General CAUTION

Whenusinganarcwelder,alwaysdisconnect thegroundleadfromthelifttruckbatteryto preventalternatororbatterydamage.Attach theweldinggroundclampasclosetotheweld areaaspossibletopreventweldingcurrent fromdamagingthebearings.

Thediodesandresistorsintheelectricalsystemcanbedamagedifthefollowingcautions arenotfollowed:

•Donotdisconnectthebatterywhentheengineisrunning.Thevoltagesurgecandamagethediodesandresistorsintheelectrical system.

•Donotdisconnectanelectricwirebeforethe engineisstoppedandtheswitchesare"OFF".

•Donotcauseashort-circuitbyconnecting theelectricwirestothewrongterminals. Makesureacorrectidentificationismadeof thewirebeforeitisconnected.

•Makesureabatteryisthecorrectvoltageand polaritybeforeitisconnected.

•Donotcheckforcurrentflowbymakinga sparkbecausetheelectroniccomponentscan bedamaged.

NOTE: Informationonalternatorsmanufactured outsidetheUnitedStatesisintheSRM(Service RepairManual)sectionsforlifttrucksthatusethose alternators.

Thissectionhasadescriptionandtherepairproceduresforthealternatorwithavoltageregulatoras partofthealternator.

Description

NOTE: ForthisSRMsection,thealternatorsarein twogroups,TypeAandTypeB.Thetwotypesare verysimilar,buttheTypeAalternatorshaveasetof threediodes(diodeset)aswellasthediodebridge. TheTypeBalternatorhaszenerdiodesaspartof thediodesinthediodebridge.Thisalternatordoes nothaveadiodeset,butdoeshaveanadditionalfan insidetherearhousing.Thebasicoperationofboth typesisverysimilar.

Thealternatorgeneratesanalternatingcurrent whentheengineisrunning.Thealternatoriseither ON or OFF.Thealternatorgeneratesmaximum currentwhenitis ON andnocurrentwhenitis OFF.Theregulatorswitchesthealternatorbetween ON and OFF togettheaveragecurrentneededto chargethebattery.Alternatoroutputisdirectly changedbyenginespeedandrotorfieldcurrent.The alternatingcurrentischangedtoadirectcurrentby thediodebridgeinsidethealternator.

