ISSUE 64 May/JunE/JulY 2009

DIESEL

PERFORMANCE

EDGE IS THE LEADER IN INNOVATIVE PERFORMANCE TECHNOLOGY Edge Products pioneered the way for in-cab monitoring and control with its revolutionary Juice with Attitude product. Since then, Edge has developed other in-cab control devices, like the Evolution programmer and the Insight, all of which fit a number of domestic late model gas a diesel trucks. Edge’s products provide perfect, flexible power for any need with power to tow, go, or blow away the competition. And nobody does fit and finish like Edge. Would you even be able to tell what aftermarket product is on this truck if we hadn’t circled it? We take pride in not only making the best performing product, but also the best looking. Make no mistake: Edge pioneered and revolutionized this industry, and our competitors have been trying to catch up ever since. For the finest performance electronics for your truck call (888)

And we’ll be setting the bar even higher with better and more innovative products in the future. At Edge Products, we take the time to do things right. We don’t just slap our name on some privatelabeled piece of cheap plastic – we design, manufacture, and produce all of our products in house. From the concept to the parts to the process, we do it all under one roof. So don’t settle for purchasing products from an imitator – buy from Edge Products, the innovator!

490-EDGE or visit www.edgecummins.com

4

EDITORS

Robert Patton Bob Vallier Jeannette Vallier

CONTRIBUTORS

Jim Anderson Mark Barnes Kevin Cameron Joe Donnelly John Holmes Doug Leno Andy Mikonis Andy Redmond Gary Wescott

Bruce Armstrong Don Bunn Scott Dalgleish Ken Freund Polly Holmes Sam Memmolo Jerry Nielsen Bill Stockard G.R. Whale

ILLUSTRATOR Bob Pierce

OFFICE STAFF

Be a TDR Writer Contest/ATF Change

14 Member2Member

Steering Improvements/TAG 3 Update

Mini Version of Member2Member Members’ Solutions to Members’ Questions

18 10 Back

Issue 24 Examined

A Look Back Ten Years Ago in the TDR Magazine

20 First Generation

Fuel Filter Leak/Spring Hanger

Owner-Specific Articles on the ’89-’93 Trucks

24 12-Valve Engines

Transmission Shifting/Installations

28 24-Valve Engines

Fuel Filter Leak/Installations

Owner-Specific Articles on the ’94-’98.5 12-Valve Trucks Owner-Specific Articles on the ’98.5-’02 24-Valve Trucks

32 5.9 HPCR Adjustments/Injectors

Owner-Specific Articles on the ’03-’06 5.9 HPCR Trucks

38 6.7 HPCR

Oil Analysis/DTCs/TSBs/New Fuel Filter

52 Technical Topics

Media Gibberish/Fuel and Oil Additives

GENO’S GARAGE

Owner-Specific Articles on the ’07 and Newer Trucks Service/Parts Updates

56 Cummins Column Ask the Engineer

Discussions with Contacts at Cummins

58 Blowin’ in the Wind

Pam Rose

Responses from the Readers

10 Turbo Tips

ALL DIFFICULT WORK

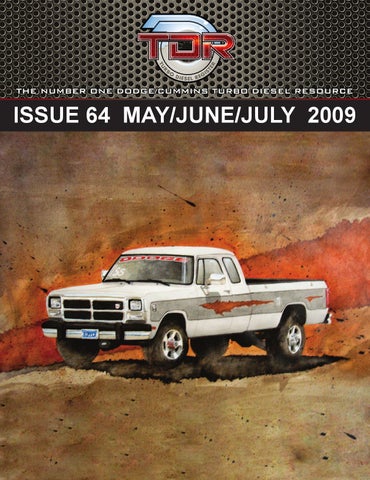

Issue 64 Challenge/Cover TDR

6 Letter Exchange Your Letters

Tina Bean

Robin Patton Andy Bishop Brandon Parks Wendy Poole Scott Sinkinson

Tailgating

Letter from the Editor

Ford and Navistar Divorce is Final

Industry News

60 TDReview New 2010 Turbo Diesel

An Article or Product Review

64 Your Story A MEMBERSHIP/SUBSCRIPTION TO THE TURBO DIESEL REGISTER IS $35.00 PER SUBSCRIPTION. PLEASE SEND ALL SUBSCRIPTION INFORMATION, CORRESPONDENCE, LETTERS, RENEWALS, ADDRESS CHANGES, ETC., TO:

TDR 1150 samples industrial drive cumming, GA 30041 THE TDR IS PUBLISHED QUARTERLY BY DIESEL REGISTRY, INC. DISTRIBUTION TO MEMBERS VIA PERIODICAL POSTAGE IS IN THE MONTHS OF FEBRUARY, MAY, AUGUST AND NOVEMBER.

‘06 3500 SRW Becomes a DRW

Feature Article on a Member Vehicle

66 Four Whaling

Fiat and Chrysler

Journalist G.R. Whale talks about all things Diesel

68 Idle Clatter

Many Topics

A Review of Frequently Asked Questions by Jim Anderson

72 Ranch Dressing

Equipping the New ‘99

Esoteric Dissertations on Manure Shoveling by John Holmes

78 Polly’s Pickup

82 Have Ram Will Travel

Joe Donnelly’s Truck and Travel Stories

90 Motor Minded

Barrett-Jackson

A Feminine Perspective by Polly Holmes

TST PowerMax CR/NV5600 Rebuild

Reflections on the Human Side with Psychologist Mark Barnes, Ph.D.

The Proverbial Glass

ARTICLES ARE WELCOMED FROM ALL SUBSCRIBERS. LET US HEAR FROM YOU! WE RESERVE THE RIGHT TO EDIT ANY SUBMITTED MANUSCRIPTS. WE WILL ACCEPT MANUSCRIPTS IN IBM ASCII TEXT FILES OR FROM ANY POPULAR IBM WORD PROCESSORS, ON COMPUTER DISK, OR SCRIBBLED ON A RESTAURANT NAPKIN.

92 Chapter News Local Contacts

THE TURBO DIESEL REGISTER IS NOT AFFILIATED WITH CHRYSLER CORP., CUMMINS INC., OR ANY OF THEIR SUBSIDIARIES. ADVERTISING OF PRODUCTS OR SERVICES IN THE PUBLICATION DOES NOT CONSTITUTE ENDORSEMENT OR APPROVAL. WE ARE NOT RESPONSIBLE FOR DAMAGES, ACCIDENTS, INJURIES, INVALIDATION OF WARRANTY, FAILURE TO PASS EMISSION STANDARDS OR SAFETY INSPECTIONS AND WILL NOT BE HELD ACCOUNTABLE IN ACTIONS RELATING TO OR RESULTING FROM ANY SUCH SITUATION.

COPYRIGHT © 2009. ALL RIGHTS RESERVED. REPRODUCTION IN WHOLE OR PART WITHOUT PERMISSION IS PROHIBITED. POSTMASTER: Send address change to TDR, 1150 Samples Industrial Drive, Cumming, GA 30041. USPS number 014234 ISSN number 10888241

Happenings at Local Chapters

94 TDR/R/R

Referrals/TcDR/High Mileage

Referral/Recognition/Reward

98 Earn Your Stripes

Horsepower Recognition

Recognizing Big Horsepower

100 Backfire

Rail Pressure, Fuel Mileage and the TDR

Corrections, Clarifications, Crow Eating

102 TDRV

Wax the RV/Follow Up

106 Shop Floor

The Truck’s Computer

Turbo Diesel Perspective on RVs Tips From Turbo Diesel Repair Shops

112 Product Showcase Amsoil Dual By-Pass Filter

Featured Products

117 TDRelease New Products

Vendor Press Releases

119 Exhaust Note

Thought-Provoking Discussions with Kevin Cameron

122 Advertiser Index

Diesel Alternatives How to Contact

TDR 64

www.turbodieselregister.com

3

DO WHAT YOUR MOTHER SAID As I scanned a recent newspaper, my wary editor’s eye was caught by a bold-faced message, one that should hit squarely between the eyes of every columnist, TV talking head, blogger, and radio news commentator: “Americans (and the world) are clamoring for the slightest bit of good news. It is called ‘consumer confidence’, and so much rides on the psyche of the consumer. Perception is reality.” Regular readers of my editorials know how I feel about the irresponsibility of much of the national media, its strident alarmism, how instead of responsibly reporting a problem, it often seems intent on overstating the point. We steer the TDR out of this tide. In this challenging time, we are resolved to cut the rant. We keep our eye on what makes the Turbo Diesel world go ‘round. And therefore herewith is the focused theme for Issue 64: we recall what your mother said (or should have said) when there was too much scary stuff on the tube: “Turn off the television, young ‘uns, and go outside and play.” THE ISSUE 64 CHALLENGE With this issue you will find your 2009 TDR Member decal inserted into the cover wrap. It will proudly take its place alongside your ‘07 and ‘08 decals, to be emblazoned in a prominent location on your truck. As I reflect back to a year ago when we completed 15 years of publication and made our move to a full-color magazine, I noted too the challenge I issued then to the full membership, that they help to spread the good word about the TDR. On that occasion, several of our staff writers issued the same challenge to readers (an idea they must have conceived intuitively, or, in more down-toearth inspiration, via e-mails bounced back and forth in the giddy days before the deadline for copy). We all knew it was going to be a difficult year. And difficult it has been.

