21 minute read

News

Scottish timber initiative plants seed of construction sustainability

Greater use of homegrown timber in UK construction is taking a significant step forward through a new demonstrator project, which could lead to a major boost for Scotland’s economy and the industry’s environmental impact.

A consortium of partners – comprising of Construction Scotland Innovation Centre (CSIC), Edinburgh Napier University (ENU) Centre for Offsite Construction and Innovative Structures (COCIS), Scottish Forestry, Confederation of Forest Industries (Confor), and SNRG – has secured funding from Innovate UK’s Sustainable Innovation Fund to prove the business case for using Scottish timber to create the structural elements of buildings. The initiative will manufacture the first Scottish-sourced cross laminated timber (CLT) and nail laminated timber (NLT) housing unit – including wall, roof, and floor – using the UK’s only vacuum press at CSIC’s 35,000 sq. ft. innovation factory in Hamilton. The demonstrator project could ultimately lead to the mainstream use of home-grown timber in Scotland and the rest of the UK construction, as well as the development of the country’s first engineered timber manufacturing plant. The CLT and NLT superstructure will be showcased at the COP26 United Nations conference on climate change, set to take place in Glasgow between November 1 and 12 2021.

Sam Hart, innovation manager at CSIC, said: “The project is an important milestone in the move towards more mainstream use of homegrown timber in the UK’s construction sector, the majority of which is grown in Scotland. Research has proven that, with the right treatment and processing, our timber can be used for a wide variety of higher-value purposes beyond its relatively limited set of current applications. Through its increased use in commercial construction and housebuilding, we can also reduce our reliance on imported timber. The next step from there will be to make the industry aware of this transformational potential and make it a reality. Greater use of our natural and renewable resources will deliver a range of environmental, cost, and economic benefits for Scotland and the wider UK. COP26 is a once in a generation opportunity to showcase what can be achieved.” Among a range of benefits, using more homegrown timber is expected to significantly lower costs for the construction industry – initial figures suggest a potential reduction of as much as 10% compared to imported CLT – cut carbon emissions through reduced need for transportation, and open new markets to the UK-based timber sector. Analysis has suggested that around 85% of all new homes in Scotland are built using timber and recent UK Government statistics show that, in 2018, the UK was the world’s second largest net importer of forest products – including timber – behind only China.

Timber grown in the UK has historically been used for nonstructural applications, such as fencing and palettes. However, ENU COCIS has led on research and development to determine the viability of using home-grown timber for the production of mass timber products and systems, such as CLT, NLT, Glue Laminated Timber (GLT), and Dowel Laminated Timber. As a result, a number of UK-sourced mass timber products have been pilot manufactured, tested, and analysed. The latest project is a natural progression to trialling homegrown timber in a live environment, demonstrating the investment case for developing a Scottish manufacturing facility that can offer an alternative to products currently imported from Europe.

Jason Hubert, head of business development at Scottish Forestry, said: “Scottish Forestry, and the wider Scottish Government, recognises the importance of increasing Scottish timber in construction as a means of storing carbon for the long term as well as generating green jobs for the country. This project will provide the springboard for the sector to start manufacturing a great engineering product which can be used in large-scale buildings using homegrown timber. The Scottish Government is committed to getting more Scottish timber into construction and aims to increase the current 2.2 million cubic metres to 2.6 million cubic metres each year by 2021/2022.”

Wexham Golf Club unveils eco-cladding

Composite Prime has provided Wexham Park Golf Centre with a revolutionary and eco-friendly composite cladding system for its new driving range in a £500,000 project. RB Structures, using Pontrilas Timber Merchants supplied Composite Prime’s HD Clad Pro for the club’s new driving range.

Charles Taylor, sales director at Composite Prime, said: “We’re delighted to have collaborated with RB Structures on the project at Wexham Park Golf Centre. We’re pleased to have been able to supply one of the premier golf clubs in the country with a sustainable, long lasting and low maintenance solution for its new driving range. The project, which is 330 square metres in size, saw almost one million bottle caps being recycled. HD Clad Pro was the perfect component as it is easy to install and comes in a variety of shades with concealed fixings.”

