SPECIFICATION Magazine July 2022 www.specificationonline.co.uk ll www.letstalkspecification.co.uk This month’s features: www.mirashowers.co.uk/heatcapture Increase your SAP score with the Mira HeatCaptureTM Discover Energy Recovery Sector Reports: • Offsite Construction • Hotel, Sport & Leisure Features: • Safety, Security & Fire Protection • Doors, Windows, Entrance Systems & Rooflights • Glass, Glazing, Blinds, Louvres & Solar Control • Heating, Ventilation & Air Conditioning

As a timeless classic of interior design, elements in black are a great way to make a statement. Whether in monochrome bathroom design or to create colour contrast to tiles, the various Schlüter-Systems products in the TRENDLINE coating matt graphite black offer numerous design options in combination with premium ceramic tile or natural stone coverings. Match your shelves, tile edge trims and drainage channels for a bold and contemporary finish. To find out more, visit

MattGraphiteBlack

MattGraphiteBlack

Enquiry 44

MGS

Welcome

Delivering

The Construction Innovation Hub has completed the Value Toolkit, following a successful development programme with over 200 industry partners.

The announcements include the launch of a new BSI flex standard to underpin value-based decisions making in the sector.

Bringing together those who have contributed to its journey, including government, clients and industry partners, the Hub is now sharing the transition phase to adoption.

The Value Toolkit is a pioneering suite of tools that will be used by industry to embed value-based decision making in the built environment sector. It is a government funded industry-led initiative – with roots in the Construction Leadership Council’s Procuring for Value report and set to deliver on the ambitions of the Construction Playbook and the IPA’s Transforming Infrastructure Performance Roadmap.

The Toolkit has been developed to reframe the definition of value, and how it can be evaluated and measured, capturing wider, whole-life considerations around net-zero, user experience, productivity and social impact.

Working with partners and collaborating has been critical to the success and there are few corners of the sector that the Value Toolkit has not touched – from local authorities to central government departments, consultancies, contractors and specialist SMEs. The ambition is now for widespread adoption, driven by government and underpinned by industry.

Keith Waller, Programme Director at the Construction Innovation Hub, said: “This is a landmark moment for the Hub and our industry partners, and a gamechanger for construction and the built environment.

“Decision making in construction has been historically driven by how much something cost, or how long it took to build. The Toolkit delivers a laser-like focus on project outcomes that delivers value beyond the bottom line, and positively affect communities and those who live in them for decades to come. It will ensure a more collaborative relationship between clients and suppliers throughout the whole life of a project.”

Paul Groves || Group Editor

Paul Groves || Group Editor

3 Welcome

Enquiry 45

tools

meet tomorrow’s challenges Howells Patent Glazing Ltd - Triton Works, Woods Lane, Cradley Heath, Warley, West Midlands B64 7AN 01384 820060 www.howellsglazing.co.uk info@howellsglazing.co.uk Howells Patent Glazing, experts since 1973 in manufacturing, supply and installation of unique roof glazing systems for the private, public and commercial sectors. • Northlights, double and single pitch rooflights, patent glazing, canopies, vents & guttering • Auto CAD drawings • U values of 0.4w/m2 (under specialist conditions)

Weather tightness tested to current British standards

Quality assurance to ISO 9001:2015

Members of council for aluminium in building

Railway stations, shopping centres, schools, heritage buildings, industrial & commercial buildings, together with domestic applications, swimming pools and conservatories

Prebuilt range rooflights, 14 day turnaround

to

•

•

•

•

•

Raised access Porcelain paver system

With a vast choice of finishes available for any Design scheme, including larger formats and co-ordinating internal tiling, Levato Mono porcelain paver system is perfect for balconies, roof terraces, garden decks and piazzas. Key benefits include; high slip resistance & load bearing, fade & wear resistance – so low cost ongoing maintenance. Both of our self-levelling support pedestals promote a fast cost-effective installation process for use on delicate waterproofing or covering tired slabs. The tilting head adjustment compensates slopes up to 5% even with multiple falls. If a Fire rated pedestal is specified then the FRSL range has Class A1 classification or the SL polypropylene type which have their own key features; secure height locking, non- slip acoustic dampening pads and large height range (28 to 550mm).

LEVATO MONOTM

WWW.SURFACE360.CO.UK 0118 391 4120 | INFO@SURFACE360.CO.UK FRSL New Class A1 Pedestals Enquiry 46

5 Contents Specification Magazine July 2022 SPECIFICATION Magazine July 2022 www.specificationonline.co.uk ll www.letstalkspecification.co.uk www.mirashowers.co.uk/heatcapture Increase your SAP score with the Mira HeatCapture Discover Energy Recovery This month’s features: Sector Reports: Offsite Construction Hotel, Sport & Leisure Features: Safety, Security & Fire Protection Doors, Windows, Entrance Systems Rooflights Glass, Glazing, Blinds, Louvres & Solar Control Heating, Ventilation & Air Conditioning 6 Latest News 12 Project 18 Front Cover Spotlight 38 Safety, Security & Fire Protection 46 Doors, Windows, Entrance Systems & Rooflights 56 Glass, Glazing, Blinds, Louvres & Solar Control 60 Heating, Ventilation & Air Conditioning 68 News & Developments 70 Floors, Walls & Ceilings 71 Roofing, Cladding & Insulation 25 Offsite Construction 34 Hotel, Sport & Leisure News Features in Focus Products in Focus Sector Reports 14 30 50 70 TSP Media

Park,

T:

Follow us @MySpecNews

Ltd, Grosvenor House, Central

Telford, TF2 9TW

01952 234000 E: info@tspmedia.co.uk www.tspmedia.co.uk

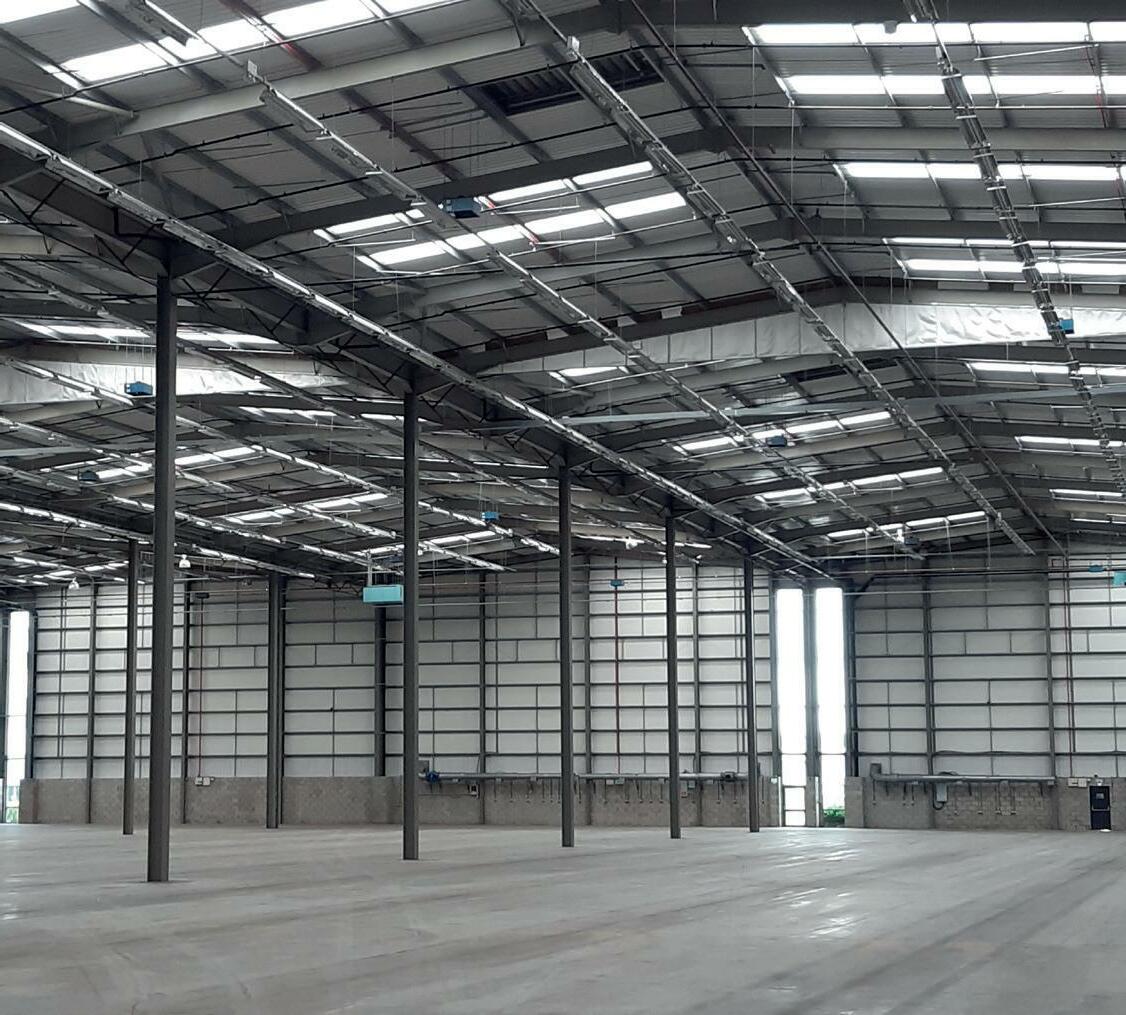

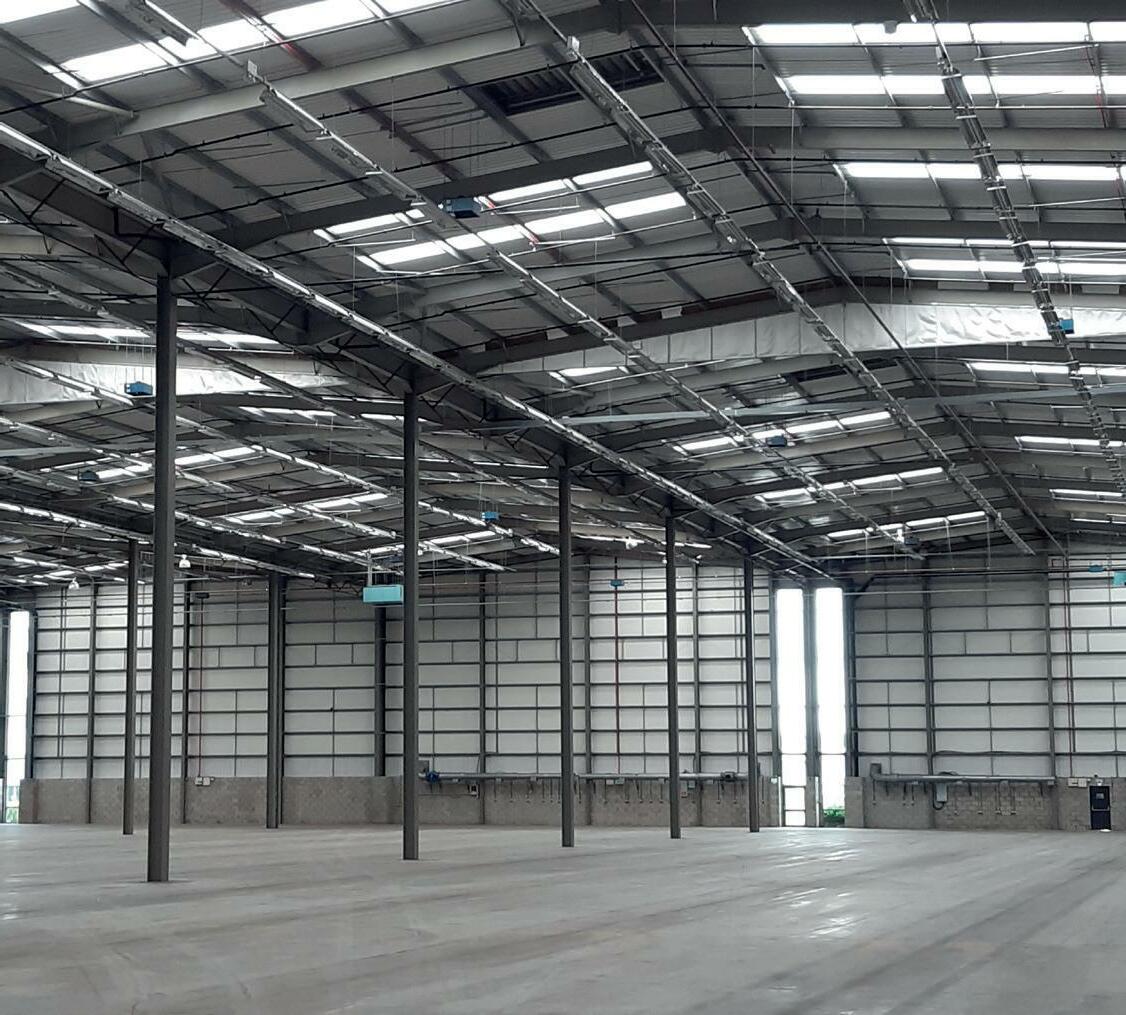

For over 100 years, Mira has created innovative, solution led products to meet the needs of specification. Products like the Mira HeatCaptureTM, that recovers heat from waste water to save energy and boost efficiency. Alongside product development, Mira has also invested in supply chain capability. The new distribution centre has been designed to respond to changes in demand quickly and efficiently, as the demand for products to meet the Future Home Standard targets increases. To find out more, turn to page 18. Enquiry - 47

Government urged to address policy gaps to achieve net zero

The Sustainable Energy Association report published today outlines the remaining policy gaps and steps the Government must take to achieve net zero by 2050.

The SEA welcomes the monumental shift in the UK Government’s focus, with Net Zero placed firmly on the policy agenda. It is a major step in the right direction. However, there are still numerous gaps that need to be addressed to help us realise this vision.

The Sustainable Energy Association (SEA) has released a new report outlining the remaining policy gaps and makes recommendations for what the Government should do to address them.

Jade Lewis, Chief Executive of the Sustainable Energy Association commented:

The SEA identifies four core areas of focus and makes several recommendations –highlighting what must be done to achieve the ambitious target of the UK becoming net zero by 2050 and delivering buildings fit for the future:

• Address the able to pay sector as this key stakeholder group is crucial to facilitate the movement away from a heavy reliance on government funding into an independent retrofit market which is selfsufficient and delivers at scale.

• Tackle the lack of consumer and supply chain knowledge & skills of low-carbon technologies compared to traditional fossil fuel heating systems. The government must ensure there is a competent workforce capable of designing, building , and retrofitting to

“The SEA is committed to eliminating fuel poverty and ensuring all homes are energy efficient, net zero-carbon, warm and healthy. As the first major country to pass net zero emissions law, the UK government has a unique opportunity to demonstrate how a nation can do it correctly.

“We would welcome collaborating with the Government and key industry stakeholders to develop the next phase of policy and help deliver homes and buildings fit for future generations.”

The Sustainable Energy Association (SEA) is a membership organisation made up of manufacturers, energy suppliers, housing providers, installers, innovators, and other organisations with expertise on energy in buildings. In a world of finite resources, the SEA exists to help create living and working spaces fit for future generations.

deliver energy efficient, net zero carbon, healthy homes, and buildings.

• The SEA advocates a fabric first, technology agnostic approach. Therefore, low-carbon technologies, and energy efficiency measures that meet the space and water heating demands of the building in question and lead to the right outcomes, should be supported by government schemes.

• The Government and Industry must work together to form a definitive National Retrofit Strategy, setting out the policies and programmes required to improve the energy efficiency of our buildings, with realistic timescales for implementation, and which places energy efficiency at the heart of the UK’s Net-Zero target.

Algeco secures £19.2m academy project

Algeco, formerly known as Elliott and a long-established brand in the European modular services and infrastructure industry, has won a new contract to build the £19.2m Laurence Calvert Academy Middleton Complex in Leeds.

The Department for Education (DfE) project was procured by Algeco through the Mod-C Secondary School Framework.

Work begins on site at the start of June 2022, with a planned completion date in August 2023. Algeco is acting as Principal Contractor to provide a full turnkey solution involving construction of a three-storey whole school block and associated external works.

It will be delivered by Algeco using its steel frame modular solution. A total of 192 modules will be supplied along with a hybrid build for the sports hall areas. The works involve construction of the whole school block and associated external works.

BAM has been appointed through the Department for Education’s high value framework to redevelop Fred Longworth High School in Tyldesley, in Wigan, Greater Manchester.

The £24m contract will see BAM create a three-storey teaching block, to be handed over in September 2023.

It will be Net Zero Carbon in Operation. BAM is utilising its in house expertise, taking on architecture, M&E, sustainability and fixtures and fittings responsibility thanks to its integrated capabilities from BAM Design,

while Hydrock is providing fire and acoustics, Nexus delivers ICT, and Dally Henderson Landscape.

The second phase involves the demolition of the majority of the existing school and construction of new sports pitches. This part of the project is due to be ready for spring 2024.

The project would increase the capacity of the school from 1,275 students to 1,350.

News

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

BAM confirmed for net zero school

6

Exterior Project Archway Tower Architect GRID Architects Dekton® Surface 3,000 m2 Façade Dekton Danae Natural Collection

Façade of Redeveloped Find more projects, technical info and inspiration at cosentino.com

Point Archway Tower 25 Year Warranty. Enquiry 48

Redefining Surfaces. Redefining Projects.

Vantage

The ultra-compact surface, Dekton® by Cosentino has been selected for use for the Vantage Point Archway Tower redevelopment project in London COSENTINO UK 01256 761229 / info.uk@cosentino.com / Follow Us: F T

TDUK moves to set skills agenda for timber construction

Timber Development UK (TDUK) has signed a strategic partnership with Edinburgh Napier University and the New Model Institute for Technology and Engineering (NMITE) to improve knowledge and skills in timber design and construction.

The partnership will see Edinburgh Napier University – a leading technical research institute for timber engineering and design – produce a written library of technical documents which will be made free to all TDUK members.

It is widely recognised that there is a ‘knowledge gap’ for specification of timber products among trainee architects, engineers and related studies.

To close this gap, TDUK and Edinburgh Napier University are working together to create a knowledge library consisting, from launch, of 150 reports authored by leading wood science and timber specialists.

The library will cover information about timber supply, design considerations and building techniques with the goal of providing architects, specifiers and engineers with all the information they need to put timber at the heart of projects. This will be a rolling contract which will see the library expand and develop each year with the aim to create the largest, most comprehensive technical timber information resource in the UK – if not the world!

In addition, the Knowledge Database will be used to underpin and inform a set of short practical courses being developed by NMITE’s Centre for Advanced Timber Technology (CATT) in partnership with TDUK.

The ‘Timber TED’ (Technology, Engineering & Design) courses will create comprehensive and flexible upskilling and reskilling training for modern methods of timber construction.

Learners will gain specialist timber construction knowledge and skills for the built environment, focusing on “better, faster and greener” delivery.

TDUK chief executive, Dave Hopkins explained: “With ESG pressures mounting in boardrooms, it is clear that increasing the use of timber in architecture and construction can provide a very positive contribution towards achieving our Net Zero goals.

“It is also my belief that the specifiers of the future will need a better understanding of wood and timber if they have any chance of hitting the ever more demanding carbon targets for construction.

“Our partnerships with Napier and NMITE will help set the timber skills agenda going forward and will provide the underpinning specification knowledge needed to achieve this.”

Transformation of Middlewood Locks to continue with £30m deal

Homes England, the Government’s housing and regeneration agency, has agreed a £30m loan to continue the transformation of Middlewood Locks in Salford.