Oops… see my commentary about avoiding the “rant”: maintain a positive demeanor. All right. How about this? As you trawl the internet or pick through newsstands, you have discovered that the membership of TDR is the most respected in the field for technical knowledge, insight into all things diesel, and helpfulness to others. You, the membership of TDR, are the Number-One resource for Dodge/Cummins Turbo Diesel owners worldwide, and you should be proud. I sure am. Thank you for the identity that this membership group has earned. Pride is only the beginning. The lull in Dodge/Cummins Turbo Diesel pickup sales signals a need to be self-sufficient. As suggested last year by writers Anderson and Neilsen (these guys were the most insistent, but the insinuation cropped up in other writers’ columns too), this was the message: “Why not put a TDR brochure inside the cover wrap and challenge each member to sign-up an additional Turbo Diesel owner. Recognize the members in the TDR/R/R and—bingo!—the membership is doubled.” All right, let’s try it. Inside the cover wrap you’ll find a TDR brochure. Put your name in the “referred by” area. Make note of “The Cost of Ignorance” section and provide some technical insight to a Turbo Diesel owner that you’ll meet along the way. Give them the brochure and invite them to join us. Need extra brochures? Call us and we will forward them to you. Go forth and hand out the brochures. As you talk Turbo Diesel to a new acquaintance, you may discover a new friend in the process.

I will spare the details about the TDR’s rocky road in this economic turmoil. For us the ruts in this downturn are manageable. Yet, if we believe the prognosticators, we still have another year to muddle through. And hovering in the background is the fact that if Dodge and Cummins are not selling trucks, we are not gaining subscribers.

“Turn off the TV and go outside and play.” A picture of TDR brochures that we’ve used over the past 16 years.

4

www.turbodieselregister.com

TDR 64

TAILGATING . . . . Continued COVER OF THE TDR THIS AND FUTURE ISSUES

THE FRATZOG—COVER OF THE TDR ISSUE 63

The “Cover of the TDR” artwork program was initiated in last issue’s editorial. The first to participate was the Forbus family: Jim Dawn and Melissa. If you’ve been to a May Madness event you know the Forbus family as they along with Mom and Dad (the Simerlys) are several of many that keep the event running smoothly. The truck that is on Issue 64’s cover has been in the Forbus family since it was new.

As you looked at Bob Pierce’s Issue 63 cover artistry, did you notice the Fratzog that he painted on the side of my ’07.5 Mega Cab/Long Box truck?

Would you like your picture on the cover? The artwork-on-the-cover idea is a worthwhile endeavor. Artist Bob Pierce is agreeable and he can be reached at (802) 893-0320; e-mail bobandstephi@comcast. net. Bob lives in Milton, Vermont. I also talked with Kelly Snyder (she did Issue 61’s cover portrait) and she is also available to do artwork for the TDR’s cover. Kelly can be reached at (520) 481-3300: e-mail dieselartist@gmail.com. Kelly lives in Tucson, Arizona. Both artists have agreed that $375 is a fair price for a painting of your truck. Get busy and send them a picture of your truck for the cover of the TDR.

The what? The Fratzog. I will save you from having to do a search on this noun. The definition from Wikipedia: Dodge’s logo from September 1962 through 1976 was a fractured deltoid composed of three arrowhead shapes forming a 3-pointed star. One of its designers came up with the meaningless name Fratzog for the logo, which ultimately stuck. As the Dodge Division’s logo, Fratzog was incorporated in various badges and emblems on Dodge vehicles. It was also integrated into the design of such parts as steering wheel center hubs and road wheel covers. And, a little bit of Fratzog history comes to us from auto. howstuffworks.com: “In 1962, Dodge cars sported a smart new emblem, triangular in shape and composed of three triangular elements. According to stylist Bob Gale, it was developed via an in-studio competition. ‘We all tried different designs,’ he recalls. ‘Mine came in second and Don Wright’s came in first, so we used his.’ “Wright, a retired Chrysler design chief, remembers the event well. ‘The company had an outside design firm working on a new logo,’ he said recently, ‘but nothing they came up with was automotive. Bill Brownlie thought we in the studio could do better, and challenged us to come up with some fresh ideas. I formed the design around elements of the Forward Look emblem, repeated three times.’

The cover for Issue 62.

“‘I thought the design looked pretty good as a 2-D graphic,’ he continues, ‘but I never did like the 3-D version the guys in the Ornamentation Studio later came up with to put on the car. Of course, being a triangular logo, it caught the attention of MercedesBenz. Their lawyers and Chrysler’s lawyers went round and round about the design for several years, but [unlike Studebaker in 1953] we never had to change it.’ “When it came time to submit a patent drawing for copyright purposes, Chrysler attorneys asked, ‘What do you call it?’ Stuck for a name, someone in the studio came up with the nonsensical Fratzog (which Wright still despises). Now you know.”

The cover for Issue 63.

Perhaps that was more than you wanted to know? What is the point of this Fratzog rambling? My truck doesn’t really have a Fratzog painted on it. But, with a clear picture of the concept thanks to Bob Pierce’s artwork, I may give it a try. It is neat what an artist with an idea can do. Is there a paint concept that you want to try on your truck? This is another reason to have your truck on the “cover of the TDR.” Yes, we will send five copies for your mother... Now, turn off the TV and go outside and play

This issue’s cover.

Robert Patton TDR Staff

TDR 64

www.turbodieselregister.com

5

NEW MEMBER/2004 TRUCK MAINTENANCE EXPERIENCE Issue 63 was the first issue I have read and was well worth the subscription. I hope Americans seriously consider G.R. Whale’s conclusion on page 60, “And if Detroit looks bad, consider the instability around the world which history shows tends to initiate wars…now is not the time to be shutting down a good portion of our manufacturing base.” It is nice to actually read commentary on current events that keep context with history—good stroke to inform and possibly enlighten young (and some not so young) subscribers. For the TDR members: Years ago when Navistar was called International Harvester, it was noted to mechanics working on DT466 engines that as a general rule, for every .001” that valve lash was off spec, the timing was off 4 degrees for that particular cycle relative to the position of the rocker depending on ratio. We could hear when valve adjustment was off. In 2004, one of our Class 8 truck customers (we operated Southwest Truck and Equipment for 25 years) stopped in and stated that his new Dodge Turbo Diesel didn’t recommend valve lash adjustment during the first 100,000 miles. Chrysler’s reason being that: “If measured valve lash falls within these specifications [intake .006”.015”/exhaust .015”-.030”], no adjustment/reset is necessary. Engine operation within these ranges has no adverse affect on performance, emissions, fuel economy or level of engine noise.” At the time, I was uncomfortable with the parameters listed.

So, as a test, our new business, S Bar X, bought a new 2004 Ram 3500, 4x4 single rear wheel to try on for size. It was placed into field service August 2004 as a heavy equipment support vehicle in the oil and gas patch surrounding the tri-corner areas of Utah, Wyoming and Colorado hauling fuel, employees and whatever else. This duty lasted until January 2008 at 100,646 miles when it was retired for an easier job: mainly on-highway use pulling a 14,000 GVW ball hitch dump trailer averaging 850-1250 miles/week. Oil field conditions in the Rocky Mountain area can get nasty, and during winter months lots of idling ensues when weather gets well below zero. With that in mind, the unit was serviced every 100-125 engine hours/2000-3400 miles and very seldom beyond. Short of deep water crossings or continual operation in muddy or extreme dusty conditions, the differential change was Shell Spirex 75-90 in late fall/winter and 85-140 during late spring/summer; transmission ATF+4 at15,000 mile intervals; transfer case Mobil 1 ATF at 30,000 mile intervals, with fifth-wheel rotation every other engine service and complete wash job at least three times a week. At 82,336 miles the fuel transfer pump quit in a Colorado winter storm about 142 miles from home at midnight. Our local dealership did their in-tank replacement under warranty and we had the tie rod ends, drag link and steering stabilizer replaced at the same time. The OEM shocks were replaced at 12,000 miles and air bags installed at 57,000. As a side note, the dealership that we had dealt with for 25 years had recently changed hands. They called and said the Cummins’ pan gasket was leaking and we probably needed a rear main seal to boot—all under warranty, no less. That one service writer’s phone call to me cost the dealership our business. With 154,800 miles today, the OEM pan gasket and rear main seal are still doing their jobs, the service writer is not; industry cannot afford those types of individuals or poor training. The rear driveshaft assembly was replaced with new at 73,799 miles (comparable cost to that of repair and balance). At 125,000 miles, the front drive axle shaft joints, front driveshaft, front and rear brake pads and caliper bolt boots were replaced. At 137,978 miles, front and rear trans-bands were re-adjusted—they were checked at 99.654 miles with the rear band out of adjustment ½ turn. Now at 155,000 miles the ball joints, upper and lower suspension arms and stabilizer bushings and links will be replaced. So far the track rod appears to be hanging in there. This was all to give you an overview of a pretty darn good working truck with reasonable service life that has served us well under some fairly adverse conditions with close attention to maintenance to ward off unscheduled breakdowns. No add-ons, all OEM, since it is our test vehicle.

