fixing the world’s disconnected supply chains

fixing the world’s disconnected supply chains

VP Andy Hancock talks digital supply chain

VP Andy Hancock talks digital supply chain

AJE Group putting sustainable into supply chain

Zalando data & technology driving procurement

Cold Chain Technologies straight talking sustainability pioneers

www.BusinessSocial.org 2023 / Issue 3

SAP

streamline procurement & finance

SAP

Logistics is rarely considered a world of opportunities. But sometimes all it takes is another perspective.

Integrated logistics holds some of the most untapped potential for business growth in this decade. Made possible by new digital platforms, connected physical assets and insights driven advice. Experience how integrated logistics can become your fast track to business opportunities at maersk.com/upside

© 2021 .PA. Moller - skrMae

Welcome

Welcome back to an exciting issue of Business Profile. Embracing technology and developing capabilities and opportunities appears to be the running theme for this edition.

Our headline feature is with SAP’s Andy Hancock who emphasises SAP’s role in the ever-changing supply chain landscape, detailing SAP’s considered and collaborative approach with customers when developing their digital road map.

Zalando’s Alejandro Basterrechea opens up on why procurement should become a data and technology led function. On a similar note PayEm offer details on how their platform can streamline procurement and finance, creating a powerful synergy.

Moving away slightly towards sustainability, we hear from AJE group’s executive leadership on how they have successfully embeded sustainability indicators within their supply chain, and get great detail from Cold Chain Technologies Nicholas Tassone and Paul Della Villa as they talk sustainability, data, and future tech opportunities.

With content from Genpact, Deloitte, GSES System, LeverX, and many more there is much to view. So get stuck in and take a look!

3

The Business Profile Team

Enjoy

06 | Leadership 22 | Procurement & Supply Chain 56 | Sustainability 66 | Technology

06 | Leadership

SAP

7

Leadership

Fixing The World’s Disconnected Supply Chains

Andy Hancock, SAP’s Global VP, Centre of Excellence, Digital Supply Chain emphasises SAP’s role in an everevolving supply chain landscape. In this vein, it isn’t simply an acceleration towards digitisation that this global heavyweight is promoting. Rather, SAP is helping businesses produce a considered, bespoke and collaborative roadmap that highlights their precise pain points and the business outcomes that can be improved with a data-driven approach.

Hi Andy. Everyone knows SAP as a globally leading tech brand, but what is the role of you and your team within the business?

Within SAP there are 3 board areas: Engineering, Marketing and Solutions and Customer Success. We are part of the Customer Success organization that directly

engages with customers to help them achieve their business objectives. My team provides global project content, we do demand management and generation, and we initiate insight that can be used to support sales teams both regionally and globally.

This could manifest in the form of keynote presentations in large auditoriums, all the way to individual one-on-one engagements with customers, providing specific subject matter expertise. It’s about thought leadership and generating demand for the digital supply chain portfolio.

To that end and from your direct exposure to the market, how would you say the customer landscape has changed in recent years, and what pitfalls have you seen organisations fall into?

Leadership | SAP

The Business Profile

Andy Hancock VP CoE, Digital Supply Chain

There are two sides to it, really. Yes, companies have had to rethink their supply chains anyway as a result of events like the pandemic. But, simultaneous, there has been a consumer shift too of course.

What we saw immediately as a result, was a quite narrow focus on trying to improve the parts that were broken in order to respond and keep up with demand, but this revolved mainly around working in siloes, and not really connecting across business units within an organisation and the partner ecosystem. There are also those who were abiding by a principle of ‘it worked last time, let’s do it the same now’. By this, I mean they were looking backwards at historical data to make decisions, rather than looking at the current situation and realising an opportunity to do something differentto change their processes, to introduce innovation, and to capture market share.

There was also this mindset of seeing the supply chain as an overhead which needed to be made as efficient as possible, so companies looked to offshore, or consolidate facilities, or to single-source logistics providers. The problem with consolidating in that way, though, was everything then became more vulnerable to the events we’ve seen in recent years, as well as smaller stoppages, blockages, trade barriers or skills shortages.

Where we have been trying to support is to promote the need for a more agile, risk resilient supply chain. To open collaboration channels, and to be more proactive in real time, to the present situation.

Within SAP there are 3 board areas: Engineering, Marketing and Solutions and Customer Success. We are part of the Customer Success organization that directly engages with customers to help them achieve their business objectives.

Going back to those perceptions of SAP as an innovator, it sounds like you’re as much a consultant and guide, especially during such challenging times?

We have a direct vantage point of global and local markets, and these challenges presented an opportunity to share our overarching perspectives and to show how disconnected some supply chains really are just because they were focusing on the wrong things.

We could pivot them to refocus on business outcomes, built around a supply chain that would be agile to opportunity and resilient to risk. And then, once those outcomes have been established, then the technology can be applied.

This all starts by not just embarking on a ‘digital transformation’. But pinpointing what they actually need to transform, relative to where their shortfalls are now, to where their status quos aren’t fit for

Leadership | SAP

The Business Profile

The new imperatives

Rethinking what it means to transform the supply chain

How do you know when you have done a good job of addressing supply chain complexity? In today’s environment, many organizations have found themselves in a highly reactive posture, figuratively putting out fires and moving from one disruption to the next—whether it is a labor strike, a transportation disaster, an insolvent supplier, or some other disruptive event.

With the complexity of supply chain disruption, measuring impact through familiar lenses like cost savings, efficiency, and service are not enough to determine success in such a dynamic environment. To help organizations and customers thrive in the future, supply chain leaders should consider an additional set of lenses for looking at business challenges, opportunities, and successes. These might include factors like resilience, value, and relationships.

Leadership | SAP

Business Profile | Premier

The

Sponsor

Becoming resilient

Supply Chain disruption is here to stay. Those who will be resilient in navigating future challenges will be agile, will anticipate disruption, will have an ability to quickly mitigate risk, and will continuously unlock measurable business value.

You need a holistic approach that connects every process, contextualizes every decision, and boosts collaboration with your ecosystem.

At Deloitte we believe in building a Kinetic Enterprise™ focused on clean ERP, intelligent capabilities, cloud scalability, and edge innovation. This holistic approach is woven into all of our work, including our modular Supply Chain offerings— enabling a resilient, agile, sustainable, decision driven enterprise.

Look for new value at the edge

The traditional means to measure value are known, but what about new value at the edge? Edge innovation allows organizations to add or subtract

capabilities and prioritize for outcomes using a modularized approach that integrates into their core system using platform technologies and a microservices approach.

As supply chains continue to become digital supply chains, enterprise leaders worldwide have a massive opportunity to innovate in areas beyond core operations while exercising the ability to prioritize spend and budgets for the biggest return, creating a roadmap that works specifically for their goals.

This might mean savings from reducing technical debt or activating use cases, leveraging cloud and intelligent solutions like AI. Use cases could be adding capabilities like intelligent sensors to gather insights across a distribution network, provide workers on the shopfloor with a new cloud-enabled app, or launch other digital capabilities that can unlock specific value for the business.

Make your relationships more strategic

In many ways, a supply chain is a relationship chain. Supply chain leaders get that. Relationships should be continuously examined through a strategic lens. The relationships on which your supply chain relies must do more than drive savings, efficiencies, and service. They should help you become more agile

over the long term. They should help you reduce risk across your business. They should help you use the talent of your people to the fullest. And they should also support your vision of a sustainable future. SAP Solutions can be leveraged to address strategic relationship needs and measure impact. For example—to increase supplier collaboration with SAP Ariba solutions or improve planning with SAP Integrated Business Planning.

The view ahead

Deloitte deeply understands what it means to strengthen strategic relationships and our approach is centered on outcomes that drive business value. For more than three decades, we have been collaborating with SAP to help bring forward innovative solutions that help SAP customers around the globe run their businesses more effectively, make a bigger impact, and drive toward becoming a resilient Kinetic Enterprise.

What will the future hold for your supply chain—and how will you navigate the next disruption as a resilient enterprise?

