Alliance. Allrights reserved.

The Pool & Hot Tub Alliance (PHTA) does not write the standards. Rather, PHTA facilitates a forum for its members, and others interested in pool and spa design and safety, to develop standards through the consensus procedures of the American National Standards Institute (ANSI). While the PHTA administers the process and establishes rules to promote fairness in the development of consensus, it does not independently test, evaluate, or verify the accuracy of any information or the soundness of any judgments contained in its codes and standards.

In issuing and making this document available, the PHTA is not undertaking to render professional or other services for or on behalf of any person or entity. Nor is the PHTA undertaking to perform any duty owed by any person or entity to someone else. The PHTA disclaims liability for any personal injury, property, or other damages of any nature whatsoever, whether special, indirect, consequential, or compensatory, directly or indirectly resulting from the publication of, use of, or reliance on this document.

The PHTA has no power, nor does it undertake, to police or enforce compliance with the contents of this document. The PHTA does not list, certify, test, or inspect products, designs, or installations for compliance with this document. Any certification or other statement of compliance with the requirements of this document shall not be attributable to the PHTA Any certification of products stating compliance with requirements of this document is the sole responsibility of the certifier or maker of the statement. The PHTA, its members, and those participating in its activities do not accept any liability resulting from compliance or noncompliance with the provisions given herein, for any restrictions imposed on materials, or for the accuracy and completeness of the text.

Anyone using this document should rely on his or her own independent judgment or, as appropriate, seek the advice of a competent professional in determining the exercise of reasonable care in any given circumstance. It is assumed and intended that spa users will exercise appropriate personal judgment and responsibility and that public spa owners and operators will create and enforce rules of behavior and warnings appropriate for their facility.

Copyright Notice

Copyright ©2023 by The Pool & Hot Tub Alliance, 2111 Eisenhower Avenue, Alexandria, VA 22314-4695. Printed in the United States of America. All rights reserved. No part of this book may be reproduced, stored in a retrieval system, transcribed or transmitted, in any form or by any means or method, electronic, mechanical, photocopy, recording, or otherwise, without advance written permission from the publisher: The Pool & Hot Tub Alliance, 2111 Eisenhower Avenue, Alexandria, VA 22314-4695.

“APSP,” “The Association of Pool & Spa Professionals,” and the APSP logo are trademarks of The Association of Pool & Spa Professionals. The Pool & Hot Tub Alliance word mark and logo are registered trademarks of The Association of Pool and Spa Professionals d/b/a Pool and Hot Tub Alliance.

©2023 The Pool and Hot Tub Alliance ii

ANSI/APSP/ICC-6 2013 (R2023)

Copyright©2023byThePool&HotTub

Foreword

This Foreword is not part of the American National Standard ANSI/APSP/ICC-6 2013 (R2023). It is included for information only.

The ANSI/APSP/ICC-6 2013 (R2023), Standard for Residential Portable Spas and Swim Spas, was approved by ANSI on January 9, 2013 and the reaffirmation was approved by ANSI on January 3, 2023.

This standard is a revision of ANSI/APSP-6 1999, American National Standard for Portable Spas.

The objective of this standard is to provide recommended minimum guidelines for the design, equipment, instal-lation, and use of residential portable spas and swim spas. It is also intended to assist local jurisdictions and other regulatory bodies, where necessary, in the development and promulgation of criteria for residential portable spas and swim spas.

The design requirements and construction practices in this standard are based upon sound engineering principles, research and field experience which, when applied properly, contribute to the delivery and installation of a safe product.

The words “safe” and “safety” are not absolutes. While the goal of this standard is to design and construct a safe, enjoyable product, it is recognized that risk factors cannot, as a practical matter, be reduced to zero in any human activity. This standard does not replace good judgment and personal responsibility. In permitting use of the spa or swim spa by others, owners must consider the skill, attitude, training and experience of the expected user.

As with any product, the specific recommendations for installation and use provided by the manufacturer should be carefully observed. This standard was prepared by the APSP-6 Portable Spa and Swim Spa Writing Committee of the Association of Pool and Spa Professionals (APSP) in accordance with American National Standards Institute (ANSI) Essential Requirements: Due process requirements for American National Standards.

Consensus approval was achieved by a ballot of the balanced APSP Standards Consensus Committee and through an ANSI Public Review process. The ANSI Public Review provided an opportunity for additional input from indus-try, academia, regulatory agencies, safety experts, state code and health officials, and the public at large.

Suggestions for improvement of this standard should be sent to The Pool & Hot Tub Alliance, 2111 Eisenhower Avenue, Alexandria, VA 22314.

This standard is published in partnership with the International Code Council (ICC). ICC develops and publishes the International Building Code (IBC) and International Residential Code (IRC), which are adopted as the basis for the building codes used in most states and jurisdictions within the United States. Additionally, PHTA and ICC have collaborated to develop the first comprehensive model swimming pool and spa code, known as the International Swimming Pool and Spa Code. This landmark document incorporates and references material from ANSI/PHTA standards and ICC’s model codes, to create a stand-alone code that is consistent with codes and standards from both organizations.

These codes and standards are the result of a joint effort between ICC and PHTA as a service to both the swimming pool and spa community, and building code professionals. It is the hope of both organizations that they will lead to enhanced safety for pool and spa users around the world.

iii ©2023 The Pool & Hot Tub Alliance

ANSI/APSP/ICC-6 2013 (R2023) Copyright©2023byThePool&HotTub Alliance.

Allrights reserved.

APSP-6 Writing Committee

v Contents Sections Page American National Standard .......................... ii Foreword iii 1 Scope 1 2 Normative References 1 3 Structure and Design ............................ 3 4 Dimensional Design ............................. 3 5 Circulation Systems 3 6 Filters ....................................... 4 7 Pumps and Motors .............................. 4 8 Return Inlets and Suction Outlets 4 9 Surface Skimmer Systems 5 10 Electrical Requirements .......................... 5 11 Air Blower and Air Induction Systems 5 12 Heater and Temperature Requirements 5 13 Instruction Manual, Safety Signs, Safety Messages and Features 6 14 Waste Treatment Supply .......................... 7 15 Energy Efficiency 7 Appendices A Chemical Operational Parameters .................. A-1 B Spa and Swim Spa Use Parameters A-6 C Use of Ozone A-7 D Use of Elemental Chlorine ....................... A-7 E Metric Conversion Table A-9 F Sources of Material A-10

Newport Controls Lee West, Chairman Acrylic Spas, ....................... Cindi Magraw Artesian Spas Lody Chandra Balboa Water Group ................. Dave Allen Beachcomber Hot Tubs Keith Scott Bull Frog Spas Richard Eddington CMP ............................. Angelo Pugliese Emerald Spas Kristin Woiteshek Emerald Spas, Alternate .............. Tony Cramer Endless Pools James Murdock Gecko Louis Nollet Jacuzzi Tony Sadati L.A. Spas Vincent Wong L.A. Spas, Altenate .................. Brad de Kowing Master Spas Nathan Coelho Marquis Spas ...................... Sam Collins NSF Rich Martin Premium Leisure Victor Kaykov Rio Spas .......................... Carl Meyer Rio Spas, Alternate Jon Wilson Speck Pumps ...................... Jan Baljon Watkins Manufacturing Mike McCague Watkins Manufacturing, Alternate Steve Macey ©2023 The Pool & Hot Tub Alliance ANSI/APSP/ICC-6 2013 (R2023) Copyright©2023byThePool&HotTub Alliance. Allrights reserved.

Copyright©2023byThePool&HotTub Alliance. Allrights reserved.

Standard for Residential Portable Spas and Swim Spas

1 Scope

1.1 This standard is intended to cover factory built residential portable (self contained) spas or swim spas that are used for bathing and are operated by an owner. This standard does not cover Non-Self-Contained Spas, public spas, public swim spas, or permanently installed residential spas, or swim spas.

1.2 Residential Portable Spa: Self-Contained and NonSelf-Contained.

1.2.1 Self-contained spa: A factory-built spa in which all control, water heating and water circulating equipment is an integral part of the product. Self-contained spas may be permanently wired or cord connected.

1.2.2 Non-self-contained spa (Not covered by this standard): A factory built spa in which the water heating and circulating equipment is not an integral part of the product. Non-self-contained spas may employ separate components such as an individual filter, pump, heater, and controls, or they may employ assembled combinations of various components that are to be installed in accordance with manufacturer’s specifications.

1.3 Residential Exercise Spa (Also known as a residential swim spa): Variant of a Residential Portable Spa in which the design and construction includes specific features and equipment to produce a water flow intended to allow recreational physical activity including, but not limited to, swimming in place. Exercise spas may include peripheral jetted seats intended for water therapy, heater, circulation and filtration system, or may be a separate distinct portion of a combination spa/exercise spa and may have separate controls. These aquatic vessels are of a design and size such that it has an unobstructed volume of water large enough to allow the 99th Percentile Man, as specified in the latest published revision of ANSI/APSP-16, to swim or exercise in place.