6

www.turbodieselregister.com

TDR 64

LETTER EXCHANGE . . . . Continued Now back to the first paragraph where I spoke about valve adjustment. We haven’t noticed a change in performance, fuel economy or level of engine noise attributable solely to valve lash. At 149,570 miles/4,357 engine hours, I could no longer stand it so I pulled the valve cover during a regular service and checked the lash. The attached chart shows the valve settings. So overall, with a vehicle that has worked hard but was rarely abused, I think Cummins and Chrysler have done rather well. However, I won’t allow any other mechanically actuated unit to go that distance without pulling covers and checking specs. Perhaps other issues of TDR have touched on this subject; please point me in that direction.

WATER-METHANOL INJECTION While reading Doug Leno’s article about water-methanol injection (Issue’s 62 and 63) I recalled the water injection system on the 1930’s John Deere Model D tractors that I spent hundreds of hours operating during WWII. These were two-cylinder tractors that ran on stove oil and were quite powerful. We started them on gasoline by cranking them by hand with the compression released. After they warmed up we switched them over to the stove oil. When the load was heavy, the engine would begin to “plink,” so we would turn on the water valve that allowed the coolant water to slowly be added to the intake manifold. This eliminated the “plinking” sound and seemed to be quite satisfactory. This was straight water and amounted to about a quart an hour of operation. Robert Olson Lewiston, ID Robert, interesting story. You wrote, “The engine started on gasoline and then switched to stove oil. Late in the run cycle it used water to keep things cool.” No doubt you enjoyed Kevin Cameron’s water-methanol history lesson that was also in Issue 62. I guess you could say your old Model D was a hybrid? You were green before being green was fashionable. 100% DODGE My heart is 100% Dodge. I have Dodge trucks from 1947 to 2004. Enclosed is a picture of my two everyday trucks. The ’97 has 238,000 miles and the ’04 is working on 100,000 and we will be there soon.

One thing is for certain, even if a little whining goes with it, old dyedin-the-wool mechanical B-series engine dogs like myself need to get off the porch. Randy Shipman Rock Springs, WY TDR IS OKAY I am 70 years of age. During this short span of time I have been a lifelong drag racer, motorcycle rider, shooter, mechanic, service manager, and magazine aficionado. I purchased the first Hot Rod magazine back in 1951. I loved reading Cycle magazine when Cook Nelson was at the helm. I still enjoy Kevin Cameron’s prose in Cycle World and in the TDR. I’ve got to say that the TDR is right up there with the best of them. Gene Sayre Chewalah, WA

I have never had the ’97 on the dyno, but the ’04 has been tested. The ’04 does real well for a work truck. She goes out everyday hauling and pulling trailers. Don’t tell anyone, but the most the ’04 2500 has hauled is 33,450 pounds. It has 535 horsepower and 935 ft-lbs of torque.

Gene, from your bio sketch, I can see that we share the same interests. Thank you for the kind comments.

Warren Milne Eaton, CO TDR 64

www.turbodieselregister.com

7

LETTER EXCHANGE . . . . Continued $35.02 AND THE TDR I had about decided that if I didn’t get some news about Chrysler in Issue 63 there would be no need to renew my subscription. But after gleaning a bit from writers Whale (pages 59-60) and Holmes (page 66) I have recanted. If TDR can’t find out much about Chrysler because it’s privately held and therefore required to release much less financial information and that ambiguous “Will O’ the Wisp” called Cerberus isn’t talking, I can’t expect TDR to print something which isn’t printable. And, I’ve siphoned some bits and pieces from newspapers which may contribute a little to this automotive jigsaw puzzle. So, I’m mailing my check of $35 for another year of TDR, and also will contribute my two-cents worth again (see TDR 54, page 8). Really, you are getting a good deal—$35 plus two cents=$35.02. I saw this Chrysler fiasco coming a few years ago, but Dodge dealers wouldn’t listen. When Chrysler buckled under to Mercedes, I even hoped (and suggested), that they put the Mercedes five-cylinder diesel in a Dakota. At that time, the Dakota had cleaner lines than the carp-mouthed Ram. Then, in 2005, I was ready to trade in my ’01 2500 for an ’05, because I wanted a slide-in camper and the ’05 was pre-drilled for the tie-down brackets. I visited three different dealers from Alabama to Ohio, and thought I had found a good deal, which included my trade-in and a $1000 factory rebate. Just as the salesman was filling out the final papers, he asked me how I was going to pay for the balance after trade-in. I never batted an eye when I said, “Cash.” His eyes didn’t bat either, but his lips moved. “You can’t have the $1000 factory rebate if you don’t finance the balance with Chrysler Financial.” Well, I had financed the ’01, and paid it off, but then my lips moved again, and I told the salesman that when the day came that Chrysler or anyone else penalized me for paying with my hard and honestly-earned cash they could keep their product. He could put his papers in File Thirteen and I’d keep not only the thousand dollars, but a few thousand others and my old truck. Now for the newspaper tid-bits to augment TDR’s meager news about Chrysler/Cerberus. In an article about Supertankers, which haul the imported crude oil, we are told that they “have the largest diesel engines in the world” and burn “tens of thousands of gallons of diesel fuel per day” (Charleston, WV Gazette). And, the refiners say that they really lost money on refining gasoline in the last part of 2008, but made it up on the sale of diesel fuel. Wonder if those Supertankers burn off-road, LS fuel, and the Feds and States get a cut of the taxes? Like Cerberus, they may not be required to reveal their financial status, but none of the foregoing seem to be bashful about asking for billions of bailout dollars from taxpayers. Chrysler may even be sociable enough now to accept my measly few thousand in cash. When Harry Truman began to sit behind the presidential desk, he said, “The buck stops here.” I’d like to add to that phrase and say, “My bucks not only stop here, they STAY here. And if you want them, partner, smile when you ask.”

8

www.turbodieselregister.com

TDR 64

Now to Chrysler President, Jim Press (USA Today, 2/16/09). Jim admits that he “erred badly” two years ago when he made some forecasts about the auto industry. He was with Toyota then, but now he is with Chrysler. But I reckon his presidency doesn’t extend to Cerberus. Well, I’ve decided to hold on to my old ‘01 Ram, with its new set of tires, batteries, and brakes. And unless Chrysler, Cerberus, or TDR can enlighten me further, for the first time in 18 years I’m ready to consider something besides a Dodge Ram Cummins Turbo Diesel. And, maybe if Jim Press moves back to Toyota, and can take a few Cummins TD’s back for the big Toyota pickup, I’ll even consider an offer sans a $1000 penalty. The first warm day, I’m about ready to slide under my old ’01, look at the new tires and brakes, trip the drain plug on the oil pan, then refill for my eighteenth oil/filter change, with a $4 Fram and about eleven quarts of Wal-Mart SuperTech 15W-40 oil. (See, I read my TDR.) And while the oil gurgles down the fill-pipe, I’ll scan those two new batteries again, before I crank over those musical-sounding injectors. You’re welcome to the two cents, anyway. P.J. Casebolt Pomeroy, OH P.J., thanks for the vote-of-confidence with your renewal. As I noted in Issue 63, we could chronicle the upheaval in the auto industry but yesterday’s government loan could very well be tomorrow’s sale, bankruptcy or protected bankruptcy. Like you, those with interest are following the daily soap-opera story by local news and trade publications. In the closing paragraph you mentioned using a Fram oil filter. Back in Issue 33 we did a visual analysis of 13 different oil filters that could be used on your engine. The Fram did not fare well. Then in Issue 34, page 105, there was notice of a product recall on the Fram oil filters used in Cummins 5.9-liter applications. Internal adhesive was coming loose and going through the engine oil system and clogging the engine’s piston cooling nozzles. Dodge warned the dealer network of this problem and listed the approved oil filters for the truck in their TSB 09-004-01, found on page 65, of the “Turbo Diesel Buyer’s Guide” pdf file at our web site, www.tdr1.com. I’ve often preached the virtues of Fleetguard’s (a Cummins subsidiary company) filter media that is known as StrataPore (see page 51 for an explanation). It is more expensive, but I believe it to be a viable alternative to the Fram filter’s cellulose filter media. That’s my two-cents. We’re up to $35.04.

TDR 64

www.turbodieselregister.com

9

BECOME A TDR WRITER—YOUR TIPS by Robert Patton Without much fanfare, last November we introduced a “Become a TDR Writer” contest at the TDR’s web site. The contest was inspired by the helpfulness of TDR member Harvey Barlow and his do-ityourself instructions for changing a 6.7-liter engine’s fuel filter. When I read Harvey’s post on the web site, I thought out loud, “This is what the TDR is all about! Members helping members with the website and magazine as channels for the flow of information.” I captured Harvey’s comments and added them to an article that I had already written that was published in Issue 62, page 40, of the TDR. So, we sent Harvey a check for $100 and announced a “Become a TDR Writer” contest. The contest lasted a month and we published the winning entries in Issue 63. For reference, grab your Issue 63 and turn to page 32 and 33 to read Ryan Battelle’s instructions on “How to Replace the Rocker Box Gasket.” Turn to page 36 for the detailed answer by “sag2” to a question about turbocharger soot on the 6.7-liter engine. Page 36 also has helpful correspondence from “Bob4x4” about the operation of the 6.7-liter engine’s EGR system.