Get more Deloitte insights that can help you leverage SAP technologies to address ongoing complexity and unlock continuous value for your business. Visit Deloitte.com/SAP to schedule a demo to see the Deloitte Kinetic Supply Chain solutions in action or to discuss a specific challenge your organization is facing.

As supply chains continue to become digital supply chains, enterprise leaders worldwide have a massive opportunity to innovate in areas beyond core operations while exercising the ability to prioritize spend and budgets for the biggest return, creating a roadmap that works specifically for their goals.

massive a cloud-enabled

Continued from page 10 purpose, and where there are the biggest opportunities for improvement.

How would a typical conversation go with a prospective customer, with this ‘disconnected supply chain’ issue in mind?

So, we’re a Centre of Excellence so there’s a constant high-level analysis of markets and industries going on which provides us with a strong starting point. However, once invited to engage with individual accounts, that’s really where we need to identify their bespoke strategic priorities. We can then apply the correct segment of data and expertise – industry, sector, sub-sector, region, etc – to those desired outcomes.

Our experts filtering that information have decades of experience to also add to this proposition, which, when combined with the data we present to them relative to their pain points, results in a best practice roadmap that we can put to the customer. A roadmap that challenges those status quos and that shows there is a better way.

And then, presumably, you can also share a similarly broad range of technologies that would suit for a customer’s specific needs?

Absolutely – with SAP, there is always a best of breed solution and within the supply chain portfolio we cater from ‘design’ to ‘operate’ (D2O). This journey is made up of five pillars: design, planning, manufacturing, logistics and, finally, operation. SAP D2O represents the entire

lifecycle of products in an end-to-end, connected, and interoperable supply chain process; from how a product is designed, planned, manufactured and delivered, to how it operates and is maintained.

Regarding the interconnection and interoperability of these departments… these siloes… these pillars, it’s not about throwing a technology into each area to augment processes there. It’s about ensuring a smooth flow of data between them, and to create a digital thread where companies can ultimately make a decision based on completely connected and reliable, real-time information.

Encouraging the creation of these digital threads obviously has operational value, but it’s also helpful from a mindset perspective. Typically and understandably, decision makers often make investments based on what keeps them up at night, and this may derive from pitfalls being presented from siloed sources of data. This might lead to a focus on the wrong priority, an overlook of a more pressing matter, or a short-term fix without getting to the route of a problem.

A connected infrastructure will show how planning for inventory might impact engineering or manufacturing, for example. The resultant cohesiveness and awareness of impacts across the whole organisation then highlights what the benefits of a change really would be, and what specific business outcomes are being targeted –for example, fewer missed shipments, less waste, improved availability…

17

The Business Profile

When dealing with niche or bespoke requirements, this must lead to some quite novel and exciting applications of your products, but also some innovative partnerships and initiatives?

Certainly – we’re in an era of machine learning and AI and things like that, but how data is generated to fuel these systems is also hugely exciting. For example, with one partner, Smart Press Shop, and its own partner Syntax, we have had our SAP Digital Manufacturing Solution extended with a computer vision solution. It is a fully automated AI camera which enables employees within industrial environments to check for component defects in a live manufacturing space. With

a single click, photos canpinpoint potential issues following a critical production step, thus removing manual error and time from the process, ensuring more accurate production, and speeding up the overall troubleshooting and manufacturing process.

With the Smart Press Shop and Syntax, their aim was to set a new milestone in automotive production with fully paperless production and automated machinery configuration. They adopted a cloud-first strategy, building core enterprise resource planning and manufacturing execution systems that run entirely in the cloud, using 100 percent green energy.

Leadership | SAP

Reimagine manufacturing with a digital factory Get the most out of your manufacturing operations using SAP software to drive productivity, improve visibility and lower your cost of ownership. syntax.com/manufacturing/digital-factory

The integration of the SAP Digital Manufacturing together with SAP S/4HANA Cloud has revolutionised their manufacturing process. With the ability to configure the production line quickly and autonomously, without manual intervention, Smart Press Shop can manufacture small batches of components much more efficiently than traditional plants.

The result? An unprecedented competitive advantage in an industry where just-in-time manufacturing is a key requirement.

Another great example that we’re excited to be a part of can be found at the Deloitte SMART Factory in Wichita, Kansas. Here, as a founding member and part of comprehensive ecosystem of innovative collaborators, we bring business outcomes

to life in a fully connected and operational production facility. We provide customers the opportunity to challenge the status quo by infusing intelligence into factories, leveraging real-time data analysis, AI, and machine learning – giving a virtual datadriven view of all operations. This enables new ways to solve business problems and generate new revenue streams, drive digital services, and keep customers engaged – all while achieving supply chain resilience.

Both of these examples lean into our emphasis on a digital transformation that focuses on agility and risk resiliency. Further they help our customers move digitalization and Industry 4.0 from a factory-focused initiative to a companywide, competition-beating business strategy.

19 The Business Profile

How does the workforce fit into the equation from the perspective of a digital enabler like SAP?

We frame it as a way to both safeguard expertise, but to also enhance job roles. Regarding the former, at present, once somebody retires or leaves, their knowledge goes with them. This isn’t to say that technology should replace them as a more evergreen source of information, but it should be introduced to allow those humans to move up to higher value tasks, and away from the more repetitive elements of their jobs.

They will be armed with more credible, accurate information in real-time, from which they can dictate more fit-for-purpose strategy. Not only that, but they’ll be able to enact decisions based on all the evidence they should need in that same real-time. We’ve all sat in on PowerPoint presentations and meetings where strategies are put forward, and then discussed, and then they’re explored before either making a change or not. Now, workers can go in armed with all the relevant information and outcomes derived from the data they have already been provided.

Ultimately, job roles are made simpler, more fulfilling and more impactful, through this data-driven approach.

Is this the sort of vision for the future you’re now promoting to customers?

Yes, it’s certainly about getting people with more knowledge making decisions based on more accurate and timely data. And,

critically, doing so armed with insight of how those decisions will impact the whole organisation, and not just their specific silo.

More than that, they can not only bring a potential change to the table, but they can also come into meetings armed with scenarios… what would be the outcomes of alternate strategies, or by not changing anything at all.

This is what we at SAP can facilitate in that we understand your business processes and how to run your business from a process perspective; but we also have the capability of providing technologies that will then ensure those processes are optimised. This is compounded by a global reach which spans around 450,000 customers globally. This brings exposure to every type of challenge and therefore solutions that we have already seen hit their mark in similar circumstances. This means taking into account not just the use case but also the region, the labour challenges and landscape, the consumer profile, the industry itself, and any events that might impact their sector or specific operations.

Last, but certainly not least, I was wondering how the theme of sustainability fits into these conversations? As an issue that spans both company and consumer concern, presumably this is now a critical part of your own presentation of the digital supply chain?

Absolutely, it would be remiss not to discuss this. What SAP can do is take the sustainability conversation beyond just

Leadership | SAP

emissions and waste figures. Consumers and regulators are of course looking at these metrics, and rightly so, but what will set companies apart is finding ways to attribute value to these efforts. Don’t just do it to tick a box, because that mindset in itself isn’t sustainable. Do it because you can know and see that it contributes X amount to your organisation from a financial perspective too.

It always sounds like this approach detracts from the matter at hand, but in reality an organisation is only going to really dive into a sustainable practice long-term if it is actually feasible to do so. If it’s not, then inevitably standards will slip or corners will be cut.

SAP can once again promote processes and technologies that demonstrate where efficiencies can be made, and how sustainability initiatives are playing out in real-time. That is why SAP announced its Green Ledger, a ledger-based accounting solution for carbon. It allows companies to manage the carbon entering and leaving their systems and to balance their “carbon books” the same way they balance their financial books. If anything, sustainability is another frontier that really epitomises the impacts SAP can have. It’s about leveraging data through a collaborative approach, to bring resilience to the organisation through the lens of a specific business outcome.

The Business Profile

Ultimately, job roles are made simpler, more fulfilling and more impactful, through this data-driven approach.

