6-7-8 JUNE 2024 - INDEXPO 2024, CIDCO EXHIBITION CENTRE VASHI, NAVI MUMBAI. JUNE 2024 | Vol. 01 | Issue 5 | Pages 56

6-7-8 JUNE 2024 - INDEXPO 2024, CIDCO EXHIBITION CENTRE VASHI, NAVI MUMBAI. JUNE 2024 | Vol. 01 | Issue 5 | Pages 56

For the first time, Indore Infoline is bringing together Industrial & Engineering Expo (Indexpo) and Space Tech India Expo at one place in CIDCO Exhibition Center, Navi Mumbai from June 6-8, 2024. By hosting the two shows concurrently, the organiser aims to highlight manufacturing opportunities in the space arena and present participants a platform to explore new business avenues.

Maharashtra, the second most industrialised state in India, contributes significantly to the country's economy. It holds almost 20 per cent of India's industrial output and accounts for 46 per cent of the GSDP. With a GSDP of Rs 35.27 trillion ($440 billion) and GSDP per capita of Rs 242,247 ($3000), Maharashtra is the largest contributor to India's economy, representing 14 per cent of the country's nominal

GDP. Indore Infoline aims to further sharpen the state's

competitive edge by hosting the 45th Edition of Industrial & Engineering Expo (IndExpo) at

CIDCO Exhibition center, Navi Mumbai (Maharashtra) for manufacturers of plants, machinery & equipment, and Industry 4.0 manufacturing. The expo supported by All India Association of Industries will provide a platform to showcase latest technologies and products for various industries to help them in their progress.

Space Tech India Expo 2024, with the theme of

(Continued on page 12)

The Indian space technology market has the potential to reach $ 44 billion by 2033 from $ 9.6 billion in 2020. Experts now believe that this growth is possible with the changed FDI norms as it allows big companies to invest freely and explore new technologies.

Space technology plays a critical role in various sectors such as traffic management, crop monitoring, border security and missile defence. India’s private space sector has steadily grown following reforms in 2020 with the number of space startups operating in India increasing to 200 in 2024 from one in 2012. This indicates the untapped potential that the space domain has. Indian Space Research Organization (ISRO) along with the right policy environment that attract investments, and encourage entrepreneurs has played pivotal role in the growth of the space technology. Thus, the space industry offers a tremendous opportunity for the private sector in the country as a new area of growth and development.

The centre envisages the space industry in India the country to $910 billion industry in the next five to ten years from the current levels of $2 billion, said S Somanath, Secretary, Department of Space and Chairman of ISRO, during an event held recently.

In the last few years, space sector has witnessed a lot of developments at the policy level and on technological front.

After announcing its intention in June 2020, the Union government set up the space regulator, Indian National Space Promotion and Authorisation Centre (INSPACe), in October 2021. This was followed by the unveiling of the India Space Policy 2023 in April. The policy set the broad framework for nongovernment entities’ participation in areas like space vehicles, satellites, dissemination of data and setting up ground stations. FOREIGN

Source: ISRO

In March 2024, the government announced 100 per cent Foreign Direct Investment (FDI) in the satellites sector, aligning with the Indian Space Policy 2023, which aimed to attract investments, encourage private participation, and accelerate the space ambitions of the nation. Being a capital intensive sector, the FDI flowing into the sector will also encourage local capital. The new FDI norm is expected to facilitate the transfer of modern technologies, putting India’s space sector on the path of more selfreliance.

While earlier private firms were involved only in making components for ISRO, but now they are rubbing their hands in glee. There are over 400 Indian space companies — about half of them are startups (including two rocket manufacturers), which have attracted $330 million in investments in the last three years.

According to INSPACe, the Indian space economy has the potential to reach $ 44 billion by 2033 from $ 9.6 billion in 2020. Experts now believe that this growth is possible with the changed FDI norms as it allows big companies to invest freely and explore new technologies. In 2023, the private sector invested $ 12.5 billion in space companies globally. As India rises on the global scene, big part of future investment will come to the country's space segment.

Source: The Hindu Businessline Under the Aatmanirbhar Bharat

initiative, the government is providing incentives to enhance manufacturing activities in the country and increase efficiency of local industries. This initiative, along with new FDI norms, will make Indian manufacturers more competitive and market oriented; thus, providing them better opportunities to integrate into the global space industry. ISRO is also playing a big role in handholding many startups, which are bringing to the take revolutionary, out of the box ideas to the table. These collaborations between ISRO and startups are a winwin situation for both sides.

Startups aiming for the sky India has entered a new era of space research. In the earlier phase, big companies assisted ISRO with its designs. Now, in the new era, innovation is emerging from the private sector.Many start ups are pursuing business ventures in space technology sector. Here are a few of them:

SFO Technologies: SFO has worked with ISRO in multiple programmes such as the RF subsystems for Chandrayaan and Aditya Missions, manufacturing of Antenna Systems, and Cryogenic Engine Control Systems for launch vehicles.

Skyroot Aerospace: It was the first startup to partner with ISRO (Indian Space Research Organisation). ISRO also granted them access to their facilities and provided them with expertise to test subsystems and launch vehicles.

Dhruva Space: It is India’s first private space tech company offering scalable, modular satellite platforms for various missions in Low Earth Orbit (LEO) and beyond.

Agnikul: It is working on building Small Satellite Launch Vehicles (SSLVs) that can carry payloads to space. Its approach emphasises simplicity and costeffectiveness.

Bellatrix Aerospace: It is focusing on developing green propulsion systems for satellites and launch vehicles. Their innovations aim to make space travel more sustainable and efficient.

GalaxEye: Started in 2020, it

is engaged in building the next generation of earth observatory satellites.

3D printing: Adding value, reducing cost

In the recent years, companies are increasing using 3D printing (additive manufacturing) in the space tech landscape. Metal 3D printing makes sense when a few components need to be printed or parts are of extremely complex geometries. In space sector, number of components required will be low and they must be of highprecision. Additive printing fits in perfectly for this. For engines, certain aspects of the tank, or systems like mounts and structures within the vehicle, 3D printing is the ideal.

Additive manufacturing allows hardware changes at the speed of iterating software. This (hardware changes) is an extremely complex thing with conventional manufacturing, where each time one needs a new part, one must start with the mould, mount, and fixture. In 3D printing, nothing is required. Using the right CAD model, 3D printing machine can design and produce new components in quick time at reduced price.

Recently, ISRO made a breakthrough by testfiring new 3Dprinted rocket engine, which is used in the upper stage of India's Polar Satellite Launch Vehicle (PSLV). The new laser powder bed fusion technique used to make the engine has brought down the number of engine parts from 14 to a single piece. This eliminated 19 weld joints and saved significantly on the raw material usage per engine. The new process uses 13.7 kilograms of metal powder, for example, compared to the 565 kg of forgings and sheets needed with the conventional technique. The new process also reduces the overall production time by 60 per cent.

India’s space odyssey has just begun Globally, satellite manufacturing and launch are the most sought after domains by the private sector. They account for 84 per cent of all the infrastructural investment made in space. Increasing installation of small satellites by companies and constant demand for launch services from governments are the key drivers of this market. The size of the global launch market is expected to grow five times and reach $47.3 billion by 2032.

This presents significantly opportunity for India to improve its position in the space economy, which is only 2 per cent of the total global estimates.

and Space Tech Expo 2024: Aiding

: 1A, Sharma Compound, Old Nagardas Road, Andheri (E), Mumbai- 400 069. Email : mazdapharmaguide@gmail.com Web : issuu.com/themazdapharmaguide Edited, Published and Printed By Prakash Anjalekar, 1A, Sharma Compound, Old Nagardas Road, Andheri (E), Mumbai - 400 069. Maharashtra On Behalf of Owners

PUBLISHER Prakash Anjalekar

DIRECTOR - CORPORATE BUSINESS (GLOBAL) Kiran Raheja +91 9821270907

DIRECTOR - SPECIAL PROJECTS Prashant Pradhan +91 9820858917 CEO

Babu Sangle +91 9773223314

SUB EDITOR

Anurag More +91 8805308299

GENERAL MANAGER Zohra Rozani +91 9860066753

MANAGER - ADVERTISING Jagruti Shyam Das +91 9167827527

Shweta Sharma +91 8591440465

CUSTOMER SERVICE EXECUTIVE Priyanka Phalke +91 8108049982

Kajal Pandey +91 8692923757

Manasvi Patil +91 9137303001 Vandana Bhalerao +91 9082184602

GRAPHIC DESIGNER Jitendra Nate +91 8779345336

India is poised to achieve a green hydrogen production capacity of 5 million tonnes (MT) per year by 2030. This, along with the opportunities in other countries, will open up a $45-50 billion potential market for Indian hydrogen equipment manufacturers. Products like compressors, storage tanks, transformers, liquefaction units, air separation units, power systems, sensors and instrumentation, pipes, etc will be in demand. Here is a sneak peek into the market…

As India's economy grows, emissionintensive sectors pose a significant concern, notably power, steel, cement, and fertilizers, accounting for over half of the nation’s emissions. India aims to slash the emission intensity of its GDP by 45 per cent by 2030 from 2005 levels and achieve Net Zero by 2070. In the power sector, India plans to boost renewable energy capacity to 50 per cent by 2030, a move expected to notably cut emissions. However, challenges persist in sectors like steel and fertilizers, demanding exploration of alternative avenues to reduce emissions while increasing production. Among the most promising options is the utilization of green hydrogen.

