SPECIFICATION Magazine

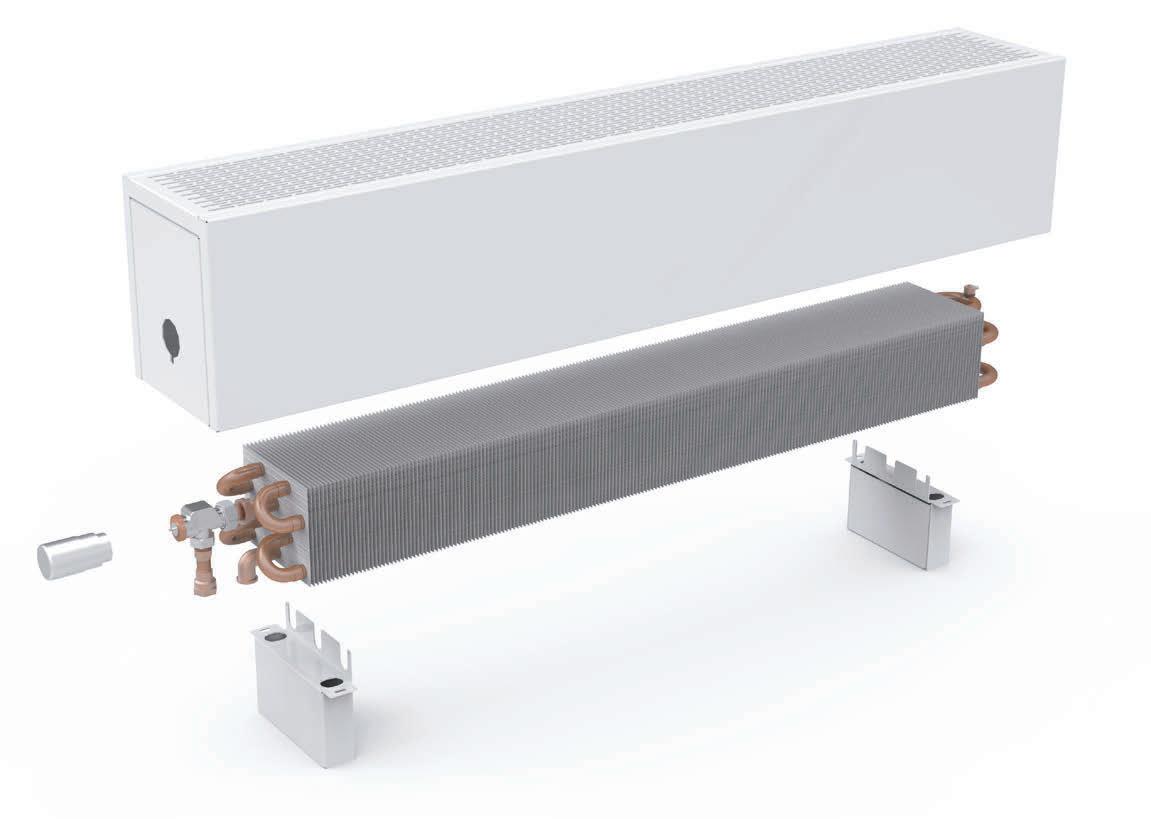

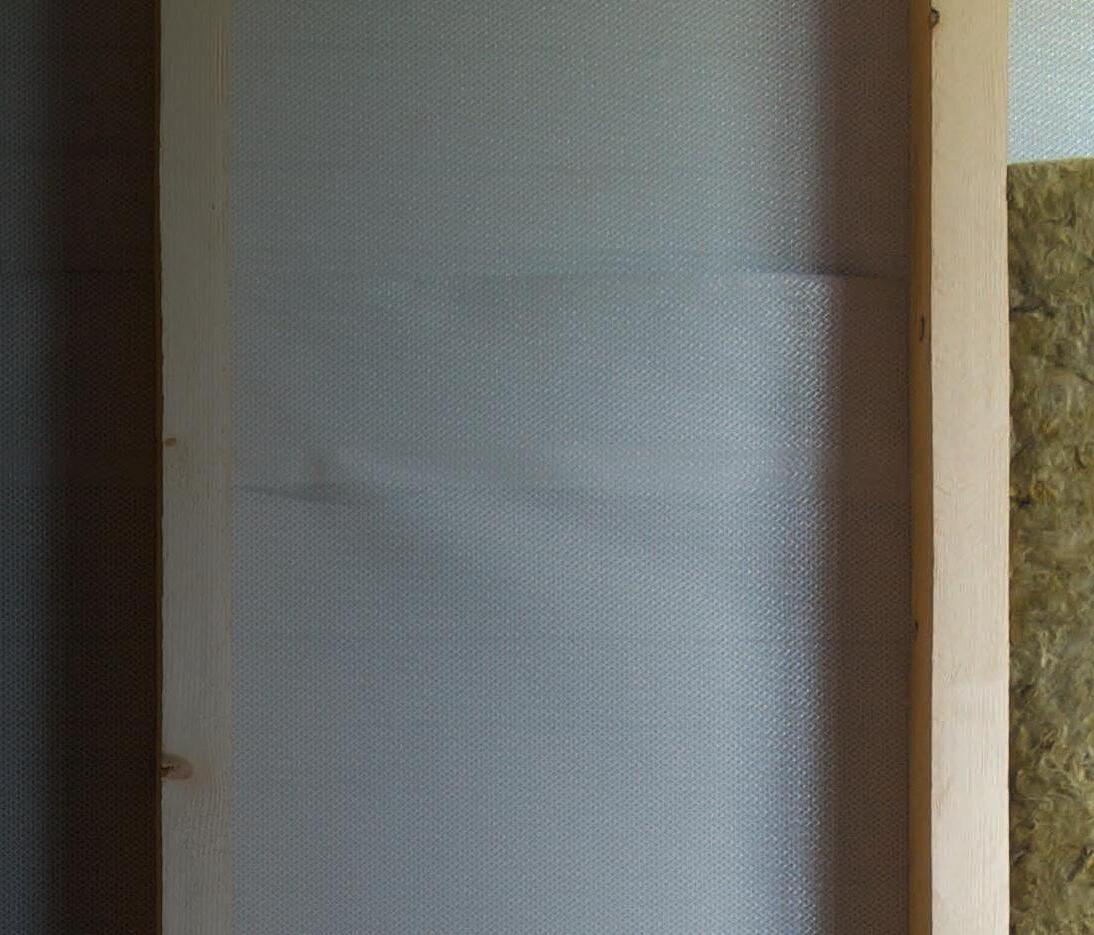

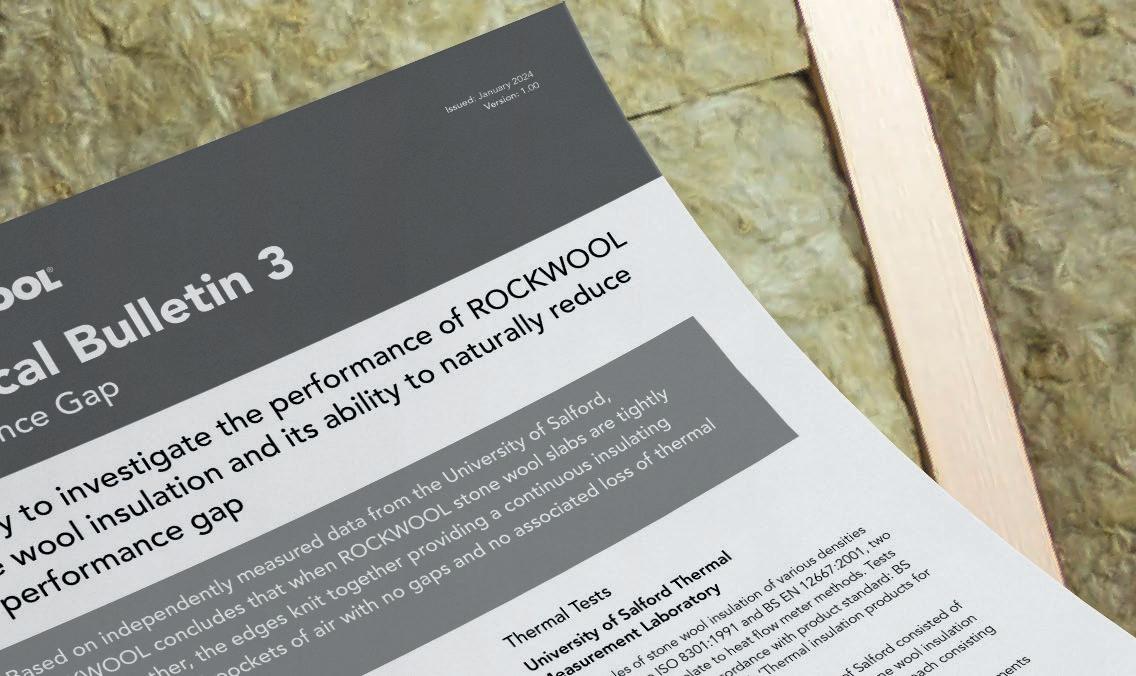

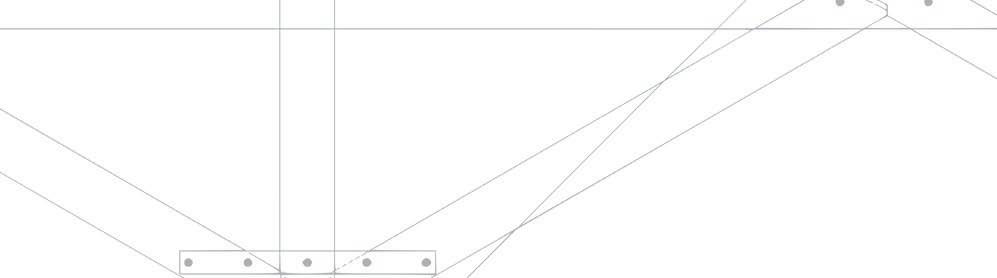

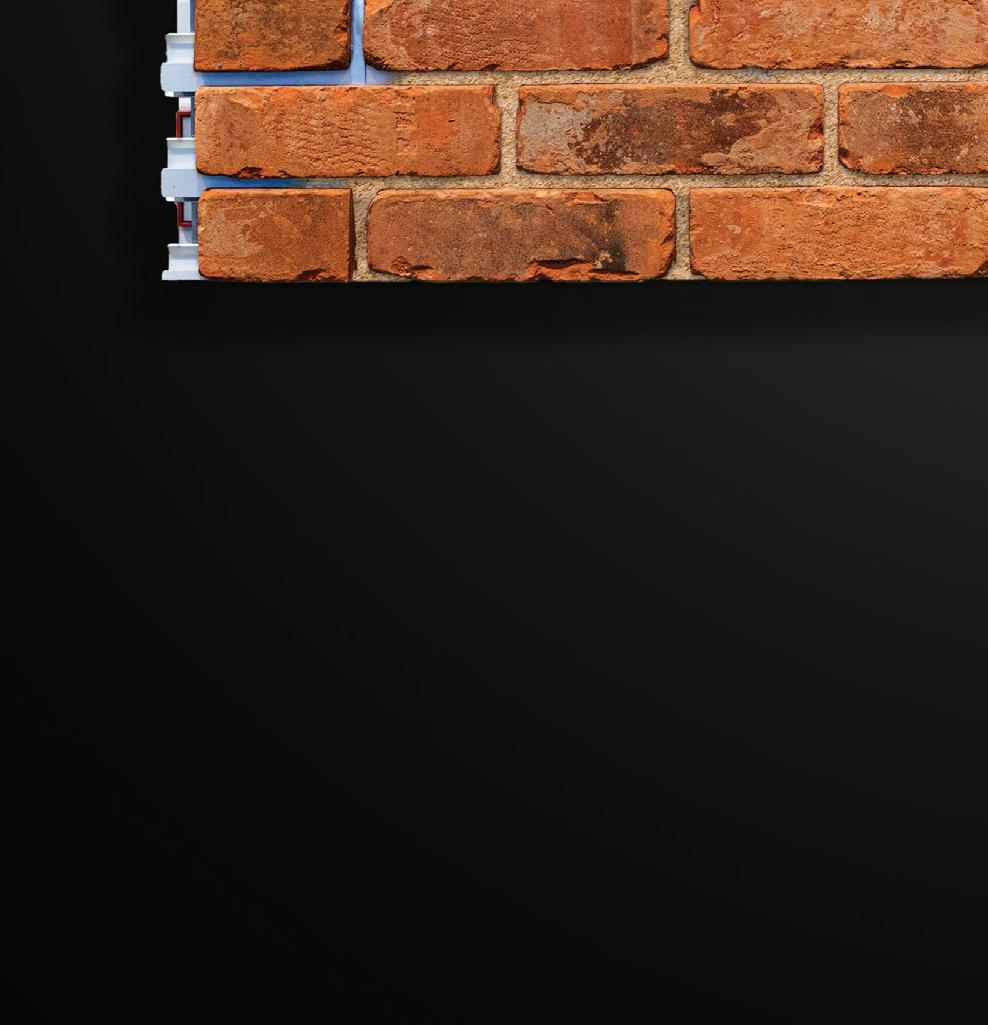

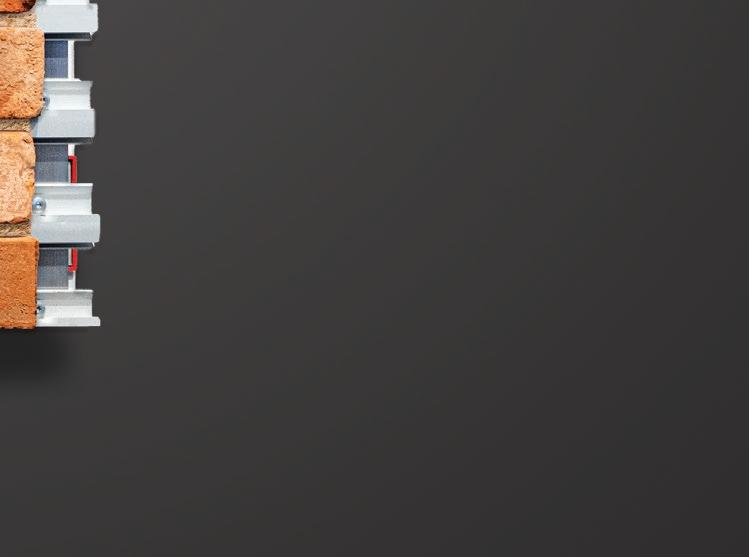

Achieve specified thermal performance with stone wool insulation that helps to close the thermal performance gap – supported by independent testing.

The new ROCKWOOL Technical Bulletin details:

•The results of independent thermal testing

•How ROCKWOOL stone wool insulation knits together to form a continuous insulating layer

•How ROCKWOOL products can contribute to improved thermal performance

The Construction Products Association has forecasted construction output to fall this year, before a economic recovery signals further growth for 2026.

After a weak start to the year following heavy rainfall in the first quarter of the year, and private house building and private housing repair, maintenance and improvement (rm&i) in the midst of subdued activity after the sharp contractions in the second half of last year, output is forecast to fall by 2.2% this year before a broader economic recovery underpins growth of 2.1% in 2025 and further growth of 3.6% in 2026.

Beneath the overall figure, it is likely to be a year of mixed fortunes for construction firms, with performance highly dependent on which sectors they are operating in.

CPA Head of Construction Research Rebecca Larkin said: “Almost all sectors of construction had a bad start to the year with persistent rainfall delaying work on site, especially outdoor work.

“While we may see a degree of catch-up activity as the weather improves, smaller sites are likely to see work simply pushed back due to capacity constraints.

“Of more concern to the industry’s near-term prospects is the sharp drop-off in activity in its two largest sectors, private housing new build and private housing rm&i.

“With both sectors forecast to contract this year, the key question remains how quickly and how effectively expected cuts in interest rates can stimulate the economy and housing market as well as how quickly they can restore house builder confidence to resume activity and spark homeowners’ appetite for large improvements projects.

“The Forecasts anticipate a return to growth of 2.1% in 2025 and further growth of 3.6% in 2026 although clearly, there is greater uncertainty around activity in 2026 given the potential for a new government resulting from a General Election this year. The impact this could have on public sector spending plans and the longer-term delivery of infrastructure and public sector projects present the longer-term opportunities – and risks – for construction.”

Paul Groves || Group Editor

Paul Groves || Group Editor

The Verta range provides a versatile solution for concealing interior & exterior concrete columns, and structural steelwork, with durable and decorative column casings.

With six separate products within the range, Verta casings can be specified in a choice of materials, standard dimensions & shapes, while fully bespoke manufactured solutions are key features in the range, alongside a wide palette of decorative finishes.

This enables us to offer column casing solutions that can meet the broadest scope of specifications, installations and project needs. We also provide a dedicated professional installation service, allowing us to maintain complete control over any Verta column casing project.

Whatever your casing requirement - we’ve got it covered.

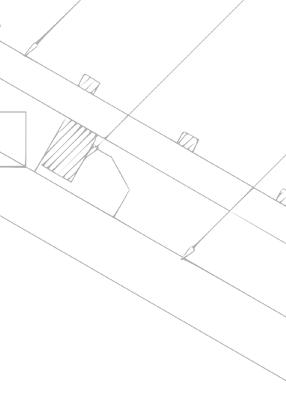

How does reaction to fire and fire resistance testing apply to building membranes?

With it’s Class A2-s1,d0 fire classification to BS EN 13501-1, Procheck A2 is considered noncombustible with no contribution to fire. It comes with a high vapour resistance, as well as being airtight, which allows its use as an AVCL in the construction.

How does reaction to fire and fire resistance testing apply to building membranes? Read more on Page 18.

Enquiry - 12

TSP Media Ltd, Grosvenor House, Central Park, Telford, TF2 9TW

T: 01952 234000 E: info@tspmedia.co.uk www.tspmedia.co.uk

Rebecca Goldsmith, Product Manager at MEDITE SMARTPLY, discusses how OSB structural panels that integrate air and vapor control can streamline the fabric-first approach for high-performance building envelopes, enabling housebuilders to achieve the airtightness and efficiency required by the new standard.

The updates to Part L and Part F of the Building Regulations are a critical step towards the long-awaited Future Homes Standard in 2025, which will see a new build home have 75% lower CO2 emissions than one built to today’s standards.1 Timber frame construction offers distinct sustainability benefits for new residential projects, with timber being a natural, renewable and low carbon material that provides versatility, flexibility, and rapid build times.

One of the key aspects of timber frame homes will be addressing the thermal performance and the design of a building’s envelope. Timber frame manufacturers that can provide high-performance, airtight envelope solutions will be well-positioned to meet these changing regulations and capitalise on the move towards low-energy construction.