AJE Group PayEm Ana Pertot

| Procurement

22

& Supply

Procurement Chain

23

Leading the Natural Revolution

AJE Group’s reputation as a global leader in beverage production is assured, but that isn’t stopping the company from assuring the preservation of the world around it. The organisation’s pioneering sustainability model already spans 14 countries, having been developed by Jorge Lopez Doriga. He is joined by Supply Chain and Procurement executives, Raul Samaniego and Raul Pausin, to discuss this exciting revolution. CEO, Augusto Bauer further confirms the mission of a truly unique company.

Hi Augusto. As CEO, it would be great to begin with a more general introduction from you, to pinpoint the company’s current strategy and the business climate you’re operating in.

There are numerous challenges in this industry, from increasing logistics costs, to the need to develop local suppliers for a stronger presence closer to production plants. In addition, there is also the pressure to address sustainability concerns and regulatory requirements, and it has been our priority for a long time to develop a truly sustainable, recycling-centric chain.

We continue to seek efficiencies in all areas of our production and commercial activities, which not only help the

environment but that also allow us to maintain our operating margins.

It is my responsibility to maintain this strategic direction and ensure these results are not just achieved in the shortterm, but consistently over the course of the future.

Raul Samaniego, having been with the company for more than nine years, you have seen this evolution of strategy first hand. Now, as VP of AJE Group’s Supply Chain, what would you consider the biggest developments or challenges to have been during this period?

Despite having more than 25 years of experience across industries, the past

Procurement & Supply Chain | AJE Group

few years have presented some of the biggest challenges I have seen. Biggest of all is the way that consumer demands and preferences have changed, especially with the impact of the pandemic which accelerated these changes, while simultaneously disrupting logistics and global supply chains.

However, out of this challenge, there has been a positive reassessment of what a supply chain management (SCM) strategy in the new world should focus on.

What would you say is the new SCM priority then, Raul?

Most certainly, digital intervention and digital transformation.

At AJE Group, we are in the process of introducing and evaluating specific technologies such as advanced analytics, artificial intelligence, IoT (sensors) machine learning, augmented reality and robotic process automation (RPA) to guide our own digital transformation. These technologies help us to streamline processes, improve efficiencies and reduce costs across our global operations.

How has your digital transformation effort manifested so far?

There has been a special focus on visibility tools, and the ability to see - in real-timethe location, status and condition of goods as they move across the supply chain. These tools enable us to identify potential

25

The Business Profile

Augusto Bauer CEO AJE Group

What differentiates

AJE Group as a business is our commitment to democratising consumption by providing accessible, quality products at a fair price.

A really good example of this has been the implementation of Fullstep, a source-to-pay cycle management platform. We have also introduced the Tableau solution as a business analytics platform to access, visualise and analyse our data.

Procurement & Supply Chain | AJE Group

Raúl Pausin

Raúl Samaniego

disruptions or delays, and to take corrective actions before they impact delivery times or ultimate customer satisfaction levels.

Another focus has been on the introduction of predictive analytics. Machine learning and AI allows us to analyse large volumes of data, and to identify patterns and trends in our systems and processes.

In turn, this data also enables us to optimise inventory levels, reduce lead times, and improve overall efficiencies across both manufacturing and supply chain operations.

Enabling this transformation of our supply chain operations are our loyal business partners. We pride ourselves on transparency, which lends to close collaboration, and an open and inclusive environment. Without this approach, innovation and creativity is impossible, and digitisation becomes more complex.

As a final note from yourself, Raul, how do you feel AJE Group differentiates itself as a business, and how have the past few years highlighted that competitive advantage?

What differentiates AJE Group as a business is our commitment to democratising consumption by providing accessible, quality products at a fair price. We believe that our success lies in our ability to adapt to changing consumer needs and preferences while maintaining our core values, and a culture of collaboration and transparency.

Raul Pausin, as Chief Procurement Officer for the global company, what has been

your role as part of this ongoing evolution of AJE Group? Presumably, you have helped pave the way for some of those aforementioned business partnerships to become a success?

My role aligns with a lot of what my colleague, Raul Samaniego explained - to lead the Global Procurement Team in way that satisfies organisational needs across areas of cost, profit margins and customer satisfaction.

With the help of new technologies as already described, the goal is to reduce or eliminate lower-cost or routine manual tasks; to not only make us more cost efficient, but to also streamline processes and to allocate more meaningful tasks to employees.

A really good example of this has been the implementation of Fullstep, a source-topay cycle management platform. We have also introduced the Tableau solution as a business analytics platform to access, visualise and analyse our data.

Both of these companies have been key to our recent digitalisation efforts. As Raul mentioned, close collaboration and transparency has been important to ensuring these solutions have made their required impacts.

One of the well-known tenets of AJE Group is the company’s commitment to sustainability. Jorge, bringing you in at this stage as Director of Sustainability and Communications, can you try to put this significance into words?

27

The Business Profile

Since 2014, I have helped merge these areas of sustainability and communications, initially starting out in marketing before seeing the potential and need for the former to be introduced more prominently.

What has happened since has been beautiful. AJE is actually quite a peculiar company – the fourth largest of its kind in the world, but not deriving from the traditional industrial world. We’re from Peru, but not even from Lima. Instead, our origins are from Ayacucho, a small village with rural surroundings.

In this respect, our history and our genesis is steeped in biodiversity, and our expansion

has been inspired by that inception. Each of the 14 countries we have moved into are chosen for their own levels of biodiversity, with a priority to protect them. We have expanded to the world’s jungles, with a promise that we will give back to mother nature, what mother nature has given to us.

Being born and raised as an organisation among the less built-up world, must present a huge competitive advantage now, where industrial-born enterprises are still learning how best to master sustainability?

I can prove this in one simple way. If you Google the words ‘Revolucion Natural’, do

Procurement & Supply Chain | AJE Group

you know what appears at the top of the ranking list? It is us, AJE Group.

Now, this might not have always been as big a competitive advantage as it is now. But we are seeing a big shift in consumer patterns which brings them more in line with our philosophy. In fact, we shouldn’t call them ‘consumers’ anymore. Rather, they are ‘conscious users’. When purchasing a product, they consider if it is good for them; for society; for the environment; for their futures.

This new relationship places sustainability very highly as a priority within the food & beverage sector, and we know we have an

advantage over the market in this area, because it has been the very essence of our growth and success.

Please talk me through how you uplift these new areas as you expand operations around the world…

Well, we do it through the very drinks we produce. We create categories of drink based on the resources and biodiversity of each respective location. In doing so, we give value to that biodiversity, and an ability to make use of that forest or jungle in a way that is considerate and sustainable. This is opposed to leaving it vulnerable to deforestation or heavy taxing.

Tradecos: strong growth with sustainable and solidarity commitment

Tradecos is an Argentine company with international projection. We began our commercial activities in the City of Buenos Aires in 1992. In a few years, we expanded and opened offices in Chile, Brazil, and Spain. We are comprehensive and tailored service providers for the food industry, specialized in processed fruit. We generate a sustainable business for the entire value chain. Our permanent challenge to provide businesses with a sustainable integral vision based on our experience, professionalism, and responsibility has made us benchmarks.

In our 30 year history, we have got a vast experience in the practice of ESG with clear objectives of generating a triple quantifiable impact in the economic, environmental and social fields. To do this, we have constant links with our stakeholders to join efforts on an integral work. We also support the communities by being consistent with their values by providing support to various entities, promoting the care of children and their food needs as well as the promotion of their education, sports and work culture.

In Tradecos we work to be the best option for satisfying the needs and expectations of our clients and suppliers. Also, we support the sustainable sourcing of products. We believe they are the tools for an evolved development.

29 The Business Profile

This approach also aids our commercial proposition. We’re making beverages from super fruits of the jungles we are present in, and giving value to the area from which the fruits come from. They are, in essence, bio-businesses, and this is a huge step on from simply being sustainable, but not really saving or championing the natural areas around the world that are most vulnerable or exploited.