The green alternative Currently, India's hydrogen consumption is estimated at about 6 million metric tonne per annum (MMTPA) with about 3 MMTPA being used in oil refineries (for desulfurisation of fuels), 2.5 MMTPA in production of ammonia (for urea & other fertilisers), and remaining quality consumed by steel & chemical industries. At present, India's 3 MMTPA of hydrogen is consumed by refineries having total refining capacity of 250 MMTPA. With refinery volumes expected to increase by 56 MMTPA by calendar year (CY) 2028, hydrogen requirement would reach about 4.5 MMTPA in the refineries, as companies look for ways to further remove sulfur from the fuel in line with the government's mission to reduce pollution.

Traditionally, hydrogen production has heavily relied on fossil fuels like natural gas or coal, primarily through methods such as steam methane reforming and coal gasification. These techniques are predominantly used in the production of hydrogen for applications like ammonia production in the fertilizer industry.

However, a transformative alternative lies in green hydrogen, sourced from renewable energy such as solar, wind, or hydro. Produced through electrolysis, green hydrogen is generated by passing direct current through water, splitting molecules into individual elements and producing hydrogen at the cathode.

In 2023, the MNRE initiated the National Green Hydrogen Mission, rolling out the Strategic Interventions for Green Hydrogen Transition (SIGHT) program. Its goal is to establish a manufacturing base for electrolyzers and green hydrogen production facilities. Component 1 of

SIGHT entails an allocation of Rs 4,440 crore for electrolyzer manufacturing from FY26 to FY30, while Component 2 is allocated Rs 13,050 crore for green hydrogen production during the same period.

Budget Allocations Under the National Green Hydrogen Mission Segment Allocation Strategic Interventions for Green Hydrogen Transition (SIGHT) programme

Rs 17,490 crore

Pilot Projects Rs 1,466 crore Research and Development (R&D) Rs 400 crore

Other Components of the Mission

Rs 388 crore

Total Rs 19,744 crore

In total, SIGHT offers a financial incentive of Rs 17,490 crore, aiming for rapid scaleup, technology advancement, and cost reduction. The State run Solar Energy Corporation of India (SECI) oversees implementation. The overarching mission aims to position India as the global hub for green hydrogen production, utilization, and export.

India is poised to achieve a green hydrogen production capacity of 5 million tonnes (MT) per year, alongside adding approximately 125 gigawatts (GW) of renewable energy capacity, thereby reducing reliance on fossil fuel imports. Meeting the Mission's objectives is projected to save a cumulative Rs 1 lakh crore in fossil fuel imports by 2030.

The targeted production and utilization of green hydrogen are anticipated to prevent nearly 50 MT per year of CO2 emissions. In August 2023, the government established standards for green hydrogen, stipulating that it must be generated using renewable energy, with non biogenic carbon emissions not exceeding 2 kg CO2 equivalent per kg of hydrogen.

Hydrogen equipment market India has awarded tenders for setting up 412,000 tonnes of green hydrogen

manufacturing and 1.5 gigawatts (GW) of electrolyser manufacturing capacity, according to the Ministry of New & Renewable Energy (MNRE), Government of India (GoI). India has an advantage in the green hydrogen production, particularly as a country with one of the cheapest sources of renewable energy. India is leading the charge towards a more inclusive and environmentallyconscious energy landscape, said MNRE Secretary Bhupinder S Bhalla, while addressing the World Hydrogen Summit 2024 in Netherlands on May 15, 2024. The expanding green hydrogen market offers significant business opportunities for equipment manufacturers. The India Hydrogen Alliance (IH2A) estimates that the market for Indian manufactured hydrogen equipment could reach $4550 billion by 2030. This assessment encompasses all equipment used in hydrogen production plants, including electrolyzers and balanceofplant (BoP) equipment, which can be both deployed in and exported from India, positioning the country as a supply chain hub for future green hydrogen projects. BoP equipment encompasses a range of products such as compressors, storage tanks, transformers, rectifiers, liquefaction units, air separation units, dispensing units, power systems, sensors and instrumentation, as well as pipeline and evacuation infrastructure.

Electrolyser stacks are expected to constitute 34 per cent of the hydrogen equipment market, while BoP equipment and specialist engineering services are projected to account for 62 per cent and 4 per cent, respectively. IH2A anticipates the domestic market for hydrogen production plant equipment to reach $9 billion by 2030, with an estimated 135 domestic plants set to be established by that time, boasting an annual electrolyser capacity of 6.8 GW. These plants are projected to produce and deliver at least 1 MMT of green hydrogen domestically for industrial use, including in refineries and steel production (in compressed gaseous form), as green ammonia for fertilizer feedstock, and as liquid hydrogen for heavyduty transport.

IH2A believes that Indian made electrolysers and balance of plant equipment have a potential export value of $34 billion, with these products expected to be utilized in an estimated 540 green hydrogen projects across the Asia Pacific (APAC), Middle East (ME), and Africa regions.

The export potential of hydrogen equipment is substantial for India. The market for BoP (Balance of Plant) equipment exceeds that of electrolyser stacks, highlighting the importance of India becoming the preferred supplier for essential hydrogen projects in the region over the coming decade. This presents an opportunity for collaboration among the government, industry, and investors to leverage India's competitive edge in industrial manufacturing and engineering expertise to its benefit.

Challenges for green hydrogen industry

The Indian green hydrogen market is projected to soar to $10 billion by 2030 and $35 billion by 2040. Governmentowned refiners are initiating green hydrogen projects, aiming to add 0.43 MMTPA of green hydrogen volumes by CY2030. According to the Emkay report, transitioning to green hydrogen from gray could incur a $3 per barrel cost to India's refining sector in gross margin. Therefore, refinery adoption of green hydrogen, starting around FY26, will likely proceed cautiously, initially blending gray and green hydrogen.

In addition to cost, there are other obstacles such as space constraints in refineries and challenges related to establishing renewable energy and electrolyzer capacities, hindering the adoption of green hydrogen.

Experts anticipate a significant increase in adoption as the cost of green hydrogen approaches that of gray hydrogen, expected by CY2030. Achieving a green hydrogen production of 3 MMTPA by then would necessitate setting up 36 GW of electrolyzer capacity and 75 GW of effective renewable energy capacity. The Emkay report suggests that meeting the CY30 targets remains feasible, considering the commissioning periods for solar and wind farms and electrolyzers. Alkaline electrolyzers are favored in the report's predictions, though other technologies could gain a larger market share if unit economics improve.

Transitioning to green energy

(Continued on page 12)

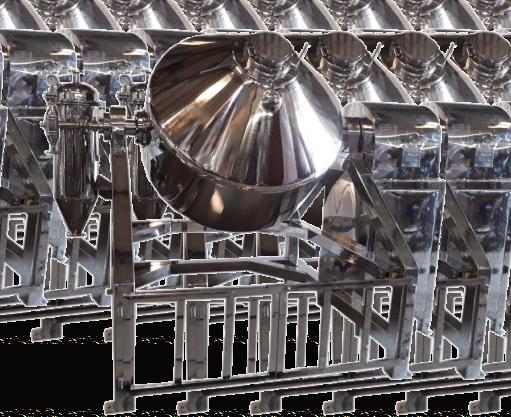

Leveraging on its industrial experience and robust infrastructure, Uma Chem Pharma Machineries has designed fluid bed dryers that are known for single stage operation and extensively used to convert solutions, suspensions, and slurries into dry powder within a few seconds without any intermediate handling. The high speed of the process and controlled temperature ensure the optimum efficiency of the process. The fluid bed drying technique is deal for the rapid, even drying of chemical, pharmaceutical and food products. The material may be in granules, powder or crystalline form. Normally, an initial moisture content upto 20% is ideal but materials with higher initial moisture content can be dried successfully. These dryers have features like uniform drying, safe earthing system, and fan motor unit (which can be placed in remote areas). They come with PLC based control panel and offer benefits like short drying time, minimum handling and are more hygienic. Besides, these fluid bed dryers can be customised and have features like bowl (which can be provided with vacuum conveying), flame proof system, HMIbased operator panel, cleaninplace (CIP) system, etc. These dryers are available in standard and GMP model, and 5 kg to 500 kg batch capacity.

Contact:

Uma Chem Pharma Machineries, Plot No J115, MIDC, Tarapur, Boisar, Dist Palghar (Mumbai) 401 506 • Mob: +91 95039 50649 • Tel: +91 2525 661083, 661088 • Email: hprasaduma@gmail.com, accounts@ucpm.co.in

(Continued from page 10)

Jetcotech Engineering has introduced perforated cable trays with optimum quality. Cable trays are highly acclaimed in the market for supporting different types of insulated cables. Further, these cable trays are manufactured using quality approved raw material and progressive technology in the supervision of its skilled professionals. Owing to their various quality attributes, these trays are widely used in various segments like industrial, infrastructure, mega projects (urban, commercial & residential), etc. Perforated cable trays made & finished with as per standards, which are fulfil all specifications as per costumers needs and used internal as well external too. Raw materials used for these trays are mild steel, pregalvanised, stainless steel 304, and stainless steel 316. For finishing, hot dip galvanized, pregalvanized, powder coated, SS 304 and SS 316 are used. They have features like maximizes ventilation, easy installation, corrosion resistance, rigid structure, high capacity, high strength, superior quality, precisely designed with cover & without cover, etc. Perforated cable trays are suitable for all applications and environments including marine environments and chemical processing factories.

