TRACKS

We’ve had another busy summer here at C&P. In May, some of our Sales representatives visited JCB HQ to attend specialist training on the upcoming JCB Agriculture products. In June, some of our technicians and customers visited Massey Ferguson in Beauvais, France for a factory tour and learnt all about the latest product launches from the brand.

This year we have been focusing on providing additional training for all of our staff, we are particularly focused on ensuring the safety and well-being of our teams – all employees across every business have now completed their first responder training and all of our sites are now equipped with Automated External Defibrillators.

In our autumn/winter issue of Tracks you can read about how our customers have been getting on with their new machines and how they use them to optimise their business productivity. We also catch up with Amy and see what she’s been up to over the last few months and read about JCB’s newest loadall.

We hope you enjoy our ninth issue! If you or your business would like to appear in the next issue of Tracks, we would love to hear from you! Email tracks@clarkeandpulman.com or give us a call on 01704 897507.

4 CUSTOMER FOCUS: THE KING OF FEEDERS Why H&C pickervance opted for a stand alone feeder

6 CUSTOMER FOCUS: THE PUMPKIN PATCH HIGHTOWN 14 MACHINE FOCUS: JCB MACHINE FOCUS 524-100

FOCUS: NICK ANDERTON – KICKING

We learn about JCB’s latest loadall

16 CUSTOMER FOCUS: HARVESTING HOLIDAY MAGIC

We catch up with Richard to see how his MF 6S is faring with the festivities

COMPANY FOCUS: MEET OUR

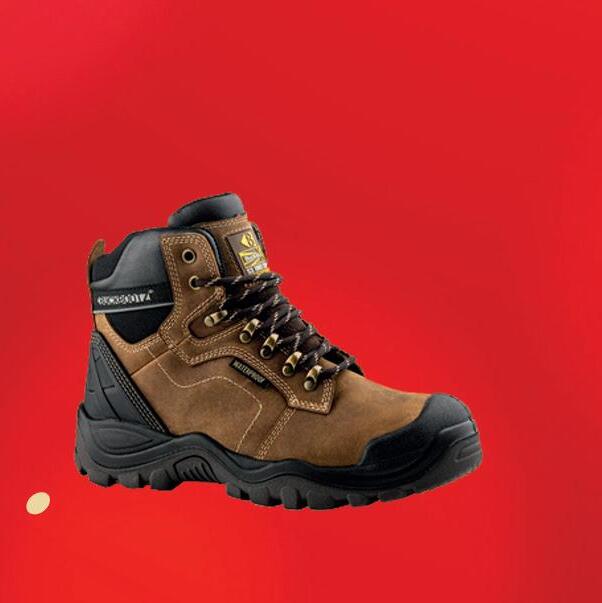

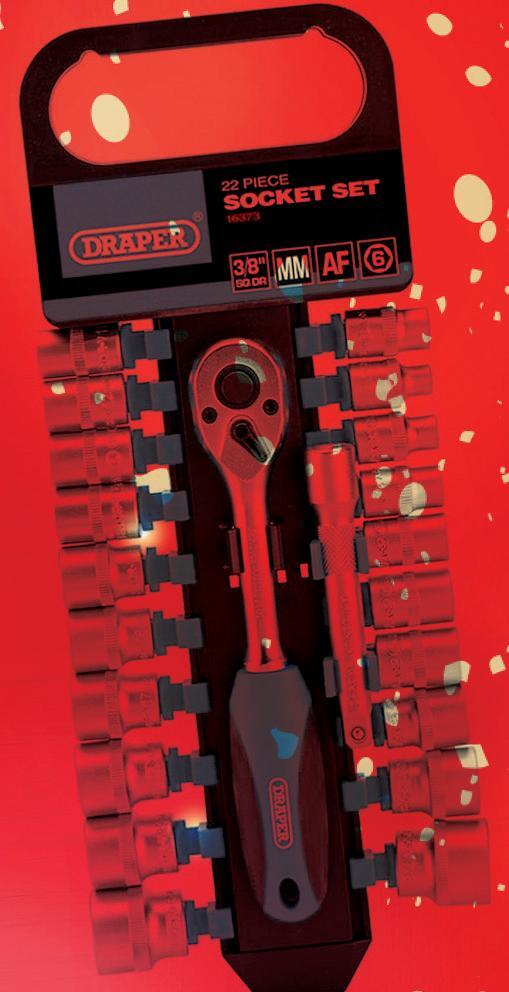

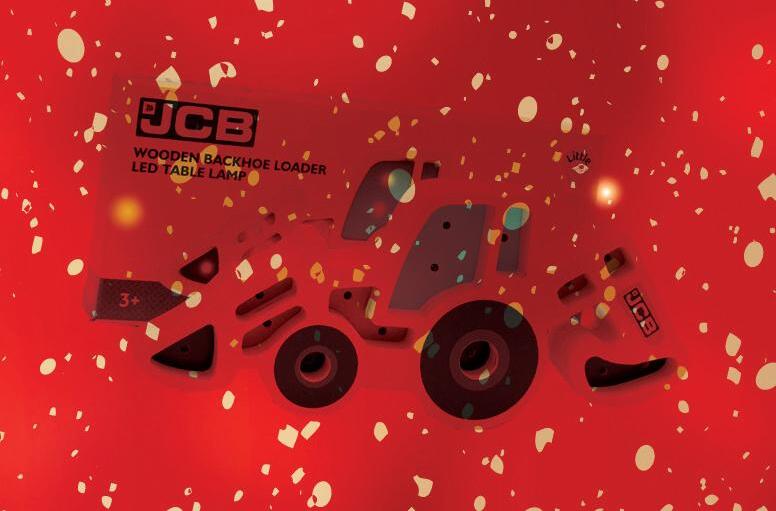

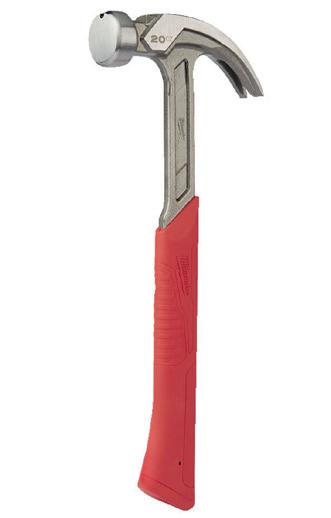

OUR PARTS CHRISTMAS

CUSTOMER FOCUS: WHY SED IS SO LOYAL TO JCB

& USED

FOCUS: FENDT ROGATOR 600

If you would like to appear in the next issue of TRACKS, just send us an email with details: tracks@clarkeandpulman.com

We are excited to invite you to our special Kverneland Siloking Feeder Event

You’ll have the unique opportunity to meet with Kverneland representatives. They will provide a presentation on the SILOKING Standalone Feeder, followed by a Q&A session to address any queries you may have.

