4 minute read

Population explosion – nutritious food sustainability – water and energy shortages – mineral resources under pressure – eco systems failing: Vertical hydroponics farming the solution?

In the major food producing countries globally, around 80% of water resources are applied for irrigation on farmland. An even higher percentage can be expected in drier areas where farmers are trying to produce a reasonable crop.

This is a cause for concern to the inhabitants of the world as, although they depend on producers to put food on the table, open land, or irrigated production systems calls for more water as it expands to supply in the fast increasing demand. Even if wastewater is used, harmful pathogens are introduced into the food supply and therefore put humans at risk. Further negative influences by irrigation practices is that it may cause waterlogging and salinization. When over-watering, the soil becomes oversaturated and plant roots get damaged, causing loss of plants. With salinization soil becomes saltier than it should be, as its water has been drawn away for irrigation elsewhere. The high salinity causes barren land because plants are unable to access what water remains in the soil. Pollution due to irrigation runoff can be a serious problem in the areas near commercial farming operations. Chemical pesticides and fertilizers are carried away from crops and into the local water supply, leading to health risks and posing a threat to natural waterways and the local environment.

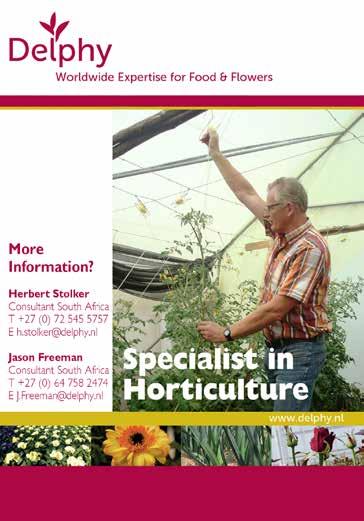

Advertisement

COMES VERTICAL FARMING

There are several pros and cons to consider in the vertical farming idea. However; should one weigh up the negative aspects – which are largely due to under-qualified management and poor business planning – this relatively new system should become the answer to multiplying nutritious food supplies quicker than conservative methods; even with its increased technologies.

13

VERTICal HYDRoPoNICS FaRMING THE SolUTIoN? 12

In a vertical hydroponics system plants are grown in water with no soil present. They are stacked vertically in towers or trays, arranged within a structure such as a greenhouse or other building. Since the growing happens indoors, matters such as climate and weather have no influence on crops. Therefore healthy crops such as leafy greens can be grown year-round in any part of the world, city or town regardless of the climate conditions outside.

STABLE YIELDS, qUALITY

Stable crop yields are possible in the vertical farming system. Production takes place all year round as the system is constructed inside a greenhouse, former warehouse or old pack house. This means there is protection against pests as the assistants are highly hygiene aware and plant quality conscious. For obvious reasons there is no movement of animals or even invasive plant species. This is in answer to food security, bringing food to people with a low carbon footprint producing up to one five to six hundred kilograms of food per square meter. Mostly leafy plants (greens) with smaller root systems are produced like salads, cherry tomatoes, strawberries, broccoli, cabbage and spinach. According to specialists in this system, it is estimated to be two thousand per cent more effective against traditional rain fed systems and up to four to five hundred per cent against other hydroponics systems at a fraction of the cost. There are no fossil fuel utilised in the process or pathogen control; CO² is taken from the air, bound with water (H²CO³) to obtain carbonic acid to regulate pH levels. When sunlight falls on the plants the photosynthesis breaks down the carbon leaving water and oxygen. Natrium chloride is used with electrolysis to control pathogens. Luminaforce is used to let only red and blue light through for better grow light in the tunnels and temperatures of between 16°C-22°C are retained for optimal growth. With the ability of growing a variety of plant species, comes the advantage of water saving as the system is designed to recirculate and purify, before adding nutrients for the next cycle. These days, it is fine-tuned to the extent that the system saves on nutrients as it manages the run-off and only adds up to the needs of the plants at a particular growing stage. This is not possible with open land farming. There are of course, some who foresee negative aspects of vertical farming; such as plants that are not open to pollination, no direct sunlight, less employment opportunities, etc. But on the contrary are the much over-arching aspects of higher food volumes, consistency in quality and supply, high water saving and more. Energy use by LED red or blue lighting (which are the colours plants flourish under) can be obtained by solar panels on the roof or even wind energy. Site, Carbon Footprint The site at which vertical hydroponics systems are constructed can be selected close to the main fresh produce outlets to save carbon footprint and transport distance. Empty standing warehouses and even open company buildings exist all over the world and often in close proximity to food outlets. As far as the economics of constructing a vertical hydroponics system is concerned, a proper business plan should be in place with costing of every aspect of the business and most important; a market that offers sustainable and even increased business from the producer. Furthermore, all lawful, environmental, employment, transport and management aspects must be in place in order to roll out such a new venture. Vertical farming has taken off tremendously in other countries and there is no reason why we in South Africa should not generate the will and funding to ensure our nations’ sustainable supply of fresh food by using this system. JS

LED lighting runs above every shelf of produce to produce even lighting.