Composite Prime manufactures ethical decking and cladding solutions for commercial and residential settings. By combining FSC 100% certified end of life hardwood timber and recycled HDPE plastics, Composite Prime’s products retain the natural look and feel of timber with the added strength and durability of plastic. For each square meter of decking produced, the equivalent of 3000 plastic bottle caps are recycled.

HD Clad Pro® is a wood grain composite cladding system that provides a durable alternative to traditional timber cladding for residential, industrial and commercial exteriors. HD Clad Pro® is manufactured using recycled plastic and sustainable timber; it is UV stable and stain resistant, providing protection against long-term degradation and damage.

Sharon Lowthian, general manager at Wexham Golf Driving range added: “We’re absolutely thrilled to have found a sustainable and attractive product to install at our new golf driving range. The product provides the perfect solution for us and we’re incredibly happy with the finished project. The cladding looks good and will be enjoyed by our members for years to come.”

Composite Prime manufactures a range of nine products, including cladding, decking and flooring, which are tested against the latest requirements to measure strength, impact resistance, weathering, extreme temperature cycles, UV resistance and water absorption. Founded in 2014 by Domenic Harrison and Charles Taylor and based in Ilkley, West Yorkshire, Composite Prime is one of the UK’s leading brands of sustainable composite decking.

More at www.composite-prime.com

New production line for National Timber Systems

National Timber Systems has invested in a new manufacturing system for its engineered joists, which will double its overall capacity. The production line, located at its Catterick site, has been dubbed the ‘Joist Super Centre’ after increasing the facility’s output from 250,000 metres per year to more than a million. This means National Timber Systems is capable of producing two million metres of engineered joists each year.

The system allows operatives to transfer engineered joists from its storage rack to the production line, without the need for a forklift. This significantly reduces handling time and has had an enormous impact on efficiency. As a result of its increased capacity, the Catterick site will now also fulfil the joist needs of its Hebburn and Sheffield manufacturing facilities.

Nick Kershaw, managing director at National Timber Systems, said: “National Timber Systems serves some of the country’s largest house builders and it’s been essential that we quickly scale up our capacity and improve efficiency to ensure we can fulfil the increased volume of orders. This investment furthers our ability to do this, and also gives us additional flexibility and room to continue with our growth plans.”

National Timber Systems combines the design, manufacturing, and logistic capabilities of Arnold Laver and NYTimber – both part of National Timber Group. The collaboration has created a high-quality national offering for house builders and developers. Its product range includes an innovative NYTROOF rapid fit roof panelised system, gable and party spandrels, trussed rafters, engineered joists, as well as floor and roof cassettes.

Richard Jarvis, Operations Director at National Timber Systems led the project, added: “The new set-up includes additional saws and racking, which has transformed the way we process our engineered joists. We simply had to make changes to meet demand.”

This follows on from National Timber Systems, shattering a monthly sales record set more than a year ago by generating sales worth £2.6 million in October 2020. It attributed a large part of its recent success to customer referrals and word-of-mouth. Many buyers, site managers, and commercial directors recommend its products when they change roles or move to a new company, generating new business.

Nick Kershaw, Managing Director of National Timber Systems, said: “The team have been working remarkably hard in difficult circumstances and it’s great to see this reflected in our figures. Hopefully, we can carry this momentum into 2021 and continue to increase our share of the engineered timber market. “The record sales month is even more pleasing when you consider that it is driven by satisfied customers. We deliver on our promises and in turn have become an asset that people use throughout their career. It’s the best sales and marketing strategy we could have wished to create.”

James Jones & Sons Ltd funds acquisition of windfarm

James Jones & Sons Ltd has announced that it has funded the acquisition of the UK’s first subsidy-free windfarm, Inverclyde Windfarm Ltd, from BayWa r.e., in tandem with London-based specialist asset manager, Gresham House Asset Management.

