Mar-Apr, 2023 Vol. 12 No. 03 1000/October, 2023 6 7 8 FRI SAT SUN Pragati Maidan New Delhi The 5th International Exhibition & Conference for Wire & Cable Industry www.cablewirefair.com 28 32 40 APAR Industries Focusing on Exports & Retail Market KSH International Crosses INR 1000 Crore Turnover Mark KSH INR Ambica Dhatu: Aiming 50,000TPA Wire Production Capacity with “Stronger, Safer, Superior” Products Leebo Group Aims Excellence in Copper and CopperFabricated Solutions UKB Electronics to Fortify in Speciality Cables Sector 14 22

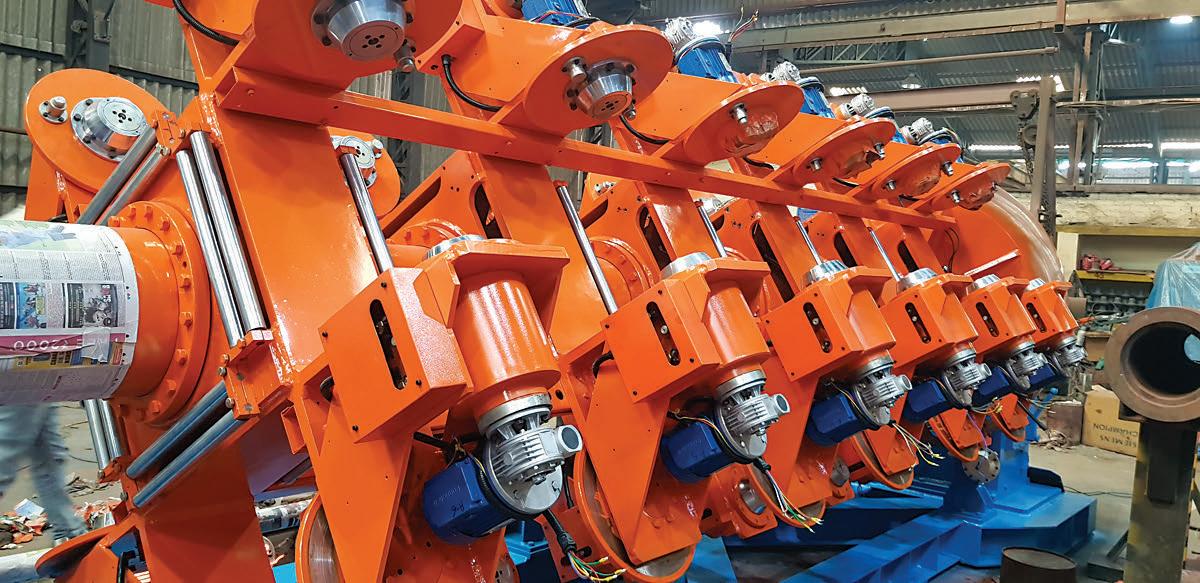

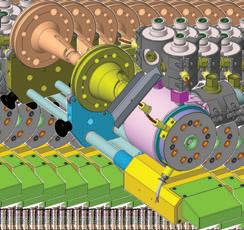

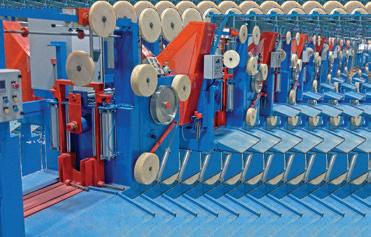

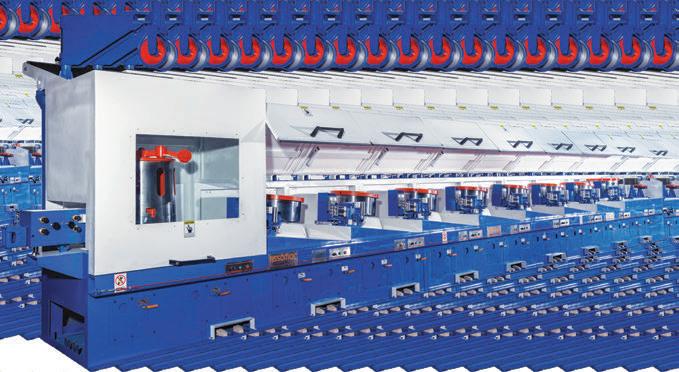

MANUFACTURING PROGRAMME

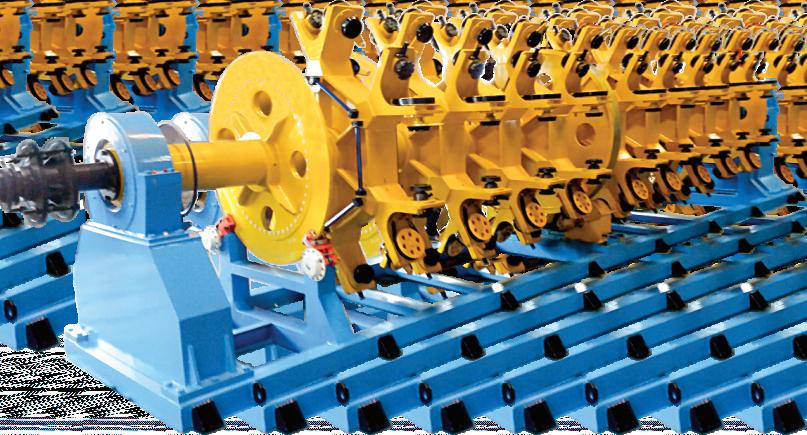

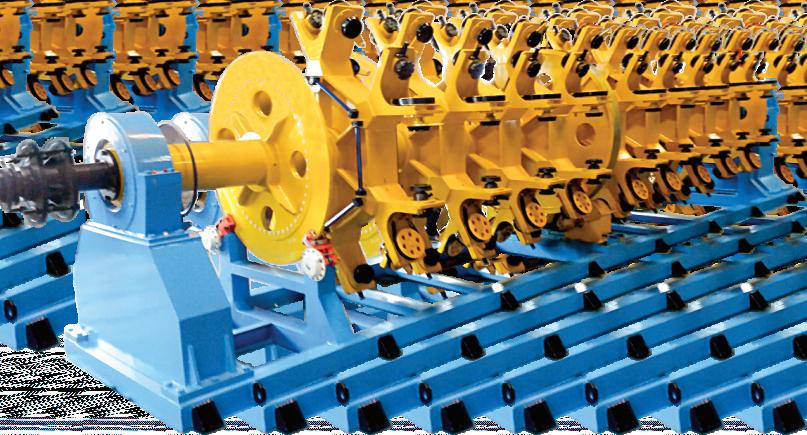

n Straight Line Wire Drawing Machines

n OTO Type Wire Drawing Machines

n Inverted Drawing Blocks (IVD)

n Vertical and Horizontal Bull Blocks

n Rod Break Down Machines

n Wet Wire Drawing Machines

n Furnace-Wire Annealing, Patenting, Stress Reliving

n Tubular / Skip Stranding Machine

n Vertical Drop Coilers (VDC)

n Dead Block Coilers (DBC)

n Wire Spooling Lines - Multi / Single Wires

n Wire Flattening Mills / Shaped Wire Mills

n TIG Wire Straightening Cutting Machines with Embossing

n Welded Wire Mesh Lines For Mesh Rolls Or Mesh Panels

TURNKEY PROJECTS

n Plants For Galvanized Wires – Hot Dipped and Electro coated (High Speed Galvanizing Line with Nitrogen / Pad Wiping)

n Plants For M.S., H.B. & Binding Wires

n Plants For High Carbon And Alloy Steel Wires (40mm to 0.20mm)

n Plants For Stainless Steel Wires

n Plants For Cold Ribbed Wires/Deformed Bars

n Plants For Tire Bead Wire (Bronzing Lines)

n Plants For Copper Coating and CO2 MIG / TIG / Saw Welding Wire

Corporate Office & Works : 546, Bisrakh Road, Chappraula, Dist. Gautam Budh Nagar - 201 009 (INDIA) Cell: 0091-9810075965 Website: www.assomacmachines.com Correspondence Address : 26/2 South of G.T. Road Site No. 1, B.S. Road Indl. Area, Ghaziabad - 201 001 (INDIA) Ph.: +91 120 2866505, 506, 507 Fax: +91 120 2866508 E-mail: info@assomac.in Website: www.assomac.in Design by: info@tulip3pmedia.in Intermediate Straight Line Wire Drawing Machine Inverted Vertical Drawing Block May 24-27, 2023 Stall No: 503, Hall No: 05 Tüyap Exhibition and Congress Center Istanbul,Turkey Meet Us At:

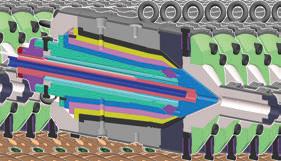

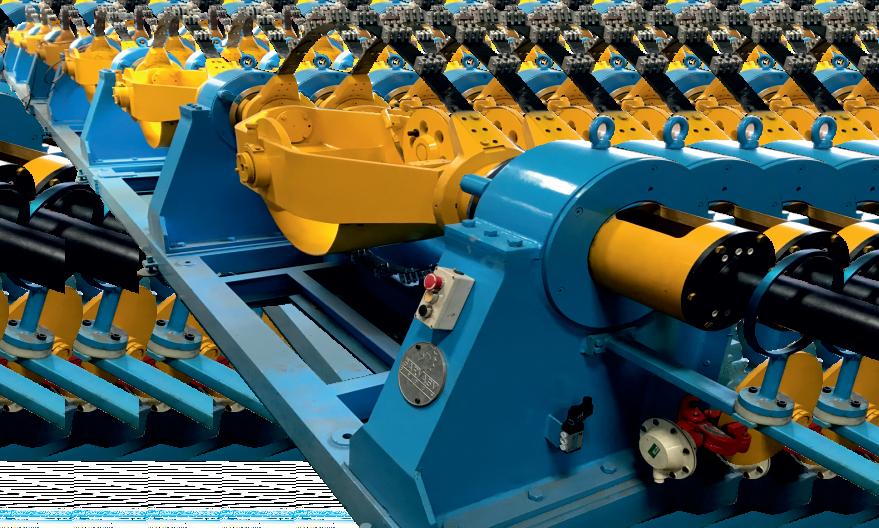

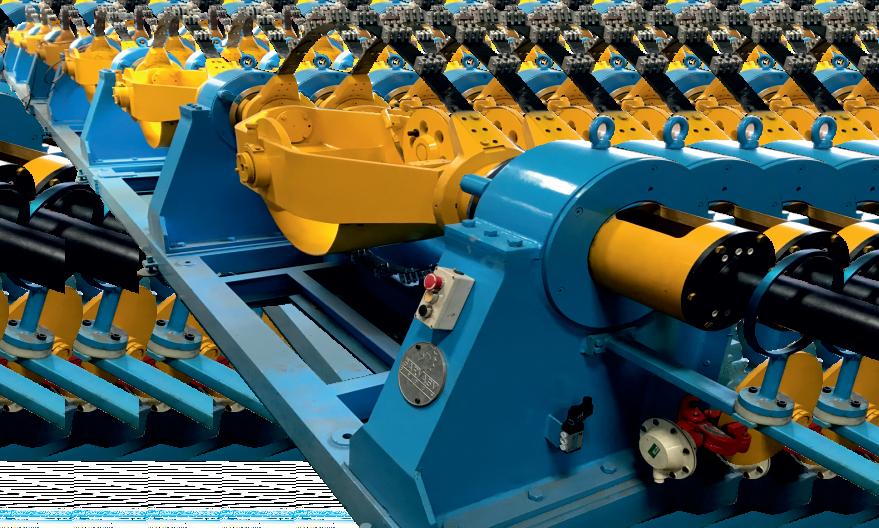

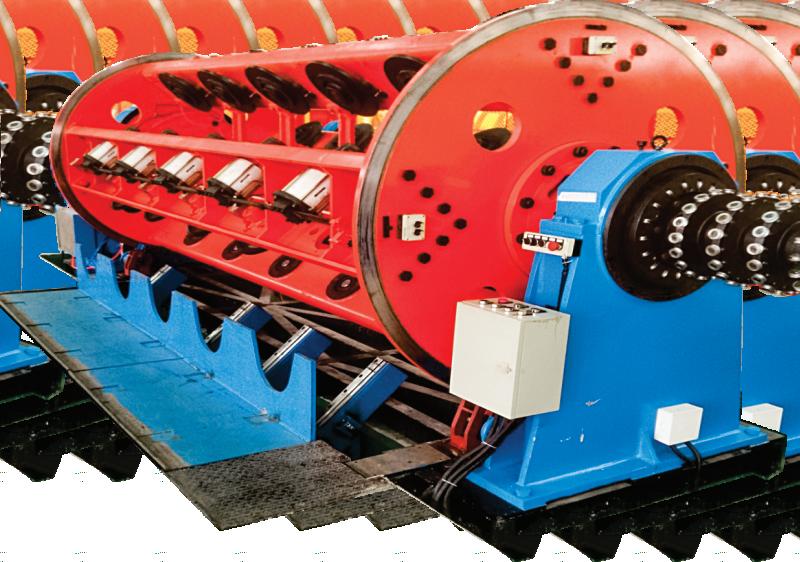

Rigid Stranding Machines

Taping Machines and Equipment

(An ISO 9001 : 2015 Company)

Rigid Stranding Machines

Drum Twister Machines

High Speed Semi Automatic Core Rewinding Line

Rigid Armouring Machines

Rigid Armouring Machines

Heavy Duty Take up & Pay off stands

Rigid Armouring Machines

Office & Works-1: Plot No.744, Sector-69, IMT, Faridabad (NCR), Distt.: Faridabad, PIN-121004, State: Haryana (India)

Landline: 0129-2977999, Mobile: +91- 9811010197, +91-8586969099, +91-8586969100

E-mail: info@cabletechindia.com, cabletechmachines@gmail.com, ctm97@rediffmail.com, Works-2: Plot No.143 & 150, NangIa - Gajipur Road, Gajipur, PO: Pali, Distt.: Faridabad, PIN-121004, State: Haryana (India) Phone: +91- 9811010197, +91-8586969099

www.cabletechindia.com

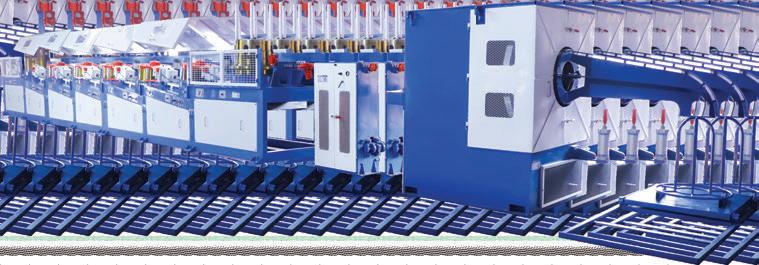

Our Services IIOT Machines Upgradation Industry Internet of Things Remote Services Your Partner in Extrusion Technology Supermac Industries (India) Limited is a technological leader in manufacturing of Extrusion machines since 1974. It is a leading FEP wire extrusion line manufacturer and rewinding machine suppliers offering a complete range of crossheads, caterpillars, belt wrap capstans, screws, and barrels. Supermac has strategic partnership with German Company- M/S Scholz to cover CCV Lines, and Simpack USA for Coiling machine and solutions. A-28, Naraina Industrial Area, Phase-I, New Delhi 110029, INDIA Phone : +91-11-45574317 E-mail : office@supermacindia.com Plot no.2, Sector-6, IMT Manesar, Distt.Gurgaon, Haryana 122050, INDIA Phone : +91-124-4690500 E-mail : office1@supermacindia.com Plot No.72, Sector-8, Industrial Estate Dharuhera, Distt.Rewari 123110, Haryana, INDIA

CONTENTS Mar - Apr, 2023, Wire Cable India 44 Inspired Manufacturing at Interwire 2023 APAR Industries

on Exports & Retail Market KSH

1000 Crore

Mark UKB

Speciality

14 22 28 Ambica Dhatu: Aiming 50,000 TPA Wire Production Capacity with “Stronger, Safer, Superior” Products Orient Electric Ventures into Wires & Cables Business Leebo Group Aims Excellence in Copper and Copper-Fabricated Solutions 36 32 40

Focusing

International Crosses INR

Turnover

Electronics to Fortify in

Cables Sector

3R Polymers Expands Plant to Achieve 36000 TPA Capacity by FY2025 52 NAVANK: Backend Tech Integration & Two Warehouses in India for JIT Deliveries 56 Universal Polychem Aiming Doubled Capacity by End of FY23-24 60 KonnArk Group Adds New Extruder Line at Silvassa Plant Lifeline Technologies Ensures High Quality Products with State-OfThe-Art R&D Takkar Polychem: Service through Quality and Innovation 64 68 72 76 SMART GRID: Access, Availability and Affordability of Power for All 88 NEWS

Speakin

IndiatoBecomethe Manufacturing Powerhouse!

In the past, developed economies created China as the manufacturing hub for low cost of production. Now is the time for India. India is not just manufacturing for itself but is set to manufacture for the world. In fact, India not just offers the capability to produce cost effectively but also go beyond and provide high quality goods backed by better credibility.

As a global manufacturing hub, China accounted for approximately 30% of global manufacturing. However, post COVID-19, the situation has changed drastically. Now the organizations are looking for suitable alternatives that will help them to reduce their risks and have more resilient supply chains, as a result of which India's positioning in the global supply chains has gained traction.

The vision for this note was clear; I wanted to talk oneon-one with the readers about all that Wire & Cable India has to offer. I wanted to share our efforts in bringing forward this edition, the concurrent events of the industry, and a small, profound piece of personal opinion. There are various ways to achieve our targets, and mine was to ensure a connection with my readers.

The China Plus One (C+1) strategy of foreign companies to de-risk their supply chains and reduce their dependence on China may provide a boost to India becoming the future global manufacturing hub owing to its strengths like comprehensive GST system, business friendly legislation, low wage rate and operational costs, low logistics costs, well-regulated financial systems, competitive skilled talent across various industries, work ethics, strong infrastructure development and incentivising government's policies like 'Make in India', 'Startup India Movement', production linked incentive (PLI) etc. Also, organizations prefer to bring their manufacturing hubs closer to their end markets and India is one of the largest and the fastest growing economy in the world, targeting to become a USD 5 trillion economy by 2025.

Disinvestment from China has led giants such as Apple, Samsung, Hyundai and many more to enhance their manufacturing footprint in India. The computer software and hardware sector, services, trading, chemicals, automobile and construction (infrastructure) activities witnessed the highest inflows helping the country record its highest-ever FDI inflows of USD 84.84 billion in 2021-22. Due to 100% FDI allowed in the power sector, total FDI in this sector reached USD 16.57 billion in AprilDecember 2022.

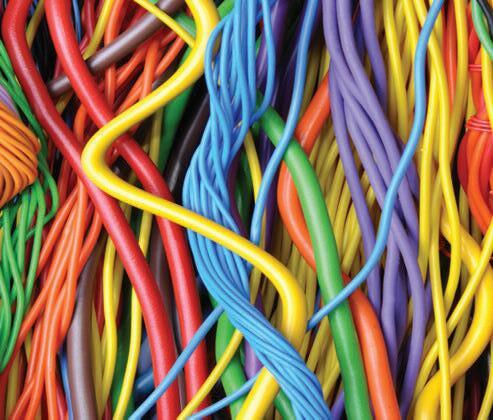

In past few years, there has been a visible thrust of Indian wire & cable companies on exports. Their export revenue had increased at a rapid pace which fuelled their performance during the covid period and do a business volume better than the precovid level. Indian companies are consistently focusing on product quality and safety certifications to enable to serve the export markets better. They are increasing their network across the globe be it developing or developed economies to harness the maximum potential of opportunities offered by the exports segment. Indian manufacturers have carved out a niche for themselves as a quality product manufacturer over the last several years. With strong organic growth in international business, companies are reporting their highest ever export numbers on YoY basis, which is expected to become stronger going forward.

We can very well see the Indian wire & cable industry investing in technology and building capacities, which will further enhance in future. Investment in the latest technology is going to be a key differentiator for sustainable growth. These investments have to be backed by continued R&D and product development.

Priyank Jain, CEO Tulip 3P Media Private Limited

Priyank Jain, CEO Tulip 3P Media Private Limited

www.wirecable.in OUTLOOK

APAR Industries Focusing on Exports & Retail Market

Powering a smarter world since

1958, APAR Industries has transformed into a billion dollar conglomerate leading the innovation and sustainability curve globally in its core businesses. Geared up to tackle the biggest challenges of the 21st century, APAR believes that with an innovation-first mindset, solutions that make anything possible can be found. Over 60 years APAR has expanded to over 140 countries as a highly trusted manufacturer and supplier of conductors, a wide variety of cables, speciality oils, polymers and lubricants. Mr. Shashi Amin, CEO, APAR Cable Solutions provided Wire & Cable India valuable insights about his company, recently launched APAR Anushakti wires, JV with Clean Max Rudra Private Limited, and its future plans.

Mar-Apr, 2023 www.wirecable.in INTERVIEW

Mr. Shashi Amin, CEO, APAR Cable Solutions

14

Wire & Cable India: Kindly share the business journey of APAR Industries' cables division, outlining the major milestones and achievements.

Mr. Shashi Amin: APAR Industries Limited is gearing up to tackle the biggest challenges of the 21st century, catering to the needs of the global energy sector through sustainable means. The company believes that with an innovation-first mind-set, solutions that make anything possible can be found. APAR's mission is to design & manufacture building blocks for energy infrastructure, transportation & telecommunication sectors that contribute meaningfully to make this world more energy efficient, environmentally sustainable and a safer place.

In 2008, APAR Industries Limited entered the cables business to expand its portfolio and forward integration by the acquisition of UNIFLEX Cables. In 2012, APAR introduced a new gentech to build the largest e-beam facility in India. In 2021, APAR was the 1st Indian player to create guidance OFC for torpedoes. Keeping exports business in mind APAR had already 12 UL approvals which includes 50+ cable types being highest in India. Currently, we are the leading manufacturer in the domestic segment for renewable sector cables and number 1 exporter of cables from India.

WCI: Could you walk us through the company's manufacturing facilities, infrastructure and machinery setup along with production capacity, with regard to APAR's cables division?

SA: APAR has a vast manufacturing infrastructure of nearly 300,000 SQM at Umbergaon and Khatalwada, Gujarat. In addition, our manufacturing plants are strategically located within 150 km of Mumbai Port.