1.4 This standard does not apply to public spas or swim spas, permanently installed residential spas or swim spas, or other spas, such as those operated for medical treatment, physical therapy or other purposes.

1.5 Other standards are referenced in this standard for items not covered.

2. Normative references

The following standards contain provisions that, through reference in this text, constitute provisions of this American National Standard. At the time of publication, the editions indicated were valid. All standards are subject to revision, and parties to agreements based on this American National Standard are encouraged to investigate the possibility of applying the latest published editions of the standards indicated in Section 2.1.

2.1 The materials of manufacture shall be capable of fulfilling the design, installation, and intended use guidelines where referenced in this standard. If the materials of manufacture, components, and accessories used in residential portable spas or swim spas consist of the following, and specifically referenced in this standard, these referenced standards shall be applicable.

Accessories and Components

Suction outlet testing and certification: Spa or swim spa suction outlets shall be tested and certified to ANSI/APSP-16 Suction Fittings for Use in Swimming Pools, Wading Pools, Spas/Hot Tubs and Whirlpool Bathtub Appliances 1

Couplings or Hose: ASTM C564 -97 or equivalent SAE J20e Specification for Rubber Gaskets for Cast Iron Soil Pipe and Fittings 2

Air Induction Systems: UL 1563 2009, Standard for Electric Spas, Equipment Assemblies, and Associated Equipment 3

Circulation Systems – Equipment: UL 1563 2009, Standard for Electric Spas, Equipment Assemblies, and Associated Equipment 4

Energy Efficiency for Portable Spas: ANSI/APSP/ICC-14 2011, Standard Portable Electric Spa Energy Efficiency 5 Entrapment Avoidance

ANSI/APSP-16 2011, Suction Fittings for Use in Swimming Pools, Wading Pools, Spas, and Hot Tubs 6 UL 1563 2009, Standard for Electric Spas, Equipment Assemblies, and Associated Equipment 7

ANSI/ASME – A112.19.17 2010, Manufactured Safety Vacuum Release Systems (SVRS) for Residential and Commercial Swimming Pool, Spa, Hot Tub, and Wading Pool Suction Systems 8

Electrical Supply: UL 1563 2009, Electric Spas, Equipment Assemblies, and Associated Equipment 9

Foam: ANSI/UL 94 2011, Test for Flammability of Plastic Materials for Parts in Devices and Appliances 10 (continued)

1

1, 5, 6. APSP, 2111 Eisenhower Ave, Alexandria, VA 22314, 703 838-0083 www.apsp.org 2.ASTM International, 100 Barr Harbor Dr, West Conshohocken, PA 19428, (610) 832-9585, www.astm.org 3, 4, 7, 9, 10. Underwriters Laboratories (UL), 333 Pfingsten Road, Northbrook, IL 60062, (847) 272-8800, www.ul.com 8.American Society of Mechanical Engineers (ASME), 3 Park Avenue, 20th Floor, New York, NY 10016, (212) 591-8562, www.asme.org (continued) ©2023 The Pool & Hot Tub Alliance ANSI/APSP/ICC-6 2013 (R2023) Copyright©2023byThePool&HotTub Alliance. Allrights reserved.

ANSI/APSP/ICC-6 2013 (R2023)

Heating Energy Source

Natural gas energy supply: ANSI Z223.1/NFPA 54 2006, National Fuel Gas Code 11

Propane energy supply: ANSI Z223.1/NFPA 54 2006, National Fuel Gas Code 12

Liquefied Gas: ANSI/NFPA 58 2011, Liquefied Petroleum Gas Code 13

Joints

Soldered: IAPMO IS 3 2006, Installation Standard for Copper Plumbing Tube‚ Pipe‚ and Fittings 14

IAPMO IS 2 2006, Installation Standard for Welded Copper and Copper Alloy Water Tube 15

Threaded: ANSI/ASME B1.20.1 1992, Pipe Threads, General Purpose (inch) 16

Laboratory Accreditation

ISO/IEC 17025 General Requirements for the Competence of Calibration and Testing Laboratories 17

Pipe, Copper Tubing

ASTM B 88 2009, Standard Specification for Seamless Copper Water Tube 18

ASTM B 88 447 2009, Standard Specification for Welded Copper Tube 19

Plastic Piping and Tubing

ABS: ASTM D 1527 12, Standard Specification for Acrylonitrile Butadiene-Styrene (ABS) Plastic Pipe, Schedules 40 and 80 20

PVC: ASTM D1785, Standard Specification for Poly (Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120 21

PVC Hose: IAPMO PS-33 2010, Standard Specification for Flexible Hose for Pools, Hot Tubs, Spas, and Jetted Bathtubs 22

CPVC: ASTM D2846 2009, / D2846M, Standard Specification for Chlorinated Poly (Vinyl Chloride) (CPVC) Plastic Hot- and ColdWater Distribution Systems 23

PB: ASTM D3309 1992, Standard Specification for Polybutylene (PB) Plastic Hot- and Cold-Water Distribution Systems 24

Steel Pipe, Galvanized: ASTM A53m 12, Standard Specification for Pipe, Steel Black and Hot-Dipped, Zinc-Coated, Welded and Seamless 25

Plastic Fittings: ABS ASTM D2235 2011, Specification for Solvent Cements for Acrylonitrile Butadiene Styrene (ABS) Plastic Pipe and Fittings 26

PVC: ASTM D 2564 2012, Standard Specification for Solvent Cements for Poly (Vinyl Chloride) (PVC) Plastic Piping Systems 27

CPVC: ASTM F493 2010, Specification for Solvent Cements for Chlorinated Polyvinyl Chloride (CPVC) Plastic Pipe and Fittings 28

Pumps/Motors

NEMA MG18 2011, Motors, and Generators 29

UL 1081 2008, Standard for Safety Swimming Pool Pumps, Filters, and Chlorinators 30 Shells

Plastic Shells: ANSI/IAPMO Z124.71997, Pre-fabricated Plastic Spa Shells 31

Stainless Steel: ASTM-A240 2012, Type 316 Stainless Steel 32

Tile: IAPMO IS-2-2003, Tile Lined Roman Bathtubs 33

Vinyl Lined: ASTM D 882 2012, 2300 psi-Tensile Strength (psi min) 34

ASTM D 1004 2009, 220 lbs/in Tear Resistance (lbs/in. min.) 35

ASTM D1204 2008, Dimensional Stability 36

ASTM E 1428 2008, Standard Test Method for Evaluating the Performance of Antimicrobials in or on Polymeric Solids Against Staining by Streptoverticillium Reticulum (A Pink Stain Organism) 37

ASTM D1593 2009, minimum 20 mils-Thickness, mils. 38

ASTM G21 2009, Fungal Resistance 39

Safety Signs

UL 1563 2009, Electric Spas, Equipment Assemblies, and Associated Equipment 40

ANSI Z-535 2011, Series of Standards for Safety Signs and Colors 41

Safety Barrier: ANSI/APSP/ICC-8 2005 (R 2013), Model Barrier Code for Residential Swimming Pools, Spas and Hot Tubs 42

Spa Heaters

ANSI Z21.56 2003, Gas Fired Pool Heaters 43

ANSI Z223.1/NFPA 54 2012, National Fuel Gas Code 44

UL 1261 2001, Electric Water Heaters for Pools and Tubs 45

UL 1563 2009, Standard for Electric Spas, Equipment

Assemblies, and Associated Equipment 46

UL 1995 2011, Heat Pumps 47

Ventilation

ANSI/ASHRAE 62.1 2010, Ventilation for Acceptable Indoor Air Quality 48

Water Supply: ANSI A112.1.2 2012, Air Gaps in Plumbing Systems 49

Water Temperature Controls

UL 1563 2009, Standard for Electric Spas, Equipment Assemblies, and Associated Equipment 50

UL 372 1994, Primary Safety Controls for Gas and Oil-Fired Appliances 51

11–13. National Fire Protection Association (NFPA), 1 Batterymarch Park, Quincy, MA 02269 (617) 770-3000, www.nfpa.org

14, 15, 22, 31, 33. International Association of Plumbing & Mechanical Officials, 4755 East Philadelphia Street, Ontario, California 91761, 909-472-4100, iapmo.org

16. American Society of Mechanical Engineers (ASME), 3 Park Avenue, 20th Floor, New York, NY 10016, (212) 591-8562, www.asme.org

17.International Organization for Standardization, 1, ch. de la Voie-Creuse, Case postale 56 CH-1211 Geneva 20, Switzerland, +41 22 749 0111, central@iso.org, www.iso.org

18, 19–21, 23–28, 32, 34–39. ASTM International, 100 Barr Harbor Dr, West Conshohocken, PA 19428, (610) 832-9585, www.astm.org

29.National Electrical Manufacturers Association (NEMA), 1300 N. 17th Street, Suite 1847, Rosslyn VA 22209, (703) 841-3200, www.nema.org

30, 40, 45–47, 50, 51. Underwriters Laboratories (UL), 333 Pfingsten Road, Northbrook, IL 60062, (847) 272-8800, www.ul.com

41, 43–44, 49. American National Standards Institute (ANSI), 25 West 43rd Street, Fourth Floor, New York, NY 10036, (212) 642-4900, www.ansi.org

42.APSP, 2111 Eisenhower Ave, Alexandria, VA 22314, 703 838-0083 www.apsp.org

48.ASHRAE, 1791 Tullie Circle, N.E. Atlanta, GA 30329, (404) 636-8400, bookstorehelp@ashrae.org, www.ashrae.org

2

©2023 The Pool and Hot Tub Alliance Copyright©2023byThePool&HotTub

Alliance. Allrights reserved.