Located in Inverclyde, south of Greenock and west of Port Glasgow, the site consists of eight wind turbines and has a total capacity of 24 MW. The clean energy produced will displace more than 18,000 tonnes of CO2 emissions annually. Earlier this year, Tesco Stores Ltd signed a 15-year Power Purchase Agreement as the energy off-taker, thereby contributing to the retailer’s commitment to use 100% renewable electricity across the Tesco Group by 2030.

James Jones Chairman, Tom BruceJones said: “James Jones & Sons Ltd is delighted to have funded this acquisition and this will further strengthen our trading and investment relations with Gresham House. We are constantly seeking ways to further enhance our carbon negative credentials for our products and activities and displacing 18,000 tonnes of CO2 via the Inverclyde windfarm now supplements the reduction of 17,200 tonnes from our in house biomass plants. We have been at the forefront of innovation with regards to all environmental matters for a number of years for all of our sawn timber, engineered wood products and pallet and packaging solutions.”

This investment is part of a Group wide 2020 capital expenditure programme that has not slowed down in the face of the Covid-19 pandemic. The Group has completed two new biomass projects at Aboyne and Mosstodloch, has opened a new pallet inspection and repair site in Coventry and is extending the Lockerbie sawmill site log yard in a £3 million project.

More at www.jamesjones.co.uk

Timber imports continue strong market recovery

Timber and panel import volumes performed strongly in October 2020 for the fifth consecutive month since June, according to the latest timber statistics for October 2020. The Timber Trade Federation (TTF) monthly report reveals total import volumes for main timber and panel products were 21% higher in October 2020 compared to October 2019 levels, as import volumes in the month soared above the 1 million m3 mark.

However, even this strong performance cannot compensate for the loss of import volume in Q2 meaning the ten months to October 2020 is still 11% below, compared to the same time last year. Solid wood imports were 8% below the same period in 2019 and panel product imports were 15% lower. The main drivers of growth in the early Autumn were OSB and softwood imports, supported by higher volumes of plywood and MDF compared to the same period in 2019. Collectively, these four products have led to a 15% (377,000m3) increase in the latest three months (August-October 2020) for which data is available.

Softwood import volume topped over 700,000m3 in October 2020, the highest October volume since 2003. The main contributors were Sweden and Latvia with Germany and Russia also exporting more to the UK in the month compared to October 2019.

OSB imports in October 2020 were 54,000m3, the highest in the ten months to October, and a 68% increase from the volumes seen in October 2019 (32,000m3). MDF imports continued a steady increase reaching its highest monthly total in 2020 with 77,000m3 and an 18% increase from October 2019 (65,000m3). Plywood imports continued to show a strong recovery reaching triple figures for the second consecutive month with 111,000 m3 in October 2020, slightly bettering the previous year’s imports (October 2019, 107,000m3.)

David Hopkins, CEO of the Timber Trade Federation, said: “This year has seen demand increase considerably across all products, while supply chains have been severely disrupted as a result of the COVID pandemic, so it is good to see imports rebound so strongly. From talking to our members, we expect the statistics for the last two months of 2020 to continue to show this trend and end the year only slightly below 2019 imports, which would be a remarkable achievement given the circumstances. However, despite this comeback in supply, we must reiterate that the supply situation remains tight with suppliers keeping most customers on allocation until further notice. These statistics are a positive sign, but we have some way to go before balancing the market demand.”

More at www.ttf.co.uk

MEDITE®

makes it real

From windows and doors to tables and chairs. To kitchen cupboards, skirting and bespoke-crafted stairs. For dolls houses and toys, putting smiles on little ones’ faces. And planters and baskets in our beloved green spaces. The clocks, the picture frames that adorn living room walls. The desks for home working and learning in schools. Engineered wood panels for imaginative builds, whether practical or playful, MEDITE® makes it real.

Join the MEDITE MDF community online to receive the latest updates and to be entered into a competition – sign up to receive a free gift.

AFI asks UK fencing contractors about timber post failures

Since the sale of traditional CCA (copper/chrome/arsenic) treatment ceased in 2006, followed by the withdrawal of chromium preservatives in 2008, there have been regular reports of the failure of timber posts in ground contact. The Association of Fencing Industries (AFI) have been monitoring the situation since its formation in 2017 and have been discussing the matter with the treatment industry via the Wood Protection Association (WPA).