STARTER DOES NOT ENGAGE Bill Thomas, “Missouri Mule,” submitted a common sense tip that can be used when you turn the key to “start” and nothing happens. So, you go through the basics— • Battery’s up to the task? Yes. • Any noise from the starter solenoid? No Rather than drag out the voltage meter to verify voltage at the starter, an often dirty and difficult-to-reach task, focus your efforts at the truck’s power distribution center. Bill suggests that you “remove the start relay and use a doublemale-sided jumper wire. Now, with the ignition in the ‘run’ position, the starter should engage as your jumper wire makes the connection from pin 30 to pin 87.”

The contest guidelines mentioned that other submissions would be printed in the TDR magazine. Publishing deadlines did not allow me to incorporate the tips in Issue 63, so we will publish the tips in this magazine. Without further delay, we present tips from the TDR audience that you will find helpful in maintaining your truck.

Your homemade jumper from #30 to #87 will energize the starter.

Does the starter engage? Yes. Time for further troubleshooting. Things to look for: • the obvious—a faulty relay • neutral safety switch • start position on the ignition switch • clutch switch From Bill’s tip you get the picture. As a part of my tool kit I now have a double-male-sided jumper wire. In Issue 62 on page 40, Harvey Barlow discovered the 1/2” drive indentation on the bottom of the 6.7-liter engine’s fuel filter canister. This same indentation is on the newly-released 6.7-liter fuel filter canister that you can read about on page 50.

10

www.turbodieselregister.com

TDR 64

Bill Thomas Smithville, MO

TURBO TIPS . . . . Continued CHANGE THE TRANSMISSION FLUID by Robert Patton “Matt B” submitted a tip that can save you from the fluid mess that accompanies an automatic transmission fluid service job. Matt’s tip also allows you to change the majority of the transmission fluid. The “majority of the fluid;” what do you mean? In a typical drop-thepan service you are only changing about half of the fluid, there is fluid that remains in the torque converter that does not drain. Okay, how do you change the majority? Matt would have been one of the contest winners, but this changethe-majority tip was presented back in Issue 42. The following is a reprint from Issue 42. This technique can be used on ‘94-’07 trucks with the 47RH or 48RE automatic transmission. Owners With the ‘94 - ‘07 47RH or 48RE If your transmission pan doesn’t have a drain plug (read: your very first transmission fluid change), to provide for an easy fluid change, or if you want to change all of the fluid (net change 10-12 quarts), try this method. Pinch-off and then disconnect the return-to-transmission cooler line from the radiator (location: driver’s side of vehicle; bottom corner of radiator just beside the radiator coolant/fluid drain petcock). Of the two transmission lines, this is the outboard line and (thankfully) it is the easily accessible line. Take the 1/2” rubber hose and bend it upward to prevent fluid drainage. Next, connect a three-foot length of 1/2” rubber “purge” hose to the metal flare coming from the radiator. Feed your rubber hose into a five-gallon container.

Owners With the ’07.5 and Newer 68RFE For this transmission the transmission cooler lines attach to the cooler assembly using crimped hoses. Regardless, you can use the same technique to remove the fluid, but you have to find a different disconnect location. Inspection of the transmission cooler lines for the 68RFE reveals that the entry and exit fittings to the transmission are on the passenger side. Which is supply, which is return? That’s why you pay your $35 TDR subscription—the editor gets to take the 50/50 challenge in hopes of discovering which line is the return line. Before exploratory removal, I tried diagnostics with an infrared temperature gun hoping to see a big temperature difference in the two fluid lines. Perhaps I should have waited for a hot summer day, but deadlines prevail and there was little temperature difference. The fitting and cooler line that was easiest to reach was on the bottom. As luck would have it, this is the return-to-transmission line. Using a 1” wrench I disconnected it from the transmission. I found a ¾” heater hose, 3’ in length, and hose-clamped it onto the threaded fitting. The hose was directed into a 5-gallon bucket.

The bottom cooler line is the return-to-transmission line. Remove it with a 1” open end wrench. Clamp a 3/4” ID hose over the threaded barb and direct the fluid into a 5-gallon bucket.

I noticed that both the supply and return lines were held with a brace on the driver’s side of the transmission. For extra wiggle-room when removing the transmission pan, I removed the brace (14mm bolt) with allows the lines to be pushed out of the way. A view of the transmission lines from the front of a Second Generation truck. Follow the “cold” line back to the transmission cooler and disconnect the line at the junction point. Attach your purge hose to the metal flare at the transmission cooler.

With the truck in Park, depress the emergency brake, chock the tires, then start the engine. Shift the transmission into Neutral. ATF will begin flowing into the container. Once the flow begins to dwindle, immediately turn off the engine. This technique will yield 10-12 quarts of fluid. Re-attach the 1/2” rubber hose/cooler line to the metal flare from the radiator. Continue with your transmission maintenance by dropping the pan. (The fluid is gone, so you will avoid the fluid bath that can happen with a full transmission sump.)

With the truck in Park, depress the emergency brake, chock the tires then start the engine. Shift the transmission into Neutral and ATF will begin flowing into the container. Once the flow begins to dwindle, immediately turn off the engine. This technique on the 68RFE yielded 10 quarts (at least that is how much I put back into the transmission to get it to the proper level). Re-attach the cooler line to the transmission and continue your transmission maintenance by dropping the pan. The pan is held on with 8mm bolts. Remove the bolts and you’ll find that Mopar TRV sealant holds the pan onto the body of the transmission. Start in the back corner and lightly tap the pan. For what it is worth, there was still enough fluid in the pan to cause a small cascade of ATF over the edge of the pan. Better a small fluid bath than a large one? Remove the pan.

Clean the pan. Change the transmission filter. Make a decision about installing a B&M drain plug or temperature sensor.

Clean the pan. Change the 68RFE filters. Make a decision about installing a B&M drain plug or temperature sensor. TDR 64

www.turbodieselregister.com

11

TURBO TIPS . . . . Continued NEXT ITEM—TEMPERATURE SENSOR In my previous ’03 Turbo Diesel truck I installed a transmission temperature sensor in the transmission pan using a B&M drain plug kit. For the four-years and 120,000 miles that I owned the truck I never saw a transmission fluid temperature higher than 195°. Highest, so far, on my ‘07.5 truck, 212°. I was pleased with this low temperature number and was thankful that I did the temperature baseline test. The data convinced me that a fancy, finned aluminum transmission pan was not necessary. This is Freddie Frugal speaking, “Establish a baseline, evaluate, modify if the need arises.” TDR members appreciate Freddie’s straight-up advice. Aftermarket vendors hate Freddie. Using the “drain the fluid through the hose” method, it was easier to drop the 68RFE’s pan and avoid the big fluid bath that occurs when the pan has not been emptied. There was some overflow on the back corner as I removed the pan. With the pan removed I drilled a ½” hole and installed a B&M drain plug. The plug for the B&M kit is a male 1/8” NPT fitting. I removed the fitting and replaced it with an oil temperature sensor that uses 1/8” NPT male threads.

Next I removed the transmission filter using a torx socket. Remove the transmission’s external filter using a strap wrench or filter claw tool. Reinstall the filters and the transmission pan. Torque the pan bolts to 13ft-lbs. (The 13ft-lb value was verified in the ’07 Service Manual and this is the same value as used back to the ’94 trucks.) Refill transmission with Chrysler ATF+4 fluid. I could not find the capacity for the 68RFE in my Owner’s Manual. Using my “drain through the hose” and pan removal method I found that 10 quarts were needed to replinish the transmission. After refill, the correct procedure for checking your transmission fluid is outlined in your Owner’s Manual. • The vehicle must be on level ground. • The engine should be running at curb idle speed for a minimum of 60 seconds. • Fully apply parking brake. • Place the gear selector briefly in each gear position, ending with the lever in N (Neutral).*** • Remove the dipstick and determine if the fluid is hot or warm. Hot fluid is approximately 180° F (82° C) which is the normal operating temperature after the vehicle has been driven at least 15 minutes. The fluid cannot be comfortably held between the finger tips. Warm is when fluid is between 85° - 125° F (29° - 52° C). • Wipe the dipstick clean and reinsert until seated. Remove dipstick and note reading. a) If the fluid is hot, the reading should be in the crosshatched area marked “OK.”

Cleaning the RTV from the 68RFE transmission pan.

b) If the fluid is warm, the reading should be between the two holes. If the fluid level indicates low, add sufficient fluid to bring to the proper level. • Fluid is added through the dipstick tube. ***I cannot over-emphasize that the transmission fluid should be checked with the gear selector in Neutral. With the vehicle in Park, there is no fluid flow! Hence, if you take a transmission fluid level reading with the vehicle in Park, the reading will always be higher than it actually is. Additionally, should your transmission fluid become too hot, shift the transmission to Neutral—not Park—to ensure that there is fluid flow and thus the opportunity for fluid cooling. Conclusion Barlow, Thomas, “Matt B” and I have given you some worthwhile maintenance ideas. The “Turbo Tips” section of the magazine awaits your input.

