MATERIALS SCIENCE &

MATERIALS SCIENCE &

Dear alumni, colleagues and friends,

As always, fall is an exciting time of year for our department, and I am pleased to share a glimpse into the innovation, commitment and talent driving our academic community forward in this edition of The Rhines Report, our annual magazine.

This past year, we welcomed two new faculty members, Jennifer Hite, Ph.D., and Guilhem De Hoe, Ph.D. Hite’s journey spans industries and sectors, from semiconductor manufacturing to national research laboratories. Her experience underscores the value of lifelong learning — an ideal she embodies and is now ready to impart to her students.

De Hoe’s early fascination with crystals evolved into a dedication to polymer science, and his research is paving the way for advances in recycling and sustainable polymer production. His work promises to position UF at the forefront of polymer research that addresses some of today’s most urgent environmental issues.

With their expertise and vision, Hite and De Hoe join a department that continues to push the boundaries of what’s possible in materials science and engineering and nuclear engineering. From next-generation nuclear fuel design to manufacturing in space, here are just a few examples of how we are shaping the future:

Assel Aitkaliyeva, Ph.D., and I are leading a team that received a $1 million Nuclear Energy University Program award from the Department of Energy to investigate U-Zr annular fuel behavior. Our research aims to enhance the safety and efficiency of next-generation nuclear reactors, contributing to the broader goal of establishing nuclear energy as a sustainable solution.

Honggyu Kim, Ph.D., has been exploring the potential of ferroelectric ceramic materials in overcoming the memory wall — a critical challenge in data processing. His work promises to reshape the landscape of electronic devices.

Tori Miller, Ph.D., is leading a groundbreaking project funded by DARPA to develop advanced laser sheet metal forming technology. This innovative approach seeks to enable the fabrication of large metal structures in space, paving the way for more ambitious space exploration projects.

Ira Harkness, Ph.D., initiated a new program to help bridge the educational gap in nuclear engineering, targeting underserved institutions and K-12 educators. This project aims to inspire the next generation of nuclear scientists

and engineers, ensuring a diverse and skilled workforce for the future.

We also celebrate the achievements of our students, including Brooke Lastinger, who participated in a study abroad program in Iceland over the summer, exploring renewable energy solutions. Her experience exemplifies the impact of the Botic Family Scholars Professional Pathways Fund, which supports hands-on, experiential learning opportunities. And, closer to home, a group of our nuclear engineering students visited the Savannah River National Laboratory, which allowed them to engage with leading experts and learn more about career opportunities in the nuclear field.

We are proud to share that Michele Manuel, Ph.D., Distinguished Professor and former department chair, has recently been appointed U.S. Steel Dean at the Swanson School of Engineering, University of Pittsburgh. Manuel joined UF’s faculty in 2008 and assumed the role of chair in 2017. During her tenure, she drove strategic planning initiatives, increased department endowments, and established new professorships, scholarships and professional development programs. Manuel earned her bachelor’s degree from UF and Ph.D. from Northwestern University. She’s a member of the National Academy of Engineering, an ASM Bradley Stoughton Award winner and a Howard Hughes Medical Institute Distinguished Mentor.

As I step into the role of interim chair, I am excited to carry forward her impactful vision, building on the strong foundation she established and continuing to advance our department’s goals and mission.

Thank you for your continued support and engagement with our community. Please stay connected with us through social media and see firsthand the achievements that fuel our shared vision of progress.

Michael Tonks, Ph.D.

INTERIM CHAIR

DEPARTMENT OF MATERIALS

SCIENCE & ENGINEERING

FALL 2024

FACULTY ...................... 4-17

FEATURE ................... 14-15

RECOGNITIONS............ 18-19

STUDENTS ................. 20-26

ALUMNI .......................... 27

Forrest Masters, Ph.D.

INTERIM DEAN, HERBERT WERTHEIM COLLEGE OF ENGINEERING

Michael Tonks, Ph.D.

INTERIM CHAIR, DEPARTMENT OF MATERIALS SCIENCE & ENGINEERING

Josephine Allen, Ph.D. ASSOCIATE CHAIR, DEPARTMENT OF MATERIALS SCIENCE & ENGINEERING

Andreas Enqvist, Ph.D. DIRECTOR, NUCLEAR ENGINEERING PROGRAM

MIKE TONKS, INTERIM CHAIR 04

12 NEXT-GEN NUCLEAR FUEL

08 MEET OUR NEWEST FACULTY

16 SHAPING THE FUTURE

Royce Copeland, M.A.

MSE|NE MARKETING & COMMUNICATIONS, MAGAZINE EDITOR AND DESIGNER

MSE.UFL @UFMSE @UFMSE

20 CAREER ENGINEERING

24 BEYOND THE CLASSROOM

STORY|PHOTO: DAVID SCHLENKER

RAISED IN A TOWN KNOWN FOR TOP-SECRET RESEARCH, DR. MICHAEL TONKS NOW LEADS EFFORTS IN DEVELOPING NUCLEAR-POWERED ROCKET FUEL, CRUCIAL TO NASA’S FUTURE CREWED MISSION TO MARS.

Michael Tonks, Ph.D., interim chair of the Department of Materials Science & Engineering, grew up in Los Alamos, New Mexico — birthplace of the atomic bomb and a desert hub for top-secret research.

“My upbringing is weird,” Tonks said recently from his office at the University of Florida. “My dad worked his whole career at Los Alamos National Lab. Having a Ph.D. and being a scientist was normal. Most of the parents had Ph.D.’s. At the time, it was the highest per capita of Ph.D.’s in the world in that town.”

He knew his dad was a physicist, but because his work was classified, Tonks never really knew what he did.

These days on family visits to Los Alamos, Tonks and his father — who retired in 2012 — talk about equations, sometimes prompting Tonks’ siblings (one a Ph.D. in biophysics) to throw in theories and formulas to stir the numerical chaos. Complex equations are sometimes a part of family gatherings.

Weird? No. This is a logical origin story for an award-winning

professor whose research is playing a key role in NASA’s quest for a crewed mission to Mars as early as 2030. For years, Tonks and his students have been researching rocket propulsion powered by heat from nuclear fission.

“Liquid hydrogen needs to be superheated and expand as fast as possible,” he explained. With the weight of carrying liquid hydrogen on the rocket, Tonks’ mission is to attain the safest and most efficient rocket propulsion.

“We need to get it as hot as possible, so they want to drive this fuel up to 3000 Kelvin,” he said. “That is the maximum temperature, which is half the temperature of the sun. And it’s above the melting temperature of almost all of the material we have, but not all.”

Tonks is seeking a correct mix to power the propulsion but also enhance safety and keep the integrity of the other materials on the rocket amid the nuclear superheat.

“With a power reactor, you need material that can take a lot of changes,” Tonks said.