To meet the evolving energy efficiency standards, there is an innovative solution to simplify the path to airtight building envelopes. The increasing demand for double sheathed timber frames in both structural applications and the development of offsite closed panels, led to innovation for producing two certified airtight OSB/3 panels.

As a solution for walls and ceilings, SMARTPLY AIRTIGHT panel can be used as the airtight layer on the warm side of the insulation in timber frame construction

systems, helping to create an airtight building envelope. Each panel features alternating layers of wood strands coated with a high quality formaldehyde-free resin and wax binder system to deliver outstanding levels of airtightness. A specialist coating is then applied to ensure vapour resistance and provide a quality assured OSB solution for super-insulated and passive buildings, and enabling the elimination of a traditional additional vapour control membrane from the construction.

By seamlessly integrating air and vapour barriers into the highly-engineered OSB panels, it streamlines the installation process and minimising the risk of air leakage that often plagues traditional timber frame structures.

For flooring and roofing, SMARTPLY SURE STEP is a tongue and groove, load bearing OSB/3 panel that provides improved durability and slip resistance in all site conditions. Similar to SMARTPLY AIRTIGHT, it can be used as an airtight layer, contributing to sustainable building practices as well as reduce the energy consumption for heating.

These cutting-edge solutions not only simplify construction but also ensure a certified, proven approach to creating airtight building envelopes that will pave the way for low-carbon, energy-efficient homes of the future.

Timber frame construction offers housebuilders a clear advantage in meeting the stringent airtightness levels and energy efficiency requirements of the Future Homes Standard. By utilising OSB that features integrated air barrier properties, timber frame manufacturers can deliver airtight, energy-efficient building envelopes needed to comply with the new regulations.

The Structural Timber Association (STA) has announced a new, free event ‘Navigating Structural Timber Construction to Address Net Zero’, taking place on the 2nd of July 2024 at RIBA’s London headquarters.

Aimed at architects and structural engineers, the event features high-profile speakers from organisations including RIBA, Waugh Thistleton, Tate + Co and dRMM Studio. The event will give delegates the chance to discover how their industry peers are transitioning to using more timber, with a focus on sharing best practice advice.

Chaired by Andrew Carpenter, the Chief Executive of the STA, the event will begin with the current positioning regarding the Government’s Timber in Construction (TiC) Policy Roadmap and what this means for the future of construction in the UK. Following this, a panel of experts will provide an overview of their experience in working with structural timber: sharing insights through relevant case studies, and how crucially, structural timber can address the challenges of attaining net zero.

The TiC Roadmap is a clear signal of the Government’s intention to use timber as a key means of achieving Net Zero by 2050. The event is designed to support architects in understanding how to use timber and signposting to the technical advice and resources the STA can provide.

The event runs from 9.00am to 12 noon (registration from 8.00am) and will be held at RIBA’s London Headquarters: 66 Portland Place, London, W1B 1AD.

Knauf Airless Finish is a highly efficient, ready-mixed direct alternative to traditional gypsum plaster for finishing walls and ceilings.

Manufactured from crushed marble, Knauf Airless is fast and easy to apply with no need for pre-mixing, eliminating the need for additional water to be added on site.

3x faster than traditional methods: 200 - 250m2 sprayed per day

Less than 1% waste and recyclable packaging

Dries white with a highquality smooth finish

Enquiry 4

The Knauf Airless Finish range is available in branches nationwide at CCF, one of the UK’s leading insulation, drywall and ceiling product distributors to the construction industry.

www.ccfltd.co.uk/content/knauf-airless

Sprayable up to 3mreducing work at height risks

No need for primers or bonding agents

Typically dries in 24 hours, dependent on humidity and temperature

Terry Wilkinson, Specialist Design & Application Engineer at ACO Technologies, discusses some of the key issues those in the industry need to be aware of when it comes BNG.

Biodiversity net gain is mandatory for most new developments in England, having come into effect for larger sites in February 2024, for smaller sites in April, and is expected to apply to Nationally Significant Infrastructure Projects from November 2025.

This has a wide-ranging impact on the construction industry. For sites that fall under the BNG rules, biodiversity and habitats will need to be taken into consideration very early in the planning stages. These include site selection, design, construction, and ongoing maintenance once the site is complete.