Because, really, we shouldn’t just be talking about ‘sustainability’. That is too easy as a word to tick off or claim you do it. Really, we should be talking about ‘survival’ and helping species’ and natural areas to survive. We can say we contribute to survival, and that’s very different from what the industrial world classes as sustainability.

This is a hugely exciting approach which must resonate with not just customers, but also business partners too?

Procurement & Supply Chain | AJE Group

Most certainly. And, even more importantly, it resonates with and positively impacts the indigenous communities in these areas too. We’re empowering them to become our partners – they are the people who collect the fruit and supply to us, which is again a very unique approach to ESG or social responsibility in the supply chain, compared to many other organisations.

It is a beautiful thing to watch develop, seeing not plantations but wild trees in primary forests being cared for and used only for the amazing fruits they would already provide. Not only that, but the people picking those fruits are those from local areas who know the forests better than anyone, and who care most about their preservation.

How far into this project are you currently?

We are already in 14 of the most biodiverse countries in the world, with Ecuador, Colombia and Thailand also being expanded into. We want to keep developing this model and to keep being the face of the natural revolution/ revolucion natural.

We want the world to see a business can be globally successful by doing things in a different way. Instead of creating products that satisfy traditional consumer needs, start creating companies that satisfy the needs of mother nature. From there, the modern conscious user will still make that model a commercial success.

We are just at the beginning of our revolution.

Thank you, Jorge. Coming back to you finally, Augusto, as CEO: how would you surmise this unique model and mission?

As Jorge rightly says, we have to make sure our brands have a purpose that transcends industry and that relates to the aspirations, emotions and experiences of people around the whole world. Those people are, after all, our customers, and they don’t just exist in industrial, urban environments. They also want to see their communities, regions and countries being preserved and protected.

We are creating value propositions that will ensure we retain a competitive advantage long into the future. This means continuously reinventing ourselves, but always in line with our core mission which is ensuring the sustainability of our business, by mastering sustainability more broadly.

The Business Profile

Jorge Lopez Doriga

PayEm –streamline procurement & finance

PayEm Co-Founder and CEO Itamar

Jobani began his professional career as a fine artist. As part of his work, he sculpted and exhibited in leading museums and galleries in the U.S. In 2014, he established a 3D printing start-up and two years later returned to Israel to join Matrix and FDNA as a developer.

In 2019, Jobani co-founded PayEm with Omer Rimoch (CTO). PayEm is a VC-backed fintech company offering a versatile, user-friendly platform that streamlines finance and procurement with customisable workflows, deep insights, and seamless integrations, delivering agility, transparency, and control across diverse industries.

Procurement & Supply Chain | PayEm

A very interesting guy heading up a super interesting business, Itamar provides the detail on PayEm.

What is PayEm?

PayEm is a globally accessible, all-in-one procurement solution offering robust budget management, extensive AP automation, and customisable workflows across industries, empowering organisations with detailed financial insights and seamless integrations for unparalleled operational agility and efficiency.

What issue does your solution solve?

Organisations often struggle with capturing and managing employees’ financial and procurement requests. With traditional processes (or lack thereof), creating requisitions (PR) or purchase orders (PO) can be complex and often discourages end users from handling

these tasks themselves. Consequently, the organization relies on offline methods as a workaround, or employees completely bypass the procurement process altogether. These issues hinder the efficient handling of finance-related requests, leading to delays, errors, and difficulties in monitoring and tracking progress.

33 The Business Profile

Tel Aviv

Photo by Shai Pal on Unsplash

PayEm provides a practical and efficient platform where employees, approvers, finance, and procurement teams can collaborate seamlessly. PayEm streamlines the entire process of requesting and approving funds, purchase orders, and other crucial financial transactions, offering a convenient and comprehensive solution. PayEm improves organizational efficiency, transparency, and communication by centralizing all stakeholders in one platform. This accelerates operations and enhances productivity, helping save time and resources.

n Customisable intake forms: Easily configure forms to capture requests accurately and efficiently. Incorporate conditional logic to dynamically display relevant questions or sections based on the provided responses, spend category, employee’s title, or affiliated subsidiary. Unlike competing products, these forms are entirely selfconfigurable, eliminating the need for assistance from the PayEm support team. This autonomy empowers Admins to personalize the forms to their needs, ensuring an efficient and user-friendly experience.

n Budget control: Empower budget owners with our user-friendly Budget Control module, providing real-time and ondemand visibility for effective budget management. Effortlessly access a comprehensive view of all spend data, including off-platform expenses, as well as stay on top of in-process requests. Get relevant data within the flow or

context of the specific request for informed decision-making.

n Dynamic, automated approval workflows: Create (no-code) decision trees effortlessly without IT involvement, leveraging hierarchical data from your HRMS and financial data from your ERP. With integration into popular communication platforms like Slack and email, employees can track their request status, while approvers can conveniently approve or decline requests without accessing the platform.

n Preferred vendors: Employees can access and select their preferred vendors from a curated list, eliminating the need for extensive research and ensuring the procurement process aligns with your organization’s preferred supplier relationships. Employees can easily identify available vendors and contracted agreements, allowing them to leverage pre-negotiated contracts and favourable rates. This helps the company save money and utilize vendor relationships effectively.

n Simplified PO creation and management: Creating POs with a straightforward process encourages employees to input vendor details, item descriptions, quantities, and pricing with ease. Once employees create the initial PO, the finance or procurement team can step in to add any relevant information and make necessary adjustments, simplifying the process from request to reconciliation.

Procurement & Supply Chain | PayEm

The Business Profile Itamar Jobani

n One comprehensive platform: Consolidate requests and approvals within the platform. Discussions, clarifications, and supporting documentation can be shared within the platform, ensuring all relevant information is readily available to the necessary parties. Furthermore, having all requests and approvals in one platform creates an audit log of actions taken, providing a comprehensive record of the entire process.

n Enhanced transparency and communication: Give all stakeholders access to real-time updates and a clear overview of the status of each request. Requesters can easily track the progress of their submissions, ensuring transparency and reducing the need for follow-up inquiries.

Who is your solution aimed at?

What does your perfect client look like?

Our target audience includes a wide range of professionals from mid-market businesses to multi-subsidiary enterprises across industries such as software, healthcare, internet, media and advertising, and business services. Specifically, we aim to empower CFOs, finance directors, controllers, AP managers, and procurement professionals with our platform’s valuable, role-specific features that enhance their operational efficiency and strategic decision-making capabilities.

What is the biggest challenge PayEm faces?

At PayEm we understand the intricate challenges faced by finance and procurement teams. We’re on a mission to transform the procurement landscape with our groundbreaking request-toreconciliation system that strikes the perfect balance between user-friendliness and powerful customization.

The key challenge lies in addressing the diverse needs of finance and procurement professionals while ensuring a seamless and intuitive user experience. Our team of experts has tirelessly worked to design a platform that empowers users to navigate complexities effortlessly. Gone are the days of clunky, rigid procurement systems – welcome to a new era of agile simplicity!

Customisation is at the core of PayEm. We recognize that every business is unique, and cookie-cutter solutions simply won’t cut it. Our platform is highly customisable, allowing you to tailor it to your organization’s specific requirements. Whether it’s automating approvals, streamlining supplier management, or optimizing budget tracking, PayEm adapts to fit your needs like a glove.

With an emphasis on end-user satisfaction, we’ve placed an unwavering focus on simplicity. No longer will your finance and procurement teams be bogged down by convoluted systems. Our intuitive interface guides users through each step, making the procurement process a breeze.

However, achieving this harmonious blend of flexibility and user-friendliness has not been without its challenges. We’ve

Procurement & Supply Chain | PayEm

tackled these hurdles head-on, dedicating ourselves to ironing out every kink to ensure a seamless experience.

Why pick PayEm?

Streamlining and optimising your technology infrastructure is a crucial step in enhancing operational efficiency and resource management. PayEm offers an all-in-one platform designed to revolutionize business processes. PayEm serves as a comprehensive solution that spans a spectrum of functions, ranging from fund requests and corporate card issuance to purchase orders, bill payments, reconciliation, and beyond.