As you gain insights into this cutting-edge feeding technology, enjoy a selection of complimentary food and drink refreshments.

Don’t miss out on this chance to network with industry professionals and learn more about how the SILOKING Standalone Feeder can benefit your operations. We look forward to seeing you there!

DATE: 23RD OCTOBER

TIME: 6:30PM

LOCATION: 119 GARSTANG ROAD, CLAUGHTON-ON-BROCK, PRESTON, PR3 0PH.

Earlier this year, we visited Harrison of H&C Pickervance to see how he was getting on with his new SILOKING SelfLine 4.0 System 500+ 2519-22 diet feeder. Operating an intensive dairy system, a total of 1,800 head reside at the family’s two sites, with 850 acres of grass and maize silage grown.

H&C Pickervance received their new feeder in December 2023, having previously run a similar model for about three and a half years. Their previous machine, bought as an ex-demo, proved its worth on the farm and allowed Harrison and his brother Thomas to tailor their new machine to best suit their requirements. For example, HD side-discharge doors were specified for rapid feed-out, along with a rear centre door for pre-mixing of feeds.

The decision to invest in a standalone feeder was driven by the need to save both time and money. “With six silo camps across our farm, time is the expensive thing to measure,” Harrison explains.

“We do a minimum of 14 mixes of feed per day, and with the new SiloKing self-propelled, we can feed 1,800 cattle in just two hours. If we had gone back to a trailed mixer, we would’ve needed a much larger tub, requiring more space and a bigger tractor too. This setup is more costeffective overall. We wouldn’t have bought another one if it hadn’t been worth it!” Harrison tells us.

Unique to self-loading machines, the 2-metre wide milling head features 42 cranked knives to gently tease material from the clamp face.

While not only leaving a clean and compacted face, its shallow working depth allows you to quickly get across the clamp face to further help reduce spoilage and waste. The head also features a scraper plate, allowing it to cleanly pick up dry and moist feeds from the floor.

Once milled, feed is transported to the tub via an elevator belt. Harrison adds “The belt has a much better design than our old feeder, it keeps much cleaner which should help in the long run.”

All loading and unloading programmes are controlled via the in-cab 7-inch screen, with SiloKing’s DataE loading program allowing automated stopping of the milling head for kilogram accuracy in every ration.

“OUR FARM IS SPLIT BETWEEN TWO SITES EXACTLY A MILE APART, AND WE USE THE SELFPROPELLED TO BRING SILAGE BETWEEN SITES AS IT SAVES US NEEDING A LOADER AT EITHER END. MANY PEOPLE ALSO DON’T REALISE THE FEEDER CAN REACH SPEEDS OF UP TO 50 KPH.”

“The feeder is brilliant to drive,” Harrison remarks. “People assume it would be difficult to handle, but it’s very similar to driving a loadall—smooth and responsive. The feeder’s four-wheel steer design makes it easy to manoeuver, and the ergonomic cab features an air suspension seat with integrated multi-functional armrest, and a joystick for convenient operation of the milling head.

“Roadwork is important to us too,” Harrison adds. “Our farm is split between two sites exactly a mile apart, and we use the self-propelled to bring silage between sites as it saves us needing a loader at either end. Many people also don’t realise the feeder can reach speeds of up to 50 KPH.”

Chosen for maximum reliability and uptime, a 252hp six-cylinder VOLVO Penta is now featured, with hydraulic drive to all elements. Tractive force is via the front axle and ultimate comfort provided by air suspended axles front and rear.

While 4wd is available as an option, 2wd is enough to negotiate slippery slopes, undulating concrete as well as an idealic level yard.

While this machine stands in at 22-cube and 3.3m tall, SILOKING also offer its Self-Line range from 13-cube compact single auger machines to its largest 32-cube larger triple auger machines.

Harrison is also pleased with the service he has received from our technicians. “Tom Hayton and Harry Jackson are great lads who really know their stuff,” he says.

∞ 750 trailed mixers produced anually

∞ 420 self-propelled produced annually

∞ 3,800 total selfpropelled mixers manufactured

∞ 15m investment in new SelfLine manufacturing facilities

For more information about our range of SILOKING machinery, contact our Sales Team on 01995 640302 or drop the team an email at saleshub@clarkeandpulman.com

As spooky season approaches, we caught up with the families behind The Pumpkin Patch Hightown to learn more about their thriving business.

James and Beth Greenwood, along with Jonathan and Rebecca Connolly, first had the idea to create a pumpkin patch in 2015. After both couples had children, they realised there was gap in the local market and wanted to have some fun. Therefore, James, who runs his family farm, and Jonathan, who owns a contracting business, brought their farming knowledge and expertise together for the project, and took a leap of faith.

By 2017, they had decided to turn their idea into reality, planting 15 acres of pumpkins in the first year — around 25,000 pumpkin plants in total. Since then, the business has expanded rapidly and today, they plant over 40 acres and transplant around 100,000 pumpkin plants each year to allow for losses. “We grow a great variety of pumpkins,” James explains, “From racer pumpkins and Jack O’Lanterns, to the weird and wonderful gourd varieties. There is the bluey/grey Crown Prince, several white varieties, a pale pink pumpkin, yellow mellow, various squashes and gourds, and, of course, the classic Cinderella pumpkins.”

From Seed to Harvest

The pumpkin-growing process begins as early as April, when the team selects the varieties they want to grow, the quantity, and where to plant them.

They work the ground down to the perfect conditions before transplanting the modules to the field. Handplanting the pumpkin plants takes four or five days, and because pumpkins can’t be sprayed for weeds or pests, the planting and growing process is incredibly labourintensive.

“Weed control is a major issue,” James notes. “We start by using tractors for mechanical weeding, but as the pumpkins grow, we have to remove weeds by hand which is back breaking if we’re honest.”

“CLARKE & PULMAN ARE ALWAYS THERE FOR US — IF WE EVER NEED HELP, THEY FIND A SOLUTION!”

“WE GROW A GREAT VARIETY OF PUMPKINS, FROM RACER PUMPKINS AND JACK O’LANTERNS, TO THE WEIRD AND WONDERFUL GOURD VARIETIES.”