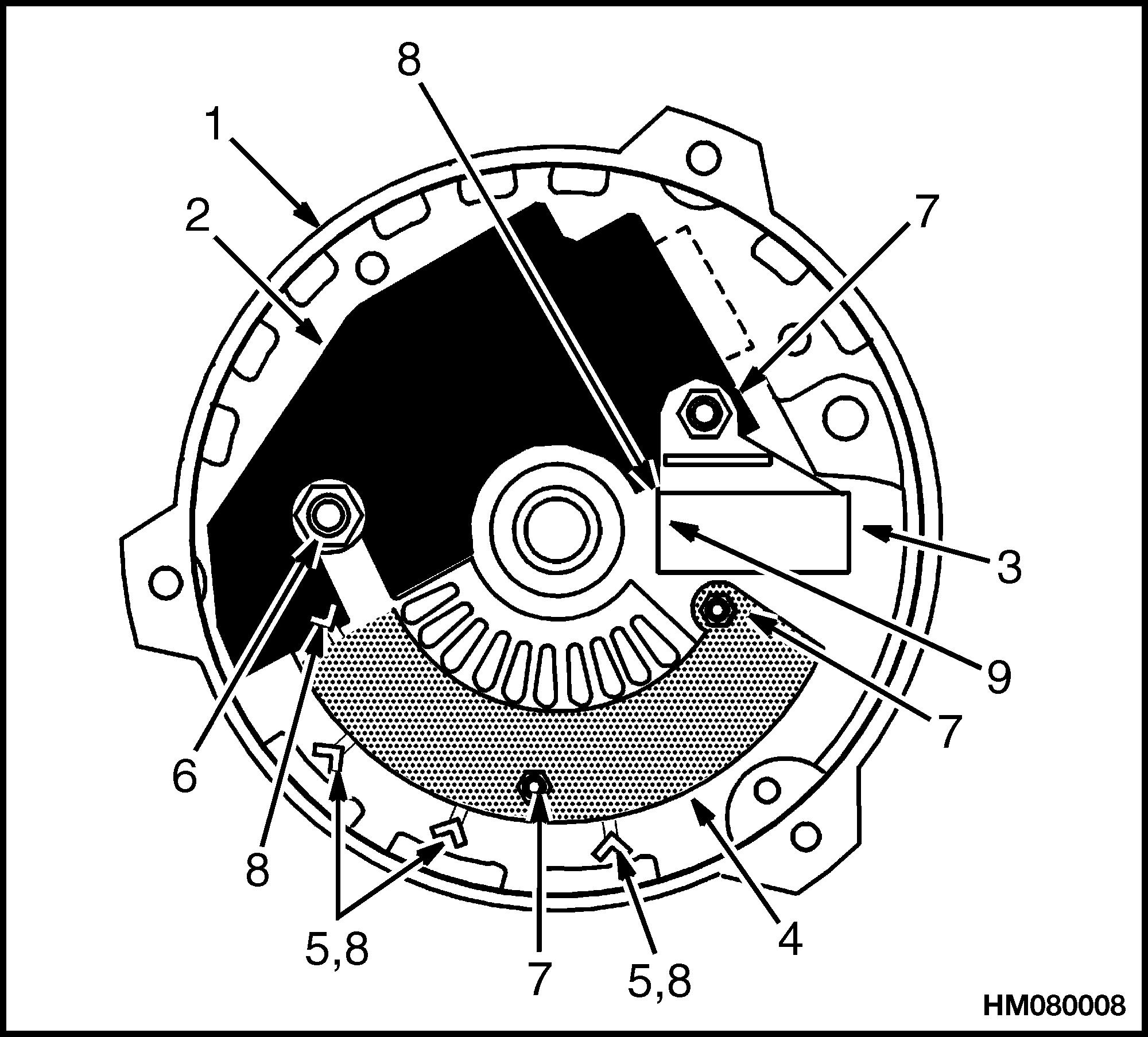

Thealternatorhastheseparts(seeFigure1andFigure2):

Astator

Arotor

Adiodebridge

Adiodeset(TypeAonly)

Twoendhousingsorframehalves

Asolid-statevoltageregulator

NOTE: DELCOTYPEASHOWN.

