SUMMER 2023

www.timbermedia.co.uk

ISSN 2517–26X (PRINT)

TRADER UK

MATERIALS & FINISHES SHOW 20

Get ready for 2024’s freshly relaunched event for the furniture manufacturing and joinery industries

CONVEYOR BELT TECHNOLOGY? 22

Panel production and safely streamlining your manufacturing process

TIMBER TREATMENTS 34

How the correct wood preservation can help you be an industry-leading carbon enabler

21

Business management software. Integrated eCommerce and PIM platform

A range of news and views from across the timber industry.

14

Maximise Your Timber Sales

A new comprehensive TDUK resource ‘The Merchant Guide to Selling Timber’ will help merchants make the most of their sales of timber and timber products.

16 Electric Moves

As all aspects of the timber supply chain attempt to reduce carbon emissions, a new trial project using electric vehicles will provide a glimpse of the future for the movement of timber.

18

Using Our Own Resources

If we are to create a healthier and less import-led supply chain, homegrown timber needs to be prioritised, says James Brennan, head of marketing for the BSW Group.

20 Cover Story:

Crafted for Business

The W Exhibition has relaunched as the Materials & Finishes Show and will run at the Birmingham NEC in May 2024, showcasing the furniture manufacturing and joinery industries.

22 Timber in Motion

Choosing the right conveyor belt for your panel processing is not as simple as you think, as Damian Marczak and Mario Buchs at conveyor belt specialist Habasit point out.

24 Dust Devils:

Keep it Clean

Simon Liddell, managing director of Leitz UK talks through recent developments surrounding the improper management of wood dust in the manufacturing environment.

28 All Angles

Visibility

The safe movement of timber products is essential with one home developer looking to a trusted and familiar name to help with its new Bicester facility.

34

The Modern Era of Wood Preservation

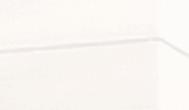

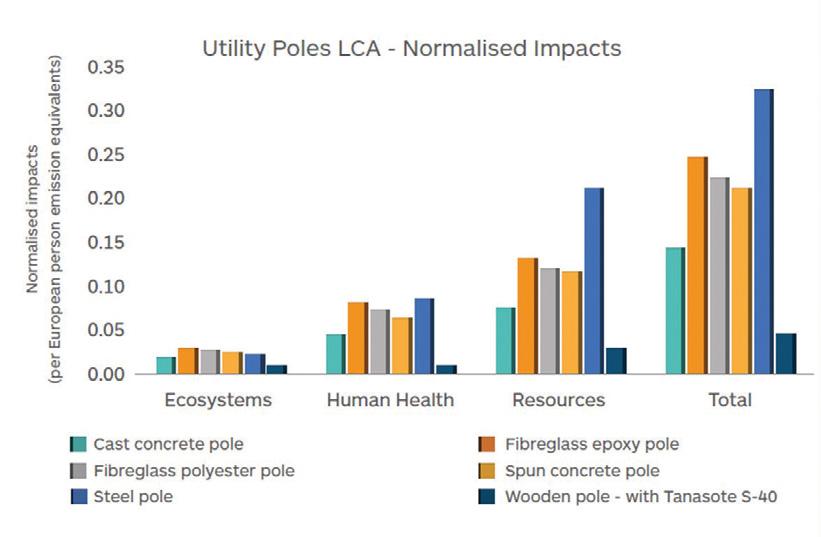

Andy Hodge, marketing director for Arxada’s Wood Protection Business Unit and WTTA president, explains how treated timber can become a carbon enabler in the modern era of wood preservation.

5

Registered address: Structural Timber Media Ltd, 101 Longden Road, Shrewsbury, SY3 9PS Company registered in England and Wales. Company Number 14537283

Timber Trader UK Magazine Summer 2023 03 www.timbermedia.co.uk @Timber_Media 14 02 18 22 34 16 20 24

Consultant Editor: Gary Ramsay

hannah.jones@timbermedia.co.uk

01743 290 001

www.timbermedia.co.uk Follow Timber Media:

@Timber_Media

TIMBER TRADER UK ISSUE 21 CONTENTS

Perfect Partner for the Timber Industry combilift.com Introducing Timber Trader UK magazine 185 x 62 Liz 2023 june.indd 1 30/05/2023 13:39:48 02 News

2

The

Terry Hanlon 1957-2023

Anyone having anything to do with this magazine either as a reader, contributor or as an advertiser will have known Timber Media’s founder Terry Hanlon well.

It is with true sadness to report that this certified ‘larger than life’ character passed away on 1 July aged 65 after suffering a long period of ill-health. Even though he was very unwell in recent months, Terry continued his relentless positive approach to work and life and pursued his love of publishing. That love of publishing and sales lasted for over 25 years from the early days of Excel Publishing based in Manchester – launching Timber in Construction Magazine in 2002 – to his own business that he began in 2017.

Terry was a passionate advocate for timber and for the people that worked within the timber industry. With his trademark style of directness and warmth, he was always willing to offer advice for those making their way in what he felt was the best material to use for nearly anything – even a timber car – and was a familiar face and friend to many on the circuit.

Terry came a long way from his birthplace on the Isle of Arran (he was a fervent Celtic F.C supporter and a proud Scotsman) to his home in Newton-leWillows, that he shared with his wife Carol and sons Liam and Michael. Terry was a champion of everything timber and his eccentric charm will be sorely missed by all that knew and worked with him.

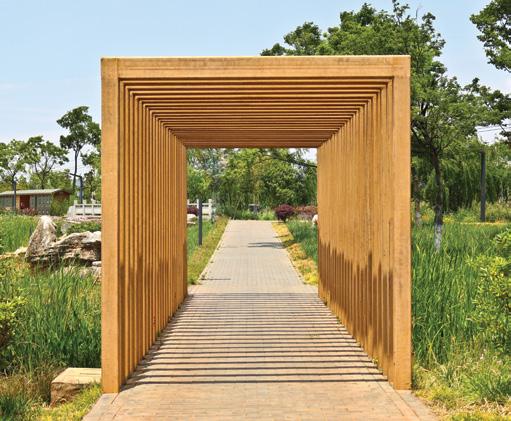

TDUK University Design Challenge another triumph

The winners of #TDChallenge23 have been announced. The ‘competition’ enables students to learn how to design and build with timber while providing skills they can take into their careers by simulating real challenges the students will face.

Fiercely competitive, from the 150+ who first registered, 34 students from 22 universities were selected from across the UK for the competition’s finals at NMITE’s Centre for Advanced Timber Technology to face a judging panel comprised of professional, academic and industry experts.

The mixed-discipline student teams came together and worked online for five months to produce their entries. They were given the task of reimagining Widemarsh Cricket Pavilion in Hereford, a timber-framed pavilion currently only used for storage.

The local community wanted a multifunctional space that is welcoming, warm, easy to maintain, produces more energy than it consumes and costs little to run. Teams had to retrofit and extend the building, and the triangle of ground bordered by roads and paths. The winners – who named their team ‘Hemphasise’ – proposed to transform Widemarsh Pavilion into a flexible learning facility and community hub which would offer opportunities for skills development, enhanced social mobility, and community cohesion. The winning design adopted a whole-building approach to meet the EnerPhit retrofit standard. Their proposed building fabric provides a medium-weight construction with thermal mass to store heat. Many of the materials are hygroscopic (breathable) and thus able to support the management of moisture.

Tabitha Binding, head of education and engagement at TDUK, said: “To have any hope of addressing the climate crisis, our future professionals need to know how to build and retrofit using the lowest

carbon structural material – timber. The TDChallenge is unique, offering students the opportunity to get beyond their course work and apply their learnings in a pragmatic way by working together as professionals do, and on a real-world project. Timber is often not taught sufficiently at UK universities, so this challenge has become an important way for the industry to ‘plug the gaps’ and ensure that incoming professionals have the skills they need to thrive and build – or retrofit - the sustainable, low-carbon buildings we need today. Specifying the right products and detailing for longevity and reuse is essential.”

The challenge is brought together by Timber Development UK in a collaborative partnership with AECB, BE-ST, NMITE, Edinburgh Napier University and Passivhaus Trust, with software from Trimble, the Passive House Institute and AECB PHribbon. Are you a student or recent graduate? Sign up to participate in our University Design Challenge 2024 – which is focused on affordable, sustainable timber housing at www.timberdevelopment.uk

Timber Trader UK Magazine Summer 2023 04 www.timbermedia.co.uk @Timber_Media

TIMBER TRADER UK NEWS

(L-R) Tabitha Binding, Head of Education, Timber Development UK. Dafyn Richards, Plymouth University. Deepak Sadhwani, Cardiff University. Daniel Green, London Metropolitan University. Beverley Gibbs, CAO NMITE. Absent: Shweta Salvankar, Cardiff University. Irene Dumitrascu-Podogrocki, Newcastle University. Martin Juricek. Heriot-Watt University.

Trades warned of equipment crimewave

Tradespeople are being warned to step up security as a crime wave sweeps through construction sites in the UK. Commercial insurer NFU Mutual’s new research reveals almost nine in 10 (89%) tradespeople have experienced theft and crime specialists are warning that the world events, including the conflict in Ukraine, is driving up demand for stolen goods.

NFU Mutual is warning people not to be complacent as its study finds over three quarters (78%) of tradespeople and contractors admit they have left machinery and tools in a vehicle overnight. Vans are a key target for criminals, with nearly six in ten experiencing thefts from their vehicle (58%). And over half (55%) have experienced theft of their items from a building site, as 83% say they have left portable tools and equipment on-site overnight. Tradespeople say the main impacts of these thefts include loss of income (55%) and extra costs to replace or hire new kit (43%), and worryingly over a third reveal theft has an impact on their mental health (34%).

Zoe Knight, commercial specialist at NFU Mutual, said: “In the current climate as supply is low and demand for stolen equipment is high, we are urging people to step up security. Tradespeople rely on their tools for their income and to keep the chain of a project on schedule. As our report findings show, the theft of equipment can have a devastating impact, professionally, financially and mentally.

“It is crucial that tradespersons are fully supported should the worst happen. The cost of replacing kit and machinery has increased significantly due to supply chain issues in recent times. We are advising tradespeople to know what they own by recording serial numbers and keeping up to date with current market values.”

Only 57% of respondents said they would be able to produce a complete list of their tools and value, leaving 43% without a recorded inventory. Only 41% keep photographic evidence of their tools and just 17% video their equipment – yet these are quick and easy ways to keep a record.

