Vol. 01 No. o3 February-March, 2023 FAIR First Tube & Pipe Fair in Delhi to Help Polarise the Industrial Growth Phase BUDGET

CML

30 46 Gallium

28 Grow

20 38 Jindal

Hissar 500,000 TPA

10 16

2023

International: No Mandrel Tube Bending Machines

Equipment to Come Up with New Plant

Ever Steel: Offering Customer Oriented Precision Steel Tubes Solutions

Industries Private Limited

Plus Greenfield Tube Plant Project in Ballari, Karnataka Utkarsh India Aims at Fortifying Market Leadership for Plastic Pipes in Eastern India

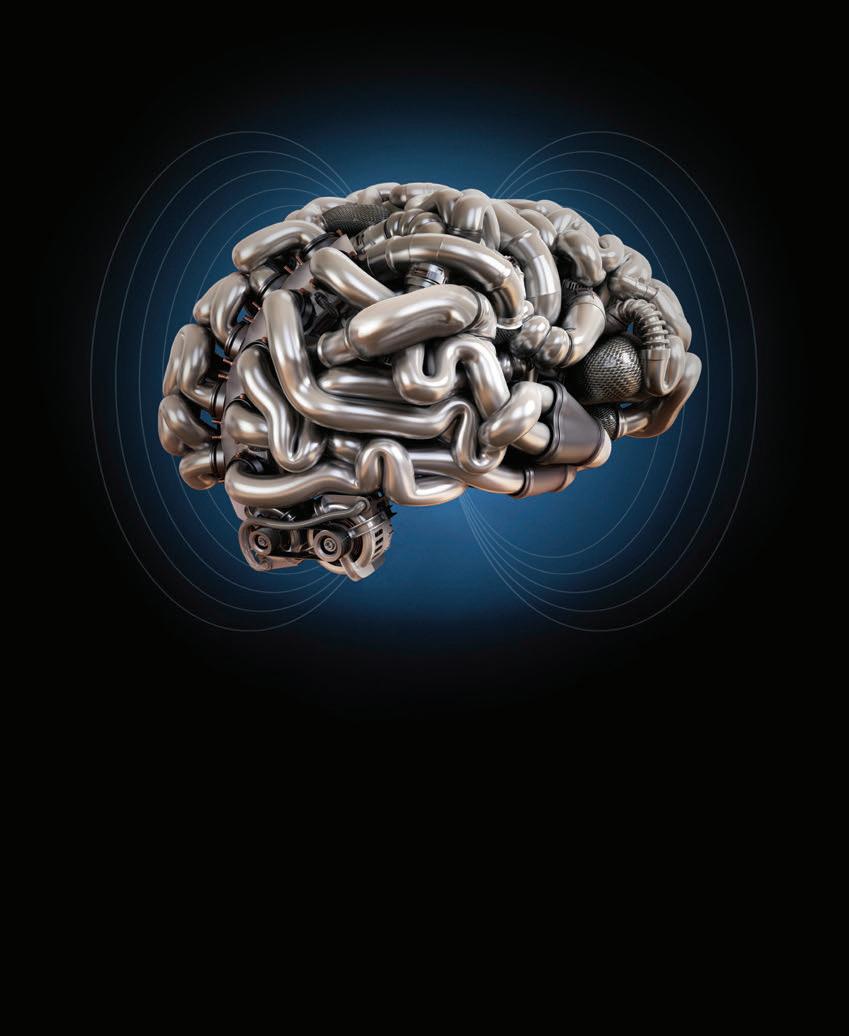

Union Budget 2023 Drives Tubes & Pipes Industry Towards India's Amrit Kaal

For booking write to info@tulip3pmedia.in or call +91 9910329829 www.tubepipefair.com Co-located with: Media Partner: Organized by: India’s Premier Tube & Pipe Expo FAIR 6th, 7th, 8th October, 2023 Hall No.: 2, 3, & 4 Pragati Maidan, New Delhi. The 1st International Exhibition for Tube & Pipe Industry Meet domestic & international buyers from the Tube & Pipe Industry.

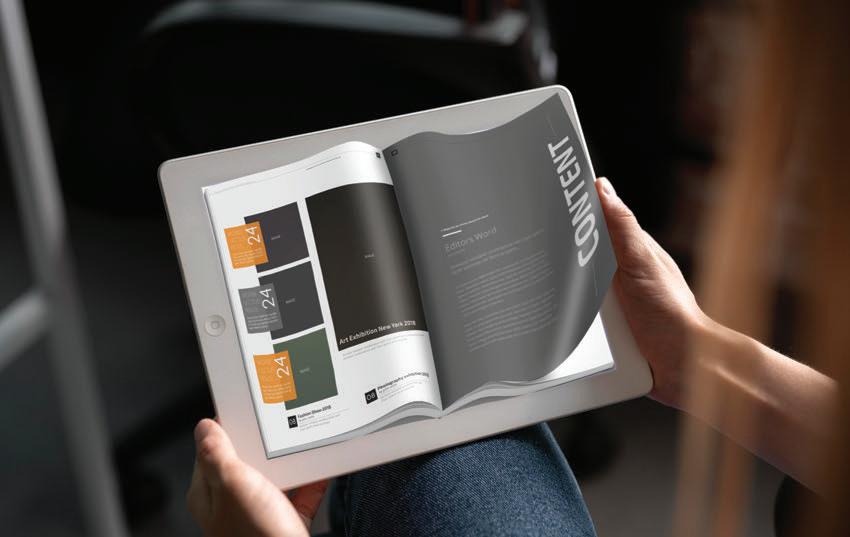

Tulip 3P Media Pvt Ltd Mobile : +91 9910329829, Email: info@tulip3pmedia.in www.tulip3pmedia.in The print version of the magazine is supported by an e-magazine. The fully interactive digital edition makes it possible to read the magazine anytime, anywhere globally and hence, delivers enhanced value for the advertisers. Each issue is posted online and past issuesarearchivedonthesite. Your Digital Gateway to Tube & Pipe Industry Metals, Plastic, Rubber A Bi-monthly Magazine for Tube & Pipe Industries www.tubepipeindia.com tubepipeindia.com/emagazine

The company has its advent in the year 1992. The foundation of this enterprise was laid with a forethought of providing superior quality, reliability and achieving the highest standards of customer contentment. Backed bytheexperienceandtechnicalknowhowof over three decades by the promoters, 'ROLLCON' offers value in the field of processingofflatsteelproducts.

ENGINEERED TO BRANDED TECHNOLOGY

Take the best that exists and make it better “ ”

Pickling Lines

Tube Mills

Color Coating Lines

Cold Rolling Mills

Cut to Length Lines Galvanizing Line Slitting Line B-21, Indl. Area-2, Mohali-160055, India. Tel: 0091-172-5090609, Fax: 0091-172-5093408 E-mail: rollcon@hotmail.com Website: www.rollcon.in We Believe in Manufactguring excellence and he portfolio of our performance. Achieving Consumer Satisfaction is our Motto. “ ” Rollcon Engg. Co. Pvt. Ltd. Air Knife

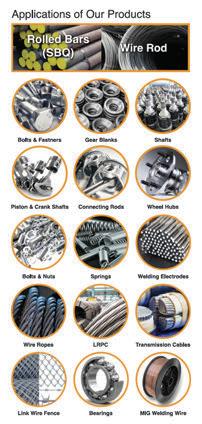

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com CONTENTS February-March, 2023 Tube & Pipe India Utkarsh India Aims at Fortifying Market Leadership for Plastic Pipes in Eastern India 16 Grow Ever Steel: Offering Customer Oriented Precision Steel Tubes Solutions 20 Global Seamless: Home to Supreme Quality Tubes & Pipes 24 CML International: No Mandrel Tube Bending Machines 30 Prime Gold: Pioneers of Stainless-Steel Pipes in India 34 Jindal Industries Private Limited Hissar 500,000 TPA Plus Greenfield Tube Plant Project in Ballari, Karnataka 10

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com Jyoti Inox Private Limited: Providing Stainless Steel Solutions 36 BUDGET 2023 Union Budget 2023 Drives Tubes & Pipes Industry Towards India's Amrit Kaal 38 Gallium Equipment to Come Up with New Plant 46 Yamazaki Mazak Offers One-Stop Multitasking Automated Machines for Expedited ROI 50 S.F.E. Group: Comprehensive Solutions to Tubes & Pipes Industry 54 Müller Opladen: Sustainability and Clean Energy is the Future of the Industry 58 Mac Bending: Catering to Customer Centric Solutions 60 Copier Machinery: Experts of Industrial Pipe Machining Solutions 62 Bhavya Machine Tools: One-Stop Shop for all Machinery Needs 65 NEWS DEMAND DRIVERS TECH UPDATE 66 74 80

10 | INTERVIEW

Industries Private Limited Hissar 500,000 TPA Plus Greenfield Tube Plant Project in Ballari, Karnataka