The AFI say: “The WPA’s view is that currently available preservatives do work if the treatment level is specified correctly and products are used in accordance with the manufacturers’ instructions. Wood intended for ground contact must be specified and treated as Use Class 4 to BS8417. It is the WPA view that failures are due to a combination of some users buying solely on cost without reference to quality or accurate specification and/or poor treatment/timber drying practice in some parts of the treatment industry.

“Whilst we at the AFI have no reason to doubt their judgement we feel the contractors in the UK have borne the cost of this failure of the treatment industry to regulate itself for far too long. The time has come to find a long-term solution to the problem and ensure that treatment of the timber products we use is ‘fit for purpose’.

“If the view expressed by the WPA is correct then the AFI feel that it should be possible to introduce a warranty scheme which will allow contractors to use the products covered by the scheme secure in the knowledge that the ‘total cost of replacement’ i.e. removal, disposal and replacement, including labour and materials, is covered by the supply chain.

“The AFI has proposed a scheme to the WPA to do this. However, the WPA board is reluctant to move forward with a scheme of this sort without further reassurance that AFI members and the contractor sector in general are committed to change, regardless of any necessary (modest) cost premium. As there will be a considerable cost to the setting up of a scheme of this sort which will result in additional costs to the ground contact products of around 2-3% it is felt that this would mean that contractors will not take up the scheme and WPA members would simply lose business to cheaper alternatives (which offer no such guarantee).”

New AFI Chairman, Cameron Glanvill, said: “We cannot allow this to continue, if nothing can be done and our customers demand a guarantee then our only option is to use alternative treatments or materials such as steel, concrete or plastic composite posts.” In order to establish the contractor’s view of the proposed scheme the AFI have set up a questionnaire available on its website, with answers going back to the WPA.

Arbor Forest Products launch new Trex division

Arbor Forest Products has signalled its ambitions within the composite decking market with the creation of a dedicated Trex business unit, and the appointment of Jonathan Cooper (pictured) as business manager for the division.

The North Lincolnshire-based business, which is one of the UK’s largest timber importers and timber products suppliers, is the exclusive UK distributor of Trex Transcend decking and more recently added the Trex Enhance collections to its offering. Under Jonathan’s guidance, the company’s aim is for Trex to become the UK’s leading composite decking brand, mirroring its position in the US. Jonathan has more than 20 years’ experience within the building products sector, and within the composite decking market in particular thanks to his previous role as managing director of Ecodek and Dekboard.

Commenting on his new role with Arbor Forest Products and Trex, Jonathan said: “I am very much looking forward to working with Trex: Arbor Forest Products has ambitious plans to develop the Trex ranges into one of the widest and most readily available collections of outdoor living landscape products for the UK market – for both domestic and commercial projects. We have plans to expand our reach into the landscape architecture and specification sectors, as well as continuing to consolidate our market share within the merchant market too, and further develop successful schemes such as the TrexPRO installer programme and expand the Trex product offering in the UK.”

Arbor Forest Products’ managing director, Jason Ostler added: “In the years since we launched the Trex brand in the UK, the decking market has continued to boom in this country and we are proud to have maintained our place at the forefront of the growing composite decking sector. We’re rightly proud of how well the product has performed, and we want to ensure that we step up our investment in the continued success of the products, which is why we have taken the decision to appoint Jonathan to lead this new division with our business. Jonathan brings with him a vast amount of experience in the landscaping sector and is here to offer a fresh perspective and to take Trex to the next level within the UK.”

More at www.arbordeck.co.uk

Anti-slip Plus smooth deckboards from Marley, installed by Deckbuilders UK.