The study by NFU Mutual comes as the Equipment Theft (Prevention) Bill has passed through the House of Commons and is expected to be signed into law later this summer. It aims to ensure high value tools and machinery are marked, registered, and traceable

if stolen, making it harder for thieves to sell stolen tools, and help reunite them with their owners. NFU Mutual has been a key contributor in helping shape the Bill and in offering insight at the consultation stage – highlighting the impact of theft, as well as the importance of security, marking tools and keeping an inventory of items.

Detective Constable Chris Piggott, field intelligence officer for the National Construction and Agri Thefts Team (NCATT), added: “We welcome NFU Mutual’s study and their support for our work and are urging people to secure their property by using marking, tracking and immobilisation as well recording all serial numbers to aid the police to detect and prosecute criminals.

“We often end up on warrants and searches where numerous high value power tools are located, if serial numbers are not recorded these will be untraceable and cannot returned to their rightful owners. There is nothing more frustrating than having to hand suspected stolen property back to a known offender, because the person who has lost them didn’t take the time to accurately record the information when they purchase them. This ultimately means that we also can’t prosecute and bring offenders to justice, meaning they can carry on stealing tools without fear of retribution.”

More at www.nfumutual.co.uk/trades-insurance

Timber Trader UK Magazine Summer 2023 05 www.timbermedia.co.uk @Timber_Media

TIMBER TRADER UK NEWS

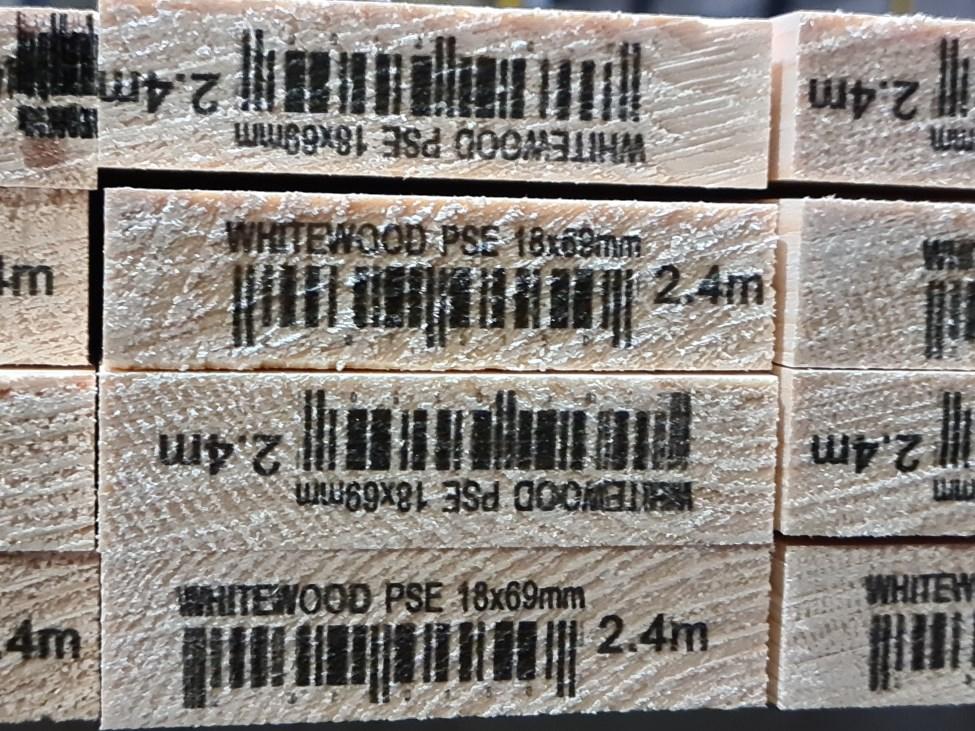

inkjet

needs Tel: 0870 803 1877 www.timbermark.co.uk

printers for all your timber marking

GMG Energy plants another 10,000 trees

In keeping with its commitment to a minimal impact on the environment and the natural world, timber products specialist GMG Energy has announced that is planting another 10,000 trees in a swathe of forest it owns in the far north-east of Scotland. The latest enhancement of its strategic reserve of timber is part of an ongoing resource replenishment programme which is based on the industry standard of one-for-one, but the company has substantially exceeded that target in most recent years..

The new planting will take place on 400 acres of softwood-planted land at Quintfall Forest, towards the east coast south of John O’Groats, which GMG Energy purchased early last year to protect future supply and increase its resilience to market shocks. It will be overseen by forestry consultant Donald McClelland, from Caithness, who will assemble a team to undertake the planting and will then manage the growth and wellbeing of the crop until maturity after 35 years.

Malcolm Morrison, Director of GMG Energy, said: “We are committed to replacing every log of timber that we use in our sawmill, biomass and timber products facility in the Strath of Halladale in Sutherland and this latest tranche of planting maintains that momentum. We are also dramatically reducing our reliance on diesel fuels with the recent installation of a solar array of more than 100 photovoltaic panels on the roof of the main production facility at the plant. Quintfall is just over 20 miles from our base of operation at Bighouse Farm, so it will not add to the road miles burden and planting there will chime with our wish to invest locally and provide a reliable resource for other local companies.”

The company, which has a turnover in the region of £2million, has also installed a high-tech preservation tank which will provide treated and stress-tested timber products for local concerns which previously had to source supply from much further afield. They have also become even more energy efficient after putting a massive solar array on the roof of its production facility into operation.

The six-figure initiative means that biomass supplier GMG Energy can now move away from the use of expensive and polluting diesel generators for its energy-intensive activities and rely instead on electricity created from the long daylight hours of the north-east of Scotland. The £100,000 installation and commissioning of the new power system has been supported by a £70,000 loan from the Energy Saving Trust, repayable over nine years, and will allow GMG to substantially mitigate its heaviest fixed cost. In addition, the £34,000 introduction of three-phase power for GMG’s electric motors and other heavy loads has been supported by Highlands and Islands Enterprise with a 50% grant and will allow the firm to provide surplus energy to the National Grid.

Alloway Timber & Builders Merchants wins Prestige Award

Alloway Timber & Builders Merchants have announced they have won the Building Merchants of the Year award for London/South East 2023/2024, as part of the Prestige Awards. .

The judges were impressed by the range of materials available at Alloway Timber & Builders Merchants, who have developed longstanding relationships with suppliers to ensure consistency and excellence, saying: “From softwoods, MDF, hardwoods, skirtings and architraves, to aggregates, blocks, bricks and lintels — the building merchant stocks every material customers require for construction projects at a price that suits all budgets. Their extensive fleet includes multiple vehicle types: from transit vans and lorry mounted cranes, all the way to their specialist loft loader vehicles, allowing versatile, same and next-day delivery to suit customers’ needs.”

Jez Avens, managing director, said:

“We’re extremely proud and humbled to win this award. It is a testament to the fantastic level of effort exhibited by every colleague within the business, our ethos of providing unrivalled customer service and our culture of maintaining high standards in everything that we do.”

Alloway Timber & Builders Merchants is a family-run business offering tools and building supplies required for construction projects at low prices. The company initially began trading as Alloway Timber Southern Ltd back in 1971 and has since expanded to include a building merchant wing to help support customers in completing their projects from conception to completion. Today, it is a one-stop shop that offers a comprehensive selection of construction materials. It trades from five sites – Kingston-upon-Thames, Byfleet, Cheam, Mitcham and Putney.

More at www.allowaytimber.com

Timber Trader UK Magazine Summer 2023 06 www.timbermedia.co.uk @Timber_Media TIMBER TRADER UK NEWS

More at www.gmgenergy.co.uk

MKM founder David Kilburn honoured with CBE

The co-founder of MKM, David Kilburn, has been awarded a CBE for services to the construction industry and to charity in the King’s inaugural Birthday Honours list. David, who is celebrating his 60th year in the construction sector this year, founded MKM with close friend Peter Murray in 1995. Starting at a single site in Hull, the business has now grown to become the UK’s leading independent builders’ merchant, operating more than 100 branches nationwide with a turnover of £818million.

MKM’s central support is still located in Hull, with the business playing a hugely important role in shaping the city’s business landscape. David now uses his platform to help influence and nurture other enterprises, which includes the formation of local mentor organisation For Entrepreneurs Only, which itself earned royal recognition via a prestigious Queen’s Award for Voluntary Service in 2021.

Speaking of his investiture, David said: “It is a very moving experience, and I think of all

the people who have contributed to what has been achieved. It is very humbling, that’s how I feel about it, and I’m very happy to receive it. This sort of recognition does not happen without the great people who have worked with us, the talent. I have been very lucky as without the support from lots of people, my wife Linda, and lots of others, it wouldn’t have been possible. It has been a very interesting journey and it is a very humbling experience.”

Kate Tinsley, CEO at MKM, added: “The whole business is so thrilled for David. His service to the construction industry, which now spans 60 years, is truly remarkable. That, alongside his notable charity work, makes him a very, very worthy recipient for this honour and it is fantastic to see him recognised at such a high level. David’s contribution to the construction sector and his ongoing work to promote businesses and entrepreneurship in Hull is something everyone at MKM is very proud of.”

David’s recognition comes at an exciting time for MKM. Last year, the business

celebrated opening its 100th branch, with a network that now spans the entire length and breadth of the UK. The merchant is also marking the first anniversary for its MKM Home offering, a state-of-the-art retail showroom located close to the business’s central support in Hull.

More at https://mkm.com

Timber Trader UK Magazine Summer 2023 07 www.timbermedia.co.uk @Timber_Media TIMBER TRADER UK NEWS

Made Smarter Awards recognises wood manufacturers

A trio of wood manufacturers pursuing digital transformation are among the first recipients of the Made Smarter Awards, celebrating excellence in manufacturing. The scheme has been launched to mark the fourth anniversary of the pioneering Made Smarter adoption programme, a government-funded and industry-led initiative helping SME manufacturers digitalise, decarbonise and drive growth.

Logs Direct, kiln-dried wood manufacturers based in Lancaster, Playdale Playgrounds, a playground equipment manufacturer based in Ulverston and Crystal Doors, a manufacturer of bespoke vinyl wrapped furniture, based in Rochdale are among the first 19 Gold award winners.

Commenting on the awards, Donna Edwards, director of Made Smarter’s North West adoption programme, said: “The Made Smarter adoption programme is a huge success story for UK manufacturing. It has inspired leadership and evoked change in hundreds of businesses through technology and new skills. Digital transformation can be hard, particularly in the current climate and given the challenges the sector has faced in recent years, so it is right we recognise the hard work, dedication and forward-thinking nature of these businesses and their employees. They have embraced digitalisation to become a leading example of UK manufacturing excellence.”