Jindal

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

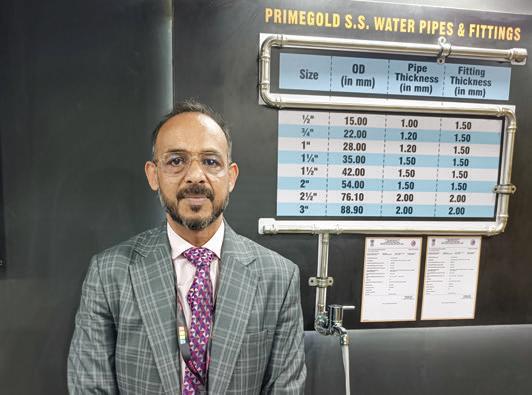

Mr. Sunil Jain, Director and CEO of JIPL

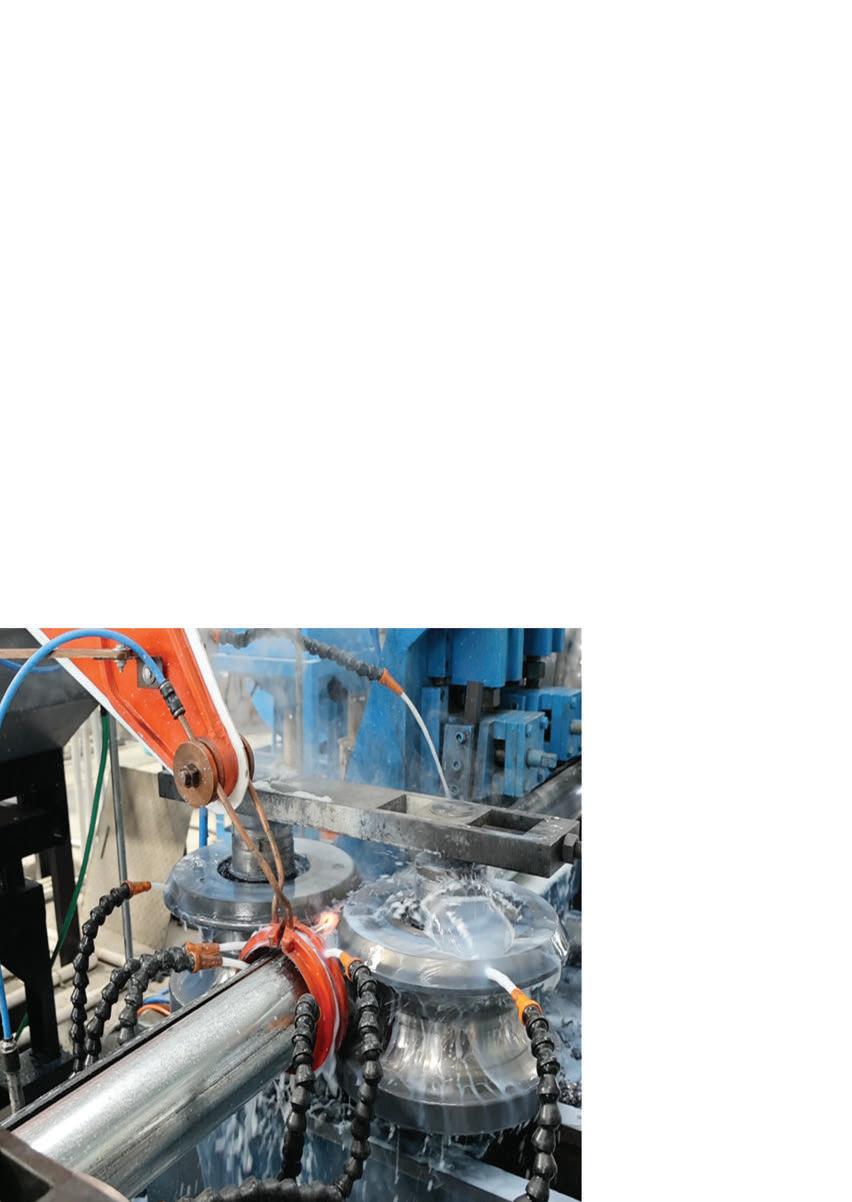

Jindal Industries Private Limited (JIPL Hissar) is a pioneer in HR MS steel tube manufacturing in

India. Even as the group celebrates its hard-earned legacy, the need for constant growth and development is priority. It is probably the reason why the group remains relatable.

An industry expert with nearly 30 years of experience in Precision and Seamless Tube Industry Mr.Sunil Jain, Director and CEO of JIPL (Hissar), was kind enough to sit in a conversation with Tube & Pipe India and share with us the various plans of the group. While participating in government projects, setting up new warehouses, MoU with other company and product line expansion are among the various future plans of the group. The Greenfield Pipe & Tube plant in Ballari simply takes the spotlight. The project will not only provide a geographically strategic location to the group, but it will also expand its capacities by an additional 500,000 TPA in 2 phases. The HR steel Manufacturer JSW will be in close vicinity of the Tube plant.

Tube & Pipe India: Please tell us about your company's historyandmajorachievements.

Sunil Jain: I am extremely proud to be part of O. P. Jindal group.

The journey has been incredible in terms of contribution towards nation building since inception and we continue to do so today and will continue to do in future as well. Looking back Jindal Industries Private Limited Hissar (JIPL) was set up more than 50 years ago by a group of friends/relatives, one of them being Mr. O.P. Jindal. Initially, a bucket-manufacturing unit, the Hissar plant has since then reimagined itself twice, first into 2,000 TPM steel and strips manufacturing plant, and then into a steel tube manufacturing plant housing two mills. Today, the

plant taps into a production capacity of 35,000 TPM with the help of 11 mills spread across an area of 32 acres, which isararityintheIndiantubeandpipeindustry.

JIPL is a pioneer in ERW steel tubing solutions. Our adherencetoqualityisourbiggeststrength.Werecentlygot certified with BIS certifications IS9295 & for higher steel grades with YST310, YST355, etc. We started production of coated tubes for gas lines within the complex this year at Hissar.

TPI: Can you elaborate on your plant setup, capacity, and market distribution?

SJ: As I mentioned, at our Hissar plant, we house 11 mills and three slitters, which are equipped and upgraded with the best technology to work at high-speed production. The

INTERVIEW | 11

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Hissar plant's installed capacity is 450,000 TPA out of which our active production ranges from 380,000400,000TPA.

Currently, we are manufacturing pipes with a rolling range of up to 16 inches outside diameter. Our plant has been manufacturing API tubes, used for oil and petroleum applications,for10-12years.

In terms of customer base, we have grown from catering to Northern India to supplying products all over India. We also supply to government's programs. Last year, we contributed over 50,000 tonnes of pipes for Jal Jeevan Mission, in Rajasthan, UP, Himachal Pradesh, Jammu and Karnataka etc., and we expect to contribute similar capacitiesinthecurrentyearaswell.

With increased capacity from Ballari plant and JSW Tube plant at Jharsuguda we have plans to export directly from 2023-24bothblackandgalvanizedtubes.

TPI: What is your current product line and have you made any recent additions to it?

SJ: Our whole product line could be classified into three categories, based on sectoral applications. The black tubes are used for firefighting purposes, our pipes are among the top choices in the industry. Thereafter, we have GI tubes that are used for potable water-based applications which are again a preferred choice for quality conscious customers specially OEMs. Lastly, we have sectional tubing, which are used for structural applications in all types of infrastructure projects. Among the three, GI tubing applications are our strongest product and are wellrecognized in the market. Customers, commercial or retail,

specifically ask for our product due to immense trust in the quality. Other applications we cater to are tube well, rollers, fabrication,solarplants,polyhousesetc.

Recently, that is about six months ago, we widened our product range to include powder coating tubes as well, whichareusedfordoor-to-doorPNGtransmission.

TPI: Do you see structural tubing as having a future in India?

SJ: Structural tubing already enjoys a huge demand and application in the residential, industrial, and commercial sectors of the US, Europe and other nations. It is a rejoicing moment for India, as the market demand for structural tubing is increasing in the domestic market as well. Although the residential market is still shy of the applications, the commercial market, such as high-rise buildings, malls, etc., is all set to embrace the scope of the applications. This demand is also getting fuelled by government policies and programs, such as Jal Jeevan Mission, and PM Har Ghar Jal Yojna. Infrastructural projects, such as railways, metro projects, airports, expressway corridors, etc., will also help in demand boost. The demand for high strength material tubing will increase and also the size range will keep moving towards higher side for structural application as the designs evolve.

TPI: Can you share with us JIPL's future plans?

SJ: JIPL has a greenfield tube plant project pipelined, whose construction shall start in April 2023. The plant will be set up in Ballari, Karnataka and shall serve our existing and expanding customer base in the Southern region of the

12 | INTERVIEW

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Indian peninsula. The overall plant shall become operational in phases due to the sheer size of its operation, as we are aiming for a higher size range. Our targeted production capacity for Phase 1 is 250,000 TPA, which we will expand to 450,000 TPA in Phase 2. We also plan to set up a DFT mill for sections in Phase 2 after covering the round tube requirement of our existing customers in Phase 1inSouthernregion.

In addition to the plant, we shall be putting up warehouses in Jharsuguda and Pune in coming year, here we already haveourcompany'ssalesoffices.

JIPL is also venturing into the plastic tubes market, with the manufacturing of uPVC and CPVC tubes, albeit at a smallerscaleandlimitedregionintheyear2023-24.

We also recently signed an MoU with JSW Jharsuguda plant to manufacture MS tube. We are expecting to reach a volume of 100,000 tonnes in 2023-24. The speed has been very encouraging in last 3 months and helping us to capture marketsinotherregions.

We are looking for a manufacturing plant facility in Western region as well, which I feel we will conclude by Q1 2023-24.

TPI: What is the base idea behind setting up the Ballari plant?

SJ: In the tubes industry, transportation time and freight are major factors, for instance, long-distance freight charges are practically for transporting air, as the tubes are hollow structures. Hence, location is a huge factor and determinant in overall transportation and distribution costs. Our Hissar plant is already catering to Northern,

North-Western, Central, and Gujarat regions, and we wanted to replicate these services in the Southern and Easternregionsaswell,henceweplannedaprojecttosetup the Ballari plant. The other advantage is being close to the raw material where in JSW plant will be hardly 20-30 Km from this plant, which will also help us to save inward freight. We also plan to export from there as the plant will havelatesttechnologyandaveryproductivelayout.

The Ballari plant is part of our strategic plan to widen our presence and better our services across India. In terms of product, the plant will target higher volumes, more precision,andbettertolerancesinthepipediameters.

TPI: How will you comment on the Indian tube industry?

SJ: The industry is inherently turbulent, for instance, in a spanofmeretwoyearssteelprices(perKg)fellfromINR76 to INR 50 and jumped again to INR 60. Although the prices have revived many market players who could not cope with thepricepressurehavetoquit.

The demand continues to grow and new players continue to enter the market. I still feel there is enough for everyone as demand is also increasing and will continue to increase based on the fact that government policies and plans are towards modernization and improvement of human life acrossIndia.

The whole setup requires immense support and coordination among the suppliers, dealers, plant, and customers. JIPL feels blessed to have extremely supportive supplier partners, namely JSW Steel, SAIL and Tata.

14 | INTERVIEW TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Metals, Plastic, Rubber A Bi-monthly Magazine for Tube & Pipe Industries Content Segment Interviews Special Feature Technical Articles Event Reports News Demand Drivers Tech Update Tulip 3P Media Pvt Ltd Mobile : +91 9910329829, Email: info@tulip3pmedia.in www.tulip3pmedia.in Most credible source of information for Indian Tube & Pipe Industry www.tubepipeindia.com

Utkarsh India Aims at Fortifying Market Leadership for Plastic Pipes in Eastern India

Utkarsh India Limited is one of the experienced players in the polymer pipes market. As the global and domestic industry looks forward to a period of booming growth, challenges and competition are as inevitable as opportunities. It is in times like these that even seasoned players like Utkarsh India are up and front ensuring leadership and growth by the confluence of quality, pricing, innovation, and acceptance of modern techniques. As Mr. Utkarsh Bansal, Director of Utkarsh India, engages with Tube & Pipe India to discuss both industrial and organizational future, one could observe the attitude and planning it takes to become an industry leader. For instance, doubling the company revenue from the eastern Indian region to reach over INR 1,000 crore in the next four years.