APAR has a manufacturing facility for elastomeric cables up to 72.5 KV, 1 core up to 1000 sqmm and multi-core up to 630 sqmm copper, aluminum

and copper clad aluminum. For XLPE cables, we can manufacture up to 66 KV single core up to 1000 Al, 630 sqmm Cu multi core up to 630 sqmm Al and 630 sqmm Cu. We have 4 eBeam facilities ranging from 1.5 MeV to 3 MeV for electron beam irradiated cables. All plants are Quality Management System (QMS) - ISO 9001, Environmental Management System (EMS) – 14001 and Occupational Health & Safety (OHSAS) – 45001 certified. Apart from this, sector specific specification is available, which includes TL9000 for OFC, IAEF 16949 for automotive, ISO/TS 22163 for IRIS. We have 2 NABL labs at the Umbergaon HT division & Khatalwada OFC division. We have taken more than 800+ tests as per various national & international specifications.

WCI: Tell us about APAR's recent revolutionary product, "APAR Anushakti", highlighting the product's features, applications and USPs.

SA: APAR ANUSHAKTI is our flagship and groundbreaking product. Keeping in mind "Tomorrow's Solution Today", this house wire meets international standards for the Indian market by exceeding the IS: 694 basic requirements with the help of e-beam technology.

APAR ANUSHAKTI wires can withstand temperatures up to 105 degree celsius, carry 50% more current than conventional wires and last for longer than 50 years. Now high-rise buildings, residential buildings, hospitals, malls, airports and railway stations can enjoy the safest and most reliable FR-PVC insulated wires.

Some major characteristics are as follow:

Ÿ Non-softening, infusible & nondripping under overload and shortcircuit conditions to prevent shortcircuit, thus ensuring fire safety.

Ÿ Does not melt easily in contact with hot objects.

Ÿ High oxygen & temperature index for improved fire retardancy.

Ÿ Self-extinguishing and does not spread fire.

Ÿ High insulation resistance avoids any electric shock.

Ÿ Rugged mechanical properties–superior abrasion, cut through & crush resistance.

Ÿ Better ageing property thus longer life of wires.

The tagline "Iss Taar Ki Shakti APAR" beautifully sums up the brand promise.

WCI: Please elaborate on the cable product range of APAR Industries, emphasizing on their features, applications and advantages.

SA: Since our inception, every year we have been exploring all the strides to deliver innovative products that solve our customers' real problems. Over the past two years our cable solutions business has developed and introduced specialized OFC cables, tether cables, tactical cables, submarine pressure tight cables, torpedo cables etc. for defence and shipyards.

Some of our major products are:

Ÿ XLPE power & control cablesManufacturing cables up to 66 kV on two high precision CCV lines.

Ÿ Screened & instrumentation cables - used in data acquisition systems, connections to instruments, computer networking, PA systems, digital/analog control/measuring & communication systems.

Ÿ Medium Voltage Covered Conductors (MVCC) - Ideal and safer solution for installations for river/lake/railway/road crossings and populated areas.

Ÿ Aerial bunched cables - used for temporary power distribution or for rural power distribution and/or for street lighting and secondary poleto-pole service cables.

Ÿ UNIDAC – ANTI-THEFT cables

Mar-Apr, 2023 www.wirecable.in

INTERVIEW 15

Light Duty Cables (LDC) &

Ÿ APAR FIRE PROTEKT - Flexible wires - flame retardant low smoke zero halogen wires (HFFR / LSZH/ LSOH) ideally suited for places where high fire performance, reliability and safety is at a premium.

Ÿ ELASTOMER & E-BEAM CablesCables up to 72 kV with thermoset elastomeric insulation and sheaths vulcanized by chemical curing, hot air curing and electron beam curing for various compounds viz. EPR, CSP, CPE, PCP, EVA etc.

Ÿ SOLAR Cables - Solar cables for emerging PV based renewable energy installations backed by its 30 years of experience in manufacturing elastomeric insulated cables.

Ÿ RAILWAY Cables / WINDMILL Cables/ NUCLEAR PLANT Cables

Ÿ Optical Fibre Cables

Ÿ Innovative cable solutionsHeavy Tow Cables, Mareech Cable / Torpedo Cable, Umbilical Cable, ROV Cable, Tactical Cable for Army, Tether Cable Air Surveillance Balloon system, Pressure Tight and Non-Pressure Tight cables up to 60 BAR for Ship Building, Airport Lightening Cable, EV Cables.

WCI: APAR recently signed a JV with Clean Max Rudra Private Limited to establish and develop wind and solar hybrid power generation facilities in the state of Gujarat. Kindly elaborate on how APAR is going to contribute towards this project.

SA: JV with Clean Max Rudra Private Limited is to establish and develop wind and solar hybrid power generation facilities in Gujarat, having wind turbine generators of 3.3 MVA capacity and a solar capacity of 2.805 MWp (DC). The power generated from the project will be supplied exclusively to APAR and SPV (APAR - 26% in the SPV Company, Clean Max Enviro Energy Solutions Private Limited - 74% in the SPV Company) will be the operator of the entire project as generator. This will help to operate our cable manufacturing plant entirely through renewable energy. This project is under execution and will share further details subsequently.

WCI: Since its inception every year, APAR has been exploring all the strides to deliver innovative products. Could you share any recent developments in terms of capacity expansion, product

To reduce AT&C losses, GoI has approved Rs 3 lacs crores over a 5 years period to help DISCOMs improve their operational efficiencies and financial sustainability, which will significantly open up opportunities for the domestic cable industry.

developments or technological innovations in the cables division at APAR Industries?

SA: At APAR, we continuously work on improving our product through technological innovations to solve unique customer problems. Currently, our R&D team has developed high ampacity cables with hightemperature withstanding capability, improving the anti-rodent properties of cables and developing other specialized cables for specific applications in defence, telecom, renewable energy and other industrial applications segments.

Mar-Apr, 2023 www.wirecable.in

Ÿ

Wires – APAR ANUSHAKTI, APAR SHAKTI.

INTERVIEW “

” 16

APAR is the largest manufacturer of electron beam cables in India, with 4 e-beam accelerators (1.5 MeV, 2.5 MeV, 3 MeV and recently commissioned another 2.5 MeV e-beam line) at our Khatalwada plant in Gujarat. Along with wires, cables & harnesses for automotive, we are manufacturing and supplying a complete range of integrated harness for electric buses, 2 & 3 wheeler electric vehicles(EV), EV chargers, solar jumpers and molded harness with an inline fuse. With increasing requirements for cable quick-to-install products and quality that outlast, we are developing a complete range of cable harness for locomotives & railway coaches, earthing kits for rolling stock, PA system cable harness and many more.

APAR is one of the major suppliers of railway harness for "Vande Bharat" train.

APAR has been associated with Indian Defence and Naval Department DRDO/NPOL for over 20 years for development of specialised import substitution cable products.

Over the past few years our cable vertical has developed and introduced specialised OFC cables, tether cables, tactical cables, submarine pressure tight cables, and torpedo cables, for defence and shipyards. Also, our ebeam powered APAR ANUSHAKTI house wire is a unique product that creates new insight on the consumers buying mentality and captures the market quickly. APAR ANUSHAKTI is melt-resistant, fire-retardant and offers 50 years of life. We are also continuously working towards expanding our manufacturing capacity as well as our product range.

WCI: Kindly emphasize on the Indian and international presence, vast clientele and market share of APAR Industries.

SA: The adoption of latest technology, growing economy, population, industrialization and urbanization has led to a steep increase in energy

demand in India. This was witnessed in January 2023, as India recorded a double-digit year-on-year growth of nearly 13% to 126.16 billion units kWh (as per government data). The government is successfully working on delivering this ever-growing electricity need with a massive expansion in renewable energy sources, led by solar power, to provide quality of life to every Indian, leading to a huge growth of the cables and wires market.

APAR is the largest Indian manufacturer of renewable sector cables and also the no. 1 exporter for cables from India. Our domestic market is not only restricted to regular routine cables but also our dedicated R&D team has developed cables for very special usage and end to end solutions for the renewable sector. APAR harness is an innovative product that will be the future of cabling in the renewable sector. Demand for our APAR ANUSHAKTI cables is increasing day by day due to its higher current carrying capacity and temperature resistance. With the mantra of never compromising quality, we expect to be one of the top 5 domestic players in the segment.

For export business, with 50+ UL cable types approval, DCA/ECA (CPR), IEC 62930, , IEC 60502 – 1 & 2, TuV & EN 50618 approvals we are eligible to sell our products in almost every country. For Indian manufacturers, we capture more than 25% of the cable exports market. Our prime focus has been the US, Europe, Australia and Latin America. Also keeping in mind the recent developments in infrastructure and lifestyle in African countries, we are keen to capture significant market capture there.

WCI: How important is brand building for APAR Industries and what branding strategies do you adopt for staying ahead of the market curve?

SA: Brand building is essential for APAR Industries as it helps to

differentiate the company's products and services from its competitors which creates brand awareness and establishes brand loyalty among customers. Building a strong brand can also help to increase the perceived value of the company's offerings, leading to higher customer acquisition and retention rates.

To stay ahead of the market curve, APAR Industries adopts various branding strategies, such as:

1. Consistency: Maintaining consistency in brand messaging, visual identity, and customer experience can help to establish a strong brand presence and build trust among customers.

2. Innovation: Introducing new products or services, using innovative marketing techniques, or leveraging new technologies can help to differentiate the brand and create a competitive advantage.

3. Thought Leadership: Establishing the company as a thought leader in the industry by sharing insights, participating in industry events, and publishing research which helps to enhance the brand's reputation and increase its influence.

4. Social Responsibility: Incorporating social and environmental responsibility into the brand's values and operations helps to create a positive image and appeal to socially conscious customers.

5. Personalization: Using data and technology to personalize the

Mar-Apr, 2023 www.wirecable.in

INTERVIEW “

” 18

The wire and cable industry was about INR 58,000 crore in FY22 and we expect it to grow at a CAGR of above 10% for next few years.

Ÿ Straight Line Wire Drawing Machine Ÿ Inline Wire Rod Preparation System Ÿ CO2 Wire Production Line Ÿ Pay-off & Take-up Systems for Galvanizing Line Ÿ Pay-off & Take-up Systems for Patenting / Annealing Line Ÿ Inverted Drawing Machines (IVD) Ÿ Wet Wire Drawing Machines Ÿ Vertical / Horizontal Spoolers Ÿ Dead Block Coilers Ÿ Pay-offs for Wire Drawing Machine Ÿ Rewinder Machines Our Product Range SWARAJ TECHNOCRAFTS PVT. LTD. Plot-40, Sector-II, Pithampur, Dist. Dhar (M.P.), India-454775 Ph.: +91 7292 407213, 407304, Email: Info@swarajtechnocrafts.com, Website: www.swarajtechnocrafts.com Mob.: +91-97522 65813 Built like a tank…. Runs like a Race car Leading manufacturer of wire drawing machine and auxiliary equipments for steel wire industry

customer experience which helps to increase customer engagement and loyalty.

Overall, a combination of these strategies has helped APAR Industries to build a strong brand and stay ahead of the market curve.

WCI: APAR Industries' shares have reportedly grown over 800 percent in the past 3 years. What according to you are the major USPs of the company and its products in contributing to this exponential growth?