Pumpkin plants produce both male and female flowers on the same plant, with only the female flowers forming fruit. The pollen from the male flower fertilises the female flower, and after pollination the ovary behind the flower develops into a fruit.

Relying on pollination, the Pumpkin Patch Hightown works closely with another local business, Simply Beeutiful Honey, which supplies around 40,000 bees to help pollinate the plants. They produce honey from all over the local area and this is then sold at the patch’s artisan market in October. But October brings its own set of challenges. The pumpkins grow under a leafy canopy, obscuring the crop until the pumpkins ripen and the canopy dies off. “It’s always nerve-wracking,” Rebecca shares. “We just cross our fingers and hope for the best, especially this year with the wetter, cooler weather.” The pumpkins are then harvested by hand, ready to be picked by the many families visiting the patch!

“The business works well because we all have different strengths and roles,” Rebecca reflects. “James and Jonathan handle the groundwork, while Beth and I manage social media, the day-to-day operations, and ensuring everything runs smoothly.”

Reliable machinery is another essential element in keeping things running. “Nearly all of our equipment comes from Clarke & Pulman. We mainly use Fendt, JCB, and Massey Ferguson machinery,” says Jonathan. Rebecca adds, “Clarke & Pulman are always there for us— if we ever need help, they find a solution!”

The pumpkin patch opens to the public on 1st October each year and operates daily from 9am to 6pm for visitors to pick their own pumpkins. While on site, visitors can explore a five-acre maize maze, pick their own sweetcorn, and pop into the weekend artisan market which features a variety of local businesses, selling everything from candles to honey.

You can find The Pumpkin Patch Hightown at Orrell Hill Lane, Hightown, Merseyside, L38 5DA.

∞ If stored correctly, pumpkins will keep for months.

∞ Store in a cool, dry place.

∞ Handle carefully (they bruise like any other fruit / veg).

∞ Once you pierce the skin, the pumpkin will start to deteriorate.

∞ Once carved therefore, the pumpkin will last around four days.

∞ All of our pumpkins are edible and are a fabulous food (prepare like butternut squash).

You can keep up with everything pumpkin related by following The Pumpkin Patch Hightown on social media @thepumpkinpatchhightown

T: 01704 897 674 E: info@howebrook.co.uk Howebrook.co.uk

Instagram & Facebook: @howebrookequinetherapy

Howe Brook is a dedicated equine therapy and holiday livery, located in an idyllic West Lancashire setting. Based in the heart of Wrightington, Howe Brook caters for horses of all disciplines, from happy hackers, to top competition horses, including those who want to improve their fitness or require rehabilitation.

Our therapists devise treatment plans tailored to the individual horse they’re working with, ensuring they get the absolute most from their sessions in a very safe environment. We take a safe, considered approach to all of our therapies, ensuring each horse is calm and happy, and gets the absolute most from their session.

Introductory Water Treadmill (approx. 12 mins)

Water Treadmill (approx. 20 mins)

TheraPlate (approx. 20 mins)

Solarium (approx. 20 mins)

Introductory Water Treadmill, Solarium & TheraPlate (approx. 30 mins)

Water Treadmill, Solarium & TheraPlate (approx. 60 mins)

Scan Here to BOOK NOW

Use code ‘HBTRACKS’ for 10% off your next therapy session.

Our livery is based at Martin House Farm, where we currently have around 25 happy horses staying on our 50-acre farm.

We operate a calm, relatively small yard with set routines, and all-round care. We currently offer both full and holiday livery.

Facilities

£20

£30

£20

£10

£30

£40

• 14ft x 14ft roomy outdoor stables

• Large wash box incorporating rubber floor and hot horse shower

• Individual year-round turnout in paddocks with specialist horse fencing

• Show jumps

• 2x outdoor manège fenced with wooden post and rail, surfaced with silica sand and fibre (35m x 55m & 40m x 20m)

• 24/7 CCTV and electric gates

Mon–Sun: 9am – 5pm

Open late night Thursdays til 8pm OPENING

Howe Brook Equine Fitness & Recovery,

SIP Industrial was founded in 1968 in Wigston, Leicester. What started out as a small operation in two small industrial units over 50 years ago, has increased in both size and popularity to become a household name, distributing products via trusted stockists across the UK and Ireland.

The business started out distributing cut industrial abrasives in the late 1960’s before adding circular metal cutting saws and blades to its portfolio of equipment. After noticing a gap in the welding market for ARC welding, SIP sought out a manufacturer in Italy to build the units.

Quality, research, and design have always been at the forefront of the company, with a particular emphasis on not only producing equipment of the highest quality and usability but also offering the very best in customer service.

Today SIP launch over 100 products a year, built and tested by SIP technicians at their HQ in Leicestershire and have built a vast collection of reliable distributors across the UK and Ireland. They have 12 core ranges suitable for home, trade and industrial use and have established trusted partnerships with premium brands including DEWALT, NARDI Compressori and AER Service.

As I write this on the 13th of August 2024, I’m struck by how different this year has been. So far, our combine harvester has only left the shed for one afternoon to harvest our pitiful oilseed rape—what little was left after winter floods and geese destroyed the rest. By now, we would usually be well into harvesting winter wheat, but given the weather last autumn and winter, we would have had better luck building an ark. As a result, we don’t have any winter wheat to harvest this year either.

Don’t get me wrong, we’re certainly not twiddling our thumbs. All the cows have been put out to grass, and we’ve taken our first two cuts of grass. However, this unexpectedly slower-paced early summer has given me the chance to take a few days away from the farm to pursue other opportunities that I’m very fortunate to have come my way. I’ve often been asked to speak to various farming groups about these opportunities, and the same remarks are always made: “So, who looks after the place while you’re off doing this?” and my personal favourite, “Your poor Dad.” But before I dive into the recent opportunities, let’s address this.

My Dad and I both work equally hard on the farm, putting in seven days a week. We get similar amounts of time off; however, Dad tends to use his time off to go on holiday— which he thoroughly deserves.

Every time I mention that “Dad’s away,” people always respond the same way: “No one deserves it more,” and I couldn’t agree more. But as a single 28-year-old with a mortgage to pay, I can’t afford holidays to the same extent. So, many of my days off are spent on the opportunities that people offer me. Dad has always encouraged me to seize any opportunity that comes my way to broaden my horizons, and to be honest, many of them pay me quite well.

