CHANGING THE LANDSCAPE OF OUR INDUSTRY

Taylor has acquired 187 companies over the past 45 years, forming one of the five largest graphic communications companies in North America.

Camp Hill Art Press

Heinrich Envelope

McPhersons, Inc.

Wiggins & Freund

Anderson’s Party Supplies (Taymark)

Artco Executive Thermographics, Inc.

Hubbard Printing

Original Smith Printing

Print Craft, Inc.

Progressive Impressions of IL

Schmidt Printing

TransCanada

Thermographing Ltd.

+ 21 more

Amsterdam Printing & Litho Corp.

Ann’s Wedding Stationery

First Marketing Company

Marketing General, Inc.

National Recognition Products, Inc.

Progressive Communications, Inc.

Thayer Publishing Corporation

Travel Tags, Inc.

+ 57 more

CCA Occasions Ltd.

Commercial Printing Associates

Cosco Industries

Curtis 1000, Inc.

Flexo Impressions

Integrated Mktg. Solutions (US), Inc.

Lillian Vernon

NowDocs, Inc.

Optima Graphics, Inc.

PhotoCraft

Walter’s Publishing

+ 44 more

CardsDirect, LLC

LifePics, Inc.

MentorMate

NEPS

Official Costumes

Red Stamp LLC

Standard Register

Staples Print Solutions

The Ligature

Vectra, Inc.

Venture Solutions Inc.