SA: We are very happy to see the growth in our share price which clearly indicates that the trust our investors have placed in APAR. However we remain grounded and are committed to improve our various business metrics going forward irrespective of the share price movement. For the first 9 months of FY23, we have seen strong growth in the cables business with increasing share of exports business leading to substantial improvement in operating profits. In this competitive environment, APAR has demonstrated its ability to implement strategies and initiatives which has differentiated us from our competitors. We have responded to technological changes as well as sociopolitical, economic and regulatory conditions in India. Not only the investors and promoters but APAR is slowly being recognised as a brand in the retail market which is committed to quality, innovative solution, customer centric approach. Our retail business of wires is growing exponentially and we are very much

focused to keep this momentum going.

APAR is IATF accredited and ARAI approved, manufactures all cabin and engine compartment wires, battery cable, ignition wire, customized wires and complete harnesses for all automotive including Electric Vehicle (EV). In 2022, we had appointed Mr. Sonu Sood as our brand ambassador for increasing brand awareness for the retail market.

For the year FY 23, APAR has been the largest exporter of cables from India, contributing more than 50% of our production. This is happening mainly due to the trust of the overseas customers on capability to produce month-on-month quality products.

WCI: Kindly provide your insights on the current scenario, ongoing challenges and upcoming opportunities in the Indian and global cables markets.

SA: As announced by the Finance Minister, this Union Budget will be the foundation and blueprint of the economy for 'Amrit Kaal', the next 25 years – from India at 75 to 100. With a major focus on R&D for sunrise sectors, sustainable solutions, and technological advancements in this Budget, we are also looking forward to a growth-driven economy in the future.

The Gati Shakti platform itself is a significant example. The Budget will also focus on laying the foundation for rolling out 5G spectrums, laying out optical fibre, and enabling easy availability of broadband services in rural areas. This will be an added boost for the wire and cable industries.

As India's economic growth is estimated to be 6.4% in the upcoming financial year, we can expect a push towards more investments and a renewed focus on Atmanirbhar Bharat. The focus on infrastructure is very evident, with an increase in capex by 35 percent. Further, to reduce

AT&C losses, GoI has approved Rs 3 lacs crores over a 5 years period to help DISCOMs improve their operational efficiencies and financial sustainability, which will significantly open up opportunities for the domestic cable industry.

With an increasing global trend for the usage of renewable energy especially in the US and Europe, and with ongoing recession, China+1 policy and higher manpower cost, the export market is opening significantly for Indian cable manufacturers. Not only in the US & Europe, Africa is also seeing a lot of infra developments. Especially post strong funding from ADB and World Bank, the African market is going to see developments in every aspect never seen before.

WCI: What are the company's long term and short term plans for growth in the future?

The wire and cable industry was SA: about INR 58,000 crore in FY22 and we expect it to grow at a CAGR of above 10% for next few years. In the domestic market, APAR has been working diligently to create awareness of its innovative light-duty cable range (powered by e-beam technology) among all the stakeholders through BTL, ATL and digital routes. Going forward, we aim to establish APAR as a renowned brand in the retail business, which will happen with an increasing share of APAR in the wires business. India remains our home market, where we deliver products of global standards. With the highest number of uL approvals, we are well accepted in the US market and will continue to further strengthen our market share as opportunities are abundant with the revival of the capex cycle in the US. We will expand our export business to other parts of the world to reduce any country-specific risk. In 2023 we will continue to lead the innovation curve globally by working diligently towards achieving our core values of Innovation, Accountability, Entrepreneurial drive and Leadership.

Mar-Apr, 2023 www.wirecable.in

INTERVIEW “

” 20

For the year FY 23, APAR has been the largest exporter of cables from India, contributing more than 50% of our production.

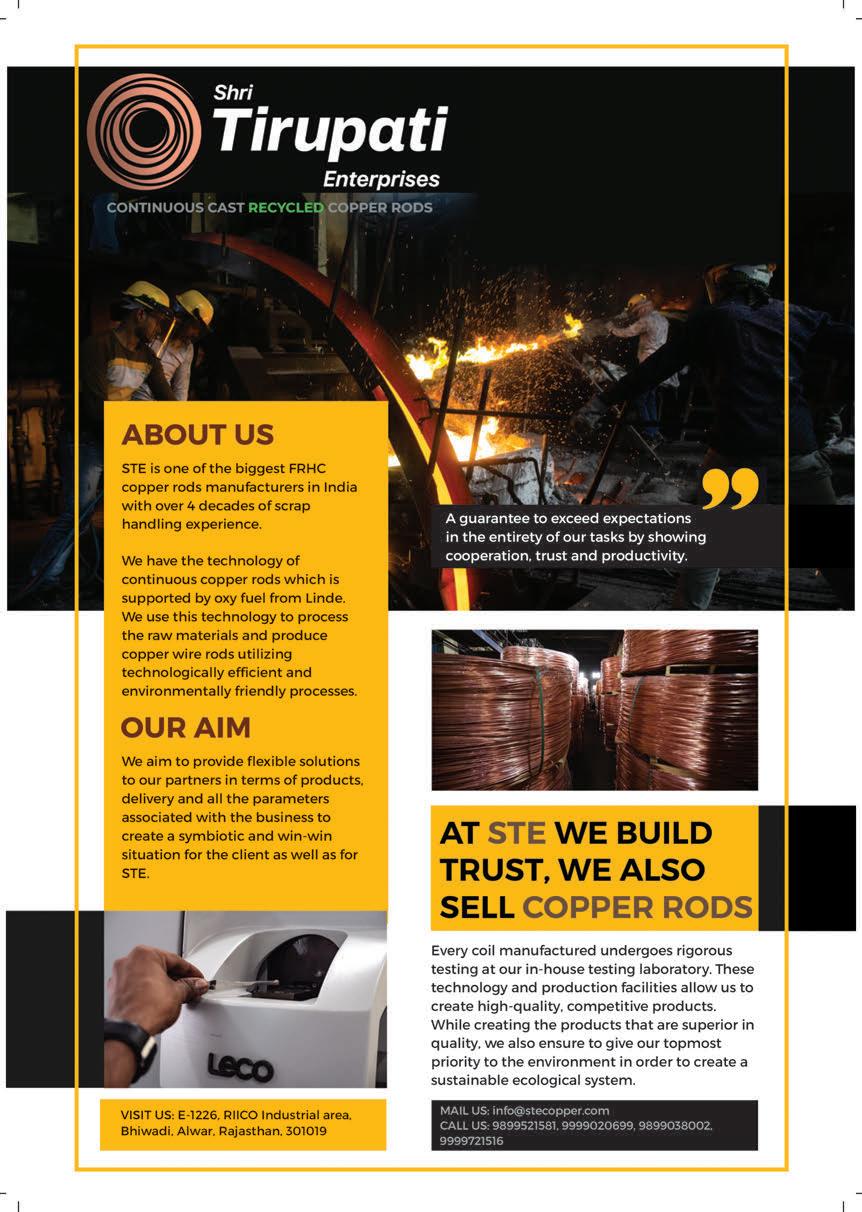

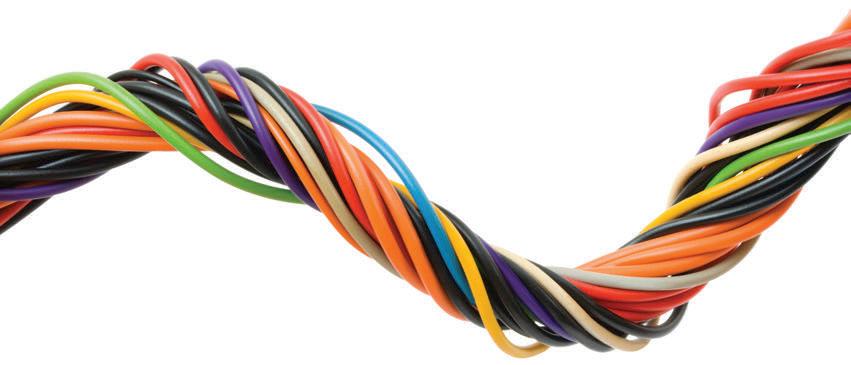

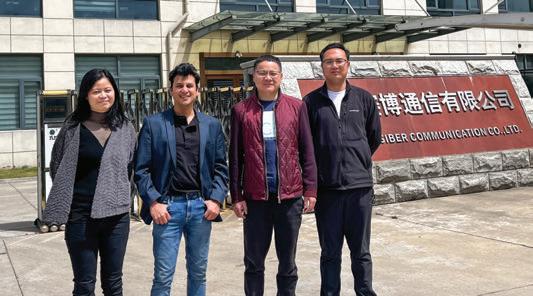

KSH International Crosses INR 1000 Crore Turnover Mark

Founded in 1981, KSH International Private

Limited is the leading manufacturer of bare and insulated rectangular & round winding wires and transposed cables in India. With 3 manufacturing plants near Mumbai and Pune, the company is known for providing customized solutions and manufacturing products as per customers' specific requirements. In a recent interaction, Mr. Sandesh Bhagwat, CEO, KSH International, shared about the company's business journey and growth, manufacturing setups, product portfolios, the company's USPs, sustainable practices and views on the export market scenario.

Mar-Apr, 2023 www.wirecable.in INTERVIEW

22

Mr. Sandesh Bhagwat, CEO, KSH International

Wire & Cable India: Please give us a brief overview of your company, along with major achievements, and crucial milestones.

Sandesh Bhagwat: Shri. Kushal Hegde founded KSH Group in 1969. KSH International was established in 1981 at Taloja, near Mumbai for manufacturing paper insulated copper conductors (PICC). The capacity was slowly & steadily increased from 1981 to 1997. A major leap in manufacturing capacity addition happened in 1998 when the capacity grew to 3600 TPA. In the year 2002, a new green field project was set up near Pune for manufacturing of enamelled copper conductors. In 2006, KSH International achieved a major milestone by setting up its own continuously transposed conductors (CTC) manufacturing facility. Ever

since there has been no looking back. KSH International has moved from strength to strength. Today, KSH Group is a well-diversified group with interests in logistics, infrastructure, distriparks as well as service & distribution. The group has more than 1000 employees and is contributing in a major way to the industrial activity in Pune industrial region. The Punebased group is promoted by the Hegde family, with Shri. Kushal Subbayya Hegde as the Founding Chairman and Mr. Rajesh Hegde as the Managing Director of KSH International. KSH International holds India's largest capacity for CTC manufacturing. KSH International achieved another major milestone in the year 2019 with the commissioning of its new green field project for enamelled round winding wires. In a short span of 3 years KSH International has doubled its capacity for enamelled round winding wires. KSH International was the first Indian manufacturer to receive 765kV transformer approval from Power Grid Corporation of India (PGCIL) in the year 2011. This was followed by HVDC transformer approval from PGCIL in 2017. As a result, KSH International has successfully supplied more than 500 jobs of 765kV transformers and more than 35 jobs of HVDC transformers. KSH International has played a pivotal role in India's power sector with its Make in India and Atma Nirbhar Bharat initiatives all along its journey. KSH International has grown consistently in the last 5 years despite Covid19 as well as war in Ukraine which had majorly disrupted the markets and supply chain. KSH International has grown at 15% CAGR over the last 5 years and crossed the INR 1000 crore turnover mark at the end of FY23. KSH is well poised to deliver similar growth rates in the next 5 years as well with its customer centric approach and ambitious expansion plans.