Logs Direct, a manufacturer of winter fuel products based in Lancaster, worked with Made Smarter to invest in a real-time kiln monitoring and heat-recovery system, which will improve productivity, efficiency and product quality. The solution is forecast to increase growth by 15%, create five new jobs, significantly reduce energy use and introduce new ecofriendly products. Liz Foulds, finance director at Logs Direct, said: “We are truly honoured and surprised to receive our Made Smarter award. Made Smarter has been instrumental in allowing us to move forward with a

greener, more efficient and cost-effective drying process, and given us the confidence to look at the next steps of improvement.”

Playdale Playgrounds invested in a state-of-the-art Smart CNC routing machine which links with CAD and nesting software, and their ERP system. The integration of the design and manufacture processes has allowed them to achieve significant improvements in efficiency, output, productivity, reduce material use, tooling and downtime, and improve quality. Paul Mallinson, technical & operations director for Playdale Playgrounds, said: “We are extremely grateful to the Made Smarter programme. Adopting technology is an essential part of our digital strategy. Their expertise and support have accelerated our future state and ambitions to become an entirely digitally integrated factory. In such a competitive market we need to be able to manufacture faster and more efficiently.”

To date, the North West programme has provided specialised support to over 2,500 businesses. Its advisors have imparted expert, impartial technology advice and digital transformation workshops to help create a digital roadmap, skills support and leadership training, and grants towards technology projects. Some businesses have adopted technologies that enable them to integrate systems, capture and analyse data, and even create simulations of their plants and processes. Others have adopted 3D-printing, automation, and robotics to solve business challenges and meet increased demand.

Customer loyalty rewarded with brand-new Mercedes

Following the popularity of the West Fraser Rewards promotion during 2022, this year’s programme saw the UK’s largest wood panel manufacturer give away not one – but two –Mercedes vans. The lucky winner of the first of the vans has been presented with the keys to his brand-new vehicle. Neil Harding of Neil Harding Loft Ladders entered the promotion after buying West Fraser boards at the Horsham branch of Jewson.

Neil Harding Loft Ladders has been supplying and fitting loft ladders and insulating and boarding attics for over 20 years in the Surrey, Kent and Sussex areas. “We always use West Fraser’s P5 when boarding out lofts and CaberMDF to create hatches. The products are

always reliable and easy to work with. I’m really pleased to have won the van. Jamie at Jewson suggested I have a go at entering the competition – it was easy to log on to the website and enter.”

The West Fraser Rewards promotion also benefited the participating builders’ merchants. James Westbrook, Jewson sales manager explained: “The promotion was a success for our business unit. We had great customer uptake which allowed us to interact even more with our customers. We have a good relationship with the West Fraser team and receive great support from them, so we were pleased to be able to participate in the promotion.”

It wasn’t just Jewson’s customers that were rewarded by the promotion. As Jamie Woolford,

customer service supervisor at Jewson, Horsham, added: “Every time one of our customers won, the branch received a £100 Just Eat voucher which enabled us to get the team together.”

More at https://uk.westfraser.com

Timber Trader UK Magazine Summer 2023 08 www.timbermedia.co.uk @Timber_Media TIMBER TRADER UK NEWS

More at madesmarter.uk

Neil Harding and his colleagues with the new Mercedes van

Sarah Woodhams, Made Smarter, and Stephen Talbot, Logs Direct

Timber Trader UK Magazine Summer 2023 09 www.timbermedia.co.uk @Timber_Media Just landed! Our NEW pre-painted OSB is a blank canvas, perfect for applying for marketing messages and graphics. With all the inherent properties of our popular OSB3, SterlingOSB Zero PrimedPlus has a primed textured finish, and is designed for hoardings, screening, exhibition stands and walkways etc, inside or out. SterlingOSBZero.com Pre-painted board, ready for graphics NEW PRODUCT No painting required

Donaldson Group announces new CFO

Donaldson Group, has appointed Alyson Donaldson as Group chief financial officer (CFO). Alyson joins the Group from leading global veterinary care provider, IVC Evidensia, where she was UK & ROI chief financial officer. Here she was responsible for the UK-wide finance operations for the billion-pound business, with a focus on transformation and performance improvement.

Alyson was promoted to the post at IVC Evidensia after working as CFO for its major subsidiary, Vets Now. Prior to this she spent eight years in senior finance and strategy roles at Diageo, latterly as finance director, international supply, where she was responsible for managing a large global finance community and performance of a multi-billionpound cost base. A chartered accountant, Alyson started her career at KPMG LLP on their graduate training programme. She graduated from Stirling University with a first-class degree in accounting and economics, and in 2020 she completed a post-graduate course

in Leadership, Strategy and Innovation with Napier University.

Commenting on the appointment, Andrew Donaldson, CEO of Donaldson Group, said: “The board and I are thrilled to have Alyson joining us as Group CFO. She has an impressive track record of demonstrative success, leading finance functions and driving strategic transformational change and improvements in industry-leading organisations. She will be a fantastic addition to our senior leadership team and we’re all very much looking forward to working with her. This is also a very proud milestone for us as a family business, as we welcome another Donaldson into the Group.”

Alyson is the first female Donaldson family member to join the Group in an executive role, in its 163-year history. She succeeds Arlene Cairns who took on the role of CFO in 2020. Alyson said: “As a family business, this is so much more than a career move for me: it’s something I feel incredibly passionate about. I’m looking forward to working with the Group Executive and finance team, supporting

Premier Forest Products makes major moulding equipment investment

Premier Forest Products has made a major investment in machinery to increase production and extend its product range for customers. Premier Forest Products has invested over £1million in equipment across the business, including its Duchy Timber and Merlwood Timber branches. The state-of-the-art, market-leading machinery, which was installed earlier this year, has already doubled the production capacity at the company’s sites in Cornwall and Pembrokeshire.

The new machinery, supplied by global specialists Weinig, includes a Powermat 1500 moulding machine which can cut widths up to 300mm, and a Powermat 700 moulding machine. The machines are entirely flexible and can be used to make most timber mouldings including, cladding profiles, skirtings, architraves, door frames, stair components, and door liners in both hardwood and soft wood.

The company has purchased the Rondamat 960 grinder/profiling machine which makes templates for profiles so they can create bespoke profiles for customers. Once the template is made, it can be used repeatedly to make precisely the same profile which is ideal for continuity in large projects, where the same product is to be supplied frequently over time. Premier Forest has also invested in an Opticontrol measuring stand which is used to accurately measure the tool cutters and a Unicut P3 crosscut saw which has more than doubled Premier’s capacity to accurately crosscut timbers to length.

the business as it continues to pioneer in its market, and I’m excited to be contributing to the success of the business for now and for generations to come.”

More at www.donaldson-group.co.uk

Terry Edgell, co-founder & CEO of Premier Forest Products said:

“Recent investment in additional state-of-the-art milling machinery is enabling Premier to increase productivity and improve efficiency at two of our key manufacturing sites. Our in-house manufacturing facilities mean that we have complete quality control and the capacity to ‘turn up’ production to meet volume orders for our customers. Together with our nationwide-wide distribution network, we can quickly turn-around orders and deliver in volume, across the UK.

“We’re now in the position that we can work with customers to support anything from bespoke, specialist renovation jobs to full-scale construction projects such as hotels, schools, apartments and housing sites. Our timber is sourced from responsibly managed forests, so we meet the stringent environmental requirements of modern building projects.” Premier Forest Products is engaged in the importation, processing, merchanting and wholesale distribution of timber and timber products from multiple sites across the UK.

More at www.premierforest.co.uk/service/premier-mouldings

Timber Trader UK Magazine Summer 2023 10 www.timbermedia.co.uk @Timber_Media

TIMBER TRADER UK NEWS

Timber Trader UK Magazine Summer 2023 11 www.timbermedia.co.uk @Timber_Media

Responding to UK and Ireland specifier calls for high-performance door components, James Latham have introduced FERRO, a premium range of highly durable and weather resistant external door blanks from leading brand Moralt.

Comprising some of the most robust external blanks currently available on the market, FERRO blanks are made from topquality natural and engineered timbers, with either paintable plywood, exterior MDF or decorative veneered plywood faces. What sets the FERRO blanks apart from others on

James Latham introduces FERRO

the market is that each one contains two thermally isolated solid steel stabilising bars in its core, helping to prevent bowing and warping.

Such is the degree of anti-bowing and warping strength achieved through the incorporation of the steel stabilisers every FERRO blank comes with a 10-year antibowing guarantee. Going even further, Moralt is committed to replace any FERRO door, freeof-charge, which warps more than 4mm over this period, including fitting costs.

The FERRO range is CE-certified and has been developed to meet contemporary specification requirements, particularly in line with evolving UK and Ireland regulations around energy efficiency and fire safety. Starting with the standard Klassikplus, specifiers can choose from a wider range of enhanced blanks with increased thermal performance, soundproofing and fire-resistant properties.

Unlike many competing products it can be used to manufacture doors which are strong and robust and deliver maximum interior comfort through optimum airtightness, with

a customisable finish for unrivalled visual appeal. This guarantees long-term value on every level. All blanks in the range meet the UK’s newly introduced sustainability requirements for residential properties, ensuring developers and asset owners remain compliant with regulation.

Commenting on the introduction of FERRO, James Latham’s group door manager, Steve Williams, said: “FERRO is one of the most exciting architectural products currently available in the UK and Irish market, the perfect balance of style and substance. Its steel stabiliser gives it unrivalled durability, particularly from a structural and security perspective, giving residents and asset owners extra peace of mind the external doors on their properties will provide extra protection from the elements and intruders. Furthermore, developers will feel reassured that the thermal performance of the FERRO range will help them meet the revised Part L requirements, which became compulsory in June 2023.”

More at www.lathamtimber.co.uk

‘Revolutionary’ new wood website launched

Woodshop Direct, a leading wood supplier in the UK, has launched its new website. With the implementation of cutting-edge technology, the company has positioned itself as the first wood supplier in the UK to offer customers the convenience of having wood cut to their specified dimensions with unparalleled speed and precision. This achievement is made possible by seamlessly linking the website and ordering system with the shop floor, providing an exceptional customer experience.

Warren Bennett, managing director of Woodshop Direct said: “At Woodshop Direct, by putting the customer first and being able to offer this first-in-class service, it will move Woodshop Direct to the forefront of the industry.”

Woodshop Direct aims to redefine the wood supply landscape by combining cutting-edge technology with superior service. The development of the new website took an entire year, during which Woodshop Direct underwent a complete overhaul of their stock management systems, as well as their ordering and dispatch systems. This comprehensive transformation ensures streamlined operations, reducing processing times and expediting deliveries to customers. With a user-friendly interface, the website allows users to specify their required wood dimensions precisely. Upon submission of an order, the website’s advanced integration with the shop floor enables immediate processing, resulting in shorter lead times and faster deliveries.