1.BRUSHASSEMBLY

2.ROLLERBEARING

3.GREASE RESERVOIR

4.LIPSEAL

5.DIODEBRIDGE

6.BALLBEARINGS

7.FELTSEAL

8.REGULATOR

LegendforFigure2

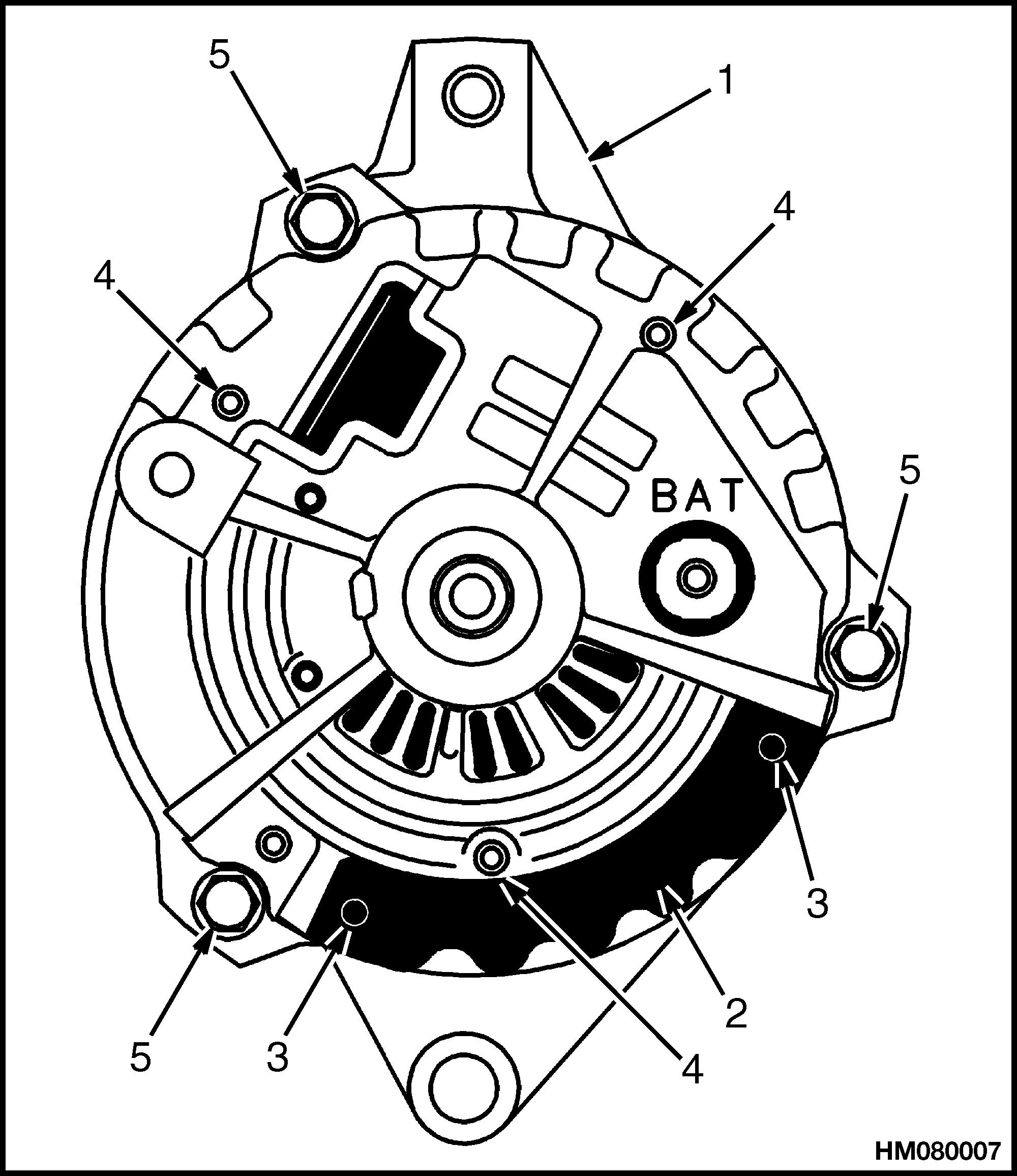

NOTE: LEECE-NEVILLENOTAVAILABLE,SIMILARTOTHOSESHOWN.

A. DELCOTYPEA(SMALLCAPACITYLIFT TRUCKS) B. DELCOTYPEB

C. MOTOROLATYPEA

D. DELCOTYPEA(LARGECAPACITYLIFT TRUCKS)

Thedirectcurrentfromthediodesofthediodebridge flowstotheoutputor"BAT"terminal.Acapacitorbetweenthe"BAT"terminalandtheelectricalground removesanyremainingalternatingcurrentfromthe directcurrent.Thecapacitoralsoprotectsthediodes fromhighvoltages.Thevoltageiscontrolledbythe amountofcurrentflowingthroughthefieldwinding inthealternatorandtherpmoftherotor.Thevoltageregulator,insidethehousing,containsatransistor,diodes,resistors,andcapacitor.Thevoltageregulatorcannotberepaired.

NOTE: Onsomelargecapacitylifttrucks,thealternatorhasanexternalvoltageadjustment.

ALTERNATORTYPEA

RemoveandDisassemble

WARNING

Thevoltageregulatorcontrolsthealternatorto chargethebattery.Thevoltageissetbythemanufacturerandisnotusuallyadjustable.Battery voltagedecreasesasthestartingcircuitandother circuitstakeenergyfromthebattery.Whenthe keyswitchisputinthe" IGN "position,thevoltage regulatorisenergized.Apositivecurrentflowsto thefieldterminal("F"or"1")onTypeAalternators "(L")ontypeB.Thebatterysendsapositivecurrent totheregulatorterminal(TypeA"R"or"2")andthe "BAT"terminal.Theregulatorsensesadecreasein batteryvoltageandincreasesthealternatoroutput tochargethebattery.

AlternatorRepair

Alwaysdisconnectthebatterygroundcablebeforemakingrepairstopreventpossibledamageandinjury.Installatagonthebatteryterminalsothatnooneconnectsthecableonthe terminal.

NOTE: UseTroubleshootingandGeneralCheckand Adjustment,LowOutputCheck(TypeAorTypeB), HighOutputCheck(TypeAorTypeB),BrushesCircuitCheck,DiodesCheck,DiodeBridgeCheck,Rotor FieldWindingCheck,StatorWindingsCheck,and VoltageRegulatorCheckproceduresofthisSRMbeforestartinganyrepairprocedures.Makesurethat repairorreplacementofthatpartisnecessarybefore removal,disassembly,orreplacementofthepart.

NOTE: Therearesomechecksofthealternatorthat aredonewiththealternatorontheengine.See GeneralCheckandAdjustment,LowOutputCheck (TypeAorTypeB),HighOutputCheck(TypeA orTypeB),BrushesCircuitCheck,DiodesCheck, DiodeBridgeCheck,RotorFieldWindingCheck, StatorWindingsCheck,andVoltageRegulator CheckproceduresofthisSRMbeforestartingany removalorrepairprocedures.

NOTE: ManypartsoftheLeece-Nevillealternator canbereplacedwithoutdisassemblingthealternator.SeeFigure5.Thealternatormustbedisassembledtoreplaceonlythediodebridge,filtercapacitor, rotor,stator,orbearings.

1. Disconnectthebatterygroundcable.SeeFigure3,Figure4,andFigure5.Installlabelsand disconnectthewiresatthealternator.Loosen thealternatormountcapscrewsandremovethe drivebelt.Removethecapscrewsthatholdthe alternatortotheengine.

2. OnLeece-Nevillealternators,removethe brushes,voltageregulator,ordiodeset.Install labelsonallwiresforcorrectconnectionduring installation.

