17 minute read

Feature

Large-scale Electro-fuel Production Set to Become Major Global Industry

Translated and adapted from an article by Morten Valestrand in Tidningen Energi. View the article in Swedish at energi.se The interest in climate change, sustainability and innovation is growing rapidly on both sides of the Atlantic. The technology to generate and store intermittent energy from renewable sources (mainly solar and wind) and to produce fossil-free (“green”) fuels is also evolving at an accelerating rate. The production of green fuels such as renewable methanol and hydrogen requires vast amounts of electricity; hence the fundamental link between the generation of renewable energy and the growing opportunity for production of green fuel.

Mitigating climate change by de-fossilizing the road, marine and air transport sectors is not going to be an easy task. The European Commission has recognized the need for an aggressive policy promoting new solutions to substitute fossil fuels. This presents a strong need and opportunity for producers of carbon neutral fuels.

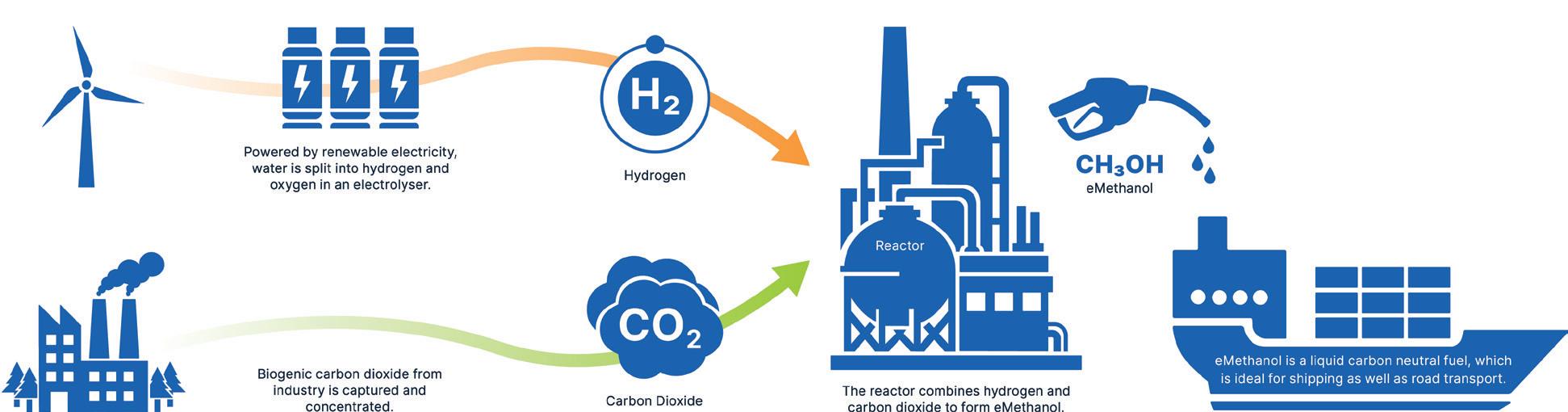

Electro-fuels (also known as Power-to-Liquid or eFuels) are an emerging class of carbon-neutral and fossil-free fuels that are made by using renewable electricity and electrolysis to produce liquid or gaseous fuels. By utilizing carbon capture to take CO2 from the atmosphere or from industrial greenhouse gas emissions, carbon neutral liquid fuels such as methanol, gasoline and aviation fuel can be produced. Electro-fuels offer a viable alternative to fossil fuels.

However, producing electro-fuels requires a vast amount of electric power. To supply the country with electricity, Sweden is pursuing six carbon-neutral alternatives to coal, oil and natural gas. These alternatives are wind power (using wind turbines); wave power (employing various methods of converting ocean wave energy to electric energy); hydroelectric power (routing water in water falls through turbines); solar power (using solar cells); nuclear power (using radioactive heating to turn water into steam which is fed through turbines); and biofuels (fuels derived from organic materials such as crops and forestry by-products). Hydro-electric and nuclear currently dominate, but hydro is already exploited to the full and nuclear raises ecological issues. Wind is therefore seen as the most promising supplement in the future.

The journey towards “liquid wind power” began a few years ago when the energy company Svensk Naturenergi was looking for storage options for its wind power. This resulted in a feasibility study of electro-fuels together with, among others, Göteborg Energi and Uddevalla Energi. In 2017, the Swedish company Liquid Wind was started by Claes Fredriksson, who has vast experience with renewable energy and cleantech, and who is the CEO of the company (see also page 10).