By consolidating multiple functionalities under one roof, PayEm offers a seamless and integrated approach to managing your financial and operational tasks. The platform’s unified platform eliminates the need for disparate tools and systems, reducing complexity and boosting productivity. No longer will you need to navigate a web of disjointed applications; with PayEm, everything is conveniently accessible from a single interface.

Consolidating fund requests, issuing corporate cards, generating purchase orders, facilitating bill payments, and carrying out reconciliations, all within the confines of a unified platform, not only simplifies your workflow but also enhances data accuracy and reporting, as information seamlessly flows between various modules. No more manual data transfers or potential errors due to data silos.

What also sets PayEm apart is our dedication to customisation, ease of use, and transparency. Our platform offers fully configurable intake forms, allowing you to fine-tune the data capture process to meet your specific needs. Our userfriendly Budget Control module offers you real-time, comprehensive visibility into all spend data, empowering you with effective budget management tools.

Moreover, our dynamic, no-code approval workflows incorporate data from your HRMS and ERP systems, facilitating efficient decision-making. And with PayEm, all your requests, approvals, and discussions are consolidated into one platform, creating an audit-ready record of all transactions. This brings an unparalleled level of transparency, letting all stakeholders track the progress of their submissions, reducing the need for follow-up inquiries, and improving overall communication.

We serve a broad spectrum of clients across industries such as software, healthcare, internet, media and advertising, and business services. Whether you’re a small business or a multi-subsidiary enterprise, PayEm is tailored to meet the needs of CFOs, finance directors, controllers, AP managers, and procurement professionals.

37 The Business Profile

Procurement & Supply Chain | Ana Pertot

Procurement - creating Ana Pertot

Procurement creating an impact

With over 12 years of experience in Procurement, Strategic Sourcing, and Procurement Strategy, Ana Pertot is currently leading Procurement at Bolt, where she divides her time between the Netherlands and Estonia, where her company’s HQ is based.

At Bolt, Ana has built the Procurement function from scratch. Although still a recent department, the team has been delivering great solutions in terms of ESG, technology, and compliance – going beyond the savings targets. Ana believes that everyone on the team can create an impact, with diversity and inclusion one of the core keys to the team’s success.

An exciting time in an intriguing business. Ana offers a few thoughts on procurements impact when all the stars align.

39 The Business Profile

Ana, how do you feel procurement is perceived in general? Why is this?

Procurement is often perceived as the blocker in what should be an agile process for hiring a new supplier for a certain organisation. The departments feel that they can easily “purchase” services or goods, based on common business sense and practice, and that is already sufficient for their needs. While that can be partially true, the procurement professional will not only discuss the final pricing and secure higher discounts in most of the cases but will also pay a closer attention to possible commercial risks that the company could be exposed to, and will work to mitigate those. (COLA, missed SLAs/delivery schedules, volume commitments, etc.)

At times, some departments also feel that procurement will force them to choose a certain supplier based on pricing only, without looking at the quality of the goods/ services.

Another point is to listen to the stakeholders, their needs, and how to incorporate a procurement strategy into it. We need to aim towards our own goals, synced with ones from that department, and consequently, with the company’s final goals

Honestly, for all those perceptions mentioned above, that’s still the case in multiple organisations. Many procurement & finance leaders focus purely on the costs and indeed transmit the message to the departments that the mandate will be to always hire the cheapest provider, not necessarily interested if this might compromise or not the quality of what should be provided. You will never win over the stakeholders like this, and you will be encountering more bypassesthan this area might face sometimes, making procurement an unpopular department by many.

What can procurement do better?

Procurement can always make it better in terms of processes. You can reinforce compliance and best practices, and still have a leaner process in place. That’s what I like about tech companies and start-ups: if you want to win over the other teams to start working with you, you need to design and build a direct and efficient process. Obviously, it’s hard to expect that when linking a P2P process with an ERP system (especially some in the market that are not user-friendly at all, making the final users frustrated about the purchase requisitions/orders and approval flows). So, the procurement team needs to always see what serves work better for its own function (nobody wants to sit for hours doing the same admin task everyday), but also what can be welcoming and less painful for the stakeholders that work with us.

Procurement & Supply Chain | Ana Pertot

Another point is to listen to the stakeholders, their needs, and how to incorporate a procurement strategy into it. We need to aim towards our own goals, synced with ones from that department, and consequently, with the company’s final goals. If the organisation needs more frugality from the teams, procurement should use this as a key argument, but not as the only one. It is important to act as a business partner, in a more collaborative and solutions-driven posture, vs being the one creating problems for the business.

Another area that still could be changed is acting full-time as a tough negotiator with the suppliers, aiming only towards savings, and not considering the bigger picture, nor playing a fair game. Suppliers should not be perceived as the enemy,but many times as the enablers for our own organisations to fulfill needs that only (or partially) an external provider can cover. Obviously, strategic negotiations need to take place to secure the best deal for our organisations, but listening to the other side is also important. (Again, the impact of listening, for successful results in our jobs).

Procurement is evolving at pace. The pace of change often calls for new skill sets and disciplines within a team. What are those expected changes?

As mentioned before, the current and future procurement landscape asks for professionals with a mindset beyond savings. No longer should we play the role of the “bad cop” either internally or with

suppliers. In fact, being collaborative has already shown higher engagement rates in our organisation, and better deals were achieved with suppliers, than the other way around. Being hands-on, and focused on the bigger picture beyond procurement is still needed, given the more volatile scenarios we are facing in our economy, politics, and environment, which will continue to impact the value chain as a whole this is vital.

We should not ignore technology either, there are use cases for excel and word documents but there is significant room for SaaS solutions and the use of the AI. The need to digitise and automate certain tasks is obvious.

All in all, an easy-to-adapt and flexible approach to embracing new ways or workings is required.

41 The Business Profile

Cold Chain Technologies

GSES Zemba 42

| Sustainability

Sustainability

43

Straight Talking Sustainability Pioneers

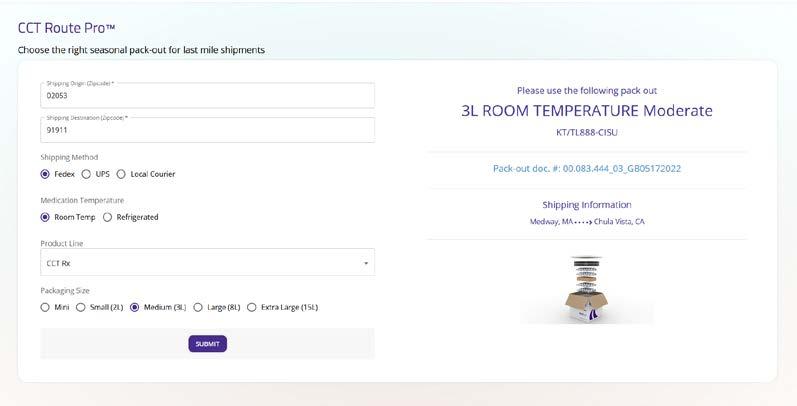

Cold Chain Technologies (CCT) hasn’t shied away from tough discussions in recent years, in order to overcome well-documented supply chain challenges. A commitment to close partner and supplier relationships hasn’t just helped to navigate challenges in recent years, but is also paving the way for positive contributions to the world’s sustainability efforts in the future. Nicholas Tassone and Paul Della Villa did their own ‘straight talking’ here, to emphasise the importance of collaboration and digitisation in CCT’s ongoing evolution.

Hi Nicholas. With more than 50 years of experience, CCT has a strong market reputation. How would you describe its evolution, and current status?

Cold Chain Technologies (CCT) is now a leading global provider of reusable, sustainable, thermal packaging, and digital

Sustainability | Cold Chain Technologies

solutions for the shipment of temperaturesensitive material; principally serving the life sciences industry.