From my study of the internal parts of the 68RFE, I determined that the best place for the drain plug was the location that I marked “B&M.”

12

www.turbodieselregister.com

TDR 64

Robert Patton TDR Staff

BD LIFT PUMPS MEET THE DEMAND OF TODAY’S DIESELS

year warranty

Electronic Fuel Demand

Mechanical Fuel Supply

NEW!

Flow-MaX with Auxiliary Fuel Filter

The stock lift pumps on the Dodge Cummins and Chevy Duramax trucks have not been able to meet the demand for fuel on modified or even stock applications. When making electronic performance or mechanical injector modifications, higher fuel flow lift pumps are required as well as additional air supply from efficient turbochargers and charge air intercoolers. BD’s Flow-MaX lift pump has been designed to deliver ample fuel flow yet are compact, quiet and more durable than competitive products. Featuring a hard anodized aluminum body and proven gerotor design, Flow-MaX is an ideal replacement for the OEM pump, which can fail even at the stock horsepower level and cause damage to the injection pump. When asked to deliver fuel, you can depend on the Flow-MaX.

nä

£Çä

Noise Level

ä Çä xä

Stock

££ä Competitor

FLOW GPH

£Îä

BD Flow-MaX

{ä

Normal Conversion

{x

Competitor #2

xä

Competitor #1

Èä

Backseat Driver

Èx xx

Flow-MaX Benefits:

£xä

Çä

BD Flow-MaX

NOISE LEVEL dB

Çx

UÊ165 * ÊvÕi ÊÃÕ«« ÞÊÃÕ«« ÀÌÃÊ ÛiÀÊÈää «Êi } ià UÊÊ*À Ûi Ê}iÀ Ì ÀÊ`ià } ÊÉÊ}Ài>ÌiÀÊÀi >L ÌÞ UÊÊ «>VÌÊ ÃÌ> >Ì UÊÊ ÜÊ ÃiÊ iÛi UÊÊ"«Ì > Êw ÌiÀÊ Ì UÊÊx Þi>ÀÊÜ>ÀÀ> ÌÞ

Fuel Flow

Cool-It Intercoolers UÊÊ } iÃÌÊV }ÊivwV i VÞ UÊÊ ÝÌÀÕ`i`ÊÌÕLiÊ`ià } UÊÊ >ÃÌÊi `ÊÌ> ÃÊÜ Ì ÊÃÕ«« ÀÌÊÃÌÀÕÌà UÊÊ-Õ«« ÀÌÊÕ«ÊÌ Ê£ää«Ã ÊÌÕÀL ÊL ÃÌ

Performance Turbocharger Kits UÊÊ >ÌV i`Êv ÀÊ` vviÀi ÌÊ *Ê iÛi à UÊÊ ii«ÃÊ /ÊLi ÜÊ£Óää UÊÊ ÌÃÊ`ià } i`Êv ÀÊÃÌ V Ê> ` modified power levels

WINNER OF THE SEMA BEST NEW

PICKUP/SUV/VAN PRODUCT 2009!

DIESELPERFORMANCE.COM

1 800 887 5030

I think you will agree with me when I categorize Turbo Diesel owners as independent people who are not afraid to try something new. You are an ingenious membership who reinvents and improves a product to make it better serve your needs. You show a strong willingness to share your shadetree solutions. With your input each quarter, we publish the “Member2Member” exchange to give you a forum to tell other members how you solved a problem. Steering improvements – part 2 by Doug Leno In TDR issue 63 (page 112) I described the use of the BD Steering Box Support (SBS) to apply additional structural support to the factory steering box. This solution corrected a steering wander which had been developing over time and then became pronounced when I installed new Toyo Open Country AT tires in size 285/7017. The Issue 63 article did not, however, address a different and unrelated steering problem which these tires also seemed to exaggerate—a slight pull to the right.

Turbo Diesel owners often use the expression “every truck is different” to describe the variability associated with manufacturing tolerances. This is especially true for the solid axle front end design of a four-wheel drive Turbo Diesel. However, it is not the purpose of this article to discuss the various front end alignment terms and specifications. For such an article, I encourage readers to consult Andy Redmond’s excellent article in the “From the Shop Floor” segment In TDR Issue 53. This article will concentrate on correcting the right-hand pull I was experiencing. Figure 1 is an exaggerated illustration of my problem. By using recently-calibrated laser-equipped alignment machinery operated by a 20-year alignment veteran, the following issues were identified: • My front axle is rotated clockwise (when viewed from above) so that the left wheel is ahead of the right. • My rear axle is rotated counter-clockwise, so that the right wheel is ahead of the left

In this article I will describe my experience understanding and correcting this problem. It is enlightening when you have to deal with the consequences of operating a truck outside of factory specifications. Problem Assessment To assess this problem, I had to remind myself that my truck’s front suspension is not factory anymore. My over-sized tires are accompanied by an after-market Kore Chase suspension upgrade, which lifts the front end about three inches. This does not substantially change the front end geometries, but there is a cause and effect. For example, the factory track bar (which I retained) pulls the axle to the left about one third of an inch under the influence of such a lift. I realized that my steering bias problem could not be understood by making routine measurements at an ordinary, highvolume tire store. So, I decided to find an experienced alignment shop. A knowledgeable and trustworthy alignment shop is worth its weight in gold, and even more golden when dealing with aftermarket suspension upgrades that take front end geometries beyond the factory design. I have great respect for the shops that demonstrate exceptional knowledge and experience in this area, especially those that let me watch and ask questions. I once had alignment work performed at three different shops within 24 hours, just to find out which ones had recently calibrated their equipment, demonstrated the most experience, and were willing to spend time explaining their work to me! Obsessive? These efforts have paid off substantially.

14

www.turbodieselregister.com

TDR 64

Figure 1: This shows an exaggerated view of the problems contributing to my right-hand pull. The right-side wheelbase is shorter than the left.

The measurements revealed that the right-side wheelbase is shorter than the left, which causes the truck to pull to the right. By itself, the left-hand shift in the front axle position (due to the lift) is insignificant, the technician explained, but may have a greater impact in my case because of the rotated axle.

Member 2 Member . . . . Continued Available Adjustments Of the front alignment adjustments available, castor* represents the only opportunity to help correct steering bias without introducing irregular tire wear or steering instabilities. Castor refers to the angle of the steering axis (as viewed from the side of the wheel), represented by an imaginary line drawn between the upper and lower ball joints. The angle that such a line forms with the vertical (a line drawn through the center of the wheel) is the “castor angle” or simply, castor. Our Turbo Diesels are manufactured with positive castor, which simply means that the lower ball joint is slightly forward of the upper one. Both ball joints are fixed, however, so there is no way to (directly) adjust castor. The variability inherent in the manufacturing process means that the left and right castor are rarely equal, and the truck will therefore tend to pull towards one side (the wheel with the least amount of castor). As fortune would have it, my truck was manufactured with a slightly smaller castor angle associated with the left front wheel, as compared to the right. This alleviates the right-hand pull somewhat, especially when driving on the right-hand side of roads with builtin crown. But the effect is not enough in my case. Fortunately, both axle rotation and castor are influenced at the same time by adjusting the eccentrics on the lower control arms. Analysis of the problem illustrated in figure 1 reveals a sensible opportunity: Using the eccentrics, I could extend the right-hand lower control arm and shorten the left-hand lower control arm. The result: • The right-side of the front axle would move forward and the left-side would move back, correcting the axle rotation problem and wheelbase difference • A very small twist would be introduced to the axle, increasing castor on the right while decreasing castor on the left The eccentric adjustment made to the right-hand lower control arm is shown in figure 2. By utilizing all of the available adjustment room provided by the factory, I obtained another .3 degree increase in “cross castor,” or the difference in castor between the left and right front wheels. My left front wheel now has .5 degrees less castor than the right wheel, the maximum difference allowed by the factory.

left-hand lower control arm. This corrected the wheelbase difference and indirectly influenced castor as well: The castor of the left front wheel is now .5 degrees less than the right front.

My alignment shop informed me that adjusting the axle in this way can introduce additional stress on the control arm bushings. The adjustment is acceptable, however, because it stays within the factory allowed adjustment range. It should be noted that the lower control arm eccentrics do not directly adjust castor, which is fixed by the upper and lower ball joints. They do, however, influence castor by pushing out or pulling in on the bottom of the axle tube, which introduces a very small amount of axle twist. Fortunately, with over 40,000 miles since adjusting the eccentrics in this way, there is no evidence of premature bushing wear. However, the effort did not completely solve my right-hand pull, and for some time now I have had to accept the fact that factory adjustments may not be able to accommodate non-factory components! Corrective Action: An After Market Steering Damper To address the remaining right-hand pull, I could install an aftermarket adjustable track bar, which would allow more latitude in left-to-right axle placement. However, I had installed the Kore Chase suspension with the understanding that the adjustable track bar, while helpful, was not necessary. So I began looking to another component that needed replacement anyway, my steering damper. As of this writing, my truck has approximately 80,000 miles on the odometer with the factory steering damper. This part has fatigued, as evidenced by a very small amount of “bump steer” instability which I experience occasionally. I had purchased the Kore race series steering damper some time ago, but I had not installed it.

