6 minute read

Innovative Solutions, Relationships ARE KEY

For John Canary, founder of Canary Closets, solid relationships and efficient technology have paved the way to success.

Technology is leading the way when it comes to closet design and manufacturing, at least that’s how it is for New Jersey-based Canary Closets. The company has a few different business strategies to thank for its successful year (sales last year were 5.6 million), including time saving software systems and maintaining relationships across the board.

In addition to supplying closet and cabinet parts across the U.S., Canary Closets started making its own five-piece doors about six years ago for two reasons. First, the company was able to go from a 15-day lead time on projects down to seven. Additionally, if there were any damage issues, wrong size ordered or any other problem, a door could be remade in minutes to get the job done. Another reason was that the company already offered the complete door line to other closet companies, refacers and cabinet shops, so making its own five-piece doors has really helped grow business. But the company needed to make sure it was keeping up with booming business, and that meant investing in efficient software programs.

According to founder and president John Canary, the use of new software systems, Allmoxy and Closet Pro, has been revolutionary. “Our online systems have been the biggest boost to building our business,” he said, noting that the system is fast

and efficient, using a fraction of the time that it would take employees. The company currently employs 27 full-time and two part-time people at its 16,000 sq. ft. location in Union, New Jersey, and the system “has helped bring everyone up to speed.” Canary went on to explain how the design process and ordering are fast, accurate and have been well received by customers. Additionally, about 80 percent of payments from customers go through Allmoxy through Stripe (like Paypal). The company pays a great credit card processing rate and ACH (check) payments cost about 25 cents each. “We would not have seen our business grow without Closet Pro and Allmoxy. It’s completely changed the way we operate.”

But efficient software systems aren’t the only thing that’s helped make Canary Closets so successful. Canary emphasized that relationships are key—and not just with suppliers and distributors, competitors too.

“We are in a very busy market and have gotten to know our competitors in two ways. First, we still do some retail (direct to the consumer) closet jobs and we also sell doors as well as parts to closet companies we compete against,” Canary said. “Since it is such a small part of our business, we are careful and back away from jobs when we find ourselves against one of our own customers.”

And the same goes for the wholesale end of the business. “When it comes to wholesale, we have a working relationship

866-418-1328 CLOSETPROSOFTWARE.COM

Are you a parts manufacturer? START SELLING CLOSET PARTS TODAY! Cloud-based design tool that works on any device (laptop, tablet, smart phone) Immersive, interactive 3D experience Realtime pricing and online proposals Stunning 3D renders created on powerful cloud servers Simple to use – ideal solution for a dealer network

Equipment:

• Mayer PS100 panel saw • B usellato Jet Optima RT21 router • CR Onsrud Mater series router • H omag KAL370 edgebander • B randt KDF 110 edgebander • W eeke BHX 055 vertical machining center • O mal HBD1300 • 2 Uhling HP300 case clamps • 4 J LT miter door clamps • Ir onwood upcut saw with Tiger stop • 2 B alestrini Pico MD2 miter machines

Software: • Closet Pro web-based design tool • A llmoxy web-based online ordering and payment software • CAD Code software for machine code panel optimization and labeling.

Materials in Design: • Canary utilizes approximately 50 different colors of 3/4" thick Tafisa and Uniboard melamine for closet and cabinet parts. Additional cabinet parts are produced out of Columbia prefinished plywood as well as other various veneers.

• Doors are manufactured to match four different profile moldings sourced from Olon and 52 colors from Tafisa, Uniboard and American Laminates.

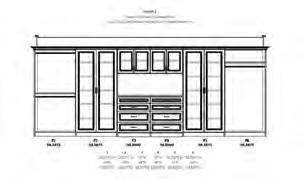

• Inventory includes 124 different combinations of door rail profile/colors as well as 171 accessory moldings (crown&base).

• Drawer boxes consist of vinyl wrapped 5/8" sides sourced from Olon that are doweled together. Some drawers are constructed using the Grass Zargen drawer system, and dovetail drawers are outsourced.

• Hardware is supplied by Richelieu and Hafele.

• Hardware kits are prebagged from Hafele.

with another five-piece door manufacturer who we share materials with and make doors for in colors they don’t offer. We find it so beneficial to align ourselves with other companies in the same industry as we have benefited in many ways with supplies, new customers and technical information.”

Distribution is essential for supplies, as the company receives deliveries every day. “When I went into this business, I knew how important my vendor relationships would be (having worked in distribution).” Canary explained how those relationships are key to operations running smoothly. “We have amazing

board vendors: Russell Plywood, Roberts Plywood, Premium Plywood and Atlantic. They all have our board materials in stock and ready to go for us. In fact, all our board products are paid for before they leave the warehouse, so we owe our plywood vendors nothing.”

It’s maintaining these relationships that helps the company thrive. Canary Closets also still retains a small retail presence, which counts for about 15% of overall business, and some fully assembled cabinetry for commercial projects such as assisted living facilities and office fit-outs.

Though software programs and the maintaining relationships are crucial, Canary also touched on the importance of keeping a close eye on industry trends, while still trying to push the more lucrative pieces. “Popular door designs now are flat doors (slab) and the shaker and transitional styles of our 5-piece doors are popular,” said Canary. “White is our #1 color but we work hard to introduce and sell more profitable woodgrains such as the Viva from Tafisa and the Riviera Oak series from Uniboard.”

With technology taking the lead and more ways to communicate and build relationships now than ever before, it’s no surprise that Canary Closets had a successful year and is looking forward to more. Because for the panel processing and design community, maintaining relationships is key and adapting to an evolving industry is essential. s&p