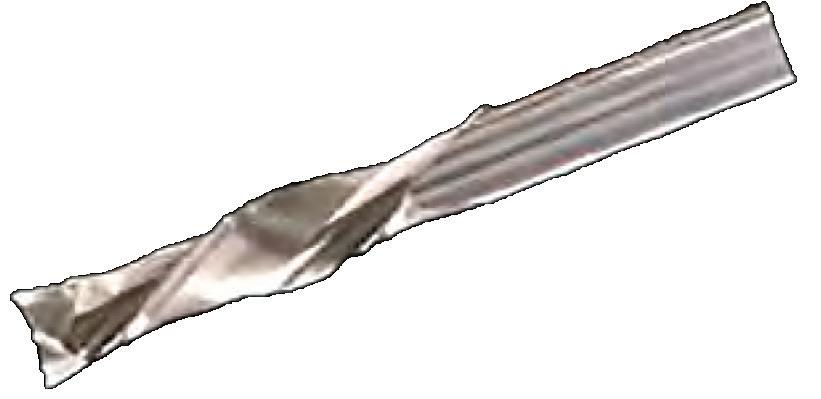

The synergy between tools and machinery is critical. Selecting the right tools involves understanding material properties, machine capabilities, run lengths, RPMs, chip loads, feed rates, and even dust collection systems. These factors directly influence efficiency, precision, and tool longevity.

The Role of Advanced Machinery

State-of-the-art Computer Numerical Control (CNC) machines continue to lead the way in 2025. These systems offer unparalleled precision, allowing for intricate cuts and even direct printing of design elements onto components. Modern CNC machines often feature self-calibrating capabilities, reducing downtime and ensuring consistent output. Advanced models with multi-tool carousels, holding up to 12 or more tools, enhance versatility and streamline complex production processes.

Maximizing Skilled Labor Through Automation

Automation is transforming manufacturing, enabling businesses to utilize skilled labor more effectively. By automating repetitive tasks, companies can focus their workforce on higher-value operations, improving both efficiency and customer satisfaction.

The Importance of Quality Tooling

Selecting subpar tools can undermine even the most sophisticated machinery. From brazed cutters and CNC router bits to saw blades and insert tooling, partnering with experienced tooling manufacturers is vital. High-quality tools ensure accuracy, speed, and durability, safeguarding operations and maximizing machine potential.

In 2025, consistent investment in cutting-edge tools and technology remains the cornerstone of success, driving productivity, precision, and innovation in manufacturing. ■

DIRECTORY

These companies are recognized for their production and distribution of tools & machinery. Please note that this list might not be exhaustive and the availability of manufacturers can vary based on geographical locations and specific market demands.

MACHINERY

Black Bros www.blackbros.com

Bürkle www.burkle.tech/us-en

Cefla North America www.ceflafinishing.com

Choice Machinery Group www.choicemachinerygroup.com

Dackor www.dackor.com

Evans Machinery www. evansmidwest.com

Giardina Group www.giardinagroup.com

Hymmen www.hymmen.com/en

Kleiberit www.kleiberit.com

Laguna Tools www. Lagunatools.com

Rittner Machinery www. rittermachinery.com

SNX Technologies www. snxtechnologies.com

Stiles www.stilesmachinery.com

Thermwood www.thermwood.com

Trotec Laser www.troteclaser.com

Uneeda www.sandpaper.com

Trends in Machinery and Tools for 2025 2O25 TRENDS

The surface and panel industry continues to embrace advanced machinery and tooling solutions in 2025, driven by innovations in automation, precision, and sustainability.

1. Smart and Connected Machines

The integration of IoT (Internet of Things) technology is reshaping how manufacturers monitor and manage machinery. Smart machines equipped with sensors now provide real-time data on performance, wear, and maintenance needs, allowing for predictive maintenance and reduced downtime. These systems enhance efficiency by optimizing tool usage and minimizing waste.

2. Precision Through AI AI-driven algorithms are optimizing

tool paths and cutting strategies, ensuring maximum material utilization and faster processing times. Machine learning is also enhancing calibration processes, allowing tools to adapt to varying material properties with minimal human intervention—in fact, automation continues to dominate the manufacturing landscape. Fully automated “lights-out” factories, where machines operate with no human presence, are becoming more common, not only improving production efficiency but also reducing labor costs and accelerating time-to-market.

3.