Figure 3: Factory steering damper: The passenger-side mount point (left hand side of the photograph) is welded to the axle tube, while the shaft end is attached to the steering tie rod (far right of the photograph). This design absorbs vibrations in the steering system without introducing any significant bias. Figure 2: Adjusting the eccentric on the right-hand lower control arm extended the bottom of the axle forward (to the left in the photograph). The opposite adjustment was performed on the

*Doug uses “castor.” I’ve always seen the word as “caster.” The dictionary says that both are acceptable.

TDR 64

www.turbodieselregister.com

15

Member 2 Member . . . . Continued The Kore Steering damper was designed to perform in situations where the factory damper quickly fails—the use of high traction, large diameter tires running at low pressures over rough terrain for long periods of time. Supplied with 200 psi nitrogen charge, it also provides a very useful bias to the steering tie rod which tends to force the truck to back to the left. I had postponed taking advantage of this benefit long enough.

The Kore steering damper fits into the passenger-side factory mount point, which is welded to the axle tube. This is also the location of its nitrogen charge/bleed valve (see figure 6).

Figure 6: Kore damper installed in the passenger-side factory mount point which is welded to the axle. The nitrogen charge/bleed valve (bottom center) is also visible. Figure 4: Compared with the factory steering damper (bottom), the 2-inch diameter Fox/Kore steering damper (top), is able to tolerate the abuse of off-road driving with large-diameter tires.

Removal and Replacement Removal of the factory damper from the axle mount point is easy. Removing the shaft end from steering tie rod can be a pain due to its taper-fit. With some patience and judicious use of penetrating oil, I was able to break mine loose (see figure 5).

Figure 5: Factory steering damper’s taper-fit partially removed from the steering tie rod. This step may require penetrating oil and patience!

16

www.turbodieselregister.com

TDR 64

Attaching the Kore damper to the factory steering tie rod is a different matter: Instead of utilizing the factory tapered mount point, Kore uses a two-piece machined aluminum clamp. Correctly positioning the clamp onto the tie rod is not difficult, but it is very important to correctly center the damper within the truck’s steering range. I used a floor jack, laid on its side and positioned against the left front tire (figure 7), to compress the damper enough to correctly position the clamp before tightening it down. The completed installation is shown in figure 8.

Figure 7. A floor jack can be used to compress the Kore damper to correctly position the clamp prior to tightening.

Member 2 Member . . . . Continued TURBO AIR GUIDE/TAG 3 UPDATE Notice to all TDR members that may have installed a Third Generation Turbo Air Guide known as a TAG 3. Carson Dodge has seen two turbos fail due to pieces of an early version of the TAG 3 breaking off and being sucked into the turbo. Let me emphasize, this doesn’t apply to the all-metal TAG 1 and TAG 2 models. It ONLY applies to some of the first editions of the TAG 3 models with the plastic housing manufactured before 2004. (Remember, old stock could still be sitting on the shelf somewhere.)

Figure 8: Completed installation of the Kore steering damper. A custom aluminum clamp attaches to the steering tie rod, avoiding the factory taper mount, which is visible to the left of the clamp.

Results Installation of the Kore steering damper not only eliminated that small bump steer instability, it also caused my truck to pull to the left! This was good news, for two reasons: First, this meant that my suspension was very close to factory limits, even with the Chase system installed along with the factory track bar. Second, it confirmed that it would be possible to obtain perfectly neutral steering by bleeding some of the nitrogen pressure from the damper itself. This was a matter of experimentation: I drove for several days under various road conditions, mentally keeping track of the truck’s pull to one side. After proving the left-side bias under all conditions, I bled a small amount of nitrogen from the damper by measuring it with a digital gauge. Careful! The volume of nitrogen is so small that every measurement removed about 20 psi or so.

How do you tell if you have one of the models that might be subject to failure? Carefully examine how the stainless steel “honeycomb” is inserted into the plastic housing. If yours has the honeycomb “molded” into the plastic, you’re okay. However, if you see a very thin band of steel around the circumference of the honeycomb, that allowed the unit to be pressed into the plastic housing, that’s the one that has the possibility of failing. (I’ve found two so far among our trucks because I worked with the manufacturer in testing some of the first ones built.) If you identify yours as one of this type, contact Brian Howell at (866) 379-8685 for information on how to exchange the unit. John Holmes TDR Writer

After several weeks of experimentation, I achieved the neutral steering performance I was after at a nitrogen pressure of 115psi. Conclusions • Aftermarket upgrades or component changes may have side effects that are past the limits of factory adjustments to correct. • The services of an experienced and helpful alignment shop are invaluable to properly set up a stock truck, and even more so when dealing with aftermarket suspension upgrades. • I’m thankful for experienced off-road component manufacturers, such as Kore, who have thoroughly tested everything they sell, and know what works. Doug Leno TDR Writer For more information about Kore products, contact: Kroeker Off Road Engineering www.koreperformance.com 760-749-8687 TDR 64

www.turbodieselregister.com

17

I have often lamented that as a society we don’t properly honor the inventiveness and achievement of our elders. So let us give that bygone achievement some proper and regular observance in our pages in the “10 Back” column.

Whale was the photographer and member Andy Perreault’s truck was the truck on the cover and featured in our “All Dressed Up” column. By the way, where are those member stories that can make a good All Dressed Up story?

In each installment of the “10 Back” column I will reprise the accomplishments of TDR trailblazers by recalling an article still as relevant in today’s Turbo-Diesel world as it was the day it was written. Ten-year-old article reprints will then be posted in the magazine archives section of the TDR web site.

What else was interesting about Issue 24? Part-time writer Andy Mikonis and full-time writer Joe Donnelly were added to the writer masthead. The page count of Issue 24 was 124 pages, 12 pages larger than Issue 23.

So, without further ado, we present our ever-new feature column: 10 Back: Issue 24 – May, June, July 1999 In Issue 24 the TDR membership was abuzz about the TDR national event that was scheduled for August and hosted by Cummins in their hometown of Columbus, Indiana. The ’99 TDR Nationals would represent the fourth national gathering that Dodge and Cummins had sponsored in a five year period. The theme for the ’99 TDR Nationals – A 10-year Celebration of the Dodge/Cummins Partnership. Yes, those were the good ‘ole days. Were you in attendance? A bit of trivia—the cover picture for Issue 24 marked the first time a TDR member’s truck was on the cover. The previous TDR covers were photography supplied by Dodge. Members had not sent in professional-grade photography that we could use. Our own Greg

Interesting and still relevant articles? Consider the following: • TDR member Jeff Prince wrote in to tell us about his 3500 Turbo Diesel that he had modified and taken to his local drag strip. Using mathematical formulas we estimated Jeff’s truck to be at the 450-475 horsepower level. • The May of ’99 Issue 24 magazine marked the one-year anniversary of the merger of Chrysler and Daimler. My review of Issue 24 and the previous “10 Back” articles and old magazines show that there was not much ink devoted to the merger. Hindsight is 20/20 and the merger would draw ample attention as news would surface in late 2000 that the merger had, in fact, been a takeover. But, thinking back to 1999, the merger was perceived as good news. • Thumbing through the pages, I noted that TDR members were purchasing diesel fuel in the 87¢ to $1.09 price range. • I was alerted by a tip that an exposed nut on the alternator that is charged with 12-volts and can arc if grounded by a stray wrench made me examine the same item on my ’07.5 truck.

A picture of our Issue 24 cover that featured photographer Whale’s photo of Andy Perreault’s truck.

18

www.turbodieselregister.com

TDR 64

It is difficult to see the exposed terminal on the back of the alternator, but it is there. From our look at trucks in the parking lot we found the ‘03 and newer trucks have adequate insulation shielding.