3. Putamarkoneachhousingandonthestatorfor correctalignmentduringassembly.Removethe boltsthatholdthehousingstogether.Separate thehousingsandstator.

4. Puttherotorinavisethathassoftjaws.Donot tightenthevisetocauserotordistortion.Usea socketwrenchtoremovethepulleynut.Remove

thepulley,fan,collar,spacer,shield,orother partsbetweenthefanandhousing.Removethe fronthousingfromtherotor.

5. Removeanynutsorscrewsthatfastenpartsinsidetotherearhousing.Then,removethestatorassemblyfromtherearhousingsothatthe otherpartscanberemoved.Removethescrews forthecapacitor,diodebridge,diodeset,brushes, andotherpartsasnecessary.Ifthestatorwill beremovedfromthediodebridge,makesurethe wireshavetagsforcorrectconnectionduringassembly.

6. Markthestatortoshowthepositionofthe brushesandconnectorordiodebridgeassembly. Usepliersasaheatsinktokeepheatfromthe diodes.Useasolderingirontoremovethestator leadsfromthediodeassembly.

7. Removethebearingsfromthehousingsonlyif theywillbereplaced.

Clean

CAUTION

Neverusesolventonthepartsofthealternator.

NOTE: Ifnecessary,usefineabrasiveclothtopolish thesliprings.Theabrasiveclothmustbenumber

500to600.Removealldust.Turntherotorwhile polishingthesliprings.

Usecompressedairtoremovedirtfromthealternator.Cleanthebrushesandslipringswithaclean, drycloth.

Assemble

1. ForDelco(TypeA)alternators,installanew bearing(s)inthehousingasfollows(seeFigure3,Figure4,andFigure5):

a. Installanewplugandsealintherearhousing.Pushthebearingfromtheoutsideofthe housinguntilthetopofthebearingiseven withtheoutsideofthehousing.Holdthe

housingwiththecollarontheinsideofthe housing.Keepthelipofthesealawayfrom thebearing.Lubricatethebearingareawith Delco-Remygrease,partnumber1948791.

b. Installanewbearinginthefronthousing. Fillonequarterofthegreasereservoirwith Delco-Remygrease,partnumber1948791, orequivalent.Movethegreasesothatit touchesthebearingwhentheretainerplate isinstalled.

c. Addthesametypeofgreasetofillthearea betweentheretainerplateandthebearing. Installthespacer,gasket,andretainerplate onthebearing.Fastentheretainerplate inpositionwiththethreescrewsandlock washers.

2. ForMotorolaandLeece-Nevillealternators,use apresstoinstalltherearbearingontherotor. Installthebearingandbearingretainerinthe fronthousing.Ifused,installthespaceronthe bearing.

CAUTION

Holdtherotorinavisethathassoftjaws.Do nottightenthevisemorethannecessary.

3. Installthefronthousingontherotor.Ifused,installthespacerorshield,shaftkey,andwasher. Installthefan,pulley,lockwasher,andnut. Tightenthenutto54to81N•m(40to60lbfft).

CAUTION

Besuretoinstalltheinsulators.Makesurethe heatsinkdoesnottouchthehousing.

4. Installthediodebridgeandheatsinkinthereverseorderofdisassembly.Makesuretheinsulatorsandwashersareinthecorrectpositions. Installthecapacitor.

5. OnDelcoalternators,installpartsasfollows:

a. Installthebrushandholder,voltageregulator,anddiodesfromtheinsideofthealternator.Makesuretheinsulatorsleevesareon thescrewsforthebrushholder.Installthe capacitor.

b. Installthestatorintherearhousing.Connectthethreewiresfromthestatortothe diodebridgeandfastenatthestuds.Connectthewiresfromthediodestothestuds

onthediodebridge.Installandtightenthe threelockwashersandnuts.

c. Installthebrushesinthebrushholders. Toholdthebrushesinposition,putapin throughtheholeinthebrushholders.Apply athinlayerofoiltothelipofthesealforthe bearing.

6. OnMotorolaalternators,installpartsasfollows:

a. Installthediodebridgeonthestator.Use plierstokeeptheheatfromthesolderingiron awayfromthediodes.

b. Installthecapacitor,diodeset,andterminalonthediodebridge.Alignthemarks madeduringremovalandinstallthestator andbridgeassemblyintherearhousing.

7. Alignthemarksmadeduringdisassembly.Carefullyinstallthestatorandtherearhousingover therotor.Donotdamagethesealwhilesliding thehousingovertherotorshaft.Installthefront housing.

8. Installthefourscrewstoholdthealternatortogether.OnDelcoalternators,removepintoreleasethebrushes.

9. OnMotorolaalternators,installthebrushholder andbrushes.Makesurethewasherisonthe right-handscrew.Installthevoltageregulator andtightenthescrews.

