5 minute read

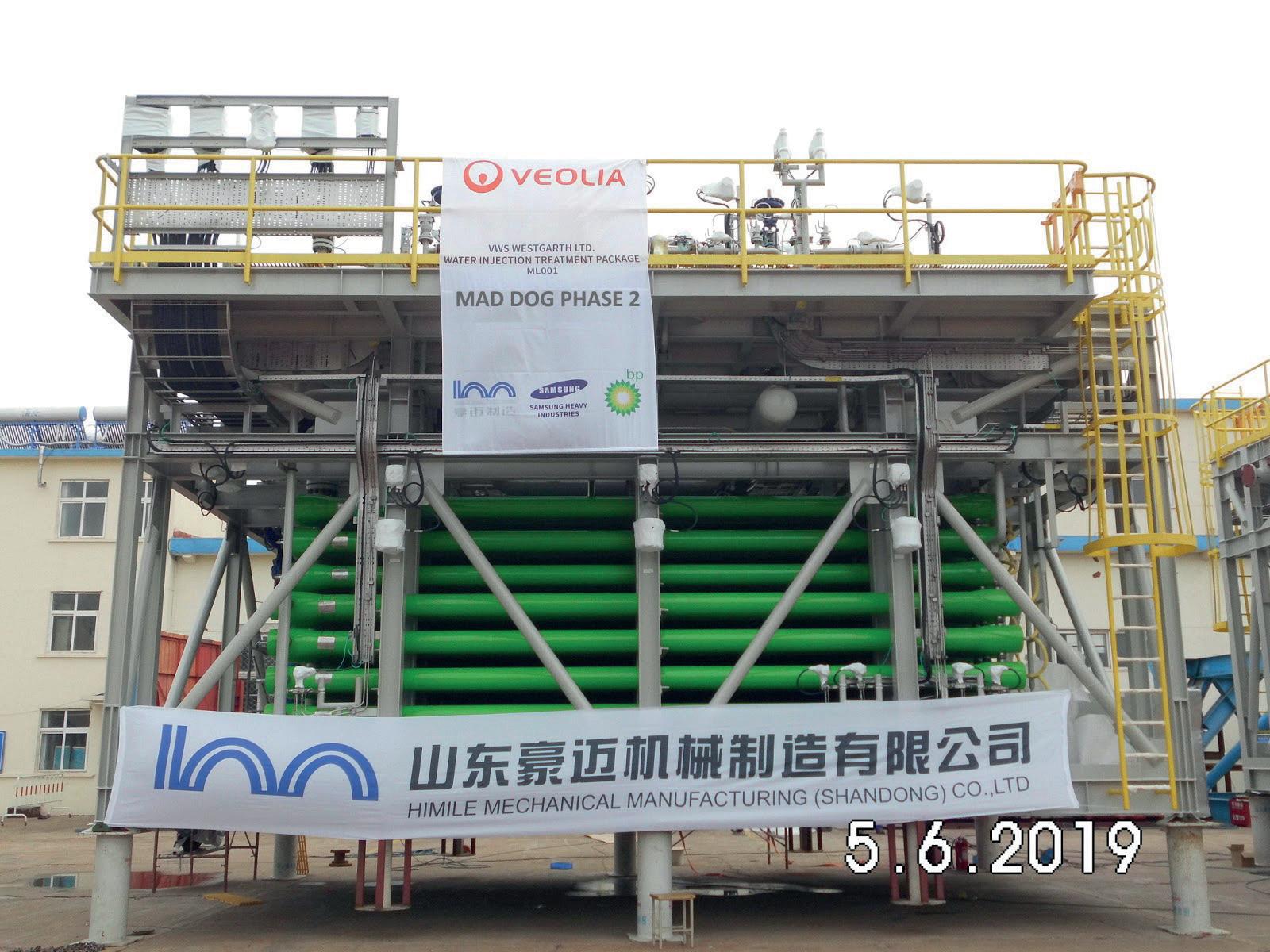

VWS Westgarth

How is VWS Westgarth thriving?

The company has secured a number one position in upstream water injection service solutions, with proven success in chemical innovation, asset integrity and digital technology, delivering a minimum 10:1 return on investment for oil and gas clients.

The challenge

A company solely dedicated to a specific business segment is highly vulnerable to the ebbs and flows of its market. For oil and gas suppliers focusing only on design and construction services, this vulnerability becomes more evident. The last decade has witnessed major changes in the O&G market, mainly attributable to the global recession in oil and gas production and the resulting lack of new projects. A strategy to increase a company’s service offering to clients is therefore essential, particularly in times of industry downturns.

The solution

Veolia Water Technologies, a Veolia part of, was fully aware that a focus on oil and gas design and build (D&B) services for the water treatment segment was very niche and that it had to boost its service offering. After all, it was what clients both needed and wanted. The company had been developing the concept of diversification away from solely D&B for many years but really started to craft a service solution strategy just before the 2014 downturn in the oil and gas market.