Visitors to the site can easily shop for timber, sheet materials, tools and accessories, wood finishes and doors. The new website also

allows customers to shop by use, such as internal wood, external wood or repairs, as well as by tree species, including Ash, Beech, Redwood Pine and Walnut. The new Woodshop Direct website also boasts an informative blog, packed with timber knowledge and woodworking tips. Woodshop Direct caters to both DIY and professional woodworkers. Whether customers require hardwoods, softwoods, or specialist timber, Woodshop Direct offers an extensive selection, ensuring that every project can be accomplished with the finest materials.

More at www.woodshopdirect.co.uk

Timber Trader UK Magazine Summer 2023 12 www.timbermedia.co.uk @Timber_Media

TIMBER TRADER UK NEWS

UK manufactured Racking Systemsengineered to last

One of their established customers – specialist timber merchants Thorogood Timber – first had some of Stakapal’s cantilever racking installed back in the 1990s which is still in perfect working order.

Based in Ardleigh, Colchester Thorogood’s take their timber very seriously, promising customers that they will source only the best possible range of timber products. With four dedicated storage buildings on-site, they are also committed to ensuring their complete range is stored correctly to guarantee it remains in top quality condition.

As part of their ongoing development programme, Thorogood’s recently established they needed to improve the storage capacity of their finishing and softwood warehouse. This initially involved the reorganisation of their existing racks to accommodate some new handling equipment as well as enabling them to expand the overall storage area.

Some additional cantilever racking was also required in an area where they were currently bulk-stacking multiple lengths of product. Using this traditional method meant they were moving smaller lengths of stock around in order to be able to gain access to longer lengths at the bottom. This was ultimately affecting the company’s overall bottom line due to increasing levels of handling resulting in damage to their valuable stockholding. Investing in new racking as well as altering the lay-out of their warehouse wasn’t a decision to be taken lightly. Having dealt with Stakapal previously, Thorogood’s were confident that they would again come up with a design solution that would meet their exacting standards.

Peter Thorogood, owner of Thorogood Timber stated: “There are many companies offering cantilever racking, but we know through experience that Stakapal’s quality is very high. Their equipment that was first installed in the 1990s is still working as it should, remains in excellent condition despite its age, and has required very little maintenance during

this period. As designers, manufacturers and installers of racking systems, we know they always deliver on their promises. Despite the amount of work involved everything ran very smoothly and was completed within a one-week deadline.”

Stakapal’s in-house Storage Equipment Installers Registration Scheme (SEIRS) team, installed the new racking during Thorogood’s normal working week with minimal disruption to their operation. Their staff were able to move timber around the warehouse creating enough space for the new runs of cantilever racking to be installed in sections. Once the first area was finished, they could then load their timber on to the new racks creating enough space for the next area to be installed and loaded.

As full manufacturing members of Storage Equipment Manufacturers Association (SEMA), Stakapal offer a complete range of timber storage options including cantilever racking, A-frame/vertical storage and pigeon hole racks.

More at www.stakapal.co.uk

Timber Trader UK Magazine Summer 2023 13 www.timbermedia.co.uk @Timber_Media ADVERTORIAL STAKAPAL

With over 55-years manufacturing expertise behind them, Stakapal have been supplying the timber industry with a full range of bespoke racking solutions that stand the test of time.

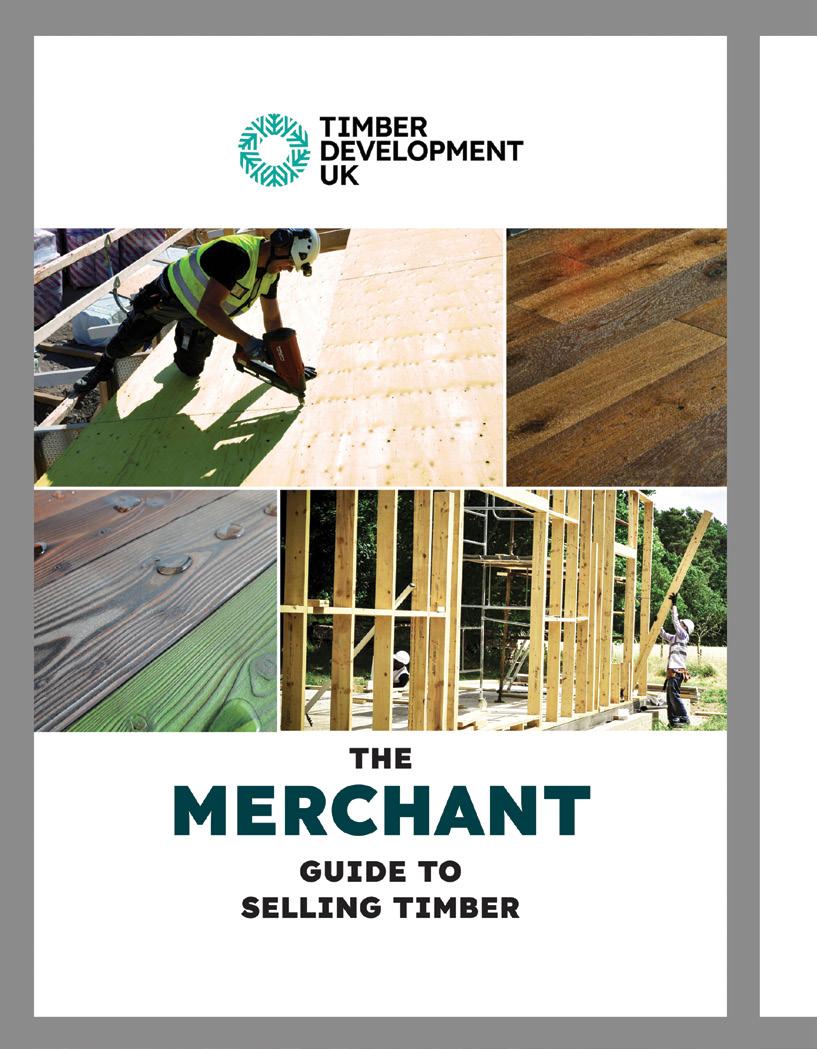

Maximise Your Timber Sales

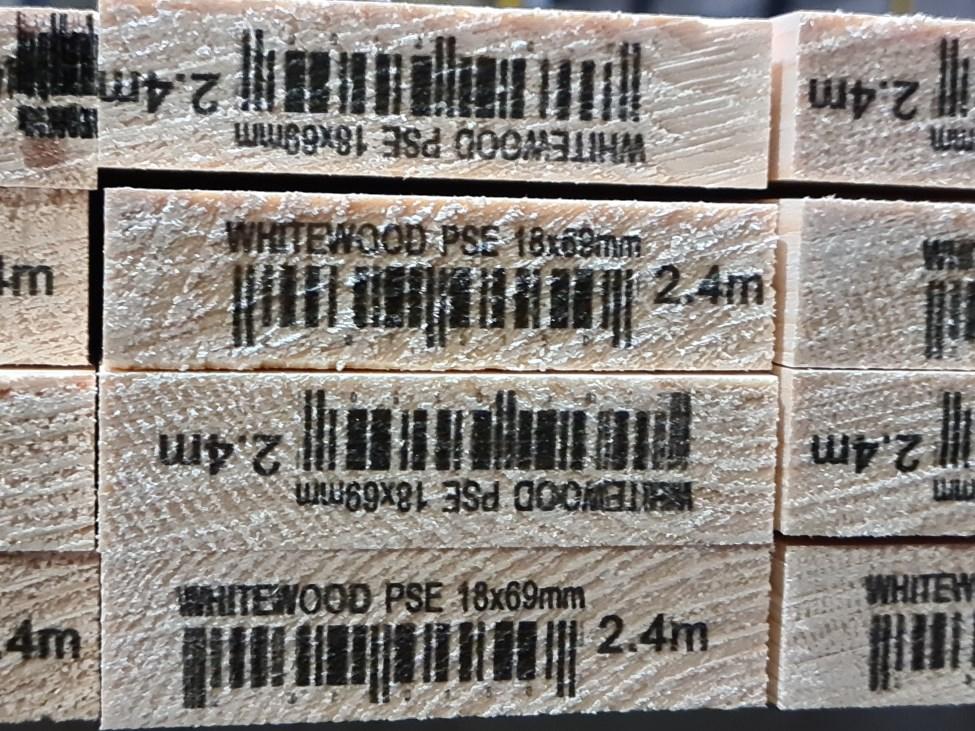

The aim of the Guide is to be an introduction to timber and timber products written specifically for timber and builders’ merchants, which staff can use to learn more about the different types of timber available on the UK market. Thanks to the information in the guide, merchants should be better able to understand the different timber types and species and what they are best used for, and to answer any timber questions they may be asked by their customers.

The Guide includes an overview of the benefits of timber as a construction material, as well as separate sections dedicated to all the different types of timber, such as plywood, hardwoods, panel and sheet products, structural and framing timbers, machined softwoods, MDF mouldings, modified woods and decking, fencing and landscaping products.

so you know you’ll always give them the best advice and stock the right products. The Guide also includes key information that merchants should always ask their timber suppliers, to make sure that they are receiving the highestpossible quality product to sell on to their customers.

Crucially for merchants, each section also includes suggestions on how to upsell different timber products, as well as complementary products you may wish to consider stocking, such as the fixings, adhesives, paints and PPE that could add significant value to any timber sale.

David Hopkins, chief executive of Timber Development UK, said: “Timber and wood products are recognised as among the most profitable product categories for many builders’ merchants. Representing up to a quarter of a general merchant’s turnover, wood products now offer a huge range of

Waugh Thistleton Architects. Aimed at developers, investors and policy makers, Timber Typologies outlines the variety of build options and methodologies available for lowcarbon timber construction and details the building types each method is suitable for.

Written with Waugh Thistleton Architects, one of the leading ‘timber first’ architects’ practices in the UK, the book is intended to be a beginners’ guide to the variety of timber solutions available. It will help decision makers understand the options open to them and make the right choices to deliver the best outcomes. Timber Typologies is the first

Within each section, you’ll find an outline of timber’s main product types and uses, as well as details of the common timber species used for different applications. Key facts around sustainability, safety and quality are included for each product type, along with details of the relevant certifications and British and European standards that apply to each. There are technical tables allowing merchants to compare the different timber species, as well as pictorial examples of the different timbers in-situ. There is also information on any timber treatments that may be required, and the due diligence you should carry out on any timber stocks you order.

You will also find top tips around availability and lead times, as well as key questions you may wish to ask your customers,

both standard and special use materials, designed for more specific applications.