10. OnLeece-Nevillealternators,installthe brushes,voltageregulator,ordiodesetin thereverseorderofremoval.

Install

1. Installthealternatorinthebracketontheengineandadjustthetensionofthebelt.

2. Connectallwiresandtheconnectoraccordingto thelabelsmadeduringremoval.Alsoseethe schematicdiagramforyouralternatorinFigure2.Makesureallwiresareconnectedcorrectlyandallfastenersaretight.SeeFigure3.

3. Checktheindicatorlightortheammetertocheck theoperationofthealternator.Theindicator lightforTypeAalternatorswillonlybeONifthe batteryisdischarged.

LegendforFigure4

ALTERNATORTYPEB

RemoveandDisassemble

WARNING

Alwaysdisconnectthebatterygroundcablebeforemakingrepairstopreventpossibledamageandinjury.Installatagonthebatteryterminalsothatnooneconnectsthecableonthe terminal.

NOTE: UsetheTroubleshootingandGeneralCheck andAdjustment,LowOutputCheck(TypeAorType B),HighOutputCheck(TypeAorTypeB),Brushes CircuitCheck,DiodesCheck,DiodeBridgeCheck, RotorFieldWindingCheck,StatorWindingsCheck, andVoltageRegulatorCheckproceduresofthisSRM beforestartinganyrepairprocedures.Makesure thatrepairorreplacementofthatpartisnecessary beforeremoval,disassembly,orreplacementofthe part.

NOTE: Therearesomechecksofthealternatorthat aredonewiththealternatorontheengine.See GeneralCheckandAdjustment,LowOutputCheck (TypeAorTypeB),HighOutputCheck(TypeA orTypeB),BrushesCircuitCheck,DiodesCheck, DiodeBridgeCheck,RotorFieldWindingCheck, StatorWindingsCheck,andVoltageRegulator CheckproceduresofthisSRMbeforestartingany removalorrepairprocedures.

1. Disconnectthebatterygroundcable.SeeFigure6,Figure7,andFigure8.Installlabelsand disconnectthewiresatthealternator.Disconnectthewireconnector.Loosenthealternator mountcapscrewsandremovethedrivebelt.Removethecapscrewsthatholdthealternatorto theengine.

2. Putamarkoneachhousingandonthestatorfor correctalignmentduringassembly.Removethe boltsthatholdthehousingstogether.Separate thehousingsandstator.

3. Puttherotorinavisethathassoftjaws.Donot tightenthevisetocauserotordistortion.Usea socketwrenchtoremovethepulleynut.Remove thepulley,collar,fan,outsidecollar,fronthousing,andinsidecollarfromtherotor.

NOTE: Thecovermustbereplacedifthepartswill beremovedfromthestator.Ifnecessary,removethe statorasdescribedinStep4andStep5.

4. Useapunchtoremovetherivetsorpinsthat fastenthecover.Removethecoverforaccessto thestatorleads.Discardthecover.SeeFigure7.

5. Cutthestatorleadsasclosetotheconnectorsas possible.Installlabelsontheleadsforcorrect connectionduringassemblyandremovethestatorfromtherearhousing.

6. Useapunchtoremovethethreebafflepinsand removethebaffle.SeeFigure7.

NOTE: CarefullymakeanoteofthesequenceofremovalofpartsinStep7andStep8forcorrectinstallation.Alsomakeanoteofalltypesofconnections (crimp,soldered,orwelded)aswellasallmechanical fasteners.

7. Removethethreemountscrewsand"BAT"terminalnut.SeeFigure8.Liftthebrushholder, voltageregulator,anddiodebridgefromthe housing.

8. Openthecrimpsoruseasolderingironand disconnecttheconnectorstoseparatethebrush holder,voltageregulator,anddiodebridge.

9. Ifthebearingwillbereplacedintherearhousing,removethebearingandretainerring.

CAUTION

Neverusesolventonthepartsofthealternator.

NOTE: Ifnecessary,usefineabrasiveclothtopolish thesliprings.Theabrasiveclothmustbenumber 500to600.Removealldust.Turntherotorwhile polishingthesliprings.

Usecompressedairtoremovedirtfromthealternator.Cleanthebrushesandslipringswithaclean, drycloth.

Thank you very much foryourreading.Please Click Here Then Get MoreInformation.

NOTE: If there is no response to click on the link above, please download the PDF document first and then clickonit.

Assemble

1. Ifthebearingwasremovedfromtherearhousing,installanewretainerring.SeeFigure6.

CAUTION

Thebearingisnotcompletelyinstalleduntil Step11iscomplete.