WCI: Can you shed light on your manufacturing setup, capabilities and equipment involved?

SB: KSH International has a robust manufacturing set up with most of its

machineries from reputed and well known European, US, China and Indian manufacturers. KSH International also has a very wellequipped laboratory for validating the quality of the wires both online as well as off-line. KSH International has invested in advanced equipment like analyzers, high resolution microscopes, rapid profile projectors, etc. to ensure trouble free products are supplied to our customers. All the facilities of KSH International are certified for ISO 9001, ISO 14001 & ISO 45001. Both round wire as well as rectangular wires facilities are also IATF 16949 certified in order to cater to the automotive segment. Currently, KSH International has an installed capacity of close to 30000 MT per annum. KSH plans to double its capacity by FY2030.

WCI: Please elaborate on your product portfolio and your USP.

SB: KSH International has more than 4 decades of experience in this field of manufacturing winding wires. Our company has the widest range of portfolio in the industry of enamelled winding wires and is highly focused on gaining expertise and achieving excellence in developing customized product solutions.

Our company's USPs include our commitment to reliably service customers in domestic and international markets by providing design inputs that suit customer applications, our online and offline quality controls ensures that technologically advanced products are delivered in this demanding winding wire industry, as well as our robust system,

Mar-Apr, 2023 www.wirecable.in

INTERVIEW

“

”

KSH International has grown at 15% CAGR over the last 5 years and crossed the INR 1000 crore turnover mark at the end of FY23.

processes and advanced manufacturing set-up ensures on-time delivery

WCI: Kindly shed light on your market footprint, major segments catered and major clientele.

SB: KSH International has a loyal client base which includes both global and Indian companies across industry segments like auto electricals, motors, compressors, power transformers and rectifiers. As a result of this strong foundation, KSH International has an active customer base of more than 120 customers worldwide. KSH International specializes in HVDC and extra high voltage (EHV) power transformers and reactors with 765kV voltage rating. KSH International is

also an RDSO approved supplier for electric loco and track side transformers to the Indian Railways. KSH International caters its winding wires to special applications like furnace transformers and rectifiers. With the commissioning of the enamelled round wire facility, KSH International is now catering to a wider set of industries including auto electricals, compressors used in refrigeration industry, motors, alternators, consumer appliances, switchgears and electric vehicle (traction motors) to name a few.

WCI: What are your views on the current scenario of the export market?

SB: Globally, there is a lot of emphasis on renewable energy sources and transformation of the energy sector. Climate change is a major catalyst for this push towards green energy sources worldwide and especially in all the major economies. We are seeing a surge in demand for CTCs and PICCs in the USA, Europe, Middle East and Southeast Asian markets. KSH International is well positioned to take advantage of the emerging demand. We are already exporting 35 to 40% of our annual output to these markets. Due to the war between Ukraine and Russiaand the fact that theworld needs sustainability in thesupplychain, many countries are looking for alternative suppliers and are looking at India as an alternative source for winding wires including CTC and PICC.

WCI: Can you identify the upcoming/growing segments and key

Mar-Apr, 2023 www.wirecable.in

INTERVIEW

“

Currently, KSH International has an installed capacity of close to 30000 MT per annum. KSH plans to double its capacity by FY2030.

”

Mr.Kushal Subbayya Hegde founded KSH Group.

Foundation of Mumbai Plant, with Commercial Production of PICC.

Triple Annual Capacity to 3,600 MT.

Plant near Pune set up & launched a new product line Enamelled Copper Conductors.

CTC Product line added.

Approval for supply of 765 KV transformers to Power Grid Corporation of India PGCIL.

Market Leader in Manufacturing of CTC.

Approval for supplying Windings wires for HVDC transformers to PGCIL.

Commissioned Round Enamelled Wire plant.

24

Doubled Annual Capacity in Round Enamelled Wire.

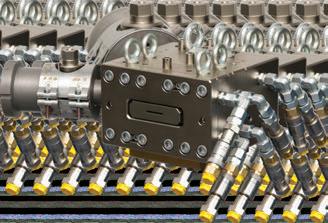

Arunav Technology & Systems Pvt. Ltd. S-16, Malik Plaza, IInd Floor, Plot-5, Sec-4, Dwarka, New Delhi-110078 Cell: +91-9818061025 | Phone: +91-11-28080670 | Fax: +91-11-43019966 Email: navin@arunavindia.in | Mr.Navin Agarwal 40+ Years of Experience in the Cable and Tube Industry info@erocarb.ch www.erocarb.ch Switzerland Extrusion Crossheads for: Building Wire Insulation. Jacketing | Automotive Wire and Tubing Medical Tubing | Composite Tubing

market trends for the wire and cable industry?

SB: The power generation segment is expected to dominate the market, owing to the high usage of large power transformers in renewable energy generation. This is expected to boost the market in the next decade. As companies strive to reduce their carbon footprints, some of the major transformer manufacturers are developing new low-carbon transformers insulated with biodegradable oils which generate reduced CO2 emissions. Increasing advancements in the power transformers technology coupled with initiatives for reducing carbon footprint is expected to provide ample opportunity for growth to all the market players. Increasing investments in the renewable energy sector are expected to boost the large power transformer market. India has reached 100 GW of renewable energy capacity in 2021 and is the fastest growing market among major economies. India also has a vision of reaching 500 GW by 2030. Through these investments, the Indian government is aiming to meet its commitments given in COP26 wherein 50% of its energy requirements will be from renewable energy sources and will reduce cumulative emissions by one billion tons by 2030. E-mobility is an emerging market for the magnet wire industry for two wheelers, passenger as well as utility vehicles. In 2022, more than 1 million electric vehicles were added which is a jump of 150% over the previous year. The shift from IC engine vehicles to

EVs is underway in India, which has outlined EVs to account for 30% of its mobility requirements by 2030. KSH International is getting ready to address this upcoming market. KSH International has obtained IATF 16949 certification for both enamelled round as well as rectangular winding wires. With our strong technical background, expertise and experience in enamelled winding wires KSH International is well poised to cater to this emerging market in near future. There has also been a quantum jump in the electrification projects of Indian Railways over the last 6 to 7 years. Indian Railways has recently achieved 100% electrification of the railway lines. Being an RDSO approved vendor KSH International is already catering to this demand.

WCI: KSH International has been taking consistent steps to include sustainable practices in its opera-

tions. Can you detail the initiatives you have undertaken in this regard?

SB: Sustainability is at its core at KSH International. We have always strived to adopt the principle of reduce, reuse and recycle in our plant operations and maintenance. One of our recent initiatives was the installation of rooftop solar of 1 MW power generating capacity. We also have a 12,000 sq. m. rainwater harvesting system in our facility to help recharge the groundwater. By way of a 12000 LPD bio-filter based sewage treatment plant, we recycle the precious water for our other day to day requirements thereby reducing the load on freshwater requirements. Last but not the least, we also reuse all the wooden packaging materials to reduce the burden on the plantations.

WCI: Can we get an insight into KSH International's vision and mission?

SB: Our vision for KSH International is to be a global leader and preferred partner, providing customized solutions across industry segments. Based on scientific, technical and commercial expertise, our mission is to provide innovative wires, cables and customized solutions for automotive, power, consumer durables and all other electrical industries to create value to our customers, shareholders, and employees.

Mar-Apr, 2023 www.wirecable.in

“

INTERVIEW

”

Due to the war between Ukraine and Russia and the fact that the world needs sustainability in the supply chain, many countries are looking for alternative suppliers and are looking at India as an alternative source for winding wires including CTC and PICC.

26

UKB Electronics to Fortify in Speciality Cables Sector

UKB Electronics Private Limited

Mr. Manoj Tayal, Managing Director, UKB Electronics Private Limited

is a leading manufacturer and supplier of wires, cables, wiring harness, power cords and many other electrical & electronic products in the Indian and global market since 1996. The company has a global presence, with 9 plants spread across India and exporting to over 14 countries. The company is planning to invest a large amount of USD 50 million for further expansion, consolidation and modernization of plants all across India and in overseas territories. In a recent conversation with Wire & Cable India, Mr. Manoj Tayal, Managing Director, UKB Electronics Private Limited, shared information about the company's business journey, challenges in the Indian electrical industry, current market trends and the company's future plans.

Wire & Cable India: Kindly give us a brief walkthrough of your company.

Manoj Tayal: UKB is a 25 years old company. We were the first Indian company in the organized sector to collaborate with the multinationals coming to India for white goods production. Our target was to localize the parts which the multinational companies were buying from import markets. Today, almost every multinational company is working with UKB. Initially, we were exclusively present in the consumer

Mar-Apr, 2023 www.wirecable.in INTERVIEW

28

“ Our company's current turnover is around INR 550 crore and we plan to achieve INR 2,500 crore of revenue by 2028

”

We specialize in: Masterbatches for Wire & Cable

Kund Kund Polymers is a well-established company and well - versed with the diverse needs of Wire & Cable Industry with a strong focus on providing high-quality and innovative masterbatches and have been servicing for over 50 years.

We expertise in color and additive masterbatch such as; Ultra- Violet, Anti-Rodent, Anti- Termite, OIT Booster, Line Speed Booster & many more.

Kund Kund Polymers emphasizes to sell product on consistent quality & technical strength and regularly doing Value Engineering in product to bring down coloring cost without compromising on quality, hence, duly maintaining the properties of base compound. Our customer- centric focus helps us to identify their needs and develop customized sustainable product. We have state-of-the-art R& D facilities and have a wide range of colors matching to International shades that of PANTONE, RAL,UL, BS, MUNSELL, CMYK and customized masterbatches for Auto sector and White goods.

Company main strength - 3 layer Quality check, strong R& D with latest technology and on- time delivery. Our well qualified and experienced QC team with well-equipped R&D will meet the most rigid requirements and expectations.

Address: 70/A-8 & 10, Rama Marg, Najafgarh Road, New Delhi -110 015

SCAN ME

9001:2015

darpan@scjgroup.net Website: www.kundkundpolymers.in | Help Line: +91-93136 89368 Marketing: +91-6000900041 Despatch: +91-6000900039 | |

Email:

SCJ Group, a Leader in INDIA with Rich Experience of over 5 Decades equipped with State of Art Lab, R & D and Production facilities.

electronics sector for production of white goods parts and recently we established our footprints in specialty cables through Electron Beam Cross linked technology (EBeam) by putting new state of the art plant in Rajasthan, where we are focusing on various sectors like strategic electronics (navy, defense, aerospace, nuclear , railways and metro sector), industrial automations and robotics. Our company's turnover last year was around INR 550 crore and we are planning to achieve INR 920 crore of revenue by this year and INR 2,500 crore of revenue by 2028. Following our company's slogan of “Nek Niyat, Dur Drishti, Pakka Irada”, we inculcate honest principles across the organization and in all our endeavors.