2.2 Material surfaces. All material surfaces that come in contact with the user shall be finished, so that they do not constitute a cutting, pinching, puncturing, or abrasion hazard under casual contact and intended use.

3 Structure and design

3.1 Plans. The structural design and materials used shall be in accordance with generally accepted structural engineering practices.

3.2 Freezing. In climates subject to freezing temperatures, the spa or swim spa shell owner shall follow the manufacturer’s instructions to protect it from structural damage due to freezing.

3.2.1 Manufacturer’s specifications shall be followed for providing a means to protect the spa or swim spa from direct sunlight exposure when not in use.

3.4 Slip-resisting surface. The surfaces within the spa or swim spa intended to provide footing for users shall be slip-resisting surfaces. The texture of such surfaces shall not cause injury or discomfort during normal use.

3.5 Installation. Spa equipment or swim spa equipment shall be supported to prevent damage from misalignment, settling, etc.

4 Dimensional design

4.1 Shape. This standard is not intended to regulate the shape of the spa or swim spa. It is the designer’s responsibility to take into account the effect a given shape will have on the safety of the occupants and that the minimum required level of circulation will be maintained to ensure sanitation.

4.1.1 There shall be no protrusions, extensions, means of entanglement, or other obstructions in the bathing area, which can cause the entrapment, or injury, of the user.

4.1.2 Water depth. The maximum water depth shall be 4 ft (1219 mm) except swim spas, where the maximum water depth shall be 6 ft (1829 mm), measured from the manufacturers’ specified waterline.

Exceptions: Spas and swim spas that are designed for a special purpose and approved by the authority having jurisdiction.

4.1.3 Multi-level seating may be provided, but the maximum water depth of any seat or sitting bench shall be 28 in. (711 mm) measured from the manufacturer’s specified waterline.

4.2 Human measurement for swim spa. The design shall allow for dimensions that allow the 99th percentile male to swim utilizing swimjets for an aquatic workout as per The Measures of Man and Woman by Alvin R. Tilley, John Wiley & Sons, Inc.

4.3 Floor slope. The slope of the floor shall not exceed 1 inch in 12 inches (1:12).

4.4 Steps and seats

4.4.1 Seats or benches intended for use as entry and exit shall have a maximum water depth of 24 in. (610 mm)

4.4.2 The design and construction of spa or swim spa steps, where used, shall conform to Sections 4.4.2.1 through 4.4.2.5.

4.4.2.1 Step treads shall have a minimum unobstructed horizontal width of 12 in. (305 mm) and a minimum unobstructed horizontal depth of 10 in. (254 mm). Treads shall have a minimum unobstructed surface area of 120 sq. in. (774.19 sq. cm)

4.4.2.2 Riser heights shall not be less than 7 in. (178 mm) nor greater than 12 in. (305 mm). The bottom riser is permitted to be less than 7 in. (178 mm). Where the bottom treads serves as a bench, the bottom riser may be a maximum of 14 in. (356 mm) above the spa or swim spa floor.

4.4.2.4 Handrails, when provided, shall be installed so that they cannot be removed without the use of tools.

4.4.2.5 Spas and swim spas are intended for entry and exit from the surface supporting the spa or swim spa. If the rim of a portable spa or swim spa is designed by the manufacturer for use as a step, a handrail shall be provided.

5 Circulation systems

5.1 Complete circulation. A circulation system consisting of pumps, piping, return inlets, suction outlets, filters and other necessary equipment shall be provided for circulation of water throughout the spa or swim spa and to meet the requirements of the authority having local jurisdiction.

5.1.1 The system shall operate a minimum rate of 12 water turnovers within a 24-hour period in a clean filter media condition. The water turnover rate is calculated by dividing the total volume pumped through the filter in a 24-hour period by the spa volume.

5.1.2 Circulation system components. Components which require replacement or servicing, shall be accessible for inspection, repair, or replacement, and shall be installed in accordance with the manufacturer’s specifications.

5.2 Drainage. The circulation system shall be designed and fabricated to provide drainage from the circulation equipment.

3

ANSI/APSP/ICC-6 2013 (R2023) ©2023 The Pool & Hot Tub Alliance Copyright©2023byThePool&HotTub

Alliance. Allrights reserved.

5.2.1 The spa or swim spa manufacturer shall inform the owner on the proper method for the removal of water from a spa or swim spa and associated piping. The owner shall refer to the manufacturer’s instructions.

5.3 Time clocks. Time clocks are permitted to set the operating period. When time clocks are used, they shall also govern the operating time of appurtenant devices, such as chemical/sanitizing feeders, etc., that are dependent upon the circulation pump.

6. Filters

6.1 Design Filtration System shall be designed so that after cleaning per manufacturer’s specifications, the system can provide the water clarity noted in Appendix A, Subsection G.

6.1.1 All filter elements, media and other components which require servicing shall be accessible for inspection, removal, and repair, and shall be installed in accordance with the filter manufacturer’s instructions.

6.2 Pressure-type filters. On pressure-type-filters, a means shall be provided to permit the release of internal pressure.

6.3 Maintenance instructions. Pressure filters and separation tanks shall have operation and maintenance instructions permanently installed and clearly visible on the filter. They shall include a precautionary statement warning not to start up the system after maintenance without first opening the air release and properly reassembling the filter.

6.4 Piping. Piping furnished with the filter, shall be of suitable material capable of withstanding 1½ times the working pressure of the pump.

7 Pumps and motors

7.1 Design sizing. Pumps shall be sized to provide sufficient flow to meet the circulation rate as specified in Section 5.1.1. Spa pumps or swim spa pumps shall be tested and listed by a laboratory that has been accredited to the latest published edition of the ISO/IEO 17025 standard by an ILAC-recognized accreditation body. Pumps rated shall comply with the latest published edition of UL 1081, Standard for Safety Swimming Pool Pumps, Filters, and Chlorinators.

7.2 Rating. Pump horsepower rating and labeling shall not exceed the brake horsepower of the motor.

7.3 Pumps shall be mounted per pump manufacturer’s specifications.

7.4 Pumps shall be accessible for inspection, service, and maintenance.

7.5 Pumps shall be supported to prevent damage to the pump and piping due to settling or other movements.

8 Return inlets and suction outlets

8.1 Suction outlet testing and certification. Spa or swim spa suction outlets shall be tested and certified to the latest published edition of ANSI/APSP-16 by a laboratory that has been accredited to the to the latest published edition of ISO/IEC 17025 standard by an ILAC-recognized accreditation body.

8.1.1 Fittings other than suction outlet fittings shall be tested and certified to the latest published edition of ANSI/APSP-16 by a laboratory that has been accredited to the latest published edition of the ISO/IEC 17025 standard by an ILAC-recognized accreditation body.

8.1.2 A combination hydrotherapy fitting that incorporates a suction outlet and hydrotherapy inlet shall be designed in such a way as to avoid body entrapment, hair entrapment, and entanglement, and shall be tested and certified to the latest published edition of the ANSI/APSP-16 by a laboratory that has been accredited to the latest published edition of the ISO/IEC 17025 standard by an ILAC-recognized accreditation body

8.2 Suction system testing and certification. The spa or swim spa suction system shall be tested and certified to the latest published edition of UL 1563, by a laboratory that has been accredited to the latest published edition of the ISO/IEC 17025 standard by an ILAC-recognized accreditation body.

Exception: Under no circumstances shall any submerged suction outlet be located on entry steps, seating or lounge areas, or on the backrest(s) of such areas.

8.2.1 Systems other than spa suction configurations shall be tested and certified as a complete product to the latest published edition of ANSI/APSP-16 by a laboratory that has been accredited to the latest published edition of the ISO/IEC 17025 standard by an ILAC-recognized accreditation body.