One essential process to ensure compliance and success with BNG is to involve ecologists from the very beginning. Architects, site planners, engineers, and specifiers must design schemes and projects with nature and habitats at the forefront of their minds and, to do this, will need comprehensive specialist ecological input. The earlier collaboration begins the better, as professionals responsible for various aspects of a building project can be sure that their plans are in line with BNG requirements at every stage.

Habitats will need to be created or enhanced as part of a project, so ecologists will play a

fundamental role in guiding architects on how this can be achieved. Better collaboration from the very beginning also means complications arising from site development can be mitigated from the outset. These include designing habitats to account for underground services (such as gas, water, electric, communications services, etc.), geographic and geological challenges, above ground infrastructure, roads, and street furniture. Not to mention, wildlife and habitats will need to be considered in conjunction with people using and interacting with these green spaces as well.

Besides engaging with ecologists, developers will need to think about BNG when looking

at – and selecting – new development sites. Brownfield and greenfield sites will have different BNG requirements and careful thought and evaluation will need to be undertaken to determine if BNG is feasible for a specific site.

If BNG is not possible directly on the site, then the implications of offsite BNG or purchase of statutory credits will need to be considered. Importantly, a BNG plan must demonstrate that habitats both onsite and offsite are secured, monitored, and managed for at least 30 years, and in some circumstances, maintenance may need to be “in perpetuity”. The plan must be approved by the planning authority before works can start on site, so this must be factored in when it comes to project timelines and plans.

Sustainable Drainage Systems (SuDS) and Nature-based Solutions (NbS) can significantly help towards meeting the requirements of BNG as part of a holistic site wide design.

SuDS design specifically rests on the four pillars of water quantity, water quality, amenity and biodiversity as defined in the CIRIA SuDS manual. Hence, good SuDS designs can directly benefit habitats by effectively managing surface water at source and utilising it on site.

To quote Chapter Six of the SuDS manual: “Habitats within any new SuDS scheme should link with other local and or regional habitats to help build and enhance habitat connectivity. This will help mitigate the problems associated with habitat loss and fragmentation within urban areas. SuDS schemes should aim to have a range of habitat types, as this will encourage biodiversity and result in self-sustaining and resilient ecosystems.”

The Pendock Radius range provides architects and specifiers with the perfect solution for concealing interior or exterior columns & structural steelwork with decorative, durable and practical column casings.

Incorporating both standard and bespoke shapes in a range of materials, finishes & sizes, Radius offers unrivalled versatility and choice. They can also be installed by our experienced teams to ensure the perfect fit and finish are achieved.

*Dependent on material The Radius range includes:

Material: Ply/MDF; aluminium; stainless steel; GRP and GRG

Shape: Circular; square; rectangle; ellipse; triangle; polygon and bespoke

Finish*: Site-finish; HPL; PPC; brushed; polished, textured; patterned and Gelcoat

Pendock Radius is part of our extensive casings, enclosures and decorative architectural products range, which combines aesthetics with practicality and design flexibility.

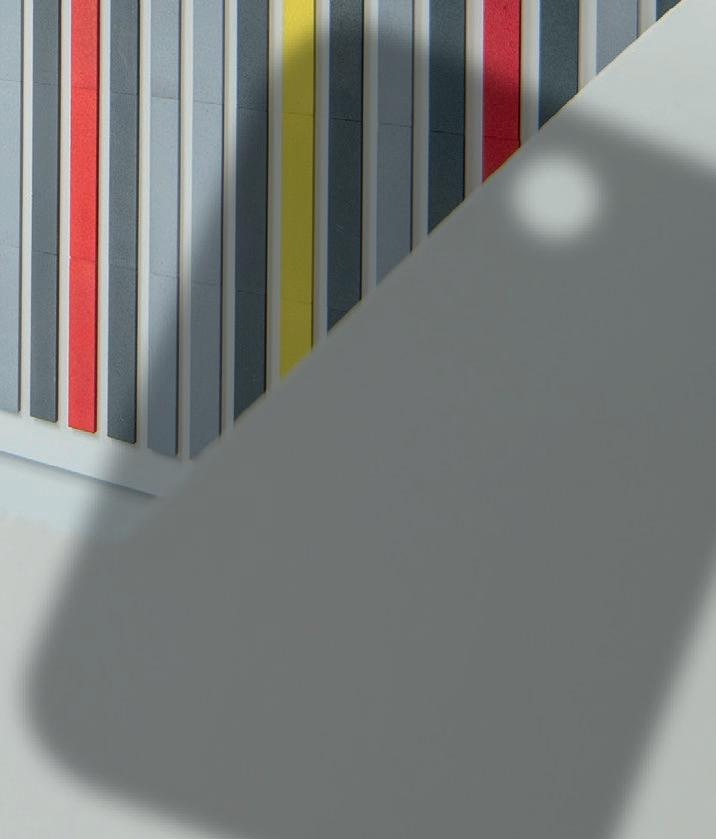

We speak to Britt Smid and Rianne Dijkslag, Designer and Product Manager for Vinyl at Forbo Flooring Systems, to get their insight into the process of a new product launch

Launching a new collection or adding new solutions to an existing range is a big decision for any manufacturer, with new trends emerging all the time and functional requirements changing regularly. To ensure those making the decisions are as well informed as possible, there are a range of factors to be considered.

What considerations do you make?

We always start with what we already have, using pre-existing designs or colourways for inspiration. We then go to the market and ask for feedback, to understand what our customers need and if there is anything they feel are missing. For example, with the most recent refresh to our Step safety vinyl flooring collection, we worked closely with our sales team and reached out to their customers via a roundtable event. We took this opportunity to research what the market is looking for in a modern safety

flooring solution, as well as pitching a series of concept designs that we’d created from previous colourways and our internal colourcards. These colour-cards are shared by all design teams company-wide, allowing us to coordinate our designs across all of our different flooring solutions, to fit together seamlessly across a building.

In addition to this, with sustainability a core pillar at Forbo, with every new range we launch we try to level up its sustainability credentials. This was no different with our Step collection, being manufactured using 100% renewable electricity and actually having the lowest embodied carbon (cradle to gate) of any safety vinyl on the market, with an average of 24% recycled material content.

What type of information do you look at?

For new products, there is a lot of different information that needs to be reviewed. Whether that be trend reports, industry feedback or the gaps within a competitor’s offering. Members of our design team also hit the road and attend various industry

events, where they pick up a lot of colour trend information. This in turn helps to inform the types of tones and shades that the industry is looking for, allowing us to begin forming an idea of the collection as a whole. It was from such events that we identified the popularity of warmer, wooden tones, which led to us incorporating a series of new stunning wood designs into our refreshed Step collection.

Another important consideration is, of course, where the floor coverings are going to be installed. You can’t design a product collection without understanding its application and the demands of that space.

For the Step refresh, this was care homes, bathrooms, leisure facilities, hospitals and so on. By exploring the applications, you can get a better idea of the types of designs each sector typically needs and further streamline a collection.

How do industry demands inform your decision making?

What your customer has to say on a product is incredibly important – at the end of the day, they’re the ones who will be purchasing and specifying it.

In the case of the Step refresh, we received a very clear brief from our UK team to create a collection that was suitable for use across care homes, leading to the creation of a brand-new range – Surestep Balance – as well as to add more colourways that could fit in within a wider flooring scheme. As well as this, feedback from our customers made it clear they wished to be able to use the same colourways across multiple different application areas.

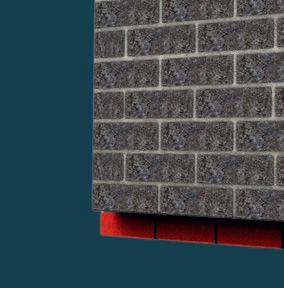

A contemporary addition to our concrete paving portfolio.

Developed with UK designers, our unique granite-inspired blends are brought to life through a patented colour application - creating a multihued, subtle and elegant aesthetic.

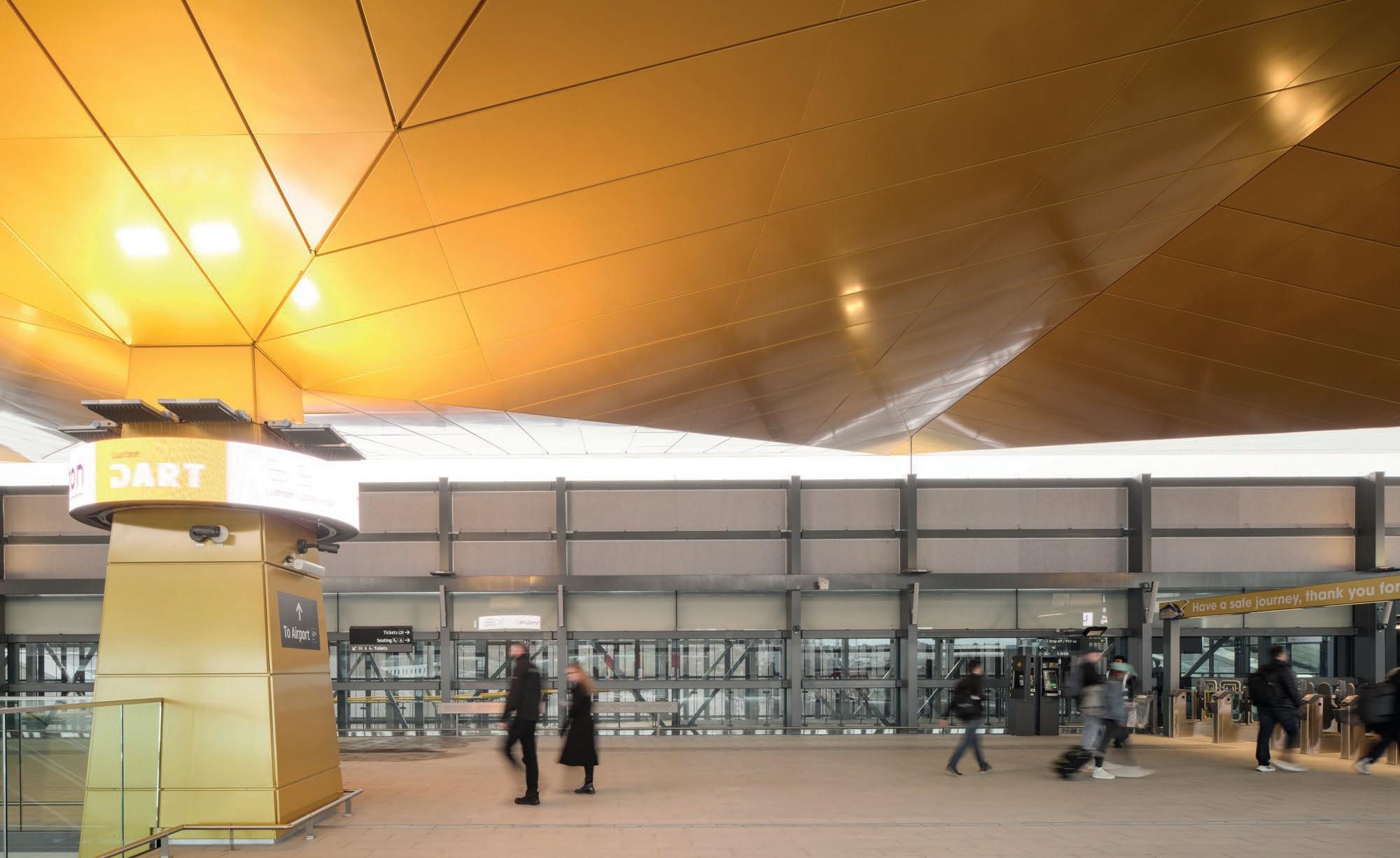

Project: Luton DART (Direct Air-Rail Transit)

Architects: Arup

Suppliers: Pilkington; Sika; AkzoNobel; British Gypsum; Delta Balustrades; F. P. McCann; Marshalls; Prater Ltd; Promat; SAS; Bilco

The Luton DART (Direct Air-Rail Transit) is a pioneering fully-automated people mover, designed to transport travellers from the Luton Airport Parkway railway station to the terminal of London Luton Airport in well under four minutes.