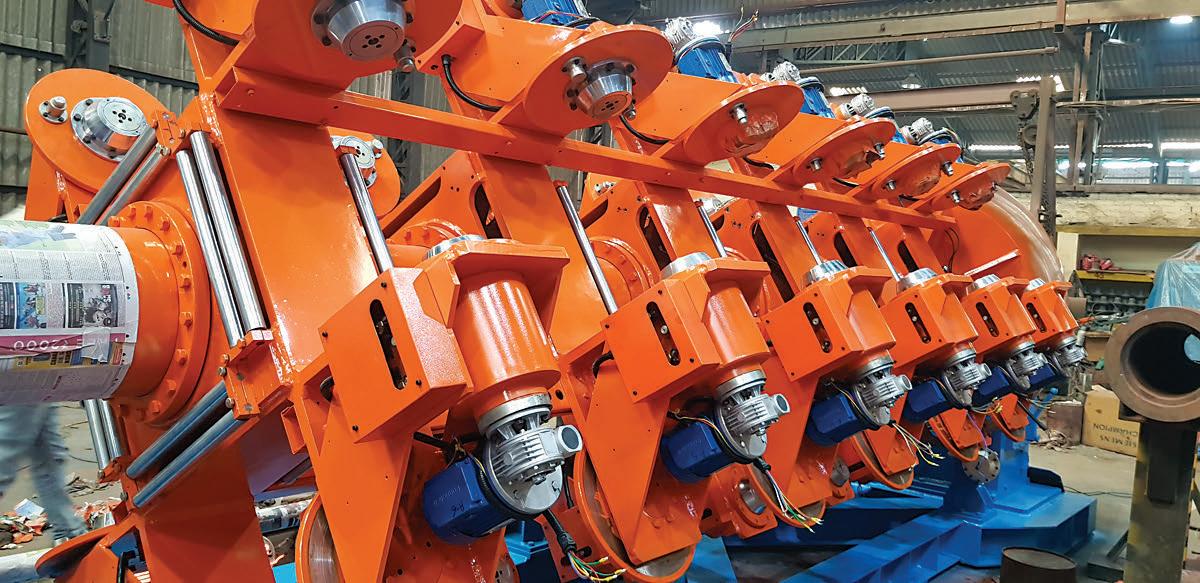

WCI: Could you please shed some light on the manufacturing facilities as well as clientele of the company?

MT: Currently we are present with nine manufacturing locations established across India. We have three plants in Noida, three in Pune,

one in Goa, one in Chennai and one in Neemrana, Rajasthan.

We have backward integration with a complete copper drawing plant from RBD to bunchers from Niehoff, Germany. We manufacture our own PVC compound and high temperature compounds and have more than 25 extruders from best in class manufacturers globally. In addition there are many more specialized machines to manufacture specialty cables.

The unique capability available in our company is the 3.0 MeV Electron Beam Machine(EBEAM) used to manufacture EBXL wires and cables. We are in the process of adding another 1.5MeV EBEAM machine within this quarter to further enhance our capabilities and capacity.

In the last three years, we expanded our footprints to export markets and now export our products to 14 countries. All our plants are strategically located with close proximity to our customers which make us always stay connected with our customers. Our export business primarily focuses on Europe and USA markets. Our clientele includes companies like Samsung, LG, Sony,

Panasonic, Godrej, Haier, IFB, Liebherr and others. Almost every big company in India in the white goods sector is a customer for UKB.

WCI: What according to you are the current market trends influencing the electrical industry and how are you contributing to them?

MT: India currently has very low penetration of electrical and electronic equipment and with availability of electricity across India in towns and cities, increase in per capita income, improvement in standard of living and various government initiatives, demand for all the electrical equipment are increasing in a very fast manner due to which electrical industry is registering robust growth and expected to move with exponential growth in future as well.

The government has also made a very conducive business environment with various policy initiatives, motivating all Indian manufacturers to make parts locally in India for the world. The government is bringing competitiveness in Indian products through various schemes like PLI, MSIPS, SPECS etc.

Mar-Apr, 2023 www.wirecable.in INTERVIEW

30

With various energy conservation programs, industry is also coming up with new products and the latest entrant is BLDC fan, which consumes one third of energy as compared to conventional fans. We have also given our participation in this new technology by development and with extensive research, we developed very critical components like PCB controllers and remotes.

We are always at forefront for fulfillment of customer needs and to provide effective solutions in the electrical and electronic industry. We always focus on being at the right time in the right market and with that we can increase our business opportunities.

WCI: What are the current challenges in the Indian electrical industry?

MT: There are hardly any challenges

considering the opportunities available in the domestic and international market.

The challenge is always about the quality of the product. We as an Indian manufacturing industry need to prove ourselves in the international market with respect to quality and cost. The customer needs to be confident about the quality of our product, which can be ensured by having a good process to make customers comfortable. In China, there is a special kind of wire called EBXL (Electron beam cross linked) Wire , which has a very high melting temperature and generally doesn't catch fire and in turn never melts and produces zero smoke. As per various policies in China, the government always promotes the use of this EBXL wire in all sectors like housing and commercial for safety. In India, BIS

has given the standard for this wire cable but has not yet mandated it for industries. However, we are proposing the government approve these cables for at least high rise buildings, malls or any place having large footfalls.

WCI: What are UKB's future plans for growth?

MT: In the upcoming years, we are planning to invest approximately USD 50 million for expansion, consolidation and modernization of our manufacturing plants all over India as well as to establish manufacturing facilities at overseas destinations as per customer requirements. We are focusing on manufacturing of specialty cables for special purposes, we aim to create cables which have a shelf life of 40-50 years, like the EBXL or cross linked cables which are only being manufactured by very few companies in India

Mar-Apr, 2023 www.wirecable.in INTERVIEW 31

Ambica Dhatu: Aiming 50,000 TPA Wire Production Capacity with “Stronger, Safer, Superior” Products

mbica Dhatu Private Limited is a

pioneer in manufacturing zinc derivatives like zinc oxide, zinc sulphate, zinc chloride etc., and holds a large market share in this field across pan India. They have a manufacturing facility in Kolkata and Hyderabad and offices in Kolkata, Hyderabad, Raipur, and Mumbai. Considering the idea of “Make in India” project in the field of transmission and distribution of electricity, Ambica Dhatu has diversified their business and started up a modern and equipped ISO 9001:2015 certified wire drawing and galvanizing unit to manufacture a variety of products like G.I. wire, G.I. stay wire, earth wire, ACSR core wire, barbed wire, P.C. wire, umbrella wire, spring steel wire, etc. with an investment of Rs. 150 million in West Bengal and an initial capacity of 24,000 tonnes per annum which is planned to expand upto 50,000 tonnes per annum. In a recent interview with Wire & Cable India, Mr. Satyam Bubna, Managing Director, Ambica Dhatu Private Limited, talked about the company, their manufacturing capabilities, clientele in the wire and cable segment.Cable India, Mr. Satyam Bubna, Managing Director, Ambica Dhatu Private Limited,

Mar-Apr, 2023 www.wirecable.in INTERVIEW

Mr. Satyam Bubna, Managing Director, Ambica Dhatu Private Limited

A 32

Wire & Cable India: Could you please give us a brief overview of your company?

Satyam Bubna: Ambica Dhatu

Private Limited is a 40 years old group, founded by Mr. Ramesh Kumar Bubna. Our first business venture was manufacturing zinc derivatives, which we are still into and we are manufacturers of zinc chloride, zinc sulfate, zinc oxide and other zinc-based chemicals. We are channel partners of Hindustan Zinc Limited for Maharashtra, Chhattisgarh and Telangana. We import zinc and cater to domestic users. We produce around 1000-1500 tonnes of zinc. Last three years back, we started our steel wire division, where we do the whole manufacturing from wire drawing to galvanizing and stranding. Our business has mainly 2 parts, firstly trading i.e. import and supply of zinc based metals and secondly, manufacturing for the zinc derivatives chemicals and steel wires segment. Ambica's main motto is serving the best quality material. We want to be known through our quality and aim to convey the message of “Think Quality, Think Ambica” to our consumers. Even if we supply to a limited number of consumers, we must provide quality products as per consumer requirements so that our consumer recall value is high.

WCI: Kindly shed some light on your product portfolio, manufacturing capabilities and clientele with regard to the wire segment.

SB: For our steel wire division, we have

a fully in-house facility for the entire manufacturing procedure, that is from production to maintenance to quality check. We have set up a modern and equipped ISO 9001:2015 certified wire drawing and galvanizing unit to manufacture a variety of products like G.I. Wire, G.I. Stay Wire, Earth Wire, ACSR Core Wire, Barbed Wire, P.C. Wire, Umbrella Wire, Spring Steel Wire, etc. with an investment of INR 150 million in West Bengal and an initial capacity of 24,000 tonnes per annum which is planned to expand upto 50,000 tonnes per annum. We have 2 physical offices in Mumbai and Noida for sales and supply.

Our main target audience for wire products are PSUs, more specifically electricity boards. We are approved vendors with 10-12 electricity boards and supply to the West Bengal state electricity board. Companies like L&T, Bajaj Electricals, Kalpataru etc. buy materials from us fortheir EPC contracts. In the wire segment, our current clientele is in Hyderabad, Telangana, Coimbatore, West Bengal, Bihar, Jharkhand, Uttar Pradesh and Orissa.

WCI: Can you tell us about Ambica's theme for Elecrama 2023?

SB: Ambica Dhatu's slogan is “Stronger. Safer. Superior.'' which is also our theme for the exhibition. Our company focuses on strengthening the product quality so that it becomes our benchmark. Elecrama 2023 has the theme 'Reimagine Energy for Sustainable Future'. Reimagining energy refers to green energy, and it is necessary that any industry related to

green energy have to upgrade themselves in order to harness green energy. Our company is also working towards embracing the future of green energy like Schneider, which has recently launched their net zero program, which means zero emission and zero pollution.

WCI: Could you tell us about the company's upcoming or future plans?

SB: Our wire manufacturing unit is currently in its second year of operation and we are on a 2,000 TPM production trajectory. In the upcoming 4-5 years, we aim to reach 5,000 TPM production capacity, including both export and local markets. In the wire division, we are currently in the process of trying to develop aluminum clad steel and megasteel, which are being imported to India and not being manufactured domestically as of now. In our chemicals manufacturing division, we do regular R&D for development and upgradation of products.

WCI: How do you envision the future of the wire industry?

SB: India is projected to double its current electricity generation of 400 GW to 800 GW in the next 7 years, that is by 2030. As we will develop our infrastructure to harness this magnitude of electricity for transmission, distribution and storage, every part of the electrical sector will be involved. This means that there will be great demand for all electrical sector vendors in the upcoming years and thus the future of the wire industry will flourish.

Mar-Apr, 2023 www.wirecable.in

INTERVIEW 34

C-164, Site-1, BSR Industrial Area, Ghaziabad-201 001.

Email: info@zenithmachines.com | zenithmach@gmail.com

Website: www.zenithmachines.com

Weldaids Ltd.

PRODUCTION PROGRAMME

Ÿ Straight Line Wire Drawing Machine (SLM)

Ÿ Inverted Vertical Drawing Machine (IVD)

Ÿ Rod Preparation Systems

Ÿ Wet Drawing Machines

Ÿ Rod Break Down Machines

Ÿ Stress Relieving & Strand Annealing Furnace

Ÿ Stranding Machines

Ÿ Vertical Drop Coilers

Ÿ Spool And Coil Take Ups.