8.2.2 Where installed, safety vacuum release systems (SVRS) shall be tested and certified to the latest published edition of ASME/ANSI A112.19.17 (SVRS) or ASTM F2387.

8.3 Entrapment avoidance. Spas or swim spas that are tested and certified to the latest published edition of UL 1563, and suction outlets that are tested and certified to the latest published edition of ANSI/APSP-16 by a laboratory that has been accredited to the latest published edition of the ISO/IEC 17025 standard by an

4

ANSI/APSP/ICC-6 2013 (R2023) ©2023 The Pool and Hot Tub Alliance Copyright©2023byThePool&HotTub

Alliance. Allrights reserved.

ILAC-recognized accreditation body shall be deemed to be in compliance with the entrapment prevention provisions for portable spas or swim spas of the VGB (Virginia Graeme Baker Pool and Spa Safety Act.) 1 and this standard.

8.4 Vacuum cleaning systems. Any vacuum cleaning systems shall have the access fitting mounted outside the spa or swim spa. The access fittings shall not be accessible to the spa or swim spa user.

8.5 Return inlets. Return inlet(s) shall be provided and arranged to produce circulation throughout the spa or swim spa.

9 Surface skimmer systems

9.1 Design and construction. A spa or swim spa with surface skimming devices shall be constructed to skim the spa or swim spa surface when the water level is maintained within the operational parameters of the system.

9.2 Safe operation. Surface skimming devices shall be designed and installed so as not to constitute a hazard to the user and shall comply with the latest published edition of UL 1563 or other equivalent test standard.

10 Electrical requirements

10.1 Testing and certification. Electrical components used in a portable spa or swim spa shall be evaluated for the application and listed by a laboratory that has been accredited to the latest published edition of the ISO/IEC 17025 standard.

10.2 Compliance. All electrical components installed in and/or adjacent to a spa or swim spa shall comply with the requirements of the National Electrical Code (NEC)® Article 680 or the authority having jurisdiction.

10.3 Grounding and bonding. Grounding and bonding required in a portable spa or swim spa shall comply with the latest published edition of UL 1563 and the authority having jurisdiction.

10.4 Accessibility. Electrical components which require replacement or servicing shall be accessible for inspection, repair, or replacement, and shall be installed in accordance with the manufacturer’s specifications.

10.5 Maintenance disconnect means. Disconnecting means shall be accessible, located within sight of the spa or swim spa electrical equipment and shall be located at a minimum of 5 ft (1524 mm) horizontally from the inside walls of the spa or swim spa.

11 Air blower and air induction systems

11.1 Air intake source. Air intake sources shall not introduce outside water, dirt, or contaminants into the spa or swim spa.

11.2 Electrical. Any component requiring electrical connection shall be evaluated for the application and listed by a laboratory that has been accredited to the latest published edition of the ISO/IEC 17025 standard.

11.3 Backflow/shock. To prevent electrical shock hazards, all air blower systems shall have backflow protection per manufacturer’s instruction, and shall comply with the latest published edition of UL 1563.

11.4 Installation. The air blower system shall be installed in accordance with the manufacturer’s specifications and shall comply with the latest published edition of UL 1563.

11.5 Safe operation. No part of the air blower system shall cause a hazard to users of the spa or swim spa.

11.6 Sizing. The air induction system shall be properly sized. Refer to manufacturer’s sizing specifications.

11.7 Make-up air. When installing an air blower within an enclosure, adequate ventilation is required. The air induction system shall be installed in accordance with the manufacturer’s specifications.

11.8 Accessibility. The air blower shall be accessible for inspection and service.

11.9 Air passages. Integral air passages shall be pressure tested at time of manufacture to provide structural integrity to a value of 1½ times the intended working pressure.

12

Heater and temperature requirements

12.1 Source. This section pertains to appliances used for heating spa or swim spa water.

12.2 Testing and certification. As applicable, heaters shall be tested and shall comply with the latest published editions of ANSI-Z21.56 for natural gas application, or UL 1261. Heat pumps shall comply with the latest published edition of UL 1995, as it pertains to heat pumps and be evaluated for the application and listed by a laboratory that has been accredited to the latest published edition of the ISO/IEC 17025 standard.

12.3 Water temperature controls

12.3.1. Water temperature regulating controls. Water temperature regulating controls shall comply with the latest published editions of UL 1563 and UL 372.

5

ANSI/APSP/ICC-6 2013 (R2023) ©2023 The Pool & Hot Tub Alliance Copyright©2023byThePool&HotTub Alliance. Allrights reserved.

1. U.S. Consumer Product Safety Commission Technical Guidance Section 1406 of the Virginia Graeme Baker Pool and Spa Safety Act: Minimum State Requirement for Grant Eligibility February 10, 2010. http://www.poolsafety.gov/wp-content/uploads/grants.pdf

12.3.2 Water temperature limiting controls. Water temperature limiting controls shall comply with the latest published edition of UL 1563. Water temperature at the heater return outlet shall not exceed 122 °F (50 °C)

12.4 Installation. The heater shall be sized and installed in accordance with the manufacturer’s specifications.

12.4.1. Support. The heater shall be installed on a surface with sufficient structural strength to support the heater when it is full of water and operating. The heater shall be stable and not able to move after plumbing, natural gas and/or electrical connection are completed.

12.4.2 Combustible surfaces. If the heater requires a non-combustible mounting surface per the adopted building code and manufacturer’s specifications, it shall be placed on a concrete or other accepted surface and comply with the latest published edition of ANSI Z21.56.

12.4.3 Clearances. The heater shall be installed and maintained with the minimum clearances to combustibles for which the heater has been tested as specified by the manufacturer.

12.4.4 Ventilation. All spas, swim spas and their related components installed in an indoor spa or swim spa environment, shall comply with the latest published edition of the ventilation requirements of ANSI/ ASHRAE 62.1, Table 2-Section 2.1. (For additional information on ventilation/humidity guidelines for indoor spas and swim spas, see the ASHRAE Handbook, HVAC Applications, I-P Edition, 4.5, 4.6, and 4.7.)

12.4.5 Make-up air. When installing a fossil fuel heater indoors, proper ventilation openings to the room are required. The heater shall be installed in accordance with the authority having jurisdiction and the manufacturer’s specification for properly sized and located air openings to the enclosure.

12.5 Heating energy source

12.5.1 Natural gas energy supply. The heater natural gas supply piping shall comply with manufacturer’s specifications and the latest published edition of ANSI Z223.1/NFPA 54.

12.5.1.1 Important safety note. Install a gas cock, properly sized and readily accessible outside the jacket, to stop the flow of natural gas at the heater for service or emergency shutdown.

12.5.2 Propane energy supply. When propane (LPG) appliances are used, they shall comply with the latest published editions of ANSI Z223.1/NFPA 54, and the ANSI/NFPA 58. The storage tank, supply piping, and regulator shall be adequately sized to ensure

operating fuel pressures as specified by the appliance manufacturer.

12.5.2.1 Important Safety Note. Propane gas is heavier than air and therefore can create an extreme hazard of explosion or suffocation if the heater is installed in a pit or enclosed area. The latest published edition of ANSI/NFPA 58, contains provisions for installing valves and controls in pits and similar areas.

12.5.2.2 Important Safety Note. Install a gas cock, properly sized and readily accessible outside the jacket, to stop the flow of propane (LPG) at the heater for service or emergency shutdown.

12.5.3 Electrical supply. Electric heating appliances shall be installed and shall comply with the latest published edition of UL 1563.

12.6 Heater circulation system

12.6.1 Water flow through the heater, any bypass plumbing installed, any back siphoning protection, and the use of heat sinks, shall be done in accordance with the manufacturer’s specifications.

12.6.1.1 Note. Some manufacturers recommend that the heater be turned off prior to stopping the water flow. Mechanisms such as a “fireman’s switch” adapted to the time clock will turn the heater off long enough for it to cool down before the time clock turns the pump off.

12.6.1.2 Note. The “fireman’s switch” does not protect against a manual override or a system shutdown in the event of power failure.

13 Instruction Manual, Safety Signs, Safety Messages and Features

13.1 Instructions. An instruction manual or the equivalent shall be provided with the unit. The manual shall specifically warn the user of each potential risk of fire, electrical shock, or injury to users and state the precautions that should be taken to reduce such risks. The instruction manual shall include installation instructions which contain information on proper wiring and connection to the supply circuit. Water treatment instructions shall also be included in the instruction manual (See Section 14.1 Treatment). The important safety instructions shall be a permanent part of the manual but separated in format from other instructions that may be provided and shall appear before the operating instructions in the manual. The manual shall specify that waste water may be discharged into an approved air gap, or into a subsurface disposal system, or by means approved by the authority having jurisdiction. (Also refer to Appendix B, Spa and Swim Spa Use Parameters.)