Renewable hydrogen from wind power combined with carbon dioxide – these are the raw materials which Liquid Wind will draw upon to produce renewable fuel on a large scale for use by ships. The fuel is known as electro-

methanol, or eMethanol. “With electro-fuels from renewable hydrogen, Liquid Wind wants to be at the forefront of industrial change. Thanks to ample wind power potential, Sweden is in an excellent position to make clean fuel,” says Fredriksson.

Liquid Wind is focusing on eMethanol mostly for strategic reasons. Technically, the company could be making synthetic diesel or some other fuel, but methanol is a versatile chemical compound with many applications, shipping being one of them. At present, shipping companies around the world lack an environmentally clean alternative to heavy oil. Since their fuel supplies are often purchased on longterm contracts, they offer a stable and bankable market opportunity. “The shipping industry is large enough to be able to provide the commercial weight and security needed to get the large facilities up and running,” says Fredriksson.

The shipping industry is comfortable with using methanol, which is a relatively easy fuel to handle. Methanol also fits in well with existing storage and delivery infrastructures. Shipping may prove to be the gateway for introducing electro-fuel in the rest of the transport sector – on land, at sea and in the air. In addition, both the chemical industry and the manufacturing industry have a growing need for renewable fuels. For example, eMethanol can help reduce the pulp & paper industry’s carbon dioxide emissions.

Liquid Wind intends to buy electricity from new wind power facilities, financed through PPA (Power Purchase Agreements). These will be long-term, fixed price agreements valid for 10–15 years. The strategy is that each subsequent eMethanol production facility will establish its own PPA with wind power producers.

Along with hydrogen, biogenic carbon dioxide is the other major raw material needed to produce eMethanol. Liquid Wind plans to locate its first

Liquid Wind’s first eMethanol plant is planned for early 2024, probably in Örnsköldsvik. Photo: Övik Energi. production facility near the biofuelfired combined heat and power (CHP) plant Hörneborgsverket in Örnsköldsvik. If everything goes according to plan, carbon dioxide will be captured and used in electro-fuel production. Every year 70,000 tons of carbon dioxide will be upcycled into carbon neutral fuel, preventing the emission of 100,000 tons of new carbon dioxide into the atmosphere.

When carbon capture and storage (CCS) technology reaches the energy industry in the future, there may be interesting spin-off deals for energy companies that burn biomass and waste. Channelling carbon dioxide to the production of electro-fuels rather than sending waste to landfill is clearly an idea with a future. Instead of bioCCS with storage, it will be bio-CCU, carbon capture and utilization.

To achieve cost-competitive electrofuel, access to low cost renewable electricity and concentrated sources of carbon dioxide is essential. Over the coming years, it will be important to identify and leverage these conditions to increase the supply of carbon neutral fuel, to reduce our dependence on fossil fuels, and to reduce global carbon emissions.

Photo: Enanuchit/123rf

Electro-fuels Lead the Way to Global Sustainability

Interviewed by Peter Berlin

Juergen Puetter. Photo © Alexander Puetter

Juergen Puetter has had a distinguished career converting innovative concepts into successful businesses. He has extensive experience in the development of indoor environmental control products, wind farms and methanolbased gasoline. He is currently the Chairman and CEO of Renewable Hydrogen Canada (RH2C) which is slated to produce low-carbon, renewable fuels in British Columbia, Canada. See also www.rh2ca.ca.

Juergen was born in Switzerland and grew up in Germany. At the age of 17 he spent one year in California on a scholarship, and then returned to Germany. In 1972 he moved to Canada for good, becoming a Canadian citizen in 1977.

“My father was a pilot with Swissair,” says Juergen. “I myself have two airplanes and I fly everywhere I can. Aviation plays a central part of my life.”

Juergen has been involved with many businesses, beginning in Montreal where in 1977 he founded a company called Bionaire which made air purifiers. In 1993 he created a company called Hydroxyl Systems which dealt with water and wastewater treatment, also for cruise ships. Then 9/11 happened which killed that business. He went on to found Aeolis Wind Power which produced renewable electric energy from wind farms. “We built the first commercial wind farm in British Columbia,” Juergen explains. “I was able to acquire a large number of wind sites which ultimately led me to set up Blue Fuel Energy, Canadian Methanol Corporation and, most recently, Renewable Hydrogen Canada (RH2C).”