High-Durability Tooling

Tools are evolving to match the demands of advanced machinery. Innovations in tooling materials, including advanced

Venjakob www.venjakob.in

TOOLS

Leitz www.leitz.org/en-us

Leuco www.leuco.com

Peak Toolworks www.peaktoolworks.com

Rinaldi www.rinaldi.it/en

Shopbot Tools www.shopbottools.com

Union Tool www.uniontool.co.jp

Vortex Tools www.vortextool.com

Wagner www.wagner-group.com

carbide and diamond-tipped tools, are extending tool life, ensuring precise cuts and reducing maintenance. And high-speed tooling optimized for modern materials, is gaining traction.

4. Advanced CNC Technology

CNC machines are becoming smarter, faster, and more versatile. Modern systems feature multi-tool carousels, self-calibration, and real-time monitoring, reducing downtime and enhancing precision. CNC technology now integrates with design software for seamless transitions from digital concepts to physical components, allowing for intricate cuts and designs.

5. Sustainability in Manufacturing

Energy-efficient machines and recyclable tooling materials are gaining traction as more manufacturers prioritize sustainability. Dust collection and waste management systems are being optimized to align with ecoconscious practices. ■

2025

THE BEST OF THE BEST

Welcome to the eighth edition of the Surface & Panel Masters of the Industry, in which we seek to recognize the innovative companies that supply the surfacing and panel processing industries with the latest materials, technology and design. Throughout these pages, you will find leading suppliers electing to be featured in this original publication that showcases our industry’s products, processes and services.

We are truly grateful for these amazing companies that share our vision and we thank them for their continued support in this industry with this valuable, year-long reference and source of supply information.

SCHATTDECOR schattdecor.com

SHELTER FOREST PRODUCTS tigerply.com

SHOPBOT shopbottools.com

SIMONA POLYGRAIN simonapolygrain.com

SPECIFIED

specifiedcomponents.com

STATES INDUSTRIES statesind.com

STEVENSWOOD stevens-wood.com

SUGATSUNE sugatsune.com

SURTECO NORTH AMERICA surteconorthamerica.com

SYNERGY

TAFISA tafisa.ca

TAURUS CRACO tauruscraco.com

THERMWOOD thermwood.com

TOPPAN tia.toppan.com

UCS - UPPER CANADA/SIERRA ucfp.com / sierrafp.com

UNIBOARD uniboard.com

UNILIN unilin.com

HARDWARE

PANEL PRODUCTS

PANEL PROCESSING MACHINERY

SURFACE TREATMENTS

DECORATIVE SURFACE MATERIALS

EDGE TREATMENTS

INSPECTION & TESTING

DECOR DESIGN

FINISHED PRODUCT

FLAT LAMINATORS

MATERIAL HANDLING

DISTRIBUTION

3A COMPOSITES USA

Earlier this year, 3A Composites introduced 19 new designs for the innovative MONARC™ wall panel, demonstrating its focus on current market trends and commitment to continuous improvement. These new designs include six stones from The Quarry Collection, two woodgrains from The Woodland Collection, and eleven abstract and metal patterns from The Urbanesque Collection. Developed with the aim of empowering architects and designers, these designs encourage creative exploration while delivering solutions that excel in both form and function.

MONARC interior wall panels were developed for use in the design of bath and shower enclosures, kitchen backsplashes, living rooms, and other interior spaces, and a specialized manufacturing process allows for the production of high quality finishes and premium properties that ensure an extremely flat, light weight, and waterproof panel.

MONARC wall panels are easy to install with no trim work or grouting required, and offer significant savings in transportation costs as well as easier handling and installation compared to natural stone, wood, tile and metal. They’re easy to cut and fabricate and can be formed into curves or dimensional panels for custom applications.

The high quality finishes of MONARC wall panels are easy to maintain. Resistant to both fading and surface damage, they can be cleaned with common household cleaning products.

MONARC wall panels are available in 3mm thickness and standard sizes of 48-inch by 96-inch, and 60-inch by 96-inch, as well as custom sizes on request. They are also self-extinguishing and have Class A fire rating (ASTM E-84).

See all 19 new designs in person at the International Builder Show in February – Visit booth #C9111 to learn more!

ACMOS

ACMOS is a leader in the woodworking industry, specializing in high-performance release agents, table lubricants, coolants, and cleaners. With a longstanding commitment to woodworking, ACMOS collaborates closely with OEMs and adhesive producers, enabling the development of innovative solutions tailored to the evolving needs of the industry. Our diverse product range serves applications such as cabinet making, edge banding, furniture, veneering, laminated panels, high-pressure laminates, decorative foils, plywood, MDF, OSB, and particleboards.