So, back to what I’ve been up to recently! At the end of June, I was thrilled to be asked to judge the Commercial Beef/Beef Feeding category for the Cheshire County Farming Competition.

Then, in early August, Farmers Guardian asked me to guest host their podcast covering the fantastic event that is Farm24. Farm24 is the largest online celebration of British farming, aimed at giving the public an insight into a farmer’s day. It’s ran by Farmers Guardian and sponsored by Morrisons. Having worked with several of the FG team before, I was basically told to just be my chaotic self. My day started at 5 a.m. at the Preston office, where I interviewed different members of the team, hopefully providing a behind-the-scenes glimpse while having a good laugh.

The day involved being driven around Cheshire—quite fancy for a Lancashire lass like me—to visit different beef farms where farmers shared all the details of their operations. Judging between these farms was like comparing apples and oranges.

Each setup was so different, and it was clear that each farm excelled in its own way, whether it was data-driven rearing, high-volume finishing systems, or incredibly low-input, New Zealand-style grazing systems. It was an incredibly educational day that I thoroughly enjoyed.

We then travelled to Skipton Morrisons to interview staff and shoppers, before heading up to Malham for a very windy drive to interview one of the event’s ambassadors, Frank Carr of Lee Gate Farm.

We had a good chat in the brew shed for the podcast and then faced the daunting task of conducting a BBC-worthy interview and video. We must have done reasonably well, as it made it onto the BBC (or, as I like to call it, the big boys’ club). We finally returned to the Preston office, and I was asked to end my day by heading to Merseyside to interview Oliver Harrison—better known as Ollyblogs— while he was combining wheat. It was an incredibly long day, but I really enjoyed it and got to use skills that I don’t get to practice on the farm every day.

Why am I writing about this? Mainly, I want people to know that it’s okay to take time away from the farm and to embrace any opportunity that comes your way. Since doing so, I’ve learnt so much and gained a lot more confidence in myself. So just go for it!

“I WAS THRILLED TO BE ASKED TO JUDGE THE COMMERCIAL BEEF / BEEF FEEDING CATEGORY FOR THE CHESHIRE COUNTY FARMING COMPETITION.”

Professional footballer and part-time farmer Nick Anderton was diagnosed with cancer in 2022, bringing an abrupt end to his football career. After the diagnosis, his father, Nick Snr, decided to lift his son’s spirits by purchasing a new Fendt 720 Vario tractor. We caught up with Nick a year after his diagnosis to see how he’s doing and how he’s enjoying his new Fendt.

Nick grew up working on farms around Brindle, where he developed a passion for both football and farming from a young age. Like many kids, Nick spent his time split between these two loves. Recognising their son’s talent on the pitch, Nick’s parents encouraged him to pursue a career in football. “All he wanted to do was farm, but we pushed him to pursue football. Farming is a hard life, and there are easier ways to make a living these days. Farming will always be there for Nick to come back to.” Nick Snr tells us.

Nick left school in 2012 at the age of 16, having secured a two-year scholarship with Preston North End F.C., where he turned professional in 2014. As a left-back, Nick was loaned out to various National League clubs, including Barrow A.F.C., who signed him permanently in 2016. He later played for Blackpool F.C. and Carlisle United F.C., where he was appointed captain ahead of the 2020-21 season, before joining Bristol Rovers in 2021. Bristol Rovers saw a dramatic promotion to League One, clinched with a 7-0 victory over Scunthorpe United on the final day of the season. Unfortunately, Nick’s time at Bristol was cut short, and it ultimately marked the end of his professional football career.

While playing for Bristol Rovers, Nick began experiencing pain in his leg and knee, which worsened over time. After about six months, he decided to seek medical advice.

As a professional footballer, Nick was swiftly sent for a scan by his physiotherapist, which revealed a tumour on his femur. In July 2022, Nick was officially diagnosed with osteosarcoma, a rare form of cancer. I was fortunate as a footballer to be referred for scans so quickly”, Nick reflects. An initial biopsy determined the tumour was not aggressive, so Nick was scheduled for surgery three months later. During this time, he kept himself busy on the farm, driving tractors, and helping out around the yard.

Surgeons removed and replaced 12 cm of Nick’s femur, replaced his knee, and removed the tumour. It was during the operation that surgeons discovered around 10% of the tumour was high-grade, aggressive cancer, leading to the decision to treat Nick with chemotherapy to ensure all cancerous cells were eradicated. Nick underwent 28 weeks of chemotherapy, followed by eight weeks of antibiotic treatment. During this time, he developed lifethreatening sepsis but was fortunate to survive.

The Anderton family have been loyal customers of Clarke & Pulman for nearly 20 years, typically favouring Massey Ferguson machinery. However, after Nick’s diagnosis, his father decided to surprise him with a Fendt 720 Vario. “We’ve always been Massey customers, but when Nick got ill, he needed something to lift his spirits. All common sense went out the window, and we bought the Fendt. We hid it from him initially and surprised him in January 2023. He was over the moon!” The 720 Vario now holds pride of place on the farm, used primarily for cultivation and hedge cutting.

Following Nick’s diagnosis, the football community rallied around to support him and his family. Bristol Rovers players and staff shaved their heads, raising £50,000. Bristol Rovers fan Nik Weeks ran seven marathons in seven days, raising £8,000 for Nick and the club’s community trust.

Liverpool F.C. also donated a signed ‘Anderton 16’ Liverpool shirt, in honour of Nick’s shirt number, which was auctioned off to raise funds.

In January 2024, Nick was appointed assistant head coach of National League club AFC Fylde. “It’s tough not playing football anymore, but being back around the game and within the football community feels good. I never thought I’d be back working full-time in football so quickly.

It’s been good for me; I like to keep myself mentally occupied, especially between check-ups to ensure everything is still okay and I remain in remission. It can weigh heavily,” Nick admits. “I’m devastated I can no longer play, but I’m glad I left no stone unturned in my career. Overall, I’m thankful for the experiences I’ve had over the last two years. I see life very differently now. The future is hard to think about, as I still worry about my check-ups, but I guess I’ll just see where football takes me!”

“WE’VE ALWAYS BEEN MASSEY CUSTOMERS, BUT WHEN NICK GOT ILL, HE NEEDED SOMETHING TO LIFT HIS SPIRITS. ALL COMMON SENSE WENT OUT THE WINDOW, AND WE BOUGHT THE FENDT. WE HID IT FROM HIM INITIALLY AND SURPRISED HIM IN JANUARY 2023. HE WAS OVER THE MOON!”