Tonks’ degrees are in mechanical engineering. He became interested in nuclear propulsion during his seven years working at the Idaho National Lab, where he wrote a research proposal about using the tools developed for power reactors in space reactors at NASA.

Later, he started teaching and researching at Penn State, where NASA gave him $50,000 to prove the proposal was feasible. It was. By the time he started at UF in 2017, NASA was funding the project at a much larger level, he said.

“NASA’s fuel-development program needs a good concept that will operate well. NASA wants to have it all sorted out within 10 years,” Tonks said.

You cannot duplicate space conditions on Earth, so there is no exact way to test it.

“We can do modeling assimilation (at UF) to start to predict how these materials are going to behave under these harsh conditions,” Tonks said. “That’s the reason this is attractive to NASA. It allows them to make faster development on materials they can’t test yet.”

How do we guarantee there is enough fuel to operate a reactor all the way to Mars and back?

“There was a big focus on fuel loss,” Tonks said.

Safety on the ground and in space. A Mars mission will have astronauts exposed to constant cosmic radiation.

“Part of this is getting people there as fast as possible because the trip will be highly dangerous due to cosmic radiation,” he said. “The less time, the better. The propulsion system is a big part of that, making it so we can decrease the time the astronauts have to be transporting between here and Mars.”

To be sure, Tonks is looking forward to the day when that crewed mission to Mars blasts off with the rocket fuel he helped refine. “But honestly,” he said, “there is a lot in between that I look forward to, as well. The first time they test this in a reactor is going to be really exciting.”

“Dr. Tonks has been an invaluable asset to our college, bringing not only exceptional expertise in the nuclear field but also a profound dedication to advancing research and education,” said Forrest Masters, Ph.D., interim dean at the Herbert Wertheim College of Engineering. “His leadership in the department has significantly elevated our program, fostering innovation and collaboration that resonate throughout the academic community.”

When Tonks is not teaching or dabbling in nuclear-powered rocket propulsion, he often can be found singing. He sang in the choir as a child, his college minor was music, and he has sung in the Gainesville Master Chorale. At a Get to Know Us faculty event at UF, he once sang “You’ll Be Back” from “Hamilton.”

His other hobby?

Step inside his office in Rhines Hall, and you will see an old manual typewriter and a globe. Take a closer look. They are made with LEGOs. Tonks is, and always has been, a LEGOs fanatic.

It’s a family passion, too.

“Our house is totally decorated in LEGOS. Think about a kitchen. You have the counters and the space up top where people usually put flowers. We have LEGO sets there,” said Tonks, husband to Margaret and father to Avery, 21, and Anna, 18. “We have this big treehouse set, a bunch of ‘Star Wars’ stuff — the big walkers and ships.”

In the family library, there is a LEGO set depicting Rivendell from “The Lord of the Rings,” as well as “realistic” LEGO flowers stationed throughout the house.

Tonks has been the associate chair of the Department of Materials Science & Engineering since 2019. He was promoted in July to interim chair.

“His contributions are a testament to his unwavering commitment and have profoundly enriched our institution’s legacy in nuclear science,” Masters said.

BY KAREN DOOLEY

STORY|PHOTO: ROYCE COPELAND

Lifelong learning is the idea that education should extend beyond formal settings and specific stages of life. It stresses the importance of continuous personal development.

Personal experiences also play a crucial role in this ongoing education, offering valuable knowledge and growth opportunities. Unlike structured curricula, real-life experiences are dynamic and provide unique learning chances, especially through our challenges, successes and failures.

It’s those types of instances that led new Department of Materials Science & Engineering faculty member Jennifer Hite, Ph.D., to the University of Florida … and back again.

Growing up in a military family, Hite moved around more than most, living in Germany, Arkansas, Louisiana, and Nebraska before the age of 14, and eventually landing in Florida for high school. She chose UF for her higher education because of its proximity to home and the reputation of the Herbert Wertheim College of Engineering.

“I initially pursued a bachelor’s degree in chemical engineering because I thought it gave me the broadest knowledge base and the best options for career choices,” Hite said. “But about halfway through the program, I realized the main recruiters were petrochemical, chemical and paper mill companies. With that in mind, I decided this was not my path — too loud and too dirty.

“While working with the Particle Engineering Research Center at UF, I

found a project studying the stability of slurries used to polish semiconductor surfaces. I reset my sights on a slightly different, and much cleaner, career path: semiconductors.”

After completing her bachelor’s degree in chemical engineering, Hite joined Lucent Technologies’ semiconductor fabrication division in Orlando as an equipment engineer.

“While working there, the most interesting and important part of the semiconductor manufacturing process was in the area we termed process control — understanding how the material was deposited, how to ‘tweak’ the recipes, and how those small changes impacted the final product,” Hite said. “I understood then that materials science really seemed to be the lynchpin to both understanding the processes and improving the devices.”

That realization sparked a plan to eventually return to UF for a master’s degree in materials science and engineering. As fate would have it, corporate restructuring led to a pink slip, and Hite was back in Gainesville sooner rather than later.

“In less than three weeks, I was back on campus and enrolled,” she said.

While studying under Cammy Abernathy, Ph.D., the William H. Wadsworth Director of the Engineering Leadership Institute and former dean of the college, she made another career shift, this time moving away from silicon and into compound semiconductors.

“I only intended to get my master’s degree, and then head back into industry. But I wound up loving the research aspect, received a graduate fellowship and stayed for my Ph.D.,” Hite said.

After passing her dissertation defense and earning her doctorate, Hite had a choice between returning to industry or conducting research at a national laboratory. Still feeling the sting from her layoff, she accepted an offer from the U.S. Naval Research Laboratory (NRL) in Washington, D.C.

“It was essentially a call back to my roots as a military kid,” she said. “I’d be back on a base, and my efforts would help protect the country.”

While carrying out 16 years of impactful research and collaborating with other scientists at NRL was fulfilling, the increasing amounts of red tape, restrictions, and rising overhead costs had her thinking about changing things up again. Despite a lack of formal teaching experience, when a faculty position in electronic materials opened at UF, she decided to pursue it.

“Coming out of graduate school, I never even considered academia, and looking back now, I realize I wasn’t ready for that move yet. First and foremost, I needed to prove to myself that I could have a successful research career,” Hite said. “With that experience now in hand, I felt more confident in my ability to research, write proposals, secure funding, and take on higher education.”

Hite said she always enjoyed mentoring

young engineers and helping NRL’s summer interns navigate the joys and pitfalls of experiments. She also volunteered and helped form the curriculum for K-6 STEM experiences with the Children’s Science Center in Northern Virginia.