As you say, we have more than 50 years of proven product assurance in transit, leading to our reputation now as the life sciences industry’s most innovative and dependable provider.

When you partner with CCT, you benefit from resilient, high-performing systems, cost-effective & proven designs, sustainable options, compliant and connected solutions, unrivalled engineering expertise, and industryleading customer service

In terms of our current status, as the global leader in reusable and singleuse sustainable thermal packaging shippers for the life sciences industry, we are committed to the safe transport of life-saving medications and also to environmental leadership.

As part of our three-year Strategic Plan, we have embarked on a major sustainability journey to: positively impact the health of our communities and our planet through the safe and sustainable transport of medications; to generate social and environmental change to benefit the planet, our partners, and global health; and to reduce 60 million pounds (lbs.) of landfill waste by 2025.

Finally, we are looking to decarbonize our products and services based on a circular economy model.

And, briefly, what is your role in this ongoing effort?

My role as Vice President of Global Strategic Sourcing and Operational effectiveness, enables CCT to optimise our supply chain partners and their manufacturing locations. We have the ability to deliver across the globe due to partners and locations that are - and continue to be - established.

We are working internally to better understand the manufacturing footprint, make calculated decisions as around the manufacture of key product lines that will greatly reduce lead and transit times to our customers.

My team is also responsible for the expansion of our global operations network. This will allow us to open new CCT-operated and partner-operated physical sites (manufacturing and distribution networks) across the globe.

You always have an eye on what’s coming from an industry trend standpoint. Where do you perceive the current challenges to be, to that end?

Our current challenges revolve around determining what our stocking inventory levels should be. As we are coming out of supply chain constraints of the past few years, many customers have stocked heavily on finished goods, and we have done the same with long lead time materials. We are therefore working closely with customers and suppliers to right-size inventory levels.

45 The Business Profile

Sustainability | Cold Chain Technologies

Supply chain lead times have challenged all organisations and we weren’t exempt from that. We have faced challenges of lead times extending in some cases from two weeks to 20 weeks, but have focused on the importance of partner relationships on a global, holistic scale.

Nicholas Tassone Vice President Global Strategic Sourcing & Operational Effectiveness

This includes straight-talk conversations to determine what current capabilities are, as well as discussing any constraints. For far too long supplier discussions have been: “yes we can handle the volumes, we can handle the requested lead-times.” When, in reality, equipment and materials weren’t available, and there really wasn’t time to discuss alternative solutions.

As companies are right-sizing inventories, demand continues to climb. Suppliers that have not moved materials have taken down stocking positions so when new demand converts into new orders, the chain is placed under huge stress once again.

What is your strategy to combat this particular issue?

Supply chain lead times have challenged all organisations and we weren’t exempt from that. We have faced challenges of lead times extending in some cases from two weeks to 20 weeks, but have focused on the importance of partner relationships on a global, holistic scale.

We worked with many locations and had to make sure we were tooled up where the labour and manufacturing capacity was at all times, to ensure we could deliver a steady state of materials during some incredibly trying times for all. We worked with manufactures to establish stocking positions and created several versions of programmes depending on the commodity, as well as the increasing lead time situation.

“Straight Talk” is also very key to our suppliers and our customers. We all need to understand current, true, lead times. We can no longer accept estimated delivery dates that may be too aggressive and may (probably will) slip. The supply chains are running too tight, and suppliers and manufactures are running very lean due to either labour issues or raw material constraints.

Customers need to understand what their real delivery dates are going to be. They need to be able to plan accordingly and if they need to come up with a backup plan, they need to be given that opportunity ahead of time to ensure they are prepared for a worst-case scenario. Our customers rely heavily on being able to ship medications and in some cases, lifesaving medications; so the better prepared we are the better prepared they are.

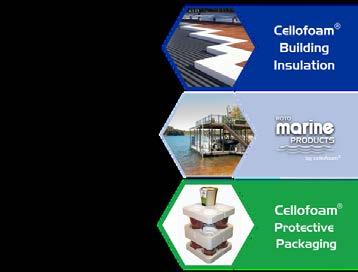

Paul, I’d like to bring you in at this juncture, to explain the role of technologies and digital transformation as part of this effort to become more predictive, and to enhance communication levels across the chain.

The digitisation of supply chains is important for both Cold Chain Technologies to manage our product supply chains, but also downstream to our customers.

Upstream, CCT has focused on improving our ERP, forecasting and demand management tools to help automate and streamline supply and inventory management. One of the key success factors is working internally with our supply chain and sales teams to

47 The Business Profile

By connecting the different supply chain signals with clear defined data, we are helping to drive our customers’ supply chains to be able to leverage newer machine learning and artificial intelligence technologies which are the future of the industry.

Paul Della Villa Director Digital Solutions & Services

Sustainability | Cold Chain Technologies

to ensure clean data input through our S&OP process, and to make sure the correct data and signals are driving our internal supply chain. The old adage of garbage in and garbage out holds true. By focusing on the data within our systems, we are able to improve our ability to react to the ever-changing pharmaceutical packaging market.

Downstream, CCT is focused on bringing tools to market to help provide many of those same signals we use to help provide additional visibility to our customers. In the pharmaceutical supply chain, outside of the medicinal products themselves, there are three key pillars of the supply chain: Packaging, Logistics and Monitoring

(Temperature). Our focus has been on building and developing tools that help to interconnect the other two legs (monitoring and logistics), which allows our customers to get a consolidated view of their entire logistics, and to identify areas of risk.

By connecting the different supply chain signals with clear defined data, we are helping to drive our customers’ supply chains to be able to leverage newer machine learning and artificial intelligence technologies which are the future of the industry.

Paul, to confirm, where have you channelled investment most prominently when it comes to this digitisation effort?

The Business Profile

Sustainability | Cold Chain Technologies

Within our own supply chain, we are leveraging our ERP, demand planning and CRM systems to provide a clear and clean vision of our demand needs. We have also invested heavily in digitised tracking tools to manage our reusable/rental packaging business. While the tools are important to our success, identifying the processes and dataflows are equally as important in driving a successful SCM strategy.

For our customer-facing applications our focus has been to digitise the ordering and tracking process (ecommerce) as a conduit to provide more information to our customers. In certain instances, our self-designed, bespoke tools allow our customers to order for same-day

shipments and integrate full track and trace ability which is a goal across the supply chain.

In conjunction with our Cold Chain Technologies Smart Solutions Platform, we have focused on integrating with TMS systems, Track and Trace platforms as well as IoT technology tracking platforms; to give customers a holistic view of their temperature-sensitive supply chains.

Back to you, Nicholas: blending this ‘man and machine’ advantage when it comes to communications and more seamless operations, how vital have your partner relationships been to this strategy’s success?

Protect your product. Protect your brand Protect what matters with Cellofoam Industry Alliance Member Plant Locations in Georgia, Florida, Oklahoma & Virginia www cellofoam com 800-468-3626 C e l l o f o a m ® B u i l d i n g I n s u l a t i o n P r o d u c t s C e l l o f o a m ® P r o t e c t i v e P a c k a g i n g P r o d u c t s Exceptional Products and Services

I feel vendor relationships are the key to success when you are in very tight and difficult times. Being straightforward with discussions and expectations has been instrumental throughout my career and has massively helped in recent years.

As a key starting point and example of positive partnerships, you could look at the topic of sustainability. CCT and many of our suppliers are members of the Sustainable Packaging Coalition (SPC), a membershipbased collaboration that leverages the power of industry to make packaging more sustainable.

As the leading voice on sustainable packaging, we are passionate about

creating packaging that is good for people and the environment. The SPC’s mission is to bring sustainable packaging stakeholders together to catalyse actionable improvements to packaging systems, and to lend an authoritative voice on issues relating to packaging sustainability. Along with that, we’re working with several large, recycled material manufacturers to develop a coalition directly focused on the life sciences industry.

And more broadly, how vital has this approach to industry collaboration being in combating those aforementioned ‘tough times’?