The new airport transfer facilitates faster journeys from over 60 locations across the rail network, and passengers travelling from London St Pancras to the London Luton Airport terminal can now do so in as little as 32 minutes, making this one of the shortest airport connections to and from central London.

Providing travellers with a speedier, greener, and more efficient journey to the UK’s fifth busiest airport, the Luton DART will help radically reduce the proportion of passenger and employee trips to the airport by car, and support delivery of the airport’s sustainability targets.

Luton DART also marks a significant investment in the town’s civil infrastructure by Luton Borough Council’s airport company Luton Rising. Arup has played a key role working alongside Luton Rising on this landmark infrastructure project from the outset, assembling a large team of architects, engineers, and specialists

to help meet the client’s aspiration for a world class airport experience. This role has covered all aspects of the planning, costing, procurement, and design, including station architecture, operating systems and operational readiness.

The DART is one of the largest infrastructure projects ever undertaken in the area and represents an ambition from Luton Rising, a business and social enterprise, to deliver positive social impact and economic growth to the local community. As the airport

grows and generates a return, there is a direct benefit to the people of Luton.

It forms part of a wider development of housing, hotel and other facilities that are being built around Bartlett Square fostering community and employment.

Operating 24 hours a day, DART will help boost the rail modal share for passengers accessing the airport and support Luton's vision for a carbon-neutral town by 2040.

The electric-powered system will lessen the environmental impact of journeys both to and from the airport and reduce congestion on surrounding roads.

It will also provide rail passengers with a much-improved experience by offering a seamless journey covering the Thameslink and East Midlands Railway network. Arup has optimised the DART’s timetable to ensure a high frequency of service during the busy passenger peaks, with a reduced running pattern during quieter periods to save energy.

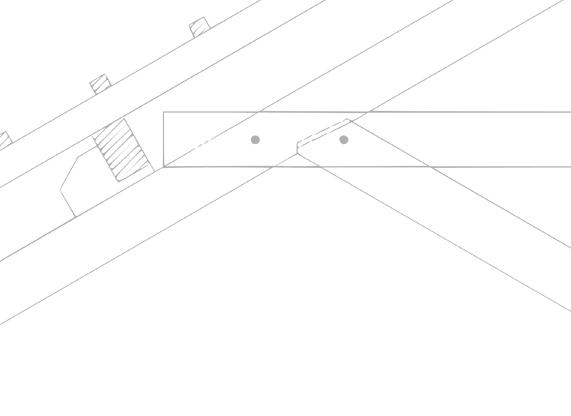

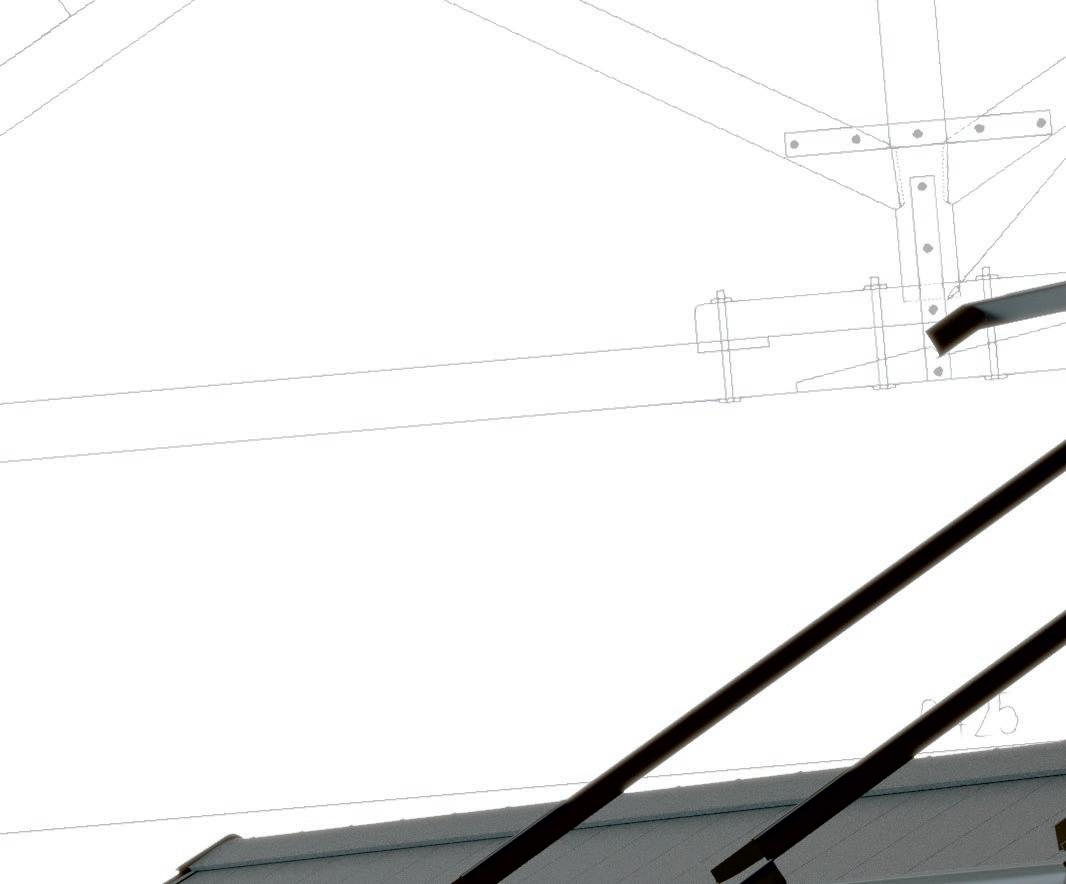

The scheme comprises two stations, a viaduct, a signature bridge and a ‘cut-andcover’ tunnel beneath a live taxiway. Arup’s ambition was to create a sense of place for passengers, with intuitive and easy-tonavigate spaces. DART Parkway and Central Terminal stations are characterised by a simple, functional, and pared-back style that delivers a consistent, high quality and unified architectural experience for the passenger from start to finish of their journey.

It begins at the concourse level of Luton Airport DART Parkway Station and ends with the seamless transfer of passengers at the Central Terminal Station. The accessible design includes new lifts, escalators, tactile paving, audio frequency induction loops and several help points installed across the stations.

The two stations have created a new identity for Luton Airport with their signature parasols that are repeated across the wider development. Each parasol is held by a single centrally loaded column and cantilevers across approximately 20m in width. The parasols protect passengers from the weather whilst allowing for spacious, open, and naturally lit concourses.

This task required the collaborative engagement of Arup’s architects, engineers, and experts across disciplines to formulate a design that formed a synthetic whole.

Arup’s concept design considered the likely changes to the airport’s requirements through the long life of the structural assets and made accommodation for a variety of systems to be installed in future, including airport expansion, operating more trains and additional passenger facilities.

Additional carriages can be added to the DART as passenger numbers increase, with platforms designed to accommodate longer trains and minimise the need for costly changes and disruptive construction in the

future. Both DART Parkway and Central Stations are naturally ventilated throughout the concourse and platform areas, lowering the operational carbon footprint of the stations against a mechanical approach.

The transport system is powered by an efficient electric drive system which incorporates energy recovery during braking.

The energy can be consumed in the vehicle (HVAC) and elsewhere in the station facilities, reducing the total energy consumption of the whole system.

Arup’s design of the stations, with their highly reflective parasol cladding, maximises direct and indirect daylighting, and aims to improve passenger and staff wellbeing.

At DART Parkway Station, the glazing to the façade has been designed to minimise solar gain whilst maintaining excellent levels of light transmittance.

● Elegant partitioning with maximum transparency

● Single- and double-leaf doors and fixed glazing up to 5000 × 4000 mm

● Carbon neutral as standard for all residential construction products, including steel loft doors and residential internal doors

Aico has had a longstanding relationship with Southend-on-Sea City Council for many years, supporting the installation of their fire and carbon monoxide (CO) alarm systems.

Southend has pledged to reach net zero emissions by 2030 and is now launching a proactive retrofit program for its 6,000 homes, which currently constitute 46% of the organisation's carbon footprint.

Supported by Ben Harrsion, finalist for Aico’s Rising Star award in their 2024 Community Awards, the programme is currently implementing a wide range of projects from internal training and data improvement, to insulation projects including Social Housing Decarbonisation Fund (SHDF) wave 2.1.

The standout initiative within this programme is the retrofit show home which opened in November 2023. By partnering with several council departments and obtaining support from the DEFRA-funded ‘Catchment to Coast’ project, the housing team led a comprehensive retrofit of a solid wall 1950s semi-detached home which included:

• External wall and loft insulation

• Triple glazing

• De-centralised mechanical heat recovery ventilation

• Air source heat pump and electrical appliances

• Solar panels with a 6kW battery

• Grey water recycling Hydraloop that recycles shower water for toilet flushing

• Sustainable drainage and Hydrorocks to reduce risk of flooding

• Low maintenance bio-diverse and

drought tolerant garden planting

• Aico’s 3000 Series fire and carbon monoxide alarms and HomeLINK Environmental Sensors

The project stands out for its holistic approach to sustainability, which included using recycled materials, local products, and future-proofing the home from overheating and drought risks in the home.

Hosting 250 visitors, the show home served as an educational resource for the entire community and enabled the council to showcase exemplary practices. The test-andlearn approach to the show home also allows the project to inform which measures to roll out to the wider programme.

All retrofitting carried out in the show home adhered to PAS 2035 and will undergo ongoing assessment with Aico’s HomeLINK Environmental Sensors, which were used both prior to and after the retrofit to ensure that there are no unintended consequences, and that indoor air quality is being maintained moving forward.

Southend-on-Sea Council’s show home is fully equipped with a Category LD1 fire and CO system using Aico’s Grade D1 3000 Series multi-sensors, future proofing it for any revisions to British Standard 5839-6. By using Aico’s HomeLINK Gateway and Environmental Sensors, temperature, humidity, and CO2 levels can be monitored, giving insight into issues such as damp and mould, indoor air quality, fuel poverty and void properties.

This information is seamlessly transmitted to the online HomeLINK Portal, so that Southend Council and its property management company, South Essex Homes, can see in real-time exactly how the house is functioning and can intervene before any issues occur.

“The retrofit show home involved taking a holistic approach to sustainable housing which meant that we installed a wide range of interventions. The project is designed to test the latest innovations to inform us on where we should focus our efforts in the wider retrofit programme. Aico's environmental sensors are crucial for understanding the impact of these measures and ensuring that we continue to evaluate the performance of the home beyond installation.” – Ben Harrison, Housing Sustainability Officer, Southend-onSea City Council.

The utilisation of Aico’s HomeLINK App for Residents has played a significant part in this project, enabling residents to take control of their own environment and take a proactive approach to their health and well-being. The app facilitates direct real-time communication between Southend Council, South Essex Homes, and the tenant, through its messaging feature.

In addition to this, Southend Council and South Essex Homes have collaborated with Aico on Smart Meter Integration, to offer the tenant and council an additional dimension to the app.

