About Kayospruce

Established as one of the leading distributors in the UK for supplying technical fabrics and hardware to the marine and leisure industries, bespoke cutting services, and on hand expert advice, we, at Kayospruce Ltd, are proud to have reached new heights with our outstanding products set to take us even higher. Supplying an extensive range of fabrics for innumerable applications, from sailcloth on the high seas to seat covers in your garden, Kayospruce have penetrated many industries with our outstanding quality textiles and accessories and continue to reach new customers across expansive realms due to the versatility of the products available.

Technical & contract fabrics at its finest

As the textile industry continues to evolve, we have taken it in our stride to accommodate Kayospruce's growing market and are persistent in offering high quality products for the upholstery markets from companies such as Sauleda, Vico Marine, Sunbrella, Marlen Textiles, and Tuvatextil to name only a few.

Through Kayospruce's dedication to maintain the growing demands, we remain true to our core market however also deliver outstanding quality textiles to the awning and marquee industry designed to withstand demanding conditions. Due to the fast-moving environment, Kayospruce remain steadfast in designing and adapting products which has improved the reputation of products throughout the marine and textiles trade.

Kayospruce’s innovation to penetrate multiple industries with our textiles and hardware has undoubtedly contributed to our renowned outstanding reputation across the UK and Europe.

Established over 30 years ago, Kayospruce now occupies a 20,000 square ft warehouse along with a team of 30 dedicated staff and continues to soar with the intention to grow even further. Priding ourselves with the in-house customer service and sales team, who hold a wealth of information about product ranges, technical specifications, and enquiry recommendations, Kayospruce is highly desired for most projects.

As a leading supplier in various markets, Kayospruce continues to advise and support customers in the marine and leisure industries by supplying expert knowledge and materials. We are keen to support our customers projects which persists in showcasing the endless capabilities and diversities of our products and undoubtedly inspires our audiences across the field.

ECOPACKTM Technology

Groundbreaking Innovations Now Coming to Sailcloth

In 2020, Challenge launched a new company called Challenge Outdoor, spearheaded by world champion sailor and technical textiles expert, Hale Walcoff. Hale had a vision to produce light, durable, and UV resistant materials for the outdoor sports industry using 100% recycled polyester. He wanted to produce fabrics that were best in class for the industry while being environmentally friendly. What outdoor enthusiast doesn’t want to protect the outdoors?

Starting in September 2020, we have designed and developed over 100 new products which contain recycled plastic bottles (PET) repurposed into polyester film and fiber. These materials are laminated into composite fabrics, using our proprietary adhesive which does not contain any polluting solvents or VOC’s (Volatile Organic Compounds). Others laminate with solvent-based adhesives along with energy-intensive drying ovens. They may claim to be ‘carbon neutral’ by buying carbon-offsets after polluting; Challenge has taken the progressive step of eliminating harmful chemicals from the start!

As polyester film is the building block for most sailcloth and outdoor laminates, we developed Challenge RUV™ – the first 100% recycled PET film that is 97% UV resistant. Challenge RUV™ lasts 5 times longer in the sun than conventional film used in other fabrics – a big breakthrough in extending performance.

Marblehead ECOPAKTM

Recycled Fabric

The worlds only composite fabric with 100% recycled fiber and film.

Constructed with REPREVE® rPET fibre, Eco is longer lasting, absorbs 80% less moisture, and has better UV resistance and colour retention

Hundreds of customers worldwide are currently using and appreciating the benefits of ECOPAK™ fabric as we continue to develop new styles and colours. We have proven the concept, the manufacturing processes are in place, and the critical supply chain of recycled raw materials is nailed down. We are now developing racing and cruising sailcloth using the same environmentally friendly technology, and on-thewater testing has shown superior shape-holding and durability. Later in 2022 we will be offering ECOPAK™ technology in sailcloth with 100% recycled fiber, film, and taffeta. The only non-recycled component will be our own environmentally friendly adhesive, which has about 30% better bond strength than conventional solvent-based systems. Every yard of Challenge recycled sailcloth will contain about 20 plastic bottles and save about 1 lb. of carbon emissions compared to standard laminates.

As lovers of the outdoors and dreamers riding the wind and the waves, the sailing industry should be at the forefront of Reusing, Repurposing and Recycling. Until now, sustainable sailcloth options have been somewhere between limited and non-existent. This is about to change, and Challenge is leading the way!

Sustainable Composite Textiles

Non-Toxic Adhesive

Laminated into composite fabrics, these materials do not contain toxic solvents or volatile organic compounds.

Recycled Film

The proprietary film backing is 100% recycled and 97% UV resistant, lasting 5 times longer in the sun than conventional film used in other fabrics – a major breakthrough in extending performance.

Innovations

Challenge Research & Development has leveraged advanced technology to produce a full range of product lines for our customers. Our innovations meet every force that a sail will face. Our R&D engineering team has produced the highest quality constructions for both racing and cruising woven applications. Our fabrics have more interlockings than those of our competitors, leading to the Challenge mechanical advantage.

Fiber 104

Fiber 104 is the highest shrinking polyester yarn used in sailcloth according to our tests. The high shrinkage makes the tightest woven fabrics. It is much more expensive than the other leading fibers and is the most exclusive polyester yarn in the industry, proprietary to Challenge Sailcloth.

Power Shrinkage

Strong sailcloth contains fibers that are highly shrunk during the manufacturing process, before it is sewn into a sail. This creates a fabric that is already in its equilibrium state before it is put to use. Challenge Power-Shrinkage technology allows yarns and fabric to achieve maximum shrinkage. It improves the performance of sailcloth in the warp, fill and bias direction. Challenge Fiber 104 has the highest power shrinkage properties of any fiber used in the industry.

Warp-Drive

Challenge Warp-Drive fabrics use patented weaving technology that aligns the strength of zero crimp warp fibers to match the load of the sail. It is the most important woven sailcloth innovation in decades. Radial sails load fabrics in the warp direction. In order to align the mechanical strength of the sailcloth with that load, Challenge weaves Warp-Drive with zero crimp warp fibers. The straight warp yarns do not stretch under load and allow radial sails to hold their shape. As seen on Sir Robert Knox Johnston’s Open 60 Grey Power, the fabric maintains its shape under heavy use. For the first time ever, Challenge woven sailcloth can be used on large tri-radial sails and sailors can have the strength of a laminate with the durability of a woven, and it does not mildew.

Interlockings

Interlock is a unique Challenge process which quantifies the tightness of the weave. The number of yarn crossings in sailcloth is what matters most for performance. In woven fabrics, yarns pass over the first fiber and curve under the next, “locking” them into each other. These yarn crossings, or interlockings, are what create the mechanical advantage in woven sailcloth and resist bias loading. The higher the quantity of interlockings, the higher the performance of the sailcloth. Challenge Fiber 104 has the highest power shrinkage properties, which creates the greatest quantity of interlockings. Our fabrics have more interlockings than those of our competitors. Other fabrics rely more on resin for stability. Resin breaks down over time and these fabrics are prone to bias stretch.

High Mass Fibers

Challenge aligns higher mass fibers on the surface area of the sailcloth, to protect against UV degradation, tearing, breaking and abrasion. Our woven dacron has been proven to offer excellent durability in sails. The most important factors are fiber diameter (denier) and fiber type. The more massive the fiber, the longer the fabric will last in the sun.

High Tenacity

Every line of Challenge Sailcloth woven fabric contains high tenacity yarn. Our fabrics perform under load and abrasion. High tenacity fibers match the load. Challenge engineers have invested time and resources to find the highest quality high tenacity yarn for our customers.

UVR Technology

Challenge UVR Technology is the most efficient, cost effective way of extending sail life. Our sailcloth is designed to endure the elements and maintain performance under extended use in the sun.

Understanding Sailcloth

Low Aspect Sailcloth

Challenge makes two versions of many of its super premium & premium woven dacrons. We engineer different constructions to align the strength of the fibers with the load direction of the sail. One is not better than the other. They are both engineered for a specific application.

A Low Aspect Sail is short and wide. The loading directions are not parallel, and run more toward the center of the sail. Low Aspect cloths generally have larger warp yarns than in a high aspect fabric, and while the fill yarn is bigger than the warp yarn, they are closer to equal size than in a High Aspect Cloth. There is more even crimp between the two fibers. The even crimp allows the yarns to grab each other, this creating a strong resistance to bias stretch.

What does low aspect sailcloth look like?

Low aspect sailcloth has larger warp yarns than fill yarns, however the two fibers are proportionally closer to the same size than a high aspect cloth. The proportional sizes of the years allow them to grab onto each other generating a greater resistance to bias stretch. The strength of the bias is matched with the more bias-prone loading direction of the sail (as seen in the picture to the left).

High Aspect Sailcloth

Challenge makes two versions of many of its super premium & premium woven dacrons. We engineer different constructions to align the strength of the fibers with the load direction of the sail. One is not better than the other. They are both engineered for a specific application.

A high aspect sail is tall and thin. It generates the most load along the leech. A High Aspect cloth generally has larger fill yarns and is very strong in the fill direction. The warp yarns almost touch each other in the weave, creating tunnels in the construction which keeps the fill yarns geometrically straight and low stretch.

We design constructions to align the strength of the fibers with the load direction of the sail. As seen below, a high aspect sail has a different loading direction than a low aspect sail. They would use different cloth.

What does high aspect cloth look like?

High Aspect sailcloth has very large fill yarns and is very strong in the fill direction. There is a high quantity smaller warp yarns that are crimped. As shown in the picture to the right, the warp yarns (vertical) almost touch each other, creating tunnels which keep the fill yarns geometrically straight, which generates low stretch.

Warp Fill & Bias

You will often hear sailmakers talk about a “fill oriented” or a “warp oriented cloth. Sailcloth is woven on a loom. The loom beams long yarns down the vertical direction of the cloth. These vertical yarns are called warp yarns. The loom also shoots fibers horizontally across the loom, allowing the warp yarn to go “over and under” it. The yarns then “interlock” together, however one yarn is always straight, and the other yarn “crimps” around it.