A WORLD OF CHEMICAL PRODUCTS STOCKED AND SERVICED FOR THE NORTHEAST

Astro Chemicals is proud to support Cold Chain’s growing business. We stock over 1000 chemical and adhesive products in New England, ready for next day delivery. Give us a call to see how we can help streamline your supply chain.

51 The Business Profile

astrochemicals.com

Supply chain issues were pretty familiar even before the advent of COVID-19 and its legacy of complications. However, when the global health crisis upended business as usual, the need for truly effective supply chain management became paramount. Since 2020, the industry has spiked, revealing the difficulties caused by a lack of communication, regardless of advances in technology and processes. We now know a successful supply chain is ultimately built and maintained on supplier relationships, in the never-ending pursuit of common objectives.

What do you believe constitutes a ‘positive’ relationship then, to help navigate more challenging periods?

CCT believes in showing respect, being honest, and continuously letting our partners and their workforces know how much we appreciate them and the long hours they must put in to guarantee allaround success.

Going back to sustainability, this includes bringing partners and suppliers with us in globally significant efforts.For example, our suppliers have aligned with our focused on re-engineering single use products to aid us in our goal of reducing 60 million pounds of landfill waste by 2025. This includes decarbonising their products and services, exchanging the typical cycle of make, use, and disposal, with as much material reuse and recycling as possible.

Extending the life of products and materials prevents the overgeneration

of waste. Their extensive single-use sustainable and reusable offerings help customers reduce their CO2 emissions, avoid landfills, and slim their carbon footprints.

Naturally, CCT’s supply chain strategies and methods are impacted by this strategy. CCT works with several key suppliers that are focused on recyclability and biodegradable production materials. Our company’s interim milestone of reducing 25 million pounds of landfill waste by the end 2023 was recently surpassed in October 2022; achieving 30 million pounds instead.

This alone is a fantastic achievement, and I understand it has been formally recognised too?

Indeed, CCT was awarded a 2023 silver medal sustainability rating from EcoVadis, the world’s only universal sustainability ratings provider who assess companies and their commitments to ESG.

They recognised that, through our extensive portfolio of sustainable offerings coupled with our digital platform for tracking and decision support, we are reducing the negative impact on the environment and helping the life sciences industry achieve a reduction in CO2 emissions, landfill waste, and more. At CCT, we take our commitment seriously and will continue to invest in the development and growth of sustainable solutions for the protection of our world.

Sustainability | Cold Chain Technologies

Brilliant, congratulations! And this is also very commendable as a future-looking mission. Is there anything you would like to add to confirm what you hope to achieve in the industry, in the years to come?

We want to continue to design and deliver temperature-controlled distribution solutions that meet the high quality, performance, and regulatory expectations of the life sciences industry.

Moreover, we want to be the missioncritical partner that life science organisations rely on to protect their temperature-sensitive products throughout the global supply chain.

We will pursue innovation and excellence in all aspects of our business to meet this goal; making a positive difference in the world as we do so.

53 The Business Profile

GSES - remove your sustainability reporting hurdles

Oriane Wiser is GSES’ Program Manager. Her dedication for the preservation of future generations’ needs and her academic background in sustainable & international development has led her to promote sustainability professionally. At GSES, her background has elevated her at the front lines of GSES’ global expansion. Along with her team, Oriane contributes to the organisation’s mission; to promote transparency within the realm of sustainability with the aim to end green-washing and achieve a sustainable present and future.

Oriane offers snapshot into GSES System.

Oriane, what is the GSES System?

GSES was founded in 2019 by Kelly Ruigrok, CEO, to address the hurdles of communicating with transparency on sustainability for organisations. Kelly set the ambitious goal to deliver a digital product that is a) sector agnostic, b) for any organisation, public or private, of all sizes, c) scalable with currently a capacity outreach of 110 countries.

Today, in 2023, GSES has conquered the Dutch and European markets amidst

challenging times, and has initiated its global expansion with a country manager located in Dubai, UAE, and a strong and fruitful partnership in Malaysia, enabling the market penetration for a completely different market than where GSES originally set its roots.

2023 has been an exciting year for GSES and its team, as a higher demand is felt due to the fast-approaching European Union’s sustainability reporting regulations. With significant and impactful clients such as ABN Amro, Johan Cruijff ArenA, or Zevij Necomij, and partners such as ABB Measurement & Analytics, GSES is

Sustainability | GSES

accelerating its mission and achieving symbolic landmarks. Stay tuned for what the rest of 2023 has in store for GSES.

What issue does your solution solve?

GSES saves organisations, suppliers, and product owners from the hurdles of reporting on their sustainability performance. Nowadays, it is becoming increasingly required to report on the environmental, social and governance (ESG) impacts of one’s business, products and supply chain. Moreover, it translates complex sustainability achievements into one ESG score that recipients can present to all their stakeholders in the most simple, transparent, and effective way. A common understanding of sustainability enables partnerships to be made and actions to be taken, in order to achieve a sustainable way of doing business.

An important solution GSES provides to its stakeholders is transparency, as its third-party auditing network – with all its members being accredited under their local board of accreditation – ensured an antigreen washing layer too-often omitted in the world of sustainability reporting.

Who is your solution aimed at? What does your perfect client look like?

Our solution is size/industry agnostic, and GSES can service more than 110 countries by facilitating third-party audits on the ground through its third-party auditor network and its partnership with Audit Independer.

A perfect client would be one who wants to commit to transparently reporting on its sustainability performance, whether because they are bound to regulations or wanting to be a front-runner in their field/ sector. Additionally, large corporations who must report on their supply chains in the years to come, or want to measure and present their scope 3 emissions, are an excellent fit to benefit from GSES’ solutions. GSES services a supply-chain dashboard to create a line of communication on sustainability metrics between buyers and suppliers, unlocking visibility and promoting sustainable procurement practices.

What is the biggest challenge GSES faces?

Challenges in the field of sustainability are numerous and must always be reassessed, so one manageable challenge is to stay aligned with the regulations and governance needs of our clients. Working closely with accountants, and experts, gives GSES the necessary tools to overcome the challenge of legislation and time changes.

Why pick GSES?

GSES’ USPs are the transparency and universality the platform enables, accurately reflecting our worlds’ societal status – one that is powered by globalisation and a greenwashed communication regarding sustainability performance. Additionally, our affordable membership schemes are allowing and helping companies get futureproofed and annually audited at the lowest prices on the market.

55 The Business Profile

Historic tender launched accelerate deployment of emission shipping

ZEMBA launched a Request for Proposals (RfP) for 600,000 twentyfoot containers (TEUs) over a threeyear period on ocean vessels powered by zero-emission fuels. Through this tender, ZEMBA will help its member companies reduce nearly 1 million metric tonnes of carbon emissions, equivalent to taking 215,000 cars off the road. The RfP is the first major buyer-led initiative to accelerate the transition to zero-emission maritime fuels in one of the most challenging sectors to decarbonize.

Amazon, Bauhaus, Brooks Running, Chewy, Electrolux Group, Flexport, Green Worldwide Shipping, IKEA, Levi Strauss & Co., lululemon, Meta, Moose Toys, New Balance, Nike, Patagonia, Philips, Schneider Electric, Sport-Thieme and Tchibo.

The ZEMBA RfP is seeking bids for shipping services, from individual carriers or consortiums, that achieve at least a 90% reduction in greenhouse gas emissions compared to traditional

ZEMBA was launched as a nonprofit membership organization in March 2023 by the Aspen Institute, Amazon, Patagonia, and Tchibo to fast-track commercial deployment of zero-emissions shipping services at scale, create a competitive market for these services, and help reduce emissions. For this first tender, ZEMBA has secured more than 20 members, including:

fossil fuels on a lifecycle basis. Fuel choice will address safety and land use concerns, particularly those that relate to biogenic substances. Delivery of shipping services powered by new, cleaner fuels is anticipated in 2025.