Contact:

Jetcotech Engineering

Opp. Old Pipli BusStation, Jetpar Road, Morbi 363 642, Gujarat • Mob: +91 75750 07114

Email: marketingjetcotech@gmail.com, sales@jetcotech.in

India has the potential to become a regional supply hub for hydrogen production plants, capitalizing on its competitive edge in engineering design, manufacturing, and services. Leveraging its lowcost manufacturing base, India can emerge as a global production hub for green hydrogenrelated equipment and systems. However, to realize this

(Continued from page 1)

potential, companies need to invest in the right technologies to enhance their manufacturing capabilities in electrolysers and balance of plant equipment, thereby generating significant export revenue and establishing India as a supply chain leader. The projected $50 billion market indicates the possibility of creating 1520

green hydrogen equipment manufacturing companies (both public and private sectors) in India, each with estimated revenues of $2 billion. This presents a significant opportunity that necessitates largescale manufacturing build out and investments, particularly in electrolyser stack manufacturing and balance of plant equipment. Before committing

"Transform Space Technology into Manufacturing", will be a concurrent show.

Magnificent Maharashtra Maharashtra is a major player in exports, holding a share of 17.3% in India's total exports. Maharashtra boasts a strong infrastructure, including numerous airports, seaports, and extensive power production capacity. It houses 289 industrial complexes across 2 lakh acres and various specialized parks for different sectors like wine, silver, and textiles. Additionally, Maharashtra is home to 27 IT parks and 9 SEZs.

Being a hub for skilled labour, Maharashtra is an attractive destination for knowledgebased and manufacturing industries. In the fiscal year 202223, the state witnessed a significant increase in new investment projects, amounting to Rs 3,92,557 crore. The private sector alone announced investment projects worth Rs 287,433 crore, marking substantial growth compared to the previous year.As a frontrunner in the IT &ITeS sector, Maharashtra contributes over 20% to the country's software exports. With Mumbai being known as India's financial and entertainment capital, it is poised to transition into a prominent 'tech capital' in the foreseeable future.

The Maharashtra Government has sectorspecific policies designed to attract

investments by offering facilitation and incentives. They emphasize skill development, with the government subsidizing training costs for employees.In 2023, the state government introduced targeted policies for IT and exports. They are also working on policies for the leather products & footwear, circular economy, and MSME sectors.

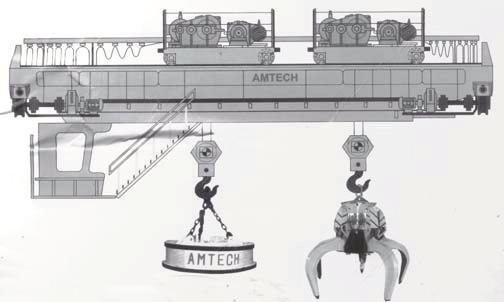

A new logistics policy is in progress, focusing on a state master plan that will incorporate district logistics nodes, mega hubs, and multimodal logistic parks to enhance Maharashtra's logistical network and reduce transportation costs. Maharashtra is home to over 34 lakh registered MSMEs, employing over 1.37 crore individuals. Schemes aimed at women have boosted female participation in MSME units, with women leading over 19% of them. The Raising and Accelerating MSME Performance (RAMP) initiative, supported by the World Bank, aims to assist over 1,00,000 MSMEs and encourage greenfield and brownfield MSMEs in Maharashtra. IndExpo 2024 will provide an opportunity to companies in Maharashtra for knowledge sharing, to learn about emerging trends and upgradate their manufacturing facilities with latest technologies. Exhibitors from industries such as machine tools, boilers/heaters, pollution control, fabrication, industrial automation & robots, instrumentation, lab equipment, laser technology, material handling

equipment, electrical & electronics, UPS & batteries, auto components, solar equipment, etc will participate in the expo.

Launchpad for Space Tech Expo India is going to be the world leader in the field of space technology. The success of Chandrayaan3, Mars Mission and many more space missions has provided a cuttingedge benefit to the countries space missions and manufacturing.Space technology includes space vehicles such as spacecraft, satellites, space stations and orbital launch vehicles; deepspace communication; inspace propulsion; and a wide variety of other technologies including support infrastructure equipment, and procedures. A high level of precision and expertise required in space technology. Now, this space technology knowledge is used for the benefit of the mankind and industry and the growth of the country. Space Tech India Expo will bring together the suppliers of components & parts and space technology companies on one platform presenting them a good opportunity to explore new business avenues. Exhibitors participating in SpaceTech zone will be Space Craft and Shuttles, Propulsion Fuel, Laser / Space Communication, Space Automation, Telescopes, Quantum Computing, Satellites and Launching vehicles, Testing Equipment, geared motors & actuators,

substantial capital investments, project developers and equipment majors are awaiting government initiatives on demand aggregation and secured offtake for early projects. However, the estimated $45 50 billion equipment market opportunity is achievable and has the potential to transform India into a global supply chain hub in the burgeoning green hydrogen economy.

robotic welding, drones, 3D Printing, AL/VR, data Mining and Processing, etc.

In 2017, Maharashtra became the first state to formulate an Aerospace and Defence Policy by creating a Rs 1,000 crore fund through angel investment. Today, this fund has led to the formation of 600 MSMEs, who are working towards selfreliance in aerospace and defence (A&D) equipment sector. Now, the Maharashtra government is in process of revising this A&D Policy to further enhance the success of MSMEs. At the same time, the state government plans to have four defence manufacturing clusters at Nagpur, Shirdi, Pune and Ratnagiri.

Space Tech Expo will bring together all the stakeholders to discuss collaboration to establish a supply chain for A&D manufacturing.

Maharashtra's industrial prowess is unrivalled. The state is strategically poised to lead the charge towards India's $5 trillioneconomy dream. Exhibitions like Industrial & Engineering Expo will be the right avenue to chart the new roadmap to attract investment in manufacturing. By hosting the two shows (IndExpo and Space Tech) concurrently, the organiser aims to highlight manufacturing opportunities in the space arena and present participants a platform to explore new business avenues.

KPT Pipes' Greentherm pipes also known as polypropylene random copolymer (PPRC) thermoplastic pipes are used in various heating and cooling systems. Because of their durability, flexibility, and strength, these pipes are a fantastic choice for many systems. They are used in industrial operations, particularly in the petrochemical and chemical sectors, as well as HVAC systems, geothermal systems, solar thermal systems, and other systems. As these PPR pipes & fittings are lightweight, flexible, and easy to install, these pipes are appropriate for restricted spaces or around obstructions. Due to their excellent resistance to UV radiation, thermal expansion and contraction, and corrosion, they are also wellsuited for use in adverse environments. They are environmentally advantageous since they are recyclable.The distinctive feature of Greentherm pipes is that they are constructed from a robust, highdensity polyethylene substance that can tolerate extreme temperatures and pressures. They are a fantastic choice for outdoor and industrial use because they are UV and corrosionresistant. Greentherm pipes are also simple to install and maintain, which might eventually save energy expenses. Because they are made of recyclable material, they are also ecologically beneficial. Thanks to this feature combination, they are a flexible and reliable alternative for a range of heating and cooling applications. Greentherm pipes are highly resistant to various acids and bases. These pipes suit industrial cooling water, drinking water systems, and extremely corrosive locations. These pipes and fittings may handle up to 20 kg/sqcm. It is perfect for highpressure uses like compressed air lines. The pressure loss is less than metallic pipes due to the highly smooth, nonporous inner surface of the pipes and fittings, which results in significant pumping energy savings. Capable of withstanding 95°C, it is the best pipe for solar applications to transport heated water. According to DIN 1998 T2, KPT PPRC pipes are certified foodgrade pipes. They are the best plumbing system for RO plants, DM Plans, and drinking water. KPT PPRC pipes are nontoxic during a fire, in contrast to PVC pipes. PPRC is a recyclable material. The KPT PPRC pipe system has properties quite similar to SS. KPT PPRC pipes will be superior to SS for the demands of the particular application.