Warp & Fill

Warp yarns run vertical along the roll of the cloth. Fill yarns run horizontal. A fill oriented cloth has a straight fill yarn and a crimped warp yarn. A crosscut sail is fill oriented, meaning that the fill direction is stronger than

Crosscut & Tri-Radial

A crosscut sail uses fabric that is woven such that the fill yarn is stronger than the warp yarn. A Tri-Radial sail uses fabric where the warp yarn is stronger than a fill yarn. Traditionally, tri-radial sails were only made with laminate or membrane cloth, because it is extremely hard to weave a warp-oriented cloth. Challenge Sailcloth invented the first warp-oriented woven dacron, allowing a warp oriented woven dacron to be used in a tri-radial sail.

Please read High Aspect and Low Aspect to understand the loading direction of a fabric.

the warp direction, due to the crimp. Crimped fibers can be pulled until they are straight. Over time and under pressure, this will happen, causing the fabric to stretch in that direction.

Bias Direction

The bias direction of cloth is the diagonal direction, where there is no yarn directly aligned with the load. This is the weakest direction of cloth, and is what we spend much of our time developing. Challenge Fiber 104 “interlocks” more than any other type of cloth. The interlocks create mechanical advantage, which strengthens the bias. We engineer our constructions to math the load of a sail.

Crosscut

A crosscut sail uses cloth that has straight fill yarns and crimped warp yarns. It aligns the strength of the fill yarn with the load bearing direction of the sail.

Tri-Radial

A tri-radial sail uses Warp-Drive cloth that has straight warp yarns and crimped fill yarns. It aligns the strength of the warp in the load bearing direction of the sail.

How do the yarn strengths dif fer between a Crosscut sail and a Tri-Radial sail?

A crosscut sail aligns the straight fill yarn with the load direction.

A Tri-Radial sail using Challenge’s Warp-Drive aligns the straight warp yarn with the load direction.

Weaving Crimp

Sailcloth is woven on a loom. During the weaving process, one yarn becomes straight and the other crimped.

Sailcloth is woven on a loom. At the beginning of the weaving process of a crosscut dacron, large spools of warp fibers are wound off a creel through fairleeds onto large warp beams. The warp beams hold thousands of fibers before feeding them onto a loom. The warp fibers are then fed down the loom and go “over and under” fill yarns, which are shot across horizontally. During the process of going “over and under” the fill yarns, the warp yarns crimp.

The picture to the right shows a crimped warp yarn on top, and a straight fill yarn on the bottom. Crosscut oriented sailcloth is stronger in the fill direction because the fill yarn is already straight. It is more prone to stretch on the warp direction, because the warp yarn can have it’s crimp pulled out of it

Challenge engineers design constructions to optimize threadline strength.

The picture to the right shows a microscope photo of sailcloth, that has been specifically dismantled to demonstrate crimp.

The fibers going horizontally on the picture are the fill. The fibers going vertically are the warp. As you can see, the fill is straight and the warp is crimped.

Challenge Sailcloth designs each warp and fill yarn, taking into account many factors, including denier and tenacity. We use numerous combinations of warp and fill constructions to generate the greatest mechanical advantage in sailcloth.

The more times the warp and fill yarns Interlock together, the strong the sailcloth. Challenge Premium Fabrics have the highest interlock count of any woven cloth in the world.

Meet our sail Expert: Chris Owen

Chris Owen has been thriving in the Sail industry for over 45 years, collaborating exclusively with Kayospruce's Sailcloth range.

Joining Kayospruce in 2017, Chris Owen has taken the sailcloth range to new heights with driving technological investments. Some recent innovations include Kayospruce's brand new, state of the art, automated conveyor cutting machine. This groundbreaking investment means that Kayospruce can now offer a fast, convenient, and reliable cutting service to any customer project.

Starting his career as an apprentice, Chris began by perfecting the basics of old styled sail-making, from laying out sails on the floor, to templating world championship winning sails.

Shortly after, Chris began designing and building dinghy and keelboat sails which provided various opportunities, including working with world class sail-makers and sailors from around the world, like Michael McNamara. It was here that Chris expanded his skills in sail-making and coaching and started to make a name for himself in the sailing world.

To bring these skills into the 21st century, Chris was introduced to, what was, a very basic computer program which proved to be an utterly groundbreaking moment in his career.

Chris quickly mastered the 'Sail-making soft-ware' technology which introduced new versions and the soft-ware developments continued, enabling Chris to assist bigger and more innovative sails. Graphic development remains an integral function to the design process, with his sails having won World Championships in GP 14's and Class Wins at both Scottish Series and West Highland Week.

To discuss sail related enquiries, please contact chris@kayospruce.co.uk

Only the best

Sailing with legendary Merlin Rocket sailor, Spud Rowsell, and make the sails for his Phil Morrison designed trimaran "Exmouth Challenge", which finished 3rd in The Round Britain Race. "They certainly were a challenge; the biggest sails I had made to date,

Winning Gold

"Undoubtedly my highlight as a Sail Designer, so far, is to witness my sails be successful. Peaking specifically after winning a gold medal, at The Olympic games (Beijing, 2008). My Spinnaker, after 2 years of development, crossed the line in the medal race in the Yngling class to win the gold medal with the Yngling girls, Sarah Ayton, Sarah Webb and Pippa Wilson - a truly fantastic feeling."

2012 Olympics

In 2010, Owen invested in the Azure Project for Sail Design software and analysis software, exposing designs to Aero and Structural analysis. 'The following year, he coached Stevie Morrison and Ben Rhodes at Weymouth ahead of the 2012 Olympic games.' Since then, Chris has been appointed Chairman of the Azure Project User Group, providing him with access to cutting edge software for Sail Design.

Newport Start Something New

The Challenge Sailcloth Newport brand is the most recent addition to our highest end sailcloth. Newport is a complete product line with three main construction types: All Purpose, Low Aspect and Pro Radial.

Newport is produced using the best sailcloth fiber available; Challenge Fiber 104. This new product line combines all of the R&D Technology which Challenge has learned from the production of famous brands (such as Marblehead, WarpDrive and High Mass Fiber Weaves). Challenge has designed constructions with very strong fill 1% numbers, rugged denier combinations for AP applications, and strong radial performance in Newport PR.

Fiber 104 can pack more fibers in a sail than competing sailcloth. Challenge has developed a mechanical advantage. The results are tight weaves, excellent shape holding, rugged durability and high UV protection. Sailors who need a high quality sail can choose from one of the three Newport lines for trust, quality and fantastic satisfaction with their sail.

NewportTM All Purpose

Code Fabric Warp x Fill Description Width

CNAP645XW D6.45 220 x 440 6.45oz Newport AP 54”/137cm

CNAP745XW D7.45 275 x 500 7.45oz Newport AP 54”/137cm

CNAP795XW D7.95 275 x 750 7.95oz Newport AP 54”/137cm

CNAP945XW D9.45 350 x 1000 9.45oz Newport AP 54”/137cm

NewportTM Low Aspect

Code Fabric Warp x Fill Description Width

CNLA703XW D7.03 250 x 420 7.03oz Newport LA 54”/137cm

CNLA803XW D8.03 300 x 500 8.03oz Newport LA 54”/137cm

NewportTM Pro Radial

Code Fabric Warp x Fill Description Width

CR51XW D5.1 150 x 250 5.1oz Newport Pro Radial 54”/137cm

CR61XW D6.1 250 x 350 6.1oz Newport Pro Radial 54”/137cm

CR71XW D7.1 350 x 440 7.1oz Newport Pro Radial 54”/137cm

CR81XW D8.1 440 x 520 8.1oz Newport Pro Radial 54”/137cm

CR91XW D9.1 500 x 750 9.1oz Newport Pro Radial 54”/137cm

NewportTM Classic

Newport Classic styles are the same great fibers and constructions used across the product line. Designed specifically for classic yachts, the rich Tanbark and Cream colours are achieved using an autoclave dyeing process with high pressure and heat. They are one of

the foundations in the yachting industry, and demand a very high standard of quality which few have been able to achieve. As a result of the difficult nature of producing these colours, please enquire about special orders with longer lead times.

Code Colour Fabric Warp x Fill Description Width

CNC38XWTT Tan DT3.80 150 x 250 3.8oz Newport Classic Tan 54”/137cm

CNC553XWTT Tan DT5.53 250 x 300 5.53oz Newport Classic Tan 54”/137cm CNC788XWTT Tan DT7.88 500 x 650 7.88oz Newport Classic Tan 54”/137cm

Code Colour Fabric Warp x Fill Description Width

CNC38XWEC Cream DC3.80 150 x 250 3.8oz Newport Classic EC 54”/137cm

CNC653XWEC Cream DC6.53 250 x 400 6.53oz Newport Classic EC 54”/137cm

NewportTM Colours

Challenge Sailcloth is the world leader of dyed woven sailcloth. The premium constructions use high tenacity yarns and high mass fiber technologies. The autoclave dyeing process with high pressure and heat produce vibrant and long lasting colours. Custom colours can be matched to Pantone shades with 1000 yards MOQs.

C38YEXW D3.8Y Yellow 150 x 250 54”

C38DBXW D3.8DB Dark Blue 150 x 250 54”

C38MBXW D3.8MB Med Blue 150 x 250 54”

C38REXW D3.8R Red 150 x 250 54”

C38GRXW D3.8G Green 150 x 250 54”

C38PUXW D3.8PU Purple 150 x 250 54”

C38ORXW D3.8O Orange 150 x 250 54”

CHM603XW D6.03 Natural 250 x 400 54”

CHM603XWYE D6.03Y Yellow 250 x 400 54”

CHM603XWBL D6.03DB Dark Blue 250 x 400 54”

CHM603XWRE D6.03R Red 250 x 400 54”

Fastnet

Leading Offshore & Voyage Sailcloth

Challenge Fastnet is the most durable offshore cruising style available. Fastnet is the 2018 upgrade from Challenge’s successful High Mass Fiber Weaves product line. The result of now 15 years of development, Fastnet combines all of the technology and lessons learned from the past six Clipper Around the World Races. Unlike a professional race, Clipper Around the World is crewed by ambitious amateurs. The sails must perform and last for over 60,000 miles, without professional maintenance crews or paid sailors. Challenge Sailcloth has supplied Clipper for two decades, and is excited to launch Fastnet to allow sailors who need bulletproof durability and UV resistance!