“Becoming faculty at a top tier university means I can continue the impactful research I love, but with fewer restrictions on collaborations and direction, as well as better infrastructure and support personnel. On top of that, I get to educate the next generation of engineers,” Hite said. “Leaving an established, productive position at a national laboratory was not a light decision, and there are very few institutions I would ever consider. With MSE’s established record, its resources, and university and college support, UF was at the top of that very short list.”

Now settling into her new role as an educator, Hite’s vision for her future at UF is bright, indeed.

“My main goal is to raise our standing as a center for compound semiconductor research,” she said. “There is already a critical mass of faculty working in applications of (ultra)wide bandgap materials, characterization, processing, and heterogeneous integration of those materials. What I am bringing back is the ability to grow advanced structures of these materials in-house, so we vertically integrate across the entire college.”

Hite’s journey, marked by unexpected obstacles and opportunities, highlights the value of lifelong learning and demonstrates how life’s twists and turns often guide us back to our roots.

“As awful as it was at the time, if I hadn’t been laid off from Lucent, I would never have pursued a doctorate degree or gotten to where I am today. It would have been a completely different road,” Hite said. “My path has not been straight by any means, but everything in my adult life has seemed to circle back to UF, and I am extremely excited to be here.”

STORY|PHOTO: ROYCE

Nature’s diverse structures, processes and adaptations provide a limitless source of inspiration for materials scientists and engineers. For Guilhem De Hoe, Ph.D., joined the department as an assistant professor in January 2024, crystals provided the first sparks of curiosity.

“I think at the time, I envisioned I would be a geologist or something similar,” De Hoe said. “When I later realized that there is so much diversity in the properties of natural materials, my interest became more ‘organic’ focused. For instance, butterfly wings with a structure that generates color, the anti-biofouling nature of shark skin, and desert beetles whose backs condense water from the air were fascinating to me.”

He didn’t know it then, but De Hoe’s early fascination with crystals and their formation had already set his career in motion.

De Hoe’s family emigrated from Europe when he was young and settled in California. During high school, he developed a fondness for chemistry, leading to a doctorate from the University of Minnesota.

“Though my Ph.D. is in chemistry, during my last two years as an undergrad, I became interested in polymer science and engineering,” he said. “That focus grew even more during graduate school and my two post-doc appointments.

“From a research perspective, I am most passionate about polymers and their so-called ‘end-of-life,’ including experiments on the processing and recycling of plastics and their biodegradation in different environments.”

De Hoe feels that there is tremendous potential in designing approaches to better circularize plastics and mitigate negative environmental impacts, but practical challenges in reprocessing plastic waste as well as knowledge gaps and misunderstandings in the biodegradation of plastics are hampering progress.

“As a scientist, I’m here to help in both of those areas,” he said.

As an educator, De Hoe has equally worthy intentions.

“Ultimately, my goal is to help students develop into great

scientists and engineers and get them into the careers they want,” De Hoe said. “Along the way, I also want to establish a unique research portfolio that contributes to UF’s reputation for excellence in polymer science and engineering. It would be very validating to me if my work informs decisions made in industry regarding which products to pursue and in government regarding which policies to enact.”

After more than 40 years at the University of Florida, Christopher Batich, Ph.D., professor, retired in September 2023.

After earning his doctorate in organic chemistry from Rutgers University and a post-doctoral fellowship at the University of Basel in Switzerland, Batich worked as a staff scientist at DuPont’s Central Research Department. He joined UF in 1980, where, in addition to his research and teaching, he was the founding director of the Graduate Biomedical Engineering Program, which eventually became UF’s Biomedical Engineering Department. He later served as the founding associate director and chief operating officer of the Clinical and Translational Science Institute.

Most notable among Batich’s innovations is Bioguard®, an advanced wound dressing and a bacterial barrier developed with co-inventors at UF and a local startup company. It was adopted in multiple burn units and nursing homes throughout the United States.

Beyond Bioguard®, Batich’s diverse research portfolio spans from polymeric materials analysis to the development of drug delivery systems for neurodegenerative diseases. More recently, he collaborated with UF Entomology and Nematology Department faculty and U.S. Department of Agriculture scientists to focus on protection against disease-carrying insects, which led to a commercialized mosquito-killing device.

Batich was elected as a fellow of the American Institute for Medical and Biological Engineering and holds 56 U.S. patents. In 2020, he was inducted into the Florida Inventors Hall of Fame for his contributions to science, technology and medicine.

Brij Moudgil, Ph.D., distinguished professor, has retired from the Department of Materials Science & Engineering, which he joined in 1982.

Over his four-decade-plus tenure at UF, Moudgil’s research interests encompassed nanostructured multifunctional materials, corrosion inhibition, polymer coatings, and particulate materials-based systems for enhanced performance in microelectronics, advanced materials, energy, water purification, and biomedical applications.

His contributions to materials science and engineering extend beyond the lab, with patented technologies such as nanoengineered particulate coatings for citrus crop protection.

He was the director of both the Particle Engineering Research Center and the Center for Particle and Surfactant Systems. He also served as the director of the UF Mineral Resources Research Center.

Moudgil holds fellowships in several major professional organizations, including the American Association for the Advancement of Science and the Society for Mining, Metallurgy and Exploration. He is a foreign fellow of the Indian National Academy of Engineering and is a member of both the National Academy of Inventors and the National Academy of Engineering.

His numerous awards include the Distinguished Alumni Award from the Indian Institute of Science, Bangalore, and the 2020 KONA Award, recognizing lifetime achievement in powder and particle science and technology. Moudgil has been granted 31 patents and is the author or co-author of 13 books and more than 300 technical publications.

As the world grapples with the need for carbon-free power generation, advanced reactor designs are crucial to the transition. A Department of Energy (DOE) Nuclear Energy University Program (NEUP)-funded investigation into the behavior of U-Zr annular fuel will not only address uncertainties in advanced reactor designs but also contribute to the broader goal of establishing nuclear energy as a sustainable and viable solution for the future.

The $1 million NEUP award to researchers at the University of Florida’s Nuclear Engineering Program within the Department of Materials Science & Engineering supports cuttingedge research and underscores the DOE’s commitment to fostering collaborative efforts between academia and industry. In partnership with TerraPower and Idaho National Laboratory (INL), faculty members Mike Tonks, Ph.D., professor and interim chair in the department, and Assel Aitkaliyeva, Ph.D., associate professor, aim to expedite the development of innovative solutions that could shape the landscape of nextgeneration nuclear energy.

Understanding the intricacies of U-Zr annular fuel behavior could pave the way for enhanced reactor performance, improved safety protocols, and increased public confidence in nuclear power. As Generation IV nuclear reactors like the TerraPower NatriumTM strive to redefine the standards for efficiency and environmental sustainability, insights gained from this study may play a pivotal role in shaping the regulatory frameworks and technological standards of the future.

The potential implications of this research are profound.