2. Installanewbearingbypushingonthenew bearingouterraceuntilthebearinghitsthe bottomintherearhousing.

3. Assemblethevoltageregulator,diodebridge,and brushholderonaflatsurface.Putcrimpsinthe connectorsorsoldertheconnectorstofastenand connectthepartsasoriginallyassembled.Usea pintoholdthebrushesinthebrushholder.

4. Putathincoatingofsilicongrease(Delcopart number1974984)ontheinsideoftherearhousingunderthediodebridge.

5. Installthebridge,regulator,andbrushholder assemblyintherearhousingandinstallthe screwsasremovedduringdisassembly.

6. Installthebaffleanduseapunchtofastenthe pins.

7. Alignthemarksmadeduringdisassemblyand installthestatorintherearhousing.Usepliers ontheconnectorsofthediodebridgetokeepheat fromthediodes.Useasolderingirontoconnect thestatorleadstotheconnectors.

NOTE: TYPEBONLY.

1.REARHOUSING

2.COVER

3.COVERRIVETS ORPINS

4.BAFFLEPINS

5.BOLTSTOFASTEN HOUSINGS TOGETHER

8. Installanewcoverusingrivetsorpinstofasten

9. Ifnecessary,installthebearinginthefronthousing.Puttherotorinavisewithsoftjawsandinstalltheinnercollar,fronthousing,outercollar, fan,collarpulley,andnutontherotor.Tighten thenutto54to108N •m(40to80lbfft).

10. Alignthefrontandrearhousingsusingthe marksmadeduringdisassembly.Pushonboth theinnerandouterracesoftherearbearing topushthetwohousingsandstatortogether. Installthethreeboltsthatfastenthealternator together.

11. Pushonboththeinnerandouterraceoftherear bearingsothattheouterraceis1.9to2.2mm

(0.075to0.087in.)belowthesurfaceoftherear housing.

NOTE: TYPEBONLY.

1.REARHOUSING

2.VOLTAGE REGULATOR

3.BRUSHHOLDER

4.DIODEBRIDGE

5.TERMINALSFOR STATORLEADS

Install

6.NUTON"BAT" TERMINAL

7.MOUNTSCREWS

8.SOLDERED ORWELDED CONNECTOR

9.BRUSHPIN

1. Installthealternatorinthebracketontheengineandadjustthetensionofthebelt.

2. Connectallwiresandtheconnectoraccordingto thelabelsmadeduringremoval.Alsoseethe schematicdiagramforyouralternatorinFigure2.Makesureallwiresareconnectedcorrectlyandallfastenersaretight.SeeFigure7.

3. Checktheindicatorlightortheammetertocheck theoperationofthealternator.Theindicator lightcana lso beONifthealternatoroutputis toohi gh onTypeBalternators.

GeneralCheckandAdjustment

Therearenoadjustmentsforthealternatoror mostregulators.OneDelcoalternatorandthe Leece-Nevillealternatorhasavoltageadjustment. Alwayscheckthegeneralconditionofthecomplete systembeforedoingacompletecheckoneachpart. Checkthegeneralconditionofthefollowingparts: (1)battery,(2)batterycablesandconnections,and(3) alternatorandregulatorwiresandconnectors.Also checktheconditionandtensionofthefanbeltforthe alternator.

CAUTION

NEVERoperatetheengineifthealternator output"BAT"terminalisnotconnectedtothe battery.

Donotshort-circuitorconnectjumperwiresto anyofthealternatorterminalsunlesstoldtoby theprocedures.

Makesurepolarityiscorrectbeforeconnectingabatterychargeroranotherbattery.

Removethebatterycablesandcleantheterminals andcableconnectors.Inspecttheinsulationonthe wires.Makesureallthefastenersandconnections arecleanandtight.Ifnecessary,useawaterand sodasolutiontocleanthetopofthebattery.DoNOT removethecellcapsorpermitthewaterandsoda solutiontogetinthebattery.

WARNING

PutthetransmissioninNEUTRAL.Applythe parkingbrake.

CAUTION

Donotchangethepolarityofthecircuits.Do notconnectanywiresinthecircuits,exceptas describedintheseinstructions.Neverconnect thewirefromtheterminalmarked"BAT"toan opencircuit.

Whenconnectingachargeroranotherbattery,connectthepositiveterminalstothepositiveterminal ofthebattery.Thenconnectthenegativeterminal toacleanmetalpartoftheengine.Disconnectthe chargerorotherbatteryinthereverseorder.Problemsinthechargingcircuitareindicatedbyoneor moreofthefollowing:

• Thestartermotorturnsslowly.Thebatteryvoltage islowbecauseoflowalternatoroutputorabad battery.

• Thespecificgravityreadingsarelow.Batteryis notfullychargedorisdamaged.

• Thebatteryusesmorethan30ml(1oz)ofwater percellpermonth.Thealternatoroutputistoo high.