Fastnet achieves the high level of durability and UV resistance by using massive high tenacity warp fibers. The low aspect constructions and High Mass Fiber Technology are the most efficient and cost effective way of extending a sail life.

Code Fabric Warp x Fill Description Width

CFA668XW D6.68 250 x 400 6.68oz Fastnet 54”/137cm

CFA738XW D7.38 300 x 500 7.38oz Fastnet 54”/137cm

CFA788XW D7.88 500 x 650 7.88oz Fastnet 54”/137cm

CFA888XW D8.88 500 x 750 8.88oz Fastnet 54”/137cm

CFA988XW D9.88 500 x 840 9.88oz Fastnet 54”/137cm

CHP988FO D9.88 500 x 940 9.88oz Storm Orange 54”/137cm

Marblehead

Marblehead gets its name from the East-Coast sailing town of Marblehead, Massachusetts.

Challenge was asked to develop the highest quality woven for the most demanding and quality conscious sailors. As many sailors know, a boat is fast when its sail keeps its air-foil shape! When a sail stretches and loses its shape, it starts to luff and flutter and does not sail as fast. As a company, Challenge Sailcloth focuses on woven technology. They have not invested in membrane technology, and have continued their pursuit of the best sailcloth. Our philosophy is to make weaves that rely on the strength of their proprietary fibers and constructions.

What matters most for a strong and durable sailcloth is the number of yarn crossings. In a woven fabric yarns pass over the first fiber and curve under the next, ‘locking’ them into each other. It is these yarn crossings, or ‘Interlockings™’, which resist shape distortion. Challenge developed Fiber 104 with the sole intention of creating a fabric with most Fiber Interlockings. When Fiber 104 is woven in both directions of a sailcloth, it leads to a sail that relies on the strength of a tight, dense weave, rather than short-term chemical finishes. It allows sailmakers to design with lighter fabrics in heavier applications. This Interlock technology created Marblehead.

Code Part# Description Warp x Fill Width

CMAP542XW D5.42 5.42 Marblehead AP 150 x 350 54”/137cm

CMAP642XW D6.42 6.42 Marblehead AP 220 x 420 54”/137cm

CMAP742CW D7.42 7.42 Marblehead AP 275 x 570 54”/137cm

CMAP842XW D8.42 8.42 Marblehead AP 350 x 700 54”/137cm

CMAP942XW D9.42 9.42 Marblehead AP 350 x 1000 54”/137cm

CMAP1042XW D10.42 10.42 Marblehead AP 440 x 1300 54"/137cm

CMECO647XW D6.47ECO 6.47 Marblehead ECO 50% 250 x 400 54"/137cm

CMECO747XW D7.47ECO 7.47 Marblehead ECO 100% 300 x 500 54"/137cm

CMECO847XW D8.47ECO 8.47 Marblehead ECO 100% 300 x 720 54"/137cm

CMECO947XW D9.47ECO 9.47 Marblehead ECO 100% 300 x 940 54"/137cm

Warp Drive

Warp Drive styles are the best choice for sailors who want the performance of a laminate, but the durability of a woven. Warp Drive styles have very high Warp load path strength, but unlike a laminate, will not mildew, delaminate or crack over time. It will last as long as a traditional crosscut sail, and hold its shape very well. This fast growing style has become very popular with sailmakers who have performance cruising and club racing customers who demand performance, but are really not a good fit for a laminate or membrane sail. These styles are made using Challenge’s patented process for weaving straight warp yarns in heavy fabrics. The specialized fill yarns take the crimp during weaving and encapsulate the loaded bearing Warps. Warp Drive styles have won races against laminates and membranes, and have also been used as fantastic offshore voyages.

Fabric Properties

Warp Drive has six styles with true zero crimp for ultimate performance. 4.11, 5.11, 6.11, 8.11, 10.11 and 12.11 are woven with absolutely zero crimp. Warp Drive has four styles that are woven with our famous High Mass Fiber Technology. In these styles, we use larger fill yarns for enhanced UV and Abrasion resistance.

Read more about High Mass Fiber technology at www.challengesailcloth.com/HMF.

Warp-Drive is fast and powerful. My sails held their shape, and had smooth, clean leeches even in highest wind conditions. After 20 days on the brutal Route de Rhum the WD fabric looked as good as new.”

Sir

CCW511XW

CCW611XW

RobertKnox-Johnston, Open 60 Grey Power

Super Premium Radial SailclothCode-Tec

Innovative Polyester Code Sail and Gennaker Fabric

Challenge is excited to announce Code-Tec, a series of new fabrics specifically designed for the new generation of asymmetric and reaching sails used on modern racing and cruising designs. As off-the-wind sails designed for tighter sailing angles continue to evolve with the new structured luff and cableless Code sail designs, Challenge has developed this unique new range of fabrics to meet the performance requirements

for this new generation of sails. Code-Tec uses high tenacity fibers and proprietary immersion coating chemistry to make a high performance but durable Code sail fabric which boasts low stretch, high tear strength and the ability to withstand repeated furls on modern roller furling storage systems. Code-Tec has tear and breaking strength not seen to date in polyester spinnaker fabrics.

A breakthrough in asymmetric fabric technology

High tenacity fibers developed out of kitesurf and wingfoiling fabric technology provide excellent breaking and tear strength

Double-beam matrix ripstop pattern for rugged durability

Leading edge kitesurf finish, with outstanding adhesion and life performance compared to spinnaker cloth or traditional dacron

Code-Tec has tear and breaking strength not seen to date in polyester spinnaker fabrics

New immersion-coating technology

Proprietary chemistry for high performance and durability

Sun-Tec UV roller furling available for UV resistance comparable to much heavier fabrics Code

CCODE55P

CCODE135P

Code Zero Laminates

Challenge MCZ Laminates are ultra-high performance racing styles, which use Black Aramid Fibers in the Warp and Cross Ply. The complete product line is complete in two colours: White and Optic Grey. The same three styles are available for those sailors who

CCZ002T

CCZ004T

want to match a high end woven, or a black/grey membrane. Sailmakers can use Challenge to design sails for both markets. These styles are precision laminated in America with light weight taffetas and superior films for high performance.

XRP

Race Laminates

These durable and high value sailcloth styles are a great choice for classes that restrict the use of exotic fibers. XRP styles were designed with high strength to weight ratios. They use efficient fiber inlays without square scrims for reduced weight and increased off angle load bearing capacity.

XRP uses high tenacity black coated fibers that have good UV, stretch, and tear resistance. Constructions are black high tenacity polyester warp, strong fill-X inserts, precision laminated.

XRP are perfect for racing and club racing headsails and mainsails, multihull screechers, and reinforcements, and large yacht code zeros.

Code Style Warp Fill-X Degree Weight (gsm) Width (cm)

CPXRP6 XRP6 6000 60 130 150

CPXRP9 XRP9 9000 60 160 150

CPXRP13 XRP13 13000 60 190 150

CPXRP18 XRP18 18000 60 220 150

DINGHIES SMALL - SOLO GP 14 SCORPION XRP6

SPORTSBOATS LARGE - 505 OSPREY CONTENDER XRP9

Boat Length

20-25FT MAIN XRP9 NO2 XRP6/9 JIB XRP9

25-30FT MAIN XRP13 NO2 XRP9/13 JIB XRP13 30-35FT MAIN XRP18 NO2 XRP13/18 JIB XRP18

XRP CL

Innovative Cruising Laminates

XRP13, 18 and 24 are upcoming UHMPE Hybrids

These modern cruise laminates use all inlaid fiber without scrims for highest performance and efficiency. Sandwiched between taffetas, they are soft and strong with tremendous lamination adhesion for excellent durability. Using large and tough black polyester high tenacity fibers in several directions, they both handle off angle loads, and are untearable.

The combination of black fibers between white taffetas produces a light grey color

Four styles are available with increasing density of warp fiber inserts

Special UV resistant polyester film is used

Both sides are bonded with polyester taffetas which increase in density on the heavier styles, for better abrasion and UV resistance

Palma

Performance Cruising Laminates

Our new Palma Cruise Laminate line are cutting edge UPE enhanced fabrics, specifically designed for modern cruising boats and sailors who are interested in performance and good sail shape while enjoying their leisure time on the water. Cruisers like to go fast as well!

UPE is short for UHMWPE, which is an acronym for the chemical name of branded fibers like Spectra and Dyneema. UPE is a high modulus fiber like aramid (Kevlar) and carbon fiber. This means the fiber is very low stretch, which is important for good shaping holding, the key to boat speed. But unlike Aramid and carbon, UPE fiber is very tough and durable. It is exceptional in UV (much better than Dacron), hydrophobic (does not absorb water), and all but impossible to cut or tear, making it the perfect high modulus fiber for cruising sailcloth. The result is a high performance sail able to carry high loads without sail shape distortion, and at the same time being extremely durable and long lasting.

Environmentally, Palma sets the standard by which all other laminate sailcloth will be judged. 100% recycled polyester fiber and recycled film. Challenge uses a propriety adhesive system that contains no PFAS’s or solvents to bond all the materials together. Our adhesive system also leads the industry in terms of both adhesion and weathering. While others are content with purchasing carbon offsets and trumpeting their green washing credentials. Challenge focuses on maximizing the use of recycled materials, eliminating forever chemicals, and building the most sustainable products.