Contact: KPT Pipes, Unit No 306, PP trade Center, Plot No P1, Netaji Subhash Place, Delhi 110 034, Mob: +91 81784 02742, 93549 40961 • Email: info@kptpipes.com

Tinita Engineering Pvt Ltd manufactures tantalum heat exchangers, which have low investment and run for longtime with low maintenance costs. Tantalum heat exchangers are mainly used in highcorrosive environments in the chemical and pharmaceutical industries and are highly corrosionresistant to hydrochloric acid, nitric acid, phosphoric acid, strong organic acids, bromine and their mixtures. Tinita tantalum heat exchangers are used in industries like photovoltaic, corrosive chemicals, polysilicon, metallurgy and mining. The increasing life expectancy, reduce downtime and profitability are all important factors for selecting tantalum heat exchangers. These heat exchangers are welded fully and won't get the leak. Tantalum heat exchanger is cost effective as compared with ceramic and graphite heat exchanger and with PTFE. There the elimination of downtime is seen because of equipment failure. There no spare parts are needed for keeping in inventory. It is offering excellent corrosion resistance property. This heat exchanger offers greater heat transfer values. It too eliminates the crosscontamination of the process fluids.Tinita Engineering offers tantalum heat exchangers such as tantalum R05200 shell & tube heat exchanger; tantalum U tube bundle heat exchanger; tantalum grade R05252 coil type heat exchanger; tantalum double type heat exchanger; tantalum R05255 double tube heat exchanger; tantalum grade R05252 floating heat exchanger; tantalum R05200 lined heat exchanger; tantalum grade R05200 cladded heat exchanger; tantalum grade R05200 process heat exchanger; etc.Along with tantalum shell & tube heat exchanger, Tinita Engineering also manufactures custom and fabricated products in tantalum such as tantalum autoclave reactors, tantalum cladded reactors & vessels, tantalum columns & towers, tantalum alloy pipe & pipe fittings, and tantalum tanks & vessels.

Contact:

Tinita Engineering Pvt Ltd, R266, Rabale MIDC, T.T.C. Industrial Area, Navi Mumbai 400 701, Maharashtra • Tel: +91 22 5044 1001 • Email: tinita@tinita.in

TriSure closures and packaging components

Moonlight Tube Industries manufacturers a qualitative range of stainlesssteel welded tubes and pipes that are being designed as per the national and international standard quality of raw materials. The company's stainless steel ERW pipes have an amazingly enhanced formability and can be welded in the course of superior grace by all standard means. These products are used in various industries such as paper, textile, sugar, dairy, cement, engineering, oil refining, petrochemical, gas & chemical processing, power generation, nuclear, etc. Adherence to high level quality standard is monitored with the help of sophisticated inspection facilities available inhouse. This includes hydrotesting, NDT using magnetic flux, ultrasonic & Eddy Current testing and laboratory testing of microstructure, tensile, impact, hardness etc.

Contact:

Moonlight Tube Industries, Office No. 1203/1204, 12th Floor, Prasad Chambers, Tata Road No.2, Roxy Cinema Opera House, Girgaon, Mumbai 400 004 • Tel: +91 22 6743 8307

Email: moonlighttube@gmail.com, hbb@moonlighttubes.com

Contact Person: Mr Hemant Bhansali, MD (Mob: +91 94084 96996)

CM Pumps & Systems Pvt Ltd manufactures sealless magnetic drive centrifugal pumps for industries such as chemical, pharmaceutical, petrochemical, refineries, water treatment plant, metal processing, recycling, refrigeration, etc. The company offers a wide range in magnetic drive centrifugal pumps according to DIN EN 22858/ISO 2858 Standards. Magnetic drive pumps are typically used where leakage of the pumped liquid poses a great risk such as with aggressive or risky liquids, exotic materials, acids, alkalis, corrosives, pollutants and toxics. They are also used for ultrapure liquids and hardtoseal liquids. CM Pumps offers 2 types of sealless magnetic drive chemical process pumps CZ Series (SS magnetic drive chemical process close coupled pump) and CZB Series (SS magnetic drive chemical process). It also offers PFA lined magnetic drive pumps CZ Series and CZB Series.

Contact:

CM Pumps & Systems Pvt Ltd Unit No. 10, 1st Floor, ShamrozIndl. Estate, Ram Mandir Road, Opp. Movie Star Cinema, Goregaon (W), Mumbai 400 104, Maharashtra • Tel: +91 22 2676 4504/05 Email: info@cmpumps.com, cmpumpsystems@gmail.com

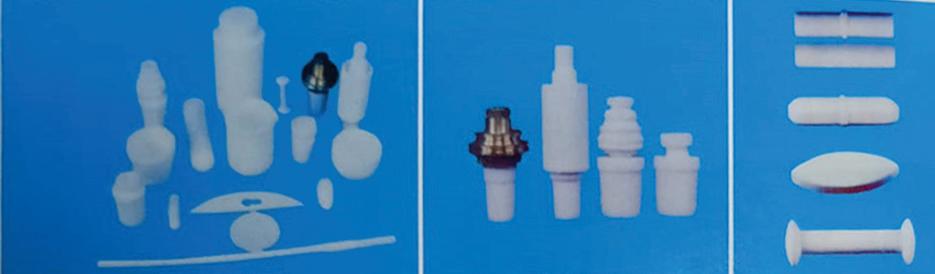

Balmer LawrieVan Leer Ltd's TriSure is a global leader in industrial closures and packaging components. Throughout the world, hundreds of millions of containers are secured with its closure systems, which have been developed and enhanced in conjunction with drum manufacturers, fillers, reconditioners and users. Universally recognised as the world’s most secure closure, the TriSure closure system provides total protection and security for all industrial drum packaging applications. These closures are engineered and manufactured as a total system consisting of the components such as Octagonal Flanges, Flage Washers, LabelRings or Liners, PlugWashers, Plugs, and TabSeal Caps. This unique system is designed to ensure ease of application and maximum security in drums of material thickness from 0.6 mm to 2 mm. Standard TriSure plugs and flanges are made from mild steel and can be supplied in a range of finishes for maximum product compatibility. After the plug has been securely tightened, the closure is completed using the tamper evident TriSure TabSeal cap. This provides the final level of protection sealing the contents from leakage, tampering and pilferage.

The TabSeal cap is crimped on either by hand or pneumatically operated TriSure sealing tool. Customers with automated filling lines can take advantage of a flexible pneumatically operated sealing tool which is available to TriSure closure users around the world. Each component in the Tri Sure closure system is totally interchangeable. Replacement parts are available without the need to replace the entire closure system. TabSeal Caps can be supplied in plain colours or printed with the customer's logo or message.

Address: Balmer LawrieVan Leer Ltd, D195/2, T.T.C. Indl. Area, Turbhe, Near Turbhe Telephone Exchange, Navi Mumbai 400 705, Maharashtra • Tel: +91 22 6739 6400

Email: response@blvlindia.com

A flame arrestor is used to prevent the propagation & transmission of flame generated in the line from an unprotected side to the protected side of a flame arrestor but at the same time to allow the vapours to pass to the protected side. Flame arrestors are installed on the vents of storage tanks and vessels or in process lines where flammable gases are being transferred. Amarama Engineers manufactures flame arrestors according to ISO:16852,IS16485(ISO:16852), IS:11006 & IIB3, International Electro Technical Commission code IEC 600791:2007. Arrestor Bank, which is the heart of the flame arrestor, consists of finely crimped metal ribbons to form a corrugated element which is easily maintainable & replaceable. The corrugated gap i.e. the Maximum Experimental Safe Gap (MESG) depends upon the gas group IIA1, IIA, IIB1, IIB2, IIB IIB3, IIC of the solvent / material. Amarama Engineers maintains the MESG according to ISO:16852 and IEC 600791 for various gas explosion groups like IIA1, IIA, IIB1, IIB2, IIB3, IIB & IIC. There are two types of flame arrestors end of line type (used for above ground storage tanks) and inline type (used for underground storage tanks, reactor vents and in continuous process lines).The company manufactures deflagaration& detonation flame arrestors for diesel, solvents, resins, polymer, corrosive atmospheres which are used across the process industries like pharmaceutical, paints, speciality chemicals, petroleum, FMCG, etc. The company also provides the customer with assistance in sizing and selection of flame arrestors according to API 2000.Flame arrestors have key features such higher flame quenching area; finely crimped arrestor element; replaceable arrestor element; SS weather hood for end of line flame arrestors; bidirectional; easy maintenance; solutions for highly corrosive atmospheres; flow test conducted at Fluid Control Research Institute, Palakkad; lesser pressure drop; etc.

Contact: Amarama Engineers EL68, Electronic Zone, Mahape MIDC, Navi Mumbai 400 705, Maharashtra • Mob: +91 85918 48579, 86570 00280 • Email: sales@amaramaengineers.com

The composite glass and metal material of Aditya Glass Line's glass lined vessels delivers the advantages of both main components. Besides, the outer steel structure provides strength while the internal lining provides nearly global corrosion resistance as well as a seamless noncontaminating surface. The outcome of this kind of integration is lifted corrosion resistance to varied bases and acids. These vessels additionally deliver resistance against lifted operating pressures and temperatures. Glass lined vessels have capacity to remove or add heat to the batch. The procedure of integrating material include the glass combination to the steel. Some of the glass lined vessels offered by Aditya Glass Line are glass lined reactor (for pharma and distillation unit), reglass lining, glass lined industrial pan, etc.