6

ANSI/APSP/ICC-6 2013 (R2023) ©2023 The Pool and Hot Tub Alliance Copyright©2023byThePool&HotTub

Alliance. Allrights reserved.

13.1.1 Owner’s manual warning or marking. The spa or swim spa manufacturer shall provide instructions that the Owner/operator is to routinely check the spa or swim spa water temperature to ensure that it does not exceed 104 °F (40 °C). Any adjustment, if required, shall be performed in accordance with manufacturer’s specifications.

13.1.2 Important Safety Note: The instruction manual shall contain the following or equivalent statement: Disconnecting means shall be accessible, located within sight of the spa or swim spa electrical equipment and shall be located at a minimum of 5 ft (1524 mm) horizontally from the inside walls of the spa or swim spa.

13.2 Safety signs. Spa or swim spa manufacturer shall provide instructions that instruct the owner to post signage in a prominent location which states the safety and emergency aspects of the spa or swim spa. The language and layout of the safety signs shall comply with the latest published edition of ANSI Z-535 and the latest published edition of UL 1563.

13.2.1 Location of signs. The spa or swim spa manufacturer shall provide instruction that a sign shall be posted in the immediate vicinity of the spa or swim spa, stating the spa or swim spa address, the location of the nearest telephone, and that emergency telephone numbers are posted by this telephone. Those emergency telephone numbers shall include the name and phone number of the nearest available police department, fire department, ambulance service, and/ or rescue unit, and/or “911,” if available.

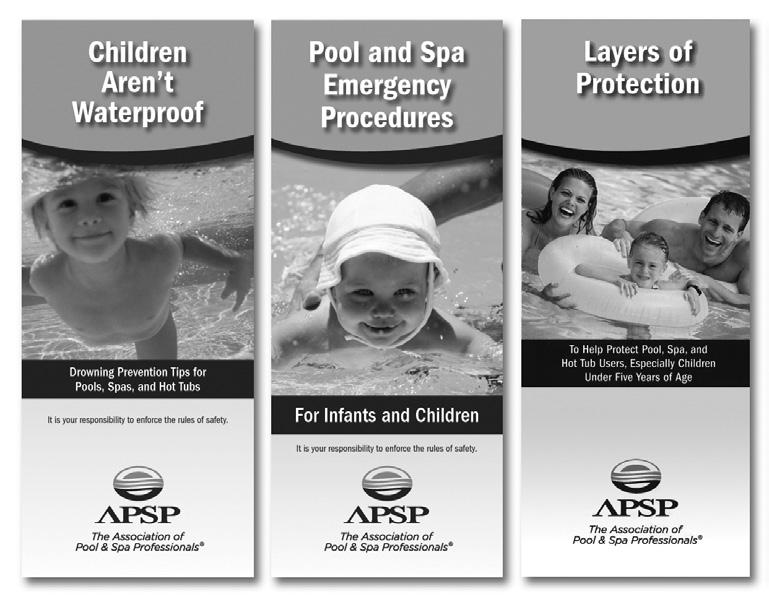

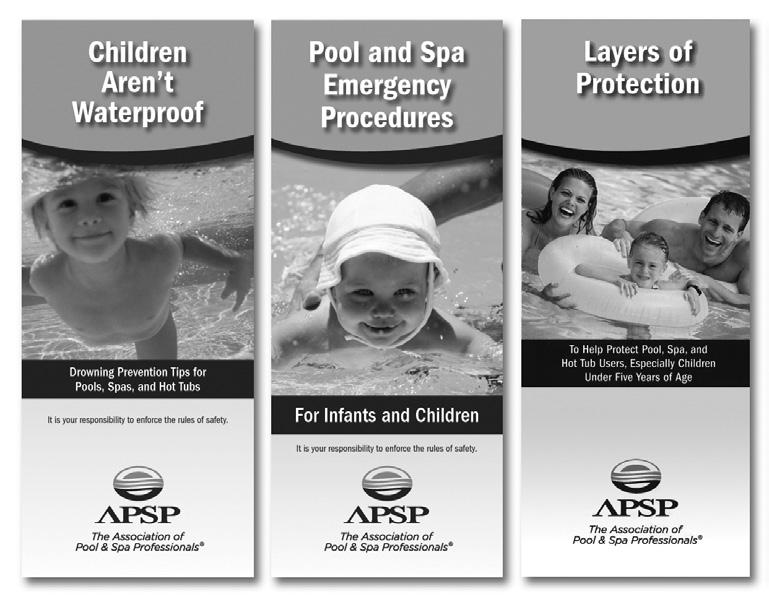

13.4 Safety literature. The spa or swim spa owner, or his/her representative shall be advised by the installing agent of the available publications related to spa or swim spa safety. These documents may include, but not limited to, APSP booklets entitled: Children Aren’t Waterproof, Pool and Spa Emergency Procedures for Infants and Children, and Layers of Protection (see Figure 1)

14 Water treatment supply

14.1 Treatment. The spa or swim spa manufacturer shall provide instructions stating that the water shall be tested and treated to meet the guidelines of Appendix A before the bather uses the spa or swim spa. (See Section 13.1)

14.2 Backflow. No direct connection shall be made between the potable water supply and the spa or swim spa, sanitizing equipment, or the system of piping for the spa or swim spa, unless it is protected against backflow and, back siphonage in a manner approved by the authority having jurisdiction or through an air gap, and shall comply with the latest published edition of ANSI A112.1.2.

14.3 Water temperature. The spa or swim spa manufacturer shall provide instructions stating that the temperature of the incoming make-up water shall not exceed 104 °F (40 °C) (See Section 13.1.1.)

15 Energy efficiency

Portable electric spas shall be in compliance with the latest published edition of ANSI/APSP/ICC-14. For access to these and other free safety publications, visit www.APSP.org

13.3 Unauthorized access. The spa or swim spa manufacturer shall provide instructions that the spa or swim spa shall be secured to protect against unauthorized access. All barriers shall meet the guidelines of the latest published edition of ANSI/APSP/ICC-8.

7

ANSI/APSP/ICC-6 2013 (R2023) ©2023 The Pool & Hot Tub Alliance Copyright©2023byThePool&HotTub Alliance. Allrights reserved.

Figure 1 APSP safety brochures

Copyright©2023byThePool&HotTub Alliance. Allrights reserved.

Appendix A Chemical Operational Parameters

This Appendix is not part of the American National Standard ANSI/APSP/ICC-6 2013 (R2023). It is included for information only.

These guidelines set forth the suggested operational parameters for the proper chemical treatment and maintenance of spas. Applicable health department guidelines and label directions supersede these parameters. Chemical treatment alone will not produce sanitary spa water. A filtration system in proper operational condition is also required to attain clear and sanitary water.

KEY

APSP-3 Permanently Installed Residential Spas and Swim Spas

A. SANITIZER LEVELS

1.Sanitizer Residual

APSP-6 Residential Portable Spas and Swim Spas

A residual of an EPA-registered sanitizer shall be present at all times and in all areas of the spa. One of the following EPA-register ed sanitizer systems shall be used: Chlorine; or Bromine; or PHMB; or Metal-based systems.

1.Free Chlorine, ppm

APSP-3 APSP-6

2.0−4.0 The U.S. EPA has established a maximum chlorine level of 5.0 ppm for re-entry of swimmers into spas.

• Residential Spas and Swim Spas: Maintain these levels continually. Test water before use. During extended use test water hourly. Shock treat water after use. Hot water/heavy use may require operation at or near maximum levels.

• Test kits are available for a variety of free chlorine ranges. Free chlorine test color (DPD) may be completely or partially bleached by chlorine levels greater than 5 ppm to give a false low reading. For appropriate test kit, consult spa professional or test kit manufacturer.

• Regular oxidation is recommended and remedial practices may be necessary.

2.Total Bromine, ppm

NOTE: Refer to manufacturer’s product label for specific use concentrations. Use concentrations vary between different types of brominating compounds.

spas and swim spas

The U.S. EPA allows maximum bromine levels of up to 8.0 ppm for re-entry of swimmers into the water.

3.PHMB (polyhexamethylene biguanide), ppm as product

All aquatic vessels

30 30–50

50

• Hot water/heavy use may require operation at or near maximum levels. Regular oxidation is recommended.

• Residential: During hours of operation, maintain these levels continually. Test water before use. During extended use test water hourly. Shock treat water after use.