The agreement with Middlewood Locks KLM, a partnership between Scarborough Group International and its joint-venture partners Metro Holdings and Hualing Group, will see 189 new homes built as the third phase of the 25-acre brownfield site.

Middlewood Locks is a significant regeneration project in Salford, being created over a number of phases. Once complete, it will deliver over 2,000 homes, 900,000 sq. ft of commercial space, including a hotel and leisure amenities set in a calm canal side environment with 4.5 acres of public realm and event space.

The Chartered Institute of Building (CIOB) has welcomed Michael Yam as its new President for 2022/23.

Malaysia-based Michael has over 35 years of experience in the construction, real estate, and corporate sector, not only in his home country but also in the UK, Australia, and South Africa. He has been a CIOB member since 1983.

He gave his first speech as President at CIOB’s annual Member’s Forum, which took place between 28 and 30 June, and was held virtually for the third successive year.

He spoke of his ambition to promote and improve sustainability in the built environment sector and the “gradual reset” needed to reach Net Zero commitments along with his belief that sustainability will be a “catalyst for greater innovation and new skills.”

Michael said: “I look forward to using my time as CIOB President as a platform to help bring about change to the sustainability agenda, along with our 47,000 global members who are well placed to be hugely influential on this important matter which will affect all our futures.”

Michael also intends to use his presidential year to support and further CIOB’s work to improve health, safety and wellbeing in the global construction industry, where there are vast differences in provisions across the world. He will also use his experience of working across the globe to promote CIOB and strengthen the links between its international hubs.

He added: “I believe that with understanding of the diverse cultures and histories of countries around the world, CIOB can lead the way in sharing valuable knowledge and harmonising best practice.”

Just a stone’s throw from Salford Central station and a short walk from Manchester’s Spinningfields business district, the site includes substantial public realm within the design, incorporating the attractive waterside setting of the restored Manchester, Bolton and Bury canal.

News To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

8

New CIOB President makes sustainable construction number one priority

Del Carmen: Celebrating thirty years of excellence

In 1992, SSQ became the first and, to this day, the only company to bring Del Carmen’s outstanding natural slate to the UK.

The stunning blue-black material is the result of millions of years of heat and pressure – and has the strength to take whatever nature throws at it. That’s why, even thirty years on, when architects, contractors and homeowners want to crown a property in style, they choose Del Carmen.

30 years with

Want to find out more?

www.ssqgroup.com

Speak to SSQ. Call 020 8961 7725 or email info@ssq.co.uk Enquiry 49

EN 10169 – What does it mean and why does it matter?

The long-awaited changes to the EN 10169 standard are finally live and represent a major change for the coated steel industry. Ultimately, these amendments are good news for architects and specifiers, helping them to better differentiate between system performance and be more discerning about the pre-finished steel products they specify on future projects. With the ongoing emphasis on sustainability, architects will naturally want to be using building products that are sure to stand the test of time and the new EN 10169 standard feeds into this idea.

The first change to EN 10169 relates to corrosion resistance. When it comes to measuring a pre-finished steel product’s corrosion resistance, RC5 used to be the highest classification achievable, requiring test evidence of two years natural weathering. Now, the amended standard includes a RC5+ classification. To achieve this, pre-finished steel products have to undergo four years of natural weathering testing at a C5 exposure site with satisfying results – i.e. they must resist blistering, coating damage and edge peel to less than 2mm.

With the requirement for double the length of testing, the new RC5+ classification really

puts products to the test. By specifying products that have achieved this higher classification, architects and specifiers can be truly confident in the product’s performance, knowing that it will deliver on both excellent durability and longevity.

The other classification that has changed relates to UV resistance, with the introduction of a new Ruv5 classification – replacing Ruv4 as the highest performing. To achieve Ruv5, products have to undergo a minimum of four years weathering at UV exposure site, with satisfying colour and gloss retention levels.

UV resistance should always be a key consideration for architects and specifiers on any project where aesthetics is key. Thanks to many manufacturing developments and innovations in the pre-finished steel sector, architects can now benefit from a wide array of different colours and finishes, all helping to create a truly beautiful building. For example, Tata Steel’s Colorcoat Prisma® range has 5 collections with different effects containing over 40 different colours, including a selection of natural metal colours. As such, maintaining this aesthetic should be a priority and selecting products with the new Ruv5 classification is one way of doing so.

While the amended EN 10169 standard is undoubtedly valuable in helping architects and specifiers choose the right product for their project and better differentiate between the performance characteristics of products available on the market, there are also other factors to consider.

The first is the duration of the test period manufacturers subject their products too. EN 10169 and the new RC5+ and Ruv5 classifications dictate a test period of four years, which is already double of what was previously required. However, by looking for manufacturers who have test evidence stretching beyond this – up to five, eight or even ten years – you can be provided with even more confidence in the product’s performance.

The guarantee period promised by a manufacturer is another means of judging a product, providing additional peace of mind.

Tata Steel’s industry-leading Confidex® Guarantee offers up to 40 years protection on its Colorcoat Prisma® and Colorcoat HPS200 Ultra® pre-finished steel products, meaning that you can be confident the products will continue looking great for years to come.

News To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card 10

The amendments to the EN 10169 standard have been one of the biggest changes witnessed by the pre-finished steel market for many years, with an increased emphasis placed on corrosion and UV resistance. Here, Dr Peter Barker, Manager New Product Development at Tata Steel, explores the new standards.

CERTAINTY BUILDING BETTER

Enquiry 50

The black & white building pushes the boundaries of sustainable architecture

Workspace specialist TOG (The Office Group) marks the beginning of a new chapter with the launch of The Black & White Building in Shoreditch, designed by Waugh Thistleton architects.

Known for its history of sensitive and considered retrofitting and refurbishment, and its track record of transforming existing buildings into contemporary design-led ‘Work Spaces’, TOG has broken with tradition – The Black & White Building is the first project that the company has chosen to build from scratch.

Constructed in partnership with sustainable design experts Waugh Thistleton Architects, The Black & White Building is, from the ground up, one of the tallest mass-timber office buildings ever built in central London, standing 17.8 metres above the Shoreditch streetscape. Created using renewable materials and highly innovative construction methods, it is both a landmark in sustainable architecture and a powerful statement of TOG’s commitment to ecologically progressive development.

Although both the building’s exterior and interiors are visually beautiful, nothing is purely decorative. Every element of the building serves a purpose, from the timber louvres that envelope the façade, which are angled to optimise light and heat, to the furniture consciously designed to encourage social connectivity. In The Black & White Building, TOG has delivered a perfect balance of form and function – and an industry benchmark for sustainable commercial construction.

Charlie Green, co-Founder and co-CEO of TOG commented: “The Black and White Building

Project: Black & White Building

Architects: TOG & Waugh Thistleton Suppliers: Pollmeier; Hybrid Structures; CTI; Opera

is

>>

Project To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card 12

set to be Central London’s tallest mass timber office building.

Enquiry 51

>> “Alongside Waugh Thistleton, we have worked to reduce embodied carbon as much as possible, delivering a building that represents what future workspaces should be.

“It has never been more important to develop techniques and approaches that deliver buildings for a better world. Innovative construction processes and sustainable materials, like those employed here, will form a central part of the sector’s journey to net zero over the coming years.”

The Black & White Building stands on one of London’s first ultra-low emission thoroughfares – Rivington Street in Shoreditch – a stroll away from the tech hub of Old Street and Silicon Roundabout. The site was previously home to an 11,000 sq ft building that TOG had painted black and white, giving its name. This provided workspace for several small creative businesses in the area, but the footplate of the building was ultimately too restrictive to meet local demand, and the fabric of the building would not accommodate a retrofit to expand the space.

Having rejected a conventional new-build design for the site, TOG co-founders and co-CEOs Olly Olsen and Charlie Green were determined that if they were to build from scratch, it should be using the most advanced, meaningfully sustainable construction methods and materials available. It was while exploring such methods that they encountered Waugh Thistleton Architects’ Andrew Waugh presenting a timber-construction scheme during an eco tour of Hackney – and realised that their own vision and the architect’s were in perfect alignment.

To realise their shared vision, TOG and Waugh Thistleton Architects turned to the innovative materials of cross-laminated timber (CLT) and laminated veneer lumber (LVL) – high-performance wooden materials that are rapidly renewable, highly durable, easily recyclable and less waste-generating than more common building materials such as iron, steel and cement. This means that The Black & White Building creates 37% less embodied carbon than a comparable concrete structure, and serves as a longterm carbon store for 1,014.7 tonnes of CO2

equivalent (55% of the building’s total) in the timber structure.

A total of 1,774 trees have been used to make the core structure – a combination of beech (227 trees) and pine and spruce (1,547), harvested from certified, sustainable forests in Austria and Germany. For a sustainable forest to regenerate the quantity of wood used in the construction of The Black & White Building would take 137 minutes – in other words, you can grow enough to construct a building in less time than it takes to bake a loaf of bread.

CLT is also significantly lighter and easier to transport than conventional building materials such as concrete and steel, which means that fewer deliveries are required to bring the necessary quantities to the construction site. This not only represents a carbon-reduction in terms of logistics, it also makes building in dense urban areas a more efficient, less disruptive process.