Contact:

Aditya Glass Line

Road No. B18, Plot NoA2439/1, Phase IV, GIDC Estate, Vitthal Udyognagar, Anand (Gujarat) 388121

Mob: +91 80372 61499

Contact Person: Mr Hardik Patel (Proprietor)

L&T Valves offers a range of customised SIL 3 capable High Integrity Pressure Protection Systems (HIPPS) for overpressure protection that leverages our expertise of over five decades in flowcontrol and system integration. In industrial plants, flammable gases released by pressure relief valves during unplanned overpressurization is primarily flared. Flaring and venting pose health and safety hazards and constitute a significant source of greenhouse gas emissions. High Integrity Pressure Protection System (HIPPS) is a Safety Instrumented System (SIS), which by definition is a distinct, reliable system used to safeguard a process to prevent a catastrophic release of toxic, flammable, or explosive chemicals. HIPPS can be employed to prevent overpressurization of a plant by shuttingoff the source of the highpressure gas rather than by releasing it to the

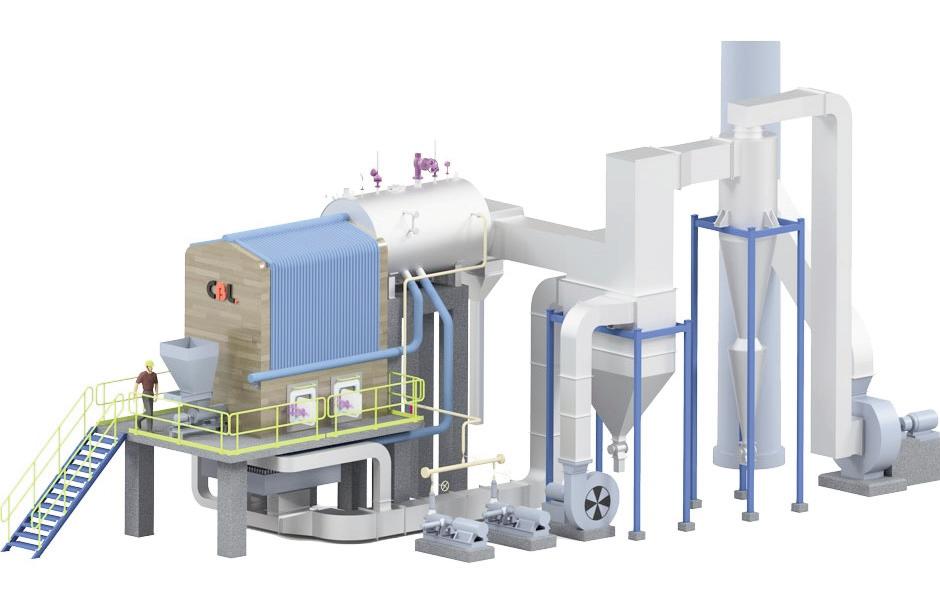

Cheema Boilers Ltd's (CBL) HYPAC is proficient and economical boiler, which combines the benefits of water tube and smoke tube design. It is easytooperate & environment friendly, and has high thermal efficiency & low operational cost. HYPAC has versatile design for use with different fuel types and as a multifuel firing unit. Its smoke tube portion has a large water holding capacity along with a large watersteam interface area. This ensures 98% steam dryness inspite of load fluctuations. The extended height in the furnace enhances efficiency and increases longevity. CBL HYPAC is designed to offer the users the most efficient and hasslefree operations. Apart from being the most economical option, its functioning is designed to increase the effectiveness of the operations achieving economies of scale and generating higher returns. It ensures low fuel consumption because of minimum heat loss (due to membrane type water wall design); most efficient combustion with an optimum residence time of flue gases in the furnace; better heat transfer and longer tube life (due to optimum velocities in smoke tubes); variable frequency fuel feeder (VDF) for complete combustion of fuel; and swirling air injection for better postcombustion burning of fuel. HYPAC is environment friendly as it is most suitable for renewable fuels, its cyclones are provided with antiabrasive filling for long Life, its highefficient furnace ensures complete combustion; has an efficient heat recovery unit, etc. Multiplefuel options making HYPAC an ideal investment.

Contact: Cheema Boilers Ltd Industrial Plot No D188, Phase 8B, Sector 74, Mohali (S.A.S. Nagar) 160 071, Punjab Tel: +91 172 509 0487, 505 5666 • Email: marketing@cheemaboilers.com

atmosphere. This system closes the source of overpressure within seconds and has at least the same reliability as a safety relief valve or flare system.

A typical HIPPS system comprises the following:

• Three pressure sensors (2oo3 voting) that detect the over pressure in the line

• A logic solver which receives and processes the input signal from the sensors and transmits the output to the Solenoid Valve in the final element.

• A final element (Actuated Valve) which perform the emergency closure action via a Solenoid Operated Valve (SOV) to bring the process to a safe state. Typically, 3 SOVs are

• used a manualreset SOV (M), an autoreset SOV (A) and one for Partial Stroke Testing (PST).

Fuji Electric is the leading Japanese Process Automation Solutions provider for variety of industries like Steel, Cement, Power, Boiler, Water and Waste to Energy (WtE) applications. Fuji automate process plants using their extensive domain knowledge to achieve stable operation with minimal maintenance by providing both highspeed control and monitoring while using optimal control technologies to achieve efficient operations and energy use.

Contact: Fuji Electric India Pvt Ltd 119, 120, 120A Electrical and Electronics Industrial Estate Perungudi, Chennai 600 096 Mob: 78100 09955 • Email: enquiry.fei@fujielectric.com

Empire Cables supplies control cables that are used for control circuits in power plants and other similar industrial installations and signaling network of railways, with or without FR/FRLs properties in sizes normally up to 61 cores. Voltage grade is 650/1100 volts (Uo/U); and provided with ISI marking against IS 1554 (Pt1). The cables conforming to standard specifications like IS 1554 (Pt1), BS 6346, IEC 227, etc. Configuration: Multicore/Multipair. Construction: Conductor – solid/stranded, circular annealed, bare/tinned copper wire of 1.5 sq mm, 4.0 sq mm. Insulation is PVC, and fully color coded cores. Core identification by printed numerals/letters is also available on request. Screening by copper braid or aluminium mylar tape of aluminium wire for reinforced armour types. Drain Wire of solid/stranded, bare/tinned copper wire normally provided. Mechanical protection: Galvanized steel wire or strip for double helical steel tape armour; Inner and outer sheath.

Contact: Empire Cable Industries (P) Ltd Plot No: 115, PhaseII, Badli Industrial Area, Delhi 110 042 Tel.: 011 – 2387 4632 • Fax: 011 – 2386 1610 Email: empirecables@yahoo.co.in

Innovus Cleanroom Technologies offers cleanroom wall and ceiling solutions for industrial use. The company has developed modular cleanroom partition products for use by, and in conjunction with leading cleanroom designer and end users. Clean room systems from Innovus can be applied to any clean room facility or manufacturing setup requiring controlled environment. These systems can be integrated with new as well as existing systems. Modular & simplified construction methods are used for reducing overall construction time and cost. Connection between partition and existing fabric will utilise its preformed closing channel and special detail can be produced where required, again with various coving options available to meet specification. Integration between partition head and ceiling is achieved by utilisation of standard top channel together with various coving option, if required. The partition walls can be designed to facilitate and incorporate the various design principles, utilised in laminar and non laminar airflow cleanrooms. Cleanroom ceiling system is mainly composed of modular cleanroom panel and ceiling system. The ceiling system can be perfectly connected with the modular cleanroom panel system products. The ceiling system connection gap is the same as the gap width to ensure the appearance of a clean room. cleanroom panel sheet is very resistant to bending and has very strong characteristics. The ceiling membrane is of vital importance to the integrity and performance of any cleanroom. The concept of ceiling can vary from simple suspended layin grid types to sophisticated ‘Walk on construction plenums.The INNOVUS ‘Walk on ceiling’ is a product that offer amazing option in creating custom and system build solutions the most complicated of enclosures for the demanding environments of the cleanroom users. Subject to specifications, each plank will hold a superimposed load of 25Kg/m2 together with point load 100 kilos.

Contact: Innovus Cleanroom Technologies , Plot No: 81, Yogi Estate 4, Post – Jitali, Ankleshwar, Bharuch 393002, Gujarat • Mob: +91 93275 92055, 87806 27792 • Email: info@innovuscleanroom.com, innovuscleanroom@gmail.com

DavsGemini Valves Pvt Ltd offers the both unidirectional and bidirectional knife edge gate valve for industrial as well as commercial applications. These knife edge gate valves, which are available in different sizes and specifications as per customer’s requirements, are maintained for long time period due to their quality features. Valves are tested for parameters like performance, durability, flexibility, material quality, working pressure and heat resistance. Knife edge gate valves, manufactured in compliance to meet the international standards, are economical as it requires less maintenance. These heavy duty gate valves cut through the high viscous liquids, slurry, corrosive/abrasive media and solids. In many industries like mining, oil & gas, chemical, power plant, paper & pulp, highquality knife edge gate valves are used for the viscous media handling, paper stock lines, dry solid and powder handling, slurry lines, shut off/on suspended solids and many more. They can withstand high temperature and abrasive slurries in such industries. These valves come with features like highly durable, reliable and portable, longer life service, anticorrosive, light weight, low operating torque, simple design, and leak proof body & seal. They find applications in wastewater treatments, slurries, dry ash, chips, viscous liquids, and suspended solids.