This system has garnered positive feedback and is not only being implemented in SHDF trials and void properties equipped with Environmental Sensors, but has also prompted a Category LD2 upgrade programme across all of Southend Council’s properties. This initiative underscores the commitment to prioritise tenant safety and compliance for both the council and South Essex Homes.

Southend Council’s retrofit programme has enjoyed remarkable success, achieving such acclaim that it has been honoured with the following awards and nominations:

• Winner of ACES Retrofit Housing award 2023

• Highly Commended at Essex Housing Awards’ 2023 (Retrofit)

• Shortlisted for RICS’ Eastern Region

• Shortlisted for MJ Awards’ Innovation in Delivering Sustainability and Social Value

• Shortlisted in the Unlock Net Zero Awards

Enquiry 11

Enquiry 11

Navigating the complexity of fire safety in buildings has placed greater scrutiny on all components in external wall build-ups. Airtightness membranes and vapour control layers are no exception. Specifiers routinely ask about the fire performance of these products, but can find themselves confusing reaction to fire and fire resistance. Pamela Howat, Senior Technical Advisor at A. Proctor Group looks at the difference between the two.

The ability of certain products to meet the very highest standards of fire performance is limited by their primary function. Building membranes are one such product. The nature of the materials used to make a product – like our Wraptite membrane, for example – that offers airtightness and vapour permeability in a self-adhesive format, makes non-combustibility very difficult to achieve.

This delicate balancing act of performance characteristics was recognised in amendments to Approved Document B, with the inclusion of a list of components exempt from noncombustibility requirements in relevant buildings.

Nevertheless, there has been a level of expectation that manufacturers would work to offer equivalent products capable of achieving better levels of fire performance. A Proctor Group has offered membrane products with a fire performance declaration for many years, and we have expanded the range of options available in response to the industry’s changing requirements.

What is reaction to fire testing and classification?

All of the membrane products we offer with fire safety performance have a reaction to fire declaration in accordance with BS EN 13501-1. Reaction to fire testing establishes the spread of flame behaviour of products when they are exposed to heat and fire, and how they contribute to a fire as they decompose due to that exposure.

Characteristics assessed include how easily the product ignites, whether it burns, and its calorific value. The tests required for the classification will consider different performance depending on the expected performance. For example, if you are only declaring a Class E you don’t need to carry out the same onerous levels of testing as you do if you wanted to declare A1.

Results from individual tests are then used to classify the product’s reaction to fire in accordance with EN 135011:2018 Fire classification of construction products and building elements. Classification using data from reaction to fire tests. From best performing to worst performing, a product can be classified A1, A2, B, C, D, E or F. Class F can also mean a product is untested.

A1 and A2 are non-combustible materials, while B classifies a material as very limited contribution to fire.

Many classifications except A1, E & F, include additional designations for production of smoke and flaming droplets. These designations appear as s1, s2 or s3, and d0, d1 or d2 respectively.

What is fire resistance testing and classification?

Reaction to fire testing is helpful for assessing the contribution of an individual material or product to fire. What it cannot do is assess a complete system build-up featuring multiple components, which is where fire resistance testing comes in.

Fire resistance actually covers three different areas of performance: resistance to collapse (denoted as R and applying to loadbearing elements only); resistance to

fire penetration (denoted as E, and also called integrity); and resistance to transfer of excessive heat (denoted as I, and known as insulation).

Construction elements may need to achieve performance in one, two or all three of these areas. That performance is declared in terms of a number of minutes, added after the relevant letters. For example, a classification may read REI 60, or E30.

Like reaction to fire testing, fire resistance testing results are classified in accordance with a particular standard – this time EN 13501-2:2023 Fire classification of construction products and building elements. Classification using data from fire resistance and/ or smoke control tests, excluding ventilation services.

What is a membrane’s fire resistance in minutes?

This is a common enquiry received by the A Proctor Group technical team, and it points to a fundamental misunderstanding of the two types of fire testing.

Our Procheck® FR200 and Fireshield® membranes both achieve Class B, s1-d0, while our Probreathe® A2, Probreathe® A2 Air and Procheck® A2 achieve Class A2, s1-d0. These classifications show that the products can help to resist the spread of flame, as their composition means they make limited contribution to fire or are non-combustible, respectively.

Alongside their composition, membranes are thin products and have inherently little calorific value. In the wider context of a whole building’s fire safety, a membrane’s role in a fire depends on what substrate they are installed over and how they are fixed. This can only be established through system testing to measure the fire resistance of a complete wall build-up.

What is behind a membrane has a marked impact on how a fire develops. A non-combustible thermal insulation material can actually cause heat build-up to intensify, while other materials (calcium silicate boards, or steel or aluminium components) can help to dissipate some heat.

In that context, does the membrane play its part – however limited that might be – in the full system performing as it needs to? Does it help the wall build-up to achieve the R, E and/or I classification required?

What are the risks with product substitutions?

Adhering a membrane can provide a complete ‘seal’ to the substrate, whereas mechanical fixing allows the possibility of air gaps behind the membrane. And where membrane laps are taped, how does the tape impact on performance?

At A Proctor Group, we test our fire performance membranes with taped overlaps to provide extra reassurance. Proposing a product substitution for an ‘equivalent’ membrane solution does not guarantee that the alternative has been tested in the same way. Modifying through-wall build-ups changes fire safety outcomes, and you can never expect a fire to behave as you ‘want’ it to.

Legislation now requires higher-risk projects to demonstrate decision-making about specifications throughout the design and construction process. While fire engineers can assess limited modifications to tested build-ups, culture change and strict insurance requirements are making it even more important that what is installed on site is what was specified in the first place.

A Proctor Group is happy to discuss any aspect of our membranes’ fire performance, and we routinely support customers carrying out their own full system tests. Find out more at https://proctorgroup.com/fire-solutions

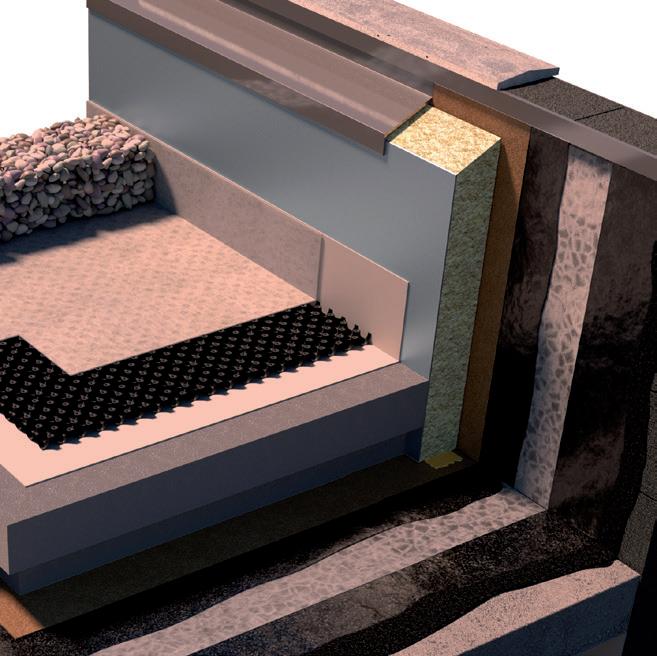

Leaks and dampness are not what an architect or building contractor wants to deal with post-build. Often damaging reputations and bringing significant financial consequences. Here, Kevin O’Connell, Business Development Manager at Soprema UK, offers advice on how to access the latest waterproofing techniques in UK construction be that for a building envelope or civil infrastructure project.

Innovations that simplify the installation process, product developments that improve performance, the increasing use of smart technologies, and sustainable approaches like green roofs all contribute to the complexity of waterproofing today. There are multiple ways a waterproofing manufacturer can assist.

Below ground to walls and roof – discuss performance including sustainability Working together closely from the project’s early stages will ensure effective design, installation, and ongoing maintenance of waterproofing systems.

To avoid waterproofing issues, it’s advisable for architects, engineers, contractors, and waterproofing specialists to discuss the performance requirements in relation to water resistance, durability and longevity. Other details to cover should include flexibility and movement of the building, adhesion and bond strength, breathability and vapour penetration, as well as installation and maintenance.

Look for manufacturers where sustainability is prioritised. At Soprema, a circular approach is now integral, with raw materials sourced increasingly in the circular economy. The company’s cradle-to-cradle philosophy is evolving so that customers receive responsible more across-the-board advice and

assistance to foster better building envelope performance, waste reduction at source and end-of-life recyclability.

Unravelling the waterproofing product minefield

To identify the potential water ingress points, a waterproofing specialist can conduct a comprehensive assessment of the construction site. By assessing sitespecific conditions, the most appropriate waterproofing solutions for the project can be recommended to meet performance criteria, durability expectations, and budget constraints. Seeking advice on the selection of membranes, coatings, sealants, drainage systems, and other components will ensure compatibility and optimal performance. This way, all the latest product developments can also be accessed.

For some projects, bespoke waterproofing systems to meet the most complex needs and challenges may be more appropriate. This could integrate multiple waterproofing systems or address unique site conditions to achieve comprehensive water protection, for example in an urban area with a high water table and poor drainage. Supporting specifiers and contractors, Soprema shares a wide range of technical drawings and data sheets with any necessary

calculations provided. For instance, roofing drainage calculations to look at the size of the outlets and determine how many are needed on the roof area in question, and with WUFI calculations to assess any moisture movement throughout the construction and the validity of the thermal performance of insulation panels to be used in a building. Seeking out a company that offers in-house CAD drawing too, guarantees a complete solution.

Why develop the specification from product to maintenance

Use the expert knowledge and experience of the installation processes available from a waterproofing manufacturer to assist in developing a detailed waterproofing specification that meets regulatory requirements, industry standards, and project objectives.

Apart from product specifications, it may include installation methods, performance data, and quality assurance measures.

This reduces the likelihood of programme delays, issues such as leaks, mould growth, and structural damage throughout the building's lifecycle, which is why understanding the latest waterproofing technologies is so important.

Avoid errors - single point of warranty and contact

Ensuring the waterproofing systems are specified and installed correctly in

accordance with manufacturer recommendations, minimises the risk of installation errors and secures long-term performance.

To stay up to date, Soprema provides technical training and Continuous Professional Development (CPD) support on product specification, installation, application techniques, and best practices.

It’s also important to make sure that specific guidelines are provided before the start of the project – from the accessories to be used to the project safety conditions and actual execution, with any training on the installation of the waterproofing products for construction workers provided.

During the construction phase, onsite support and guidance to contractors to address any challenges during installation are preferable. This could include inspections, quality control checks, and troubleshooting to ensure the waterproofing system is installed properly and performs as intended.

Testing and certification of waterproofing systems to verify compliance with regulatory requirements, industry standards, and performance specifications can also be facilitated.

In fact, Soprema is not just a waterproofing company but a one-stop shop, acting as a single point of contact for the entire building envelope, including insulation and soundproofing.

Once a final inspection and report are complete, the contractor can apply for a

warranty, which would be issued for the duration of the particular project (twenty, twenty-five or even thirty years).

Explore the benefits of new technology Technology advances, such as drones, have transformed the inspection process for waterproofing systems, particularly for larger or hard-to-reach roofs.

Compared to handheld equipment, Soprema’s drone service offers significant advantages, including heightened safety, superior imaging capabilities, and minimal site intrusion. It also eliminates the need for physical roof access, ensuring a safer and more efficient survey process.