Project To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

14

We have worked to reduce embodied carbon as much as possible, delivering a building that represents what future workspaces should be

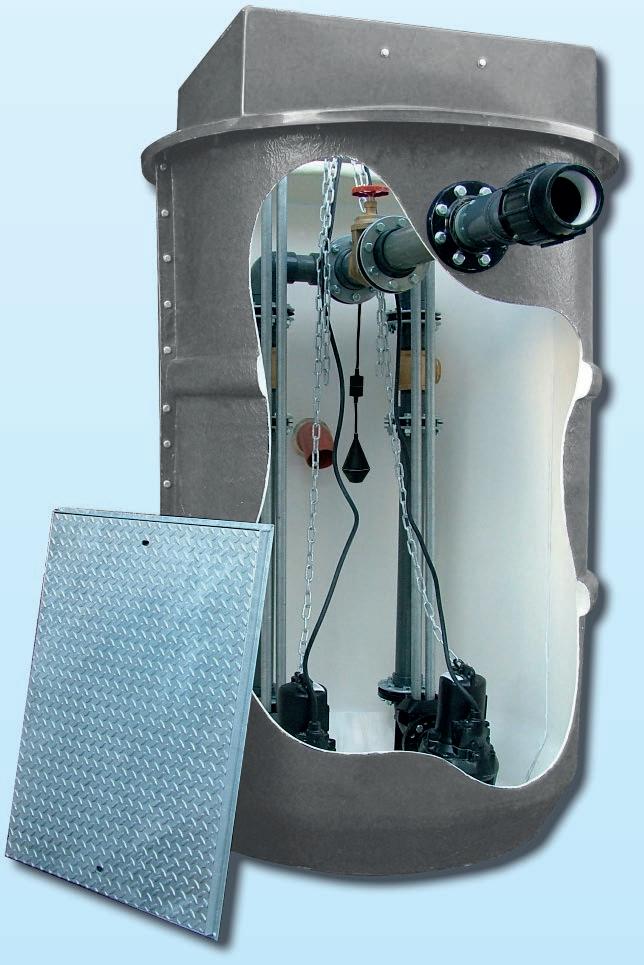

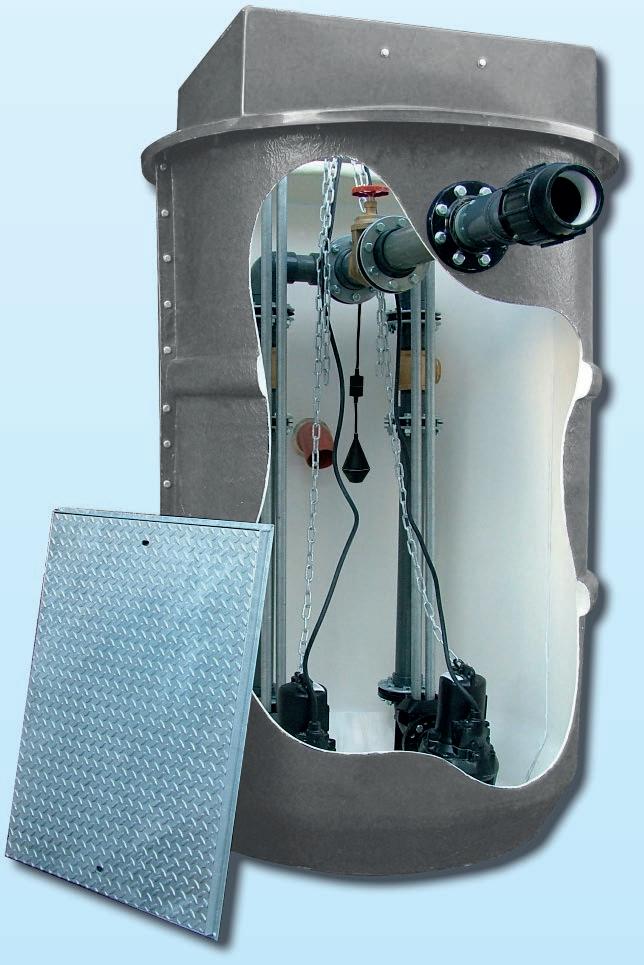

Project 15 Enquiry 52 Enquiry 53 Design 209-22 Brand quality for underground and collective garages 01530 516868 doorsales.lei@hormann.co.uk ● Underground garage rolling shutter as an external rolling shutter for tight spaces ● NEW: Sectional doors with full passage height with 200 mm required headroom* ● Non-protruding up-and-over and sliding doors for long-lasting, quiet door travel * For track application L under certain circumstances POWERED BY www.pumptechnology.co.uk Aldermaston, Berks, RG7 4PW Below Ground Pumping Stations 0118 9821 555 PROVEN PUMPING SYSTEMS RIGHT FIRST TIME! Experienced Support Team - Fast Response Specification - Right First Time Product Support - Nationwide Self-contained Shower Sump Pump Under Sink Wastewater Pumping Systems Floor Mounted Lifting Stations www.jung-pumps.co.uk

Rendered Walls? Cavity Trays Ltd responds with a solution to conflicting considerations

Should rendered walls have weeps over openings or not?

1.

The difference between an externally rendered elevation and one of fair faced masonry is there are no visible perp joints or bedding courses in which to incorporate (and thus minimise the appearance of) the weeps. Weeps in a rendered elevation can create a rather punctuated appearance.

Omitting weeps completely removes the visual interruptions, but assumes the entire elevation is relatively waterproof throughout its total surface area including alternative surface finishes and features and wherever they abut. It also assumes the rendered surface will not suffer cracks, fissures or movement ever over its intended 60 years+ lifetime.

It is more realistic to construct on the basis a rendered finish will minimise wind-driven rain ingress rather than eliminate it. Wind-driven rains will eventually penetrate - it is to what extent that will be determined over time.

Many factors affect a rendered elevation; Height – is there an extensive absorption area above the opening? Is the total elevation rendered or are other dissimilar materials and finishes present?

Is the elevation facing, exposed or elevated to wind-driven rain? Are there features that are not rendered – sills, lintels, string courses, quoins, verges? Are render cracks or fissures present anywhere? What type of render is present, how thick is it and has it been competently applied?

A rendered wall will reduce water penetration but it cannot be relied upon to prevent it. Behaviour will vary from building to building and site to site. Providing a draining escape route makes sense in preventing water initiating visual and eventual fabric deterioration.

Cavity Trays Ltd offers an alternative approach to manage accumulating water that penetrates a rendered cavity wall; The Type C + SD option consists of a preformed Type C Cavitray that protects the opening head, with self-draining outlets incorporated within its base.

These permit arrested water to evacuate via tubes which terminate not on the elevation face, but either side of the opening in the reveal, just forward of the frame. Conventional visible wall weeps are eliminated.

The functionality of the Type C + SD option might be compared with the accepted practice of having an overflow pipe from a bath, a basin, a WC cistern or a water tank – these outlets exist to function should and when the need arise. By so doing, they prevent damage visually and structurally. Fair faced-masonry has perp joints and bed courses in which conventional weeps can hide. There is now a way forward for the rendered wall, that can improve the appearance of the elevation and address water evacuation whenever it occurs. Type C + SD information packs available from Cavity Trays Ltd of Yeovil upon request.

Photo captions:

1. Omitting stop ends and omitting weeps allows end discharge into the reveal, behind the rendering coat

2. Arrested water trapped between stop ends across the head because no weep holes are present.

3. Type C + SD provides a discharge route in the reveal observing NHBC 6.11.19 (Appearance) that consideration should be given to detailing that will avoid obvious staining (e.g. the positioning of discharge pipes).

Cavity Trays Ltd – Enquiry 54

News

make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card 16

To

2. 3.

Enquiry 55

Mira helps to create the house of the future

The UK’s race to net zero by 2050 continues and with the built environment accounting for 40% of the nation’s carbon footprint, the housing sector faces a significant design and innovation challenge.

Supporting the housing sectors journey to net zero, shower manufacturer Mira Showers is proudly working with the University of Salford and Bellway Homes on the unique Future House @ Energy House 2.0 (EH 2.0) project. EH 2.0 is the largest test and research facility of its kind and is focussed on developing low carbon technologies to accelerate the progress towards net zero housing in the UK.

The environmental chambers within EH 2.0 contain houses under controlled conditions. The academic and technical teams can recreate a wide variety of weather conditions, with temperatures ranging between -20°C and +40°C and simulations of wind, rain, snow and solar radiation put in place to test the energy performance of numerous technologies under a variety of climatic conditions.

Mira Showers has spent the last 100 years creating innovative, solution-led products to meet the demands of specifiers, proudly demonstrating the brand’s commitment to sustainability. Committed to supporting specifiers and new property developers in their bid to reduce their carbon footprint, Mira Showers has provided both existing technologies and yet-to-be-released innovations to the EH 2.0 project, including Mira HeatCapture™.