TURN KEY PROJECTS

Ÿ Plant For Stainless Steel Wire

Ÿ Plant For P.C Wire

Ÿ Plant For Galvanised Wire

Ÿ Plant For ACSR Conductors

Ÿ Plant For Ribbed Wire

Ÿ Plant For Bead Wire

Ÿ Plant For Spring Steel Wire

Ÿ Plant For MIG Wire

Ÿ Plant For Brass Wire

Orient Electric Ventures into Wires & Cables Business

Orient Electric Limited, a one-

stop provider of electrical lifestyle solutions, is an established market player, and its growth is characterized by its smart and timely leveraging of ongoing success for new launches and ventures. The brand presence of Orient is solidified by Mr. M.S. Dhoni being its brand ambassador. Adding to the series of expansions, the company ventured into the wires and cables segment in 2022. In conversation with Wire & Cable India, Mr. Puneet Dhawan, Executive Vice President & Business Head (Lighting, Switchgear & Wiring Accessories), highlights the company's journey, and robust market and product strategy. He shares how the company adapts itself to changing times and customers' needs and applies its networking and distribution channels toward the expansion of its market share and presence. In his words, OEL is the one-stop provider of electrical lifestyle solutions.

Orient prioritizes mind-share gains over marketshare gains. We have launched many integrated campaigns featuring our longstanding brand ambassador, Mr. M.S. Dhoni, to enhance our brand visibility and recall.

Wire & Cable India: Walk us through Orient Electric, its history, achievements, and crucial milestones.

Mr. Puneet Dhawan: Orient Electric is a part of the diversified CK Birla Group, with a valuation of USD 2.8 billion. Orient Electric is a distinguished name in the consumer electrical space for more than 68 years and has established itself as a onestop provider of fans, lighting, home appliances, switchgear, wires, and other electrical accessories. In the domestic market, we have a well-organized distribu-

Mar-Apr, 2023 www.wirecable.in INTERVIEW

“

Mr. Puneet Dhawan, Executive Vice President & Business Head (Lighting, Switchgear & Wiring Accessories) Orient Electric Ltd.

” 36

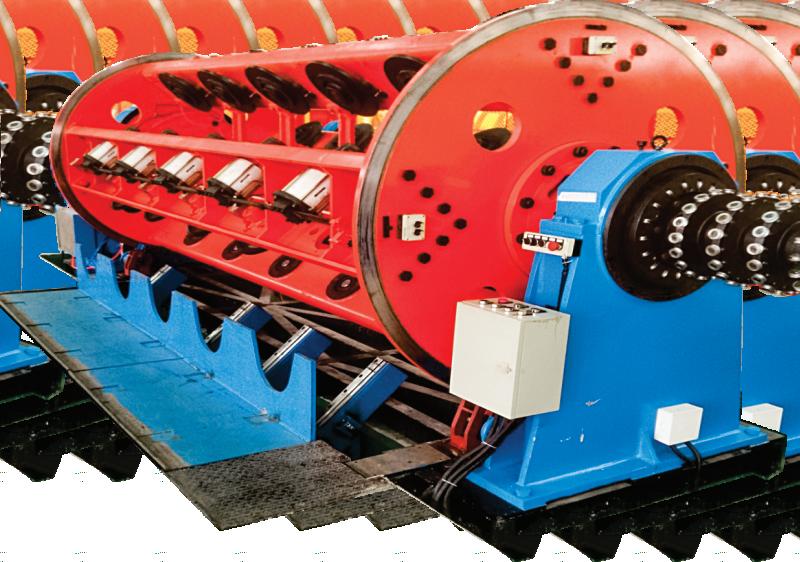

ABROL ENGINEERING COMPANY PVT. LTD. EST. 1958 Copper Conductors ISO : 9001:2015 | 14001 : 2015 ROHS & REACH COMPLIANT Bare & Tinned for all Cable Manufacturers Specialising in Electroplated Tinned Unilay & Concentric Bunched, Parallel & Single Wires State-of-the-art Plant In KAPURTHALA, PUNJAB, INDIA More than 6000 MT per annum capacity for Bare Copper More than 3000 MT per annum capacity for Electroplated Tinned Copper Supplying to Automotive, Solar, Defence, Railway, Special & Signalling Cable Manufacturers Mobile: +91 9888555846 | +91 9779090919 | Email: abelabrol@aecoindia.com | sales@aecoindia.com Website: www.aecoindia.com/copper-conductor ROD BREAK DOWN LINE 16 MULTI WIRE DRAWING LINE ELECTROPLATING TINNING LINE DOUBLE TWIST BUNCHERS D630 & D800

tion network, reaching1,25,000 retail outlets, and a strong service network, covering over 450 cities. Internationally, we have a strong marketing presence in more than 35 countries.

I am proud to share that we have successfully expanded our product offerings across categories over the years.

Leveraging on our strong brand identity for fans, which we developed over a long span of time, we forayed into the lighting business in 2008. As of today, we offer a diverse LED-centric portfolio covering diverse segments, such as home, office, retail, and industrial application. We have an established competence center, focusing on the electronics and design of drivers and PCB for LED products. In 2011, we ventured into the home appliances segment, offering a wide range of products including air coolers, water heaters, and other small kitchen appliances. In 2015, we stepped into the field of switchgear with a smart range of energy-efficient LV switchgear products, and in 2022, we forayed into the high-potential segment of wires and cables.

As a consumer-centric company, our focus is on bringing forward innovative products, which are healthier, safer, energy-efficient, and add convenience to everyday life. Our innovation spree is well demonstrated by first-to-market products, such as the EyeLuv series of health-centric lighting, energy-efficient fans & air coolers, silent Aeroseries fans, MCBs with SDB technology, Cloud 3 cooling fan with revolutionary Cloudchill technology, and Stella modular switches, among others.

We draw a sizable advantage from

our proprietary production facilities at Noida, Faridabad, and Kolkata. At Orient Electric, business growth is consistently facilitated by R&D through developing new and upgraded products.

WCI: Can you elaborate on your existing market footprint for the wires and cables industry?

PD: We have an entrenched retail network in the country, and as we grow we continue to engage with last-mile selling points. For the wires business, we are aggressively working on establishing our channel in all the states and UTs across the country. We have our branch offices and local representatives in each state.

Our commitment to our retail partners lies in offering excellent service and competitive prices for our products.

WCI: What are the current market trends that are most beneficial to your expansion plans?

PD: The Indian wires and cables industry is estimated at about INR 65,000 crores, which is more than 40 percent of the whole Indian electrical industry. The industry is growing at a healthy pace, sup-

ported by expanding urbanization and strong infrastructure push by the Government, especially in Tier 2 & 3 cities. Moreover, consumers are becoming more involved in this category, and product quality and brand have become key considerations driving the growth of the organized segment.

The brand, Orient, is well respected and recognized across India, which will help us in driving growth in the wires and cables business. Furthermore, we develop our products with a focus on three defining aspects; safety, durability, and performance, and the response from our channel partners and customers have been encouraging.

WCI: Orient Electric has been recognized with awards like- 'Most Trusted Brand of India 2023' & 'Prestigious Brands of Asia award'; MS Dhoni is your brand ambassador! How important is brand building for Orient Electric and what strategies do you adopt for staying ahead of the market curve?

PD: Every consumer company is built on its brand promise, a proxy to the value, reliability, and quality of the company's products. At Orient, we have collectively

Mar-Apr, 2023 www.wirecable.in INTERVIEW

38

resolved to prioritize mind-share gains over market-share gains, which places a huge emphasis on our marketing engine. Over the years, we have launched many integrated campaigns featuring our longstanding brand ambassador, Mr. M.S. Dhoni, to introduce and promote new productsand enhance our brand visibility and recall. Our digital marketing component has also expanded over the years, which is in line with emerging consumer touch points. Our continued expenditure on digital mediums for brand building ensures us visibility and maintains brand salience.

We constantly work on integrating technology to enhance the consumer experience and present our products in innovative ways. We place a major emphasis on showcasing the right products and planograms at our retail counters,

whichallowscustomerstosee, touch, and feel theproductof their interest. One approach that has been consistent in our advertising strategy is that we always connect a consumer benefit to a product feature, and present it in an engaging and relevant format to our customers. This serves our end goal; to create an emotional connection with our customers.

WCI: What are your future plans for OEL's wires business?

PD: The addition of wires strengthens our switchgear & switches portfolio, consolidating our position as a one-stop provider of electrical lifestyle solutions. Our plan is to scale up swiftly in this category, by introducing new products and channel expansion, backed by BTL and other marketing activities. We are regularly

I am proud to share that we have successfully expanded our product offerings across categories over the years. The addition of wires strengthens our switchgear & switches portfolio, consolidating our position as a one-stop provider of electrical lifestyle solutions to enhance our brand visibility and recall.

connecting and engaging with category influencers, including electricians and architects, as part of our ongoing efforts in channel strengthening. Given the increasing demand from real estate and other private sectors, OEL is looking at a good growth phase, going forward.

Mar-Apr, 2023 www.wirecable.in INTERVIEW

“

”

39

Leebo Group Aims Excellence in Copper and Copper-Fabricated Solutions

Mr. Rajesh S Agarwal, Managing Director of Leebo Group

Astrong foundation is needed to harness the best of

opportunities and to do so consistent and deliberate efforts need to be made, such as self-education, market analysis, and supporting the demand graph through innovative solutions. These practices are the 'way of being' for Mr. Rajesh S Agarwal, Managing Director of Leebo Group, who shared with Wire & Cable India, the company's deliberate efforts to follow the right processes, practices, and ethos to develop excellence for manufacturing copper and copper-fabricated solutions. Our conversation with him regarding Leebo Group's history, future plans, and strategic steps to achieve those plans leads us to believe that the industry's copper-based demands can easily find a resolution with Leebo Group.

Mar-Apr, 2023 www.wirecable.in

INTERVIEW 40

Wire & Cable India: Please introduce us to your company and its major milestones.

Rajesh S Agarwal: Leebo Group's history dates back to 1987 when Omega Rolling Mills Private Limited was set up in Tarapur, Maharashtra. Thereafter, in 1995, we incorporated Leebo Metals Private Limited Company in Taloja near Mumbai, and in 1999 a manufacturing plant in Daman was set up. Today, together, the plants have a production capacity of 24,000 metric TPA. Our dedicated scientific researches and innovations make us a pioneer in copper-based products. We supply copper-based products and OFC products to both domestic and international markets, especially in the Middle East.

Ourmottois'Makelocally,Serveglobally'.

WCI: Please elaborate on your company's product portfolio and your USP.

RSA: We offer a cross-sectionally diversified product portfolio in both

OFC and ETP grades. Our OFC-grade products contain 99.95 percent and up copper content and less than 10 ppm of oxygen presence, while ETP-grade products contain 99.90 percent and up copper and less than 50 ppm of oxygen. We offer solutions like copper upcast rods sizes, such as 12.5, 16, 20, 25 &30 mm., copper flats and strips, copper foils, and copper wire rods in these variations. We also offer EC-grade copper wire, copper sections and profiles, electrolytic-grade copper tubes and pipes, and copper conductors and PICC. We can resolve all copper-based problems of our customers as it is our area of specialization.

Our USP is in the types of solutions we provide and the way we provide them. It is my personal belief that specialization triumphs over market volatility. Hence, we have built a range of products that could be applied in accordance with customers' requirements, such as electrical conductivity, heat transfer, and other metal properties that affect the end result.

WCI: Please tell us about your major clientele and market footprint.

RSA: We have a wide customer base in both B2B and B2C verticals, and our most reputed customers include Hindalco, Legrand, Suzlon, and ABB. We supply pure copper and copperbased products to various industries, naming a few, switchgear, transformers, power generation, telecommunications, infrastructure, transmission and distribution, electrical, railway, and automobiles.