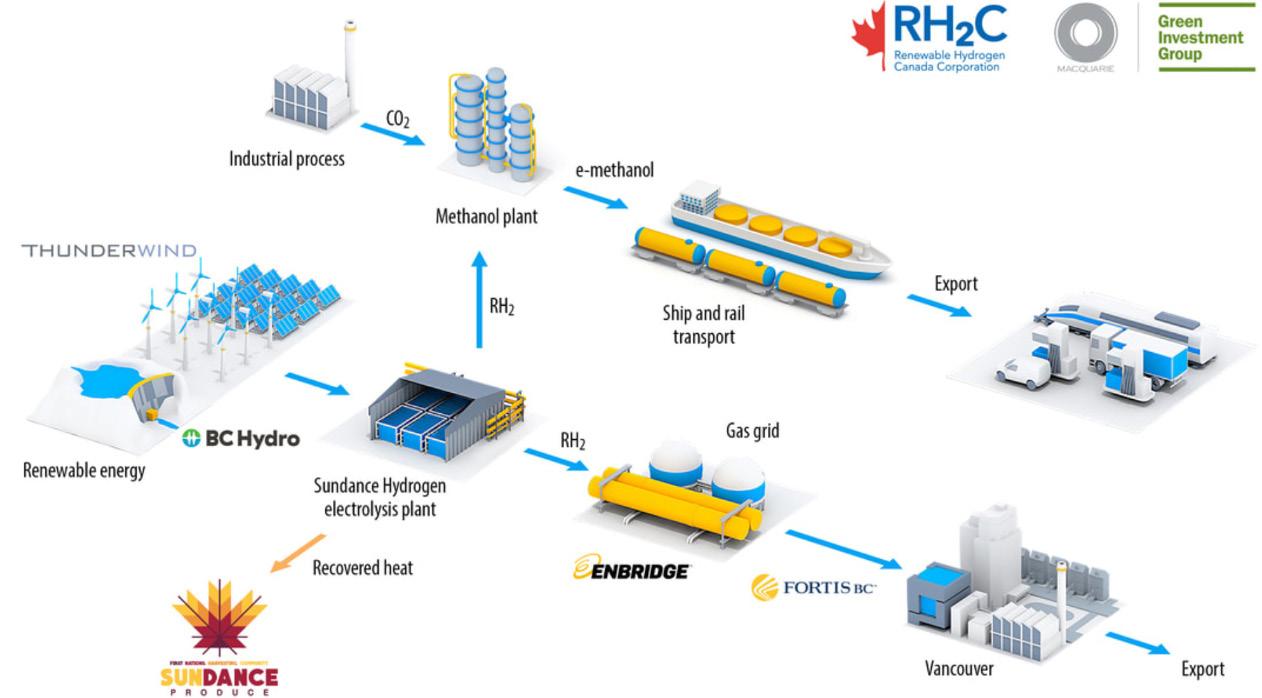

Juergen continues: “With the growing requirement for low-carbon fuel, be it liquid or gas, the underlying energy has to come from somewhere. We have these very large and productive wind sites which allow us to produce electricity at low cost. Clean, carbon-free hydrogen is produced by submitting water to electrolysis, and the electrolytic process requires a great deal of electric power. We control several thousand megawatts of low-cost, high-energy wind farm sites in BC.”

Juergen founded the company Blue Fuel Energy for making methanol using a combination of natural gas and renewable electricity, and then converting it to low-carbon gasoline. “The technology worked, the economics worked, we had big strategic partners, but the large oil companies closed in on us and wouldn’t allow us onto the market,” he laments. “So we basically had to put the company and the project on the back-burner and instead concentrate on hydrogen which is the focus of RH2C. We have two major projects, one of which amounts to building very large wind farms that would drive electrolyzers to make hydrogen, firmed by BC Hydro Electricity to be inserted into the gas pipeline grid. We are now just waiting for permission to inject the gas into the pipeline.”

The other RH2C project is an ocean-based facility which will also facilitate production of hydrogen at a very low cost. The hydrogen can be exported from British Columbia to the most promising hydrogen markets – California, Korea, Japan and China.