Tube & Pipe India: Utkarsh enjoys pioneer status in the polymer pipes market. Please elaborate on your market position and the steps that you take to maintain your brand loyalty and market leadership.

Utkarsh Bansal: Utkarsh India is one of the leading brands for polymer pipes of various categories in eastern India with the highest brand recall amongst channel partners, influencers, contractors as well as the public at large. Whether in the agriculture, boring or plumbing segments, our range of PVC and HDPE pipes and fittings have become one of the most trusted and preferred brands. We have a network of over 5,000 channel

partners and over 20,000 influencers who are in touch with us on a regular basis. Utkarsh Polymer Division has a production capacity of more than 36,000TPA. We are the first to manufacture and introduce SWR pipes and fittings and UPVC leadfree pipes and fittings in the eastern region. We are the first to use Leak Proof Gold Seal in the SWR range of pipes and fittings. We are among the PHED-approved PVC Brands complying with various standards like ISO, EN, BIS, BS, DIN, TSEC, IS, ASTM d, SGS, OHSAS, etc.

To maintain our brand loyalty one of the foremost steps we undertake is to be one of the most quality-conscious brands in the market so that the market has an automatic sense of

16 | INTERVIEW

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Mr. Utkarsh Bansal, Director of Utkarsh India

trust when buying our product. We are one of the only fully automated plants for the production of plastic pipes and fittings in the eastern region which allows complete control over quality, process, and output. We also ensure our procurement only happens from the top suppliers in the world, that is from Japan, Thailand, etc. Moreover, we have a very active quality team who is hands-on with attending to any complaint that we may receive with immediate solutions so it gives both our customers and partners a sense of comfort at all times. We are constantly adding to our range of products with innovation to ensure that we have the most cutting-edge products that match the need of our market as well as the remotest requirement of our customers. We are also very active in terms of influencer marketing by doing more than five plumber meets per day across all our customers on average to ensure product awareness among our influencers and constant touch with the brand. We take their feedback as well to understand their issues and perception and make changes accordingly.

We also make sure that we maintain a very strong channel policy, with most of our partners having been with us for decades and growing with the company, which ensures that we have their loyalty at all times. We also have a dedicated team looking after approvals, certifications, project sales, etc. to ensure that any marketing support that is needed by our partners is always catered for. Moreover, we believe in complete transparency and accessibility so all of our channel partners and customers alike have access to all the people responsible for the brand and the product so that we can constantly adapt to the market feedback and solve any challenges we may face.

We are already doing more than INR 250 crore of sales of plastic pipes and fittings in the eastern region, and aim to grow this figure to about INR 500 crore within the next couple of years to further amplify our leadership position. Furthermore, we

are investing in new forms of marketing, such as digital marketing, for lead generation and connecting with new channel partners, tapping on all ends of the market catering to both rural and urban demand and to all applications of plastic pipes and fittings. We are determined to maintain the best balance of quality and price to ensure that our customers get top-quality products at the most competitive pricing as per the ethos and mission of the company.

TPI: Discuss your product portfolio along with its application areas.

UB: Utkarsh India Limited is an ISO 9001:2015 certified organization with an annual group turnover of INR 2,000 crores, and 40+ years of manufacturing experience in the infrastructural sector. Our group owns ultra-modern manufacturing units, consistent premium quality products, a pan-Indian robust distribution network, and an export setup to more than 35 countries.

Our polymer production unit located at Gurap, West Bengal is equipped with the best in manufacturing technology and backed with stringent quality control and checks. Utkarsh Polymer products meet national & international standards and specifications and are certified by plumbing governing bodies around the world.

Our Polymer Portfolio includes:

• CPVC Plumbing Pipes and Fittings

• uFLO UPVC lead-free Pipes and Fittings

• SWR Pipes and Fittings

• uPVC Column Pipes and accessories

• Agriculture Pressure Pipes and Fittings

• PVC well casing Screen Pipes

• HDPE Pipes

• PLB HDPE Duct

• Garden Pipe

TPI: Tell us about your Indian and International presence in this industry.

UB: We have a strong channel market in the eastern region with over 5,000 active dealers, channel partners, and retailers working with us for various markets. In the industrial segment, we have buyers on a pan-India basis from various sectors. Due to our presence in various infrastructural sectors such as roads and highways (via crash barriers), railway electrification (via OHE structures), urban development (via lighting poles and Highmasts), water transportation (via PVC, HDPE and steel pipes), power transportation and distribution (via steel tubular poles, transmission like towers) and telecom (via telecom towers) through our diversified product portfolio, we have become the brand of choice for

INTERVIEW | 17

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

all these sectors on a pan-India basis. Utkarsh India Limited, a Government of India-recognized export house, has achieved the EEPC India award for export excellence for two consecutive years and has gained footholds in various countries, including Germany, Australia, Canada, Denmark, Iraq, Kuwait, Qatar, Mozambique, Nigeria, Northern island, Sri Lanka, UAE, and UK among others.

We have supplied major projects and agencies, such as NTPC, NALCO, PHED - Aizawl, Rajasthan & West Bengal, Tata Steel, ONGC, Hindustan Petroleum, L&T, Kalpataru Power, NHAI, BHEL, Coal India, SAIL, ESL, TISCO, Indian Railway, Power Grid, CESC, WBSEDCL, ESL, and DMC Corp.

TPI: What are your future shortterm and long-term goals to serve the plastic pipes industry?

UB: Our short-term plan is to become the market leader for all kinds of plastic pipes and fittings in the eastern India market. We understand this market very well and our brand has high visibility and recall here, so we would like to further strengthen that. Within the next two years, we are aiming for plastic pipe revenues of over INR 500 crores from the eastern market and over INR 1,000 crores within the next four years from eastern and surrounding markets. For this, we have planned a network of over 10,000 retailers and channel partners across the eastern market in 2 years with a clear presence in every district across Bengal, Bihar, Jharkhand, the northeast, Orissa, and Chattisgarh. This is in line with the company's target of becoming an INR 5,000 crores revenue company within the next three to four years.

TPI: PVC pipes & fittings market is expected to experience a big boom in the near future. Kindly shed some light on this statement highlighting the significant areas of growth.

UB: Despite being the third largest selling plastic commodity after polyethylene & polypropylene, the PVC pipes & fittings market is

expected to grow at a CAGR of 10.2 percent to reach USD 6,224 million by 2023. The Indian plastic pipe industry has a bright future with increasing application demand in areas such as potable water supply, wastewater supply, electrical and telecommunication cable protection, agriculture, chemicals, and oil and gas.

Government policies are also major contributors. The Jal Jeevan Mission scheme in every state has added to the demand for plastic pipes (specifically PE pipes) in India, creating a further boom in this category. The Pradhan Mantri Awas Yojana and other housing schemes have also ramped up residential and construction needs which has automatically also amplified the need for plastic pipes in the market.

TPI: What message would you like to float about the future of polymer pipes to the industry?

UB: The polymer pipes industry in India is booming, especially in the building products and agricultural application segments. It will continue to boom for years to come as India has huge potential for housing and construction and we have only touched the tip of the iceberg. At the same time, India will continue to be an agricultural economy with a constant need for the agricultural

sector. Moreover, with water transportation at its peak via the Jal Jeevan mission, this is the golden period for the industry. The current market is of consolidation and the customer becoming more and more quality and brand conscious. A product that is the best in the market will continue to stand out and take market share from the others that are providing subpar offerings, and we, at Utkarsh, believe that we will be able to capitalize on this to make sure we're the leading player in the market

TPI: What is your outlook toward the role of exhibitions and fairs in the growth of the industry?

UB: Exhibitions and fairs in this industry, just like any industry, tend to be extremely important as they help us connect with the end customers, especially the decision makers as they provide a platform for them to come and see all offerings in one arena. Moreover, they provide an opportunity for the project and actual user sales to meet a variety of consultants, contractors, infrastructure customers, and government agencies. Additionally, they provide an opportunity to showcase the quality and new innovations in our products to various key people, which is otherwise a difficult and lengthy procedure.

18 | INTERVIEW

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

India’s only Magazine on Tube & Pipe Industry For booking write to info@tulip3pmedia.in or call +91 9910329829 www.tubepipeindia.com Metals, Plastic, Rubber A Bi-monthly Magazine for Tube & Pipe Industries www.tubepipeindia.com Tulip 3P Media Pvt Ltd Mobile : +91 9910329829, Email: info@tulip3pmedia.in www.tulip3pmedia.in

Grow Ever Steel: Offering Customer Oriented Precision Steel Tubes Solutions

Grow Ever Steel (India) Private Limited, an ISO 9001:2015 certified company, specializes in manufacturing of ERW MS Precision Steel Tubes, Hollow Sections (RHS, SHS, Oval & Capsule), Stamped and Tubular Components. Set up in 2008, the state-of-the-art factories are located in Falta, West Bengal. With a current capacity of 30,000 MTPA, their exclusive made to order mills include additional features such as air cooling for better weld quality and solid-state welders giving their products the extra edge in the market. In a recent interview with Tube and Pipe India,

Mr. Rajat Sarawgi, Managing Director, Grow Ever Steel (India) Private Limited shared with us the company's business journey, market footprint, clientele and future plans.

Tube & Pipe India: Could you please give us a brief outline of the business journey of your company since inception along with its crucial milestones?

Rajat Sarawgi: 2008 was a year of great significance not only nationally, but globally. While on one hand, the industry was battling the downturn in the market caused duetothedownfallofLehmanBrothersanditsaftereffects, ontheotherhand,peoplestartedtolookatIndiaastheland of opportunity and the next big thing in manufacturing.

20 | INTERVIEW

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Mr. Rajat Sarawgi, Managing Director, Grow Ever Steel (India) Private Limited

Grow Ever Steel was established the same year to carve a nicheinthealreadycompetitiveprecisiontubeindustry. ItstartedasanideaonpaperonceweidentifiedtheLacunain this industry segment for a time committed & quality conscious manufacturer for predominantly the OEMs. Initially offering a very limited product offering, Grow Ever has consistently grown over the last few years in scale and in scope overcoming various hurdles while being adaptive to the market changes and demands of the industry. We believe

that today we are one of the preferred choices of partner to majorOEMsnotonlyinIndiabutacrosstheglobe.

