2 minute read

Sustainability Pavilion

Making less go further

The Sustainability Zone saw everything from nanotechnology to drones for making the MRO industry more efficient

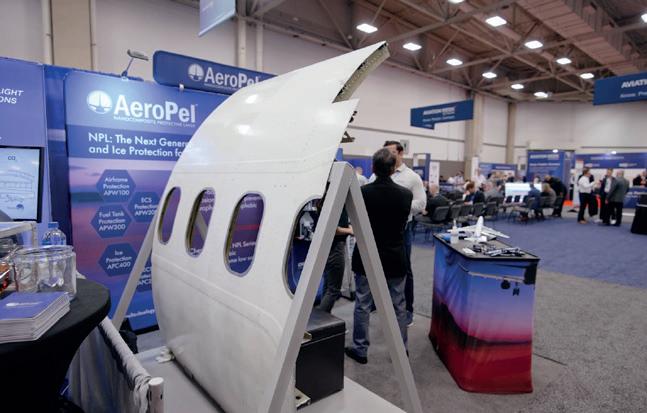

The Sustainability Zone at MRO Americas is for companies that support investment and planning to tackle today’s issues for a sustainable tomorrow and to showcase their products and services. From water treatment to laser applications and energy management, the companies on the Sustainability Zone were leading examples of how the aviation industry can meet its net-zero goals. The International Air Transport Association (IATA) 77th Annual General Meeting in October 2021 approved a resolution for the global air transport industry to achieve net-zero carbon emissions by 2050. World Kinect Energy Services, a division of World Fuel Services, participated at the Sustainability Zone. “We provide energy solutions for customers worldwide. Sustainability for energy is evolving. We are helping our customers to find ways of reducing their energy use, optimizing