Juergen: “Your friends at Liquid Wind in Sweden are aiming to make renewable methanol primarily from wind power. We view methanol as a hydrogen carrier. Paradoxically, a litre

of methanol contains more hydrogen than a litre of liquefied hydrogen. The beauty of methanol, compared to hydrogen, is that it is a liquid at room temperature. It is no more difficult to transport than water. Methanol is a wonderful hydrogen carrier, in many applications better than using it directly as a fuel.“

The conversion of electricity into hydrogen does not occur without losses – around 20 to 30 percent depending on the conversion method. These losses are released as waste heat which can be fed to very large greenhouses for growing organic food. Food security is seen as essential among First Nation communities in British Columbia, and re-using waste heat in this manner is an ideal method for obtaining both First Nation support and political support for the project.

“In our Sundance project we generate approximately 40 megawatt of waste heat, available for greenhouses at no cost,” according to Juergen. “We can heat greenhouses on a massive scale. We think it is a very elegant way to put all the pieces together.”

Hydrogen in liquid or compressed form has many uses – to decarbonize the build sector for heating and cooking using gas, and the transportation sector for trucking, to name a few. On the other hand, methanol is the ideal medium for delivery over large distances.

Then there is the matter of socalled fuel cells which use gaseous

Hydrogen via electrolysis: Water + electric current = hydrogen gas + oxygen gas + waste heat. Hydrogen from methanol: Methanol + water + heat = hydrogen gas + carbon dioxide. Methanol production: Captured carbon dioxide + hydrogen gas = methanol + water. Electricity from fuel cell: Hydrogen from methanol + oxygen from the atmosphere = electricity + water + heat. Copyright: Renewable Hydrogen Canada Corporation

hydrogen and oxygen from air to produce electricity efficiently, albeit mostly on a small scale so far. If methanol is used as a carrier, then hydrogen is produced by “cracking” or reforming the methanol. We asked Juergen whether methanol-fed fuel cells will make battery-driven electric cars obsolete. “No, there is no competition,” Juergen replied. “Take for example a Tesla electric car. The volume under the hood of the car is empty. If you put a methanol tank and a methanol fuel cell there, you can double the range of a Tesla. You keep the methanol in liquid form in a small tank. You then reform the methanol into hydrogen and feed it into the fuel cell which yields electric power to charge the battery. The problem with electric cars is that the batteries are expensive and heavy, and they take a long time to charge compared to filling up with conventional, fossil-based gasoline. An innovative company in Scandinavia, Blue World, is proposing to use methanol as a substitute for gasoline. Gas stations can be converted to dispense methanol very inexpensively. If the methanol is renewable, then you have a carbon-neutral hydrogen carrier. In a fuel cell you combine the hydrogen with oxygen from the atmosphere and out comes carbon-neutral electricity to charge the battery.”

Summing up, Juergen offers the following thought: “These are exciting times. Electricity is clearly the end fuel of the future. Hydrogen and electricity are totally complementary; they are not in competition with one another. It is true that you can drive a truck directly on hydrogen or methanol, but neither is as efficient as when they are converted to electricity in a fuel cell.”

Talking to the customers... Global Swedes

Henrik Henriksson – President and CEO of Scania AB, the Swedish manufacturer of heavy commercial vehicles

Henrik Henriksson. Photo © Scania AB

Henrik Henriksson is President and CEO of Scania, a leading supplier of solutions and services for sustainable transport that is driving the shift towards a fossilfree transport system for heavy commercial vehicles. A fierce advocate for sustainability, Henrik is an advisor to the Swedish government and part of its Agenda 2030 delegation. He recently co-authored a book called “Sustainability Leadership: A Swedish Approach to Transforming your Company, your Industry and the World,” available on Amazon.

Please tell us about your background.

I am the current CEO of Scania after spending close to 25 years in the company. I started off as a so-called management trainee. I have spent most of my career in the Sales and Service functions. Our company has roughly 52,000 employees, and half of them are working in our own Retail and Wholesale organisation, near customers. Compared to most of our competitors and other global original equipment manufacturers (OEMs), we have integrated forward rather than sideways, i.e. we have not bought our competitors like many of our peers have done over the last 30 years. Instead, we have spent our money integrating forward into our value chain, taking over our distributors, importers and dealers. That is the organisation I have been trained in. Before that, I studied business and economics at the University of Lund and also at New York University’s Stern School of Business.

Tell us about Scania today – its product line, ownership, and competitive advantage especially in North America.