“We wanted to create a useful resource that would help merchants better understand these differences and how timber can be best used as a construction material, giving you all the information, you need to support your customers and maximise timber sales. ‘The Merchant Guide to Selling Timber’ is designed to be an introduction to the world of timber – we would always recommend that you seek additional advice from your TDUK supplier if you have any questions.”

TDUK also recently published ‘Timber Typologies: Understanding options for timber construction’ – a ground-breaking new book created in collaboration with

in a trio of books that will be produced to increase understanding among construction decision makers. It will be accompanied by Timber Policy – a guide to the different ways countries and city authorities are encouraging timber construction around the world, and Timber LCA, which will compare lifecycle analysis between buildings constructed of different materials. Both

Timber Trader UK Magazine Summer 2023 14 www.timbermedia.co.uk @Timber_Media

Timber Development UK (TDUK) has created ‘The Merchant Guide to Selling Timber’, a comprehensive new resource to help merchants make the most of their sales of timber and timber products.

publications

available

download from TDUK at www.timberdevelopment.uk

are

to

FEATURE TDUK

“We wanted to create a useful resource that would help merchants better understand these differences and how timber can be best used as a construction material, giving you all the information, you need to support your customers and maximise timber sales.”

David Hopkins, Timber Development UK

DESIGN|MANUFACTURE|INSTALLATION|SUPPORT PERFECT FORTIMBERSTORAGE, WICKENSRACKINGCANHELPYOUWITH… •Increasingstoragecapacityonsite. •Allowingaccesstoselec�vestockandenablingstockrota�on. •Reducingproductdamagefromstorageonthefloor. •Decreasingmaterialhandling�meandimprovingsite efficiency. TIMBERSTORAGE Getintouchtoday forasitevisitand abespokerackingquotation: WWW.WICKENS.CO.UK sales@wickens.co.uk 01905456780

Electric Moves

Scottish Forestry has awarded £452,000 towards a three-year trial which will test the use of state-of-theart electric timber wagons to transport timber. As part of the project, which is the first of its kind in the UK, two Scottish timber companies, James Jones & Sons Ltd and Scotlog Haulage, are partnering with the Volvo Group and Cleaner EV to undertake the demonstrator project.

Around seven million tonnes of wood are harvested from Scotland’s forests each year and transported to sawmills, board manufacturers and other processors, mostly on 44 tonne diesel lorries. The forestry sector, whilst inherently green, is keen to use modern technology to tackle timber transport issues as part of its overall efforts to decarbonise and reach net zero.

Announcing the funding package, rural affairs secretary Mairi Gougeon said: “Forestry is vital to helping Scotland achieve its net zero target by 2045. Around 7.6 million tonnes of harmful CO2 is taken out

of the atmosphere from Scotland’s trees each year and the timber used in houses and other wooden products lock away carbon for its lifetime. The forestry sector is innovative and continues to adopt new technology to increase its business efficiencies. I welcome this new trial and look forward to hearing more about the findings as we drive closer to net zero.”

James Jones & Sons new electric truck made its first appearance at the Royal Highland Show with Lorna Slater, minister for green skills, circular economy and biodiversity, stopping by to find out more about the project and to see the new electric truck.

James Jones & Sons will trial a 40-tonne articulated lorry from its sawmill in Lockerbie to transport timber to its Hangingshaw national distribution centre as well as trialling this vehicle in moving logs, coproducts and sawn goods to its customers. The company harvests and processes more than 1.4 million tonnes of roundwood per annum. Its co-products are supplied to the UK’s principle board manufacturers and

Timber Trader UK Magazine Summer 2023 16 www.timbermedia.co.uk @Timber_Media

FEATURE MERCHANT FOCUS

As all aspects of the timber supply chain attempt to reduce carbon emissions, a new trial project using electric vehicles will provide a glimpse of the future for the movement of timber.

TP Commit to Decarbonisation

biomass power generators. Homegrown sawn timber is used for the construction, pallet, packaging, fencing and agricultural sectors and pallets and packaging for blue chip, domestic and exporting businesses.

“Whilst James Jones & Sons is prioritising reducing timber miles through local round wood purchasing and selling sawn goods to markets close to the Group’s sawmills,” said joint managing director, David Leslie. “The trial will give the industry a valuable insight into the suitability of such vehicles in the timber sector over the next three years. Timber is our only natural renewable resource and whilst transport is a major factor in the country’s CO2 emissions, growing commercial trees is the most effective way of capturing the CO2 and storing embodied carbon in timber products, such as construction timber and pallets, for the future.”

A key element of the three-year trial is that all the partners involved are committed to sharing their experiences of running the electric lorries with others in the timber and rural haulage sectors. Scotlog Haulage will trial a 44-tonne truck in the Highlands, moving roundwood timber from Inverness Harbour to West Fraser and other local mills.

Zero Carbon Journeys

Last year CFF launched the UK’s first 27 tonne curtainside Battery Electric Vehicle (BEV), with 287kwh traction batteries.

The new vehicle represents CCF’s commitment to drive innovation across its customer operations in support of a low-carbon future. The brand-new 27 tonne BEV, which is the first of its size and type in the UK, is the product of three years of development driven forward by CCF. The BEV has been manufactured and supplied through Electra, to complete zero emission customer deliveries.

The UK’s largest distributor of building materials, Travis Perkins recently announced that the Group has continued to make good progress against its Science Based Targets initiative (SBTi) accredited, 1.5 degreealigned carbon reduction targets.

In July, Travis Perkins started to take delivery of its new electric forklift trucks as part of Project Switch – the largest programme of its kind – which will see up to 1,100 diesel powered forklift trucks across the Group being replaced with electric alternatives by mid-2024 (eight years ahead of schedule); saving 6,600 tonnes of carbon a year.

Creel Maritime consultants will monitor the use of the lorries and arrange knowledge exchange opportunities over the course of the following three years. Neil Stoddart, director of Creel Maritime, who are managing the project, added: “In terms of road haulage, the timber industry is pretty advanced in looking for solutions to decarbonise. For example, we are reducing diesel lorry miles on many projects and opting for transport by sea.

“Additionally, we are reviewing using an alternative fuelled barge to transport logs across a remote Loch in the Highlands. This is a very exciting project but there are big challenges in running articulated lorries on electric power, mainly on cost grounds and infrastructure. This three-year trial will look into all these aspects and I’m keen to share as much detail on this with the industry.” During the trial, the vehicles will be evaluated for their achievable mileage vs battery consumption, durability, viability and total cost of ownership.

Timber Trader UK Magazine Summer 2023 17 www.timbermedia.co.uk @Timber_Media FEATURE MERCHANT FOCUS

More at www.jamesjones.co.uk

www.forestry.gov.scot www.travisperkinsplc.co.uk

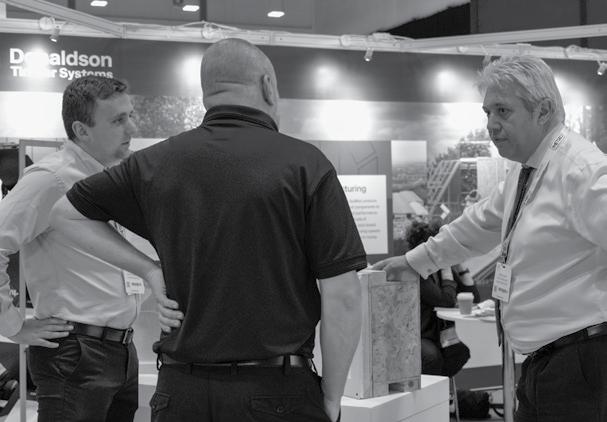

Using Our Own Resources

Building homes for the future, and with a focus on net zero, will demand a shift in mindset from a nation hooked on steel and concrete. It will also take industries, such as ours in forestry and timber, to push forward with an array of materials that have taken second place to others, up until now.

As a nation, we are the world’s second highest importer of timber according to a 2022 report from the Environmental Audit Committee, with a huge 82% of our wood coming from overseas in 2020. This puts us in second place behind China – known the world over for burning through natural resources at a rate of knots. With such a stark statistic, along with 25% of global emissions coming from the built environment, isn’t it about time that we considered the benefits of homegrown timber and what it can offer the construction industry. UK-grown timber can offer several benefits.

Perfectly suited to construction

Using homegrown timber should be a point of pride for construction in this country – something that brands boast about on their marketing materials. But it is often overlooked by the construction industry in favour of imported wood, or even for other materials such as concrete. But as the COP26 house (built with BSW Group homegrown timber) demonstrated, it’s an excellent raw material for sustainable, modern and beautiful homes. Homegrown timber can have more knots than some imported varieties, which is a reason why some don’t take advantage of UK-grown wood, but this makes no difference to the product. In fact, UK timber is well-suited for all sorts of needs from timber frames to landscaping to stud walls.

Housing demand

Timber is an essential tool for building sustainable, affordable homes in a cost and time-effective manner. It allows us to build heat efficient, carbon reducing homes, which ultimately helps to reduce fuel poverty. In fact, in some cases building homes with timber can reduce energy bills by 90%.

Furthermore, timber build times are up to 30% faster compared to other materials, which will help the construction industry to quickly meet the growing demand for new, high-quality homes in the UK. The faster build times also reduces time on-site and disruption to the local area and research even shows that waste is reduced by up to 90% for timber constructions compared to other materials.

Timber Trader UK Magazine Summer 2023 18 www.timbermedia.co.uk @Timber_Media

FEATURE HOMEGROWN TIMBER

Homegrown timber needs to be prioritised, says James Brennan, head of marketing for the BSW Group, if we are to create a healthier and less import-led supply chain.

The road to net zero

The UK is facing a high demand for affordable homes. Councils face a difficult battle to prioritise this need whilst also reckoning with environmental targets. Homegrown timber has the benefit of being a much more environmentally friendly option for construction. Timber is a fully renewable resource but it also provides benefits long before it reaches a building site. During their lifecycle, trees absorb carbon from the atmosphere, helping to reduce the impact of climate change – while using timber as a building material then locks away that carbon. A 2019 study by Bangor University, on behalf of the committee on climate change, suggested using timber products as opposed to masonry could lead to a 20% reduction in emissions and 50% increase in carbon storage.

Lower reliance on imports

82% of wood overall in the UK is imported, and the figure is around two thirds when looking at sawn timber. Importing the vast majority of our wood adds a huge carbon footprint to construction due to the impact of transporting the raw material from other countries. Another effect is the threat to our ecosystem. According to the Woodland Trust, at least 20 serious tree pests and diseases have been unwittingly brought to the UK since 1990 as imports have skyrocketed, leading to the loss of tens of millions of trees. With consequences like this, the short-sighted focus on importing is ironically making it even harder to produce timber locally.