Five styles with increasing density of warp fiber inserts. Polyester taffetas on both sides, which increase in weight on the heavier styles, for better abrasion and UV resistance

Low stretch

High durability

High percentage of re-cycled materials No solvents or PFAS chemicals

Code Fabric ID Name Insert DPI Fiber Type Taffeta Film Weight Width Warp | X: 45°/1.5” (mm) (sm) (gsm) (in) (cm)

CPALMA6 Palma 6 CL6 UPE 6000 | 1000 Poly/UPE Light 1.00 5.86 251 60 1.5

CPALMA9 Palma 9 CL9 UPE 9000 | 1000 Poly/UPE Light 1.00 6.47 277 60 1.5

CPALMA13 Palma 13 CL12 UPE 12000 | 1000 Poly/UPE Medium 1.25 7.94 340 60 1.5

CPALMA18 Palma 18 CL18 UPE 18000 | 1000 Poly/UPE Medium 1.25 9.80 420 60 1.5

CPALMA24 Palma 24 CL24 UPE 24000 | 1000 Poly/UPE Medium 1.50 10.50 450 60 1.5

Super Durable Spinnaker Fabric

Challenge is excited to announce its next generation coated cruising spinnaker fabric. Proven in the Clipper Cup Around the World Race, spinnakers made of Fibermax were used without replacement on boats sailing over 50,000 miles. All but one person on the many boats are amateurs, so the chutes are used and abused over and over again. No spinnaker cloth but Challenge has been used on the Clipper Cup sails for the last 20 years.

Coated finish for easy cutting on vacuum tables

High tenacity nylon fibers provide excellent breaking and tear strength, and abrasion resistance

Very tight weave, dense constructions

Durable coating has excellent adhesion, with no crazing or white-out common on lesser fabrics

Firm finish provides low stretch and high performance for big boat or dinghy racing

Dyed bright white finish offers superior UV resistance to natural Fabric width is 60” / 150 cm

Insignia & PSA Fabric

PSA Fabrics

Challenge PSA fabrics use an acrylic based pressure sensitive adhesive that bonds aggressively to woven and laminated sailcloth.

Insignia Fabrics

Polyester Insignia Fabric adhesives are specifically formulated to peel away from the sail without leaving residue.

Code Fabric Description Weight(gsm) Width(in) INS1422WP IUV54 TiO2 Coated Polyester Taffeta with PSA 150 54

Flo Orange Code: INS1422FO Weight: 141gsm Width: 56.75in

Flo Pink Code: INS1422FP Weight: 141gsm Width: 56.75in

Black Code: INS1422BK Weight: 141gsm Width: 56.75in

Blue Code: INS1422BL Weight: 141gsm Width: 56.75in

Green Code: INS1422GR Weight: 141gsm Width: 56.75in

Flo Yellow Code: INS1422FY Weight: 141gsm Width: 56.75in

Navy Code: INS1422NA Weight: 141gsm Width: 56.75in

Dark Grey Code: INS1422DG Weight: 141gsm Width: 56.75in

Red Code: INS1422RE Weight: 141gsm Width: 56.75in

White Code: INS1422WH Weight: 141gsm Width: 56.75in

Clipper Canvas

The cruising cloth for traditional and classic craft with the authentic look and feel of canvas.

Spun polyester yarns in both warp and weft

Colouration system imparts UV protection

Anti-soil and water repellent finish

Range of 5 different weights

Superior durability

Rot proof

Advisory Note:

To maintain the authentic feel of canvas, spun polyester as opposed to continuous filament (Dacron) is used. A feature of spun polyester, is a greater level of yarn and fabric irregularities. The customer must accept this as a natural characteristic of this authentic canvas product. Clipper Canvas can also be subject to occassional colour variation due to the traditional processes employed.

Code Weight Width (cm) US oz UK oz

H13440N 7.2 9.1 165

H15450N 9.8 12.4 60

H16545N 12.5 15.8 60

H22600N 13.5 17.1 60

H24800N 17.4 22.1 60

Code Weight Width (cm) US oz UK oz

H13440T 7.2 9.1 150

H15450T 9.8 12.4 60

H16545T 12.5 15.8 60

H22600T 13.5 17.1 60

H24800T 17.4 22.1 60

225 Years of Sailmaking

Kayospruce is a proud supplier of Clipper Canvas, Ratsey and Lapthorn’s ideal sailcloth for achieving an authentic and traditional look.

The broad range of items stocked, and their speedy and efficient staff, make Kayospruce a lifeline to the sailmaking industry" Ratsey and Lapthorn

Ratsey and Lapthorn have been world renowned sailmakers since 1790 and are considered the oldest sailmakers in the world. Based in Cowes on the Isle of Wight, the knowledge, passion, and innovative approach remains at the heart of the Ratsey and Lapthorn sail loft, with their team consisting of keen racers and medal winners on both classic and modern yachts.

Natural

Tan

Natural

Tan

Kayospruce

Conveyor cutting

Kayospruce

excited to launch the new state of the art, 8 metre, automated conveyor cutting machine. Offering 3 types of cut;

PLOTC

PLOTCM

PLOTCWL

PLOTMISC Plotter

PLOTSRL

Newport Low Aspect Applications

#1

#1

#1

#1

#1

#2

#3

#1

#1

#1

#2

#3

#1

Med #1

#1

#2

#3

Light #1 • • Med #1

• Heavy #1 • • Heavy #2 • • Heavy #3 • • 50 55 15.0 16.5 Main • Light #1 • • Med #1 • • Heavy #1 • • Heavy #2 • • Heavy #3 • 55 60 16.5 18.0 Main • Light #1 • Med #1 • • Heavy #1 • • Heavy #2 • Heavy #3 • 60 70 18.0 21.5 Main

Light #1 • Med #1 • • Heavy #1 • Heavy #2 • Heavy #3

APPLICATION CHARTS FOR MONOHULL ONLY. FOR MULTIHULL APPLICATIONS ADD 10-15 FEET. THESE ARE LOW ASPECT CONSTRUCTIONS. FOR HIGHER ASPECT SAILS USE HEAVIER WEIGHTS.

APPLICATION CHARTS FOR MONOHULL ONLY. FOR MULTIHULL APPLICATIONS ADD 10-15 FEET. THESE ARE LOW ASPECT CONSTRUCTIONS. FOR HIGHER ASPECT SAILS USE HEAVIER WEIGHTS.

#1

#2

#1

#1

#1

#2

#3

#1

#1

#1

#2

#3

#1

#1

#1

#2

#3

#1

#1

#1

#2

#3

#1

#1

#1

#2

#3

Light #1

#1

Heavy #1

#2

#1

#1

#1

#2

#3

#1

#1

#1

Heavy #2

#3

#1

Med #1

#1

Heavy #2

#3

#1

Med #1

#1

#2

#3

#1

#1

#1

#2

#3

#1

Med #1

#1

#2

#3

#1

#1

#1

#2

#3

APPLICATION CHARTS FOR MONOHULL ONLY. FOR MULTIHULL APPLICATIONS ADD 10-15 FEET.

APPLICATION CHARTS FOR MONOHULL ONLY. FOR MULTIHULL APPLICATIONS ADD 10-15 FEET.

#1

#2

#1

#1

#1

#2

#3

#1

#1

#1

#2

#3

#1

#1

#1

#2

#3

#1

#1

#1

#2

#3

#1

#1

#1

#2

#3

#1

#1

#1

#2

#3

Sailcloth Slit Tape

Not all sizes and weights held in stock but supplied to order

Sold by roll

White

Code Weight (US oz) Size (mm) Size (in)

SLT04WH050 4 50 2

SLT04WH063 4 63 2.5

SLT04WH076 4 76 3

SLT04WH102 4 102 4

SLT04WH127 4 127 5

SLT05WH050 5 50 2

SLT05WH063 5 63 2.5

SLT05WH076 5 76 3

SLT05WH102 5 102 4

SLT05WH127 5 127 5

Code Weight (US oz) Size (mm) Size (in)

SLT06WH038 6 38 1.5

SLT06WH050 6 50 2

SLT06WH063 6 63 2.5

SLT06WH076 6 76 3

SLT06WH102 6 102 4 SLT06WH127 6 127 5

SLT07WH050 7 50 2

SLT07WH063 7 63 2.5 SLT07WH076 7 76 3 SLT07WH102 7 102 4

Code Weight (US oz) Size (mm) Size (in)

SLT07WH127 7 127 5

SLT08WH076 8 76 3

SLT08WH102 8 102 4

SLT08WH127 8 127 5

SLT09WH076 9 76 3 SLT09WH102 9 102 4 SLT09WH127 9 127 5

Insignia Slit Tape

Dacron® Insignia Tape slit to various widths

Useful for sail repair tape and protection against wear

Designed in widths suitable for draft stripes

Code Description Width (mm) Roll Length (m)

INS0012BK Insignia Slit Tape 12 45.7

INS0015BK Insignia Slit Tape 15 45.7

INS0020BK Insignia Slit Tape 20 45.7

INS0025BK Insignia Slit Tape 25 45.7

INS0030BK Insignia Slit Tape 30 45.7

Code Description Width (mm) Roll Length (m)

INS0050BK Insignia Slit Tape 50 45.7

INS0075BK Insignia Slit Tape 75 45.7

Black Blue

INS0040BK Insignia Slit Tape 40 45.7

Code Description Width (mm) Roll Length (m)

INS0012BL Insignia Slit Tape 12 45.7

INS0015BL Insignia Slit Tape 15 45.7

INS0020BL Insignia Slit Tape 20 45.7

INS0025BL Insignia Slit Tape 25 45.7

INS0030BL Insignia Slit Tape 30 45.7 INS0040BL Insignia Slit Tape 40 45.7

Code Description Width (mm) Roll Length (m)

INS0020GR Insignia Slit Tape 20 45.7

INS0025GR Insignia Slit Tape 25 45.7

Code Description Width (mm) Roll Length (m)

INS0050BL Insignia Slit Tape 50 45.7

INS0075BL Insignia Slit Tape 75 45.7

Code Description Width (mm) Roll Length (m)

INS0012RE Insignia Slit Tape 12 45.7

INS0015RE Insignia Slit Tape 15 45.7

INS0020RE Insignia Slit Tape 20 45.7

INS0025RE Insignia Slit Tape 25 45.7

INS0030RE Insignia Slit Tape 30 45.7

INS0040RE Insignia Slit Tape 40 45.7

Code Description Width (mm) Roll Length (m)

INS0012WH Insignia Slit Tape 12 45.7

INS0015WH Insignia Slit Tape 15 45.7

INS0020WH Insignia Slit Tape 20 45.7

INS0025WH Insignia Slit Tape 25 45.7

INS0030WH Insignia Slit Tape 30 45.7

Code Description Width (mm) Roll Length (m)

INS0050GR Insignia Slit Tape 50 45.7

INS0075GR Insignia Slit Tape 75 45.7

Code Description Width (mm) Roll Length (m)

INS0050RE Insignia Slit Tape 50 45.7

INS0075RE Insignia Slit Tape 75 45.7

Code Description Width (mm) Roll Length (m)

INS0040WH Insignia Slit Tape 40 45.7

INS0050WH Insignia Slit Tape 50 45.7

INS0075WH Insignia Slit Tape 75 45.7

Tapes

Venture Tape

Venture Tape is the premier double-sided tape for the sailmaking and cover making industries. Polyester Film is coated on both sides with an ultra high peel acrylic adhesive which is designed to adhere immediately to most types of sail cloth and canvas. It is virtually non yellowing and resists most strains of mildew.