“Maritime shipping is an essential service for global companies like Amazon, and we

Sustainability | Zemba

launched to of zero

urgently need this sector to make clean fuel investments to reach our climate goals,” said Adam Baker, Vice President of Global Transportation at Amazon. “We are proud to be a founding member of ZEMBA because we need to collaborate to solve this massive challenge, and by working together, ZEMBA members can offer committed demand to make significant reductions in ocean shipping emissions.”

“Decarbonizing the global movement of our cargo requires collaboration. We know from experience that moving an industry cannot be done by individual companies but is best achieved by a collection of forward-thinkers who are ready to show the way, as leaders together,” said Paolo Galli, VP Group Logistics, Electrolux Group. “ZEMBA allows us to come together to advance a transition we cannot facilitate on our own, and show the entire value chain that we must have a zero-emission shipping solution that is affordable, scalable, and long-lasting.”

“Our ability to provide high-quality healthcare depends on a healthy planet. We have been carbon-neutral in our

operations since 2020 and continue to innovate and bring to market, scalable solutions to reduce both our own environmental impact and enable our customers to achieve their environmental sustainability goals,” said Robert Metzke, SVP and global Head of Sustainability at Philips. “ZEMBA is an innovative collaboration that provides a direct incentive to shipping companies to reduce their carbon emissions. It marks an important step as we work towards achieving our 2025 climate targets.” ZEMBA will consider bids that meet the following criteria:

n Sufficient capacity to cover ZEMBA members’ aggregate demand of 600,000+ TEUs across a distance of 6,000 nautical miles/~11,000 km over three years.

n Access to fuels that provide GHG emission reductions of at least 90% compared to traditional fossil fuels on a lifecycle basis.

n Transparent fuel lifecycle emissions to validate emission reduction claims. This will be enabled through rigorous

The Business Profile

Sustainability | Zemba

in-sector book-and-claim approaches that assure highly credible emissions reductions, while allowing companies to maintain reliable supply chains necessary for our global economy.

Through the RfP, ZEMBA will negotiate a “green premium” for the aggregated demand of its members. The green premium accounts for the added cost of operating a vessel using zero-emission fuels. Final contracting will be bilateral between ZEMBA members and the winning bidder. Additionally, as part of the RfP bidding process, ZEMBA is requesting vessel and fuel assurances from bidders. The winning bidder will also be required to provide third-party verification of the emissions reduction ZEMBA members can claim.

ZEMBA’s RfP is focused on stimulating a new marketplace for zero-emission fuels and deploying long-term, scalable solutions for the entire shipping industry. With this in mind, future RfP criteria for lifecycle emissions may move upward from 90% as technology innovation unfolds and sustainable fuels, infrastructure, and supply chains are implemented.

“This RfP is a significant milestone toward a zero-emission maritime future,” said Ingrid Irigoyen, President and CEO of ZEMBA. “With over 20 climate-leading companies engaging in ZEMBA’s inaugural tender process, and more to come, we’re building the business case for a surge of investment in zero-emission maritime solutions, including new fuels and technologies that are not yet commercially

available. Real leadership means taking action to solve problems, even the most challenging, and being willing to try innovative approaches. Advanced market commitments can be a game changer for harder-to-abate sectors like ocean shipping. I applaud our ZEMBA members for their leadership.”

ZEMBA’s RfP was developed in association with partners from Lloyd’s Register, a leading provider of classification and compliance services to the maritime and offshore industries, Neoteric Energy and Climate LLC, a specialized climate and energy advisory firm with experience running RfPs for the Sustainable Aviation Buyers Alliance (SABA), and the law firm of Pillsbury, as outside legal counsel.

ZEMBA is an initiative of Cargo Owners for Zero Emission Vessels (coZEV), a platform for cargo owners to work together toward a decarbonized maritime sector, facilitated by the Aspen Institute’s Energy and Environment Program. The coZEV 2040 Ambition Statement has united 19 global brands to date around an ambition to use zero-emission shipping for their ocean freight by 2040 exclusively. At COP27 in Sharm El Sheikh, Egypt, coZEV released the coZEV Roadmap to 2040 which outlined actions available to cargo owners to enable full decarbonization of their ocean freight by 2040. ZEMBA will make subsequent announcements in the coming months.

For more information, please visit www. shipzemba.org Interested bidders should email rfp.zemba@aspeninstitute.org.

With over 20 climateleading companies engaging in ZEMBA’s inaugural tender process, and more to come, we’re building the business case for a surge of investment in zero-emission maritime solutions, including new fuels and technologies that are not yet commercially available.

The Business Profile

Zalando SAP Joule Mastercard 60 | Technology

Technology

61

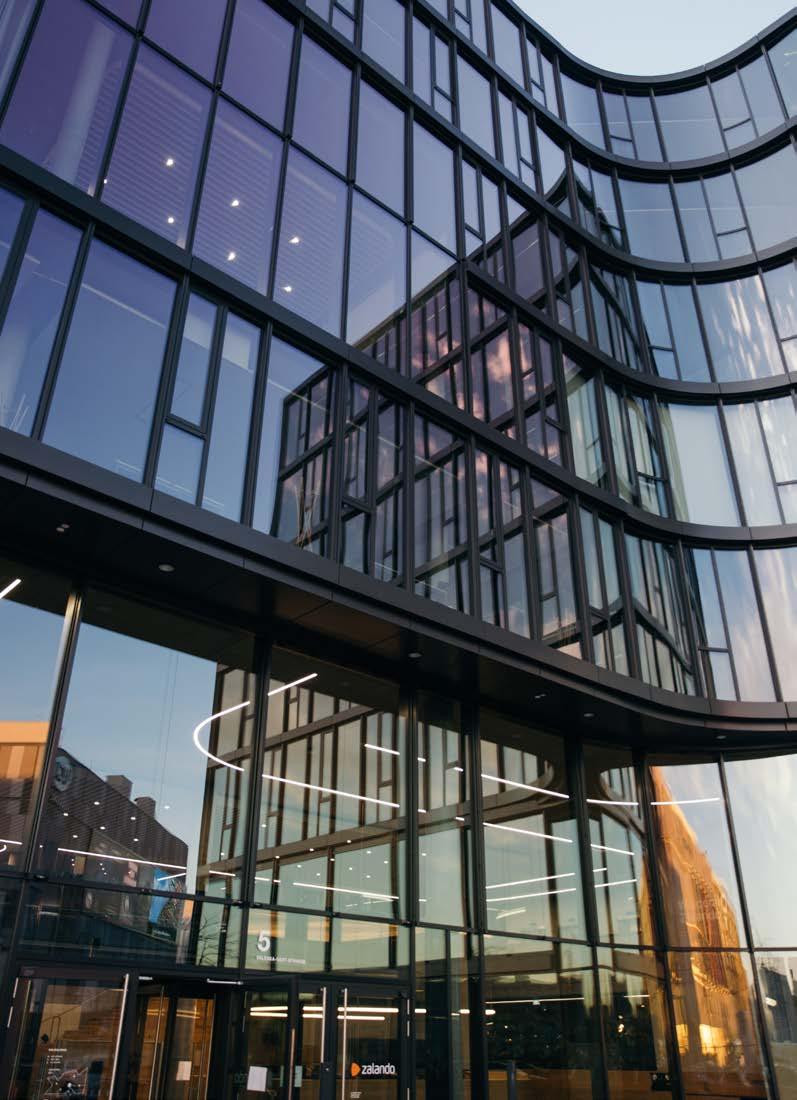

Data & Technology should drive procurement

Technology | Zalando

Alejandro Basterrechea is an award winning procurement executive, early stage investor and advisor to procuretech startups. Presently serving as Director of Indirect Procurement at Europe’s leading online fashion and lifestyle platform Zalando SE, Alejandro offers insight into why procurement should become a data and technology driven function. With reference to how Zalando alongside strategic partners such as Genpact are putting this into practise Alejandro offers the detail behind his beliefs.

Alejandro, tell us about your procurement journey?

I have more than 18 years of experience in different procurement roles across four different industries. I started as a Sourcing Manager for professional services in the semiconductor industry, where I learned the basics of strategic sourcing.