The TerraPower NatriumTM uses a sodium-cooled fast reactor (SFR) as a heat source with metallic uranium-zirconium (U-Zr) as its fuel. While this design draws on the extensive experience gained from previous SFR projects at DOE national laboratories such as INL, there are still uncertainties about how the U-Zr metallic fuel will behave during reactor operation.

Transitioning from the discussion of U-Zr metallic fuels, which offer enhanced stability, efficiency, and accident tolerance compared to traditional uranium oxide (UO2) fuel, it is crucial to address the challenges associated with these advancements. Despite their benefits, concerns arise, particularly in terms of potential fuel swelling and compatibility issues with coolant materials.

STORY: ROYCE COPELAND

Amidst these challenges, Generation IV nuclear reactors emerge as a promising solution, marking a significant leap toward cleaner and more sustainable power generation. These reactors are not only more efficient but also environmentally friendly when compared to conventional reactors or fossil fuel-based power plants.

“Historically, SFRs utilize a closed fuel cycle, and the metallic fuel slugs used were designed with a large sodium-bonded gap to accommodate swelling,” Tonks said. “However, these new commercial reactor designs may require an open fuel cycle, which precludes the use of a sodium bond. But when you change the fuel slug geometry, you can introduce room for swelling.”

A closed fuel cycle involves the recycling of used nuclear fuel and extracting reusable materials to minimize waste and enhance resource utilization. An open fuel cycle uses nuclear fuel only once, generating more waste with less reprocessing, and storing the entire spent fuel without recycling. With that in mind, Tonks and Aitkaliyeva are considering a slightly different fuel slug model than has been used in the past.

Known as an annular or ring-shaped design, it’s essentially a cylinder with a hole down its center. This configuration avoids the need for liquid sodium surrounding the fuel but has also been shown to change how the fuel microstructure evolves during reactor operation. While the reason for this behavior shift is unknown, the research team has some theories.

“We propose that Zr redistribution and swelling contribute to the shrinking of the center annulus and that the high porosity in the outer region results in low thermal conductivity. Those conditions cause higher fuel temperatures that, in turn, create more Zr redistribution and swelling,”

Aitkaliyeva said. “We will test our hypothesis using structure and property data from annular fuel and multiscale modeling and simulation using the BISON and MARMOT fuel performance codes developed by Dr. Tonks.”

Assel Aitkaliyeva, Ph.D.

If they can determine what’s triggering the change, it could be a significant step in the future of nuclear energy.

“We are excited for the chance to investigate the novel behavior that occurs in annular metallic fuel and help enable advanced reactors for carbon-free power generation in the future,” Tonks said.

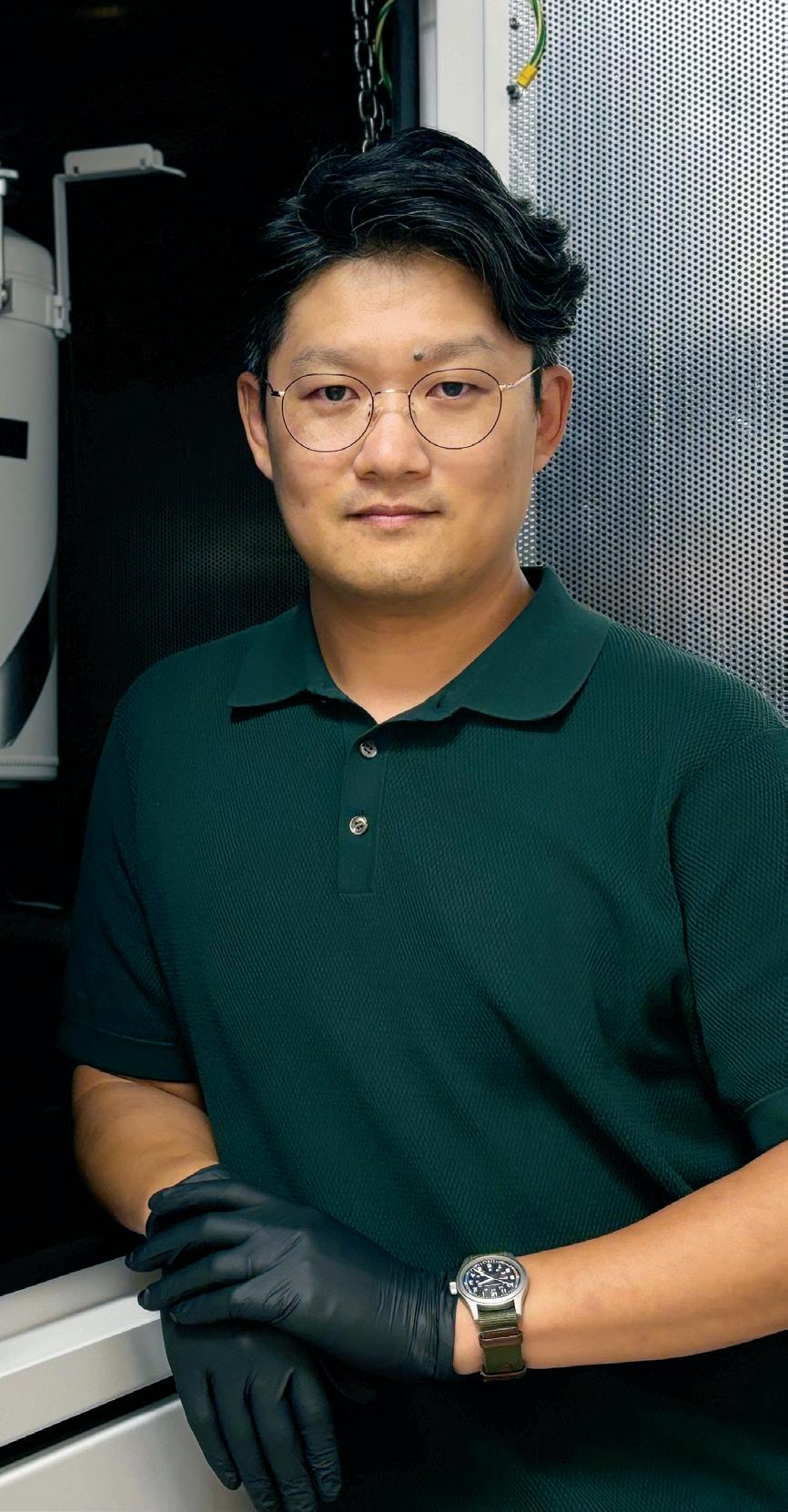

STORY|PHOTO: ROYCE COPELAND

In the internet age, the landscape of human-generated data has undergone a remarkable transformation. From the early days of website creation to the current era of cloud storage, social media, big data and artificial intelligence, the collective output of information has soared with each passing year, marking a substantial increase in the volume and complexity of the content created.