TPI: Kindly cast some light on the infrastructure, manufacturing capabilities, and machinery installed at your factory.

RS: While we began with humble beginnings 15 years back, Grow Ever now boasts of a dedicated team of over 500 people who are equally committed to the growth of the organisation. Currently we have 3 manufacturing units

INTERVIEW | 21

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

providing the best available infrastructure and superior technology for producing MS ERW Precision Steel Tubes, RHS, SHS, Oval and Capsule sections as well as a wide varietyofTubular&StampedComponents.

Our 4th unit is expected to be commissioned in January 2024.

The installed capacity is over 30,000 MTPA for precision tubes. We also offer additional value products like cut to length sizes to our partner companies which makes it easier forthemtousethetubesalmostimmediatelyonreceiptand as per time bound schedules. Complete inline fin cutting along with Non Destructive Testing for the higher quality consciouscustomerisalsoavailable.

We have set-up a state-of-the-art facility offering a wide variety of precision components made on multiple machines like Automatic and Laser Cutters, Chamfering and De-brushing, Hydraulic Presses, CNC Turning Centres,Threading&TappingEquipmentsandotherSPMs amongstothers.

With technology imported from Germany, USA, Taiwan as well as the best manufacturers within India to support the Make in India campaign, we genuinely believe that only the best of equipment offer the best of products and thus invest heavily on latest and advanced machinery.

Our Marketing teams operate from Pune, Aurangabad, Bangalore, Indore and Delhi. They work in tandem with the corporate office located in Kolkata in providing round the clockservicestoourclients.

TPI: Tell us about your product portfolio along with its key strengths and applications.

RS: Our Tubes are offered in the range of OD 8 mm to OD 80 mm and a thickness range of 0.25 mm to 4.5 mm and we use only Prime Quality Raw Material in grades like CRCA, CRFH, CRMA, HSLA, HRPO, HRSPO and many more, sourced from all major RM manufacturers across the country.

We take pride in knowing that our products find place in numerous applications in a wide gamut of industries as givenbelow:

● Automotive

● Bicycle

● Construction

● Electrical

● FMCD

● Furniture/Fitness

● LightEngineering

● Medical

● Power

● Umbrella

TPI: What are the recent developments at your end? Also, what will be your future plans?

RS: We have recently installed a High Speed Line for manufacturing tubes at a speed of over 150 mpm. An advanced R&D lab has been set up to analyse requirements of other industries not previously catered to by us. Multiple CNCs and SPMs have been installed in our component division to give our partners the option of Value Added Components from under the same roof of the Grow Ever Group. This is in line with Our Motto of 'We All Together – Grow For Ever'.

In the near future we plan to set up an annealing unit to cater to the growing demands of our export division and also further strengthen our existing portfolio by understandingandworkingcloselywithourclientsontheir consistentlyevolvingrequirements.

Wewouldliketoaddherethatwearealsoonthelookoutfor exploring possible growth opportunities with interested companies and being their partners in progress. The companies must share value systems similar to ours i.e. hardwork,honestyandbeinghungryforsuccess.

TPI: Share your outlook on the tube and pipe industry. How do you see the market evolving in the future?

RS: According to a market research report by Industry ARC, the global Precision Tube market size was valued at $17.8 Billion in 2020 and is projected to reach $26.3 Billion by 2026, growing at a CAGR of 6.2% during the forecast period. The report also notes that the demand for these tubes is driven by the growing demand for lightweight and fuel-efficient vehicles, increasing construction activities andtheadoptionofautomationinmultipleindustries.

The Covid-19 pandemic has also had an impact on the industry. According to a report by ResearchAndMarkets, the global steel tube market declined by 4.4% in 2020 due to disruptions caused in supply chains and manufacturing operations. However, the market posted a strong recovery in2021andhascontinuedtogrowsincethen.

In short, the industry is definitely on its way to recovery fromthe post pandemic aftereffects andthe overalloutlook appears positive in the next few years backed by strong demandandhigherconsumptionpatterns.

TPI: What is your technology and business roadmap?

RS: At Grow Ever, we place our bets on the best of technology and all machines have been made keeping our customers quality processes in mind. The above mentionedR&Dfacilityhasbeensetuptokeepabreastwith the fast changing parameters across all departments and adapt faster to offer the best solutions to our business partners.

We sincerely believe that honesty towards our work will always give us the desired results and our aim is to keep building to our strengths and keep growing – slowly but steadilyaswehavebeendoingsinceInception.

22 | INTERVIEW

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Global Seamless: Home to Supreme Quality Tubes & Pipes

Global Seamless Tubes & Pipes

Pvt. Ltd. is a leading manufacturer of Hot Finish and Cold Drawn Carbon Steel Seamless Tubes with an installed output capacity of 24,000 Metric Tons per annum. Located in West Bengal, the company has advanced MPM continuous rolling mill and other state-of-the-art equipment. In an Interview with Tube & Pipe India, Mr. A.R. Biswas, President, Global Seamless Tubes & Pipes Pvt. Ltd. shares interesting details about the infrastructure and machines.

Tube & Pipe India: Could you please give us a brief outline of your company along with its journey and vision?

A.R. Biswas: Global Seamless was established in 2019. Although it has been a journey of just three and a half years, ourleadershipteamcomprisesseasonedtechnocratswitha combined average industry experience of 36 years. The deep domain knowledge of the seamless tubes and pipes industry has helped us become one of the most notable mechanical seamless tube manufacturers and that is the reasonwewereabletocommissionourplantinashortspan oftime.

Our seamless pipe factory in Bagnan is spread over 3,00,000 square feet. Having such a big factory space gives us the distinct advantage of having hot-finished, hot-

24 | INTERVIEW

Mr. A.R. Biswas, President, Global Seamless Tubes & Pipes Pvt. Ltd.

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

pierced, and cold-drawn industrial seamless tubes and pipes-making processes integrated into the same unit.

GSTP (HFS) Pvt. Ltd. for the hot finishing process and Global Seamless Tubes & Pipes Pvt. Ltd dedicated to cold finishing process are located in the same compound and have a combined yearly capacity of over 24000 MT. Our corporate office is in Salt Lake, Kolkata. Our vision is to produce internationally-acclaimed seamless steel pipes and tubes, from the best raw material, world-class technology,andscientificmanagement.

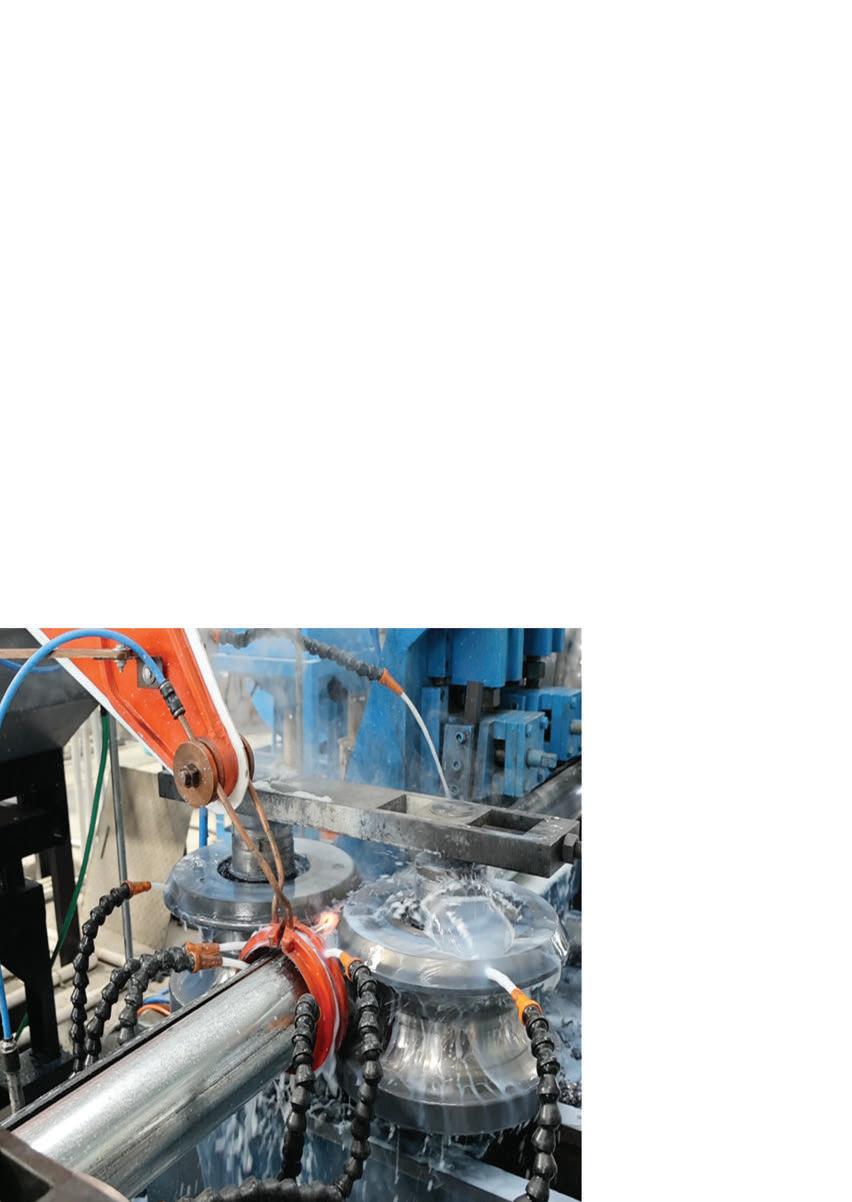

TPI: Please cast some light on infrastructure, manufacturing capabilities and machinery.

ARB: We carry out the entire process from planning to executionstageswithprecision.InourHFSplant,wehavea furnace with a capacity of eight tonnes per hour. We boast the most advanced MPM continuous rolling mill and other state-of-the-art equipment like bright annealing furnace, cold rolling mill, elongtor-sizing continuous hot rolling mill, cold-drawing machine, eddy current, and ultrasonic testing NDT machines, fully automatic hydrostatic tester, draw benches, and tube processing equipment. Such a wide variety of equipment allows us to produce marine pipes, line pipes, mechanical and automobile pipes, machining tubes, high-pressure boiler tubes, high-strength oil pipelines, and petroleum machinery parts. We produce everything in-house and we have got a very good laboratory withtestingequipmentfromJapan.