10 BACK . . . . Continued Speaking of dangerous sources of 12-volt + electrical power, take a look at he exposed + terminals on both of your batteries. I’ve been looking for a suitable cover to sell to 1.75 million Turbo diesel customers. Help! • Issue 24 reported much discussion of exhaust brakes and their use with automatic transmissions. How relevant was the information? Would you believe that the text was used for emphasis in last issue’s discussion of exhaust brakes? See page 75 of Issue 63 and realize that some things do not change. • Joe Donnelly did a thorough review of Dana differentials, differential rebuild and backlash setting and reviewed the MagHytec differential cover. • Scott Dalgleish installs several Banks Engineering products on his ’98, 12-valve engine and bumps the performance from the stock 215hp (188hp at rear wheels) to 277hp (238hp at rear wheels). The cam plate was changed, the turbo’s exhaust housing changed from 12cm to 14cm, and the exhaust system was replaced. Old-school horsepower. • Dodge showcased a Power Wagon concept pickup truck at the Detroit/North American International Auto Show. The truck had a 7.2-liter Caterpillar diesel engine under the hood and the rumor mill was set into motion. Would the upcoming 2003 Third Generation truck use a Caterpillar engine? Perhaps the Daimler merger would force Dodge to use a Mercedes Benz diesel? Rumors‌

• At the same show there was a Dodge Durango with a 4.0-liter V-6 with a Detroit Diesel “Deltaâ€? engine. More rumors. • Jim Anderson notes that “by far the largest number of complaints on the 24-valve engine center around lower-than-expected fuel mileage.â€? The aftermarket vendors were busy trying to modify the engine’s ECU and/or change the performance by use of an add-on box. There weren’t yet many products in the performance market for the engine. • Jim Anderson writes in his newly created (Issue 23 was the first) “Idle Clatterâ€? column that Joe Donnelly’s Air + Fuel = Power article from Issue 23 was well received by the TDR members. As you know, in Jim’s “Idle Clatterâ€? column he documents the frequently asked and newbie-type questions and responds in a patient manner. I thank Jim for his easy-going, even-tempered personality. The Issue 23 Donnelly article is a part of the TDR archives at our web site, www.tdr1.com. As we have done in previous “10 Backâ€? columns, we have captured the text of several of the above articles and added them to the archives, too. Oh yeah, the Y2K thing‌it was now just 7 months away. Robert Patton TDR Staff

No More Tracking Bar Problems )PX UP DIFDL GPS USBDLJOH CBS QSPCMFN )BWF TPNFPOF NPWF TUFFSJOH XIFFM JO CPUI EJSFDUJPOT XIJMF ZPV PCTFSWF UIF VQQFS FOE PG USBDLJOH CBS GPS VQ BOE EPXO NPWFNFOU JO CBMM BOE TPDLFU

4 " ' &3

-VLF T -JOL

&"4: */&91&/4*7

&

5*-& 7 &3 4 "

SOLVING THE STEERING PROBLEM ON THE DODGE RAM 4 X 4 1994-2002 FOR LESS THAN $100 The problem with the steering on the Dodge 4x4 is a loose tracking bar. The end that is attached to the frame is a joint with a ball and socket. The joint will become loose and cause a serious steering problem. Replacing the tracking bar will only temporarily solve the problem. Luke’s Link will rebuild this joint for the life of the truck. •

Luke’s Link is a heavy-duty rebuilding kit made from ductile iron. (Ductile iron is rated 40,000 psi) No special tools are needed to install the kit. No welding.

•

It can be installed in less than 30 minutes using only a grinder and hand tools.

•

This kit is adjustable by using adjustment spacers.

•

The internal parts may be purchased separately, making this a lifetime unit.

This kit also fits Dodge tie rods, Ford truck tie rods, and Jeep Cherokee track bars. P.O. BOX 466, LA JUNTA, CA 81050

Call Anytime – Johnnie Laucus TOLL FREE: 1 (800) 962-4090 CELL: 1 (719) 980-9476

L&L Industries – Since 1982

This kit will not fit MOOG track bar. Your truck is equipped with a MOOG track bar if the bar is 2� in diameter across the grease zerk end. If your truck has this track bar call us about our exchange program. US Patent #4613250

www.lukeslink.com

TDR 64

www.turbodieselregister.com

19

Coverage of the ’89 through ’93 Model Trucks. Web Site Correspondence Edited by Bill Stockard and additional Q&A written by Joe Donnely. REPLACE BULBS IN CAB LIGHTS A couple of bulbs in the cab lights on my ‘91 Turbo Diesel D350 have burned out. What size bulb is required? When replacing the bulbs, is it necessary to replace the gaskets? peobryant, Goshen, KY The replacement bulb for the roof clearance light is a number 194 bulb which has a flat end that pushes into the socket. I have replaced several bulbs and successfully reused the original gasket by leaving it in place. If the gasket isn’t cracked, carefully clean and reuse it. I’ve had one off a couple of times, but it didn’t require replacement. tugboatphil, Floyd, VA REPLACE THE FUEL FILTER I need to replace the fuel filter on my ‘92 Turbo Diesel W250. Is it easier to replace from the bottom or from the top? Is there anything that can be removed to make the job easier? It’s winter and I don’t have access to a shop. CSchoepp, AB Remove the fuel filter from the top using a filter strap wrench. Make sure the heater stays in place as well as the fuel filter stud. Be aware that there is a rubber square O-ring on top of the fuel heater between it and the filter head. pepecat, Davis, CA

LEAK ON FUEL FILTER HOUSING There is a fuel leak near the top of the fuel filter housing on my ‘92 Turbo Diesel W250. It appears to be from the fuel line that feeds the filter from the fuel lift pump. However, it was the square cut O-ring above the fuel heater which is between the filter housing and the fuel filter. The replacement O-ring is Fleetguard Part Number 383418-S and is available from a Cummins dealer. BGore, ME Thanks for the information. I too have a fuel leak near the top of the filter housing. southpaw, San Diego, CA/Monett, MO HEATER VALVE When I replaced the heater hoses on my ‘93 Turbo Diesel D250, I forgot to note the position of the coolant On-Off control valve and I am unsure of the correct coolant flow. Should the arrow on the valve point towards the firewall or the radiator? BHerring The hose that attaches to the pipe coming out of the top of the engine will be pressurized and should have the valve in it. WJones, So CA The arrow on the valve should be towards the firewall. LBARTLETT LOWER RADIATOR HOSE

I’ve always changed the fuel filter from the top and never used a filter wrench on the fuel or oil filters. I’ve never had a problem with leaks.

I purchased a Goodyear replacement lower radiator hose for my ‘93 Turbo Diesel D250 and it doesn’t have a spring wire inside it like the hose I removed. Is this spring wire needed? BHerring

Remove the old fuel filter and remove the water sensor. Replace the O-rings on the top and bottom and reinstall the water sensor. Reinstall the new filter until it is almost tight and then back it off a little. I use the lever on the fuel pump to fill the filter, which requires about 15 or 20 strokes. When the fuel begins to spill out, tighten the filter and start the engine. I’ve changed the fuel filter using this method probably close to 30 times without an issue so far. BGore, ME

The coiled spring is to prevent the hose from collapsing under suction or should there be a cooling system malfunction. I have seen them in hoses previously, but new quality replacement hoses are very stiff and contain more fiber reinforcing material and probably don’t require the springs as did the older hoses. If you maintain a clean cooling system and the spring is in good condition, shove it into the new hose. upsyes

It’s a simple ten minute job. While unscrewing and screwing the filter back on, be careful not to twist the wire harness for the water separator. If the weather is cold, replace the fuel filter after the engine is warmed up. Standing on a block of wood or a tire helps too. glhs, Cheyenne, WY/Brighton, CO

I am on my third set of hoses in 215,000 miles, including the original hoses, and none had springs in them and there have been no problems. All of the replacements have been Goodyear except the heater hoses which are silicone and all have been trouble free. Bob Beauchaine, Portland, OR

20

www.turbodieselregister.com

TDR 64

FIRST GENERATION . . . . Continued LOOSE STEERING I recently purchased a ‘93 Turbo Diesel W250 with 204,000 miles on the odometer. The steering feels loose with lots of play. No front axle and steering components have been replaced except front axle U-joints. What components are associated with the loose steering problem? I need a checklist for parts that affect steering performance. Firstgenfanantic, Bremerton, WA I would look at kingpin bushings, tie rod ends, and possibly replacing the original steering shaft with a Borgeson Steering Shaft. After the repairs are completed, get a thorough front end alignment from a reputable alignment shop. pepecat, Davis, CA

I contacted Geno’s Garage and discovered that they can order any model number of Isspro products. If you see a brand you like at Geno’s, but not the specific part number, just ask. They will get it for you. Thanks for the suggestion. Firstgenfanantic, Bremerton, WA SPRING HANGER BUSHINGS Has anyone replaced the rear spring hangers on the front springs? Where can I buy replacements?