As the amount of stored information exponentially increases over time, the gap between accessing that data and processing it also widens. In other words, while computer processors become faster and faster, the inability to pull data from memory chips at those same speeds creates data analysis bottlenecks in everything from medical research to engineering. This phenomenon is typically described as the memory wall.

Honggyu Kim, Ph.D., assistant professor, thinks the pathway through the memory wall lies in ferroelectric ceramic materials.

“The pivotal role these materials could play in future technological innovations, ranging from advanced memory devices to semiconductors, is unquestionable,” Kim said. “With

their potential applications in compact electronics, energy storage and energyefficient data processing, they’re likely to redefine electronic devices as we know them.”

To help unlock the power of these materials, Kim plans to use his recently funded National Science Foundation Faculty Early Career Development Program (CAREER) Award. The funding supports his research on filling a critical knowledge gap in functional materials: controlling and characterizing metastable phases in ferroelectric ceramic materials.

Ferroelectricity is a property of certain materials exhibiting a natural electric polarization that can be reversed when subjected to an external electric field. Kim’s focus is on developing material characterization techniques for hafnium oxide (HfO2), a nanoscale ferroelectric material with promising applications in information storage and processing technologies.

“The ultimate objective is not only to enhance our understanding of these materials but also to devise strategies for their precision engineering,” Kim said. “The challenge lies in pinpointing and stabilizing them, given their nuanced structural disparities.”

Kim’s focus centers on leveraging the distinctive attributes of ceramic materials, with a particular emphasis on their thermodynamically metastable characteristics, aiming to craft innovative ferroelectric materials with customizable features.

“Utilizing thermodynamically metastable phases presents a new avenue for creating novel functionalities of ceramic materials for technologically critical applications such as nanoscale electronics and energy-storage technologies,” Kim said. “However, identifying design pathways to stabilize metastable materials poses a significant challenge due to the difficulties in characterizing the structure of their ground-state and metastable phases, not to mention how they will change while actually in service.”

Kim will collaborate with UF Department of Electrical & Computer Engineering faculty members Toshikazu Nishida, Ph.D., professor and associate dean for academic affairs at the Herbert Wertheim College of Engineering, and Roozbeh Tabrizian, Ph.D., an associate professor and holder of the Nelms Rising Star Endowed Professorship. Nishida is a renowned expert in ferroelectric materials and devices, while Tabrizian provides critical insights

into the importance of understanding the structure of HfO2 thin films for ferroelectric and piezoelectric devices.

“This award propels our research group’s capability, pushing the boundaries of materials characterization with atomic-scale spatial resolution and high sensitivity to diverse atomic structures,” Kim said. “Ultimately, we’ll generate insights into the structural origins of breakthrough materials.”

Kim earned his Ph.D. in materials science from the University of Illinois at Urbana-Champaign in 2015. After his postdoctoral studies in advanced electron microscopy, functional ceramics, and quantum materials at the University of California, he joined the University of Florida in 2017. In 2023, Kim also received an NSF grant for his shape memory alloy research.

The CAREER Award represents the NSF’s highest accolade for junior faculty, aiming to establish a solid groundwork for a lifelong journey of scientific leadership, and is granted to exceptional early-career scientists who embody the teacher-scholar role by seamlessly combining research and education.

In 1969, space was much less complicated. Only a few nations had launched satellites into orbit, and the race for dominance was between just two — the United States and the Soviet Union. The Moon, recently claimed by the Apollo 11 mission, belonged to America alone.

Fast forward 50 years and Earth’s orbit has become significantly more congested. Dozens of countries and privately owned companies have filled it with tens of thousands of manufactured objects. The scale of our ambitions beyond Earth has grown, too. Now, we’re talking about human-crewed missions to Mars, permanent lunar bases and massive telescopes to explore the far reaches of the cosmos. To help realize these goals, the University of Florida has launched the Space Mission Institute, an interdisciplinary hub for space research.

One of the institute’s key researchers is Tori Miller, Ph.D., assistant professor in the Department of Materials Science & Engineering. Miller is leading a fiveyear, $1.08 million project funded by the Defense Advanced Research Projects Agency (DARPA) to develop advanced laser sheet metal forming technology. The goal is simple: make it possible to fabricate large metal structures in space that are too big to launch from Earth.

Today, everything sent into orbit— whether it’s a telescope or a solar array—has to be built on Earth first

and is constrained by the size and weight limitations of a launch vehicle. Miller’s research could change that by allowing astronauts to manufacture parts in space, reducing the cost and complexity of space missions. This breakthrough could benefit a wide range of space applications, from astronomy to telecommunications and national security.

The challenge Miller is taking on is nothing short of groundbreaking: enabling the assembly of enormous structures,

the demands of space engineering. The process isn’t yet ready for prime time, though. Although laser bending can produce intricate geometries, the final material properties remain too unpredictable. As a result, laser-formed parts are not yet reliable enough for use, particularly in critical applications like spacecraft.

Miller’s approach to solving this problem is innovative. While past research has focused on controls and systems engineering, she is taking a materials

“NEARLY ALL PREVIOUS RESEARCH TREATED MATERIAL PARAMETERS AS CONSTANTS, BUT IN REALITY, THEY CHANGE DURING THE LASER FORMING PROCESS. WE NEED TO PREDICT HOW THOSE CHANGES WILL AFFECT THE FINAL PRODUCT.”

like solar arrays up to 100 meters in diameter—several times the size of those currently on the International Space Station. Her approach, called laser sheet metal forming, uses laser-induced thermal distortion to bend and shape metal without physical contact, much like metallic origami.

But Miller’s focus goes beyond just forming metal in space. Her work takes on the challenge of developing reliable manufacturing methods that meet

Tori Miller, Ph.D.

science approach, examining how the metal evolves during the laser forming process. She’s developing models that track how material parameters—like strength and grain size—change as they undergo repeated laser passes. Her goal is to achieve unprecedented control over the fabricated components’ geometry and mechanical properties.

“Nearly all previous research treated material parameters as constants,” said Miller. “But in reality, they change during

the laser forming process. We need to predict how those changes will affect the final product.”

This modeling strategy could unlock new possibilities in space manufacturing. If successful, it would enable astronauts to build massive, complex structures in orbit with precision and reliability. From solar arrays that power space stations to trusses for large telescopes, laser sheet metal forming could support the future of space exploration.

The concept isn’t entirely new. In the 1970s, the Grumman Beam Builder could cut, bend and ultrasonically weld aluminum alloy sheets into triangular trusses. While promising, it was limited to a single geometry and a narrow range of materials. Ultimately, research shifted to on-orbit assembly instead of manufacturing. Now, with modern technology, Miller and her team are taking a fresh look at space-based fabrication, pushing it further than ever before.