Thetwoproblemsofthechargingcircuitarelow outputandhighoutput.Lowoutputcausesalow batteryanddifficultstarting.Ahighoutputcauses heatingofthebatteryandevaporationofwaterfrom theelectrolyte.Thefollowingtwocheckswillfind outifthealternator,regulator,orwiringhasthe chargingfault.Thetwocheckswillalsofindoutif thechargingsystemhasacorrectoutput.Dothe followingtwochecksbeforeremoval,disassembly,or replacementofalternatororregulator.

NOTE: Informationonalternatorsmanufactured outsidetheUnitedStatesisintheSRM(service repairmanual)sectionsforlifttrucksthatusethose alternators.

LowOutputCheck(TypeAorTypeB)

CAUTION

Donotconnectthewirefromthe"BAT"terminaltotheelectricalground.

NOTE: Makesurethewirefromthevoltmetermakes contactwitheachterminalonthealternator.

1. Connectavoltmeterbetweenthe"BAT"terminal andtheelectricalground.Turnthekeyswitchto the"ON"positionandcheckthereading.

2. Connectavoltmetertothefieldterminaland theregulatorterminal.Followtheprocedurein Step1andcheckthereadings.

3. Iftherearenoreadingsonthevoltmeterduring Step1andStep2,checkforanopencircuitbetweeneachterminalandthebattery.

4. Iftherearereadingsonthevoltmeterduring Step1andStep2,disconnectthecableforthe electricalgroundonthebattery.

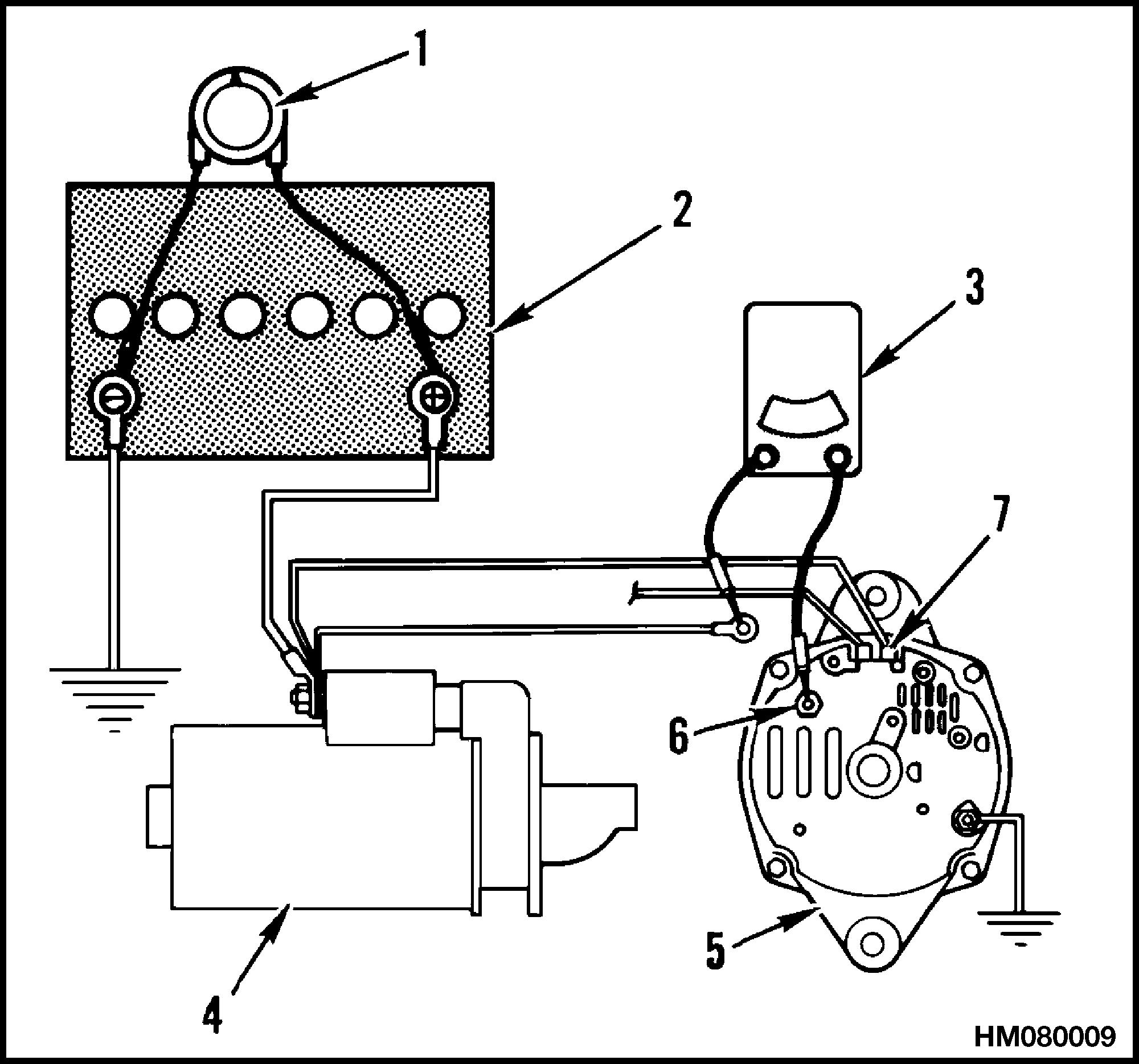

5. MakeconnectionstotheTypeAalternatoras showninFigure9.MakeconnectionstotheType BalternatorasshowninFigure10.

6. Connectthecablefortheelectricalgroundonthe battery.

7. Connectacarbonpileacrosstheterminalsofthe battery.

8. Runtheengineat2000to2500rpm.Adjustthe carbonpileuntilthemaximumchargingrateis reached.

9. Readthevalueofthemaximumchargingrate shownonthealternatorhousingorinthesection CapacitiesandSpecifications foryour lifttruck.Readtheammeter.Thereadingon theammetermustbewithin10%ofthemaximumvalue.

a. Thevoltagesettingcanbeincreasedby changingthepositionoftheadjustment plug."LO"isthelowestvoltagesetting."2" ismediumlowand"3"isthemediumsetting. Thevoltagesettingishighestwhen"HI"is alignedwiththearrowonthealternator. Changethesettingasnecessary.

NOTE: TYPEAONLY.

1.CARBONPILE

2.BATTERY

3.AMMETER

4.STARTER

5.ALTERNATOR 6."BAT"TERMINAL 7.FIELDTERMINAL

Figure9.AlternatorOutputCheck

