5 minute read

Banana fibre

Advertisement

Highlight of the article

Banana fibre, also known as musa fibre is one of the world’s strongest natural fibres. The fibre consists of thick-walled cell tissue, bonded together by natural gums and is mainly composed of cellulose, hemicelluloses and lignin. Banana fibres can be used to make ropes, mats, woven fabrics as well as handmade papers. Offset Warehouse previously partnered with an NGO in Nepal and is offering a thick, handwoven fabric made from banana fibres. The traditional process of fibre extraction from the off shoots of Banana plant is laborious and time consuming. The extracted fibers are sun-dried which whitens the fiber. The women of East and West Godavari districts have been practicing the skill of spinning coir ropes for the local vendors since the last 7 decades.

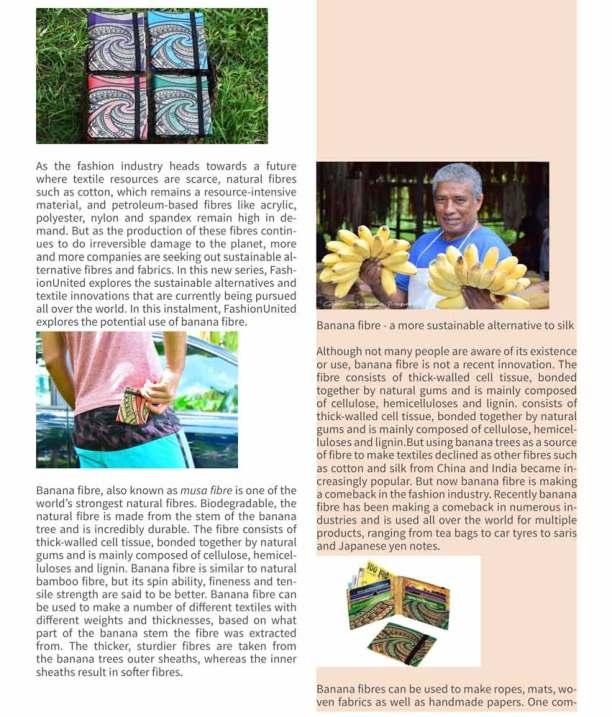

Green Banana Paper uses the banana paper to make wallets and weaves the raw banana fibres to create hand woven items such as purses and laptop bags. While Green Banana Paper avoids using chemicals whenever possible, Simpson is aware of the possibilities of using more natural colourants. “We prefer avoiding the use of chemicals however possible, but natural dyes such as indigo are definitely on our radar for ways we can create variations and intriguing designs.” Fabrics made from banana fibres are soft and supple, as well as breathable and a natural sorbent. They tend to have a natural shine to them as well and are often compared to silk. In addition, banana fibre is now seen as a sustainable alternative to cotton and silk. Banana fibre, which is said to be nearly carbon neutral, is also often compared to hemp and bamboo, although it is not as durable as the former fibres. At the moment, however, there are certain limitations to what can be made from banana fibres. “Unfortunately, our papers are not quite strong or stretchy enough to be used in super stressful applications where the item will be subjected to a lifetime of washings in a washing machine,” pointed out Simpson. Which is why the company has refrained from branching out into more common fashion garments, such as t-shirts, trousers or jackets. However this has not stopped other companies, such eco-textile company Offset Warehouse, fabric distributor THIS Co. and Frabjous Fibers from offering artisan fabrics made from banana fibres. Offset Warehouse previously partnered with an NGO in Nepal and is offering a thick, hand-woven fabric made from banana fibres. THIS Co. features a semi-sheer banana fabric made in the rural Philippines on wooden pedal looms and Frabjous Fibers offers handspun and painted banana silk fabric. However, despite the many potentials offered by banana fibre, the material has yet to make a complete resurgence within the fashion industry. While most companies and brands prefer to stick to more conventional materials, banana fibre offers a sustainable alternative to those looking for a unique and eco-friendly option. Fibre Extraction and Spinning of Banana fiber waste Traditional Fiber extraction Process

The traditional process of fibre extraction from the off shoots of Banana plant is laborious and time consuming. The layers separated from the banana stems are processed through various retting techniques generally in the water tanks, local canals for a period of 10 to 15 days. The retted layers of the plant beaten manually to loosen the fibers, washed and cleaned further to leave the waste.

Traditional practice of this kind, yield the best quality of this fiber. The fibers have good luster and are very affordable for the hand spinning and weaving.

Mechanized White Fiber extraction Process

Alternatively, mechanical process using either de-fibering or decorticating equipment process the separated layers of the stems can be separated directly into fibers. The beater in the machine helps to open the fibers. By using revolving drums the course long fibers are separated from the short fleshy parts and the pith. The stronger fibers are washed, cleaned and dried.

Technical Modification in the Machine

The rotating blades available in the machine are sharp and are good to extract coir fiber as the fiber is rough. Banana being a smooth, soft fiber, the sharp blades while extracting the fibers may cause harm to the strength of fibers by beating and cutting them into short lengths.

The outer bark which is brown green colour is peeled off and the fiber strips are cut through hand extraction machine composed of either serrated or nonserrated knives. The peel is clamped between the wood plank and knife and hand-pulled through, removing the resinous material. The extracted fibers are sun-dried which whitens the fiber. To get a dark brown shade to the fibers we have to keep the bark strips for much longer time.

The sponge like structure behind the strips is to be completely scraped to avoid fungus problems in humid conditions.

There will be a fine fiber strip at the both ends of the bark layers is a very good fiber to explore. It is a smooth, light brown and pure fiber which we use it to make screens.

We dry the processed fibers naturally. Initially we used to extract fiber in our own unit. Now days Kora support people who want to start a unit, train the techniques of extracting fiber and buy it from them.

Process of hand spinning

The usual practice through ages is the hand spinning where the fibre is rolled into short length of 6 to 9 inches, giving a clock-wise twist by hands. When the sufficient quantity of the yarn is made, two of these short lengths are taken in hand together and made into yarn of two plies by giving counter twist, using both hands.

When the counter twist reaches near the end of the striking, further pieces of short lengths kept ready are added one after the other. The counter twist using both hands is continued till it reaches the required length of being a knot, reeled in the form of hank for further usage.

Though this process is very laborious and time consuming, it always have a soft twist and better feel.

Traditional Spinning Ratt (manual & motarised)

To prepare two-ply coir yarn on the spinning wheel, one set of two wheels, one stationary and one movable is required. The stationary wheel usually contains two spindles set in motion through the center