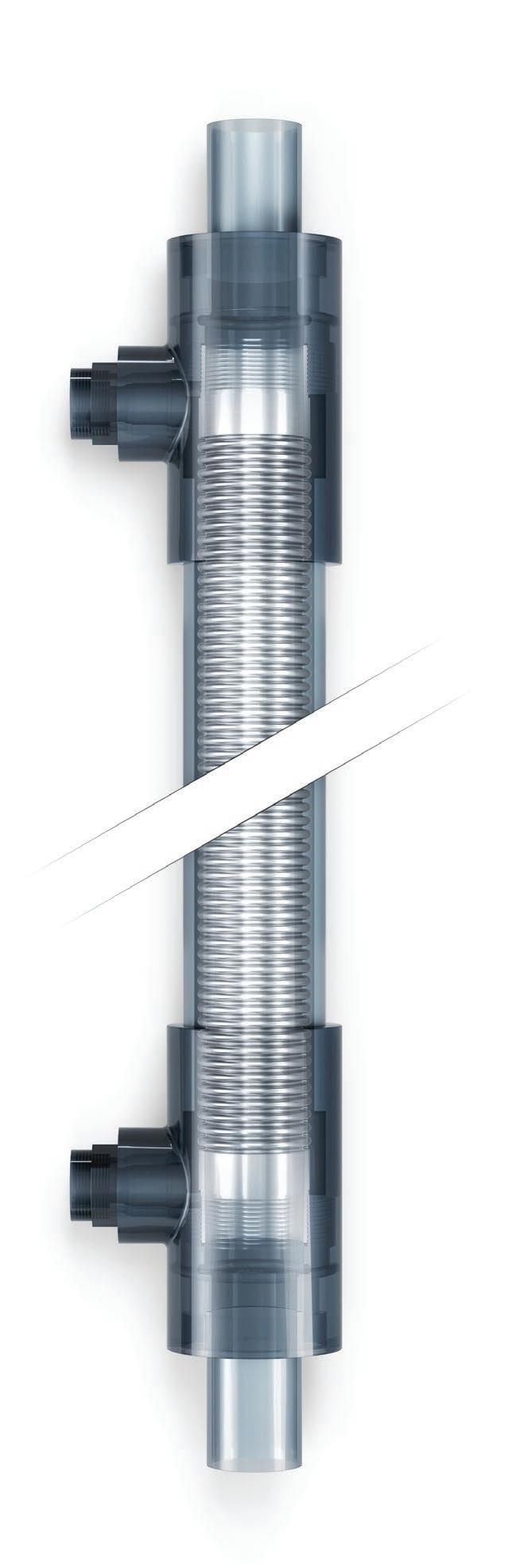

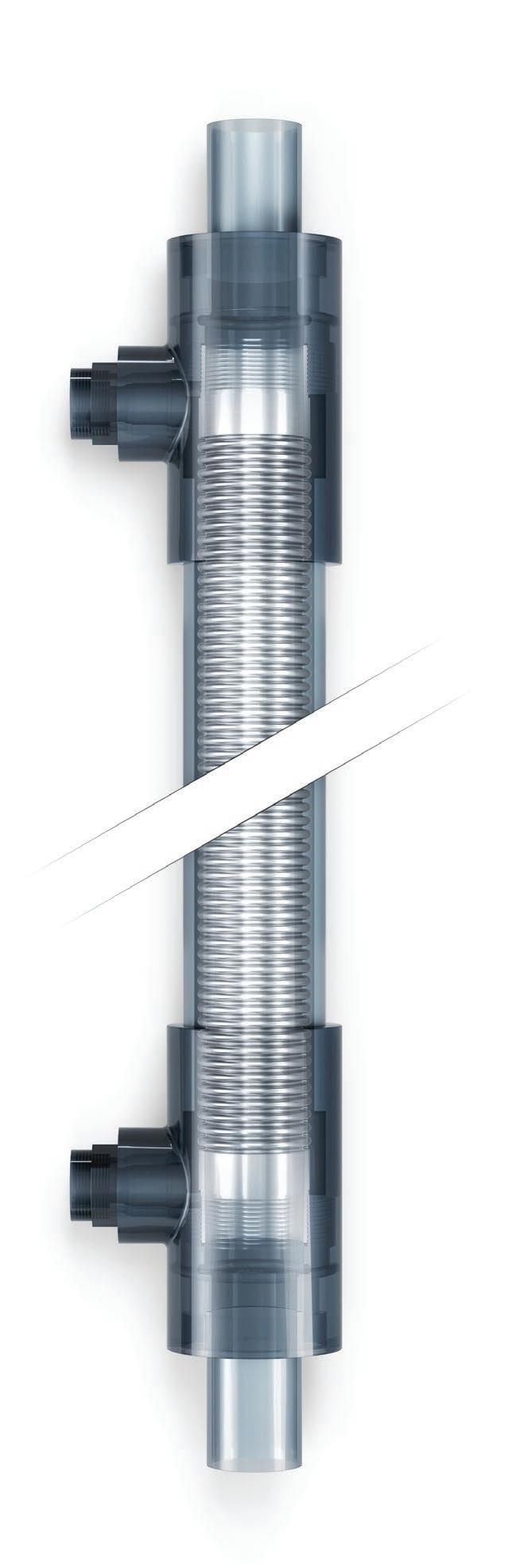

Mira HeatCapture™ is an energy-saving system that utilises the heat from bathroom wastewater to increase the efficiency of a domestic heating system, so that the boiler applies less energy to heat water as the required heat rise has been reduced.

With hot water demand being added to the Standard Assessment Procedure (SAP) regulations for 2025, Mira HeatCapture™ helps specifiers and new property developers ensure building projects are in-line with regulations from the onset.

In fact, the product will increase the overall hot water efficiency of a new home by up to 10%!

Designed with a unique double wall stainless steel exchanger, Mira HeatCapture™ has a ridged stainless-steel core that ensures water exiting the shower waste or bath clings to the side of the tube to transfer its heat to the cool incoming mains. Conforming to EN1717, the steel heat exchanger is perfect for new build applications.

The technology not only provides incredible value to its SAP points ratio but offers KIWA-approved efficiencies of up to 64%, too. Plus, once installed, it requires no further maintenance by the homeowner – meaning they can fit and forget whilst gaining all the benefits of the efficient system.

Improving the efficiency of new homes, Mira HeatCapture™ has been designed to provide specifiers and developers the opportunity to offer an effective and sustainable wastewater heat recovery system. Tested and certified by WRAS, KIWA, BRE as well as being SAP registered, it has undergone rigorous testing and validation to ensure its performance, quality and longevity meet the high standards the brand has built its reputation upon.

Mira HeatCapture™ along with other Mira product innovations are currently being installed into the EH 2.0 facility ahead of testing and research programmes taking place, which are expected to continue until Spring 2023. These programmes will spearhead future technologies for the housing sector and help to inform the development of Mira’s new product pipeline.

For further information, please visit the Mira Showers website: www.mirashowers.co.uk/heatcapture

Front Cover Spotlight 18

Mira – Enquiry 56

Simple. Innovative. Effective. www.mirashowers.co.uk/heatcapture Increase your SAP score with the Mira HeatCaptureTM. Introducing Mira HeatCaptureTM a waste water heat recovery system to help you obtain your sustainability targets.

0.007 W/m•K Quantum® PLUS+ U-value req. W/m2 K Quantum ® (mm) Extruded (mm) Expanded (mm) 0.15 220 235 0.14 70 230 255 0.13 70 250 275 0.12 75 270 295 0.11 80 290 320 0.10 100 320 355 Enquiry 57

Divine insulation for repurposed Glasgow Church

Castlehead Church, an imposing, stone built Presbyterian Church in Paisley, SW Scotland which dates back to the late 18th century, had lain empty since its closure in 2010.

Local historic records link the Church to both Robert Tannahill, a popular poet from Paisley and contemporary of Scotland’s National Poet Robert Burns, and former US President, Ronald Regan who, with his Wife Nancy, visited the Church in 1991 to view the grave of his great-great grandparents who are buried there.

Glasgow based property developer, Cleveden Homes Ltd recognised the potential of the now empty building and in 2017, submitted plans to convert the site into luxury apartments. Alex McGurk of Cleveden takes up the story.

“The basic shell of the building was still in good shape despite being well over 200 years old. It’s a rectangular plan gable hall structure with rubble walls and ashlar dressings. The fenestration is impressive with an imposing door to the main gable, flanked by tall windows and five tall windows to both of the side walls,” said Alex.

Cold and draughty

As with similar buildings constructed centuries ago, the builders of old thought little of how to prevent heat loss through both walls and roof of the building. Alex continues. “Churches throughout the country have a reputation for being cold and draughty places and Castlehead was no different. Our top priority was making the structure as airtight as we could and brought up to a high standard of thermal insulation”.

Cleveden brought in insulation specialists

JSJ Foam Insulation of Eaglesham, Glasgow for guidance. Jim Shearer of JSJ recommended insulating the entire inner surfaces of the building with H2Foam Lite, a breathable spray foam insulation system from Huntsman Building Solutions [HBS].

HBS H2Foam Lite, open-cell insulation

H2Foam Lite is a high-performance spray applied foam insulation, originally developed in Canada to cope with their severe winter conditions and now manufactured at Huntsman’s facilities in Kings Lynn. According to Jim Shearer, the system is now widely used in Scotland and the rest of the UK in both commercial and residential buildings.

News 22

A redundant Glasgow church with historic connections to former US President Ronald Regan has been given a comprehensive makeover with the help of high-performance spray foam insulation from Huntsman Building Solutions.

1.

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

2. 3. 4.

6.

H2Foam Lite is a flexible “open cell” material with an elastic, yielding texture. It provides outstanding levels of thermal insulation yet allows the building to breath naturally, resisting internal condensation and at the same time eliminating air leakage – more commonly known as draughts.

“Up to 40% of a buildings heat loss can be attributed to air leakage,” said Shearer, “so it’s vital that reducing air leakage is included in any programme of measures to improve a building’s thermal performance.”

H2Foam Lite is installed using a pressurised gun system. Foams are applied as a two-component mixture that come together forming a foam that expands 100-fold within seconds, closing off all gaps, service holes and hard to get to spaces that conventional insulation materials fail to reach.

Low environmental impact

Unlike the polyurethane foams of 20 years ago, modern spray foams such as H2Foam Lite uses water as the blowing agent.

This means that the reaction between the two components produces a small amount of CO 2 which causes the foam to expand. Cells of the foam burst and the CO 2 is replaced by air.

From an environmental perspective, H2 Foam Lite has a Global Warming Potential [GWP] of 1 and an Ozone Depletion Potential of 0 [Zero].

Insulation was applied to the inside of all external walls as well as the roof structure. Walls were sprayed to a thickness of 165mm between timber studwork and to a thickness of 320mm within the pitched roof.

Studwork dividing walls within the building were also insulated to provide a high level of both thermal and acoustic insulation.

Spray foam converts Cleveden has created a development of seven luxury 1, 2 & 3 bed apartments over four floors with ground floor parking and lift access to floors above. There is approximately 1000sqm of floor area overall.

Commenting on the use of spray foam insulation, Alex McGurk said; “Speed of installation and minimal waste were key factors in our decision to use spray foam.

"That and the overall lower cost of spray foam, because we didn’t need to commit trades to the time-consuming process of cutting and fitting rigid board type insulation really clinched it. We are spray-foam converts!”

Cleveden are progressing well with the Castlehead Church repurposing project and anticipate completing in winter 2022.