Certain classes of chemicals or treatment processes are incompatible with PHMB sanitizer. The spa owner should consult with the supplier of PHMB if there is any question about compatibility of an auxiliary chemical or process. These include, but are not limited to: Chlorine/bromine sanitizers, copper-based algicides, monopersulfate peroxymonosulfate) oxidizers, phosphate-based chelating (metal sequestering) agents and detergents. For electrolytic chlorinators or metal-based ionizers when used with ozone, follow manufacturer’s directions. Consult professional or test kit manufacturer for appropriate test kit. Regular oxidation is recommended with a compatible oxidizer, such as hydrogen peroxide.

4.Metal-Based System

Any metal-based system that is not EPA registered as a sanitizer must incorporate an EPA-registered sanitizer; follow product manufacturer’s EPA-accepted label for use and/or operation requirements.

A-1

Standard Minimum Ideal

Maximum Comments

2.0

APSP-3 APSP-6 2.0 2.0–4.0 Residential

(continued) ©2023 The Pool & Hot Tub Alliance ANSI/APSP/ICC-6 2013 (R2023) Copyright©2023byThePool&HotTub

Alliance. Allrights reserved.

B. CHEMICAL VALUES

NOTE: When operating outside the ideal ranges, an LSI calculation should be performed to ensure the water is balanced.

1.pH

2.Total Alkalinity (Buffering) ppm as CaCO3*

All aquatic vessels 60 80–100 for calcium hypochlorite, lithium hypochlorite, and sodium hypochlorite

All aquatic vessels 60 100−120 for sodium dichlor, trichlor, chlorine gas and bromine compounds

3.Total Dissolved Solids (TDS) ppm

All aquatic vessels NA NA

7.8 If pH is too low:

• rapid dissipation of sanitizer

• plaster and concrete etching

• eye discomfort

• corrosion of metals

• vinyl liner wrinkling

180 If total alkalinity is too low:

• pH bounce

• Corrosion tendency

If pH is too high:

• low chlorine efficacy

• scale formation

• cloudy water

• eye discomfort

If total alkalinity is too high:

• Cloudy water

180

• Increased scaling potential

• pH tends to be too high or to drift upward more rapidly.

* These target values are based on the alkalinity from bicarbonate and carbonate only. Alkalinity should be corrected to account for cyanuric acid (see APSP-11, Section A 7.5).

4.Calcium Hardness, ppm, as CaCO3

1500 ppm greater than TDS at spa start-up. (Start-up TDS includes source water TDS and any other inorganic salt added at start-up or later.)

An increase in TDS may indicate an accumulation of impurities during the course of operation. Excessively high TDS (excluding the amount of sodium chloride added) may lead to hazy water, scale formation, and corrosion of fixtures, and may inhibit sanitation. For Spas: TDS should be periodically reduced by draining.

(See Section I, Water Replacement Procedure)

Total alkalinity and pH may need to be adjusted to the lower end of their respective ranges if hardness is over 500 ppm.

5.Heavy Metals

All aquatic vessels NA NA

If excessive heavy metals (such as copper, iron and manganese) are present:

• Staining may occur

• Water may discolor

• Filter cycle may decrease and require more frequent backwashing

• May indicate pH too low, corrosion, metallic source water, excessive metal ions from treatment chemicals, etc.

6.Langelier Saturation Index (LSI)

A-2

Standard Minimum Ideal Maximum Comments All

7.2 7.4–7.6

aquatic vessels

APSP-3 APSP-6 100 150−250 800

All aquatic vessels −0.3 0.0− ±0.5 ±0.5 ©2023 The Pool and Hot Tub Alliance ANSI/APSP/ICC-6 2013 (R2023) Copyright©2023byThePool&HotTub

Alliance. Allrights reserved.

C.STABILIZER (when used)

1.Cyanuric Acid, ppm

All aquatic vessels

10 30−50 100 If stabilizer is too low: Chlorine residual is rapidly destroyed by sunlight. If stabilizer is too high: May reduce chlorine efficacy against algae and pathogens. The effect of cyanuric acid on slowing the oxidation of organics, kill rates of bacteria, viruses, and algae has been demonstrated, primarily in controlled laboratory studies. However, no disease outbreaks linked to cyanuric levels in properly sanitized spas have been reported.

NOTE: Cyanuric acid is not recommended for indoor spas where protection from sunlight is not necessary. Cyanuric acid does not stabilize bromine sanitizers.

D.OXIDATION

(Regular oxidation is recommended for spas with normal bather load as a preventive treatment.)

1.Chlorine Products

APSP-3 APSP-6 As needed At the end of each day spa is used.

2.Potassium Monopersulfate

APSP-3 APSP-6 As needed At the end of each day spa is used.

Determined by bather load, weather conditions

Determined by bather load, weather conditions, etc.

Some high-use spas may require oxidation several times per week. Regular oxidation is recommended to prevent the build-up of contaminants, maximize sanitizer efficiency, minimize combined chlorine, and improve water clarity. Chlorine should not be used to oxidize a spa sanitized by PHMB.

Some high-use spas may require oxidation several times per week. Regular oxidation is recommended to prevent the build-up of contaminants, maximize sanitizer efficiency, minimize combined chlorine and improve water clarity. Potassium monopersulfate will measure as combined available chlorine in DPD test system. Refer to test kit manufacturer’s directions. Potassium monopersulfate should not be used to oxidize a spa sanitized by PHMB.

3.Hydrogen Peroxide

All aquatic vessels

Monthly As needed Determined by bather load, weather conditions, etc.

E. REMEDIAL PRACTICES

1.Superchlorination

All aquatic vessels

3.Shock Treatment and Shock Oxidizers

All aquatic vessels

Hydrogen peroxide should be used only with PHMB sanitizers. Hydrogen peroxide should not be used as an oxidizer for spas sanitized by chlorine or bromine.

Follow label directions. Use a registered chlorine sanitizer. Do not re-enter spa until water meets the prescribed values in Section A. Do not superchlorinate a spa treated by PHMB.

Some symptoms that may indicate a need for superchlorination are: cloudy water, slime formation, musty odors, and difficulty in maintaining a sanitizer residual, algae and/or high bacteria counts and eye irritation from chloramines. For fecal response guidelines, refer to http://www.cdc.gov/healthywater/swimming/ index.html

Some conditions that may indicate a need for a shock or a shock oxidizer are:

• Cloudy water

• Difficulty in maintaining a sanitizer residual

• Periods after heavy bather use

• Adverse weather.

Shock oxidizers are not sanitizers. They are effective in oxidizing organic contaminants. If the purpose is to treat bacteria or visible algae, an EPA-registered shock product should be used; follow label directions.

Spas should be shocked or shock-oxidized on a daily basis when used.

A-3

Standard Minimum Ideal Maximum Comments

(continued) ©2023 The Pool & Hot Tub Alliance ANSI/APSP/ICC-6 2013 (R2023) Copyright©2023byThePool&HotTub

Alliance. Allrights reserved.

4.Clarification

Standard Minimum Ideal Maximum Comments

All aquatic vessels As needed Follow manufacturer’s directions.

5.Algicides

All aquatic vessels As needed Use U.S. EPA-registered products. Follow manufacturer’s directions. Use of some algicides may cause foaming.

6.Foam Control

All aquatic vessels As needed There shall be no persistent foam (foam remaining in a spa after the jets are turned off).

F.Temperature

All aquatic vessels Personal preference Up to 104 °F (40 °C) depending on spa type and use

Foam may harbor persistent microorganisms.

If foaming is not adequately controlled, consider a daily shock or oxidation treatment, water replacement, or an appropriate anti-foam agent. Follow manufacturer’s directions.

104 °F (40 °C) If temperature is too low:

• Bather discomfort

If temperature is too high:

• Excessive fuel requirement

• Increased evaporation

• Bather discomfort

• Increased scaling potential

• Increased use of sanitizers

Overexposure to hot water may cause nausea, dizziness, and fainting. The Consumer Product Safety Commission states: “Hot tub water temperatures should never exceed 104 degrees Fahrenheit.”

Temperatures well below 104 °F (40 °C) are recommended for extended use (exceeding 10−15 minutes) or for pregnant women, people with certain medical conditions or medications, and young children.

G. WATER CLARITY

Standard Minimum Comments

All aquatic vessels The bottom of the spa at its deepest point shall be clearly visible. This test shall be performed when the water is in a non-turbulent state and bubbles have been allowed to dissipate.

H. SUPPLEMENTAL SANITIZERS

1.Ozone

(See Appendix C, Use of Ozone)

All aquatic vessels

2.UV

All aquatic vessels

If water is turbid:

• Sanitizer level may be low

• Filtration/circulation system may require maintenance or increased run (filtering) time

• Improper chemical balance (Section B)

• Consult remedial practices (Section E)

• Serves as oxidizer of water contaminants.

• Ozone shall be used only in conjunction with an EPA-registered sanitizer.

UV lamps shall be used only in conjunction with an EPA-registered sanitizer.