Demonstrating the scale of the opportunity at hand, estimates show that just 0.5% of new buildings in the UK will be constructed with timber by 2050. However, research suggests it’s conceivable that this figure could reach as high as 90% if the UK puts in a concerted effort

to increase mass production of timber domestically. Timber has the added benefit of requiring less energy to produce than other materials, further boosting its green credentials.

As a nation we need to come together and invest in homegrown timber. Of course, as the UK’s largest integrated timber and forestry business, BSW Group has a role to play, but this is bigger than any one company. We need the buy-in of stakeholders across the industry from architects and suppliers to construction companies – to specify homegrown timber on suitable projects moving forward. We see a future where UK timber is the go-to material for creating sustainable, affordable and beautiful homes. We see homegrown materials being a priority for the construction industry. We see net zero targets hit, and the nation enjoying millions of affordable and energy efficient homes. What future do you see?

More at www.bsw.co.uk

Timber Trader UK Magazine Summer 2023 19 www.timbermedia.co.uk @Timber_Media

FEATURE HOMEGROWN TIMBER

Crafted for Business

The Materials & Finishes Show will attract buyers from every corner of the industry, and with over 50 years of heritage to draw on, the new and reinvigorated format will continue to provide a platform for manufacturers, processors and installers working in a wide range of disciplines.

All areas of the material journey, from the initial stages of raw processing through to finishing and component supply for completed products, will be represented and visitors will have the opportunity to see running machinery together with components, materials, technology and services for the manufacturing and processing phases of materials, alongside the latest products and developments for finishes.

Event director, David Todd says: “The Materials & Finishes Show aims to build on the success of the W Exhibition. Since the show’s conception in 1974 it has passed from being a woodworking machinery exhibition to covering the full range of technology and materials for industrial woodworking. We aim to take this further providing a more valuable, time and resource effective solution for both our exhibitors and visitors from a more diverse community.

“We conducted an extensive market research exercise and worked closely with our stakeholders which has concluded that there is still

a huge appetite, and indeed need, for a platform for the industry, specifically across the UK and Ireland. A lot has changed since the last edition of W Exhibition in 2018 and we have adapted the show’s proposition to reflect the evolving needs of the market both now, and in line with our anticipations for the future.

“Wood and stone are two of the most widely used natural materials in construction and design, often used together in various ways. Whilst timber will remain a core focus for Materials & Finishes Show, it was a natural progression for us to incorporate stone and broaden the delivery for our community. This more holistic view of the industry paves the way for other products such as stone kitchen countertops and natural stone flooring. The show will deliver a true end-to-end proposition for our visitors.”

“As an organisation, Montgomery Group is fully committed to protecting and building on the legacy of W Exhibition and the communities we serve. It’s our responsibility to preserve the long-term success of our platform for the sector, which is why we have been through this extensive period of consultation to reimagine and develop the show to meet the changing needs of the market, culminating in the relaunch with Materials & Finishes Show.”

Timber Trader UK Magazine Summer 2023 20 www.timbermedia.co.uk @Timber_Media COVER STORY MATERIALS & FINISHES SHOW

The UK’s flagship trade show for the furniture manufacturing and joinery industries, formerly know as W Exhibition, has relaunched as the Materials & Finishes Show and will run at the

Birmingham NEC from 19-22 May 2024.

Hanex® UK joins show lineup

Hanex® UK, the exclusive distributor for Hanex® Solid Surfaces in the UK, has joined the lineup for Materials & Finishes Show 2024. The company, which is headquartered in Southampton, will utilise the show as a platform to raise brand awareness to the UK market, with a key objective being to meet customers face-to-face and showcase the plethora of applications and colour options available for domestic and commercial application. The brand will also seek to build on its network of approved UK installers who can benefit from a range of support benefits including specialist training, marketing and technical support, and a ten-year warranty once approved for the scheme.

Speaking about the announcement, Hanex® UK Ltd marketing manager, Emma Naylor said: “Whilst people may be familiar with the Hanex brand, we want to demonstrate the benefits of partnering with us in the UK. We stock a larger range of Hanex sheets than ever before in the UK in our custom-designed distribution and support centre, which we’ll be showcasing at Materials & Finishes Show, along with a full range of adhesives, sink, basins and ancillary accessories ready for nationwide delivery. We’re experts in solid surface, with diverse experience ranging across fabrication, installation, distribution, specification and logistics. Materials & Finishes Show will be the perfect platform for us to demonstrate this next May.”

David Todd added: “We’re delighted to announce that Hanex UK will be debuting at Materials & Finishes Show, when we relaunch next May. The KBB market is a key growth area for the show and Hanex will are a very welcome addition to the lineup, which already includes a broad mix of machinery, materials and finishes brands.”

Hranipex announced as relaunch partner

Hranipex, one of the leading European manufacturers and suppliers of products and expert consulting for the furniture industry, has been announced as an official partner for the Materials & Finishes Show 2024. The group, which is headquartered in the Czech Republic, has a global

presence in over 60 countries, Hranipex have established themselves as a key player in the furniture industry. The extensive product portfolio encompasses a diverse range of offerings, including furniture fittings, edge banding, adhesives, cleaners, and various components essential for furniture production.

This wide array of high-quality products showcases Hranipex commitment to delivering comprehensive solutions to meet the needs of furniture manufacturers worldwide. The comprehensive collection encompasses a wide array of fittings designed for kitchens, offices, and diverse commercial and domestic spaces. In addition to locks, handles, lights, and electrical equipment, Hranipex takes pride in offering a diverse selection of top-quality products that cater to a broad range of needs.

“We’re excited to announce Hranipex as a relaunch partner for Materials & Finishes Show, says David Todd. “To have secured the support of such a forward thinking and ambitious elements company is a real coup for the show and will perfectly complement the machinery and materials brands who are already part of the exhibitor lineup.

Materials & Finishes Show is the UK’s leading trade show for machinery, manufacturers, processors and installers of wood and associated materials. It is free to attend and is set to attract 8,000 visitors from across the entire industry. You can stay up to date with the latest news and product launches by visiting www.materialsandfinishesshow.com

Timber Trader UK Magazine Summer 2023 21 www.timbermedia.co.uk @Timber_Media COVER STORY MATERIALS & FINISHES SHOW

“The Materials & Finishes Show aims to build on the success of the W Exhibition. Since the show’s conception in 1974 it has passed from being a woodworking machinery exhibition to covering the full range of technology and materials for industrial woodworking.”