Thanks go to the following in the preparation of this article: Cleveden Homes Ltd www.cleveden-homes-limited.co.uk Also to JSJ Foam Insulation www.jsjfoaminsulation.co.uk

For more information on Huntsman Building Solutions visit: www.huntsmanbuildingsolutions.co.uk

For more information about HBS H2Foam Lite products: https://huntsmanbuildingsolutions.com/ en-GB/products/open-cell-insulation

Photo captions:

1. Castlehead Church, Paisley, had lain empty since its closure in 2010.

2. H2Foam Lite, a breathable spray foam insulation system from Huntsman Building Solutions.

3. The entire church interior was stripped out prior to repurposing.

4. Layout of the proposed floorplan comes together.

5. External walls were lined with timber studwork to accept insulation

6. Insulation was applied to the inside of all external walls as well as the roof structure.

News 23

– Enquiry 58 5.

Huntsman Building Solutions

Sustainable Restoration with Nordic Copper

Although considered to be a thoroughly modern material offering limitless possibilities for contemporary architectural design, copper is also – of course – one of our oldest building materials, traditionally covering the domes and spires of city skylines. Nordic Copper Special Patina has been developed specifically to help with repairs, restoration or extensions to historic copper buildings.

Copper’s unique architectural qualities are defined by its naturally changing patina – which cannot be successfully replicated using other materials with surface coatings. Within a few days of exposure to the atmosphere, a copper surface begins to oxidise, changing from the ‘bright’ mill finish to a chestnut brown, which gradually darkens over several years to a chocolate brown. Continued weathering can then result in development of the distinctive green patina –or blue in coastal locations.

Mineral Based Pre-patination

All these naturally developing surfaces can be provided straightaway with the ‘Nordic Copper’ range. The factory processes involved are generally similar to those taking place over time in the environment utilising copper mineral compounds, not alien chemical processes. The surfaces form an integral part of the copper, generally continuing to change over time, and are not lifeless coatings or paint.

The extensive Nordic Blue, Nordic Green and Nordic Turquoise ranges have been

developed with properties and colours based on the same brochantite mineralogy found in natural patinas all over the world. As well as the solid patina colours, ‘Living’ surfaces are available for each with other intensities of patina flecks revealing some of the dark oxidised background material.

Matching Original Copper

With Nordic Copper Special Patina, unique pre-patinated copper material can be produced to match naturally patinated copper, especially for historic buildings. An original sample from the building is used but initial development can be started with the help of a Special Patina Tool (which can be downloaded from www.nordiccopper.com and printed). The card is simply placed on the original copper surface and photographed. Once a specific patina mixture has been established and product supplied, the project

mix is retained in case of follow-up orders. Aurubis can also recycle the original copper removed from a project. Copper’s ability to be recycled repeatedly, without any loss in performance, is an important sustainability benefit. All Nordic Copper architectural products are manufactured using 100% recycled raw-material and Aurubis is part of the world’s leading integrated copper group and largest copper recycler. For more information and to read project stories visit: www.nordiccopper.com or email: g.bell@aurubis.com

Aurubis – Enquiry 59

News

– Go

or

Free Reader Enquiry Card 24

To make an enquiry

online: www.enquire2.com

post our:

Offsite project focus Social housing development Glidevale Protect provides a full range of roofing, ventilation and construction products as part of a major new social housing development in Belfast, which is taking a fabric first approach to building healthy, sustainable homes. Read more on page 28 www.glidevaleprotect.com Energy efficiency, airtightness, ventilation and condensation control solutions ideally suited to offsite construction projects. Enquiry ? Offsite Construction Enquiry 60

How roofing industry leaders can help address specifiers’ insistence on more extensive fire testing

As architects, clients, building control and other specifiers are rightly insisting on fire test certificates that directly reflect the exact roofing system being installed, Dean Grady, Senior Product Engineer at Sika, discusses the role of EXAP testing and how industry leaders can help.

Without question, today’s roofing industry is experiencing a greater focus on the fire performance of roofing systems than ever before. While events of recent years have heavily influenced this - and, in part, clients, building owners and insurers have their own criteria to be satisfied - changes in regulations have played a major role.

These regulations, while extensive, are reasonably clear, stating that, in general, roof systems must be classified to BS EN 13501-5 BROOF(t4); the exception being that ‘attachments’ on buildings over a certain height (18m in England and Wales and 11m in Scotland), meaning the insulation must also be non-combustible. Furthermore, there must not be any ‘views’ offered by manufacturers as to the performance of their products in lieu of testing.

As those within the industry have been leaning on manufacturers to demonstrate performance, rather than make their own judgement or interpretation, historically, manufacturers have tended to offer a range of fire tests considered representative of performance.

Historically, in the absence of directly representative test data, there has been a tendency to supplement limited test data that is perceived to be representative and supplement this with opinion and experience.

However, at Sika we fully support the redundancy of this approach and move towards a purely evidence-based demonstration of fire performance only, which has been independently verified by an appropriate accredited third party.

We have seen for a while now that architects, clients, building control and other specifiers are increasingly insisting on fire test certificates that cover the exact system being installed, becoming more commonplace - and moreover it’s something the regulations ask for too.

While it is clear the market is becoming acutely aware of fire safety and that specifiers are looking to industry leaders for help, the problem for manufacturers is how to test such a large range of possible system permutations, taking into account numerous substrate types, air and vapour control layers (AVCLs), insulation types and thicknesses and waterproofing membrane types and thicknesses - the variations are almost endless, as no two projects are ever exactly the same.

Offsite Construction 26 To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

1. 2.

Sika already had a large body of test data available, which has been a huge advantage in what has been a mammoth undertaking spanning more than two years.

3.

Thankfully, the industry is in consultation through its trade bodies and associations to find a fair way forward and establish a simplified and unified approach. However, with issues such as this involving collective agreement between the industry and regulatory bodies often taking a substantial amount of time, Sika has opted to act ahead of this.

Uncovering the role of EXAP

Based on our own experience of what was being requested by way of fire test evidence, while also consulting with accredited fire test houses such as Warringtonfire, Sika embarked on a project that has seen a substantial amount of time, finance and resource invested in a solution that covers ranges of system permutations.

With tests and test data extrapolations only able to be done by accredited fire test houses, it became clear that there was already an established and recognised solution to cover the myriad of roofing systems that Sika offers. Fire tests on individual roofs/roof coverings are now carried out in accordance with CEN/TS1187, the results from this testing are then classified in accordance with EN13501-5.

CEN/TS 16459 External fire exposure of roofs and roof coverings - Extended applications of test results from CEN/TS 1187 provides bodies like Warringtonfire with methodology or ‘rules’ for optimising the number of tests required to cover the maximum field of application. This methodology is what’s commonly termed an ‘EXAP’ – Extended Application, while CEN/TS 16459 provides the means to classify a range of permutations to EN13501-5.

Far from an easy way out of testing, the process is demanding because it still involves physical testing to CEN/TS1187 and of course this must still be passed. However, it does allow for tests to be done in increments and to then cover the range in between. Sika already had a large body of test data available, which has been a huge advantage in what has been a mammoth undertaking spanning more than two years.

Sika Sarnafil single ply and beyond In October 2021, we were delighted to announce that Sika had completed Extended Application Assessments, testing to CEN/TS 1187:2012 Test method 4 for the entire Sika Sarnafil range of PVC single ply membranes. Subsequently, the most common Sika Sarnafil roof systems are now all classified under BS EN 13501-5 as BROOF(t4).

This covers every membrane type, AVCL, thickness of PIR insulation 50mm and beyond, up to a 70-degree pitch and on any structural substrate.

With Sika Sarnafil roof systems classified as BROOF(t4), we’re able to demonstrate and facilitate regulatory compliance for fire safety and satisfy current market demand.

Having this comprehensive BROOF(t4) classification - which indicates the highest external fire performance for roofs - means that specifiers and other stakeholders can use Sika Sarnafil on their roofing projects with a very high degree of confidence, assured that they’re complying with fire regulations.

Working with an accredited, independent fire test house (the only people who are permitted to undertake any degree of desktop/extrapolation studies now) also clearly removes the ability for anyone else to interpret or extrapolate the fire test data that may have been practised in the past.

Not only is it a clear way forward in terms of mitigating roof fire risk, but it is also a great step towards helping support those with the heavy responsibility of ensuring people’s safety by increasing the confidence and reassurance specifiers are looking for.

Continuing to strengthen Sika’s position as an expert and leader in testing and compliance, we now have plans to extend the initiative across the entire Sika roofing range, starting first with liquid-applied membranes and Sikabit bituminous membranes.

If you would like to find out more about Sika’s roofing solutions and services, call 01707 394444, email enquiries@uk.sika.com or visit www.sika.co.uk/roofing.

Image captions:

1. Dean Grady, senior product engineer at Sika

2. Sika had completed Extended Application Assessments, testing to CEN/TS 1187:2012 Test method 4 for the entire Sika Sarnafil range of PVC single ply membranes

3. Sarnafil membrane was used on All Saints Primary School, Hull

Sika Sarnafil – Enquiry 61

Offsite Construction 27 To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

Glidevale Protect delivers total wall, roofing and ventilation package for Belfast housing development

Leading building materials manufacturer, Glidevale Protect, has provided a full range of wall, roofing, ventilation and other construction products as part of a major new social housing development in Belfast, built offsite using a timber frame panellised system and delivering a scheme which is taking a fabric first approach to create healthy, sustainable homes.

One of the largest mixed tenure developments to be constructed in Northern Ireland to date, the new scheme for a leading social housing provider includes 244 homes, which are a mix of social and affordable housing, a community facility, a linear park and a children’s play park.

Working with main contractor Kevin Watson Group, specialist offsite manufacturers and installers of the timber frame panels Leadon Timber Frame and established Belfast-based roofing subcontractor Prentice Roofing, Glidevale Protect delivered a full portfolio of whole house solutions, ensuring thermal efficiency, condensation control, airtightness and ventilation.