+ 22 more

ONE OF THE FIVE LARGEST GRAPHIC COMMUNICATIONS FIRMS IN NORTH AMERICA

78 production facilities

40,000 customers

10,000 employees

Operations in 25 states and eight countries

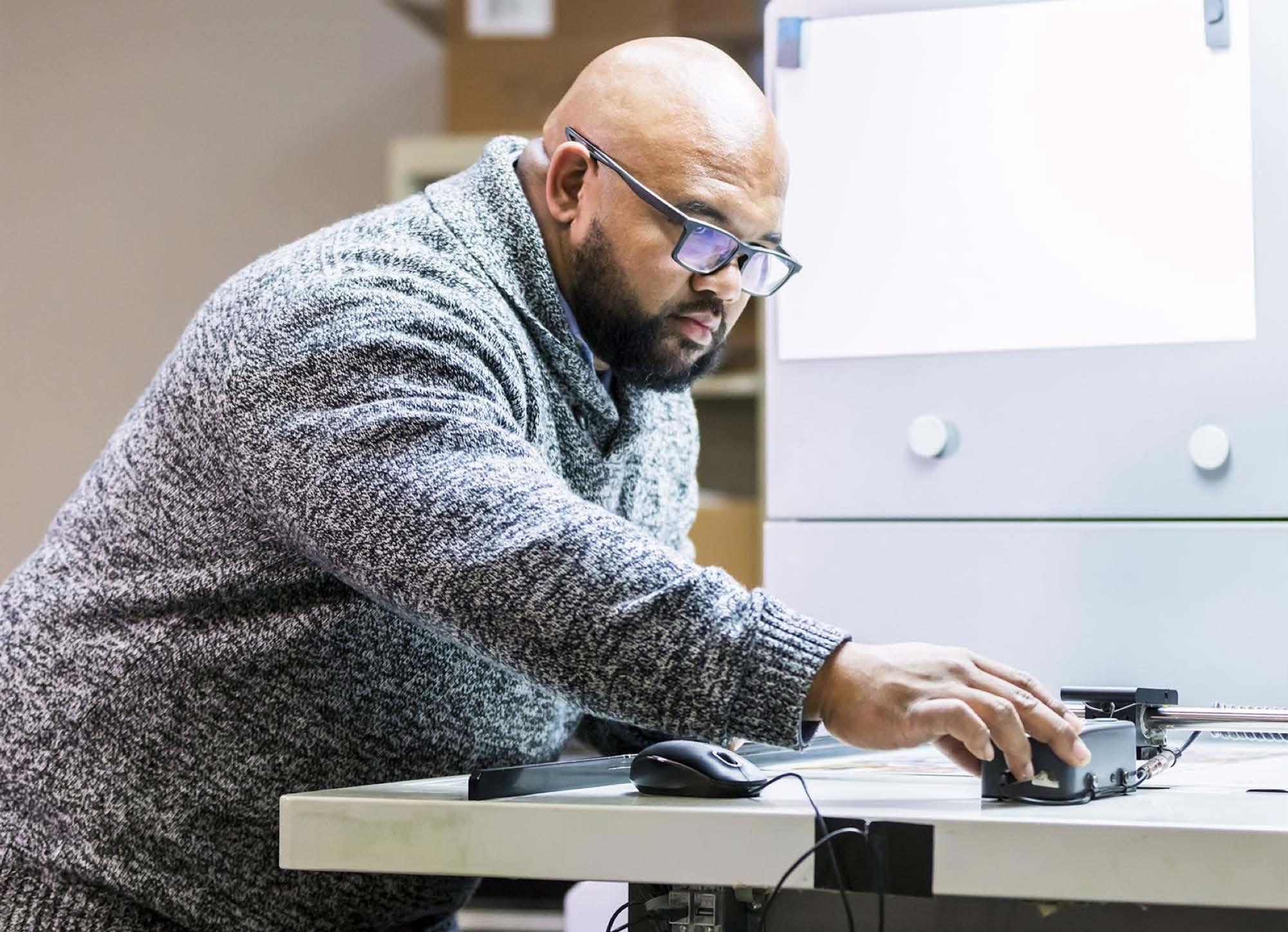

THE SIMPLICITY OF A SINGLE SOURCE

CORPORATE IDENTITY & BRANDING

PROMO MARKETING

SIGNS & GRAPHICS

PRIME LABELS & PACKAGING

MARKETING, DATA & ANALYTICS

DIRECT MAIL

PROGRAMS

GIFT & LOYALTY COMMERCIAL PRINT

DOCUMENT MANAGEMENT

WAREHOUSING & DISTRIBUTION

LABELING

SOLUTIONS

CUSTOMER COMMUNICATIONS MANAGEMENT

● Recycle more material from our facilities

○ 40,973 tons recycled in 2019

● Produce less non-recyclable waste

○ 12% less hazardous waste in 2019

● Divert more waste to waste-to-energy facilities

○ Four of Taylor’s production facilities now divert 100% waste-to-energy

Community Enrichment

● Create jobs and be a good corporate citizen

● Offer flexible hours for employees who volunteer

● Support nonprofit organizations that serve those in need

Heath, Safety and Respect

● Maintain a work environment free from discrimination

● Work proactively with diverse supplier partners

● Focus on safety and hazard prevention in all workplace settings

“We will protect the environment and the quality of life of our colleagues, customers and community.”

● Products that support the monitoring of animal health and prevent disease outbreaks

○ Estimated $10+ billion market in the U.S. annually

● All labels and packaging must follow strict cGMP guidelines enforced by the FDA

○ Guidelines are continuously updated

○ Ensures safe, contamination-free manufacturing

Complete Pre-Press Integration

● Graphic artists

○ Label design and conversion

○ Mock-ups for presentations

● Digital workflow

○ Computer-to-plate in all facilities

Pharmaceutical-Trained

Customer Care

● Team approach with members trained in cGMP processes

● Consistent order processing and documentation storage

● Seamless communication between customer service, graphics support and manufacturing

Work with a team of professionals who truly understand pharmaceutical labels.

Technical Service and Quality Control Staff

● In house laboratory support

○ Material component analysis

○ IR adhesive scans

○ Environmental exposure

○ Accelerated aging

○ Printer compatibility

○ Barcode evaluation and support

● Dedicated field technicians

● Materials stored in separate warehouse

● Designated and marked production areas

● Labels stored in locked cages or tubs

● Line clearance at all stages of production

● Plates remade for each run; no printing plates are stored

● Staff members are formally trained, tested and qualified in the special requirements of pharmaceutical labels

● Presses capable of producing 4pt text with no fill-in

● UV inks for sharp contrast and easy readability

● Barcode verification using GS1 DataBar (RSS)

● Multiple quality control checks from production through boxing

● Traceable lot numbers and material tags on every master roll

● HP 25k Indigo digital press

● Flexible packaging pouch converting equipment

● Thermal lamination

● ABG digital finishing device

● Mark Andy P7 flexo presses

We continuously invest in technologies to support this special category.

ENSURING EACH LABEL ROLL IS CORRECT

Vision Inspection

100% vision inspection capability with return and replace technology

Finished Roll Inspection

A detailed visual roll inspection plus finished count verification

Liner Numbering

Sequential numbering on liner enables tracing through photo-luminescent ink

ENSURING EACH LABEL ROLL IS CORRECT

Rolls are stored in secured, locked cages to prevent lot contamination

Each shipment is palletized and photographed to document configuration for customer

Challenge

A large, multi-national animal health company needed pharmaceutical labels in small to medium production quantities. The customer was seeking short turnaround times, absolute color consistency and crisp, easy-to-read lettering in multiple languages.

Results

● Unwavering color consistency

● Crisp images and clear lettering, even in small fonts

● Increased confidence with foreign-language text

● Quick turnaround times

Taylor utilized its pharmaceutical cGMP capabilities and digital production equipment to deliver exactly what the customer needed.

A pharmaceutical and laboratory products company was looking for a better approach to lot numbering. Incoming prime labels were lot numbered as needed, an inefficient and error-prone process that necessitated additional post-production inspection steps.

● Quick turnaround times

● Eliminated lot numbering process step

● Eliminated post-production inspection step

● Crisp, easy-to-read print in small fonts

Taylor used its digital production technology to create labels that incorporated lot numbers and expiration dates on each label as they were printed.