TPI: Tell us about your portfolio along with its applications.

ARB: Our main product is the seamless steel pipes, covering nearly all the sizes of small diameter seamless

steel tubes like OD 10mm - 168.3mm, WT 0.89mm - 14mm. in CDS tubing, and OD 26.7mm – 88.9mm, WT 3mm –15mm, in HFS pipes. We cater to a maximum length of 12.8 meters. We produce casing pipe, drill pipe and petroleum cracking tubes. Besides round tubes, we also manufacture square and rectangular tubes. Our tubes are used in myriad industries like mining, oil & gas transportation, automobiles, cranes, hydraulics, boilers, power plant, cooling tower, nuclear power stations, chemicals, etc. Pipe & joints for air brakes for freight & coaching stock of Indian Railways are our other key products. Recently, we have started manufacturing recessed pipes. Global Seamless develops GB, JIS, ASTM, DIN and other specifications & standards and is ready for immediate execution as per customization.

TPI: What are the key strengths of the company that helps you stay ahead of your competitors?

ARB: At all stages from raw materials to finished products, Global Seamless Tubes & Pipes are produced under an integrated system using the most advanced equipment, with rigid quality control exercised at each process. Our tubes & pipes come in surface finishes that exactly meet customer requirements or match the specifications for the intended applications. Inherently excellent properties are further enhanced by advanced heat-treating technology to offer a smooth, pleasing surface texture. To meet increasingly severe standards for dimensional accuracy, we exercise extra care in producing and inspecting pipe and tubes to particularly rigid dimensional tolerances. We make sure that the products we deliver exhibit consistent and uniform strength, workability and durability.

INTERVIEW | 25

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

TPI: Please share some light on the market condition and market footprint of your company.

ARB: There has been a COVID-driven recession in the market; however, we don't face much competition as far as pressure tubing is concerned as such tubes are not manufactured much in India and the USA. However, the pricesofrawmaterialsaregoingupwhichisachallenge.

We manufacture our products for domestic as well as international markets. Around 50% of our products are exported. We have a good presence in North America and South America. We export our products to countries like

Mexico and Brazil. In Europe, we have a footprint in Italy, GermanyandPoland.

TPI: Share your outlook on the tube and pipe industry along with your expansion plans.

ARB: For transmitting anything in high pressure, you need seamless pipes. Hence, there is a huge opportunity for seamless pipes in India. As far as our expansion plans are concerned, we have plans to expand our capacity from 6-inch pipes to 8-inch and 10-inch pipes. There is a huge market in the tube industry and we want to explore that.

26 | INTERVIEW

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

with the

An upcoming media company, Tulip 3P Media brings out publications for different B2B verticals. Theactivitiesofthecompanynowembraceeventsandmarketresearchaswell.Tulipiscurrently on its way to further expanding its publication portfolio through publications for other business verticalsandarichofferingofothernichemediaservices.

Tulip 3P Media Pvt Ltd 501-502, ABW Tower, MG Road, IFFCO Chowk, Gurugram-122003, Haryana Mobile : +91 99999 35011 / 22 / 44, Email: info@tulip3pmedia.in www.tulip3pmedia.in Our Services:• Magazine Publishing • Events • Market Research • Bespoke Publishing • Digital Marketing Growing

Industry Our Brands:www.cablewirefair.com Mommy & Baby Fair www.mommybabyfair.com www.mommybabytimes.com www.tubepipeindia.com www.papermart.in papermart.in/emagazine www.wirecable.in wirecable.in/emagazine mommybabytimes.com/emagazine tubepipeindia.com/emagazine Magazines Events Online Platform www.papermartdirectory.com FAIR www.tubepipefair.com

First Tube & Pipe Fair in Delhi to Help Polarise the Industrial Growth Phase

Tube & Pipe Fair's first edition, to be held from 6th to 8th October 2023, will assist the global tubes and pipes industry in harnessing the benefits from a period of growth, development, achievements, andsky-rocketingreturns.

As per various market research reports, the global tubes and pipes industry has been thriving since 2017. Although Covid-19 threw a setback on the industry's upward growth in 2019-2020, the recovery and bounce backhavebeen phenomenal.Thebest news forthe industry is that irrespective of forming material of tubes & pipes, the products have managed to find a wide market demand and presence. For instance, even while steel pipes and tubes gain appraisal of the global industrial market, the PVC pipes and tubes industry has been sized at USD 76.5 billion in 2021, with a recorded average CAGR of 10 percent over theFY16-FY21period.

Among all these trends, India is appropriately placed to

reap the best of benefits as it took the world's second or third-largest market position in the FY17-FY22 period. It is among the top five countries whose market share combines tobe49percentoftheglobalindustry.

These facts however now belong to the pages of history, and the bright future of the tubes and pipes industry demandsourattentionnow.

A YOY CAGR of 5.4 percent is predicted for the global steel tubes and pipes industry for the FY22-FY32 period, meanwhile, for the plastic tubes and pipes industry this CAGR is expected to range between 11-14 percent. The overall market size of USD 225.5 billion is predicted for the steel tubes and pipes industry in 2032 and USD 129 billion for the PVC tubes and pipes industry in 2030. In the Indian

n Tulip 3P Media is organizing the first edition of Tube & Pipe Fair from 6-8 October 2023.

n B2B exhibition brings together technology providers, manufacturers, suppliers, and distributors of the tubes and pipes industry.

n Exhibition to help polarize the forecasted CAGR of 5.4% for steel tubes & pipes and 11-14% for plastic tubes & pipes during the FY22-FY32 period and Union Budget 2023 announcements.

n USD 225.5 billion global market size for steel tubes & pipes is expected by FY32.

n India holds the second largest share of global industry and is among the top five markets which together account for 49 percent of the global market.

28 | PRESS RELEASE

FAIR

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Glimpse of Cable & Wire Fair 2022

context, Mrs. Nirmala Sithraman, Union Finance Minister, unveiledherFY23-24budget forIndiaonFebruary1,2023, and many of her announcements conform to India's potential to harness these predictions of growth and benefits.

UnionBudgetFY23-24Highlights

● Increase in capital expenditure by 33 percent, quantitativelyINR10lakhcrore.

● AdditionalfundsofINR69,684corestowardsJalJeevan Mission for the supply of piped water to every Indian household

● Increasing the outlay for Pradhan Mantri Awas Yojana by 66 percent, quantitatively INR 79,000 crore towards thehousingsector

● 27 percent capital expenditure growth in the oil and gas sector, quantitatively over INR 100,000 crores, of overall expenditure as announced by State-owned Oil Companies

All these announcements mean an increase in demand for tubes and pipes, in all types of forming materials, such as steel, iron, plastic, zinc, aluminum, etc., for application in varying industries, including Oil and Gas, Petrochemicals, Power and Water Supply, Construction, Automotive and Transportation, Sanitation, Agricultural Irrigation, Process Plants, and Mechanical Engineering Units.

Tube & Pipe Fair (TPF) is going to be a highly focused B2B exhibition in New Delhi, alongside an established exhibition – Cable & Wire Fair 2023, with over 300 exhibitors participating in the fair. The event shall be organized in the designated halls at Pragati Maidan, New Delhi, Delhi, on the 6th, 7th, and 8th of October 2023.

Tube, Pipe, Profile Manufacturing Machinery; Tube, Pipe, Profile Processing Technology; Steel Processing Technology; Auxiliary Tools & Equipment; Measuring, Control, and Testing; Materials and Consumables; Specialist Areas; Rebuilt and Reconditioned Machinery; Steel and other forming Metals; Plastics and Composites; Tube, Pipe, Profile Manufacturers and Traders; Fittings,

Fasteners, Pump, and Valve, etc. over an area of over 1,50,000squarefeet.

TPF 2023 will be a one-stop showcase platform allowing the exhibitors to directly communicate with various industry players, from suppliers to customers, and reap the benefits of the convergence of established industrial giants, global companies, and start-ups. Exhibitors will have a chancetobuildbrandawareness,advertisetoawidepoolof industry players, and build a network of cordial relations, business deals, and joint ventures. Fair competition is the lifelineofanyindustry,andTPFgivesalltheparticipantsan equal chance to harness growth opportunities with the only limitbeingtheirimagination.TPF2023willtakeathematic approach to showcase all the products, technologies, successful R&D, and possible innovations impending in the industry'sgrowth.

Our visitors can expect to find all the latest products and technologies, state-of-the-art machinery, equipment, applications, and developments in the global tubes and pipes industry. You will also find information about new applications related to the industry among user segments, and about developments and the best practices in analysis, design, and construction methodology pertaining to tube and metal fabrication. As you walk the aisles of TPF 2023, you will gain a deeper understanding of the global manufacturing industry and attain know-how of the innovationstakingplace.

AboutOrganizers

TPF 2023 will be organized by Tulip 3P Media Private Limited and backed by Tube & Pipe India (TPI). TPI is a bimonthly magazine publication aimed at disseminating information about all that is happening in the dynamic and evolving tube and pipe industry. Tulip 3P Media Private Limited, established in 2006, is one of the leading media groups widely acknowledged for industry-oriented publications for different B2B verticals, aimed at furnishing the latest news, opinions, market outlooks, and trends. Apart from publishing leading journals like Paper Mart, Wire & Cable India, Mommy & Baby Times, and Tube & Pipe India, the group also serves various industries through exhibitions, conferences, market research, online portals,andseminars.

PRESS RELEASE | 29

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

CML International: No Mandrel Tube Bending Machines

Founded in 1973, CML International S.p.A. started out as an Italian manufacturer of small push-type benders and their line of business includes developing and patenting portable tube bending machines. During an interaction with Tube & Pipe India, Mr. Michael Simonelli –Area Manager, CML International S.p.A., shares the company's journey, their smart factory infrastructure, innovative nomandrel machines, industry trends and the company's future plans in India.

Tube & Pipe India: Could you please give a brief outline of the business journey of your company, along with its crucial milestones?

Michael Simonelli: Our Company was established almost 50 years ago. It started with a simple machine that was used for bending small copper tubes for kitchens and baths. Our products have now evolved into a market that currently serve automotive, ship building, petrochemicals, oil & gas industries. From the small handheld machine for half inch copper tubes in 1974, we're now bending 8-inch pipes with our fully automatic CNC solutions. So the company has grown considerably in the last few years. In 2018 we purchased a company called Pedrazzoli, who have been in business for 75 years. They were the company that invented the first circular saws in the 1950's, which has a unique feature that clamps and cuts

30 | INTERVIEW TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Mr. Michael Simonelli – Area Manager, CML International S.p.A.

with a singular motion. From that unique saw, they came up with the first Left/Right-handed bender in 1963. CMLGroup of companies have a combined experience of 125 years, offering metal forming/cutting products, from simple manual solutions for metal working shops, to automatic HD shipbuilding and high-end production cells, we are the leaders in the industry for the cold deformation of metals.