Contact:

DavsGemini Valves Pvt Ltd, A Wing, FL03, Sahil Residency, Plot No.17 Sector No.09, Near Spine City Mall, PCNTDA, Moshi, Pune 411035, Maharashtra Mob: +91 99232 08816, 98903 17654 • Email: enquiry@davsgeminivalves.com

VEGA India offers new 6X radar level sensor, VEGAPULS 6X, for highprecision and accurate measurement. A radar sensor that doesn’t care if it's measuring liquids or bulk solids. With VEGAPULS 6X, the user gets a sensor that can handle any application, no matter if the medium to be measured is liquid, solid, hot, cold, hazardous or corrosive. The company can put together a level measuring instrument that is tailormade for specific operational parameters and process conditions. Since all settings in VEGAPULS 6X can be preconfigured to the required application in advance, it’s ready for immediate use. The display and adjustment module is clear, concise and easy to understand. The instrument has Bluetooth for wireless adjustment with the VEGA Tools App. The radar chip inside VEGAPULS 6X combines the experience gained from 30 years of radar level measurement engineering. At the sensor’s heart, is the pulsating technology that empowers it to fulfil our high expectations in terms of precision and reliability. And this is mainly thanks to its ability to selfdiagnose during operation, which makes it possible to seamlessly and continually monitor the accuracy and performance of the sensor. The new radar level sensor VEGAPULS 6X now combines the best of the previous 80 GHz, 26 GHz and 6 GHz sensors, such as VEGAPULS 64 and VEGAPULS 69, in one device.

Contact: VEGA India Level and Pressure Measurement Pvt Lt , Plot No. 1, Gat No. 181, VillagePhulgon, Tal. Haveli, Pune 412216, Maharashtra ¥ Tel: +91 20 6731 4000

Email: sales.in@vega.com

Plasto Fab Engineering provides a comprehensive range of highdensity polyethylene (HDPE) tanks. These tanks are fabricated using high grade HDPE & PP, which is procured from reputed vendor of the market. Besides, customers can avail these products at various capacities and shapes such as cylindrical, vertical, horizontal and rectangular. Furthermore, these products are completely tested on standard parameters before being dispatched to the customers.Plasto Fab Engineering also supplies polypropylene HDPE blowers for scrubber. These polypropylene HDPE blowers are ideally suitable for handling most corrosive industrial gases up to 100°C. It explores versatile utility where conventional blowers shows limitations especially for exhaust of highly polluted and corrosive industrial gases and acidic fumes.

Contact:

Plasto Fab Engineering, Plot 5728, 4th S Rd, near Seven Water Tank, Ankleshwar GIDC, Ankleshwar 393001, Gujarat, Mob: +91 93746 22246

Email: info@plastofabengineering.com

Triveni Boiler Pvt Ltd has introduced the groundbreaking technology of India's first plasticfired boiler. As a pioneer, the company has successfully manufactured and installed these innovative boilers, revolutionising the way nonrecyclable waste is handled and address energy needs especially designed for the user's needs. Plasticfired boilers provide an innovative and environmentally friendly solution to the waste management problem. By utilizing non recyclable waste as fuel, boiler effectively addresses two pressing issues simultaneously: waste management and energy production. This product is engineered to cater to the unique needs of paper mills, helping them address waste disposal concerns and offering significant cost benefits reducing the cost of running the paper mill. Triveni Boiler specialises in delivering tailored boiler solutions, which are designed to maximize efficiency, minimize energy consumption, and reduce overall operational costs. By optimising performance and streamlining processes, Triveni helps companies achieve significant savings while maintaining the highest standards of quality and reliability. The utilization of waste as a fuel source reduces the reliance on expensive fossil fuels, offering cost savings over the long term by reducing the steam cost for our clients. Plasticfired boilers employ advanced combustion technology and emission control systems, resulting in lower emissions of pollutants which lie within the permissible limits as set by the government. By incinerating nonrecyclable waste, these boilers significantly reduce the volume of waste destined for landfills, and the cost of transportation thus helping to mitigate the environmental impact.

Contact: Triveni Boiler Pvt Ltd, A1/903 & 904, GIDC, Panoli 394 116, Ankleshwar, Gujarat • Mob: +91 97128 82171 • Email: triveniboiler@yahoo.com

Contact Person: Mr HPS Chauhan, Director (Mob: 98251 24385)

Meera Laser Solutions offers Fiber lasers that are best suited for highcontrast markings like metal annealing, etching, and engraving. They produce an extremely small focal diameter (resulting in intensity up to 100 times higher than a CO2 system), making them the ideal choice for permanent marking of serial numbers, barcodes, and data matrix on metals. Fiber lasers are widely used for product traceability (direct part marking) and identification applications.

Contact:

Meera Laser Solutions Pvt Ltd

#2 Noor Market, Pillaiyar Kovil Street, Kanchina Kuppam

Abattur Industrial Estate, Chennai 600 098

Tel: 044 – 4861 0396 • Mob: 98404 00396, 98403 33616

Email: info@meeralasers.com

Ambetronics Engineers Pvt Ltd has developed smart gas analyzer, GA3500FLPS, for monitoring and detecting oxygen, toxic, and combustible gases. It employs advanced electrochemical sensor technology for accurate and rapid gas detection. GA3500FLPS offers comprehensive gas detection and is optimised for the detection of the smallest gas leaks, including oxygen and various toxic gases. It is robust and highly resistant to poisoning and etching, ensuring consistent performance. It is a versatile gas detector capable of detecting gas concentrations down to parts per million (PPM) and percentage by volume (%V/V). It features a 2line, 4digit 8mm high Seven Segment LED display and 8 LEDs to indicate the instrument’s status. GA3500FLPS provides a 420 mA signal output with configurable range, suitable for interfacing with PLC, DCS, and Winlog SCADA software. It is easy to handle and program with three keys for flameproof models. Passwordprotected programming with a passwordchanging facility offers enhanced security. Smart gas analyzer, GA3500FLPS, displays the peak value of gas concentration with a single key press. It offers optional alarm relay contacts with two configurable alarm levels and one relay for failsafe relay. It features an optional RS485 communication port with MODBUS RTU Protocol for remote monitoring. Smart gas analyzer, GA3500FLPS, is used in plant shops, refineries, welding, painting, cold rooms, tank farms, power plants, steel industry, pharmaceutical, water treatment, building protection, chemical plants, etc.

Contact: Ambetronics Engineers Pvt Ltd 17B, Tarun Industrial Estate, Mogra Pada, New Nagardas Road, Andheri (E), Mumbai 400 069, Maharashtra • Mob: +91 93207 37646 • Email: sales11@ambetronics.com, sales8@ambetronics.com

Mascot Systems Pvt Ltd is offering LESER range of safety valves for industrial applications in India. The primary purpose of a safety valve is the protection of life, property and environment. A safety valve is designed to open and relieve excess pressure from vessels or equipment and to reclose and prevent the further release of fluid after normal conditions have been restored. There are number of reasons why the pressure in a vessel or system can exceed a predetermined limit. API Standard 521/ISO 23251 Sect. 4 provides a detailed guideline about causes of overpressure. The most common are blocked discharge, exposure to external fire (often referred to as “Fire Case”), thermal expansion, chemical reaction, heat exchanger tube rupture, and cooling system failure. Each of these events may occur individually and separately from the other. They may also take place simultaneously. Each cause of overpressure also will create a different mass or volume flow to be discharged, e.g. small mass flow for thermal expansion and large mass flow in case of a chemical reaction. It is the user’s responsibility to determine a worstcase scenario for the sizing and selection of a suitable pressure relief device. LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding, heating and air conditioning industries use LESER safety valves for optimal results. LESER safety valves safeguard plants and processes from overpressure incidents. The basis is the LESER product range with nine product groups, 40 types, 1,500 options and over 2,000,000 possible configurations. LESER has constantly adapted its product range to new challenges cropping up every day and is today one of the world’s market leaders for safety valves.

Contact:

Mascot Systems Pvt Ltd, 801, Ambience Court, 8th Floor, Sector19D, Palm Beach Road, Vashi, Navi Mumbai 400703 • Tel: +91 22 4122 6500/ 6501 • Email: sales@mascotsystems.com

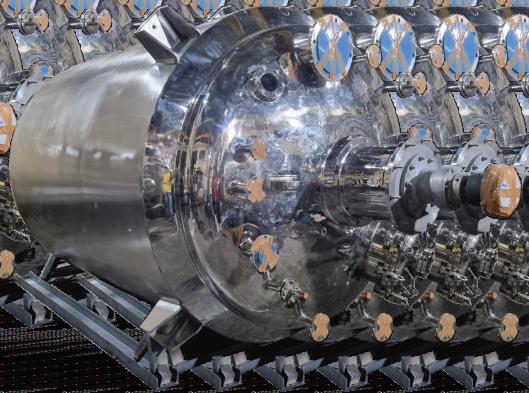

Reaction

Poly PlastChemi Plants manufactures process/reaction vessels of different sizes and shapes as per the customer's specifications, ranging from 200 Ltr to 100,000 Ltr capacity with conical, dished or flat bottom and top. The material of construction depends on chemical, temperature and pressure conditions of the process requirement. The company also supply these equipment with complete stirring assembly with independent mounting structure and suitable sealing arrangements as per the customer's requirements. Stirrers are fabricated out of MS/SS materials, lined with plastic materials as per service warranted and tested with HVHF spark testers for leak proof functioning. All thermoplastic liner weld joints are provided with nonmetallic conductive materials to facilitate spark testing. Similarly, FRP lined metallic vessels are also tested with spark testing for pin hole or discontinuity of lining. These vessels are ideal replacement to the conventional MS glasslined and Nobel metal cladded vessels. Poly Plast also provide cooling or heating coil made out of different materials as per the customer's requirement.