By taking advantage of the latest technology, expertise and support services of waterproofing and insulation experts like Soprema, architects, specifiers, and building contractors can develop reliable and effective waterproofing specifications that ensure long-term protection against water ingress and associated damage as well as successful outcomes for their projects.

Learn more about effective waterproofing strategies at www.Soprema.co.uk.

Soprema – Enquiry

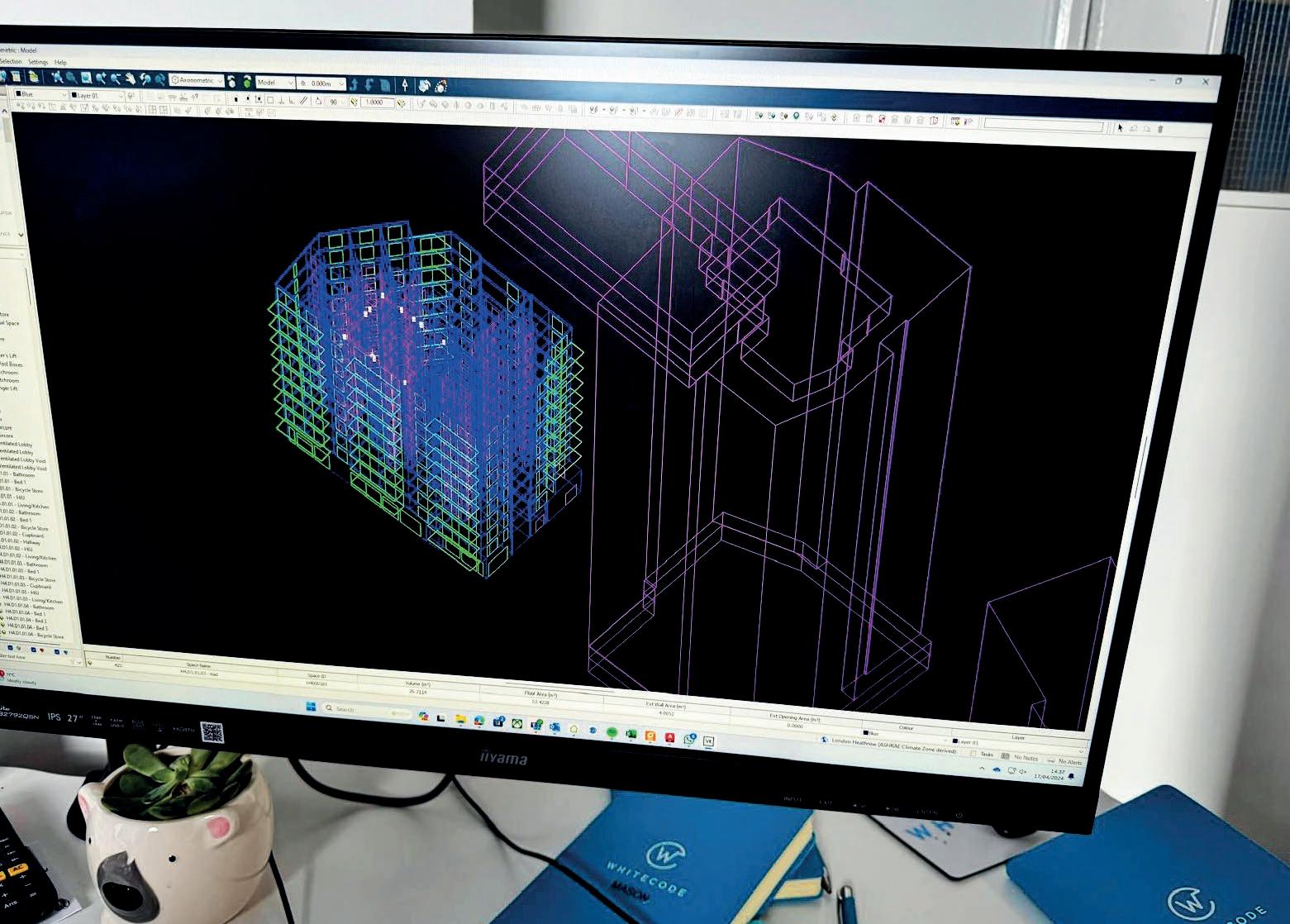

The global standard for smart buildings, WIREDSCORE and SMARTSCORE certifications help developers and property owners build smart buildings that drive cost efficiency and meet high standards of sustainability. Whitecode’s William Auloni reveals the important role these certifications will play in the building industry in the future.

The demand for better built and smarter buildings means architects, designers and contractors need to focus on not only sustainability, buildability and cybersecurity but also connectivity, occupant wellbeing and telecommunications.

With that in mind, WIREDSCORE and SMARTSCORE certifications provide clarity on what constitutes a smart building, guidance on how to achieve the status and proof of the value it adds to an asset.

They do this by assessing each building against the benefits and outcomes expected of a smart building, scoring the user stories implemented and assessing the technology, procedures and processes that support their implementation. Doing so means the building will be set up to meet the expectations of occupiers and be future-ready to improve user functionality.

In a highly competitive market, especially in major towns and cities, attracting and

retaining residents and commercial occupants is increasingly gaining importance. Achieving certifications from WIREDSCORE and SMARTSCORE can help to position any property owners or commercial brands as technology and sustainability focused.

As a result, occupants are more likely to be attracted to the property and then just as likely to want to stay there long term.

Meeting superior quality and sustainability standards

The biggest benefit of WIREDSCORE and SMARTSCORE certification is that building developers will be provided with all the tools and data they need to ensure they

are managing and delivering technology effectively throughout the building.

Having instant access to all relevant tools will help specifiers and developers meet the ever-evolving demands of occupiers and build cutting-edge smart buildings that drive cost efficiency, are future-ready and meet incredibly high standards of sustainability.

Furthermore, doing so could enhance trust and increase the likelihood they are retained by the end user in the future.

Paying close attention to WIREDSCORE and SMARTSCORE certification can enable building developers and housebuilders to demonstrate to investors and the wider market that the asset is being designed and built with future sustainability and building demands in mind.

Put simply, the better designed and more sustainability-focused the building, the more attractive the property and the developer will be in the future.

With sustainability increasingly coming into focus in the built environment, it’s imperative that building owners, architects and contractors ensure developments are technologically forward-thinking and attractive to the next generation of tenants. WIREDSCORE and SMARTSCORE helps all involved to understand, improve, benchmark and promote a building’s digital infrastructure. >>

>> Student accommodation boom

The development of new student accommodation has emerged as one of the most promising residential sectors for securing new work contracts this year.

Against a background of a mixed outlook for new housing work generally, the April edition of the Glenigan Construction Review notes that work starting on site on student accommodation schemes was worth £502 million in the first quarter alone, a rise of 34% on the period a year ago. In all, student accommodation now accounts for a 5% share of total housing starts.

Student numbers, both domestic and particularly from overseas, are continuing to climb; up by 4% in total during 2022/23. And despite budget challenges across the higher education sector, the building programme for new student housing at universities and colleges is gathering pace.

The upturn in activity in the sector is in keeping with the latest Glenigan Construction Industry Forecast 2024-25, published in November 2023, which predicts a 16% increase in student accommodation starts in 2024, followed by a further 10% upturn in 2025.

The mood at Unite Group, the country’s largest owner and developer of student accommodation, is positive. Earlier this month, the group said that it was seeing continued strong demand for student space and that it had sold 86% of its ‘bedrooms’ for the 2024/25 academic year. Its rents are set to rise by 6% in the coming academic year.

Today, Unite is progressing a £1.3 billion development pipeline and it has recently secured planning approvals for major student schemes involving 1,450 new bedrooms in London and Bristol.

With demand from universities continuing to grow, Unite has also secured agreements for a further 1,000 student bedrooms since March. Demand from international students – who occupy 13% of rooms –remains robust despite recent changes to UK visa rules. (Overseas students are a key market for developers as they are more likely to stay in purpose-built student accommodation throughout their studies).

Unite has recently secured planning approval on a 500-bed student accommodation project close to the University of Bristol’s new Temple Quarter Enterprise Campus. Glenigan data shows that work is set to start on the £73 million Freestone Island, involving almost 18,000 sq m of space, later this summer and run for 13 months (Project ID: 22350495).

Elsewhere at Meridian Place, in Stratford, East London, Unite has won a resolution to grant planning permission for a 952bed project to be delivered in time for the 2028/29 academic year.

Meanwhile, in a joint venture with Newcastle University, Unite is set to put in a planning application on a £250 million student accommodation scheme involving around 2,000 new bedrooms at Castle Leazes in the city.

Plans have been submitted to demolish existing buildings ahead of construction starting in early 2025 (Project ID: 19376827).

Glenigan data highlights numerous other significant student accommodation projects in the pipeline in cities nationwide.

In Manchester, plans have been submitted for the redevelopment of the former Hotspur Press complex in Gloucester Street with an £84.4 million student scheme involving some 580 units above a ground floor commercial/amenity space (Project ID: 18270098).

Across the Pennines in Leeds, detailed plans have been submitted by developer Brigade Central for a £34.24 million scheme to provide 198 student accommodation apartments at Kirkstall Road where work is set to start later this year and run for 12 months (Project ID: 23351417).

Meanwhile, in London, detailed plans have recently been approved for a £29.45 million student accommodation project in Newham to provide 325 purpose-built units. Work on Marshgate Lane Accommodation, involving over 10,000 sq m of space, is set to start this autumn and run for 12 months (Project ID: 18397804).

Enquiry 15

There are several benefits to choosing bathroom wall panels over other, more traditional surface products such as tiles, that will not only ensure bathrooms are 100% waterproof, but are stylish and cost-effective.

Whether student accommodation is a new build or a refurbishment, it has little weighting on the benefits that wall panels bring as the speed and ease of install remain the same. On average, panelling a bathroom will save over five hours installation time on an average sized ensuite sized bathroom compared to other surface materials. If used throughout a student accommodation block, the potential for significant time savings is there, along with the associated cost savings through a reduction in labour.

Installation is so quick thanks to Multipanel’s unique Hydrolock® technology. Precisely engineered, Hydrolock® allows panels to be joined together without the use of midjoints, to create a smooth, almost seamless expanse of waterproof walls. Multipanel’s easy cleaning properties of being grout-free make maintenance hassle-free. Best of all, Multipanel can be conveniently fitted over existing tiles, reducing the need for extensive preparation work.

As bathrooms within student accommodation can often span across several floors, a leak could have a huge impact and may not be instantly noticed by current occupants.

Hydrolock® technology ensures that wall panels are 100% waterproof as there is no human error when it comes to grouting or the need for regrouting months down the line. This in turn makes cleaning them easy, requiring just a wipe down with a sponge and warm, soapy water.

Damp and mould pose significant challenges in maintaining a safe and healthy living environment within student accommodation, especially in areas prone to moisture build-up and humidity such as bathrooms. Retrofitting bathrooms with moisture-resistant wall panels presents a proactive approach to addressing these issues, regardless of the specific product used. Unlike traditional tiling, which is susceptible to grout deterioration and water seepage, panels provide a seamless and waterproof barrier that prevents moisture ingress and inhibits mould growth. This not only safeguards the structural integrity of the property but also reduces the need for frequent maintenance and repairs.

In addition to their functional benefits, wall panels also offer aesthetic advantages, enhancing the visual appeal of bathroom spaces. With a wide range of design options available, including contemporary finishes and classic motifs, and the latest Tile Collection, panels allow the overall look and feel of student accommodation to be high-end, while simultaneously addressing practical concerns.