TPI: Kindly cast some light on the infrastructure and machinery installed at your facility.

MS: Our facility is a true Smart Factory 4.0 company having approximately 20,000 sq. meters of building, with over 90 machine tools, that are connected via CAD-CAM to our production department. Our technical office is also online with production, which sends/monitors the drawings directly to our machines. That's where we passionately produce everything, with pride, in our Italian factory near Rome. Regarding our commercial network, we have over 200 partners in almost 80 countries across the globe. We also have branch offices in the United States, South Korea, France, Germany, Singapore and even Russia. However, they're only distributors, all the machines are made in our office in south-central Italy. Even for our Pedrazzoli products, we manufacture the parts for the machine down in Southern Italy, and then send the finished parts up North to our factory in Bassano Del Grappa, where the machines are completed and tested. From there, the machines are dispatched to their respective destinations.

TPI: Could you tell us about the manufacturing capabilities of the company?

MS: For small machines, we sell about 100 machines a month. They are fast moving machines and sell at about 8000-10,000 Euros. As far as the large CNC machines go,

the smallest CNC machine we make (the 65-76 size) is manufactured at 2 to 3 machines a month. Larger machines, like the 6-inch gas and up, that is 1 or 2 machines a month. These “mandrel bending machines” have been around since the 1950's, and we've made numerous contributions to this technology such as our patented overhead clamping system and monobloc tunnel design, but what we're known for is our “non-mandrel machines”. That is where we truly shine. The unique aspect of our nomandrel machines is its simplicity. We don't need a mandrel or complicated mechanical systems that require qualified machine operators. With our easy to operate no mandrel benders, simply position a tube to the machine, step on the pedal, and make great looking bends. Not only great looking but performing. Ercolina leads the industry with tight radius bends that have very low ovality, and reduced wall thinning, even with thin wall tubes. And that's wherewe'remostpopular.

TPI: Tell us about your product portfolio along with its key strengths.

MS: We started off with a small handheld push bender which grew into our first no-mandrel machine. These machines do not require a mandrel, all thanks to the special geometry of our tooling that we are able to make small radius bends even with thin wall tubes. They look great and perform great, we make sure to maintain the wall thickness sothatwedon'tlosepressurecapacity.Whenyoubendwith a mandrel, you are stretching the material, thinning the wall and creating a rupture point in the system. Whereas, with our no-mandrel solution we maintain the wall thickness and a good ovality, which is important for the flow of the material. This is because if we have a flat bend, besides the fact that aesthetically it does not look nice, it also performs poorly because that flatness is a restriction in the flow. So with these solutions, we are ASME B36

First Saws from the 50's

INTERVIEW | 31 TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

First L/R Handed Mandrel Bender

compliant, with wall thinning and flow regulations. The cost of the machine (with tooling) is equal to just the cost of tooling for a CNC machine. Again, very competitive products as it's very economical, simple to use and performsverywell.

TPI: What are the company's plans for the Indian market?

MS: Our future plan is to be more active and pertinent with the tube and pipe industry of India. I was recently asked by CML owner why we are not doing more business with BEM (Big Emerging Market) country like India. After some research, I learnt about the Quad coalition, which states thatJapan,UnitedStatesandAustraliaintendtoshiftsome production to India, diversifying the supply chain instead of depending much on China after the supply chain crisis. I went to Bangalore and Chennai with my Indian partner Sajith of ADM Solutions Pvt and talked to some of our customers who are tier-one automotive suppliers that confirm the automotive industry is gearing up in India and OEM's are suggesting their suppliers to organize accordingly. From that visit, I am about to close on two large CNC machines of our company's existing customers who have our smaller machines and are upgrading their productive capacity. So, immediate plans pertinent to India are to increase the market's knowledge of our solutions, then our involvement with hopefully our sixth branch office. Because I believe the best way to get into large companies of the market is through a direct chain to the mainoffice.

TPI: Please shed some light on the market footprint and the clientele of your company.

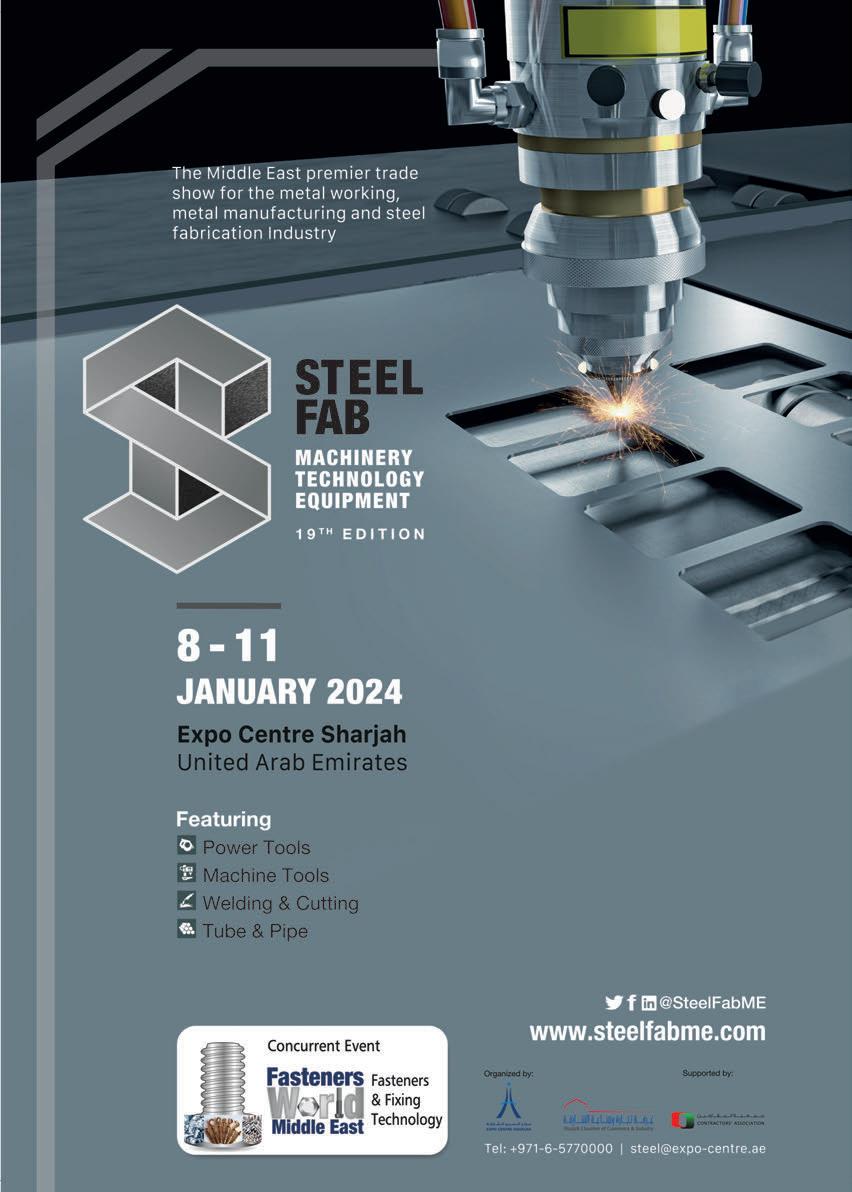

MS: Our machines are well dispersed around the world. We have 200 dealers in 80 countries around the world. In the Middle East, we've been exhibiting at the SteelFab expo in Sharjah for years, this is the 7th edition we have participated in, the first with our new partner PassTech who serves the entire G.C.C. From Nuuk Greenland in the Artic, to Nouméa Nuova Caledonia in the South Pacific, I've literally sold our fabrication solutions all over the world. In particular,IremembertheAirGreenlandprojecttomaking parts for their helicopters and airplanes with one of our mandrel machines. Though the capital of Greenland, Nuuk is a very isolated area surrounded with ice having only 14 kilometers of road, but not the most desolate home of an Ercolina,weevenhaveonerunninginAntarctica!

TPI: Please share your insights on the ongoing and future trends in the tubes and pipes industry.

MS: With new technologies, snap-together systems have been created. For example, now when you go to an airport and see handrails, they are assembled parts, not fabricated. There are bends at pre-bent angles that can snap together with a piece of tube to make a handrail. Due to this we are losing a bit of the stainless handrail market. However, we provide solutions to industrial manufacturers and work especially well with petrochemical, shipyards, oil & gas, etc. These sectors don't only look for aesthetics, but also for performance. When you cold bend, you not only eliminate welding, you also avoid heat treatment to normalize the welding zone;thatbecomes morebrittleduringthewelding process, x-rays to check and control if there are any holes in the wall, as well as other things like pressure test. Once the QC of the part has been made, then the process of grinding, cleaning, and polishing of the part are to be done afterwards. It is expensive to cut and weld. As you see, when you bend you not only make the component stronger and quicker, it also saves on the considerable costs involved with welding. People do not necessarily consider all aspects involved in part fabrication, that is why our products are very demo oriented. People understand and appreciate the value in it when they see it, therefore I hope you come visit us at the Tube & Pipe Fair in New Delhi this October. I'll be looking forward to discussing your fabrication requirementswithyou!

