3 minute read

Dripper comparison

254∗10∗(��������.����������������∗ 44∗1.0² ��������.�������� ����������������)² = 254∗10∗(��������.����������������∗ 44∗1.0² ��������.����������������)² �������� = 7.7 �������� = 7.7

NETAFIM TALKS:

Advertisement

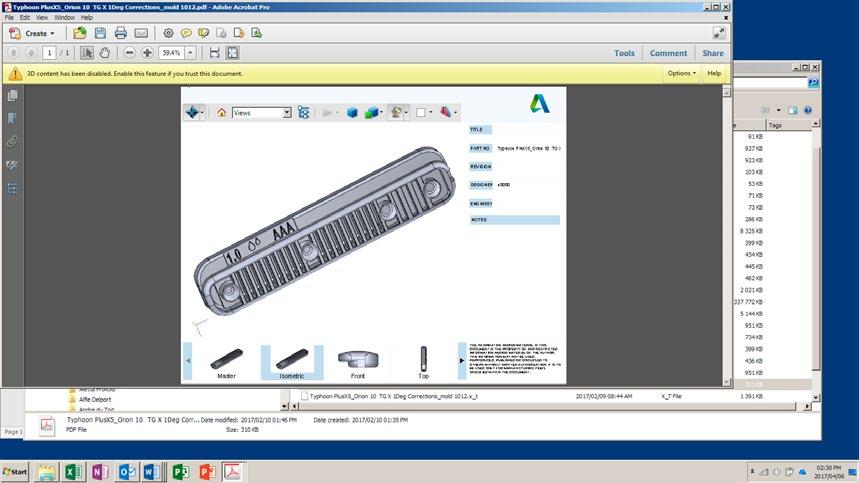

Figure 1. The filter at the inlet to a modern boat‐shaped non‐PC dripper Figure 2. The labyrinth of a non‐PC dripper with the exit ‘bath’ to the left, where a hole would be made through the dripperline wall for the droplet to exit the irrigation system Figure 1. The filter at the inlet to a modern boat-shaped non-PC dripper Figure 2. The labyrinth of a non-PC dripper with the exit ‘bath’ to the left, where a hole would be made through the dripperline wall for the droplet to exit the irrigation systemFigure 1. The filter at the inlet to a modern boat-shaped non-PC dripper Figure 1. The filter at the inlet to a modern boat‐shaped non‐PC dripper Figure 2. The labyrinth of a non‐PC dripper with the exit ‘bath’ to the left, where a hole would be made through the dripperline wall for the droplet to exit the irrigation system Figure 1. The filter at the inlet to a modern boat-shaped non-PC dripper Figure 2. The labyrinth of a non-PC dripper with the exit ‘bath’ to the left, where a hole would be made through the dripperline wall for the droplet to exit the irrigation system Figure 2. The labyrinth of a non-PC dripper with the exit ‘bath’ to the left, where the droplet exits the irrigation system. Figure 2. The labyrinth of a non‐PC dripper with the exit ‘bath’ to the left, where a hole would be made through the dripperline wall for the droplet to exit the irrigation system

Dripper Comparison

A farmer and his crop care not about devices are unique specific drippers Coefficient, the lower the dripper’s the specifics and technical details of and are not measurable. sensitivity to clogging and the better a dripper. It is what comes out of the dripper that they care about. They A method has now been devised to quantify the common features, its ability to maintain a constant flow rate. This is achieved by the vortexes Figure 2. The labyrinth of a non‐PC dripper with the exit ‘bath’ to the left, where a hole would be made through the dripperline wall for the droplet to exit the irrigation system need a dripped supply of water into formulate a score to evaluate quality, that develop in the labyrinth and the wetted bulb-shaped root zone on and make an educated choice that create a self cleaning stream demand during the life of the crop. best suits the application in question. which purges contaminants This dripped supply may not vary or The concept involves two aspects: out of the dripper. decrease over time. It must be accurate and constant over the crop’s life. the dripper’s net filtration area and its Turbulence Coefficient. The higher the Turbulence Coefficient, the better the quality. To work out the We know in reality, that there is a vast difference in drippers and specifically The Turbulence Coefficient Turbulence Coefficient, simply follow the formula below: dripper quality. A good quality dripper may be defined as one that emits A dripper’s structural features can be defined as an inlet filter, an inlet K = 254 x P x (W x D) a predetermined flow rate that is orifice, a flow path whose shape is N x Q2 accurate and constant. a labyrinth with teeth, an exit ‘bath’ K – Turbulence Coefficient Features that contribute to keeping and finally an orifice that is made P – Pressure differential through a dripper clean and working are through the wall of the drip line from the labyrinth in metres essentially those that contribute to the dripper’s quality. The main structural which the droplet leaves the irrigation system and goes into the root zone. W – Width of labyrinth water passage in mm features, such as the filtration area, the labyrinth depth, width, and length, are common to all drippers and are With the exception of the inlet filter, the Turbulence Coefficient embraces all of the structural features of the D – Depth of labyrinth water passage in mm all measurable. Other features, such dripper and contributes to its quality. N – Number of teeth in the labyrinth as anti-root intrusion and anti-siphon In essence, the higher the Turbulence Q – Labyrinth flow rate in litres per hour

Orange Pumps strives to build reliable, effi cient, high performing and cost competitive water pump products. Designed and developed in Melbourne, utilising our heavy duty electric motors and uniquely shaped pump internals for maximium performance.