Contact:

Poly PlastChemi Plants (I) Pvt Ltd, Thakore Industrial Estate, KurlaKirol Road, Vidyavihar (West), Mumbai 400 086, Maharashtra • Tel: + 91 22 2511 6659, 2511 2294

Email: mktg@polyplast.co.in

Prima Equipment offers PSGM1DAGS (CEMSC) online continuous emissions monitoring system, which can monitor gases, including SO2, NOx, O2, dust, humidity, temperature, pressure, flow parameters, etc. In addition, it can monitor gases for a particular occasion such as HCI, HF, CO, CO2, NH3, H2S, Cl2, VOC, etc. Prima is a technologydriven company and has a full set of intellectual property rights of flue gas monitoring. Its independent research and development products include ultraviolet flue gas analyzer, dust monitor, temperature pressure flow, humidity meter, HCI analyzer, HF analyzer, pretreatment system, monitoring software, etc. Technology platforms offered are either extractive, hot extractive, hotwet extraction, dilution or insitu measurement system with electrochemical, PID, NDIR, TDLAS (Laser), FID, and UVDOAS measurement technology. These systems are used for emission monitoring and process analysis of power plant, cement, glass, lime factory, ceramics factory, sinter, coke oven, desulfurization, and denitration. Prima is known for manufacturing environment monitoring gas analyzers instruments such as online and portable fuel efficiency monitor, air sampler, continuous emission monitoring systems (CEMS), portable digital dew point meter, portable gas monitor, gas detection system, gas analyzer, combustible gas detector and ambient air quality monitoring system (CAAQM).

Contact: Prima Equipment

21, 3rd Floor, Lohana Building, Raopura, Vadodara 390001, Gujarat Mob: +91 79696 67000, 79696 67001, 79696 67002 Email: info@primaequipment.com

SBC Cooling manufactures customised industrial chillers as per the customer requirement. The company supplies chilling plant and chillers to a wide variety of industrial processes and for production machinery applications, ranging from selfcontained portable units to completely installed turn key systems. Fresh water was used freely for cooling production processes. Industrial chillers provide cooling in a controlled closed circuit. This means that the water used for the production processes is reliable, constant and defined. The capacity of these chillers varies exactly as per the fluctuating load conditions, to have the energy efficiency at its best. Industrial screw chillers are widely used in the fields of plastic, electroplating, electronics, chemical, pharmaceutical, printing, food processing and other industrial refrigeration process. Large shopping malls, hotels, factories, hospitals, soft drinks, soda, bulk drug manufacturing, beverages, bakery, laboratories, petrochemical and refineries and other central air conditioning projects need to use chilled water concentrated cooling areas. Tonnage capacity available in industrial screw chiller uare from 20 TR to 300 TR (Single Circuit) to 600 TR (Multi Circuit).

Contact:

SBC Cooling Pvt Ltd, 98, Khatodara GIDC, B/h Sub Jail, Ring Road,Surat 395002, Gujarat. Tel: +91 85111 48243, 85111 48244 • Email: admin@sbccindia.com

Brightech has developed pressure reducing valves, pneumatic operated PCV100 Series. It is a globe type, single seated, top & bottom guided, single spring & diaphragm actuated, pneumatic/motorized operated pressure reducing valve. PCV100 series pneumatic/motorised operated pressure reducing valve is high in demand where accurate downstream highpressure control with high flow is required. Its top & bottom guided design offers high stability & accurate pressure control. Cage guided design is offered for highpressure requirement. Top & Bottom guiding provides maximum support to the plug for its stability and eliminates the side thrust effect of pressure drop across the plug. These valves are designed to control fluid flow at high pressure. Upstream & downstream pressure control for air/gas/steam/liquid. This design provides tight shutoff capability for such processes. Brightech's pneumatic/motorised operated pressure reducing valve can be used for many industrial application where reducing high pressure of steam, gases and other fluids to be kept constant with high pressure & high flow. It comes with accessories such as pressure transmitter, PID controller, air filter regulator (AFR), positioner, quick exhaust, volume booster, extended/finned bonnet, bellows seal, and hand wheel.

Contact:

Brightech Fluid Control Solutions, Survey No. 98, Near Water Tank, KubadthalLalpur road, Kubadthal Village, Daskroi, Ahmedabad 382 430, Gujarat • Mob: +91 99090 29165, 97254 55442

Email: info@brightechvalves.com

CPVC industrial piping system, ChemPro

Astral ChemPro is a reliable CPVC piping system that meets the demanding requirements of industrial applications. It has been providing troublefree service to various industries for years. In industries where aggressive chemicals are encountered, metal equipment often corrodes, leading to process leaks, flow restrictions, and premature failure. Even other thermoplastics used in such environments can be affected by these chemicals at elevated temperatures and pressures, resulting in premature failure. To ensure the success and growth of firms in the process industry, it is crucial to have a piping system with long service life, minimal downtime, and compliance with environmental standards. The Astral ChemPro industrial piping system is capable of handling temperatures up to 93°C (intermittently up to 110°C), as well as pressures based on pipe sizes. It is suitable for a wide range of industrial needs, including metal treating pumps and risers, food and beverage applications, industrial wastewater management, and chemical processing. Piping system is designed in accordance with standard industry practice for thermoplastic industrial piping systems and will take into consideration such factors as pressure and flow requirements, friction loss, operating temperatures, support spacing, anchoring, bracing and thrust blocking, temperature correction factors, joining methods, chemical environment, collapse and loading, and thermal expansion and contraction. Astral Ltd is the sole Indian manufacturer of industrialgrade Chlorinated Polyvinyl Chloride (CPVC) Pipes. It offers schedule 40 and 80 pipes, as well as schedule 80 fittings, conforming to ASTM standards. These pipes are available in sizes ranging from 1⁄2” (15mm) to 12” (300mm). All Astral ChemPro CPVC industrial pipes are produced from compounds that meet ASTM D1784 standards.

Contact: Astral Pipes, Astral House 207/1, Behind Rajpath Club, Off. S G Highway, Tel: +91 79 6621 2000 • Email: info@astralpipes.com

Briflon offers SafeLine fully FEP/PFA lined safety/pressure relief valves, which are manufactured with high accuracy to assure the performance of the valve, over protection for unfired pressure vessels/equipment and plant system from dangerously high pressure used with highly corrosive liquid, gases & vapours. These valves are available in the size range: 150 x 200.For safeguarding of pressure vessels and plant systems against overpressure, set pressure up to 15 Kg & max. temperature 180°C. These valves are used for corrosive media, where metallic materials cannot reach an adequate service life or where special metals cause high costs. They are used where over protection for unfired pressure vessels/equipment and plant system from dangerously high pressure used with highly corrosive, gases & vapours.

Contact:

Briflon Lined Products

Survey No. 98, Near Water Tank, KubadthalLalpur road, Village: Kubadthal, Daskroi, Ahmedabad 382430 • Mob: +91 99090 29165, 97254 55442 Email: info@briflon.com

Microfilt manufacturers an advanced cross flow filtration system, MiCross, which is also known as tangential flow filtration. Cross flow membrane filtration is pressure driven technology which is used for to separate/concentrate solids and molecules of colloidal size up to ions. In cross flow technology, first the separation of suspended solid particle from inlet stream takes place. For this mostly ceramic membrane is used. This is also called as microfiltration (MF). For further separation, fractionation and concentration of smaller molecules like protein, salt, sugar, colouring agent etc, polymeric spiral membrane is used.In MiCross system, feed is pumped through the channels, inside the channels there is an active membrane layer. The membrane layer separates all the element being bigger than the membrane pores, filtrate is permeated through membrane layers and support. Boundary of formation of cake thickness is control by cross flow of retentate. Cross flow filtration kit consists of microfiltration, ultrafiltrtion combination with nanofiltration, designed to suit the critical requirement of industry specific application right from highend biotech system to a very lowend effluent treatment.Microfiltis one of the leading providers of crossflow technology in process industry and deliver the crossflow filtration system which is specially designed according to various process and customer requirement.MiCrossfiltration system is used in many industries such as food,beverages, chemicals, pharmaceuticals and biotechnology. It is used in filtration of highly demanding pharmaceutical, bulk fermentation process (antibiotics, food additives, ferments, enzymes, etc) and biopharmaceutical (vaccines) applications. It is used in separation of plasma, antibodies and fractionation of various factors from blood. It is used for recycling of used CIP solutions, and continuous separation of catalyst from process solution.

Contact:

Microfilt Filter Media Pvt Ltd, 705, Oriana Business Park, Opp. to New Passport Office, Road No. 22, Wagle Industrial Estate, Thane (W) 400604, Maharashtra • Mob: +91 93240 73022, 93240 03330 • Email: innovations@microfiltindia.com

Trimech designs and manufactures highquality, robust PSA nitrogen generation plant. The capacity of the nitrogen generator is 1000 NM3. PSA nitrogen generator is a standard method by which nitrogen is manufactured for industrial purposes.