Veolia evaluated the service solutions they could offer, and digitalisation was one of them. Prompted by an increasing drive towards a reduced number of people on board offshore O&G facilities, the company realised it had to digitalise its services to provide operational support remotely. After assessing the appropriate digital data monitoring solution for their needs, the company quickly developed and deployed its real time data monitoring

division of which VWS Westgarth is service.

Called ‘Aquavista’, this system is an all-in-one cloud-based set of digital solutions consisting of four complementary components: Aquavista Portal, Aquavista Insight, Aquavista Assist and Aquavista Plant. Together, they provide a complete overview of a facility’s key information, in addition to visualization tools, information sharing and predictive analysis capabilities. A major benefit of Aquavista’s monitoring is related to its ability to track the condition of the water treatment membrane, a key asset which guarantees effectiveness of an operator’s water injection

capabilities and, consequently, its oil output capacity.

Thanks to Aquavista, Veolia secured a key contract with SBM Offshore. The floater specialist awarded the company a contract to provide a bespoke asset integrity service on water injection modules present on 11 FPSOs across the world. Benefiting from Aquavista’s capabilities, SBM is able to increase the operational efficiency of its vessels by 30%, enabling cost savings of US$3-4 million (equivalent to a 10:1 return in investment on the Veolia contract).

Another service solutions strategy involved water treatment chemicals optimization. Veolia already has a corporate-level chemical brand called Hydrex, which provides water treatment chemicals for industrial and municipal usages around the globe. The company then took the opportunity to develop a specific chemicals range for offshore water injection applications.

Clearly there are many chemical suppliers, but Veolia differentiates from the rest as they are technology specialists also offering chemical solutions – as opposed to simply offering chemicals as a commodity item. The company’s new chemical range offers alternatives in terms of chemical strength and quality, which offers logistical benefits while providing enhanced performance for the water injection system.

Veolia’s chemicals for the offshore segment found an opportunity with Total. In 2015 the oil major awarded a contract for 1,500 cubic metres of chemicals, of which two third were delivered over a year. Higher performance supported by a bespoke antiscalant chemical solution enabled a US$2.4 million saving to Total. After this successful experience, the operator has negotiated a multi-million-dollar contract extension with Veolia.

Story type

#service/solutions (main category)

#digital #technology

Benefits

• Massive savings to clients due to increased operational efficiency • Enhanced portfolio of services and solutions

Key findings

For industry

• No digital solution can manage and learn from itself – people remain the company’s greatest asset • Innovation is key and having a business that can adapt to the dynamics of the industry is a must • Being adaptive, creative, innovative and able to react quickly are all essential requirements of a modern business The success of Veolia’s strategy is self-evident in terms of year-to-year growth and the expansion achieved. Introducing its digital support package to the market and breaking into the upstream O&G water injection chemical segment combined with its growth in its offshore physical presence was also crucial to maintain the business during the challenging downturn in the oil and gas market in 2014 and beyond.

Moreover, these solutions have provided clients massive benefits in terms of increased uptime, capacity and efficiency of the operation of their water injection systems.

Market challenges never cease, however, and the company’s services solutions continue to evolve and adapt in order to unlock additional value to customers across the world.

For government

• Promote successes by UK companies • As the COVID-19 pandemic illustrates, our planet is subject to abrupt changes. Energy transition is not tomorrow’s issue, but a current one.

Government support?

VWS Westgarth has benefited from the Apprenticeship Levy as well as R&D tax credits. The company has also received support from the Engineering Construction Industry Training Board (ECITB).

Energy transition lessons

• Count on the skills and expertise of staff when looking at the development and implementation of energy transition solutions

About VWS Westgarth

A world leader in seawater sulphate removal systems, VWS Westgarth specialises in the design and fabrication and operation of water treatment plants for seawater injection and produced water in the upstream offshore oil and gas sector as well As part of Veolia Water Technologies (VWT), VWS Westgarth cooperates with other VWT subsidiaries around the world in Europe, Africa, the Americas, Middle East and APAC.

This allows VWT to cover the full scope of water treatment processes for the oil and gas industry (both upstream and downstream) and ensures they are able to satisfy local content requirements where needed by clients.

• The planet’s oceans represent a huge untapped potential when it comes to energy transition. They naturally store the energy the planet produces • In the context of energy transition, some geographical regions may be more lucrative than others (e.g. wind power in Scotland)

VWS Westgarth at a glance:

Key products and services: design, build commissioning and operation of offshore water treatment systems

Main industries served:

• Upstream O&G – 100%

Headquarters: East Kilbride, UK Year established: 1962 Number of employees: 150 Revenue: £50millon GBP Revenue from exports: 90%