If I start from a global perspective, Scania today is a company that is positioning itself as the main driver for transforming heavy commercial vehicle transport to become sustainable. We do that by focussing a lot on the here and now – not talking so much about technology that might come in the future, but how do we solve the issue right now. That is why we spend most of our efforts trying to convert both our existing rolling fleet and also new vehicles to run on sustainable biofuels such as bio-ethanol, biogas and biodiesel. That can really reduce CO2 emissions by up to 90 – 95 percent when produced in a sustainable way.

In parallel, we are developing electric vehicles, as well as selfdriving, autonomous vehicles. These are big technology shifts which affect the competitive landscape. We are winning the game by providing higher quality, being more energy efficient, reducing the cost for our customers, and also reducing the CO2 emission for the benefit of society as a whole.

We are owned by Traton, a German group that represents the heavy commercial vehicles under the Volkswagen umbrella. In North America we sell our stand-alone industrial and marine engines. We are also in a partnership with the U.S. truck manufacturer Navistar International. Through our close cooperation with Navistar, our technology will be available in North America.

From a business viewpoint, does it make sense to develop vehicles for renewable, sustainable fuels?

Yes, it does. I am a firm believer that sustainability and profitability go hand in hand. Both in the short and long term this will be a very good investment. To be successful in selling vehicles that can run on

Global Swedes

... and the customers’ customers.

renewable fuels – like biofuels produced from corn, sugar cane or wheat, or residuals from the forestry industry – you need to find someone who will produce it, and you need to have stakeholder dialogue to make sure it is not taxed to death which sometimes happens, like in Spain a few years ago where biofuels were taxed just like whisky or vodka or brandy. You also have to find someone willing to sign long-term supply contracts so as to provide predictability for our customers in the transport sector if they are going to use these fuels.

We have also realized that we need to talk not only to our customers, but also to our customers’ customers like Walmart, Carrefour, big timber logging companies, big mines. They are not buying any trucks, and we get no revenue from them, but they are designing the logistic systems, and they have demands that lead to a more sustainable transport system. By talking to them we can join our primary customers to basically change the system.

Electro-fuels such as electro-methanol are quickly growing in interest. When will Scania have an electromethanol-ready truck and bus?

Maybe in the future, but for the moment I think there are many other alternatives which are better when it comes to total cost of ownership for the customer. One has to take a “well-to-wheel” perspective – the value chain for producing the fuel, and then the value chain of producing the vehicle, and then the transport that is carried out by this vehicle. If you add up the cost and energy losses, as well as the CO2 footprint in the process, then we think that there are other ways which are better.

But if some day there will be a surplus of electric power from wind and solar, and if that energy can be stored and converted into some kind of liquid fuel like methanol or hydrogen, then so much better. We have been running vehicles on methanol since 1989, and that works well. We are also running vehicles on hydrogen in fuel cells which is also working well. But the internal energy losses going from pure electricity, turning it into a liquid fuel, and then running it in a vehicle, amount to almost 50 percent. So then you are basically back to the combustion engine. This is why we believe that battery-driven electric vehicles will have fewer losses in the value chain, and they will be more realistic as an alternative for customers.

As for surplus electricity, we would rather like to see it used to make electro-methanol or even hydrogen for industries that are more difficult to run sustainably, like in steel, concrete and fertilizer production. Such industries may be willing to pay a higher price for these kinds of synthetic fuels than our customers who are running a transport company and could use either biofuels, which are naturally liquid from the beginning, or use battery-electric vehicles. We are not saying that electro-fuelled vehicles will never happen, but we think there are other alternatives in the near term.

In which areas do you feel Sweden contributes most globally?

We are a small country, but we are punching above our weight. We have a fairly holistic view on society and the planet. Sustainability issues belong in the sweet spot of what we can achieve, not only when it comes to policies, targets and being a role model in “decarbonizing” our society, but also changing the whole industry within which we are operating. Part of my ambition as the CEO of Scania is to not only transform Scania but to transform our whole industry. I think these ambitions are fairly powerful for such a small country in the far north.

Are there any other current or upcoming projects or events that you would like to highlight?

As one of the first global OEMs of heavy trucks, we launched a series production of battery-electric trucks last month. It is a big step that showcases our technology leadership, as well as our determination to drive the shift towards sustainable transport solutions. So that is exciting! Interviewed by Peter Berlin