Grant Westfield recognises the importance of environmental stewardship in today's world and are committed to ensuring that all products meet stringent sustainability standards. All Grant Westfield products are 100% recyclable, FSC certified®, and MIB accredited. Furthermore, they recently obtained an Environmental Product Declaration (EPD) across

all products. This provides greater visibility on the environmental impact of materials, to allow for the most sustainable options to be specified. For example, choosing Multipanel or Naturepanel over tiles results in a 60% CO2 reduction, in 2023 that reduction would have been the equivalent to driving around the Earth’s circumference 628 times! In terms students may be more familiar with, using wall panels over tiles for the average number of new student bed spaces built each year in the UK is equivalent to CO2 consumed in 13.5m pot noodles.

With a dedicated specification team and a distribution network spanning the whole of the UK, Multipanel is positioned to be able to help with any new-build student accommodation or retrofit projects.

Grant Westfield – Enquiry 16

The Nantgarw student Campus is part of Coleg y Cymoedd (College of the Valleys) in Wales. When the campus required a fast refurbishment of their Library, they turned to international flooring specialist Gerflor to supply Gradus Carpets for the much-used library.

This successful renovation, then resulted in the specification of a vast selection of other Gerflor products for other areas of the campus.

The project provided Gerflor with the perfect platform to showcase a raft of other high-quality flooring solutions ideal for the demands of the modern-day education environment. The project would amount to an immense 5300m2 of Gerflor products being specified.

Commenting on the project Tony Thorne, Specification Manager, Gerflor, South Wales said, “The end user was so pleased with the final result they chose to work with Gerflor and Carpet Services for other areas of the refurbishment programme across the entire campus.” The installation would be the

responsibility of Carpet Services Flooring, Cardiff. Ray Gallivan, Contract Manager at Carpet Services said, “The Gerflor flooring products that were specified for this iconic project are really meeting the high standards required for the end user. We would continue to use Gerflor on a weekly basis. The final result at the college is extremely impressive.”

The design and specification of the Nantgarw Sports Centre of Excellence would fall to Cardiff-based architects Austin-Smith: Lord. Jonanthan Jones, Associate at Austin- Smith: Lord commented, “The Gerflor flooring products specified are absolutely

meeting the high specifications set for the education project and client’s brief. We would definitely specify Gerflor again.”

To learn more, visit gerflor.co.uk for the latest flooring innovations.

Gerflor – Enquiry 17

St Joseph's Primary School, recently undertook a project to rejuvenate their outdoor play area. Recognising the need for a safe and top-quality play space, the school turned to Playrite, a brand name synonymous with multi-sport surfaces, to replace the old existing synthetic turf with a new 15mm in situ pad and Playrite's versatile Multi Sports Surface (MUGA).

St Joseph's Primary School faced a challenge with an aging synthetic turf that had seen better days. It was crucial to replace it to ensure pupil safety.

The project commenced with the removal of the old surface and pad, making way for a fresh start. The school's decision to install a 15mm in situ pad combined with Playrite's Multi Sports MUGA Surface proved to be a wise one for several reasons.

Playrite's Multi Sports MUGA Surface is renowned for its versatility. It's perfect for various sports and activities, making it an ideal choice for a school play area. Students at St Joseph's Primary School would be able to enjoy playing a variety

of sports from football, hockey, and tennis, on the same surface.

One of the key benefits of choosing a Multi Sports MUGA Surface is its ability to withstand heavy use, ensuring its longevity and reducing the need for frequent maintenance. This not only saves the school money but also guarantees a consistent, high-quality playing surface for years to come.

Sports MUGA Surface offers exceptional shock properties and impact protection, minimising the risk of injuries during play.

With outdoor surfaces, a primary concern for any school becomes the safety of the users and the level of shock absorption that can be achieved. Playrite's Multi

To discover more about Playrite’s MUGA surfaces and other product ranges, contact us to speak to one our experts by calling (0)1924 412488 , emailing info@playrite. co.uk, or visiting www.playrite.co.uk/muga

130+ Exhibitors | 3000+ Exhibition & Conference Attendees | 120+ Speakers | 700 Awards Dinner Guests

Registration has just opened for the UK’s leading learning environments event, Education Estates ® , held in partnership with the Department for Education on 15-16 October in Manchester Central.

Every year, Education Estates® brings together the education community: from policy makers and designers to suppliers and educators. It is a key resource to gain valuable insight into upcoming policy, be inspired by innovative new projects and derive practical knowledge from experts in the sector.

The event comprises a two-day conference over six themed stages, an exhibition showcasing some of the most innovative solutions around and an awards ceremony celebrating excellence in the sector. It is the largest event of its kind in the UK, focusing on educational infrastructure: the funding, design, build, maintenance and management of schools, colleges and universities.

This year looks set to be the biggest and best yet, with over 80% of exhibition space already sold and the highest ever number of attendees registered at this stage in the campaign.

There was a record number of conference submissions, which will soon be expertly crafted into a programme that offers innovative solutions to current challenges, with presentations exploring every facet of the project and experiences from concept through to end user.

According to the Organiser, the exhibition will see a 20% increase this year, with new names including A-Z Design & Furniture Solutions, Able Canopies Ltd., Baldwin Boxall, Blink Charging UK, Clevertronics, Curl la Tourelle Head Architecture, Eomac UK Ltd, Epwin Group, Evolution Doors, Fagerhult Lighting, Mitsubishi Electric Europe BV, Pagabo, P McVey Building Systems, Safesmart Ltd, SFG20, Tel Group, Titan Furniture and Trust Electric Heating. Meanwhile, look out for the Awards Shortlist to be announced at the end of June.

Meanwhile, look out for the Awards Shortlist to be announced at the end of June. The Education Estates® Awards is a sell-out event every year with entertainment from popular comedian, Hugh Dennis.

The Education Estates® exhibition and conference are free to attend for the public sector. Early booking rates are currently applicable to private sector delegates –the private sector can visit the exhibition for free. Register now via the website: www.educationestates.com.

Programme Highlights:

Following the sell-out SEND and Net Zero conferences earlier this year, the conversation continues at Education Estates ® ! Highlights include: Climate adaptive school grounds: a new frontier - Matt Robinson, Learning through Landscapes; Acoustic Design Watchlist - What the Building Bulletins don't cover! - Emma Greenland, Anderson Acoustics; Building Quality from design to handover - Nick Coke, WT Partnership, Linda Stevens, CIOB & Jo Marchant, The Boxing Academy; Does Design Review Deliver for Education Development? - Matthew Blythin, DHA & Catherine Ward, HLM; Enhancing Higher Education Spaces Through Data-Driven Insights - Becky Hayward, Buro Happold; The integration of academia and community and commercial spaces,- Robert Hopkins, AHR & Tim Hosker, University of Huddersfield; and Education in the Secure Environment - Dave Clark, Lincolnshire County Council & Lorna Crowther - Managing/Regional Lead Architect, Kier Design.

Education Estates ® 2024 Sponsor

Partners:

Arcadis, AtkinsRéalis, Clevertronics, Galliford Try, i AM Compliant and TG Escapes modular eco-buildings.

Education Estates – Enquiry 19

Discreet watertight joint with Hydrolock® Grout free

Multipanel bathroom panels are precisely engineered and equipped with a unique Hydrolock® tongue and groove joint which allows seamless installation in any wet room or bathroom, reducing bathroom installation costs by up to £30/m2

Driving around the circumference of the Earth 628 times is equivalent to the CO2 reduction in Multipanel being used instead of tiles.

Children are among those affected most by air pollution. They breathe more rapidly than adults and so absorb more pollutants, plus they have smaller airways. Additionally, they suffer from more respiratory infections than adults, making them more susceptible to the effects of air pollution.

Astudy* by Airflow has shown that more than a million UK children are being educated in areas with high levels of harmful air pollution. Poor classroom air quality can have a huge impact on school children’s behaviour, concentration and overall health.

With up to 30 pupils in one room, you can only begin to imagine how polluted the air quality is. The importance of effective ventilation is paramount, not just to improve the quality of air, but to aid studying, as documented in BB101 (Guidelines on ventilation, thermal comfort, and indoor air quality in schools). The build-up of pollutants and Volatile Organic Compounds (VOC’s) contribute to highly polluted air that is inhaled by students and teachers. Cleaning products, sprays and glue are just some of the contributors to the poor atmosphere trapped in classrooms. Installing a ventilation system can help reduce the pollutant build up by removing toxic air.

Airflow’s Susurro range offers discrete decentralised ventilation with heat recovery for

classrooms and offices. This new generation of efficient, energy-saving, and ultra-quiet units provide the highest quality of indoor environments, perfect for educational settings. The integral C02 sensors actively monitors the indoor air quality inside a room, enabling Susurro to automatically adjust its ventilation based on occupant demand; maintaining a healthy, fresh indoor air environment without having to open a window.

The Susurro’s slim design is ideal for both new-builds and retrofits and ensures optimum use of space. The units can be ceiling mounted and are therefore ideal for retro fitting into classrooms. This range of MVHR also offers low specific fan power (SFP), excellent air circulation, automatic 100% bypass and the option for additional frost protection facilities. With the option of 3 sizes, all Susurro units incorporate exceptional casing insulation (40mm) to minimise thermal bridging and achieve extremely low noise levels, making

them a particularly popular option for school ventilation systems.

Selecting the right product

Airflow’s advanced and user friendly Duplexvent Selection Software makes it possible to select the most suitable product in just a few simple steps. This freely available software gives a quick survey of the right choice of product and easy access to relevant planning information.

*Source: https://www.airflow.com/about-us/ blog/article?article_id=32&article_desc=TheAir-Quality-in-UK-Classrooms-Report

Airflow – Enquiry 21

Education Estates® is the UK’s leading learning environments event –the largest gathering of education estates and facilities professionals.

The event comprises a two-day multi-stream conference, an exhibition showcasing some of the most innovative solutions around and an awards ceremony celebrating excellence in the sector.

Register to attend at www.educationestates.com

Design, Construction, Delivery

Good Estate Management

Policy & Funding

Refurbishment & Retrofit

Special Educational Needs & Disabilities

Sustainability

Bathrooms and showers in student accommodation need to withstand the rigours of student life, whilst staying both stylish and low maintenance. Although traditional tiles can offer both style and substance at first, over time they can become discoloured and chipped if not looked after. The solution is PVC wall panels from Zest Wall Panels.

The ZX wall panel and 1 metre wide shower panel collections from Zest are the perfect partner for any student dormitory bathroom. Both are easy to install – they can even be fitted directly over existing tiles - and even easier to maintain, requiring only a wipe with a clean cloth to keep them looking like new. These panels are durable, 100% waterproof and do not require grout.

The ZX range features panels with a solid core construction, which makes them impact resistant, and a highly realistic, textured finish. Zest’s 1 metre wide shower panels are the largest in its range, measuring 1000mm by 2400mm, which makes installation simple, straightforward, and swift.

Zest wall panels have already proved their worth in student accommodation across the UK, including at sites in London, Essex, Northampton, Manchester, Loughborough,

and Glasgow. To explore the range and find out more about the many benefits of Zest wall panels and how they can transform a bath or shower room in a matter of hours, call Zest

today on 01827 317200 or visit www.zestwallpanels.co.uk.

Zest Wall Panels – Enquiry 23

Supacord, Heckmondwike’s bestselling carpet celebrates over 50 years of success

Supacord is a renowned contract carpet synonymous with exceptional durability and longevity. Its palette of 42 colours and availability in both sheet and tile offers maximum versatility. Plus, Supacord has an acoustic tile backing option, ideal for reducing impact noise in schools.