All the external timber frame walls of the homes were fitted with Protect TF200 Thermo, a market-leading, low emissivity, insulating and reflective wall membrane, providing enhanced aged thermal resistance to improve energy efficiency and the perfect example of a fabric first approach in action. The non-reflective external breather membrane, Protect TF200, was used on spandrel panels to provide weather protection during the construction as well as helping to avoid interstitial condensation risk within the timber frame panel.

Glidevale Protect’s construction membranes were installed offsite in Leadon Timber Frame’s factory with the units then being craned and installed onto site to create the homes.

Glidevale Protect roofing products were also used on the build, including the Protect VP300 vapour permeable roofing underlay which was specified to provide watertightness and weather protection with its wind uplift resistance creating a second line of defence to protect the homes from the elements.

This was teamed with the universal dry fix ventilated ridge and hip system, Protect Fulmetal RediRoll, to provide a full cold roof solution of condensation control and provision of ventilation to the roofspace. Fascia vents, eaves skirts, rafter rolls, as well as tile ventilation and ridge ventilation products were also installed, designed to bring natural ventilation into each building and ensure the correct balance of ventilation and airtightness was achieved.

Completing the project were Glidevale cavity trays and airbricks as well as loft access hatches, which have been designed and engineered to meet the energy conservation and air leakage requirements of Building Regulations (Approved Documents L and C) with integral seals to significantly reduce water vapour migration into the loft space, thereby reducing condensation risk.

Cornelius Ward, director at Kevin Watson Group said: “In order to deliver the highest quality standards to meet client’s expectations, we like to collaborate with

supply chain partners who can ensure our sub-contractors are provided with top performing building materials using a fabric first approach.

“Glidevale Protect’s wide breadth of solutions used on this development meant full peace of mind during the construction process, helping to create energy efficient and healthy homes.”

For more information on Glidevale Protect, please visit www.glidevaleprotect.com, email info@glidevaleprotect.com or call +44 (0)161 905 5700. Keep up to date with our latest news by following us on LinkedIn.

Glidevale Protect – Enquiry 62

Offsite Construction 28 To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

Offsite airtightness for zero carbon homes

In a move to address the housing supply shortage, developers turning to offsite construction are installing the Wraptite air barrier system as an essential component in controlling and reducing air leakage while delivering effective temporary weather protection.

Without the correct air barrier protection, the problem of air leakage through cracks, gaps, holes, and improperly sealed elements such as doors and windows causes a significant reduction in the performance of even well thermally insulated building envelopes. With the increasing requirements and emphasis on thermal insulation, the proportion of energy lost through air leakage has become more evident. However, thermal insulation will be rendered ineffective unless the airtightness of the structure is addressed. Air leakage dramatically reduces the effect of thermal insulation and must therefore be a critical focus to improve energy efficiency within houses. In addition, energy-efficient heating systems will be ineffective if warm air can escape the building and cold air can seep in.

External vs Internal Air Barrier

The two main ways to achieve airtightness in the building envelope are internally or externally (“inside or outside the services zone’.) In offsite manufacture, the use of traditional internal air barriers can be more complex and costly to install due to the need to accommodate building services such as electrical, lighting, heating, and drainage systems. The internal air barrier is only as good as its installation. If all the service penetrations are not adequately sealed, performance will be compromised.

By moving the air barrier to the external side of the structural frame, external air barrier systems such as Wraptite from A. Proctor Group allow for an almost penetration-free airtight layer that can be installed faster and more robustly. Far simpler than internal options, an external air barrier system like Wraptite will maintain the envelope’s integrity, with fewer building services and structural penetrations to be sealed, and less room for error.

Simplifying airtightness

The traditional forms of VCLs and airtightness membranes will often require mechanical fixing.

The self-adhered nature of Wraptite allows for a fast and straightforward installation process, minimising the use of additional sealants and tapes and requiring no specialist contractors to achieve a robust result.

This one-step solution provides both a damage-resistant air barrier layer and effective secondary weather protection in one installation process, allowing a wind and watertight envelope to be achieved more quickly than traditional methods.

Wraptite chosen for zero carbon homes offsite development

The Wraptite external air barrier system has been installed on an exciting low energy homes offsite project for developer Osco Homes. Commissioned by Kirklees Council, the site will demonstrate how high quality, energy-efficient housing can be achieved using offsite construction. The bungalows are designed to be light, spacious, and desirable but must also mitigate fuel poverty and provide a safe and healthy environment where residents can live.

The superior airtightness performance of the Wraptite membrane from the A. Proctor Group is the perfect solution, delivering significant benefits to the combination of in-factory manufacture and on-site housing construction.

Gwen Beeken, Managing Director at Osco Homes, describes how Wraptite was key to achieving a quality airtightness solution suited to offsite construction. “Although an essential requirement is that the homes had to meet Building Regulations, both the client and OSCO Homes were keen to exceed this. The use of high-quality panels, with a high-performance membrane, built in a factory and assembled on-site, enables OSCO Homes to achieve a better airtightness and higher level of insulation, helping to reduce heating bills.

“Applying it in a factory environment, we can be confident of the quality of the installation, and the specially provided Wraptite Tape means making the joints onsite is simple. Wraptite performs really well. We used to use a membrane, which would get damaged during transport, flapping around, and would then be difficult to make the joints neatly. Now, using the Wraptite detail means no edges are exposed during transportation.”

The Wraptite air barrier system provides a fully self-adhered vapour permeable air barrier certified by the BBA. Wraptite is easily applied in the factory, bonded externally to the substrate, to ensure that the membrane is held firmly in place, even during transportation, maintaining the quality of the system from manufacture, to install, to completion.

A. Proctor Group – Enquiry

63

29

The ease with which Wraptite achieves a high level of airtightness and its ability to be joined across panels was key to its selection.

Offsite Construction

Standing still not an option for Euramax Solutions

With the UK offsite and modular sectors set to play an ever-increasing role in the future of construction, one company is primed to continue what has been a rapid rise in both in a brief period of time.

Leading uPVC window and door manufacturer Euramax Solutions, which also supplies to national builders’ merchants and new build and holiday home markets, is growing rapidly thanks to high demand.

And the Modular Group Investments (MGI) company is gearing up for even more growth thanks to an ambitious plan that will be set in motion over the next 12 months to grow the company by more than 35%.

New Managing Director Emma Chapman, who was brought in to streamline processes and maximise company growth within the growing modular market, explained: “After a successful first half of 2022 we are in a position to push forward and while our plans are certainly ambitious, the volumes are there in the marketplace.

“The modular market is so fast-paced, there really is no time to stand still. And that’s why we’re looking at all areas of the business to help us to achieve it and not only put us in a good position for now, but for the future too.”

Continued investment

The Barnsley-based company is currently targeting more partnerships in the modular

and merchant world while continuing to strengthen its support for existing customers and is hoping to invest in new machinery.

“Supporting and extending our customer base is vital for moving forward and to do that we need to continue to invest in our manufacturing plant,” said Emma. “Our factory is perfect for our automotive approach to lean manufacturing and lineside delivery system for making our high-volume products, but we want separate lines that can produce more bespoke products as well. It’s all about becoming bigger and better in the modular and offsite sectors.”

Strengthening an established team

Recruitment is something Emma has ben particularly focussed on during her first two months at the helm and she acknowledges it’s a challenge that has plagued the industry for several years.

“It’s no secret that attracting people into the sector is tough, which is why we are working on a recruitment drive,” said Emma. “But it’s not only about recruitment, it’s also about putting things in place internally that will benefit our team and lead to better staff retention. Since I’ve been here everyone has been brilliant, and we want to get that across; we want to make Euramax the key company to work for as well as buy from.

“Due to the growth we intend to make, we need to make sure that we have the personnel in place to help us succeed. We’re in a growth period and we’re in a great position - and it’s only going one way and that’s upwards.”

Net zero journey

An even bigger emphasis on Euramax Solutions’ journey to reduce its carbon footprint will also take place over the next 12 months. The company is looking to link up with several programmes and local initiatives, including one on recycling and recyclable packaging, to help reduce its carbon footprint and help accelerate its journey to net zero.

“Greater expectations are now being placed on businesses in all sectors, and we want to make sure we are doing everything we can to meet and explain our responsibilities when it comes to net zero and sustainability,” added Emma. “It’s why net zero will be a significant driver in our company strategy for long-term growth, with our plans to reduce carbon meaning we will reduce our costs, and it will give our customers another big reason to work with us.”

For more information, call 0330 1340 290 or visit www.euramaxuk.com/

Offsite Construction 30 To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

Euramax

Enquiry 64

Solutions–

WRAPTITE® THE SELF-ADHERING AIRTIGHT AND VAPOUR PERMEABLE MEMBRANE 0:03 3:29 NOW PLAYING www.proctorgroup.com 01250 872 261 contact@proctorgroup.com @proctorgroup ALSO AVAILABLE IN UV FOR OPEN JOINTED CLADDING Enquiry 65

EOS – Simplifying Specification and Procurement

Architects and developers are under increased pressure to construct safer buildings on fast-track schedules whilst still achieving outstanding building performance. Here Steve Thompson, Managing Director of EOS Framing makes a strong case for a light steel frame systems approach.

Construction can be a complex business but as we evolve more advanced offsite technologies, we can help specifiers reduce risk and operate with more certainty and confidence. Through the collaborative expertise of Etex brands EOS Framing, Siniat, Promat and FSi, our light steel frame systems approach is helping construction clients to comply and compete in challenging markets.

From early design and engineering advice to simplifying specification and procurement, our products, processes and whole business philosophy show that as a manufacturer, we take our responsibilities extremely seriously. At the heart of this is rigorous testing and a systems approach to our solutions. Our full-scale testing regimes study the performance of products working together as a complete system to see how they interact in ‘real’ circumstances, such as under fire conditions or when exposed to wind and rain.