Testing will soon move into a thermal vacuum chamber at NASA and, eventually, aboard the International Space Station. If successful, Miller’s work will represent a significant leap forward in space manufacturing technology, bringing humanity one step closer to building the next generation of space infrastructure.

“Laser bending isn’t very repeatable right now,” Miller said. So, her research group analyzes the conditions that affect the final shape, everything from temperature to material thickness to even minor surface contamination. Most importantly, the final product must withstand the demands of space. “We need to ensure the material is as strong and as reliable coming out of the laser bending process as it was going in.”

As space exploration moves into new frontiers, the ability to fabricate largescale structures in orbit could be the key to unlocking humanity’s most ambitious goals.

With growing support for nuclear energy driven by multiple federal initiatives, the Department of Energy anticipates a growing need for skilled workers to meet the demands of manufacturing, construction, and operation of advanced nuclear reactors. A new program led by Ira Harkness, Ph.D., an instructional assistant professor in the Nuclear Engineering Program, is a strategic response to this growing demand, addressing workforce needs by targeting emerging talent pools in the expanding nuclear sector.

“By bridging the gap in nuclear education, this project lays the foundation for innovative nuclear research and industry practices,” Harkness said. “Developing a broad range of talent paves the way for advancements in energy, healthcare and environmental sustainability.”

The program collaborates with educational institutions lacking research reactors, bringing them into high-quality educational and research environments on UF’s campus in Gainesville. Key partners include the University of Puerto Rico at Mayagüez, Florida International University, and the University of Central Florida — all designated as Hispanicserving institutions. This collaboration underscores a commitment to broadening opportunities in nuclear

education and addressing gaps in the field.

Students and faculty from these partner institutions will be invited to the UF Training Reactor (UFTR) for immersive, week-long programs to engage in hands-on experiments, interactive presentations, technical demonstrations and guided tours.

“These experiences offer a comprehensive understanding of reactor technology and operations, expanding perspectives on nuclear science and engineering,” Harkness said. “These activities will also be made available through online modules to ensure their long-term relevance and reach.”

But the initiative doesn’t stop there. The program recognizes the power of early education with a one-week summer workshop designed for K-12 educators, with a focus on reaching underserved communities. This component will equip teachers with the tools and knowledge to effectively introduce nuclear science fundamentals in their classrooms, aiming to inspire the next wave of nuclear engineers and scientists from a young age. This “teach-the-teacher” approach will reach over 2000 K-12 students per year, facilitating long-term impact.

The idea for this innovative approach was sparked by Harkness’ realization of the potential of the UFTR to serve a broader community beyond its traditional role in research and education.

“Many of our students told us that their interest in nuclear engineering began in middle or high school,” Harkness said. “This summer workshop will prepare teachers to meet state of Florida academic standards related to nuclear technology through experiments and virtual tours of the UFTR.”

UFTR’s unique funding structure, which eliminates operator or facility time charges, allows for a significant allocation of resources toward participant support. Nearly 50% of the $200,000 funded by the Department of Energy will cover travel expenses for participants, particularly those from Puerto Rico, who might otherwise be unable to gain such valuable experience.

The program also intends to foster a collaborative community among participants and leverage connections with student chapters of various professional organizations, such as the American Nuclear Society, the Society of Hispanic Professional Engineers and the National Society of Black Engineers, to promote peer mentoring and instruction.

“One of the better parts of this initiative is that it will serve as a scalable model for other disciplines and institutions aiming to expand access to specialized resources,” Harkness said. “By combining the resources and expertise of partner institutions, the program not only levels the educational playing field but also inspires students from varied backgrounds to pursue careers in nuclear engineering.”

Harkness’ strategy of collaboration and resource sharing sets a precedent for other specialized disciplines, and its impact on the future nuclear workforce will likely be felt across the academic and professional landscapes.

“This project exemplifies our commitment to both academic excellence and diversity, as we open the doors to new talent and strengthen the pipeline of skilled professionals in nuclear engineering,” said Michael Tonks, Ph.D., interim chair of the department.

Kyle Hartig, Ph.D.

Promoted to Associate Professor

Nancy Ruzycki, Ph.D.

Promoted to Master Lecturer

DuWayne Schubring, Ph.D.

Promoted to Instructional Professor

Nekia Jones

ASSISTANT TO THE DEPARTMENT CHAIR

2024 Tony and Kathy Brennan Staff Excellence Award

In recognition of her outstanding dedication and impact as an early career teacher in materials science and engineering, ASM International has honored Tori Miller, Ph.D., assistant professor, with the 2024 Bradley Stoughton Award for Early Career Teachers.

Established in 1952, the Bradley Stoughton Award celebrates and encourages excellence in teaching materials science, engineering, design and processing. The annual award honors educators who demonstrate exceptional commitment to their students’ success through enthusiastic teaching, dedicated mentoring and promotion of the materials profession.

Miller’s teaching and mentorship have inspired students and colleagues alike, creating a vibrant learning environment and promoting innovative approaches to materials science education. In both the classroom and in the lab, she works to instill a lifelong appreciation for the field and its applications.

“I’m especially honored to be recognized for my teaching because my first experiences in front of a classroom are what convinced me to pursue a career in academia,” Miller said.

Miller received the ASM International Silver Medal in 2023 for her advancements in materials research, innovation and leadership, and is currently developing techniques for bringing manufacturing into

Before joining the department in 2019, Miller was an assistant professor at North Carolina State University. She received her Bachelor of Science in materials science and engineering from the University of Michigan in 2011 and earned her Ph.D. at the University of California, Santa Barbara, in 2016.

ASM International, the world’s largest professional society serving the materials science and engineering community, is dedicated to promoting innovation and advancement in the field.

STORY: ROYCE COPELAND

The Savannah River National Laboratory (SRNL) is a U.S. Department of Energy Office of Environmental Management research and development lab located in Aiken, South Carolina, with a history dating to the early Cold War. Established in the 1950s, SRNL has since evolved into a multidisciplinary research facility at the forefront of nuclear science, environmental stewardship and national security.

Recently, SRNL hosted a group of University of Florida nuclear engineering students, providing them with insights into some of the facility’s research initiatives, the future of the nuclear engineering field and different career paths available for young engineers.

As part of his joint appointment with SRNL, Kyle C. Hartig, Ph.D., assistant professor of nuclear engineering, helped arrange the visit to help establish a workforce development pipeline for future UF graduates.

“It was a great way to expose students to the critical national security and energy security missions of the lab and Savannah River Site (SRS),” Hartig said. “Touring SRNL provided these students with an experience that enriches both their education and their career development. By engaging with leading experts in the field, witnessing cutting-edge research up close and gaining hands-on experience in state-of-the-art facilities, we hope to provide a clear picture of what’s possible in nuclear engineering and help inspire them to continue pursuing their goals.”