Leebo Group has managed to gain repeatability in its customer base,

Mar-Apr, 2023 www.wirecable.in

INTERVIEW “

” 41 OF COMMITMENT EXCELLENCE UPPL

COMMITTED TO SERVE THE BEST

Leebo has a combined manufacturing capacity of 30,000 MTPA at its Tarapur, Daman & Bangalore facilities.

I

which is sourced in our company-wide practices. We believe in mutual support which leads to comprehensive growth for us and our customers. It is why they return to us seeking quality, excellence, and bonafide support. A significant share of our customers belongs to the MSME segment, which is a matter of pride to us as they form the backbone of the Indian economy and its future growth.

WCI: Does your company invest in R&D, if yes, please share some features of your development process.

RSA: We have an in-house testing laboratory at our Tarapur and Daman facilities. Leebo Group is committed to providing qualitative products at competitive prices to our customers. This requires excellence at our end, which we achieve with the support of our lab's testing facilities.

We engage in the product as well as process testing because process obsolescence takes a long time to reflect in the product, and all the while the market keeps growing and advancing. Hence, we put our processes to the test as well at regular intervals to compare the input and output, their qualitative performance, scope of reengineering and innovation, short and long-term effects, and feasibility.

We have derived our quality and testing standards on the basis of our customers' feedback. Hence, we are able to cater to the market with focus.

WCI: How do you see the market developing in the future?

RSA: The major player in the global economy today is information, which is perpetually available due to the internet. It has consequently pushed global as well as domestic industries to shift their focus on quality, services, and healthy market competition. This is true for every industry including wires and cables. Hence, at Leebo Group, our priority remains to learn about new developments, target them and become major players in those areas, and we carry out this process in a cyclic manner. Learning from competitors is an important part of the growth that we follow.

It is on the basis of these observations that we have put ourselves up for ambitious targets increasing output to 40,000 metric TPA by 2025.

WCI: Please share your company's short and long-term future plans & CSR initiatives.

RSA: We have major plans for the upcoming period. Over the years Leebo Group has raced ahead of its competitors in the Indian market in

terms of quality and standards. It is one of the major reasons behind our easy acceptance into the international market. We plan a more dedicated and focused foray into the international market going forward. Nearer home, there are various largescale government projects being launched, and we look forward to contributing to them. It is an obvious inference that infrastructural growth is awaited, but at the same time, sustainability remains a concern and focus, especially for Leebo Group. We are invested in ensuring that our products are durable and lead to zero defects and zero failures for our customers so that the natural resources are optimized appropriately and without wastage. We believe in adding value while ensuring recyclable power sources for an energy-driven India.

Apart from sustainable and conscious manufacturing practices, we also have our CSR initiative called UMMEED, the organization works toward “child health”, wherein we help kids who are disabled or challenged to discover their talents and reach their full potential. Leebo Group has also contributed to DNDH Justice Fund (Juvenile) Daman, and Gaushala at Daman.

Mar-Apr, 2023 www.wirecable.in

INTERVIEW 42 TRIVENIPOLYCHEM Deals in Polymer Additives 1103-1104, Tower A-1 Corporate Park, Sector 142, Noida, Uttar Pradesh - 201305 • Stabilizers • Plasticisers • Speciality Chemicals • Fillers • Lubricants • Speciality Compounds INDIA USA ITALY Major Products INDIA INDIA ® USA INDIA ® SPAIN VEERALADDITIVE Antioxidants INDIA USA A 9818332292 | r info@trivenipolychem.com | www.trivenipolychem.com 1010 / 1076

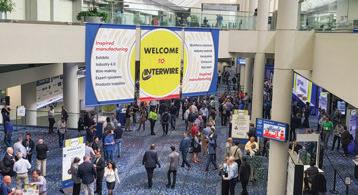

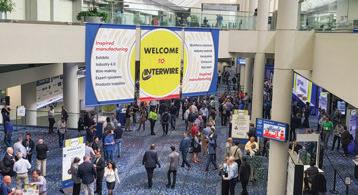

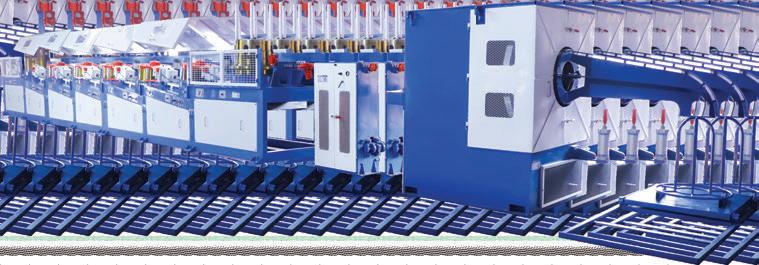

Inspired Manufacturing at Interwire 2023

Interwire was organized by Wire Association

International (WAI) from May 9-11, 2023 after a long gap of 4 years due to Covid-19 outbreak. Held at Georgia World Congress Center, Atlanta, Georgia, USA; the event focussed on inspired manufacturing while the conference created tracks in Industry 4.0.

Introduced in 1981, Interwire is the largest and longestrunning wire and cable marketplace in the Americas. Hosted biennially, Interwire is an international trade event that includes exhibiting companies, speakers, and visitors from more than 50 countries. Interwire is a

machinery show where exhibiting companies comprise suppliers to the industry and manufacturers of wire; cable; and fastener, formed and fabricated wire products. The show crosses dozens of vertical industries including automotive, construction, aerospace, transportation, and communications, fasteners, electronics, energy among others. Interwire is held in conjunction with WAI's annual convention. Industry experts give technical and operational presentations throughout the conference. Roundtable and panel discussions; production solution demonstrations; courses and workshops led by industry luminaries are among the program highlights.

Mar-Apr, 2023 www.wirecable.in EVENT

44

Mar-Apr, 2023 www.wirecable.in EVENT 45

Mar-Apr, 2023 www.wirecable.in EVENT 46

Corporate Office: A-96, DDA Sheds, Okhla Phase - II, New Delhi - 110020, INDIA Factory: Plot No 19, Ecotech - XII, Greater Noida - 201308, UP Phone: +91-11-41649535, +91 98100 01282 / +91 98108 01837 Email: info@takkarpolychem.com | Website: www.takkarpolychem.com Leading Manufacturer, Supplier & Exporter of Specialized Master Batches & Compounds 1 Fire Shield Compounds LSZH / ZHFR / HFFR Compounds 3 2 Eco Safe Compounds RoHS, RoHS 2.0 & 3.0, REACH and UL PVC Compounds, Anti Rodent, Anti Termite & UV Resistant Compounds Eco Safe Master Batches RoHS, RoHS 2.0 & 3.0 REACH PVC Master Batches 4 Black, White & Color Master Batches, Poly Kolor LSZH / ZHFR, XLPE & XLPO Master Batches

Mar-Apr, 2023 EVENT www.wirecable.in 48

3R POLYMERS PVT

OUR OFFERINGS

ü PVC Compound for Wire & Cables Segment as per IS / BS / IEC / UL Standard

- Insulation & Sheathing Compound

- FRLSH (Fire Retardant Low Smoke) Insulation & Sheathing Compound

- HR (Heat Resistant) Compound up to 125 °C)

- Low Temperature Insulation & Sheathing (up to - 55 °C)

- UV Resistant & Oil Resistant Compound

- Rigid & Soft Molding Compound Plug Molding, Injection Molding application

- Transparent PVC Compound

- Elastomeric Compound

- Customised Compound like High Abrasion Compound for Elevator Cable

ü TPE Compound for Wire & Cable Segment

Zero Halogen Flame Retardant (ZHFR / HFFR / ZHLS) Insulation & ü

Sheathing Compound

ü

ü

ü

PVC & PE Based Smart Batch

Universal Smart Batch

PVC & PE Based Anti – Rodent & Anti Termite Smart Batches

HDPE Compounds for Data Cables ü

Registered Office: info@3rpolymers.in, sales@3rpolymers.in +91 9711006346, +91 9999653077 www.3rpolymers.in E 358, Phase 1, RIICO Industrial Area, Bhiwadi 301019, Rajasthan 2011/65/EU 2

NEW

Mar-Apr, 2023 www.wirecable.in EVENT 50

Runningin: JMW,SvarnGroup, AdvanceCable,LaserCable, GlosterCable,SpecialCable, GemscabInd.,NeelkanthCables,RPGCable, Neelkanth andmanymore..

CAB DEVICE INDUSTRIES

A63,StreetNo.4,KarkhanaBagh,16/5, MathuraRoad,Faridabad-121002

ContactNo.:+911294041641

Email:info@cabledevice.com,cabdevice@yahoo.com

Mob.No.:+91-9910360641,+91-8826059696

Website:www.cabledevice.com

Runningin: KEIWire&Cable, UKBElectronics,CordsCable, TamraDhattu,KMGWires, Kopperplantwire,NICCOEastern andmanymore..

formoreinformation

ScanQRCode

Runningin: AparIndustries,Polycab, RRKabel,AdvanceCable, LAPPIndiaand manymore..

CABLE

TinElectroplatingOnCopperWire

ResistanceAnnealingMachine

Tin/NiElectroplatingMachineOnCopperWire

InductionPre-Heater OffLineMultiWireAnnealingMachine

3R Polymers Expands Plant to Achieve 36000 TPA Capacity by FY2025

Founded in 2011, 3R Polymers Private Limited

is one of the leading manufacturers in serving best quality compounded thermoplastic material solutions. With an annual production capacity of 9000 TPA, the company offers costeffective and high-quality solutions as per customer needs. The manufacturer now aims to reach a new production capacity of 36000 TPA by FY2025. In a recent conversation with Wire & Cable India, Mr. Nitin Aggarwal, Director – Sales and Marketing, 3R Polymers Private Limited shared about the company's latest product developments, USPs of the company, growth plans and outlook on the wire and cable industry.

Wire & Cable India: Could you give us a brief about your company and its product portfolio?

Nitin Aggarwal: 3R Polymers is a well-established brand having annual capacity of 9000 TPA and headquarters in Bhiwadi, Rajasthan. Over a decade of service, 3R Polymers Private Limited is achieving milestones with a mission of serving best quality compounded thermoplastic material solutions. With the growing demand of the industry, 3R Polymers has not just redefined the industry but also has been able to carve a niche reputation amongst its clients by providing cost-effective and high-quality solutions as per customer needs.

Mar-Apr, 2023 www.wirecable.in INTERVIEW

52

Mr. Nitin Aggarwal, Director – Sales and Marketing, 3R Polymers Private Limited

WCI: Kindly elaborate on the product portfolio along with the latest and upcoming product developments in your company.

NA: Our current offering of PVC and PE-based compounds and masterbatches comes with eco-friendly, non-toxic and non-polluting variants along with a cost-effective, tearproof and recyclable packaging. Presently we are offering PVC and PE based compounds, color masterbatches and smart masterbatches with various variants suitable for wire and cable, automotive, medical, home appliances applications, among others.

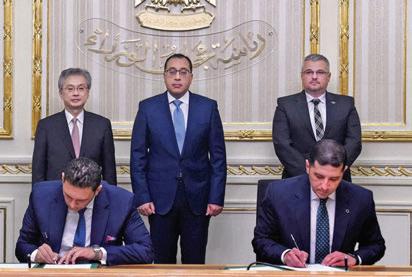

Wire and cable is the first thing that comes in the structure