David Todd, event director

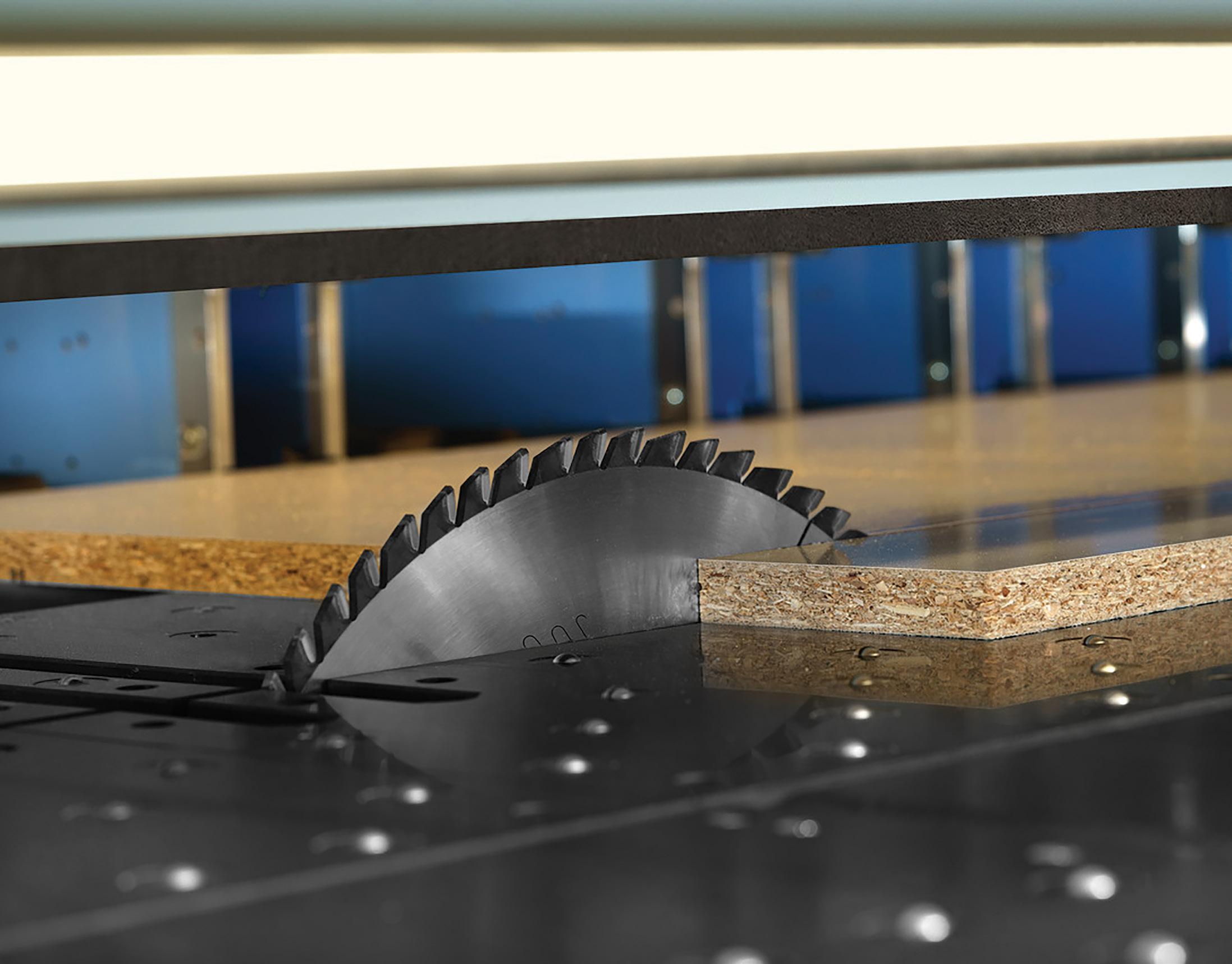

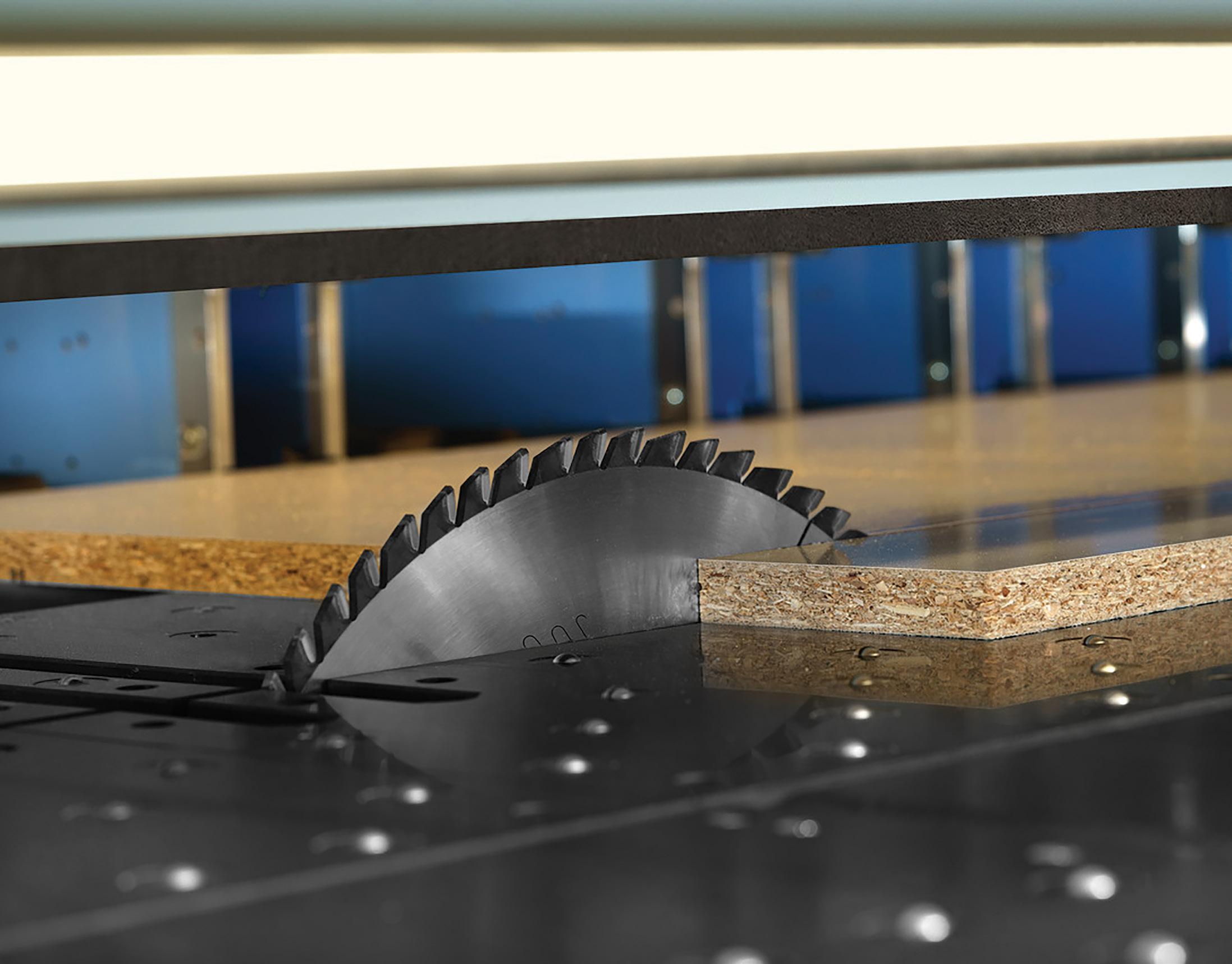

Timber in Motion

Wood-based panels are an important starting material for the building, packaging, furniture and flooring industries globally. Their processing involves turning chipping wood and recycled materials into high-quality final products. To achieve that, manufacturers need efficient conveyor belts. So how do you choose the right conveyor belts for each stage of wood panel processing? While fabric belts are the preferred choice for wood-based panels processing, the type, material and strength of the belts can influence the process efficiency and the final quality of the panel.

Chip preparation

The first step in processing wood panels is preparing the chips. Once the logs and recycled materials have been unloaded from trucks and scanned for unwanted materials like stone, metal, steel and sand particles, the chipper process begins. For this application, manufacturers use power transmission belts, which transmit power from the motor to the blade to cut the chips uniformly. Belts made from polyamide are the most suitable due to their high resistance to overloads as they absorb shock loads.

Bunker

After the chips are prepared, they are transported to the chip storage area, or the bunker. This process divides the chips into high quality material used for producing panels and rejected chips that will be used elsewhere. The most suitable belts for this application are fabric belts covered by either polyvinyl chloride (PVC) or thermoplastic polyurethane (TPU). Due to the

slow and straightforward selection of chips, these conveyor belts can last for several years, without the need for repeated maintenance.

Forming

The selected high-quality wood fibres are sent to the forming and pre-pressing stages, where they are shaped into panels. The forming belts used here are one of the longest inside the plant, up to 220 metres long and over three metres wide. These are designed to run over live nosebars with high loads and long conveying distances. Their special design, specific material types, resistance to certain chemicals and ability to handle various environmental conditions enable manufacturers to produce all types of panels, including very thin ones at varying speeds.

The most popular belt for manufacturers is the TPU-covered fabric belt, due to its high chemical resistance and ability to cope with

Timber Trader UK Magazine Summer 2023 22 www.timbermedia.co.uk @Timber_Media FEATURE MACHINERY

Choosing the right conveyor belt for your wood-based panels processing is not as simple as you think, as Damian Marczak, industry segment manager and Mario Buchs, global application engineer at conveyor belt specialist Habasit point out.

harsh processing requirements. However, TPU belts are made using chemically processed adhesives that release harmful emissions. At Habasit, we already have belts in our portfolio that use bio-based glues, which will help manufacturers increase their plant’s sustainability.

Prepressing

The raw panel-shaped matt is then compressed before being thermally processed. Pre-pressing uses a minimum of two belts arranged on top of each other. The belts need to be extremely wearresistant and capable of sustaining a high level of pressure and force, which is why belt manufacturers use aramid as a traction layer. The innovative belts from Habasit use a unique crosslink polyurethane material, which increases the abrasion resistivity of belts.

Deaeration

While the panels are compressed, this step includes removing the air from the woodfibres and creating uniform and homogenous surfaces This stage requires wire mesh belts to allow the air to be removed from the panels. The most common type is the polyester wire mesh belt, whose weaving pattern allows for high and controlled air flow rates. Lastly, the panels are processed and transferred to the pre-heater and the main press. To ensure the end products meet quality standards, manufacturers need to use the most suitable belts and materials. At Habasit, we provide end-to-end belting solutions for wood-based panels processing, designed with the customer’s needs in mind and meeting the highest industry standards.

About Habasit

Established in 1946 in Basel, Switzerland, Habasit is a familyowned company present in over 70 countries, with 3,500+ employees in affiliated companies and service centers worldwide. They help customers improve the reliability, quality and productivity of their equipment and processes through comprehensive, tailor-made solutions based on its extensive range of fabric-based conveyor belts, plastic modular belts and chains, power transmission belts, and monolithic and timing belts.

WE MAKE THE UK’S WIDEST RANGE OF STORAGE OPTIONS FOR TIMBER MERCHANTS

Timber Trader UK Magazine Summer 2023 23 www.timbermedia.co.uk @Timber_Media

More at www.habasit.com FEATURE MACHINERY WE DESIGN, MANUFACTURE AND INSTALL C ANTILEVER RACKING, PALLET RACKING, VERTIC AL STORAGE AND PIGEON HOLE RACKING

www.stakapal.co.uk www.semcoltd.co.uk www.redirack.co.uk BETTY’S LANE, NORTON C ANES, C ANNOCK, STAFFORDSHIRE, WS11 9NZ PROJEC T RACKS DESIGNED AND HIGH QUALIT Y RACKING HIGHLY COMPETITIVE BESPOKE C ALL US NOW FOR YOUR FREE SITE SURVEY ON 01543 278123 OR EMAIL sales@stakapal.co.uk

Dust Devils: Keep it Clean

Simon

With the news of the Health and Safety Executive (HSE) handing out a £20,000 fine to a London-based joinery firm for failing to adequately manage its employee’s exposure to wood dust, there’s been an awful lot of discussion about how firms can keep themselves compliant and avoid the fines.

From adjusting your processes to installing new machinery to help tackle the problem, there are a few different ways to help reduce the risk posed by wood dust, but what are the risks posed to employees in the joinery sector?

Eliminating the risk

When it comes to wood dust, the risks really can’t be overstated. Particles of wood, when cut, shaped, or sanded, become airborne, permeating the workshop atmosphere. This airborne dust can be inhaled by workers, leading to a host of respiratory ailments, including asthma, bronchitis, and even more severe conditions over prolonged exposure.

The potential long-term consequences outlined by recent research, such as nasal cancer, further underline the urgent need for preventive measures. Of course, we need to see companies take responsibility for the health of their employees. We often hear dust referred to as a silent killer, as its harmful effects can take years to develop. Excessive dust can lead to skin irritation, respiratory problems, and new research indicates the potential to develop lung cancer.

The HSE provides general principles for protecting you and your workers from wood dust in the workplace:

• when preventing dust exposure is not feasible, a combination of engineering and process controls may be suitable

• local exhaust ventilation (LEV) systems should be integrated into the machines or processes generating dust. It’s important to consider the impact of cross draughts and general air movements on their efficiency

• for on-tool extraction, choosing compatible parts is crucial.

These broad principles make it challenging for factories to find integrated solutions and avoid health and safety violations.

Tackling dust directly

Leitz UK’s approach to this is to reduce the amount of dust generated in the first place through an end-to-end system that controls both dust and noise throughout the manufacturing process. By improving process production, there’s an opportunity to increase productivity as part of the solution, leading to ongoing cost-saving benefits and a safer work environment.

Leitz tooling design and management system provides highquality cutting without the need for secondary finishing and sanding in many cases, which reduces tooling wear and lowers costs overall. As well as this, it can mean there are lower levels of atmospheric dust in manufacturing facilities.

Leitz UK’s Dust Flow Control® (DFC) technology is a tooling-toextraction system that reduces dust and noise. Our DFC extraction

Timber Trader UK Magazine Summer 2023 24 www.timbermedia.co.uk @Timber_Media FEATURE HEALTH & SAFETY

Liddell, managing director of Leitz UK talks through the recent fine levied at a London joinery firm for the improper management of wood dust in the manufacturing environment, and how companies can create safe workplaces of the future.