If you are interested in any of the machines mentioned, contact out Sales Hub on 01995 640302 or drop us an email at saleshub@clarkeandpulman.com

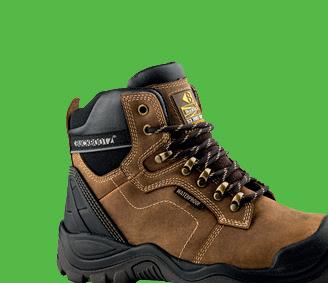

Since its UK debut at LAMMA in January, the JCB 542-100 appears to be an excellent addition and shows JCB’s continued investment in its loadall range. Developed with straw contractors and large farms in mind, the latest machine range is the most powerful yet and is available in AGRISUPER, AGRIXTRA and AGRIPRO spec. It’s multi-purpose design is built for the stability of stacking bales while still nimble enough to weave around the yard and yet remains light and manoeuvrable in the field.

With the same footprint as the previous high-lift model – the 536-95, which was the highest specification in the range – the new model offers a 16% increase in lift capacity, from 3,600kg to 4,200kg and an increase in reach from 9.5m to 9.8m. The half-ton increase in lift capacity and increased reach, while maintaining the same footprint allows for efficiency and performance enhancing features, the machine can move around the yard easily, cleaning out cattle sheds and filling feeders for example, whilst moving and loading bales at height.

More powerful than the previous loadall with 22% more tractive power, the 542-100 boasts 173hp thanks to its 4.8 litre DieselMax, stage V engine. JCB’s DualTech VT hybrid transmission, allows speeds up to 50kph. The DualTech VT, which is included in all models in the range, is JCB’s half hydrostatic, half direct mechanical drive gearbox. This provides the best of both worlds and is 25% faster than the previous model – beginning with hydrostatic drive at low speed (up to approx. 19kph) before switching to direct-drive with TORQUE lock.

The extra power further increases the machines ability to carry out big tasks such as filling spreaders and trailers, digging into grain and livestock manure etc.

JCB’s latest 542-100 benefits from brakes in both front and rear axles for greater stopping power. In addition, the new axles boast a wider stance, providing more stability and safety when stacking at height.

If you are interested in booking a demo of the JCB 542-100, please contact Richard Bradley on 07584 218267 or contact our Sales Support Hub on 01995 640302 .

WHEN

YOU PURCHASE A JCB, YOU WILL AUTOMATICALLY RECEIVE A 5 YEAR SUBSCRIPTION TO LIVELINK FOR YOUR MACHINE AS STANDARD.

The addition of the integrated reversing camera allows the operator to gain even clearer vision to the back and right hand side of the machine. Although the low engine profile already provides an excellent level of vision, the cameras provide additional security.

JCB’s weigh load system allows the operator to weigh what they’re loading which is then automatically uploaded straight to LiveLink - JCB’s innovative telematic system which allows ultimate fleet control in one place. The information will also show location via GPS, so the operator will be able to view the weight loaded and where the loading was done.

This allows the ultimate productivity tracking and is accurate to within around 50kg, very helpful when loading a wagon for example, to ensure it is not overloaded before leaving the yard.

Another welcome safety feature is the option to add a clean air filter. Due to the amount of dust associated with working with and moving straw, there is the option to add a clean air filter to the machine – pressurising the air and adding an extra filtration system for the air going into the cab.

The new model has also been fitted with a pebble guard for added safety when moving straw bales, in addition to the front screen guard.

Enjoy the peace of mind of knowing where your machine is 24/7 anywhere on the globe with the map overview allowing you to see where your machine is, accurate to a 3m x 3m square. With the mixed fleet integration you are also able to view your entire fleet from your deviceincluding data from different manufacturers and systems - without the need to log in separately to individual providers sites and systems.

The LiveLink App can be used with both Android and IOS operating systems with all of your machine data is accessible at your finger tips and can be downloaded and saved for easy access.

Geofences allows the user to place geographical, virtual ‘fences’ within any area around a machine, meaning that you will receive an alert as soon as your machine moves outside of the defined area. You will also be able to view the previous movement history of the machine and view all machines by site and region.

Benefit from out of hours alerts if your machine is being used outside of normal hours, you will receive an alert to ensure that the machine is not being used by an unauthorised person.

Get the most out of LiveLink’s advanced analytics reporting, allowing you to make informed decisions based on machine productivity including fuel consumption, idle time and emissions. You are also able to schedule automatic key reporting which are received directly into your inbox.

The Operator App (included in LiveLink subscription) allows for health checks to become a daily routine –any failed checks will send alerts via the app so you can monitor your machine health 24/7.

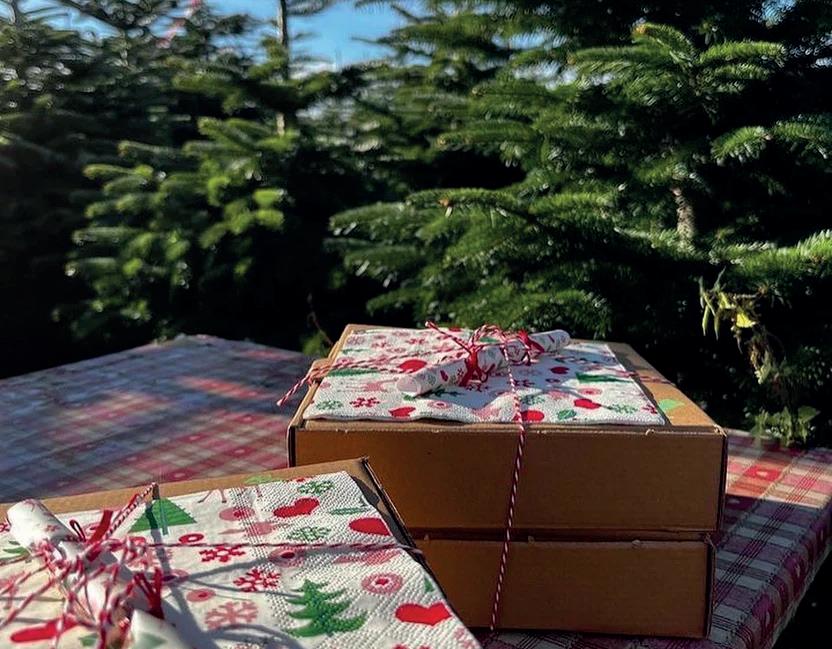

As the festive season draws near, we turn our attention to one of our most festive customers, Catchdale Moss Farm in Eccleston, St Helens.