Current Pedrazzoli CNC Tube Bender

Current Pedrazzoli Cold Saw

Current Ercolina CNC Tube Bender

32 | INTERVIEW TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Current Ercolina No-Mandrel Bender

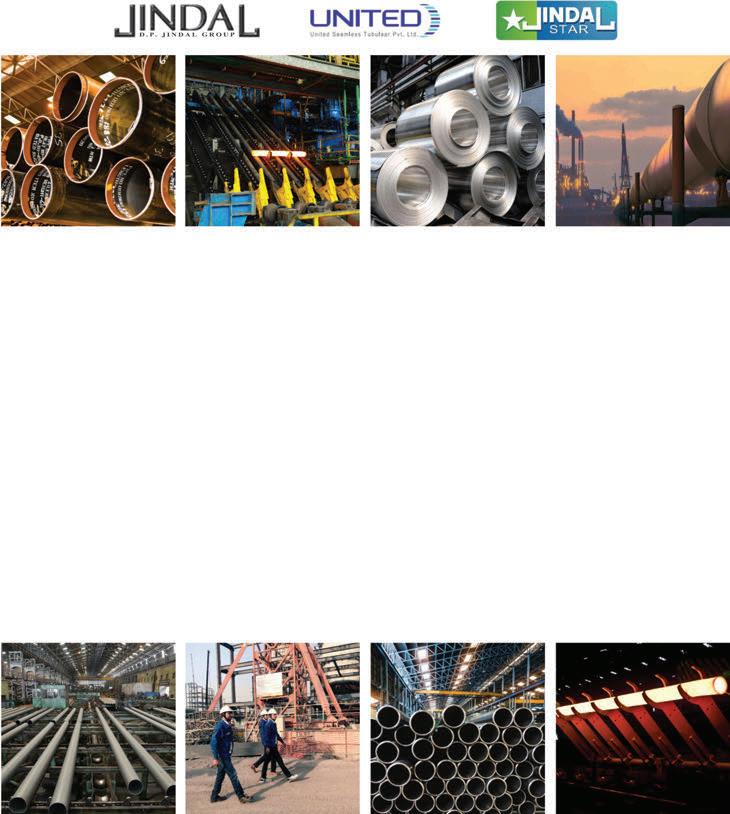

Prime Gold: Pioneers of StainlessSteel Pipes in India

Prime Gold S.S. Pipes has been working since 2004 to provide hygienic and longlasting steel pipes alternative to galvanized iron, copper, and plastic pipes in India. While their strengths have earned them reputed and lasting deals with the Indian government, renewable energy sector, food and beverages industry, and hospitals and pharmaceutical sector, the journey is still long and challenging, especially with the presence of numerous plastic pipe manufacturers and European and Chinese imports. Mr. Nimit Varshney, Vice President of Prime Gold Group, connected with Tube & Pipe India, to share all about the company's challenges, achievements, product supremacy, and future plans.

Tube & Pipe India: Could you please give us a brief outline of your business journey and crucial milestones?

Nimit Varshney: Prime Gold Group initiated its S.S. Pipes vertical in 2004 with a vision and foresight of bringing the world a strong and secure living. We started manufacturing stainless steel plumbing pipes about 20 years ago and are one of the pioneers in the Indian pipe industry. Earlier zinc galvanized iron pipes used to be threaded for plumbing applications, which due to the rusting process would deteriorate causing leakage and seepage to destroy the plumbing network of the building or infrastructure. We are among the first manufacturers of stainless steel pipes in India.

TPI: Kindly cast some light on the infrastructure, manufacturing capabilities, and machinery installed at your facility.

34 | INTERVIEW

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Mr. Nimit Varshney, Vice President of Prime Gold Group

NV: Prime Gold S.S. pipes are manufactured at our factory in Alipur, Delhi (India). We buy steel strips from Jindal Stainless Limited and manufacture steel pipes through Pressure Resistance Welding (PRW) process. Once pipes are ready we use the selected batches to manufacture pipe fittings of different sizes, based on pipe size. We manufacture ½′ to 6′ outer diameter pipes and more then 200 types of fitting.

TPI: Tell us about your product portfolio along with its key strengths and applications.

NV: We use 316L surgical-grade stainless steel to manufacture our pipes, and SS 304 food grade stainless steel pipes and fittings, like Tee, Socket, Reducers, Elbow, Union, etc., which are not only strong and non-perishable but also hygienic. Our biggest market competition is with plastic pipes, however, they are not considered hygienic for many industries, such as food and beverages and pharmaceuticals. Hence, our products have a high level of application in these industries. Our product line is Central Public Works Department (CPWD) approved.

TPI: What are the recent developments and future plans at your company?

NV: We are among the few stainless steel pipe manufacturers in India, so we have direct competition from Chinese and European exporters. However, there are many industries where it is mandatory to use stainless

steel applications, and we are gaining recognition slowly. Presently our focus is to retain our existing clientele and build upon the numbers. Though we have been fortunate to find approval and support from the Indian government, who makes it mandatory for certain sectors and infrastructures to use stainless steel pipes for plumbing, we have aspirations to increase our production capacity, reach, and applicability and venture deeper into commercial projects.

TPI: Please shed light on your market footprint and clientele.

NV: Although the Indian pipes industry is dominated by plastic pipe manufacturers and foreign imports, we have managed to build a respectable and loyal clientele. We have worked along with National Buildings Construction Corporation (NBCC) Limited and among our prestigious private sector contracts is the Ambience builder range of New Delhi and Gurugram. You can find our applications in food & beverage industry like Haldiram Snacks, various hospital & pharmaceutical industry projects, 5-star hotel projects, commercial projects and various industrial projects like metal industries & construction projects. We also have a joint venture with SAIL for iron rods, which we have been manufacturing for 35 years. Some of the government projects we have heralded include pipes and plumbing at Jaipur Railway Station, Gandhi Nagar Railway Station in Jaipur, CPWD, Ministry of Water

Resources in New Delhi, and Uttar Pradesh Nirman Nigam in Lucknow.

TPI: What is your outlook on the tube and pipe industry? What do you believe is its future?

NV: The stainless steel pipes market in India is still in the developing stage and is a very niche market due to competition with the plastic plumbing market, which is less costly, and has numerous manufacturers. However, we have faith in our product, it is not only hygienic and deterioration-proof, but it is also easily recyclable, installable, and rust-proof. Since the material mass density of steel is less than iron, it is a long-lasting alternative to galvanized iron pipes.

TPI: Do you have any dealers and distributors in India?

NV: We have many reputed customers in India. We continuously sell our products to contractors involved in fluid transportation in sectors like thermal, solar, and nuclear power, the oil and gas sector, refinery and petrochemical, dairy, chemical, fertilizer, defense, aerospace, and construction. We have a well-qualified and experienced marketing team for serving our product in various states of our country. Our group has a welldeveloped network of Dealers/ Distributor/Stockist exclusive sale depots spread over various states of India which includes the states of Delhi, Haryana, Rajasthan, Punjab, UP, Karnataka, & Maharashtra.

INTERVIEW | 35

Never miss any news on the Tube & Pipe Industry. SUBSCRIBE TODAY www.tubepipeindia.com TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Jyoti Inox Private Limited: Providing Stainless Steel Solutions

Jyoti Inox Private Limited is the group that pioneered the introduction of stainless steel material in the rice industry. The company's state of the art unit is fully equipped with advanced machinery like CNC cutting and bending machines, power shearing machine and even a complete welding workshop with arc welding. In a recent interview with Tube and Pipe India, Mr. Sahil Garg – Director, Jyoti Inox Private Limited shared with us the company's business journey, market footprint, clientele and future plans.

Tube and Pipe India: Could you please give us a brief outline of the business journey of your company, along with its crucial milestones? Sahil Garg: My father started this business in 1982, and in the 90s he started making stainless steel applications for the rice industry. After a period of time, he started making the spare parts for the rice industry machinery, which converted into manufacturing the complete machinery. Today, we are big suppliers of rice mill machinery in stainless steel only. With the newer generations joining the company, we have launched the stainless steel water tank and stainless steel plumbing for various buildings.

TPI: Kindly cast some light on the machinery installed at your facility.

SG: Currently, we have a 6-acres factory. However, we will be shifting from our current factory to a new 10acres factory for tube mills. In our factory, various laser welding and laser cutting machines are installed, which are imported from Japan, Germany and Taiwan. We have a range of welding technologies and

36 | INTERVIEW

Mr. Sahil Garg – Director, Jyoti Inox Private Limited

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

plasma cutters to suit a wide variety of production requirements as different jobs require different technologies. The factory and plant layout we have here includes stateof-the-art CNC laser cutting machines, CNC hydraulic machine, NC hydraulic shearing machine, sheet bending machine, decoiler & straightening machines.

TPI: Please shed some light on the services provided by the company.

SG: All our fittings are imported from Taiwan, Japan and Germany. Our services include stainless steel plumbing and PEX plumbing, and we import the special plumbing that is Pert-Al-Pert Completed Imported from Germany. These are the special plumbing we provide.

TPI: What are the future plans for the company?

SG: We plan to provide stainless

steel solutions all over India. We also aim to expand our business to more industries, like the food processing, automobile industry, semiconductors industry and others. In the next 6 months, we will be building a new factory for making high precision and high pressure stainless steel pipes. In the future, we aim to go for laser welding technology for the tube mills. We are preparing for this change and purchasing machines.

TPI: Please shed some light on the clientele of your company.

SG: We mainly supply to big consumers like residential buildings, commercial buildings, hotels and hospitals. We supply to major businesses like Adani, as well as many hospitals in India. Our main supply also goes to the food industry, including clients like Cremica group and Priyagold. Our clientele also includes all the big rice exporters in

India like India Gate, Daawat, Kohinoor and others. We also manufacture tanks for industries like pharma and dairy. Currently we are providing tubes and pipes for plumbing services to India's biggest hospital, Amrita.

TPI: Please share your outlook on the tube and pipe industry.

SG: The Indian tube and pipe industry is progressing really well and India has started to export very well too. It is a huge advantage that after COVID-19, India had many prospective to export. Many small businesses flourished as they received big orders. The stainless steel pipes that we work with are going to be in demand for use in hydrogen cars. This is because hydrogen cars create vapors and stainless steel will be installed to make sure those vapors don't oxidize.

INTERVIEW | 37

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

BUDGET 2023

Union Budget 2023 Drives Tubes & Pipes Industry Towards India's Amrit Kaal

Amrit Kaal

38 | UNION BUDGET TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

The status of any economy is a reflection of its economic initiatives. The Union budget FY 23-24 is an example of how an economy can harvest its benefits timely. The budget has appropriated monetary tools for seven-edged growth. Within this spectrum, the budget also has implicated the growth of the tubes and pipes industry as the country maneuvers its way through Amrit Kaal. Explore here the budget's implications and how the major players plan to meet the increased demand for tubes and pipes.

It is the duty of every economy to conceptualize its efforts timely and reap the benefits of impending opportunities. The Union Budget 2023 of Mrs. Nirmala Sitharaman, Union Finance Minister of India, was designed to make the most of the Amrit Kaal, which the Indian economy is going through. Amrit Kaal translates to a period of prosperity, development, innovation, profitability, pleasure, and peace. While some sectors of the economy are directly placed to benefit from these attributes, others find their profitability as indirect or collateral benefactors. One such benefactor is our tubes and pipes industry. According to budgetary announcements, the tubes and pipes will experience an increase in demand across all sub-sectors, irrespective of forming metal. The demand growth is expected to accelerate in multipliers, and the major drivers are:

● INR 10,00,000 crore of Capital Expenditure has been allocated in the FY23-24 budget, which is 36.7 percent more than last year's allocation of INR 7,30,000 crores. The allotment has increased by almost 2x over the span of two years. It fuels the overall infrastructural growth of the economy, wherein tubes and pipes find immense applications.