For independent guidance on your next project

Ensure your timber decking or cladding is fit for purpose through design, specification, material choice and installation. Whatever the size of your project, TDCA can offer: - an accredited materials and supplier database - impartial and expert help by phone or email - inspiration, through galleries and case studies - inspection & expert witness services - free downloadable resources including our NEW Timber Cladding Handbook

email: info@tdca.org.uk visit: www.tdca.org.uk

The Timber Decking and Cladding Association is an independent, not-for-profit technical and advisory body. It was established to promote the materials, design and installation practices required to create good quality decks, associated landscape structures and cladding on buildings.

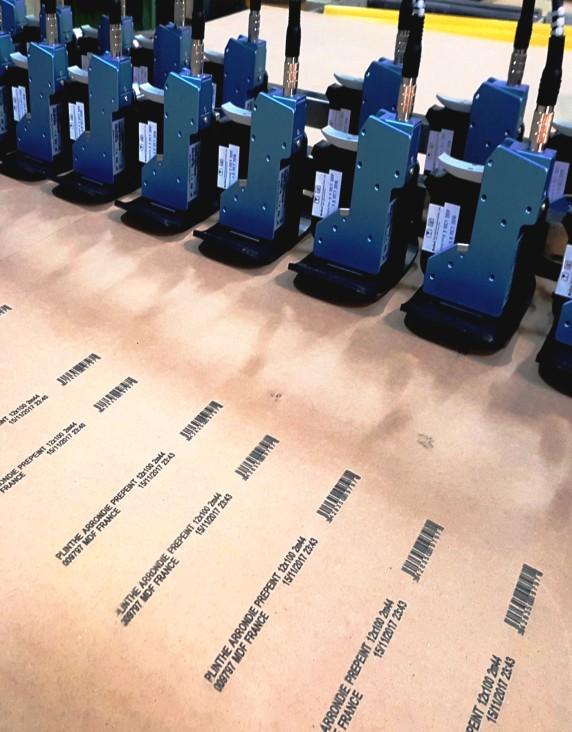

AJ Ferguson sees brand new panel cutting centre operational

Responding to the market demand and as part of its continued commitment to providing only the best quality service, they recently invested in a £85k premium numerical control beam saw, the BIESSE SELCO WN2.

“This machine is specially designed to guarantee cutting precision and rigidity. It enable us to accept a significantly larger number of orders whilst helping us to maintain a high quality of standards and offering product customisation with shorter delivery times. This improves production and machining quality by moving from conventional manual machinery to real cutting technology which is reliable and easy to use.”

BIESSE SELCO WN2 is equipped with the latest unique patented technical solutions to satisfy even the most rigorous production demands. The machine is fitted with a Twin Pusher - exclusive patented system which offers an additional pushing device consisting of two fixed collets. It permits simultaneous cutting, which drastically reduces the cycle time. In addition to this the blade protrusion of 80mm allows it to cut a stack of three boards at the same time.

A special software creates individual labels and prints them in real time, on the machine. Labels can contain e.g. panel size, edge banding indicator, panel description or any other relevant information you may require. Our machine works with the software for optimising cutting patterns. Based on the list of pieces to be produced and the panels available, it can calculate the best solution to minimise material consumption and production costs. This is beneficial both economically and environmentally.

AJ Ferguson has created a new showroom where you can see samples of the various sheet materials and other products on offer and can discuss project requirements with one of its dedicated advisors.

More at www.ajferguson.co.uk

High quality media dedicated to the timber sector

WWW.TIMBERMEDIA.CO.UK

IS AN EXCELLENT CHOICE FOR ANY GREEN BUILDING PROJECT

Using wood products from responsibly managed forests is key to any green building project. Third-party forest certifi cation standards, like the Sustainable Forestry Initiative® (SFI), are a proof-point that wood comes from responsibly managed forests that have been managed for multiple environmental, social and economic values — today and into the future. Architects and builders are turning to products certifi ed to the SFI Standard to meet their green building needs. Learn more at sfi program.org/green-building.

Products certifi ed to SFI are recognized by many leading green building rating programs around the world like the Building Research Establishment Environmental Assessment Method (BREEAM and the Leadership in Energy and Environmental Design (LEED). PRODUCTS CERTIFIED TO SFI STANDARDS ARE SOLD IN NEARLY

COUNTRIES