6 minute read

GROWING ROOM

GROWING ROOM Engineering Design Building offers new spaces for learning and collaboration. BY PAULA PRICE TANNER

On the outside, the long metal building looks programs to design and test engineering solutions. like a well-kept warehouse, with attractive This is UMHB’s Engineering Design Building—a shrubs and ornamental trees planted near newly repurposed facility designed to provide growits entrance. But the smattering of cars parked nearby ing space for the university’s burgeoning engineering and a steady stream of students going in and out inprogram. dicate this is more than a quiet storage facility. SomeEngineering is a relatively recent addition to the thing is going on here. university’s degree offerings. In 2010, UMHB entered

A step through the entrance doors reveals a into an articulation agreement with Baylor University complex of areas that are buzzing with activity. Large to offer core curriculum and pre-engineering courses glass windows between rooms and along the central that would prepare UMHB students to complete dehallway make it possible to see students engaged in all grees in electrical or mechanical engineering at Baylor. aspects of their studies, from listening to lectures and Response to the pilot program was good, and adminworking in small groups to using computer modeling istrators soon realized that there was a high demand

port the expanding program would be to add laboraing on the north end of the campus could provide the

square footage needed, and with the addition “It’s been cool to of interior walls and equipment in 2019, the Engineering Design Building was born. see the progress, The 12,610-square-foot space has been not just of the developed with the features of a modern engineering program in mind. All engineering engineering program, students at UMHB learn to use industry-stanbut also of the building being built.” dard design software such as SolidWorks and AutoCAD. They also learn to use LabVIEW, a simulation program designed to teach stu— dents principles of physics, digital electronics, Senior Molly Rodeffer and control of engineering hardware such as drones and robots. Since so much class work is done on computers, it is important for the for engineering education. In 2016, the university accommodate an entire class of students at one time. expanded the pre-engineering program into a full The new computer lab offers 36 computers loaded four-year engineering degree. Forty students enrolled with the needed design and simulation software, plus that first year, and three years later there are 110 four state-of-the-art 3D printers where students can students in the program. print out prototypes of their designs.