Sold in individual rolls Discount of 10% if purchased in Box quantities

Shore Tape

Non Woven Polyester

110g/m2 White Kraft Liner

Extra High Tack Solvent Acrylic Adhesive

120mu Thickness | -40° to +40°C

14g/m2 Non Woven PET Carrier

Foam Luff Tape

Sold by the roll

Code Description

FOA04-050 Foam White 4mm x 50mm x 120m

Code Description

Length on Roll Box Qty

TAP006 6mm Venture Tape 50m 200

TAP009 9mm Venture Tape 50m 132

TAP012 12mm Venture Tape 50m 96

TAP015 15mm Venture Tape 50m 80

TAP019 19mm Venture Tape 50m 64

TAP025 25mm Venture Tape 50m 48

TAP050 50mm Venture Tape 50m 24

Code Description Length on Roll Box Qty

TAP106 6mm Double Sided 50m 200

TAP109 9mm Double Sided 50m 132

TAP112 12mm Double Sided 50m 96

TAP115 15mm Double Sided 50m 80

TAP119 19mm Double Sided 50m 64

Luff Tape

Sewn Luff Tape

Type

Code Description Type

LUF104 Sewn Luff Tape 4mm Single 1 Row A

LUF105 Sewn Luff Tape 5mm Single 1 Row A

LUF106 Sewn Luff Tape 6mm Single 1 Row A

LUF107 Sewn Luff Tape 7mm Single 1 Row A

LUF108 Sewn Luff Tape 8mm Single 1 Row A

Code Description Type

LUF204 Sewn Luff Tape 4mm Single 2 Rows B

LUF205 Sewn Luff Tape 5mm Single 2 Rows B

LUF206 Sewn Luff Tape 6mm Single 2 Rows B

LUF207 Sewn Luff Tape 7mm Single 2 Rows B

LUF208 Sewn Luff Tape 8mm Single 2 Rows B

Code Description Type

LUF304 Sewn Luff Tape 4mm Single 3 Rows C

LUF305 Sewn Luff Tape 5mm Single 3 Rows C

LUF306 Sewn Luff Tape 6mm Single 3 Rows C

LUF307 Sewn Luff Tape 7mm Single 3 Rows C

LUF308 Sewn Luff Tape 8mm Single 3 Rows C

Code Description Type

LUF124 Sewn Luff Tape 4mm & 3mm Twin D

LUF125 Sewn Luff Tape 5mm & 3mm Twin D

LUF126 Sewn Luff Tape 6mm & 3mm Twin D

LUF127 Sewn Luff Tape 7mm & 3mm Twin D

LUF128 Sewn Luff Tape 8mm & 3mm Twin D

Use Standard Keder for economic solutions to textiles and track applications

Repair Keder is wider allowing you to cut away the old core and attach the new whilst retaining the original spacing

An economical sailing luff tape made from a heavier weave polyester tape, weldable and long lasting

Code Description Core Size Finished Size

LUF120 Standard Kedar 10mm 11mm

LUF131 Repair Keder 10mm 11mm

Code Description Core Size Finished Size

LUF121 Standard Keder 12mm 13mm

LUF133 Repair Keder 12mm 13mm

Code Description Core Size Finished Size

LUF119 Standard Keder 8mm 9mm

LUF134 Repair Keder 8mm 9mm

Code Description Core Size Finished Size

LUF123 Standard Keder 9mm 10mm

Code Description Core Size Finished Size

LUF118 Standard Keder 7mm 8mm

LUF130 Repair Keder 7mm 8mm

Code Description Core Size Finished Size

LUF116 Standard Keder 6mm 7mm

Code Description Core Size Finished Size

LUF122 Standard Keder 11mm 12mm

LUF132 Repair Keder 11mm 12mm

Sailmaker’s guide

Everything a sailmaker needs to know about Seldén sail hardware.

Introduction

This guide is intended to provide sailmakers with the information necessary for them to ensure that rig and sail will be compatible. It covers the major part of Seldén’s production from 1977 onwards. The information generally applies to Kemp products of the same period.

Masts between 1977 and 2002 are normally type D or E (conventional masts) or type R (furling mast). Masts from 2003 are type C (conventional masts) or type F (furling masts). With the introduction of new C- and F masts from 2017, these masts are now denoted C (2003), C (2017), F (2003), F (2017).Each section of the guide is marked with mast type to help the reader in locating the correct information.

Although this Guide is primarily aimed at Sailmakers, the content should assist our end customers in making the best use of our impoved product.

However, we would point out that this guide is only intended as an aid, and that variations can occur.

It is the sailmaker’s responsibility to ensure that the sail suits the rig.

The following information must be given to the sailmaker by the customer:

Mainsails

Conventional mainsail with ”short” battens.

Furling mast mainsails

Foresails Roller furling genoas.

• Mast section dimensions. • Boom section dimensions. • Sail Plan (”P” & ”E”).

• Mast section dimensions. • Boom section dimensions. • Sail Plan (”P” & ”E”). Conventional mainsail with full length battens.

• Mast section dimensions. • Boom section dimensions. • Reefing system type (Seldén furling, Furlex-Main, etc.)

• Furlex type. • Total forestay length incl. all toggles or available sail space • Sail Plan

2 Conventional masts

2.1 Mast sections

Mast section measurements are given as follows:

Section Length (170 mm)

Section Width (115 mm) Fig. 2.a

Section Length/Section Width (i.e. 170/115). Take note of the mast section shape. This will help identification and the use of correct measurements. The Section Length of the mast can usually be found in the number engraved at the mast heel. For example K23-170-1233.

Conventional masts before 2003

Mast Luff Groove mm Slider

E-Section (10° aft face) 122/85 130/93 5.5 + 1.00 4.0 + 1.00 5.0 – 0.00 511-601 138/95 155/104 170/115 177/124 189/132 206/139 224/150 237/162 274/185

5.5 ± 0.75 511-602 321/171 365/194 6.25 ± 0.75

E-Section (Round aft face) 126/85 .5 + 1.00 4.0 + 1.00 5.0– 0.00 511-601

147/95 162/104 178/115 216/139 239/162

Conventional masts from 2003

Mast Mast dim Luff groove mm

C-Section (2006) C080 C086 C096

Groove insert for bolt rope1)

MDScar Sail slider Bolt rope (mm)

79/60 87/64 96/69 4.5 ± 0.75 511-601 Ø 10

C-Section (2006) C106 C116 C126 C139

C-Section (2003) C156 C175 C193

106/71 116/75 126/79 139/85 5.0 ± 0.75 511-602 Ø 10

5.5 ± 0.75 511-602

D-Section 109/88 121/92 5.5 + 1.00 4.0 + 1.00 5.0 – 0.00 511-601

129/100 137/113 146/112 160/132 5.5 ± 0.75 511-602

P-Section 73/53 90/65 100/73 111/81 123/90

5.5 + 0.75 4.0 + 1.00 5.0 – 0.00

137/100 5.5 + 0.75 4.5 + 1.00 5.0 – 0.00 511-601 152/111 169/123 188/137 5.5 ± 0.75 511-601

211/110 227/119 245/127 264/136 285/147 304/157

10 ± 0.75 5.5 ± 0.75 511-701 or 511-702

C321 C365 321/171 365/194 16 ± 0.75 511-730 or 511-731

C section (2017) Mast Mast dim Luff groove mm

511-605 or 511-607 Ø 10

156/87 175/93 193/102 10 ± 0.75 5.5 ± 0.75 511-702 511-605 or 511-607 Ø 10 C211 C227 C245 C264 C285 C304

Groove insert for bolt rope1)

Inner wheel slider Sail slider Bolt rope (mm)

ø8-ø10

C153 153/107 10.5 +-0.7 4.7 +-0.5 ø8-ø10

C180 180/113 10.5 +-0.7 4.7 +-0.5 ø8-ø10

C137 137/98 10.5 +-0.7 4.7 +-0.5 511-729 511-605 or 511-607

ø8-ø10

C208 208/131 10.5 +-0.7 4.7 +-0.5 ø8-ø10

C225 225/141 10.5 +-0.7 4.7 +-0.5 ø8-ø10

C242 242/153 10.5 +-0.7 4.7 +-0.5 ø8-ø10

C192 192/120 10.5 +-0.7 4.7 +-0.5 511-729 or 511-760

C261 261/164 10.5 +-0.7 4.7 +-0.5 ø8-ø10

C280 280/176 10.5 +-0.7 4.7 +-0.5 ø8-ø10

1) Special groove insert and sail feeder gate are required to accept bolt rope. If sail slider are to be used in combination with bolt rope insert, use HA 258/A019 or Rutgerson 102.

Fig. 3.1.a

3 Mainsails

3.1 Fitting slides

To avoid jamming in the luff groove, slides must have freedom of movement on the sail.

Fig. 3.1.b

Several systems are available for full length battens. Seldén´s different systems (RCB, MDS, OWS & IWS) are presented in this guide. Refer to the relevant manufacturers concerning other systems.

Correct: Free-moving fixture

D & E

Wrong: Stiff fixture

3.2 Sail slides E-masts

It is imperative that the correct sliders are used on Seldén masts in order to fit the Seldén sail feeder gate.