Since atmospheric air is a mixture of many gases, separating nitrogen from the rest requires unique processes. The process requires a twin tower with carbon molecular sieve to separate oxygen gas. One tower looks after the nitrogen production cycle. Both the towers are interconnected with changeover valves that will look after the nitrogen gas flowing into the surge vessel. The back pressure regulator will keep the nitrogen gas under minimum pressure. The end product now formed is delivered to customers to use for various applications. The PSA nitrogen generator are easy to install and operate. It produces nitrogen of the purest quality or as required by the industrial process. PSA nitrogen plant eliminates the requirement of N2 gas cylinders and is compact in design that occupies the least space. PSA nitrogen generation being an inert gas is used in various industries for different reasons.

Contact:

Trimech Engineers Pvt Ltd, 7, Giriraj Industrial Area, PaldiKankaj, Old AhmedabadBhavnagar Highway, Daskroi, Ahmedabad 382425, Gujarat Tel: +91 79 2584 0557 • Email: info@trimechindia.com

Insulation for pharmaceutical industry, ArmaFlex Alu E Armacell India manufacturesArmaFlex Alu E, a superior performance insulation specially designed for the pharmaceutical industry. Clean rooms are one of the most demanding applications in pharmaceuticals industry, when it comes to insulation. Hygiene become the most important aspect of clean room application. The ducts and pipes are visible and hence should be easy to clean and aesthetically appealing. They should not retain any moisture and prohibit any possibility of microbial growth, and of course, conserve energy with minimum heat loss/gain. The traditional Aluminiumclad insulation products have always faced an everexisting problem of ugly dents, wrinkles and pockets. Thanks to the unique surface pattern, the ArmaFlex Alu E cleverly disguises most of the imperfections that may occur during installation. The cladding is embossed with ArmaFlex brand to avoid any counterfeiting which also lends an overall premium feel to the cladding. It’s highly flexible nature further aids fast and easy installation in technical sections. Water vapour and humidity are one of the biggest hindrances in enabling thermal insulation. With water vapour diffusion resistance (µ) of 60000, ArmaFlex Alu E ensures that the insulating properties are retained in the most adverse conditions. Moreover, the surface can be wiped clean effortlessly which helps in keeping the fungi and microbes at bay, another prerequisite of a clean room application. ArmaFlex Alu E is a nonfibrous, nonitchy, easytoclean product. Hence, there is no probability of air contamination due to degradation of the insulation material over a period of time.

Contact:

Armacell India Pvt Ltd, Gat No. 744 & 745, Nagar Rd, Lonikand, Pune 412 216, Maharashtra • Tel: +91 20 6678 2000 • Email: info.imea@armacell.com

Zeus Solutions manufactures Leak Testing Machines by pressure drop method such as Pump leak testing machine, UDS leak testing machine, Starter motor leak testing machine, Pressure sensor leak testing machine, Submersible motor leak testing machine, Starter motor leak test SPM, UDS leakage test bench, Vacuum leak test rig, Alternator Pump Leak Test, and Jet Calibration. Zeus Solutions is a pioneer in industrial automation and test equipments solutions since 1995. Zeus primarily serves to the enterprises involved in manufacturing of autoelectrical components that may include Starter motors, Alternators, Wiper Motors, Blower Motors, Power Window motors etc. Zeus also provides solutions to other field of AC motor manufacturers, Oil industries, and two or four wheeler manufacturers.

Contact:

Zeus Solutions

224/2 Nageswara Rao Road,Vanagaram Road Athipet, Chennai 600 058

• 044 – 2688 0963 • Mob: 88704 77753

Email: admin@zeusgroups.com

Givi Misure make Optical Linear Scales are known for proven accuracy and reliability. The SCR 3923 Scale is with extra protection of four lips, which can withstand harsher conditions and available in any desired length; ISA 2320 teel scale is slim and suited for small and compact machines; NCH Open scale is of noncontact movement with easy maintenance and wide mounting tolerance. The Reader heads of all steel scales are provided with ball bearings. The hybrid circuit inside the readerhead is calibrated with laser instruments. Steel scales are most preferred for measurements in machine tools and machinery as thermal expansion coefficient of scales, matches with machine elements. Givi’s products range includes: Magnetic Systems, Rotary Encoders, Digital Readouts, Position Controllers, etc.

Contact:

GIVI MISURE PVT LTD

Plot No: 488, VITC Export Bhavan, 1st Block, KIADB Complex 14th Cross, IV Phase, Peenya Industrial Area Bengaluru, Karnataka 560 058 Tel. : 080 – 4127 2559 • Email: info@givimisureindia.com

Ball Valve

Dinesh Plastic Products has developed a ball valve that is chemically resistant to most of aggressive chemicals up to 120°C temperature and economical compared to solid PVDF ball valve and Teflon lined metallic valves. This valve has a solid PVDF body, solid PVDF Ball, PVDF coated (Moulded) SS316 stem, only two flanged ends have inner liners (moulded 3.75mm to 5.5mm thick) of PVDF and on this liners, polypropylene flanged ends are moulded. So all chemicals comes in contact with PVDF and Teflon Materials only. Body to ends sealing & stem sealing 'O' Rings are of pure Teflon. To compress these Teflon 'O' Rings firmly, a steel ring insert of 5mm thick is moulded in flanged ends. SS 316 inserted stem, metal inserted handle and stopper ensures sturdiness and long service life. The company uses virgin imported PVDF and polypropylene materials of grades that are internationally popular, especially used for manufacturing of valves and fittings. They are available in the size range from 25 mm NB to 150 mm NB.

Contact:

Dinesh Plastic Products

Block Number 338/B, Behind GIDC, Kabilpore, Ganesh Sisodra 396 463, Navsari (Gujarat)

Tel: +91 2637 270300, 270331

Email: dineshplastic@dppvalves.com

KUSAM-MECO INTRINSICALLY SAFE INFRARED Thermometer Model IRL 7Ex P KUSAMMECO has introduced a New Intrinsically Safe Infrared Thermometer Model IRL7Ex. The Ex Class is Ex ib I Mb (Class 1). It is suitable for use in Mines, Oil and Gas Environment. Its Features: has range –32°C to 700°C; Resolution is 0.1°C; the infrared spectral response is 8 ìm to 14 ìm; the response time is 250 ms; Distance to spot ratio is 20:1; Emissivity is adjustable 0.01 to 1.00; has facility for High/Low Temperature Alarm Setup; also has Max/Min/Avg /Dif Function; Backlight LCD for reading in dark area also; Can store readings of Data. This Infrared Thermometer operates on single 9 V Battery and to save power it has Auto power OFF function. It is supplied with User Manual, Battery and Carrying Case.

Contact:

Kusam Electrical Industries Ltd Shop No: 18, 1st Floor, CIDCO Shopping Complex, Plot # 9 Sector7, Rajiv Gandhi Marg, Sanpada, Navi Mumbai 400 705 Tel. : 022 –2775 0292, 27750662

Email: sales@kusammeco.co.in

Gem Orion Machinery Private Limited offers Energy Saving Precision Inverter Chiller. Its Features: High energy saving; 8.7 kW 90 kW Cooling Capacity; As low as ±0.1oC Accuracy; Larger Chilled water temperature range (10oC 30oC); External Warning Alarm/Remote Communication with Mother Machine/Remote On/Off; VFD Driven Compressor; SS inbuilt Tank and Pump; Eco Friendly R410A; Inverter Driven Fan Motor; Optional Inverter Driven Pump; Modular Operation up to 12 units in parallel; Suitable for Ambient up to 50oC. Applications of Chillers: Plastic, Induction Heating, Textiles, Machine Tools, Printing and Packaging, Laser Cutting/Welding and Medical Applications.

Contact:

Gem Orion Machinery Private Limited S F No: 100/2A, Avinashi Road, Arasur Coimbatore, Tamil Nadu 641 407 Tel : 0422 – 236 3805, 236 3806 • Email: sales@gemorion.in

Sawant Filtech's filters add new dimensions to solid/liquid separation by introducing India’s first Zero Hold Up filter that meets all demands from a filtration system which would discharge solid free filtrate. These filters solve the majority of separation problems with additional features from the new concept of Zero Hold Up horizontal closed pressure filter as compared to conventional sparkler filters. Some of the features of SS Zero Hold Up filter are single pass filtration with no solids bypass; full batch recovery with no extra scavenging system required; proper sealing which allows the filtration of volatile, toxic & inflammable products; maximum drying of cake solid can be achieved with nitrogen; complete cake retention over the plate surface; uniform distribution of cake on each plate; and filter ranging from "8" to 33" Dia variable number of plates. Material of construction are SS 316, SS 316L, SS 904 L, Hastelloy C276 & C22, and SS 304. But, how it works? The plate pack assembly consists of plates with interlocking cups, plate rings, perforated screens and filter media. Interlocking cups arranged above other forms of single pipeline. The unfiltered liquid is centrally fed under pressure from bottom inlet. The liquid spreads out equally on each plate fitted with filter media. A pioneer in the filtration industry, Sawant Filtech, previously known as Subodh Engineering, has invented a variety of zero hold up filters striving for innovation and efficiency.

Contact: Sawant Filtech, 102/103, Ram Ashirwad Industrial Estate, Building No. 2, Ram Mandir Road, Goregaon (W), Mumbai 400104• Tel: +91 22 6725 1786, 2676 4171

Email: info@sawantfiltech.com

AUTOMATIC

(FPPLUS)