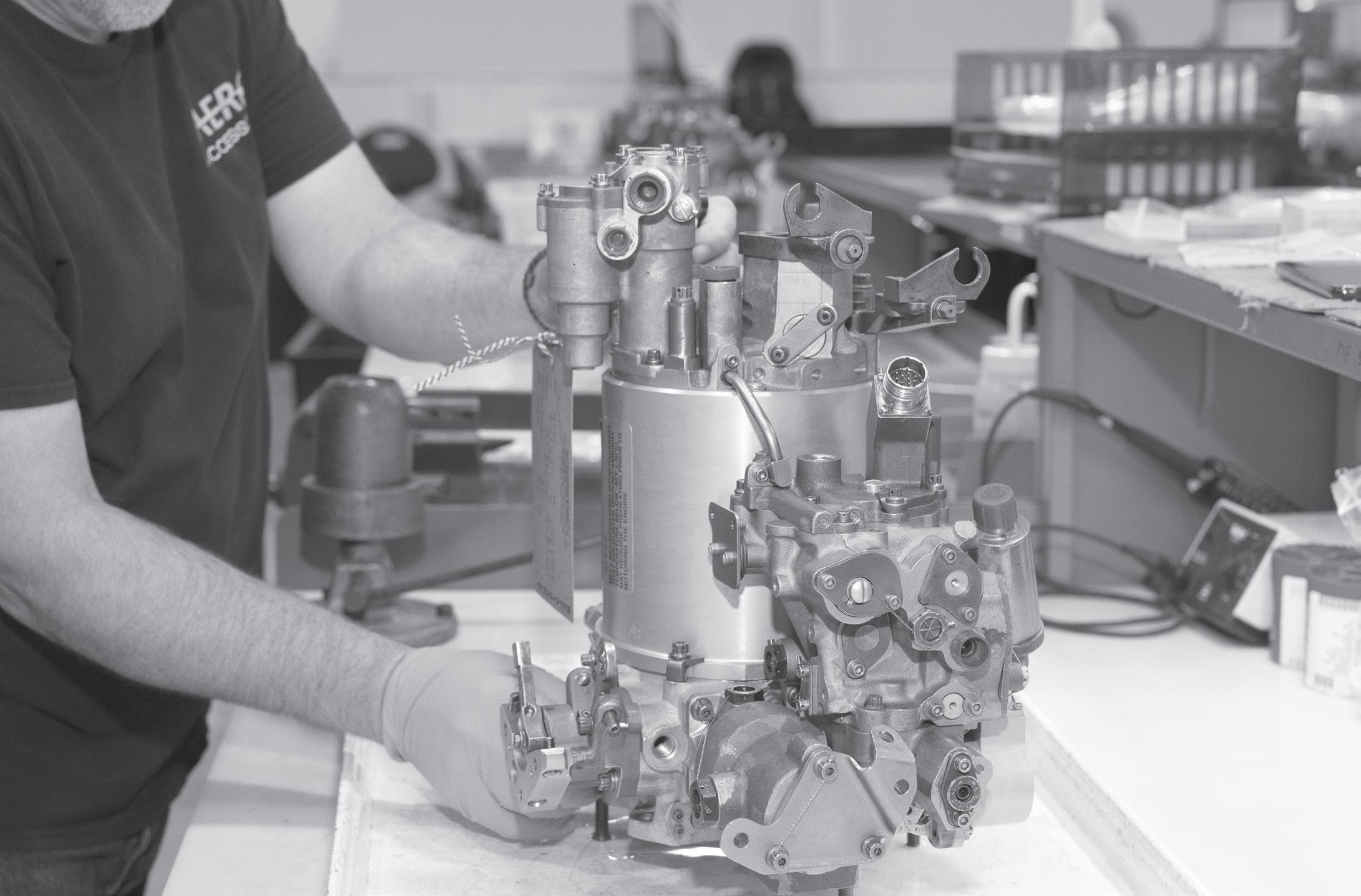

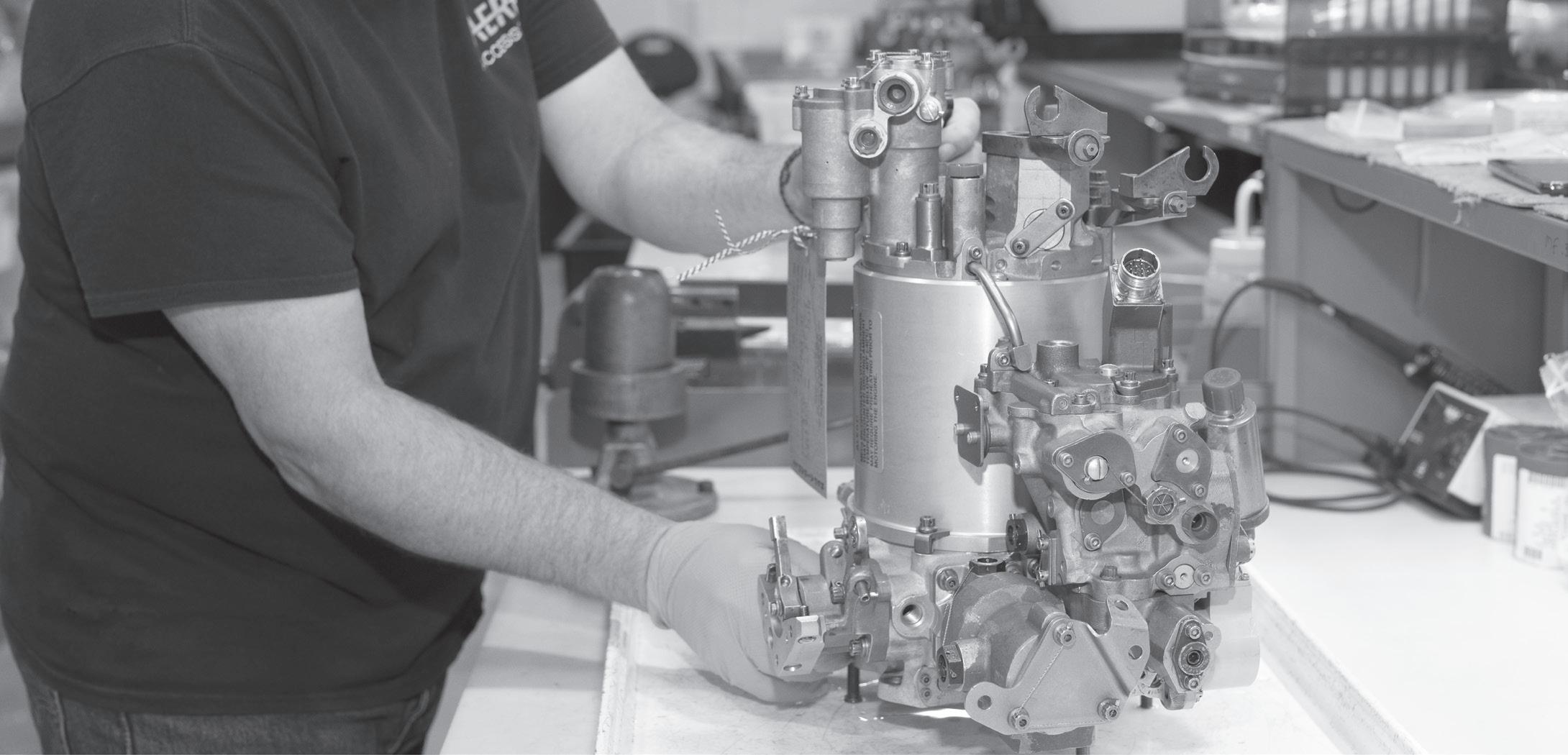

A Leader in Advanced Component Repair Solutions

how they use energy and offsetting the fuel they do use,” said Esteban Bird, Business Development Director. Such commitments will help aviation align with the Paris Agreement goal of global warming temperature rises not exceeding 1.5°C. This will be an aggressive target for the industry to meet and will cost an estimated $2 trillion. To reduce costs elsewhere, drones are an answer. “We’re working on operational sustainability which makes this a very fitting space for us. It’s a fully autonomous platform to help augment the workforce, because the industry is facing a contraction of the number of qualified AV technicians, so we want to make sure we’re sustaining the workforce and that we’re also creating a system that is able to have digital records for every aircraft,” said Colby Harvey, Co-founder and CEO of Rizse. Another approach to sustainability is the avoidance of consumables or the more efficient use of a consumable, such as water. “We have a painting hangar and we treat our own water, we treat the residues, this is one thing we do to keep the water clean,” said Debora Lage, Maintenance Engineer, GOL Aerotech. Depainting with lasers is a

“Our product is water-based. It’s something that we’re looking forward to changing in the industry. It’s safer for the environment. It’s safer for people working around it. It’s a clear coating, it’s based on nanotechnology and has very fast in drying time compared to traditional protection primer that takes 24 hours.”

way of ending the need to use consumables. “We manufacture industrial grade lasers, mostly for refurbishment, maintenance, paint removal. We’re basically replacing sand and dry ice blasting. The turnaround time is quicker, there are no consumables with ours. It’s a growing industry,” said Brad Runkel, Sales Director, Laser Photonics. The paths to sustainability are many and the ingenuity of industry is ensuring that aviation has a great many opportunities for it to meet the challenge of the environment. ■

SUSTAINABILITY ZONE EXHIBITORS

■ ■ ■ ■ ■ ■ GOL Aerotech Laser Photonics Oceanit Laboratories Inc Pall Aerospace Rizse Spire Flight Solutions, ■ A World/Fuel Services Company Trelleborg Aerospace