With the tour serving as a bridge between academic studies and real-world applications, it offered students a glimpse into the multifaceted nature of nuclear engineering. It also showed them new ways they could contribute to nuclear engineering’s ongoing advancements and challenges.

Some of the students shared their insights about the experience.

Madeleine Forbes, a Ph.D. student specializing in radiochemistry, was struck by SRNL’s industrial-scale capabilities and overall mission.

“SRNL is unique in having the only operating, productionscale, radiologically shielded chemical separations facility in the U.S.,” Forbes said. “They’re prioritizing environmental cleanup and processing spent nuclear fuel for commercial use, which I feel is a key opportunity for the future of nuclear engineering.”

“For me, the most valuable aspect of touring the lab was seeing a possible future career path,” Forbes said. “It gave great insight into where the field is heading and what my options will be as a young professional entering the workforce.”

Andrew Duckworth, a radiochemistry Ph.D. student, pointed out SRNL’s commitment to maintaining the nuclear workforce.

“Cultivating and sustaining talent was a key effort discussed during the tour,” Duckworth said, highlighting SRNL’s role in training the next generation of nuclear researchers and scientists through initiatives like the ATHENA program, made up of Pacific Northwest National Laboratory, Idaho National Laboratory, Argonne National Laboratory and SRNL. “Every person who retires or leaves the industry is a loss, and if it’s not addressed, it can lead to national security issues.”

Hannah Patz, a Ph.D. student, noted SRNL’s labs dedication to nuclear forensics and security, tritium research and plutonium dating. She was also intrigued to learn about the career progression of scientists working at the lab.

“We were able to talk to postdocs who had graduated a couple of months ago and senior managers who had been active in the field for years, and most of them did not have a straight path to their current position,” Patz said. “Some of the managers started out as a technician

after graduating high school, and then eventually went to earn a degree.”

Patz noted that most of the people the students talked to aren’t currently doing research related to their doctorate or even in their field. “There were a lot of people who had physics or chemistry degrees doing nuclear engineering,” she said.

Weslee Kersey, a Ph.D. student, was impressed by SRNL’s collaborative research efforts, which mirrored his own experiences at UF.

“Each lab we toured highlighted their ongoing efforts towards nuclear proliferation concerns. More specifically, the ongoing collaboration with the FBI to conduct rapid analysis of suspected materials or items of interest,” Kersey said, recognizing the importance of partnerships in addressing the complex challenges facing the nuclear engineering field.

BOOKS, TUITION, RENT, FOOD – THE EXPENSES OF HIGHER EDUCATION CAN ADD UP QUICKLY, AND SCHOLARSHIPS CAN MAKE A HUGE DIFFERENCE. CONGRATULATIONS TO THE FOLLOWING STUDENTS ON THEIR AWARDS FROM THE DEPARTMENT.

Alan M. Jacobs Memorial Scholarship

Jack Curley

Caitlin Martin

Mia Narinejit

Kai Schulte

James E. Swander Memorial Scholarship

Emily Gunger

Kyle Latty

Aileen Sarceno

Ohanian Scholarship

Daniel Fernandez

Enrique Medici

Jacob Wisienski

Roberto Pagano Memorial Scholarship

Fred Anduze

Brandon Bohanon

Juston Borerro

Cade Finney

Joshua Manuel

Hannah Patz

William St. Peter

Ricard Perez Scholarship

Fred Anduze

N.L. Griesheimer Memorial Fund Scholarship

Caitlin Martin

F.N. Rhines and W.R. Tarr Scholarship

Alexandre Bordas

Shornam Ghandi

Justin Ma

Garret Young

Jonathan Hack Memorial Scholarship for Materials Science

Caitlyn Rineer

Bowen Su

Richard G. Connell Scholarship

Cameron Chan

Morgan Congdon

Adriana LaVopa

Skye Sisco

Robert David Adamson Scholarship

Shannon Gerard

Aris Graber

Jason Jaquith

Steph Meikle

Gregory Peiirs

Robert E. Reed-Hill Scholarship

Maxwell David

Adrian Gonzalez-Socorro

Peter Mejia

Vladimir Grodsky Memorial

Fund Scholarship

Olivia Miller

Ric Perez Scholarship

Juan Echeverri

Yenan Leyvaw

STORY: ROYCE COPELAND

Congratulations to Flávia da Cruz Gallo, Ph.D., who was recognized as a “2023 Rising Star in Materials Science and Engineering” and attended a Rising Stars workshop hosted by Carnegie Mellon University’s (CMU) Department of Materials Science and Engineering (MSE). Gallo described the experience as a career milestone, emphasizing the value of a conference where every talk brimmed with shared knowledge.

“I was among a few researchers selected from hundreds of applicants from the best MSE Departments in the US. The faculty and presenters

at CMU provided so much insightful information, and the networking was priceless. Plus, I had the chance to share my envisioned research portfolio for my Future Faculty career and got some great feedback.” said Gallo. “It was such an important milestone in my career!”

An expert in novel metallic alloy design, failure analysis, non-destructive evaluation, and process-structureproperty relationships, Gallo is a postdoc under Michael Tonks, Ph.D., interim chair of UF’s MSE department.

CMU, Massachusetts Institute of

Technology and Stanford University organized the Rising Stars workshop to help expand inclusivity, access and preparation for academic careers in MSE.

Gallo’s achievements reflect her dedication to advancing the field of MSE, and we look forward to witnessing her continued success in shaping the future of materials science.

Once again, congratulations on this well-deserved recognition, Dr. Gallo!

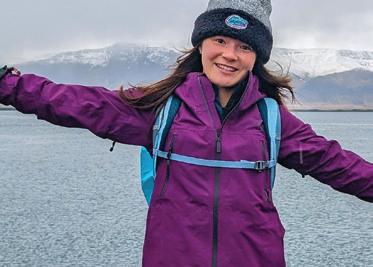

Brooke Lastinger ’s academic journey is a testament to the power of exploring new frontiers. An undergraduate student in the Department of Materials Science & Engineering (MSE), Lastinger found her path through a combination of mentorship, research opportunities and following her passion.

Her decision on a major was inspired by advice from two sources: her high school chemistry teacher and her dad, a mechanical engineer. Lastinger was looking for something in between chemical and mechanical engineering and saw MSE as the perfect mix of both. With the University of Florida’s reputation in the field and the Herbert Wertheim College of Engineering offering multiple options should she

decide to choose another major, the choice of where to apply was easy.

Currently a junior, Lastinger sees herself specializing in metallurgy and or nondestructive inspection (NDI).

“For the past two summers, I participated in the Naval Research Enterprise Internship Program at Naval Air Station Jacksonville, working in the Metals & Ceramics, NDI, and Polymers & Composites Branch of the Materials Engineering Laboratory,” Lastinger said. “I spent a significant amount of time with NDI and metallurgy, performing material engineering service requests, as well as working on failure analysis, engineering investigations, and service life assessment programs.”