10. Iftheammeterreadingiswithin10%,thealternatorisingoodcondition.Checkthestarteror wiresforproblems.Somealternatorsonlarger lifttruckshaveavoltageadjustment.SeeFigure12.Foralternatorswiththevoltageadjustment,doStepatosetthevoltage:

NOTE: TYPEBONLY.

1.BATTERY

2.CARBONPILE

3.VOLTMETER

4.RESISTOR(35 OHM5WATTTO 500OHM1/2WATT)

5.AMMETER

6.ALTERNATOR

7."BAT"TERMINAL

8.CONNECTTO"L" TERMINAL

Figure10.AlternatorOutputCheck

11. OnTypeADelcoalternators,dothefollowing checks:

CAUTION

Donotpushthescrewdriverintotheholefor morethan25mm(1in.) .

a. Iftheoutputshownis notwithin10%,puta screwdriverintothe holeshowninFigure11.

b. Runtheengineat2000to2500rpm.Adjust thecarbonpileuntilthemaximumcharging rateisreached.

c. Iftheoutputiswithin10%,checkthefield winding.Ifthefieldwindingisingoodcondition,replacethevoltageregulator.

d. Iftheoutputisnotwithin10%,checkthe wirestothebrushes,diodes,diodebridge, fieldwinding,andstator.

e. Removethescrewdriver,ammeter,andvariableresistor.

NOTE: DELCOTYPEASHOWN.

1.HOLE 2.MAKESURESCREWDRIVERTOUCHES HOUSINGANDMETALTAG.

Figure11.ElectricalGroundonFieldWinding

HighOutputCheck(TypeAorTypeB)

1. Connectavoltmeterfromtheregulatorterminal totheelectricalground.Checkthereadingon thevoltmeter.SeeFigure9orFigure10.

2. Iftherearenoreadings,checkforanopencircuit betweentheregulatorterminalandthebattery.

3. Ifthereisareading,connectavoltmeterbetween the"BAT"terminalandtheelectricalground.

4. Increasetheenginespeeduntilthemaximum voltagereadingisreached.

5. Ifthevoltageshownismorethan15.5voltson a12-voltsystemor31voltsona24-voltsystem, disassemblethealternatoranddotheremainder ofthechecks.Foralternatorswiththevoltage adjustment,dothefollowing:

a. Delcoalternator.Thevoltagesettingcanbe increasedordecreasedbychangingthepositionoftheadjustmentplug.SeeFigure12. "LO"isthelowestvoltagesetting."2"is mediumlowand"3"isthemediumsetting. Thevoltagesettingishighestwhen"HI"is alignedwiththearrowonthealternator.Do notchangethesettingwhenengineisoperating.Changethesettingasnecessary.

b. Leece-Nevillealternator.Removethescrew inthecover.SeeFigure12.Starttheengine. Connectavoltmeteracrossthebatteryterminalsanduseascrewdrivertoadjustthe voltage.