Art. no. Slider (mm) Fits luff groove (mm) Breaking load Bainbridge part no.

SEL511-601 4 700 N (70Kp) A 013

SEL511-602 5 2250 N (225Kp)) A 014

3.3 Sail slides C-masts

It is imperative that Seldén slides are used on Seldén masts in order to fit the Seldén sail feeder gate.

Art. no.

Slider (mm)

SEL511-605

SEL511-607

Fits luff groove (mm) Breaking load (N) Bainbridge part no.

10 2250 N (225 Kp) A011

10 4000 N (400 Kp) A012

3.4 Shackles for sliders

Art. no. Shackle (mm)

10.5 8.5

Fits slide (mm) Breaking load (N) Bainbridge part no.

511-602 511-603 511-605 511-607

Important! The shackle should not to be used with MDS cars.

D & E

+Other brands

Sailmaker’s Guide 40 SAIL ACCESSORIES

3.5 OWS (Outer Wheel Support) slider

Seldén OWS sliders are designed both as batten sliders and webbing sliders. Each model is available in 5 different versions. One version fits Seldén E-sections (1977-2002) and older Seldén/Kemp oval sections. Any of the other 4 versions fits most of all other mast brands on the market.

OWS sliders do not fit Seldén C-section for which MDS-sliders should be used.

OWS slider for webbing

To acheive maximum strength, the OWS slider should be attached to the main sail using a webbing strap.

2000N (200 Kp)

OWS slider for batten

The OWS batten slider is designed to take compression load from the batten in a full batten main sail. To achieve optimal function and strength, use Seldén toggle M10 stud 511-739-01.

21.4 44.6 55 40

OWS compatible sail feeder gates

The OWS E-section slider (511-740 and 511-750) can be used with, and passes through Seldén sail feeder gate 505-501-01.

The OWS sliders 511-744 and 511-754 for keelboat sections (C106-C139) can be used with and passes through Seldén sail feeder gate 505-533-02.

7.7 14

19.7 44.6 67 11 6 Ø6.3

R7

3.5.1 OWS slider - dimensions

Type

Measurements (mm)

OWS slider webbing SEL511-740-01

OWS slider webbing SEL511-741-01

OWS slider webbing SEL511-742-01

OWS slider webbing SEL511-743-01

OWS slider webbing SEL511-744-01

Type Measurements (mm)

11,2 5,75 14,4 6,7 6,2 2,9 16,5 6,7

OWS slider batten SEL511-750-02 SEL511-750-03

11 4,3

OWS slider batten SEL511-751-02 SEL511-751-03

OWS slider batten SEL511-752-02 SEL511-752-03

6,2 2,5 20,7

9,8 5,4 11 4,3 10,7 4

OWS slider batten SEL511-753-02 SEL511-753-03

10,5

OWS slider batten SEL511-754-02 SEL511-754-03

11 4,3 11,2 5,75 14,4 6,7 6,2 2,9 16,5

6,2 2,5 20,7

6,7

10,7 4

9,8 5,4 10,5 11 4,3

All sliders for webbing can be used for headboard attachments and as intermediate sliders. 1) OWS sliders do not fit Seldén C-section for which MDS-cars, C (2003) or Inner Wheel Sliders, C (2017) should be used.

3.5.2 OWS slider - range

Type

OWS slider webbing

OWS slider batten

Art. No.

SEL511-740-01

Fits luff groove (mm)

Breaking load (N)

Assembly Art. No. Parts Art. No.

5.5 5000 511-740-01

SEL511-750

OWS slider webbing 511-741

OWS slider batten

SEL511-751

OWS slider webbing SEL511-742-01

OWS slider batten SEL511-752

OWS slider webbing

SEL511-743

OWS slider batten SEL 511-753

OWS slider webbing

Big wheel SEL511-744

OWS slider batten

Big wheel SEL511-754

5.5 7000 511-750-03 511-739-01 M10 screw 153-117 511-750-02 153-117

10 5000 511-741-01

10 7000 511-751-03 511-739-01 M10 screw 153-117 511-751-02 153-117

10 5000 511-742-01

10 7000 511-752-03 511-739-01 M10 screw 153-117 511-752-02 153-117

12 5000 511-743-01

12 7000 511-753-03 511-739-01 M10 screw 153-117 511-753-02 153-117

5.5 5000 511-744-01

5.5 7000 511-754-03 511-739-01 M10 screw 153-117 511-754-02 153-117

Type

OWS

slider webbing SEL511-740

OWS slider batten SEL511-750-02 SEL511-750-03

OWS slider webbing SEL511-743-01

OWS slider batten SEL511-753-02 SEL511-753-03

OWS slider webbing Big wheel SEL511-744-01

OWS slider batten Big wheel SEL511-754-02 SEL511-754-03

Fits mast section (only geometric fit)

138/95 155/104 170/115 177/124 189/132 206/139 224/150 237/162 274/185

147/95 162/104 178/115 216/139 239/162

129/100 137/113 146/112 160/132

NF200 NF270 NF350 NF430 NF540 NF710 NF1410

F135 F195 F305 F385 F460 I620 S622 I830 S830

Z301 Z351 Z380 Z401 Z501 Z531 Z601 Z602 Z701 Z702

Seldén John Mast Soromap Sparcraft Z-spars E-section (10° aft face) E-section (round aft face) D-section 135D 148D 150D 165D 167D 185D 186D 208D 222D 245D 280D 305D 335D

220E 262E 290E

NG60 NG70 NG80 NG86 F580 F740 F1060 F1395 S1630 S2100 F2390 F3360 F4600

Z902 Z1001 Z1250 Z1400

F35 F50 F67 F78 F101 S137 S180 S260 S330 IMS80 IMS256 Sailmaker’s Guide 43 +44 (0)1489 581 696 | info@kayospruce.co.uk | www.kayospruce.com

Z170 Z190 Z230 Z265 C106 C116 C126 C139 SAIL ACCESSORIES

4 Batten receptacles

Each size of the adjustable batten receptacles is available in two models to ensure correct fit on round, flat and rectangular battens.

Safety cord secures the cover to the body.

The FA-models have access to the adjustment screw both front and rear which enables adjustment of the batten even when the sail is flaked on the boom. The adjustment screw is compatible with multiple screw heads.

Indicators to record batten tension for the ultimate trim.

M10 thread.

Easy set up and removal of batten with sliding cover and a locking screw. No need to fully release the screw to remove the cover.

Protecting collar at the backing plate prevents the forward screw heads to chafe on the mast surface.

4.1 Batten receptacle fittings

The fittings are designed to be used with toggle M10 stud (511-712-01, 511-727-02 or 511-739-01).

Fig. 4.1.a

The adjustable batten receptacles are available for either round or rectangular battens.

Fig. 4.1.c (461-210-02) Fig. 4.1.b (461-210-01)

4.2 Batten receptacle range

Type Art. No. Batten sizes (mm)

Adj. length (mm) Stud dim. Round Flat

Batten receptacle

P-30 SEL461-237-01 Ø10 5.5x31 M10

P-40 SEL461-235-01 Ø10 5.5x41 M10 A-17 SEL461-210-01 6.5x18 38 M10 SEL461-210-02 Ø8

FA-22 SEL461-220-01 9.5x23 33 M10 SEL461-220-02 Ø10

FA-30 SEL461-230-01 6.5x31 36 M10 SEL460-230-02 Ø12

3.6 MDS Full batten system for C-masts (2003)

3.6.1 MDS 45 and

68

Full batten system

Part no. A 511-701-04 140 511-701-06 225 511-702-04 118

1) See 3.6.2

Halyard to be attached in most forward hole of headboard

MDS cars should be used as intermediate connection, fastened via a webbing loop.

Important! Batten fittings must be allowed to swivel freely or the batten car may not roll properly. The use of water resistant grease on the M10 thread is recommended.

Head-Board to be drilled Ø 12.5 mm by sailmaker

Depth: 45 Normal spacing

75 A ~1000

45

68

Fig. 3.6.1.a

Important! Only MDS car 511-702 MUST be used in the masts sections below. 511-701 is possible to fit but will NOT function properly.

Mast section C156 C175 C193

MDS car

~1000 54 13 511-701 511-702

C 3.6.2 Parts and RM-limits, MDS 45, MDS 68 and MDS 68

Fig. 3.6.2.a 511-701-06/511-717-06

Assembly Max RM kNm Assembly Mh Frac

Fig. 3.6.2.b 511-701-03/511-717-03

Parts

Head board car

SEL511-702-04

SEL511-701-04

SEL511-701-06

Batten Car

SEL511-702-03

ALU

14 6 6.1 8

Fig. 3.6.2.c 511-723

Parts Section

55 40 MDS 45 511-702-01

90 70 153-117

160 120 153-117

90 70 MDS 45 511-702-01

C156 C175 C193

C211 C264 C227 C285 C245 C304

C211 C264 C227 C285 C245 C304

C156 C175 C193 MDS 45 511-702-01

160 120

SEL511-701-03

SELMDS 68 511-701-01 153-117

C211 C227 C245 C264 C285 C304 160 120 MDS 68 511-701-01 153-117 Sail Car

SELMDS 45 511-702-02

SELMDS 68 511-701-02

1) Measurement see fig. 3.6.2.c.

90 70 MDS 45 511-702-01

160 120 MDS 68 511-701-01 153-117

C156 C245 C175 C264 C193 C285 C211 C304 C227

C211 C264 C227 C285 C245 C304

3.6.5 MDS 80 Full batten system

Part no. A 511-730-06 280

Halyard to be attached in most forward hole of headboard to avoid halyard chafe

Headboard to be drilled Ø 15 mm by sailmaker

MDS cars should be used as intermediate connection, fastened via a webbing loop.

Depth: 65 Normal spacing

100 A ~1000

~1000 18 80 70

Important! Batten fittings must be allowed to swivel freely or the batten car may not roll properly. The use of water resistant grease on the M10 thread is recommended.