This unique farm, a delightful blend of holiday cheer and agriculture, is managed by Richard, a dedicated farmer who has successfully transformed his Christmas tree farm into a thriving business. We recently had the pleasure of catching up with Richard to discuss his farm, his trusted tractor, and his exciting plans for the future.

Catchdale Moss Farm

The Rainford family has been rooted at Catchdale Moss Farm since 1858. As a fifth-generation farmer, Richard’s journey into the Christmas tree business began in the 1970s, when he started selling a small number of Christmas trees from the then farm shop. His passion and expertise soon led him to establish his own Christmas tree enterprise, focusing on cultivating high-quality trees. Some of the trees at Catchdale Moss Farm reach impressive heights of up to 20 feet, making them ideal for large displays in town centres during the festive season. Richard’s commitment to quality and variety has made the farm a beloved destination for those seeking the perfect Christmas tree.

Catchdale Moss Farm has become a cherished part of the local community, especially around Christmas. Spanning 120 acres, the farm’s land is diversifi ed to support sustainability and offer a variety of produce. Richard has balanced his operations by dedicating 25% of the land to

Christmas trees, 25% to carrots, 10% to pumpkins, with the remainder used for cereals and Sustainable Farming Incentive (SFI) Stewardship practices.

With an impressive 60,000 trees growing at any given time, the farm is a hive of festive activity throughout the year. Richard cultivates a range of popular Christmas tree varieties, including Norway Spruce, Blue Spruce, Serbian Spruce, Nordmann Fir, Balsam Fir, Noble Fir, and Fraser Fir. Around 5,000 trees are harvested annually, with each 6-foot tree taking about ten years to mature. New trees are planted annually to ensure a steady supply, while commercial trees up to 20 feet tall require much longer to grow and are harvested later in their lifecycle. This careful planning and dedication have made Catchdale Moss Farm synonymous with Christmas. When asked which species of tree is his favourite, Richard says, “Norway spruce, as it is the traditional Christmas tree.”

Growing Christmas trees requires meticulous care at every stage. The team ensures the best environment for the trees to thrive by carefully managing site selection, weed control, and proper spacing. “There is a lot of manual work involved in growing Christmas trees,” Richard explains. “We undertake a process called ‘bud rubbing’ twice a year, which involves removing the central bud from each ‘frond’ of the crown layer of foliage at the top of the tree. It promotes good shape, which is important for the classic Christmas tree look.”

The trees also require cambium pruning, where a series of cuts are made into the trees cambium, to reduce nutrient flow to the leader, thus reducing height, but promoting side branches. Additionally, Richard and his team must check all trees for pests and disease six to seven times per season. These are all crucial actions in cultivating healthy, vibrant trees. After about ten years of dedicated care, the trees are ready to be harvested. Families can visit Catchdale Moss Farm from the end of September each year and choose their perfect Christmas tree. Richard and his team then harvest the trees, as required by their customers, for the festive period.

“I OPTED FOR A MASSEY FERGUSON THIS TIME AS THEY OFFERED A BETTER PRODUCT THAT SUITED OUR NEEDS. I MUST SAY I’VE HAD A VERY GOOD EXPERIENCE.”

To support Richard during this busy season, he has invested in a Massey Ferguson 6S.145. A new customer of Clarke & Pulman, Richard and his team traditionally ran Case machines. “I opted for a Massey Ferguson this time as they offered a better product that suited our needs. I must say I’ve had a very good experience; the 6S is an excellent, all-round, multi-purpose tractor. It’s better built and more farmer-friendly than my previous machines,” Richard tells us. The 6S handles a wide range of tasks on the farm, from fi eldwork and transportation to loading and yard duties, making it an essential tool for managing the farm’s workload. “We often use the 6S with our Hardi Zenit Mist Blower, as we do a lot of spraying for aphids and of foliar feeds.” Known for its power, traction, and versatility, the 6S.145 is perfectly suited to the diverse needs of the farm.

In 2016, Richard expanded the farm’s capabilities by building a dedicated barn for festive activities. The barn is home to a café, bar, and numerous stalls offering beautiful decorations, handmade wreaths, and garlands. This has become a crucial part of the farm’s preparations for the Christmas season, ensuring that every detail is perfect for the festive rush. In 2023, the family introduced ‘Picnic in the Trees’, a magical experience where visitors follow a tree-lined trail to find a table marked by a candy cane tapering high over a tree. The farm provides picnic boxes from their onsite café. The farm offers a variety of Christmas activities such as fresh wreath-making workshops, festive farm tots story time, and more to be announced!

“It offers the biggest horsepower in a smaller frame, which is perfect for our farm,” Richard explains. With five 6S models on the market, ranging from the 6S.135 to the 6S.180, the 6S is small but extremely mighty. The 6S offers low overall weight, compact dimensions, and increased manoeuvrability, yet matches the pulling, pushing, and lifting power of a six-cylinder tractor.

A wheelbase of 2.67m, along with a power-to-weight ratio of 45% front and 55% rear, delivers traction and stability without compromising manoeuvrability. Weighing 400kg less than its six-cylinder counterpart, the 6S offers a higher transport payload and minimal land impact, protecting the soil and ensuring minimal ground pressure.

Although Christmas is a crucial season for Catchdale Moss Farm, it’s not the only time they celebrate. Halloween is also a significant event, marked by murder mystery evenings, pumpkin picking, and even pumpkin floral arranging, adding to the farm’s busy calendar. As the festive season approaches, Catchdale Moss Farm is once again gearing up for another busy and magical Christmas. The farm is not just a place to buy a tree—it offers fantastic experiences for the whole family. Find your perfect Christmas tree at Catchdale Moss Farm, Catchdale Moss Lane, St Helens, WA10 5QG.

Browse and book events online at Rainfords.co.uk

Keep up to date by following Rainford’s on social media @rainfordschristmastrees

Meet the individuals who bring passion and precision to every client interaction, and discover what makes them the ultimate team for your business needs.

Tom Clarke began his journey with Clarke and Pulman in 2013, after studying at Harper Adams University. His career started in sales, where his passion for agricultural machinery and dedication to customer service grew. By 2017, Tom had advanced to Sales Director, a role in which he now oversees the entire sales team, ensuring smooth operations and supporting their continued growth. Outside of work, Tom enjoys spending time with his wife Sara, and their children George and Grace.