The Pitman arm and idler arms may need replacement too. A couple of years ago I helped a friend who had about 30 degrees of play in his steering wheel. We replaced the original steering shaft with a used Borgeson joint which eliminated about 95% of the play. It was amazing. JLEONARD, Torrington, CT Check to make sure that the steering gear box is tight on the frame. rumblefish, Decatur, IN My Turbo Diesel W350 had about 30 degrees of play in the steering when I purchased it. New tie rod ends and drag links cured about 85% of the play. The front wheel toe-in is the only thing adjustable on these trucks. Measure the track width at the front of the tire and rear of the tire to check the tow-in. The factory service manual has specifications on toe-in. dpuckett, Cape Girardeau, MO/Mt Eden, KY

Dieselman359, Saint Louis, MO

Check the flexible joint on the steering shaft just above the gearbox. Most of the steering play is probably there. Replacing those parts costs $30 to $40; or purchase a Borgeson shaft for about $200. I also recommend checking the draglink and tie rod ends. PToombs, Minoa, NY What brand replacement parts should I purchase? Thanks for the suggestions. Firstgenfanantic, Bremerton, WA I suggest Moog replacement parts. rumblefish, Decatur, IN ISSPRO TACHOMETER I have decided to purchase an Isspro R5503 tachometer with a white pointer for my ’93 Turbo Diesel W250. I want a white pointer tachometer because I want to match my other gauges which are Isspro EV gauges with the white pointers. The sellers I have contacted only sell a tachometer with a red pointer. Does anyone know a source for getting the exact tachometer with a selection of gauge cups? Firstgenfanantic, Bremerton, WA Geno’s Garage sells a tachometer that goes to 3,000 RPM and is $122. peobryant, Goshen, Ky

You will need four of Dodge Part Number 02953700. There are two bushings in each bracket. You can see the split line between the two bushings in the photo. Philip, IN The same bushings are used on the two wheel drive truck upper control arm. I purchased mine from NAPA. Since I could not remove the bushings, I took the brackets to the heavy truck shop and had them press the bushings out and then back in. Greenleaf, Ashland, OH

TDR 64

www.turbodieselregister.com

21

FIRST GENERATION . . . . Continued FRONT ROTOR DISC WEAR

INJECTION PUMP LEAK

I replaced front brake pads on my ’93 Turbo Diesel D250 with an aftermarket set. After about three weeks, I removed the front wheels to inspect brakes. I noticed the outside of the rotor had no wear on the bottom ½-inch which means the pads are not touching the rotor ½-inch from the bottom. However, the back side of the rotor shows the pad completely touches the rotor. I decided that I may have purchased the wrong pads and I ordered pads from EGR Brakes (a TDR advertiser) part number 086. Their pads are the exact dimensions of the after market. Is it normal to have ½-inch of unused rotor on the outside and full pad to rotor contact on the inside?

My 1993 Turbo Diesel has a leak in the engine area. I thought it was the power steering pump at first, but it seems to be from the injection pump above it. Do I need to get it rebuilt? L.Rose First, clean the area so you can determine what is leaking. You can smell the oil and see if it is diesel fuel, power steering fluid, or engine oil. It is fairly common for the VE pumps to develop leaks due to age and the changes in diesel fuel formulation due to emissions requirements. A Bosch pump shop can change the seals, with or without a rebuild. I recommend changing all the seals if one is leaking. The VE pump is not as easy for a novice to remove as it looks, so iyou may want to get a quote on the whole job from the shop. Joe Donnelly KILLER DOWEL PIN I have a First Generation Turbo diesel with 241,000 miles on it. I was told by the previous owner that as far as he knew the killer dowel pin had never been retained. What should I do? ESteiger TST Products offers a complete kit to tab the dowel pin into place. The kit has complete instructions and the job is not too difficult.

Outside surface of rotor.

BHerring

While you have the gear cover off of the engine, be sure to remove the four mounting bolts that you can reach directly. Two are behind “windows” in the cam gear, one is next to the dowel pin, and one is above the gear-driven oil pump. The fifth bolt is below the two behind the cam gear and also behind the gear, but offset outwards so you will have to heat and bend an open-end 10 mm wrench so it can reach in there and tighten that bolt. The other four will get cleaned with solvent, as will the holes (I recommend Mopar non chlorinated brake cleaner as it evaporates much better than other brands). Then, blue Loctite the bolts and torque to 18-22 ft-lb. Factory recommendation is 18, but I like a bit more. On the First Generation Turbo diesels, and second Generations up to 1996, there is no sealer on the threads and the bolts can vibrate out. If the washer head gets between gear teeth, you can break the block, etc. So, this problem can be much worse than the dowel pin that is too big to get between teeth and just breaks the gear case. Joe Donnelly

Inside surface of rotor.

Yes, it’s normal. On the inside of the rotor, there is no extension of the braking surface or obstruction beyond the inner area of the rotor that would interfere with the location of the caliper. On the outer side of the rotor the braking surface has been machined beyond the area used by the pads so as not to interfere with the mounting of the caliper. Give it a little more time and you will have full outside contact. B.G. Smith, Port Neches, TX

22

www.turbodieselregister.com

TDR 64

So, this problem can be much worse than the dowel pin that is too big to get between teeth and just breaks the gear case.

5 M YE IL A E R/ W 50 AR ,0 RA 00 NT Y

IS YOUR STEERING AS TOUGH AS YOUR

DODGE? Dodge trucks can take almost anything, but the OEM steering shaft can’t.

• A worn steering shaft assembly will cause loose, wandering

steering. Borgeson U-Joint and shaft assemblies give a tight precision feel to the steering.

• Original steering shaft assemblies are not designed for towing,

plowing, or off-road use. Borgeson joints are so strong, they will probably outlast your truck!

• Borgeson shaft assemblies can be easily installed with basic hand tools usually in less than an hour!

• Our telescoping shaft adds extra safety and compensates for

‘79–93 FULL SIZE

body lifts.

• For ‘79–93 trucks ExtremeDuty unit must have a removable column Rag Joint.

DODGE PICK-UP & RAMCHARGER STEERING ASSEMBLIES

MSRP

000940

$215.92

‘79–93

Full Size w/Rag Joint

000941

Replacement Rubber Rag Joint and Hardware

$16.83

000943

‘79–93

$254.43

ExtremeDuty Two-Joint System*

000945

‘94

Full Size

$287.40

000950

‘95–02

Full Size

$287.40

000952

‘03–08

1500 2WD/4WD, 2500 2WD, 3500 2WD

$338.54

000951

‘03–08

2500 4WD, 3500 4WD

$287.40

‘94–02 FULL SIZE

* Verify that the column has removable ragjoint

Custom Assemblies are Available! Borgeson zero play Needle bearing u-joints and shaft assemblies are so tough, they carry a 5 year warranty!

SI

N C E 1914

REPLACEMENT RAG JOINT

124

Call 860.482.8283 to order or for a free catalog. On-line shopping anytime at: www.borgeson.com

Coverage of the ’94 to ’98 Model Trucks (12-valve engines). Web Site Correspondence Edited by Bill Stockard and additional Q&A by Joe Donnelly RECURRING DIAGNOSTIC CODE P1389 I have a recurring diagnostic code P1389. I checked the relays and no problems were found. The tachometer and voltmeter are working. Could it be caused by a defective electrical connector? Has anyone else had this problem, and if so, how was it repaired? WBaum It is an erroneous code in most cases. Bob4x4, Riverside, CA If the tachometer and voltmeter are working, the powertrain control module (PCM) is receiving a signal from the automatic shutdown relay (ASD). There is probably an electronic “bug” in the PCM. Checking the connections at the PCM might help, but I wouldn’t worry about it. Missouri Mule, Winter Park, FL

To adjust the PVC size, cut it nearly in half. Cut two notches in the end 2 or 3-inches deep and 180 degrees apart. Using a hose clamp on the split end, the inside diameter can be adjusted. Depending how much adjustment is needed, increase the “splits” from 2 to 4, 6, 8-inches, etc. kenny61, NY The installation depth for the front crank seal is not critical. Install it so it runs on a good place. Joe G., Eureka, CA The Dremel tool took about five minutes to cut the wear ring. I fashioned an installation tool out of 2-inch PVC and a connector.

I checked the connections at the grid heater relays under driver side battery and cleaned the corrosion on all four bullet connectors and looked for others. The engine starts and runs fine. I think it could be a “bug.” WBaum FRONT CRANKSHAFT SEAL AND WEAR RING The front crankshaft seal on my ‘97 Turbo Diesel 3500 is leaking and needs replacement. I removed the front cover and installed the new seal and discovered the crankshaft has a previously installed wear ring. How do I remove and install a new wear ring? The service technician at the Cummins shop said he heats the old one cherry red with a torch and pries it off with a pair of screwdrivers. I don’t have an acetylene torch, and even if I did, I am afraid I might damage the temper of the crankshaft. I think I could use a Dremel cutting wheel, but I still have the problem of installing the new one. The same tech said to install the wear ring dry without lubricating the crankshaft. He said to start it by tapping it on with a 2”x4” block and finish by using the old wear ring to drive it on. If I cut the old one off, obviously I can’t use it for the installation. Any advice will be appreciated. GAmes, Killeen, TX Try a piece of PVC pipe. I often use it for driving bearings, seals, etc. I’m not sure about cutting the old wear ring with the Dremel. Be careful and don’t nick the shaft.

24

www.turbodieselregister.com

TDR 64

Lessons learned: Don’t use the Dremel on the very top of the ring since there is no depth perception looking straight down. Cut it off about 45 degrees from the top. Place a little engine oil or grease on the inside of the ring and the outside of the shaft before driving on the new wear ring. I had the ring about half way on before I discovered this and the last half was difficult. Remove the radiator which allows more room to swing the hammer and eliminates the chance of damaging the radiator. GAmes, Killeen, TX The correct and easiest way to remove the wear ring is to strike it with a ball-peen hammer just hard enough to deform it and it will come right off with no damage. A trick I learned while working on big rigs. Bob4x4, Riverside, CA

12-VALVE ENGINES . . . . Continued AUTOMATIC TRANSMISSION SHIFTS ERRATICALLY

LITTLE POWER GAIN WITH TST KIT?