Aft face of mast

Fig. 3.6.3.a

22 RCB 30

Min 59 Min 68

Head-Board to be drilled Ø 12 mm by sailmaker

Normal spacing

Aft face of mast section

Seldén (M10 thread)

The sail foot is usually reduced when old sails are retrofitted with the Seldén RCB Full Batten system. Cut-back should also be adjusted. SAIL ACCESSORIES

Head-board car

3.7.2 Parts

CThe slide attachment eye is easily detached from the slide and can be sent to the sailmaker separately. It also facilitates fitting the mainsail.

Fig. 3.7.2.a

Connectors

Batten car

All-Round: Fits Rutgerson batten fitting and others

The car is fitted to the mast.

Car Total assembly

RCB 22 511-595-11 511-581-11 511-595-01 RCB 22 Light 511-703-11 511-703-11 511-703-11 RCB 30 511-695-11 511-681-11 511-695-01

RCB 22 511-590-01 511-581-04 RCB 22 Light 511-703-11 511-703-11 RCB 30 511-690-01 511-681-04

Batten car

With M-10 screw: Fits Bainbridge batten fitting and others

Sail car

G F 3.7.3 Try Sail slider (Part. no.: 511-713)

RCB 22 511-598-01 511-581-11 511-581-03 RCB 22 Light 511-703-11 511-703-11 511-703-11 RCB 30 511-692-01 511-681-11 511-681-03

RCB 22 511-590-01 511-581-11 511-581-04 RCB 22 Light 511-703-11 511-703-11 511-703-11 RCB 30 511-690-01 511-682-11 511-681-04

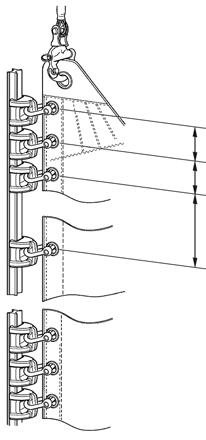

Three sliders at the head and tack of the sail c/c 50 mm (2”). Remaining cars to be fitted with c/c ~400 mm (16”)

For sufficient articulation always connect cars to sail via shackles

For less friction use Seldén Silicone lubricant (Part No. 312-506) or similar products on the track

Breaking load 2.6 kN

50 mm (2”)

400 mm (16”)

Fig. 3.7.3.a

Sail Battens

Batten Selection Guide Vinylester Battens

Boat Size Batten Position Fractional Rig Use Masthead Rig Use

Top OS 1 IS 2

Upper Middle OS 1 IS 2

Kayospruce HP Blue Streak

IS 0 HP 1.0 HEX 1

IS 1 HP 2.0 WR 1

25 Foot

Lower Middle OS 2 IS 3

Bottom OS 2 IS 3

Top OS 1 OS 1

Upper Middle OS 1 OS 1

IS 2 HP 3.0 WR 2

IS 3 HP 4.0 WR 3

OS 1 HP 4.5 OR 1 OS 2 HP 5.0 OR 2

30 Foot

Lower Middle OS 2 OS 2

Bottom OS 2 OS 2

Top OS 1 OS 1

Upper Middle OS 2 OS 2

OS 3 HP 5.3 OR 3

OS 4 HP 5.7 OR 4

OS 5 HP 5.9 OR 5

35 Foot

Lower Middle OS 3 OS 3

Bottom OS 3 OS 3

Top OS 2 OS 1

Upper Middle OS 2 OS 2

40 Foot

45 Foot

50 Foot

Lower Middle OS 3 OS 3

Bottom OS 4 OS 4

Top OS 2 OS 1

Upper Middle OS 3 OS 2

Lower Middle OS 4 OS 3

Bottom OS 5 OS 4

Top OS 2 OS 2

Upper Middle OS 3 OS 3

Lower Middle OS 5 OS 4

Bottom OS 5 OS 4

About Our Battens

Production

The range benefits from the latest production techniques, offering a stiffer, stronger product. They are moulded from stiff, high-strength VINYLESTER using compressed glass strands for ultimate longitudinal strength. On test they are up to 35% stronger than comparable battens.

The finished batten features a shrink-wrapped plastic coating to make the handling in the sail pocket easier and protect from shards and splinters.

End Caps

End Caps are provided with both Leech and Full Tapered Battens. Leech Battens have them attached at either end. Full Tapered Battens have them provided separately for ease of personalising the length.

Costs

With the benefits of new production techniques, we can offer this range at very competitive prices, allowing you to minimise your production costs. Compared with competitors, the saving can be over 50%.

Samples

A sample KEYRING of all sizes and shapes is available to sailmakers on request.

Leech Tapered Batten

600mm 750mm 930mm 1080mm 1230mm 1380mm 1510mm 1810mm 2100mm 2400mm

IS 0 Leech Inshore 0

3mm x 10mm - BATIL0

IS 1 Leech Inshore 1

3mm x 15mm - BATIL1

IS 2 Leech Inshore 2

4mm x 15mm - BATIL2

IS 3 Leech Inshore 3

6mm x 15mm - BATIL3

OS 1 Leech Offshore 1

6mm x 20mm - BATOL1

OS 2 Leech Offshore 2

8mm x 20mm - BATOL2

OS 3 Leech Offshore 3

9mm x 20mm - BATOL3

OS 4 Leech Offshore 4

10mm x 20mm - BATOL4

To order: take the part number and add the length i.e. BATIL0-0600

These feature a standard 23% ‘soft tip’ inboard taper, ideal for all leech battens, except full length. With very competitive pricing, increased strength and a comprehensive selection available, this new range offers great benefits for sailmakers.

Features

Available in 8 sizes

Length from 600mm to 2400mm

Very competitive pricing - around 50% or more cheaper than alternatives Shrink wrapped for splinter protection Uniform 23% ‘soft tip’ taper Strong, wide-moulded end fittings Provided with End Caps attached

Untapered Coil

For production sails we can offer batten extrusion, produced by the same method but untapered and supplied in 20 metre coils.

You can cut the lengths and benefit from very low costs.

Soft Tip Leech Taper 23%

Code Type Size (mm)

BATISSPLIT-20M

Split Jib Batten 20m Coil 1 x 6

BATIS0-20M Inshore 0 Coil 3 x 10

BATIS1-20M Inshore 1 Coil 3 x 15

BATIS2-20M Inshore 2 Coil 4 x 15

BATIS3-20M Inshore 3 Coil 6 x 15

BATOS1-20M Offshore 1 Coil 6 x 20

BATOS2-20M Offshore 2 Coil 8 x 20

BATOS3-20M Offshore 3 Coil 9 x 20

BATOS4-20M Offshore 4 Coil 10 x 20

BATOS5-20M Offshore 5 Coil 12 x 20

Contract Battens

Code Description Width (mm) Thickness (mm) Stiffness Length (m) Flex Rate

BAT020 Contract Batten 20 2.5 Standard 5 1.9

BAT030 Contract Batten 30 4.3 Standard 5 10

BAT040 Contract Batten 40 4.7 Standard 5 16

Code Description Width (mm) Thickness (mm) Length (m)

BAT033 Flat Contract Batten 32 3 5

BAT038 Flat Contract Batten 38 3 5

Code Description

Manufactured in glassfibre reinforced resin Diamond shaped to provide optimum stiffness to weight ratio Flex rate indicate stiffness Sold in lengths

Manufactured in glassfibre reinforced resin Flat section Sold in lengths

Dia. (mm) Length (m)

BAT006 Round Contract Batten 6 5

BAT008 Round Contract Batten 8.1 5

BAT010 Round Contract Batten 10 5

BAT012 Round Contract Batten 12 5

BAT013 Round Contract Batten 16 5

Manufactured in glassfibre reinforced resin Round section Sold in lengths

Batten Accessories

End Caps for Vinylester Batten Range

Code Description

Type

BATEND-IS0 Batten End Cap Inshore 0

BATEND-IS1 Batten End Cap Inshore 1

BATEND-IS1BLANK Blank Batten End Cap Inshore 1

BATEND-IS3 Batten End Cap Inshore 3

BATEND-OS1 Batten End Cap Offshore 1

BATEND-OS2 Batten End Cap Offshore 2

BATEND-OS3 Batten End Cap Offshore 3

BATEND-OS4 Batten End Cap Offshore 4

BATEND-OS5 Batten End Cap Offshore 5

BATEND-OS6 Batten End Cap Offshore 6

Batten Protector

Made from nylon 6 Square back prevents jamming in the mast

Sliders can be webbed directly to the batten protector Friction between protector and mast is minimised by low friction nodules

Complete with A4 stainless steel fastenings

Batten Adjuster

Full length batten adjuster that allows incremental adjustment of batten tension

Inboard end batten adjuster for full length battens Designed to sit on the luff of the sail, up by the mast where the wind is already turbulent. Allows the sailmaker to streamline the trailing edge of the sail by removing the batten hardware. It will take a 10mm batten and is easily fixed to the sail using the four nuts and bolts provided.

Round

Batten End Caps

Code Description

BAT051 End Cap for 6mm Round Batten

BAT052 End Cap for 8mm Round Batten

BAT053 End Cap for 10mm Round Batten

BATEND-IS BATEND-OS BAT053

Code Description Size

BAT081 Batten Protector 20-30mm

BAT082 Batten Protector 40mm

BAT083

Code Description

BAT084 Inboard Batten Adjuster for 10mm Batten

BAT083 Batten Protector 40mm - Heavy Duty BAT081 BAT082 BAT084

Made from glass-filled nylon and weighing only 33 grams the A.951-10

Batten Elastic

A high quality woven rubber insert elastic tape designed specially for batten applications Sold by the reel

Batten Box to Slide Connector

M10 Slide Connector to connect Seldén batten receptable to OWS Slider.

Code Description Colour Reel (m)

ELA012 Batten Elastic White 12mm White 25

ELA020 Batten Elastic White 20mm White 25

ELA025 Batten Elastic White 25mm White 25

ELA038 Batten Elastic White 38mm White 25

ELA050 Batten Elastic White 50mm White 25

ELA051 Batten Elastic Black 50mm Black 25

Code Description

BSSCA102

Batten Box to Slide Connector M10

Sail Bags

Spinnaker Bag

This is a well designed and developed spinnaker launch bag. Designed to make storage and launching of your spinnaker easier. You will find some new and innovative features throughout the bag, to ensure the product is of the highest quality.