James spent nearly 25 years at Huntapac Produce, where he took on a variety of roles, including factory and farm work, truck driving, Transport Manager, Procurement, Harvesting Manager, and Assistant General Manager. In September 2007, he joined Clarke and Pulman as an Area Sales Manager, quickly rising through the ranks to oversee all partnering brands. Currently, James serves as the Massey Ferguson Brand Manager and Burscough Depot Manager. He is also responsible for underwriting all used equipment and managing the fleet business.

Richard has always had close ties to the farming community, starting his sales career with C&P in 2013. Over the past decade, Richard has held various roles, including Area Sales Manager for East Lancashire, Preston, the Fylde Coast, and South Cumbria. He became the Fendt Brand Manager in 2021 and now also serves as the Garstang Depot Manager, where he oversees daily operations and ensures the depot’s maintenance.

Mary brings a wealth of experience across all departments at C&P, having joined us in 2018 as a Parts Manager. She later transitioned to Service Manager and now excels as one of our sales reps, where she covers Fylde, Ribble Valley north of the A59, and the Lancaster/Lune Valley areas. Mary’s strong farming background comes from her family’s agricultural contracting business, where she’s been hands-on in the field since the age of 12, driving tractors and handling grass work in her spare time.

Tom’s passion for farming started early, leading him to study mechanisation at Myerscough College before working as a contractor on various farms. He joined the team six years ago with no prior sales experience and now covers the West Lancashire area. In his free time, Tom enjoys going on outings with his wife and their two children, or enjoying a pint in his local.

Gary’s connection to farming runs deep, after growing up on a family farm in Billinge. With over 20 years of hands-on experience working on his family’s mixed farm, Gary transitioned to contracting for a large arable farm in Cheshire. Although new to sales when he joined our team in 2019, Gary’s rich farming background and practical knowledge aided his transition into the role. Outside of work, Gary loves spending quality time with his two sons, Jake and Ryan.

Martin’s passion for farming started early, growing up and working on his family’s arable farm, and has been immersed in the industry since leaving school. Martin joined C&P in 2016 as a sales representative, bringing with him a wealth of experience. After a brief 18-month stint as the Service Manager in Burscough, he returned to his sales role. Outside of work, Martin loves spending time with his wife, two children, and their menagerie of animals.

Richard brings a wealth of experience to the agricultural industry, rooted in his upbringing and ongoing work on his family’s dairy farm on the Fylde Coast. Richard worked at BAE Systems, before becoming a machinery journalist with Farmers Guardian and Profi. In his current role at C&P as Demonstrations and Sales Support, he handles tractor and machinery demos, as well as installations of new equipment. Leveraging his strong journalistic background, Richard also contributes to our marketing efforts, including Tracks and social media.

Jade joined C&P in July 2021, starting in the Service Department and quickly gaining valuable industry experience. As a Sales Administrator, Jade takes care of key responsibilities, including creating whole goods, allocating registration plates, managing pre-delivery inspections, and processing road and warranty registrations. She also handles paperwork, answers calls, checks invoices, and is regularly doing the brew run (especially when Tom Clarke is around). Outside of work, Jade enjoys riding her horse, walking her dog, or unwinding at the pub.

Amy began her career as an HGV mechanic before joining us as our Precision Farming Technician. In this role, she manages customer calls, handles troubleshooting, performs on-site repairs, provides training and is also responsible for software upgrades on machinery. With three and a half years of experience in the farming industry and a year at C&P, Amy combines her skills and passion for agriculture. When she’s not at work, Amy can be found renovating her house, or exploring the lakes with a pint.

At Clarke and Pulman, we recently had the pleasure of sitting down with Joel Baldwin of SED Services to discuss his experience with JCB machinery. Joel shared insights into how JCB have been essential in their day-to-day operations across their various sites, which include Landgate Farm, Bryn Hall Composting Facility, Kirby, and Hightown.

SED Services Ltd is dedicated to advancing recycling and sustainability, with their core business strategy centred around green waste, soil, and aggregate recycling. Their commitment to recovering potentially valuable resources reflects a broader societal need for closed-loop recycling solutions, aiming to provide a second life to materials and reduce waste.

A key aspect of SED’s operations is their innovative approach to managing non-compliant biosolids for waste water companies. By diverting 75,000 tonnes of biosolids per year from landfills and restoration, SED Services demonstrates their dedication to environmental responsibility. Their BAS accredited recycling centre in Formby plays a crucial role in transforming these biosolids into organic, nutrient-rich fertilisers, showcasing their commitment to extending the life cycle of the world’s resources.

SED Services Ltd continues to lead in developing new and effective recycling solutions, reinforcing its role as a forward-thinking player in the waste management industry.

From waste recycling to producing specialist sands, SED Services have always prioritised sustainability, providing cost-effective solutions for non-hazardous waste management. Joel explains how crucial machinery has been in maintaining these high standards.

“We’ve chosen JCB for several reasons,” Joel begins. “They’re a British brand, which is something we value, and the machinery is top quality. We’ve been using JCB for over five years, and each year we add a new machine to the fleet.”

When asked why JCB has been their preferred choice, Joel explained the clear advantages. JCB offers a range of machines tailored for different tasks, which are perfect for SED’s varied operations. For instance, their JCB 56080 telehandler is the backbone of the fleet. It’s powered by a 150 HP EcoMAX diesel engine and can lift up to 6,000 kg, making it ideal for handling heavy materials like compost, soil, and sand. The 8-metre lift height is a real asset, allowing the team to move bulk loads efficiently, which significantly improves operation times.

For more compact or confined workspaces, the JCB 542-70 telehandler has been key as the machines are incredibly versatile. “We use them in everything from loading pallets, loading compost, and mucking out. They’re robust, easy to operate, and handle challenging conditions effortlessly.”Joel tells us.

“THE LEVEL OF SUPPORT IS CRUCIAL IN KEEPING EVERYTHING RUNNING AT FULL CAPACITY AND IS ONE OF THE MAIN REASONS WE STAY LOYAL TO CLARKE AND PULMAN.”

SED also runs four JCB 542-70 models in the Agri Pro machine, offering 173hp, 160 litres per minute hydraulic flow, and a 50 kph road speed. This machine is primarily used for farm applications, such as loading grain and towing seed and fertiliser on the road. “They’re crucial when we’re moving the highest volumes.” Joel adds.