For over 50 years, Supacord has been considered the number one carpet for schools, colleges and universities. It is easy to clean, will not ravel or fray and it has low installation and maintenance costs. Made in the UK by Heckmondwike FB and available from stock.

Order a sample card today: www.heckmondwike-fb.com.

Heckmondwike – Enquiry 24

Active Flooring has completed an extensive installation, using a Mapei sustainable flooring system, at Colchester’s new Trinity School. Constructed by Bowmer + Kirkland for the Department of Education, the new school will provide 900 student places. The floor installation within the new three-storey building included a selection of Gerflor’s Vinyl Safety, Homogeneous & ESD Flooring and Burmatex® cordiale carpet tiles throughout classrooms and school office areas.

The new building, designed by Stride Treglown Architects, features a large atrium at its centre – above a dining room - and a single storey link which provides covered access to a 2.5 storey tall sports block.

During the floor preparation phase, Active Flooring installed Mapeproof Primer – a one-component, rapid drying ready-to-use waterproof surface membrane and then levelled and smoothed subfloors with Latexplan Trade – a protein-free, low odour levelling and smoothing compound with high compressive strength.

Two adhesives were used to complete the installation: for the vinyl flooring, Ultrabond Eco V4 Evolution all-in-one universal adhesive - a strong, rapid initial tack formulation with a long open time was used and Ultrabond Eco Tack TX+ - an acrylic-adhesive carpet tile tackifier in water dispersion for the carpet tiles.

Are you aware that many fire rated glazing systems only offer ‘E’ integrity protection, rather than ‘EI’ integrity and insulation? With Promat SYSTEMGLAS®, there is no need to compromise.

Available in four different framing materials, this fully tested glazing system is ideal for use in energy-efficient, naturally lit buildings, offering a durable, long-term solution with fire protection of between EI30 and EI120. All backed with Promat’s 360° Wheel of Assurance for additional peace of mind.

Promat SYSTEMGLAS Specified for a Reason

Promat UK Ltd 0800 588 4444 promatglass@etexgroup.com

As urban areas expand and the environmental impact of construction becomes a growing concern, green roofs have emerged as a sustainable solution to urban heat islands, stormwater management, and biodiversity loss, not to mention the aesthetic and social benefits. Holly Burns, Technical Lead from Soprema, delves into the key considerations for incorporating green roofs in modern architectural projects.

One of the first considerations for a green roof should be the type of roof construction and what you wish to achieve with the roof, whether this is to create a social space, a biodiversity area or something else.

As such, it is important to understand the different types of green roof and how they differ from one another:

• Extensive Green Roofs: These are lightweight, with shallow soil depths (typically 2-6 inches), and support low-maintenance vegetation such as mosses, sedums, and grasses. They are ideal for buildings with limited loadbearing capacity and require minimal maintenance.

• Intensive Green Roofs: These are akin to traditional gardens, with deeper soil layers (up to several feet), supporting a wide variety of plants, including shrubs and trees. They require substantial structural support and ongoing maintenance but offer significant aesthetic and recreational benefits.

• Semi-Intensive Green Roofs: These combine elements of both extensive and intensive green roofs, with moderate soil depths and a mix of plant types. They provide a balance between weight, maintenance, and biodiversity.

• Mentioned in the breakdown of green roofs is the importance of structural support, particularly when you wish to plant more substantial vegetation like bushes and trees. Firstly, you should assess the

existing structure's ability to support the added weight of the green roof system, including saturated soil, plants, and any additional features like irrigation systems or walkways. In many cases, structural reinforcements or modifications may be necessary to accommodate the green roof. This might involve strengthening beams, columns, and the roof deck. A key highlight here is to consider the weight of the green roof when at its saturation point, and not just as dry vegetation.

On the point of saturation, effective waterproofing and drainage are critical to prevent water infiltration and damage to the building. The installation of high-quality waterproof membranes to protect the roof

structure and drainage layers to facilitate water flow and prevent waterlogging is crucial to the entire construction. Furthermore, these membranes should be durable and resistant to root penetration to prevent any structural issues down the line.

For this aspect of green roof specification, you should partner with a specialist in the area, such as Soprema, to specify the exact products required to achieve the optimum level of root, water and drainage protection.

Perhaps one of the most important considerations for your green roof project lies within compliance with regulations.

British Standards such as BS 6229:2018 which covers flat roofs with continuously supported flexible waterproof coverings, outline key design considerations. Additionally, various national and local regulations may apply. For further guidance, refer to the GRO Green Roof Code.

Green roofs represent a forward-thinking approach to sustainable architecture, offering numerous environmental, economic, and aesthetic benefits. For specifiers and architects, careful consideration of everything outlined above is essential, and by addressing these factors and partnering with an industry expert like Soprema, architects can create resilient, eco-friendly buildings that contribute positively to urban environments and meet the growing demand for sustainable construction practices.

Gavin White, Head of Product Management - Roofing at Sika, explains the cultural shift is happening towards enhanced traceability – the ability to trace a product’s journey from raw materials to installation with documented accountability – and transparency through candid disclosure of composition, performance, and processes.

Initiated by the Construction Product Association (CPA) following Dame Judith Hackitt’s review, the new Code for Construction Product Information (CCPI) urgently promotes increased transparency and traceability in how manufacturers create, manage and present product details.

The 11 robust CCPI clauses ensure compliance around product information management. The first section (Clauses 1-3) requires clear ownership, processes and structures for creating and managing product information throughout its lifecycle. The second section (Clauses 4-7) mandates clear, accessible, up-to-date product information through regular competent reviews. It requires valid documentation for claimed certifications/standards, verifiable performance claims outside certification, and publishing descriptive/physical product characteristics online.

The third section (Clauses 8-9) covers information on handling, installation, operation, maintenance, disposal and precise

warranty/guarantee terms, exclusions and requirements published on company websites. The final section (Clauses 10-11) requires manufacturers to ensure staff competence for their roles in handling product information, provide visible technical helplines, and implement robust training programmes. It emphasises awareness of individual competence levels and limitations.

Overall, the CCPI aims to provide specifiers and purchasers confidence that available product information is correct, current, accessible, unambiguous, with clarity on warranties and guarantees, to foster much-needed trust through traceability and transparency.

Sika has historically recognised the importance of traceability and transparency within its products and services, and therefore rigorous processes were already in place prior to CCPI certification. In fact, Sika was part of the initial industry consultation process which was set up to develop the code.

To comply with CCPI, Sika followed three important steps. Firstly, it conducted a large leadership and culture survey which sampled colleagues from a number of roles that have influence over products and product information. This was crucial in demonstrating that there is a supportive and conducive environment for the adoption and implementation of best practices for construction product information.

The second phase involved providing evidence of Sika’s management systems, including those governing the creation, management and presentation of product information. The evidence focused on areas such as what systems are in place, who is in charge of maintaining and updating the systems and their competence to do so.

The last stage for Sika was the submission of product sets for assessment and verification in accordance with the 11 clauses of the code. Product set verification looks at a whole range of aspects to ensure that information associated is clear, accurate, upto-date, accessible and unambiguous. Sika is proud to have successfully achieved CCPI across all four of its product sets.

At Sika, the CCPI is viewed as a crucial initiative that must be wholeheartedly embraced. Its success hinges on industrywide acceptance, but Sika hopes the drive towards greater transparency and traceability will continue moving forward. The CCPI is just one piece of a larger puzzle, and continued dialogue and collective action are imperative to continue the cultural shift that places building safety at the forefront.

Image 1: Sika Hot Melt Structural Waterproofing System at Rhodes House, Oxford University, one of the four systems which holds CCPI Verification

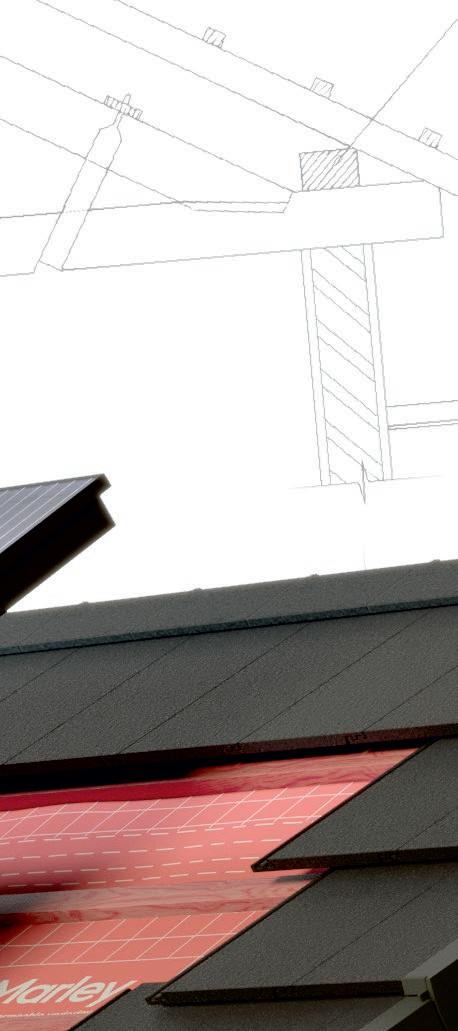

CUPA 12 natural slate has been specified for the roof of a new family home, built in the garden of a historic Grade II listed Arts and Crafts property in North London.

The design team, from Levitate architecture and design studio, needed a way to respectfully reference the traditional architecture of the area without compromising the contemporary finish of the property.

CUPA 12 slate provided the perfect balance: being a natural and historically appropriate material that could also provide a clean aesthetic with a smooth, uniform finish. This – combined with the steep pitch of the roof, overhanging eaves and series of intersecting gables – helped to make the roof of the property a defining feature. This is consistent with traditional Arts and Crafts design – and gave a suitable nod to the Grade II property the new family home would be neighbouring.

In addition to satisfying the visual requirements of the project, CUPA 12 slate is also a BRE Global Certified product that provides a more sustainable solution than other contemporary roofing materials. CUPA PIZARRAS’ direct control over every stage of the slate production process - from quarry to roof - means that it can guarantee the quality of its product and trace it back to the source. This was beneficial in promoting a sustainable approach to the construction of a new property within a conservation area

as well as helping to guarantee the timely delivery of the natural slate.

Levitate has extensive experience working in conservation areas and on properties of historical significance. Architect Toby Knipping commented: “Site context was key to this project. We used a traditional palette of brick, wood and slate to reference the historic buildings in the surrounding area yet with a modern twist. We were very happy with the results and would definitely consider using CUPA PIZARRAS slate on other projects.”

Infill developments of this kind had previously been discouraged by the local planning authority, with several neighbours having new build projects rejected.

Mark Hagan, Director of the project’s management firm Heartwood Ash, said: “Sourcing products of a high enough quality to satisfy the planning conditions was one of the primary challenges of this

project. Being able to present the planning officers with physical samples provided by the CUPA PIZARRAS team really helped us to gain their confidence in both the product’s ability to satisfy requirements and also the project itself.”

If you want to find out more about CUPA PIZARRAS and its range of natural slate, visit www.cupapizarras.com/uk/

CUPA PIZARRAS – Enquiry 29

For centuries, human beings have been building things with slate.

It’s extremely robust, long-lasting and aesthetically pleasing – and in their latest CPD, leading suppliers SSQ argue that it’s still one of the best roofing, cladding and flooring materials available today.

In “Why Specify Slate and Phyllite”, architects can learn about the many benefits of natural materials, and everything they need to know to successfully incorporate them in their projects.