Fragmented supply chains result in components being offered by a multitude of manufacturers, therefore warranties are complex, for very limited timescales or simply non-existent. This uncertainty also extends to the costs involved, the speed of build and the quality of the final outcome.

In response to these challenges, EOS has developed an award-winning range of unitised light steel frame systems. We are now able to provide real scalable solutions –delivering precision-engineered buildings at scale better than, faster than and more costefficiently than other market offerings.

Thrubuild® – Loadbearing Recently presented with Best External Product trophy at the Housebuilder Product Awards, Thrubuild® provides crucial safety, time and cost benefits. The range has multiple loadbearing applications and can be used for external or internal walls together with internal and separating floors. Thrubuild® is supplied as a tried and tested custom-designed kit of parts integrating steel framing, external Siniat Weather Defence sheathing, Siniat internal drylining, ancillary parts, fixtures and fittings.

Thruwall® – Non-Loadbearing Infill

The collaborative strength of Etex brands have researched and developed Thruwall® – fully engineered non-loadbearing infill systems which can be applied to steel or concrete mainframes. Custom-designed and manufactured offsite to meet specific requirements, Thruwall® is supplied as a kit of parts including steel framing, external Siniat

Weather Defence sheathing, Siniat internal drylining, ancillary parts, fixtures and fittings.

Pre-Assembled Frames (PAF)

An evolution of Thruwall®– EOS has taken factory prefabrication and preassembly to a new level. Developed and rigorously tested, Pre-Assembled Frames (PAF) are delivered to site as a unitised non-loadbearing panelised infill system encapsulating light steel framing and external sheathing.

30-Year Product and Performance Warranty

All components and products in the Thrubuild®, Thruwall® and Pre-Assembled Frames system range have been rigorously tested together for fire, acoustic, weathering, airtightness, durability and mechanical performance. Fire resistance periods of 60, 90 and 120 minutes are achievable. When walling and flooring systems are built with Etex Group components and materials, following a validation process — Etex award a 30-year product and performance warranty.

To discover more about Thrubuild®, Thruwall® and Pre-Assembled Frames go to the EOS information centre: www.eosframing.co.uk/information-centre

Offsite Construction 32

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

EOS

– Enquiry 66

Framing Limited

Enquiry 67 DISCOVER MORE: WWW.HAMBLESIDE-DANELAW.CO.UK/ZENON-ROOFLIGHTS T: 01327 701 920 E: SALES@HAMBLESIDE-DANELAW.CO.UK ZENON ROOFLIGHT DIFFUSION MAKES LIGHT WORK OF DARK WORKSPACES 45+ YEARS OF ROOFING INNOVATION LOW CARBON GRP DAYLIGHT SOLUTIONS Zenon Low Carbon GRP Daylight Solutions Brochure SCAN TO DOWNLOAD THE BROCHURE Perfect for both new builds and refurbishments, our innovative Zenon Pro and Zenon Evolution GRP rooflights have the potential to allow three times more natural light into an interior space than a window or other vertical glazing the same size. That means safer working environments while reducing the need for artificial lighting. Thermally efficient, insulated and constructed with significantly less cradle-to-grave embodied carbon than traditional rooflights, over the lifetime of a standard building, Zenon Evolution is the eco-conscious choice for specification. Offsite Construction 33 Enquiry 68

Designing rain gardens for sustainable drainage at top visitor attraction

As weather conditions become increasingly temperamental due to climate change, landscaping and garden experts are turning to more inventive measures to manage the effects. One emerging trend is ‘rain gardens’, and Oli Collins, product marketing manager, Home & Garden, at ACO Water Management explains how these work.

Climate reports show that the UK is becoming wetter and have led to rain gardens or bioretention facilities emerging as a popular method for sustainable water management. These shallow, landscaped depressions reduce stormwater runoff to mitigate pollution and prevent local sewers from being overwhelmed. At the same time, rain gardens can add both beauty and biodiversity to outside space.

With this in mind, the Royal Botanic Garden of Edinburgh (RBGE) has implemented a rain garden on the south side of its site. The feature serves to manage heavy rainfall events, as the location had historically suffered from waterlogged lawns and flooded paths. As with any drainage solution, a bioretention facility requires careful planning, planting and landscaping. Gardening and landscaping professionals will need to keep several factors in mind when designing a rain garden to ensure success.

Soil suitability

Soil type is crucial to rain garden design, as water must be able to drain away at a sufficient rate to manage quantity. Water is unlikely to drain away fast enough in instances where the soil consists of heavy clay.

It is for this reason that RBGE carefully considered soil composition with a mixture of compost, sand and fine gravel to allow for sufficient water infiltration - while at the same time providing nutrients to support the plants.

For gardening experts, a percolation test can be conducted to determine whether the terrain is adequate for such a feature. The test is conducted by firstly digging a 250mm-deep hole and filling it with water. Once drained, the pit should be filled with water again and the drainage speed timed. If the rate exceeds 50mm per hour, soil conditions may be unsuitable.

Plant variety

Planting a bioretention facility must be carried out with diversity in mind. The feature should consist of both non-indigenous and indigenous species for a densely vegetated bed that will attract native birds and insects.

A selection of Scottish native and non-native plants was chosen for RBGE’s rain garden to form a shrub and perennial mix. Flora of this variety serves to accommodate diverse wildlife, as the flowers will encourage insects while perennials provide a food source for seed-eating birds.

Ongoing maintenance

Maintenance is a relatively simple process that should not be an afterthought. During the first couple of years of life, occasional weeding may be required to ensure the plants will thrive. Once the rain garden is established, plant beds will fill any gaps and suppress weed growth.

Seasons should also be kept in mind throughout the feature’s life. During hot spells, it may need topping up from a water butt to maintain sufficient moisture. While in the winter months, dead plants will need removing.

With erratic patterns continuing to characterise the UK climate, it is more vital than ever that a landscaped garden can withstand such conditions. Bioretention facilities hereby offer a practical drainage method that is both sustainable and beneficial to the environment.

Hotel, Sport & Leisure 34 To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

ACO Water Management – Enquiry 69

Collaboration - the key to unlocking the full potential of offsite

Adopting offsite or hybrid construction methods as part of the project, whether it’s a complete new build or a refurbishment with an extension, can offer a host of benefits from improved sustainability to greater efficiency.

Ryan Geldard, operations director at specialist offsite manufacturer and contractor M-AR, explains how specifiers and architects can work collaboratively together to unlock the full potential of offsite.

One of the main benefits of offsite is speed as, by manufacturing elements of a build in a factory away from site, the groundworks and foundations can be prepared on site at the same time as the building is taking shape off site.

While offsite can be significantly faster, it is not a given that simply by specifying offsite a project will automatically complete at a quicker pace. To make sure a project benefits from the efficiencies offsite can bring it needs to be fully integrated into the overall design and build process from the outset.

Specialist companies like M-AR, which is both an offsite manufacturer and contractor, will often work closely with architects and specifiers to ensure a building is designed in such a way that it will work effectively as an offsite project. So, for example, ensuring the building splits easily into compact, repeatable modules makes manufacturing more efficient and provides better value and cost predictability on materials as well as making transport easier. If these considerations are factored in at the start it maximises the efficiency and cost-effectiveness of each module being built offsite.

M-AR – Enquiry 70

overcomes challenges at new Westin London City

Mapei & Middlesex Flooring recently completed a surface project at The Westin London City, the brand’s first Westin Hotels & Resorts in the UK. Designed by Architects Dexter Moren Associates and situated opposite the Tate Modern and Shakespeare’s Globe Theatre, works included creating a public walkway and transforming an existing office building.

Vascroft Contractors’ project team overcame a multitude of challenges - from the preservation of Roman archaeological ruins, to innovative methods of construction to create the interior designer’s vision – in order to deliver the impeccably designed hotel.

During the project, Mapei assisted with regular site visits and moisture testing, whilst Middlesex Flooring investing in specific FITA

training for its flooring laying team. The Mapei specification included a full Resilient System.

ECO PRIM T Plus – a solvent-free low odour all-purpose primer used to improve the adhesion of smooth compounds; Ultraplan Renovation Screed 3240 - a fibre reinforced self levelling compound - followed by installation of Ultrabond Eco Fix solvent-free, pressure sensitive, multi-purpose adhesive and Ultrabond Eco TX3 – a wet grab adhesive with early build-up of strength, designed for textile and linoleum floor coverings.

Middlesex Flooring were appointed the flooring contractor to install Ege Carpet on Duralay Durafit 650 underlay.

Mapei – Enquiry 71

Mapei

Hotel, Sport & Leisure 35

Newton drives continued development with specialist waterproofing training

Professional development is an ongoing process, and as the UK’s leading supplier of waterproofing systems, Newton Waterproofing consistently works to help architects and developers achieve the next step.

The company offers a range of training initiatives covering all aspects of waterproofing in accordance with the British Standard 8102:2022, that aim to expand knowledge and skills in waterproofing practices.

Newton Waterproofing’s Managing Director, Warren Muschialli, comments: “At Newton, we deliver long-term value to trainees and continually raise the standard of work through various means, such as our partnerships. To help our growth, we partner with some of the leading waterproofing manufacturers around the world, enabling us to offer the highest-quality training direct from our supply partners, as well as access to the best products in the industry.”

Additionally, the Newton School of Waterproofing accommodates all audiences,

offering individuals and organisations a bespoke experience.

The Newton establishment is equipped with dedicated training facilities, including a pump room with full pump installations for trainees to practice on, and an outdoor spray area to learn how to correctly apply liquid waterproofing products.

Newton’s training areas also have full-size cross-sections of both a Type C Newton CDM System and a Type A Newton HydroBond System, showing a visual representation of how these products work in conjunction with each other.

With a powerful team of technical experts, Newton have the means to frequently deliver their four RIBA Approved, double points CPDs to architects, engineers and