ACMOS stands out for its flexibility, offering both standard and custom solutions to meet specific performance requirements in woodworking. Key products include:

• Waxilit 22-74: Table lubricant for moulder machines

• ACMOS 1124B: Glue release agent for hot presses

• ACMOS 100-5475: Release agent for particleboard and MDF

• ACMOS 81-400WE: Release agent for phenolic resin plywood production

• ACMOS 101-5001: Release agent for pressing wood surfaces with PVAc white glues (D2, D3, D4)

Our products deliver multiple benefits: proven performance, global availability, adhesive compatibility, silicone-free formulations, environmental responsibility, water dilutability, improved efficiency, machinery preservation, versatile solutions, and cost-effectiveness. Each product undergoes rigorous testing in our advanced laboratory, ensuring they meet and exceed industry standards.

AETNA BUILDING SOLUTIONS

Aetna Building Solutions, began in 1937 as a humble partnership between Don Davis Sr. and Arthur Schwanke. The founders envisioned a well-diversified distribution company that offers exceptional customer service. We pride ourselves on adhering to these core principles and build on them by understanding our customers’ needs; knowing our suppliers’ facilities and capabilities and making our products readily available for quick and efficient delivery. We are grateful for our Aetna teams who take pride in their knowledge, flexibility and relationship building abilities. Their commitment is evident in how they work together to bring our customers the very best service and products. From our product managers who purchase from world class manufacturers, to our warehouse employees and truck drivers who carefully package and deliver on time, you will experience a level of service that is unmatched. We foster a partnership with our customers and bring them not only the products they need but the knowledge and service they deserve. They become an extension of the ever-expanding Aetna family as we welcome new customers into the fold. We thank you for letting us serve you and show that gratitude by always striving to maintain your trust and your business. Serving Illinois, Indiana, Minnesota, Wisconsin, Michigan, Ohio, Kentucky and Iowa.

SERVING:

• ARCHITECTURAL MILLWORK MANUFACTURERS

• FURNITURE MANUFACTURERS

• CABINET MANUFACTURERS

• CLOSET MANUFACTURERS

• KITCHEN AND BATH DEALERS

• ARCHITECTS, DESIGNERS AND SPECIFIERS

PRODUCT CATEGORIES:

• SURFACES: HPL, QUARTZ, SOLID SURFACE, WETWALL, THINSCAPE

• COMPOSITE PANEL PRODUCTS

• PLYWOOD

OUR OTHER LOCATIONS: 2112 12th Street Rockford, IL 61108

815-968-0921

6350 Brookville Road Indianapolis, IN 46219 317-353-6281

• LUMBER

• HARDWARE

• LAMINATED PANELS

• FABRICATION

4250 Otter Lake Road White Bear Lake, MN 55110

651-407-2800

2433 Mackinwood Drive Lexington, KY 40510

859-226-5687

AMERICAN LAMINATES

Discover the diversity of our three texture lines, each engineered to provide a distinct tactile experience: Fine Furniture Finish presents a smooth, timeless feel: Real Wood Texture offers a richer, more-textured sensation; Engraved in Register captures the calming essence of natural wood.

Since 1988, our Central California operation has manufactured high-end thermal-fused laminated panels on 12 acres, with 4 acres under roof. Our product portfolio includes premium panels and cabinet parts, such as edge-banded shelving, line bored, or grooved options, with efficient, just-in-time inventory management.

Please visit www.americanlaminates.com to browse our color selection and order samples.

Phone: 800-800-2536 | Fax: 209-869-4040

Email: sales@americanlaminates.com www.americanlaminates.com

RENOLITGROUP

AMERICAN RENOLIT CORPORATION

RENOLIT is a globally active specialist for high-quality 3D, 2D and 1D roll laminates and decorative lightweight wood-plastic composite sheets. Around 5,000 employees continue to further develop the knowledge and expertise gained from 75 years of business at more than 30 sites.

RENOLIT creates surfacing materials which meet the highest demands in terms of design, quality, and performance. Our laminates are used on components and panels in retail interiors, healthcare office systems, hospitality, closet organization, kitchen and bath, and Caravan.

Attributes of RENOLIT laminates include excellent impact and wear resistance. Design with the flexibility of contoured shapes and seamless soft edged components. High quality laminates and products for various markets and applications are both our passion and our profession..

Recyclate

Products

Available

INTERIOR SURFACES PRODUCTS:

• RENOLIT 3D FILMS