A more recent highlight of Lastinger’s time at UF is her study-abroad excursion to Iceland this past spring. The trip was made possible in part thanks to the Botic Family Scholars Professional Pathways Fund, which provides support for MSE and nuclear engineering students.

“UF in Iceland has been one of my favorite experiences, as it was my first time out of the country,” she said. “Plus, I had the chance to meet new people from UF and beyond.”

The UF in Iceland — Renewable Energy and Sustainability Program is an eightday study abroad opportunity that allows students to explore Iceland’s energy solutions up close. In a country where nearly 100% of the electricity

comes from renewable sources, students receive an in-depth look at geothermal energy, hydroelectric power and sustainable energy policies.

With seminars from experts, tours of geothermal and hydroelectric power plants, and visits to industries practicing sustainability. It’s an opportunity to learn about cutting-edge renewable technologies while experiencing Iceland’s stunning landscapes and power-generation initiatives.

During the trip, Lastinger stayed in Reykjavík with day excursions to waterfalls, geothermal springs, geothermal power plants and visits with local experts in the public and private sector.

“I was curious to learn about the various materials used in geothermal power plants and witness firsthand the material selection and screening process,” Lastinger said. “I was also surprised to learn about the potential of magma energy, which still needs additional material research to be better utilized.”

Lastinger also learned about just how versatile geothermal energy can be.

“One of the highlights of my trip was visiting a geothermal bakery and a greenhouse. At the bakery, they bury the dough in a large ceramic pot above a geothermal hot spring, where it bakes underground for 24 hours. It was amazing to see the steam rising from the boiling ground!” Lastinger said. “Later that day, we toured a geothermal greenhouse that produces 40% of Iceland’s tomatoes. The tomatoes were incredible, and we ended the visit with a delicious tomato soup buffet. All in all, that was one of my favorite days in Iceland.”

Created by MSE alumni Branimir “Ben” Botic (MS MSE ‘71), and his family, the Botic Family Scholars Professional Pathways Fund is designed to help students gain valuable hands-on experiences that enhance their professional skills. Botic established this

fund to ensure financial constraints do not hinder hardworking students. The fund supports experiential-learning opportunities worldwide, including industry internships, national lab placements, and other programs that provide practical experience outside the classroom.

As a Botic Family Scholar, Lastinger holds high praise for the fund and its purpose.

“My experience in Iceland introduced me to areas of research I had not considered before and may not have ever known about,” she said. “The Botic Fund helped fulfill the study-abroad experience for me, and I can’t be thankful enough for it.”

With immense pride and gratitude, we are honored to announce the Brice Turner Memorial Fund, a lasting tribute to the memory of a remarkable individual whose commitment to academic excellence and leadership continues to inspire us all.

A native of Jacksonville, Florida, Turner‘s diverse interests in athletics, F1 racing, outdoor adventures, and love of the Jacksonville Jaguars reflected his boundless enthusiasm and zest for life. Turner attended Embry Riddle Aeronautical University (ERAU) and distinguished himself through his academics and involvement in Naval ROTC and the ERAU EcoCar Mobility Challenge. He graduated summa cum laude from ERAU with a bachelor’s degree in mechanical engineering in spring 2022 and enrolled as a Ph.D. student at UF the following fall.

Tragically, Turner’s promising journey was cut short in a car accident on Nov. 12, 2023, leaving behind a void in the Gator Nation.

In honor of Turner’s memory, his parents, Bridget and Bruce Turner, have established the Brice Turner Memorial Fund to uplift and support graduate students in the UF Department of Materials Science & Engineering. This endowed fund will provide scholarships to students displaying academic excellence, exemplary citizenship, and a demonstrated passion for advancing the fields of nuclear engineering and materials science.

We invite alumni, donors and supporters to honor Turner’s enduring spirit by contributing to the Brice Turner Memorial Fund. Your generosity will ensure that his legacy lives on, inspiring future generations of Gator Engineers to pursue their academic and professional aspirations with the same spirit that defined his life.

Together, let us honor Turner’s memory and ensure his legacy continues shining brightly within our community and beyond.

SCAN THE QR CODE TO SUPPORT THE

TWO ALUMNI AWARDS ARE PRESENTED TO GRADUATES WHO EXEMPLIFY THE VALUES OF THE DEPARTMENT, DEMONSTRATE EXCEPTIONAL ACHIEVEMENT AND POTENTIAL IN THEIR EARLY TO MID-CAREERS, AND SERVE AS POSITIVE ROLE MODELS FOR OUR CURRENT AND FUTURE MATERIALS SCIENCE AND NUCLEAR ENGINEERING STUDENTS.

THE EARLY CAREER ALUMNI AWARD

Josh Stopek, Ph.D., has a background in developing minimally invasive image-guided technologies, new cancer diagnostic and therapeutic platforms, biomaterial/biosurgery and combination devices and bringing them to market.

He is currently the vice president of R&D for HistoSonics, and focused on new breakthrough oncology solutions. He formerly led R&D in various business areas at Medtronic, Covidien and U.S. Surgical. Prior to that, he was the co-founder and vice president of a startup medical device company, VMSI, working on new minimally invasive and tissue regeneration therapies. Stopek has over 200 issued and pending patents. He received his B.S., M.S., and Ph.D. in materials science and engineering from UF, where he also completed a fellowship in neurosurgery and neuroscience.

THE DISTINGUISHED ALUMNI AWARD

Sanjay Shrivastava, Ph.D., has over 20 years of experience in the medical device industry, with a focus on developing, commercializing, and evaluating innovative technologies. As the founder and CEO of Innova Vascular, he has played a key role in driving advancements in vascular healthcare. Shrivastava has held leadership positions at prominent companies like Johnson & Johnson, Medtronic and Covidien/ev3. He cofounded BlackSwan Vascular Inc., a clinical-stage startup, and currently serves on its board of directors.

With over 30 U.S. and international patents, Shrivastava’s contributions to medical device innovation are significant. He holds a doctorate in materials science and engineering from UF and a bachelor’s degree from the Indian Institute of Technology.

VP of Operations, Everest Ice and Water Systems

Everest Ice and Water Systems started in 2008 as a charitable initiative called Akoona, providing clean water and ice to rural African communities. The success of their innovative VersaVend machine led to widespread adoption, including in African national parks.

Rebranded as Everest in 2016, the company shifted to direct sales and has since grown into a multimillion-dollar enterprise. Headquartered in Apopka, Florida, Everest has expanded rapidly, driven by the success of its Everest VX machine. Despite its growth, the company remains committed to its mission of delivering clean water and ice worldwide.

DEPARTMENT OF MATERIALS

P.O. BOX 116400

GAINESVILLE, FL 32611-6131

MSE.UFL.EDU