● The FY23-24 Jal Jeevan Mission investment amounts to INR 70,000 crores. In the previous year, the mission successfully integrated nine crore rural households within the drinking water supply grid.

● The government allotted capital support of INR 30,000 crore to state-run oil refining-cum-fuel retailing companies in 2023-24.

● The Union Budget 2023-24 has allocated an enhanced outlay of INR 2,70,000 crores for the highways sector.

● The Pradhan Mantri Awas Yojna scheme allotment for FY 23-24 is INR 79,590 crores

● This budget has also announced an investment of INR 5,943 crores for Eklavya-model residential schools, which shall include infrastructure, drinking water, connectivity, and sanitization.

● Pradhan Mantri Particularly Vulnerable Tribal Groups (PVTG) Development Mission is also on paper. PM PVTG shall include actions toward housing, water and sanitation, power connectivity, etc.

● Urban Infrastructure Development Fund (UIDF) is planned for Tier II and Tier III cities.

● The union government shall also provide financial assistance for sustainable micro irrigation in the drought-prone regions of Karnataka.

Ascertaining the importance of these announcements for the industry players, Tube & Pipe India initiated a dialogue with the major companies to get a real-time picture of the expected impact. These interpretations not only confirm the general expectations but also drive the industry to gear up as their role gains more importance in the Indian economy.

UNION BUDGET | 39

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

The pipe industry has grown in leaps and bounds,

thereby becoming one of the imperative drivers of growth in the country. This growth phase is going to continue with the budget announcement of INR 1,50,000 crores for both Infrastructure development and JJM Schemes.Additionalroads,buildings,industrialsheds,and logistic hubs, will all lead to an increase in demand for pipes.

JIPL Hissar is a well-established brand synonymous with unparalleledqualityandtimelydeliveryintheERWpipes& infrastructure sector. We have already been a major supplier in the past years in JJM Scheme in UP, HP, Jammu, and Rajasthan and are further gearing up to be on board in the upcoming government schemes. We are expecting a major demand boost with an infrastructure push from the Government and for the pipe industry JJM (GharGharJal)hasbeenabigdemandbooster.

Jindal Hissar will be putting up a green field plant in the South to meet the increasing demand for pipes. We already have a presence in the East, and North; through our manufacturing facility in the South, we will be able to service customers efficiently, especially ones with a panIndia presence. We are also exploring possibilities to set up a facility in West India as well, and will soon finalize the manufacturing project there as well. Our plants will be in close proximity to Jindal Group's hot-rolling steel plants so thatresponsetimescanbefurtherimproved.

In the Union Budget 2023, Finance Minister Nirmala

Sitharaman outlined seven main targets under the 'Saptrishi' mantras, with infrastructure and investment predominating. The clubbing of infrastructure and investments in one of the seven priorities is one of the primary features, along with the second and third highest allocations for Highways and Railways at INR 2,70,000 crores and INR 2,41,000 crores respectively, after the highest allocation for the Ministry of Defence. Among the initiatives being taken is the development of the Infrastructure Finance Secretariat to encourage increased private investment in infrastructure, including trains, highways, urban infrastructure, and power. There is also a focus on reviving 50 additional airports, heliports, water aerodromes, and advanced landing groundings for improving regional air connectivity. One hundred essential transport infrastructure projects for last and first-mile connections for ports, coal, steel, fertilizers, and food grains industries have been highlighted to significantly boost India's logistics industry. Moreover, the PM Gati Shakti National Master Plan portal is now fully operational having the Department for Promotion of Industry & Internal Trade as the key entity for the seven engines: Roads, Railways, Airports, Ports, Mass Transport, Waterways, and Logistics infrastructure.

40 | UNION BUDGET

Mr. Sunil Jain, Director & CEO, Jindal Industries Private Limited (Hissar)

TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Mr. Utkarsh Bansal, Director, Utkarsh India Limited

It is very encouraging to see the investments that have been planned by the government in the various fields of infrastructure. This will not only add to the growth of the country but also allow industries like ours which directly contributetowardsinfrastructuretogrow.

Utkarsh India is one of the backbones of Indian infrastructure across highways, railways, water supply, and constructionthroughvariousproductverticals.

Among other points is the National Highways Authority of India's launch of the Pune-Bengaluru Greenfield Expressway Project at an estimated cost of INR 50,000 crores, approval of the Somasila- Siddheshwaram cablestayed-cum-suspension bridge project (NH-167K) at an estimated cost of INR 1,082 crores, and the Jabalpur Ring Road Project at a cost of INR 3,600 crores. Among the road projects, funds were approved and sanctioned for the Phagwara-Hoshiarpur Four Laning Road Project (NH344B) and the Balikuda-Mulakani Two Laning Road Project(NH-55).

The revamp of the New Delhi Railway Station, Ahmedabad Railway Station, and Chhatrapati Shivaji Maharaj

Terminus Mumbai, at INR 10,000 crores was also approved. Under Project Sampark, the Centre sanctioned funds of INR 562 crores for the Akhnoor-Tain Br-Poonch twoorfour-laneroadproject(NH-144A)aswell.

The Union Government approved the implementation of the Saraighat rail-cum-road overbridge project connecting the north bank with Guwahati on the south bank of the Brahmaputra River in Assam, at an estimated cost of INR 997crores.

There are also plans to construct new transmission lines to meet the 2030 target of 500 GW of renewable energy capacity. With states accounting for 20-25 percent of the overall infrastructure spending, the Budget has also considered an increase of over 30 percent in allocation to the scheme for special assistance to states for capital investment. The government plans to set up digital public infrastructure as an open source, open standard, and interoperable public good to enable inclusive, farmercentric solutions, and give a boost to the agricultural sector. It will also continue to focus on financial support for digital payments.

Union Budget 2023 will have an indirect impact on

raising the overall demand for the tubes and pipes industry. For instance, an increase in expenditure growth in the oil & gas sector by 27 percent, amounting to approximately INR 1,11,000 crores.

We, Maharashtra Seamless Limited (D.P. Jindal Group Company), are engaged in the manufacture of seamless pipes (1/2 inch to 20 inches) and ERW pipes (8 inches to 20 inches). Our group's company, Jindal Pipes Limited, manufactures ERW pipes (1/2 inch to 14 inches). Growth in infrastructure & real estate is expected in line with the strengthening of the local economy. It proposes more commercial, residential, and retail development for tier II and tier III cities. Municipal or government bodies will also be able to raise more funds, and all these will have a cumulative impact on the real estate sector as well as infrastructure development like Smart Cities, Roads, Bridges, Highways, Ports, etc. Housing for all with the PM Awas Yojana and the extended Credit-Linked Subsidy Scheme (CLSS) will further boost the real estate sector. As a means of addressing this gap in affordability, the central government will further boost its initiative to provide affordable housing. Increasing the outlay for PM Awas Yojana by 66 percent the Union Budget 2023 has provided the real estate sector with crucial support and incentives. All these three schemes, that is Har Ghar Jal Scheme to supply piped water, affordable housing to all, and the best infrastructure will generate more demands for tubes & pipes in MEP, ducting, Conduit, Sewage, and drinking watersupply.

42 | UNION BUDGET TUBE & PIPE INDIA • FEBRUARY-MARCH 2023 www.tubepipeindia.com

Mr. Shiv Kumar Singhal, President - Commercial, Maharashtra Seamless Limited

WIDE RANGE OF PIPES

• Line Pipes

• Boiler Tubes

• Aph Tubes

• Large Diameter Pipes

• Square & Rectangular Hollow Sections

• Low Well Thickness General

• Engineering Pipes

OUR BRANCHES

Mumbal Office:

211-213, Navratan Building, 69, P.D. Mello Road, Carnac Bunder, Mubai-400009. Maharashtra-india

Ph. +91 22 23488554 | Fax +91 22 23486356

Ahmedabad Office:

201-203, Sukhsagar, Near Hotel Fortune Lamdmark, Ashram Road, Ahmedabad-380013, Gujarat - india.

Ph. +91 79 27561123-24-25

Fax +91 79 27561224

BRANDS WE STOCK & REPRESENT

Email:

info@shahsteeltubes.com

shahsst@gmail.com

About 50 percent of the overall expenditure in the oil & gas sector will go into the expansion of refining capacity, 44 percent for exploration and production, and the balance into distribution. All these three areas will drive huge demand for seamless pipes. As our major trust is in this sector and we have been regularly supplying Seamless Production Casings, Tubings, and Line Pipes

to all state-owned oil companies like ONGC.OIL, IOCL, BPCL, HPCL, GAIL, etc., we will be a major supplier of the market for Steel Pipe Seamless & ERW in this growth story. We are fully equipped and geared up with our increased production plans in all shifts to meet the increased demands, at a rate of 10-12 percent, in FY 20232024.

The targeted focus of Government on increasing spending in the infrastructure sector will certainly create mega multiplier effect by generating demand for its input material like coal, cement, heavy machinery, and iron ore, alongwith creating mass level job opportunities in these sectors. It is bound to attract investment as well in the pipe and tube industry, which will further give impetus to this sector which has been a laggard since long. Further looking at the plethora of industries who use tubes and pipes as their input or ancillary product, the impact on this industry is surely expected to benefit fromalldimensions.

We have been quite positive on the demand outlook ever since Covid-19 started to phase down. We started bolstering our own infrastructure and human resource strength in last two years to keep up with the expected pace of growth and have developed separate wings to cater to the behaviour patterns and needs of customers in different sectors. Furthermore, we have come up with storage yards in Eastern and Southern parts of the country to ramp up the stock levels. Most importantly we have secured additional workingcapitalarrangementsfromfinancialinstitutionsto keepuspreparedforexcitingopportunitiesthatlieahead.

Government lead projects, especially infrastructure projects, are the largest consumer of steel and cement in India. Relying on the numbers coming out of the FY 23-24 budget, it is clear that the government is ready for the infrastructure push and it is now the responsibility of the Indian steel pipes & tubes industry to show their readiness to support this ambitious plan.