A-4

©2023 The Pool and Hot Tub Alliance ANSI/APSP/ICC-6 2013 (R2023) Copyright©2023byThePool&HotTub

Alliance. Allrights reserved.

I.Water Replacement

APSP-6 Water in spas that have high bather use requires partial or complete replacement of water periodically.

Water in spas that have high bather use requires complete replacement of water per the replacement guidelines below.

This procedure provides guidelines on how to determine the frequency for which spa or hot tub water should be replaced.

Test the TDS (Total Dissolved Solids) and calculate the WRI (Water Replacement Interval) to determine when a spa needs to be drained. Drain the spa completely, clean it thoroughly, and refill it with source water when either of the following conditions is met:

Water replacement is necessary to dilute dissolved solids, to maintain water clarity, and to do necessary routine maintenance.

Water replacement can be necessary even if water has been maintained properly.

High bather use is defined as amount of bathers per day, not necessarily the amount of time each bather is in spa.

Frequent water replacement is required to control TDS buildup from bathers and treatment chemicals.

WRI, days = (1/3) × (Spa Volume, U.S. Gallons) (Number of Bathers/Day)

Example 1

The TDS of the original source water was measured and recorded to be 800 ppm. The TDS of the spa water now reads 2,500 ppm. The difference is greater than 1,500 ppm (2,500 ppm –800 ppm = 1,700 ppm). Therefore, the spa should be drained immediately.

1. The Total Dissolved Solids (TDS) in the spa water exceeds the source-water TDS by 1,500 ppm or more, OR

2. The Water Replacement Interval (WRI) is less than or equal to the number of days since the last time the water was drained. WRI is calculated as shown in the following formula and examples:

Example 2

Consider a 600 gallon (2.271 kL) spa last drained and refilled on Sunday evening, with the usage pattern outlined in the table below:

The WRI is computed in the table below and compared to the interval since the last change. If the Difference (WRI–Days since last change) is less than or equal to zero, the spa should be drained.

A-5

600 Gallon (2.271 kL) Spa Usage Pattern Sun Mon Tue Wed Thu Fri Sat Sun Bathers Water changed at end of day 85 2 19 20 105 100 50 600 Gallon (2.271 kL) Spa Usage Pattern Sun Mon Tue Wed Thu Fri Sat Sun Bathers Water changed at end of day 85 2 19 20 105 100 50 WRI – 2 2 11 5 1 2 1 Difference (WRI minus Days since last change) – 1 0 10 3 –2 1 –1 Change Water (Difference = <0?) NO YES NO NO YES NO YES

Standard Minimum Ideal Maximum Comments

APSP-3

(continued) ©2023 The Pool & Hot Tub Alliance ANSI/APSP/ICC-6 2013 (R2023) Copyright©2023byThePool&HotTub

Allrights

Alliance.

reserved.

J.Testing Frequency

Standard Minimum Ideal Maximum Comments

All aquatic vessels The parameters for sanitizer, pH, clarity, and spa water temperature shall be met at all times.

EXCEPTION: when shocking/ oxidizing the spa, when closed for the season, or similar activities.

Testing frequency shall be sufficient to ensure that the sanitizer, pH, clarity, and spa water temperature standards set forth in this document are met at all times.

Several factors will determine how often testing is required. Weather, water conditions, and bather load are the primary factors for determining how often spas should be tested.

Rain and wind will introduce materials to the water such as plant debris (leaves, pollen), dirt, airborne pollutants, and other contaminants that will decrease sanitizer concentrations and increase the likelihood of chloramines. Rain also tends to decrease pH and alkalinity readings. After a major rainstorm, sanitizer, pH, and alkalinity should be tested. Bathers introduce microorganisms and body oils that increase sanitizer demand. Bathers usually will cause a decrease in pH. If there is a high bather load, the sanitizer and pH should be checked more frequently.

Appendix B Spa and Swim Spa Use Parameters

This Appendix is not part of the American National Standard ANSI/APSP/ICC-6 2013 (R2023). It is included for information only.

Optional and Additional Examples of Spa, Swim Spa Use Parameters* to Convey to the User:

1. Risk of Injury – Enter and exit slowly.

2. Risk of Injury – Keep all breakable objects out of the spa or swim spa area.

3. Risk of Shock – Spa or swim spa shall not be operated during severe weather conditions, i.e. electrical storms, tornadoes, etc.

4. Risk of Drowning – Do not allow the use of or operate if the suction outlet fitting is missing, broken or loose.

5. Risk of Drowning – Do not engage in extended breath holding activities underwater; you may black out and drown.

*Also refer to parameters in UL 1563.

A-6

©2023 The Pool and Hot Tub Alliance ANSI/APSP/ICC-6

Copyright©2023byThePool&HotTub

2013 (R2023)

Alliance. Allrights reserved.

Appendix C Use of Ozone

This Appendix is not part of the American National Standard ANSI/APSP/ICC-6 2013 (R2023). It is included for information only.

1. General

Ozone (O3) is a high energy, allotropic (i.e., containing only atoms of a single element) form of the element oxygen. Oxygen exists normally as a diatomic molecule, O2. Ozone, like oxygen, is a gas, and is partially soluble in water, being approximately thirteen (13) times more soluble than oxygen itself at standard temperatures and pressures. Ozone has a distinct odor readily identified by most humans even at very low (0.02 ppm) concentrations. The smell of ozone is often noted in the air after an electrical storm, because some ozone is generated by lightning. Ozone molecules in air or in water decompose to oxygen and energetic free radicals, which also are formed when ozone reacts with contaminants. Since ozone decomposes, it cannot be packaged, but must be generated and used on-site.

Like all oxidizing chemicals, ozone is hazardous, and ozone-generating equipment can produce dangerous levels. While its rapid decomposition makes high concentrations unlikely, and while research has shown no irreversible effects caused by accidental exposure to low, nonlethal concentrations, the United States Occupational Safety and Health Administration (OSHA) has standards for exposure to ozone.

Appendix D Use of Elemental Chlorine

In general, breathing even low levels of ozone should be avoided at all times. 1 Further information can be obtained from OSHA or from the International Ozone Association

P.O. Box 28873, Scottsdale AZ 85255 US

Tel: (480) 529-3787, Fax: (480) 522-3080

E-mail: infO3zone@io3a.org, www.io3a.org

As reported in OZONE AND OTHER PHOTOCHEMICAL OXIDANTS and published by The National Academy of Sciences, Washington, D.C., 1977, Henschler et al. reported that the characteristic pungent odor of ozone was detected instantaneously at low concentrations (less than 0.02 ppm), depending on individual sensory perception acuity. At higher concentrations, the odor was perceived as stronger and persisted for an average of thirteen (13) minutes. 2

1 The Permissible Exposure Limit to ozone, as specified by the OSHA, is 0.1 ppm, time weighted average over 8 hour day, with Short Term (up to 15 minutes) Exposure Limit of 0.3 ppm.

Ref. Federal Register 54(12): 2519 (Jan. 19, 1989)

2 Ref. Henschler, D., A. Stier, H. Beck, and W. Neumann. Geruchsschwellen einiger wichtiger Reizgase (Schwefel-dioxyd, Ozon, Stickstoffdioxyd) und Erschcinungen bei der Einwirkung Geringer Konzentrationen auf den Menschen.

Arch Gewerbepath. Gewerbehyg: 17:547 570, 1960

This Appendix is not part of the American National Standard ANSI/APSP/ICC-6 2013 (R2023). It is included for information only.

1. General

Chlorine is one of the chemical elements. The gas has a characteristic odor and greenish yellow color and is about two and one-half (2½) times as heavy as air. Chlorine is shipped in Department of Transportation specification steel containers; standard sizes contain either 100, 150, or 2000 pounds of chlorine. Residential pool and spa applicators using elemental chlorine for chemical treatment typically repackage the product from 2000 pound containers into 15-20 pound cylinders. In the cylinder the chlorine has both a liquid and a gas phase. All cylinders are equipped with the Chlorine Institute standard chlorine cylinder valve.

Chlorine is a “hazardous material” subject to Department of Transportation (DOT) requirements. When used for pool and spa disinfection, chlorine is considered a pesticide and as such is subject to pertinent regulations of the U.S. Environmental Protection Agency, as well as various state agriculture and environmental regulations. Vehicles transporting elemental chlorine must be placarded and must be operated by drivers holding a Hazmat-endorsed commercial driver’s license (CDL)in compliance with DOT regulations.

Users of chlorine must be trained as to the proper procedures for handling chlorine and as to appropriate emergency procedures. Detailed information is available from chlorine suppliers and the Chlorine Institute, 2001 L Street, N.W., Washington, D.C. 20036.

A-7

(continued)

©2023 The Pool & Hot Tub Alliance ANSI/APSP/ICC-6 2013 (R2023) Copyright©2023byThePool&HotTub

Alliance. Allrights reserved.