We were pleased to hear Joel’s feedback on the relationship between SED Services and Clarke and Pulman. “Tom Clarke has always been fantastic to work with,” he says. “The sales process has been smooth, and Tom really understands the specific needs of our business.”

“Of course, the After Sales experience is equally important, especially when dealing with heavy machinery. We were glad to hear that Jasmine and the After Sales team at Clarke and Pulman have been able to deliver timely support whenever it’s needed.” Joel adds. “Whenever we have a breakdown or need assistance, the team responds quickly. The level of support is crucial in keeping everything running at full capacity and is one of the main reasons we stay loyal to Clarke and Pulman.”

As we wrapped up our conversation, we asked Joel why SED Services has remained so loyal to the JCB brand. His answer was simple - reliability. “JCBs are just built to last. When you’re in an industry like ours, where downtime can cost you significantly, having reliable machinery is everything. JCB has consistently delivered on that.” Joel explains.

In reflecting on our conversation with Joel Baldwin from SED Services, it’s clear that JCB machinery has become an integral part of their operations. From their commitment to sustainability at Landgate Farm, Bryn Hall Composting Facility, Kirby, and Hightown,, to the reliable performance of JCB telehandlers, Joel’s feedback underscores the impact of quality equipment on their success.

HONDA TRX 520 FA6 ATV

KVERNELAND TL1875 3,225L GEOSPREAD FERTILISER SPREADER

KVERNELAND SILOKING COMPACT 15M3 FEEDER

KVERNELAND TL1875 3,900L GEOSPREAD FERTILISER SPREADER

KVERNELAND SILOKING COMPACT 15M3 FEEDER

EX-DEMO MASSEY FERGUSON 8S.265 DYNA VT

EX-DEMO MASSEY FERGUSON 5711M C/W LOADER

MASSEY FERGUSON COMPACT 1520 TURF

MASSEY FERGUSON 4710M – LOADER READY

MASSEY FERGUSON 5S.115 ESSENTIAL

MASSEY FERGUSON 8S.265 DYNA VT

MASSEY FERGUSON 5S.145 ESSENTIAL – LOADER READY

MASSEY FERGUSON 5711M C/W FRONT LINKAGE

EX-DEMO MASSEY FERGUSON 5S.135 ESSENTIAL C/W LOADER READY EX-

DEMO FENDT FREE FLOW 6M COMBINE HEADER FENDT TWISTER 7706 TEDDER FENDT 724 GEN6 PROFI PLUS SETTING 2

Powerful yet easy to control, Fendt’s Rogator 600 offers optimum crop protection and efficiency. The combination of the height adjustable chassis, weight distribution and precise spraying settings minimises crop damage. Its low maintenance design makes for an easy and effortless operating experience whilst it boasts the lowest total cost of ownership with maximum return due to its low fuel consumption, intelligent systems and reduced crop damage.

The triple activated charcoal filters and air-conditioning system makes for a very comfortable in-cab operator experience. This system meets the category 4 cab air filter requirements of EN 15695.

The AGCO Vision Cab is the largest and most spacious cab on the market with a 6.4m2 curved glass windscreen providing an excellent view for the operator and allowing maximum leg room. The primary spraying functions and controls are situated on the joystick and armrest and allows the operator intuitive control thanks to the layout of the elements, with the use of separate symbols for operating spraying functions.

The Rogator Management Center (RMC) is displayed on the VarioTerminal 10.4” in-cab screen which has both day and night settings and displays information in 4 onscreen quadrants to allow the operator maximum control with the full overview on one screen.

Height control sensors mean that the nozzles are always at the optimal height from the crop, with four or six sensors, this allows for the boom height to adjust automatically when spraying on uneven terrain. Adjustments can also be made from the cab allowing for precise boom control.

The Rogator’s high stability, single carrier chassis keeps the centre of gravity low by putting the engine in between the axels whilst the 50:50 weight distribution means increased soil protection, spreading the weight evenly over the machine. The chrome-plated ax is protected from corrosion and is self-cleaning. The position of the engine also helps to reduce noise levels in the cab.

A 35 degree steering angle enables the Rogator an inner turning radius of 3.14m which allows the machine to easily manoeuvre without causing unnecessary damage to the crop.

Rogator 645

Rogator 655

Rogator 665

/ 235

/ 272

/ 226

“ THE FENDT ROGATOR IS DESIGNED WITH PRACTICALITY, EFFICIENCY AND LOW MAINTENANCE IN MIND, BUILT TO WORK

Adjustable ground clearance of up to 120cm and up to 2.05m high tyres also help to move through the crop and any uneven ground causing less damage to plants.

Track width is adjusted via the in-cab terminal to suit different tram-lines and row widths and front/rear widths can be set independently allowing a wider contact area to help reduce compaction.

The easy access around the machine makes for straightforward maintenance, and the external storage compartments for tools, safety equipment and chemicals keeps everything safe and tidy.

The large spray tank is not only high capacity but is also wide and flat aiding the stability of the machine in transit by maintaining the centre of gravity, its automatic tank cleaning and Fendt ContiRinse feature means that you can be confident that you are preventing contamination or damage.

Engine

AGCO’s own 6 cylinder engine with 7.4 litre cubic capacity means low fuel consumption due to the HydroStar CVT drive train with efficient and automatic engine cooling.

The lower engine temperature is aided with the use of AdBlue and a hydraulic fan whereby the speed is controlled by a combination of oil temperature, air intake and coolant temperatures resulting in lower fuel consumption and noise levels.

The Rogator is also fitted with load detection to reduce fuel consumption and fitted with fixed hydraulic lines instead of hydraulic hoses to prevent leaks.

Everything about the Fendt Rogator is designed with practicality, efficiency and low maintenance in mind, built to work for your business.

If you would like to find out more about the Fendt Rogator 600, please contact our Sales Support Hub on 01995 640302 or email saleshub@clarkeandpulman.com

LOCAL TYRE REPAIR, NEW & HIGH-PERFORMANCE TYRES FOR CAR, VAN, AGRICULTURAL & COMMERCIAL VEHICLES.

Number Plates from £8.50 +VAT

STOCKIST

· New Tyres

· Free Tyre Check

· Wheel Balancing

· Lifetime Tyre Guarantee (T&Cs apply)*

New High-Performance Tyres from all major brands, including Maxxis, Nexen Tyre, Pirelli, Michelin, Bridgestone, Goodyear, and BF Goodrich

OPENING TIMES

Monday to Friday: 8am – 5pm Saturday: 8am – 12pm Sunday: Closed