FEATURES

Strong 600 denier woven polyester cloth for durability

Velcro flaps and ties to ensure security when packed

Unique elasticated strop for windward launches

Mesh bottom to aid draining

Stainless snap hooks for securing on guard wires

Carry handles

Strengthened corners and wide opening to aid launching

Dacron patch for sail referencing and numbering

Available in 7 sizes

Available in grey

Code Length Type Colour

BAG101GY 14” H x 22” L x 15” W XS Grey

BAG102GY 16” H x 26” L x 18” W S Grey

BAG103GY 18 ” H x 34” L x 20” W M Grey

BAG104GY 21” H x 39” L x 21” W L Grey

BAG105GY 24” H x 43” L x 22” W XL Grey

BAG106GY 26” H x 48” L x 24” W XXL Grey

BAG107GY 29” H x 58” L x 24” W XXXL Grey

SIZING GUIDE

Approx Sqm of Sail 230 210 200 190 180 170 160 150 140 130 120 110 100 90 80 70 60

Rolled Sail Bag

Dinghy Sausage Bag

Designed to prolong the life of your sails when not in use. The range features two versions, one with a simple drawstring close.

Strong Woven cloth for durability

Carry Handle

Dacron Patch for sail

Available in lengths 1.8m to 3.6m Available in grey

Code Length Colour

BAG402GY 2.17m Grey

BAG404GY 2.99m Grey

BAG406GY 3.80m Grey

Genoa Zip Bag

Genoa Sailbag designed and developed for both racing and cruising. Separate Tack and quick burst long zipper make hoisting easier and faster, with a mesh base to allow water to drain.

All you need to ensure the correct size is the foot length. Available in Grey.

FEATURES

Strong woven cloth for durability Quick burst zipper for racing hoists and packing

Separate tack zip Mesh base to aid water draining Dacron patch for sail numbering and referencing Ties for securing when stored

5 sizes available from 4m to 8.5m long

Available in grey

Code Length Colour

BAG201GY 4m Grey

BAG202GY 5m Grey

BAG203GY 6m Grey

BAG204GY 7m Grey

BAG205GY 8.5m Grey

Mainsail Bag

Round Draw String Sail Bag

The Mainsail bag is made from a heavy duty 600 denier Polyester designed to allow the sail to be stored to help prolong it’s life when not on board. Designed with carry handles and a draw string top to make stowing and carrying as easy as possible.

Strong woven cloth for durability Side carry handles Bottom handle

Large opening at top with drawstring closure 5 sizes available Available in grey

Code Size Colour

BAG301GY 14” x 28” Grey

BAG302GY 16” x 32” Grey

BAG303GY 20” x 40” Grey

BAG304GY 24” x 48” Grey

BAG305GY 28” x 52” Grey

Sail Slides

Round Slide Clew Slug Connectors

Clew Slug.

Code Description Slide Body (mm) Jaw (mm) Weight (g)

SLI001 Slug Slide 8 2 95

SLI002 Slug Slide 10 2 105

SLI003 Slug Slide 12 2 122

Low Friction Slide

The low friction sail slide uses silicone impregnated nylon to reduce friction and improve sliding properties.

The unique ribbed design increases strength whilst reducing contact area by 50%.

Code Description Max Width (mm) Jaw Size (mm) Hole Width (mm) Pack Qty

SLI100 Low Friction Slide 10.4 3 13.9 10

SLI101 Low Friction Slide 13.9 4.2 16.2 10

SLI110 Low Friction Slide 7.2 3 14.7 10

SLI111 Low Friction Slide 8.3 3 14.7 10

SLI112 Low Friction Slide 11.4 3 14.7 10

Round Slide

Code Description Max Width (mm) Jaw Size (mm) Hole Width (mm) Pack Qty

SLI130 Round Slide 9 3.5 12.5 10

Track Slide

Code Description

Connects our Round Clew Slugs to Endeavour Rings.

Code Description

SLIC03 Slug Ring Connectors Small

SLIC04 Slug Ring Connectors Medium SLIC05 Slug Ring Connectors Large

Max Width (mm) Jaw Size (mm) Hole Width (mm) Pack Qty

SLI120 Low Friction Track Slide 16 6 18.2 10

SLI121 Low Friction Track Slide 19 8.4 18.2 10

SLI122 Low Friction Track Slide 22 9.5 18.2 10

Kayo Slides

Kayospruce Low Friction Slides moulded from glass reinforced plastic with integral compression pad that transfers load to the aft face of the mast

Code Description Colour

SLIA1058

Kayo Slide 45 x 7.3 x 5.75mm Black

SLIA1158 Kayo Slide 45 x 4.4 x 5.75mm Black

SLIA758 Kayo Slide 45 x 11.6 x 5.75mm Black

SLIA92 Kayo Slide 45 x 17.9 x 4.23mm Black

Code Description Colour

SLIA95 Kayo Slide 45 x 15.3 x 4.23mm Black

SLIA958 Kayo Slide 45 x 8.9 x 5.75mm Black

SLIA96 Kayo Slide 45 x 21.8 x 4.23mm Black

Head Boards

Aluminium Headboards

Manufactured from ISO AIMg3 medium hard (BS approx. NS)

Marine grade aluminium Excellent corrosion resistance Available in Silver and Blue

A comprehensive range of headboards and accessories. We supply both aluminium and plastic headboards. The aluminium headboards are anodised and are available in silver and blue. Together with the headboards we supply accessories e.g. liners, rivets, leech line, slide attachments and slug slides.

Code Description Colour Size (mm) Thickness (mm) Slots (mm) Rivet Hole (mm) Liner Hole (mm) Weight (g)

HEB103 Aluminium Headboard Silver 102 x 130 1.5 23.4 5 23 29

HEB104 Aluminium Headboard Blue 102 x 130 1.5 23.4 5 23 29

HEB105 Aluminium Headboard Silver 115 x 145 1.5 25.5 5 23 59

HEB106 Aluminium Headboard Blue 115 x 145 1.5 25.5 5 23 59

HEB107 Aluminium Headboard Silver 115 x 145 3.0 25.5 5 23 118

HEB108 Aluminium Headboard Blue 115 x 145 3.0 25.5 5 23 118

HEB109 Aluminium Headboard Silver 133 x 160 3.0 25.5 5 23 73

HEB110 Aluminium Headboard Blue 133 x 160 3.0 25.5 5 23 73

Liners

Code Description Size (mm)

LIN015 Liner for Plastic Headboard 15

LIN020 Liner for Aluminium Headboard 22

Code Description Size (mm)

HEB001 White Plastic Headboard 75 x 100

HEB002 White Plastic Headboard 93 x 113

Rivets

Code Description Diameter (mm) Length (mm)

RIV109 Semi Tubular Rivet 4.8 9.5

RIV112 Semi Tubular Rivet 4.8 12.5

RIV116 Semi Tubular Rivet 4.8 16

RIV118 Semi Tubular Rivet 4.8 16

Rings & Triangles

Rings 316 S/s

Code Description ID (mm) T (mm) Weight (g) Breaking Load (kg)

RIN015 Stainless Ring 15 3 4 700

RIN020 Stainless Ring 20 4 8 1250

RIN021 Stainless Ring 20 6 18 2750

RIN025 Stainless Ring 25 4 9 1250

RIN026 Stainless Ring 25 5 13 1750

RIN027 Stainless Ring 25 6 21 2750

RIN030 Stainless Ring 30 5 15 1750

RIN031 Stainless Ring 30 6 28 2750

RIN032 Stainless Ring 30 8 46 4750

RIN040 Stainless Ring 40 6 35 2750

RIN041 Stainless Ring 40 8 58 4750

RIN042 Stainless Ring 40 9.5 86 7000

RIN050 Stainless Ring 50 6 44 2750

RIN051 Stainless Ring 50 8 68 4750

RIN052 Stainless Ring 50 9.5 102 7000

RIN075 Stainless Ring 75 8 106 4750

Stainless D Rings in 316 Stainless Steel

Code Description W (mm) T (mm) H (mm) Weight (g) Breaking Load (kg)

DRI024 Stainless D Ring 25 3 n/a n/a n/a

DRI025 Stainless D Ring 25 5 17 12 1750

DRI030 Stainless D Ring 30 6 29 27 2750

DRI035 Stainless D Ring 35 5 27 17 1750

DRI039 Stainless D Ring 39 5 25 17 1750

DRI044 Stainless D Ring 44 5 32 21 1750

DRI050 Stainless D Ring 50 5 35 23 1750

DRI051 Stainless D Ring 50 6 33 38 2750

DRI060 Stainless D Ring 60 6 30 42 2750

Aluminium D Rings

DRI116 16mm Aluminium D Ring

DRI125 25mm Aluminium D Ring

Plactic D Rings

Code Description

DRI220 20mm Plastic D ring

DRI225 25mm Plastic D ring

DRI240 40mm Plastic D ring x10

DRI250 50mm Plastic D ring x10

Stainless Triangles in 316 Stainless Steel

Code Description W (mm) T (mm) H (mm) A Weight (g) Breaking Load (kg)

TRI025 Stainless Triangle 27 4.8 25 60° 49 3000

TRI050 Stainless Triangle 50 6 43 60° 42 2750

TRI051 Stainless Triangle 51 8 50 60° 74 4750

TRI062 Stainless Triangle 62 6 34 90° 59 2750

TRI078 Stainless Triangle 78 8 45 90° 95 4750

Stainless Triangles with Bar 316 S/s

Code Description W (mm) T (mm) H (mm) A Weight (g) Breaking Load (kg)

TRI259 Stainless Triangle with Plastic Bar 50 6 43 60° 47 2750

Plastic Triangle

Code Description Pack QTY

TRI220 20mm Plastic Triangle x10

TRI225 25mm Plastic Triangle x10

TRI240 40mm Plastic Triangle x10

Tack Hook

HOK101 Tack Hook 50

HOK102 Tack Hook 75

HOK103 Tack Hook 100

HOK110

HOK112

Sail Numbers & Letters

Sail Numbers & Letters