2. Residential Spas, Equipment, and Repackaging

2.1 Chlorine cylinders must conform to applicable DOT specifications.

2.2 Chlorine valves and associated equipment should also comply with CI specifications – see CI Pamphlet 97 for cylinders, Drawing 110 for valves, and Pamphlet 6 for transfer lines and hoses.

2.3 Cylinders must be marked with an EPA-approved label, which includes the repackager’s EPA establishment number and EPA product registration number. Applicator personnel must comply with the cautions and directions for use contained on the label.

2.4 Cylinders and valves must be maintained in good repair, and inspections and upkeep must be performed and documented per regulation (see CI Pamphlet 16 for valves and 17 for cylinders).

2.5 Storage and repackaging of filled and unfilled chlorine containers must be in compliance with applicable zoning ordinances and with applicable Fire and Building Codes. Cylinders should never be stored or left unattended at private residences.

2.6 Chlorine is repackaged and also normally dispensed by weight. Scales must be maintained in good working order per regulation.

3. Transportation and Residential Application

3.1 Where required, companies and/or applicators must be licensed by municipality or state.

3.2 Transport of chlorine in any quantity must be in properly placarded vehicles driven by commercial drivers with Hazmat endorsements.

3.3 Vehicles must conform to DOT and other applicable regulations, and should comply with CI recommendations, including proper securing of the chlorine cylinders as well as the recommended safety and communications equipment.

3.4 Shipping papers or manifests, vehicle inspection and maintenance logs, driver time logs, and driver qualification documentation, financial responsibility, etc. must be maintained and available per regulation.

3.5 If the truck is unattended, vehicles and contents must be secured per regulation and in accordance with the company Security Plan.

3.6 Precautions should be taken to prevent others, including homeowners, children, and pets, from disrupting the applicator from conscientious attention to safety.

3.7 Safety issues such as cylinder discharge rate, cylinder elevation relative to the water, vacuum and suck back prevention, etc. must be addressed.

3.8 Chlorine levels should be maintained per the product labels, and in accordance with APSP chemistry guidelines.

4.Safety

4.1 All companies and personnel handling chlorine gas must follow applicable federal, state, and local laws and regulations. These primarily include (but are not limited to) DOT, OSHA, and EPA, as well as local fire agencies.

4.2 Safety devices, such as chlorine sensors, automatic safety valves, audible alarms, emergency kits for sealing or containing leaks, etc., should be in place as required, inspected per manufacturer’s directions, and in good working order.

4.3 Programs including Response Management Programs, Process Safety Management, Respiratory Programs, Security and Emergency Response Plans, Material Safety Data Sheets, etc., must be maintained and documented per regulation.

4.42 Employee safety training and awareness must be provided and documented as federally mandated. This training includes (but is not limited to) driver and transport safety, product-specific safety, and safe handling. For product safety, see for example CI Pamphlet 151.

4.5 NIOSH-approved respiratory protective and/or emergency escape equipment should be available, may be mandated by the product label. If available, training must be provided and documented per regulation.

For additional information, contact The Chlorine Institute, Inc., 2001 L Street, NW, Washington, D.C. 20036, 202-775-2790, and request a copy of the Chlorine Manual and the wall chart entitled Handling Chlorine Cylinders and Ton Containers.

A-8

Appendix D, continued

©2023 The Pool and Hot Tub Alliance ANSI/APSP/ICC-6 2013 (R2023) Copyright©2023byThePool&HotTub Alliance. Allrights reserved.

Appendix E

Metric Conversion Table (Approximate Factors)

This Appendix is not part of the American National Standard ANSI/APSP/ICC-6 2013 (R2023). It is included for information only.

ENGLISH STANDARD - METRIC Symbol When Multiply by To Symbol You Know (Approximate Factor) Find

METRIC - ENGLISH STANDARD Symbol When Multiply by To Symbol You Know (Approximate Factor) Find

square meters 10.8 square in. yd2 km2 sq. kilometers 0.4 square miles mi2

MASS

hectares (10,000 m2) 2.5 acres

TEMPERATURE (See also below)

subtracting 32)

Degrees Fahrenheit

Degrees Celsius

* Many websites provide on-the-fly metric and other conversions. This standard has used All Conversions (www.allconversions.com).

A-9

LENGTH in. inches 2.54 centimeters cm ft. feet 30.48 centimeters cm yd. yards 0.9 meters m mi. miles 1.6 kilometers km AREA in2 square inches 6.5 sq. centimeters cm2 ft2 square feet 0.09 square meters m2 yd2 square yards 0.8 square meters m2 mi2 square miles 2.6 sq. kilometers km2 acres 0.4 hectares ha MASS oz. ounces 28.35 grams g lb. pounds 0.45 kilograms kg short tons (2000 lb.) 0.9 metric tons t VOLUME tsp. teaspoons 5 milliliters mL Tsp. tablespoons 15 milliliters mL in3 cubic inches 16 milliliters mL fl.oz. fluid ounces 30 milliliters mL c. cups 0.24 liters L pt. pints 0.47 liters L qt. quarts 0.95 liters L gal. gallons 3.8 liters L ft.3 cubic feet 0.03 cubic meters m3 yd.3 cubic yards 0.76 cubic meters m3

°F degrees Fahrenheit 5/9 degrees Celsius °C (after

LENGTH mm

0.04

cm

0.4

m meters 3.3

m

1.1

km kilometers 0.6

mi.

m2

millimeters

inches in.

centimeters

inches in.

feet ft.

meters

yards yd.

miles

AREA cm2 square centimeters 0.16 square in. in2

ha

g grams 0.035 ounces oz. kg kilograms 2.2 lb. lb. t metric ton (1,000 kg) 1.1 short tons VOLUME mL milliliters 0.06 cubic in. in3 mL milliliters 0.03 fluid ounces fl.oz. L liters 2.1 pints pt. L liters 1.06 quarts qt. L liters 0.26 gallons gal. m3 cubic meters 35 cubic feet ft3 m3 cubic meters 1.3 cubic yards yd3 TEMPERATURE °C degrees Celsius 9/5 degrees Fahrenheit °F (then

add 32)

130°F 120°F 110°F 100°F 90°F 80°F 70°F 60°F 50°F 40°F 30°F 20°F 10°F 0°F -10°F -20°F 50°C 40°C 30°C 20°C 10°C 0°C -10°C -20°C -30°C

©2023 The Pool & Hot Tub Alliance ANSI/APSP/ICC-6 2013 (R2023) Copyright©2023byThePool&HotTub Alliance. Allrights reserved.

Appendix F Sources of Material

This Appendix is not part of the American National Standard ANSI/APSP/ICC-6 2013 (R2023). It is included for information only.

ANSI American National Standards Institute

25 West 43rd Street

New York NY 10036

Tel: 212-642-4900

Fax: 212-398-0023

www.ansi.org

APSP Association of Pool & Spa Professionals (formerly National Spa and Pool Institute)

2111 Eisenhower Avenue

Alexandria VA 22314

Tel: 703-838-0083

Fax: 703-549-0493

www.apsp.org

ASME American Society of Mechanical Engineers

3 Park Avenue

New York NY 10016

Tel: 800-843-2763

Fax: 212-591-7739

www.asme.org

ASTM International Standards Worldwide (formerly American Society of Testing & Materials)

100 Barr Harbor Drive

West Conshohocken, PA 19428-2959

Tel: 610-832-9500

Fax: 610-832-9555

www.astm.org

IAPMO International Association of Plumbing and Mechanical Officials

5001 E. Philadelphia Street

Ontario, CA 91761

Tel: 909-595-8449

Fax: 909-472-4150

www.iapmo.org

NEC National Electrical Code (see NFPA)

NFPA National Fire Protection Association

1 Batterymarch Park

Quincy MA 02269

Tel: 617-770-3000

Fax: 617-770-0700

www.nfpa.org

NSF NSF International

789 N. Dixboro Rd.

P.O. Box 130140

Ann Arbor MI 48113-0140

Tel: 734-769-8010

Fax: 734-769-0109

www.nsf.org

UL Underwriters Laboratories Inc.

333 Pfingsten Road

Northbrook IL 60062-2096

Tel: 847-272-8800

Fax: 877-272-8129

www.ul.com

(Approved by the American National Standards Institute January 9, 2013)

A-10

©2023 The Pool and Hot Tub Alliance ANSI/APSP/ICC-6 2013 (R2023) Copyright©2023byThePool&HotTub

Alliance. Allrights reserved.

Copyright©2023byThePool&HotTub Alliance. Allrights reserved.

ANSI/APSP/ICC-6 2013 (R2023) American National Standard for Residential Portable Spas and Swim Spas Copyright©2023byThePool&HotTub Alliance. Allrights reserved.