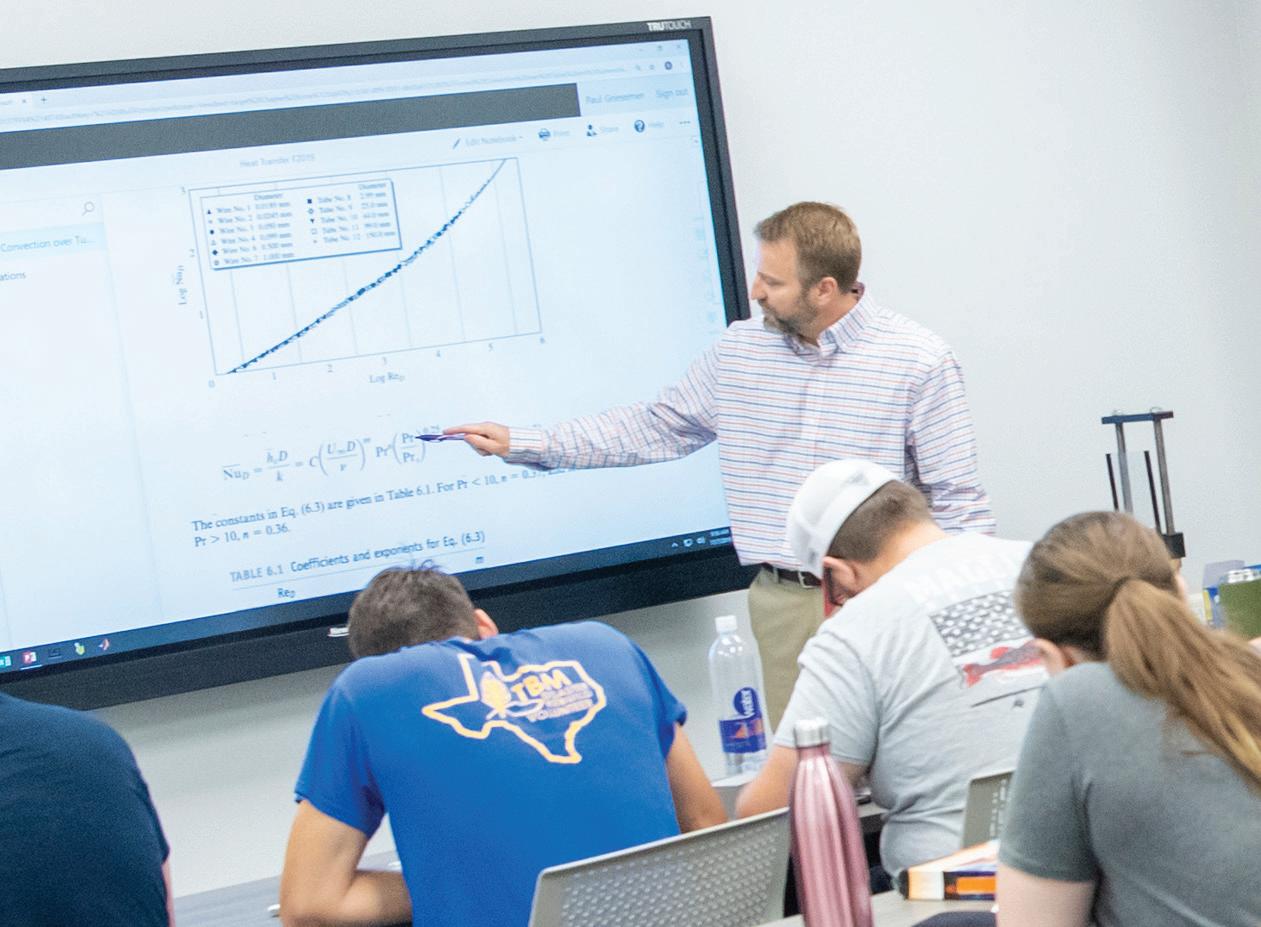

As its numbers swelled, the program outgrew the The four classrooms in the building are equipped rooms initially allotted to it in the C.J. (Red) Davidson with “smart boards” that allow professors and students Building. Administrators decided the best way to supto write out equations with their index fingers, dis- tory, workshop, and classroom spaces where students could design and build the projects required in their upper level courses. They found that an empty buildOpposite page: The new workshop offers plenty of tools and space for students to build prototypes of their engineering designs. The computer lab (above) includes 36 stations equipped with AutoCAD and SolidWorks design software. facility to include a computer lab that can

play diagrams and photos, or switch to an Internet site with just the touch of an icon on the screen. The classrooms are equipped with rolling tables and chairs that can be changed from a forward-facing configuration for lectures to set-ups for round-table discussions or small group work, all in a matter of minutes. The rooms are also equipped with rolling whiteboards that can be used to provide additional board space for students to write out their lengthy mathematical solutions to homework problems or in-class assignments.

The facility includes an electronics lab fitted with wrap-around cabinets and counters. The room provides a work area for students taking classes in Electric Circuits, Electronics, and System Dynamics and Controls, plus ample storage for electronic test equipment and the zillions of components students need to build electrical circuits.

The true “wow” factor in the building, though, is a massive metal/wood/plastics workshop equipped with power tools, a laser cutter, welding equipment, and a painting station complete with vent hood. A large caged area in the space holds portable tools that students may check out to build their projects, and the facility offers plenty of countertops and open floor space for students to work singly or in groups. Huge garage doors in the back corner allow students to build large projects and then move them outdoors for transportation elsewhere.

The spaciousness of the building is a welcome

change for the students. “We can spread out in this building,” says senior Aaron Garland. “Our projects in our capstone design class require space to work with lasers and a bunch of different components, so it is nice to have our own areas and not be on top of one another.”

The upper-level engineering classes are all taught in the new facility, so the junior and senior students spend a lot of time there. The front lobby has been designed to do double-duty as a student lounge where students can eat lunch and study. “I like that we can do work in the front lobby,” says Jonathan Rosales. “Even when the classrooms are locked up, we can still work there. The Wi-Fi access in the lobby allows us to use our laptops, and the coffee machine

there helps us stay awake.”

“There’s definitely more comradery in this building than we had when we were in the Davidson building all day,” adds Richard Rogers. “Having a building of our own has challenged me to do a better job of meeting people. I didn’t usually talk to Jonathan before this semester, despite the fact that we had all of these classes together. Now we are good friends. It really does help that you can easily go after class to get food with someone before the next one starts. And there are plenty of parking spaces!”

Senior Molly Rodeffer summarizes the impact of the new facility well. “It’s been cool to see the progress, not just of the engineering program, but also of the building being built,“ she says. “Initially, I was

planning to go to UMHB for about three years and then transfer to another school to finish my degree. It’s been a real blessing to be able to stay, to see how much the program has grown and how it has culminated in getting to take classes in these great new facilities.”

Clockwise, from opposite page, top: Students work in teams in the computer lab; a welding station in the workshop offers new fabrication possibilities; Dr. Paul Griesemer uses a graph on the smartboard to explain an algorithm; seniors demonstrate their capstone design project; and students share how they calculated solutions to problems in their Engineering Mechanics: Dynamics class.