Timber Trader UK Magazine Summer 2023 25 www.timbermedia.co.uk @Timber_Media ENQUIRE TO EXHIBIT We’re starting something new. Be part of the UK’s leading trade show, designed to expand your opportunities, start new conversations, open new doors, build new supply pipelines and strengthen your revenue streams. Crafted for your business, to do business. Materials & Finishes Show was formerly known as W Exhibition. The UK’s leading trade show for machinery, manufacturers, processors & installers of wood & associated materials. ENQUIRE TO EXHIBIT materialsandfinishesshow.com/exhibit

hoods are optimised to collect up to 98% of debris and residual dust. They are suitable for double-end tenoners and edge banders. As well as vastly reducing the amount of dust in the atmosphere of manufacturing facilities, our DFC Hoods are able to help reduce the amount of wear that your tooling sustains due to the prevention of double cutting, through specialised chip flow guidance. This will ultimately help to lower your set-up and energy costs as well.

LEV: Critical Part of Employee Protection

According to the HSE, F&E Joinery Limited was inspected in May 2022 as part of a HSE campaign targeting woodworking businesses. The HSE inspection found some of the company’s machines had been disconnected from the local exhaust ventilation (LEV) system, which is used to extract wood dust at source during machining of wood. There was no way to connect other machines to the system. LEV significantly reduces the amount of wood dust that becomes airborne and inhaled when machined. There was also no evidence that settled wood dust was being cleaned up.

HSE inspector Marcus Pope said: “This case sends out a clear message to the industry that HSE will prosecute when inspectors find serious health and safety failings, particularly when previous enforcement and advice has been provided.

“Exposure to wood dust causes various occupational lung diseases which can significantly affect the quality of people’s lives, and in some cases result in premature death. HSE continues to target the woodworking industry and strongly urges businesses to consult its website for further information to ensure that control of exposure is managed, and their statutory duties are complied with.”

Commenting on the case Kevin Simmonds, managing director of Compliance LEV, said: “Tellingly, HSE data show that many workers in the UK continue to be affected by poor or non-existent local exhaust ventilation (LEV). Shockingly, there are estimated to be around 13,000 UK deaths each year linked to past exposure at work.

“Moreover, statistics from the Institute of Local Exhaust Ventilation Engineers (ILEVE) disclose that while 65% of workplaces have local exhaust ventilation installations, only 24% of those incorporate adequate control of potentially health-damaging

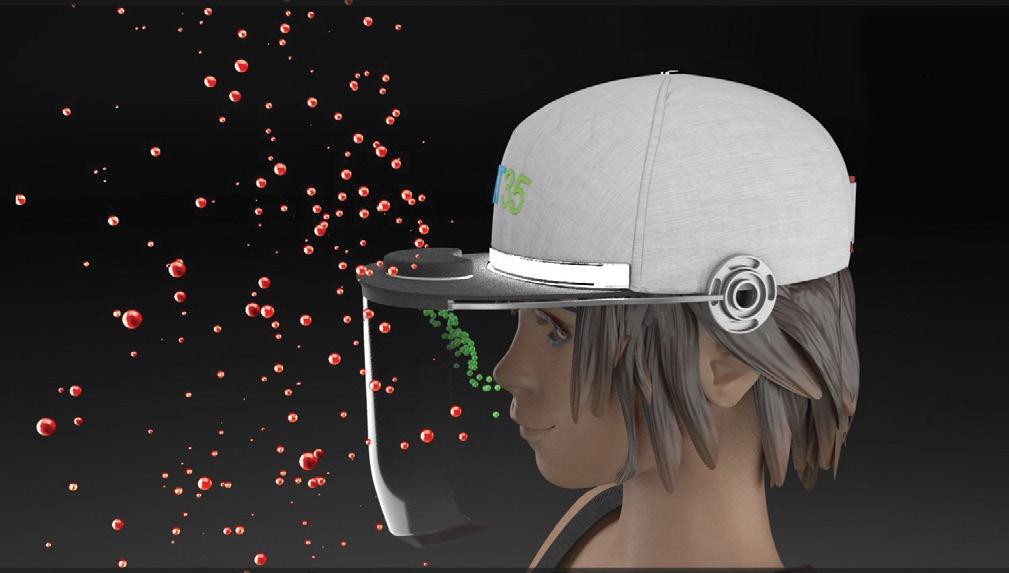

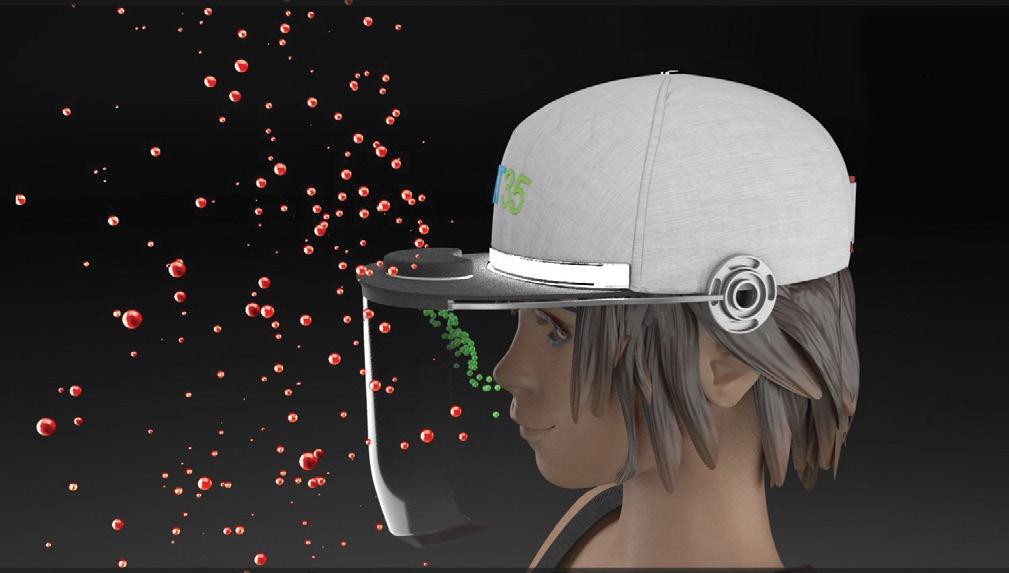

Hat 35

Compliance LEV has developed baseball cap-style headwear which filters out harmful toxins and directs a flow of clean, fresh air over the user’s nose and mouth. In early tests, the product – known as Hat 35, because its airflow is at a 35-degree angle – was shown to be 95% efficient at filtering pollutants such as sulphur dioxide and nitrogen oxides, and 99% effective on particulates. Hat 35 wearers are, in fact, air quality monitors, as well as providing the protection wearers need from toxic fumes and particulates.

Like Fitbit, which records personal data, Hat 35 is designed to continually acquire data on pollution and contaminant levels around the world, providing invaluable information to policymakers on air quality. Compliance LEV will embark on a third funding round, aimed at raising a further £500,000 to £600,000 in 2024 and, once

As the HSE intensifies its focus on dust levels in the workplace, our industry must address these issues through end-to-end solutions that not only save money but also boost productivity. Prioritising health and safety is essential for the well-being of employees and the success of joinery firms across the country. When we act in the best interest of all our employees, we’ll have a safer, more secure future, and a better industry overall.

More at www.leitz.org/en-gb

contaminants. Furthermore, says the ILEVE, 60% of LEV systems are not thoroughly examined or tested, and 60% of those that are tested are not tested competently.

“These figures make clear that all too many businesses are seriously failing to understand their obligations to install and maintain effective LEV systems. And the consequence is widespread illness and death. Harmful substances in manufacturing industry are still causing preventable health problems for workers, which could be avoided by the installation and maintenance of effective local exhaust ventilation systems.

The HSE has certainly picked up on this and is currently displaying an increasingly pro-active, hands-on approach to health and safety in the manufacturing industry. It has launched a nationwide programme of targeted and comprehensive inspections to ensure that those who are non-compliant with the regulations take responsibility and be held accountable with financially significant fines.”

More at www.compliancelev.co.uk

the Hat 35 technology has qualified through successful mission operations, will seek to license the product and possibly consider a trade sale in 2026.

Timber Trader UK Magazine Summer 2023 26 www.timbermedia.co.uk @Timber_Media

FEATURE HEALTH & SAFETY

Kevin Simmonds, managing director of Compliance LEV

Nail it down with confidence!

SR Timber PREMIUM GOLD®

Correctly graded roofing batten to BS 5534:2014+A2:2018

A trusted trademarked brand. Our unique and distinctive gold colour. Peace of mind you are installing and working with a British Standard product.

Relevant standards: BS 8417:2011 (Preservation of Timber) and BS 5534:2014+A2:2018.*

Vacsol Aqua Preservative, treated to BS 8417:2011* Impregnated to Use Class 2 by double vacuum/low pressure water based preservative. Protection with our standard 60 service life against insect attack and wood rotting fungi. (When used correctly and installed above dpc level in buildings).

Product stamped, (each piece), showing: Producer, Imported and/or species code, Graded BS5534, Size, Independent 3rd Party Accreditation*.

Third party accreditation regularly audited by CATG (UKAS Accredited) to ensure continued and consistent application of British Standards. Wood Protection Association - WPA Quality Approval Certification Audited as an approved treater and capable of producing treated wood to the correct Use Class(es). Use class of treatment is stated on a all documentation.

Factory graded roofing battens, we control by: Automated and visual grading of the raw material as well as the batten at commercial speed, final visual grading ensures nothing is missed and every piece is double checked, from dimension, knot size, wane, resin pockets, to slope of grain.

Full Chain of Custody certification FSC, PEFC. Confirms timber used in production is sourced from legal, responsible, sustainably managed forests.

Each delivery is accompanied with documentation stating; Supplier, Imported, Graded in accordance with BS 5534, Sizes, Type of treatment.

THE FUTURE IS GOLDEN!

Timber Trader UK Magazine Summer 2023 27 www.timbermedia.co.uk @Timber_Media SRGBA0323 V1 | © SIG Trading Ltd 2023. All rights reserved. *See product datasheet for more information at: sr-timber.co.uk/Product/sr-timber-premium-gold-roofing-batten.

*As recommended by the NFRC & TDUK, using an independent certification company being UKAS accredited, of which audits both material and processes verifying conformity

Full to size: Batten thickness minimum 25mm (Allowed tolerances -0mm/+3mm) Batten width 38mm or 50mm (Allowed tolerances -3mm/+3mm)

01623 446 800 | www.sr-timber.co.uk

All Angle Visibility

As part of Combilift’s drive to help customers achieve their aims of more sustainable operations, over 60% of the company’s output is now electric. Recent models such as the Combi-XLE and now the Combi-FSE focus on heavier duty application for industry sectors including timber, steel, tubes and pipes and builders’ merchants.

The company has big ambitions for the future, aiming to deliver over 10,000 ‘climate positive’ homes across the south of England by 2035. The offsite manufacturing process enables the timber frame superstructure to be erected quickly and safely, and a home is airtight and watertight just two weeks after the first panel arrives on-site.