12 minute read

SERVICE HIGHLIGHTS

SERVICE HIGHLIGHTS SUMMARY

FIT TESTING

Fit testing is required on an annual basis by the Occupational Safety & Health Administration (OSHA) and is vital to ensuring that respiratory protection is effective. Without a fit test, the employee has no idea whether or not the respirator they are wearing will protect them. Beginning in February of 2020, EHS ramped up its fit testing activities in order to support the anticipated surge of health care workers needing to wear respiratory protection due to COVID-19.

PPE EVALUATIONS & TRAINING

During the pandemic, many manufacturers have developed new PPE to meet the critical need of healthcare providers. But not all PPE is created equal, and evaluation of all PPE worn by staff is critical to ensure the appropriate level of protection. Proper use of safety equipment ensures that it provides the protection it was designed for. EHS, in collaboration with Healthcare Leadership, ensured that all new PPE used on campus was evaluated and staff were appropriately trained.

N95 REPROCESSING

The Pandemic has caused severe shortages in respiratory protection for healthcare workers. In order to ensure that UTMB workers could work safely while caring for patients, BSP tested and validated several different decontamination methods for the N95 reprocessing program in coordination with Healthcare leadership. BSP continues to coordinate and perform the N95 decontaminations for the reprocessing program for UTMB.

MEDICAL WASTE ASSESSMENT & DISPOSAL

Environmental Protection Management (EPM) provides technical services for protecting UTMB’s environmental liabilities with regulatory oversight for the Institutional medical waste processes. UTMB’s medical waste operations are permitted by the Texas Commission on Environmental Quality (TCEQ) municipal solid waste permitting and must meet regulations for medical waste transport, treatment, and disposal. EPM staff support the Environment of Care Committee with a significant role in monitoring waste trends and Institutional compliance with training for UTMB employees on proper management of pharmaceutical and medical wastes.

BIOLOGICAL SHIPPING

BSP supports shipping of biological material for UTMB researchers. BSP played an integral role in shipping SARs-CoV-2 virus and RNA, as well as one of the first infectious clones created in the world to reference laboratories and researchers nationally and worldwide to allow for swift countermeasure development and testing. BSP sent UTMB’s first shipment of SARs-CoV-2 on February 18th, 2020 and continues to ship these critical samples and infectious clones nationally and worldwide.

OVERFLOW SURGE SPACE ASSESSMENTS & MODIFICATIONS

Early in the COVID-19 crisis it became clear that our current facility capacity might not meet demand. EHS worked directly with the Texas State Fire Marshal and healthcare leadership to identify potential areas and define changes needed for appropriate levels of safety and maximum utilization. EHS actively modified spaces such as: additional sleep rooms for physicians, gymnasium infirmary, and other spaces by improving life safety systems in preparation for a potential surge. Some spaces, such as the gymnasium, have since been converted back once the initial threat abated.

SERVICE HIGHLIGHTS FIT TESTING

EHS staff put to the side their usual daily activities for several months in order to support the surge in fit testing demand across the entire health system. In addition to the sheer number of people needing to be fit tested, there were also significant challenges associated with N95 supplies, requiring EHS to help evaluate potential new makes and models to be used by our staff. UTMB EHS also supported outside health systems such as Memorial Hermann by providing them with supplies needed to perform qualitative fit testing for their employees.

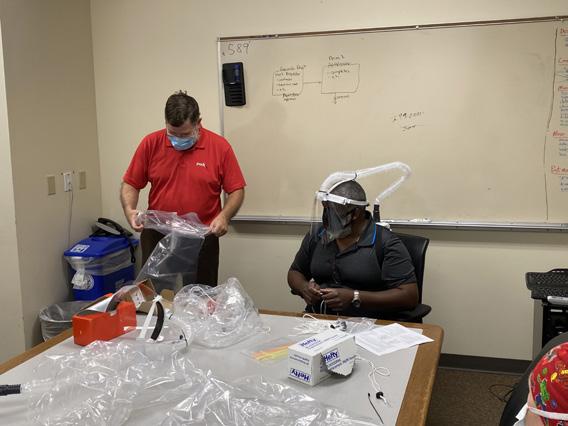

Jim Stone, EHS Consultant, and Courtney Williams, OSP Technician, providing N95 fit tests to health care workers on the front line with COVID-19

Labor & Delivery night-shift nurses getting fit tested on March 13, 2020

12000

10000

8000

6000

4000

2000

0

Number of Fit Tests Performed (Pass + Fail)

FY16 FY17 FY18 FY19 FY20

In FY20, EHS performed 9,827 fit tests. This is more fit tests than were performed in FY16, FY17, FY18, and FY19 combined (8,375)

SERVICE HIGHLIGHTS PPE EVALUATIONS & TRAINING

In response to the shortage of respiratory protection, several manufacturers have developed new models of Powered Air Purifying Respirators (PAPRs). EHS Biosafety and Occupational Health Safety Programs, in collaboration with Infection Control and Healthcare Leadership, evaluated each new model that was obtained for use in the healthcare and research areas to ensure they met safety standards. Biosafety followed up by providing training to all staff that would be using the units.

During the pandemic, modifications to the personal protective equipment (PPE) worn by healthcare staff were necessary to ensure staff and patient safety. Procedural evaluations and modifications were necessary in certain areas. Biosafety worked with the different healthcare units and departments to ensure that all staff were properly trained and comfortable in the techniques on proper donning and doffing of the PPE, and that procedures were in place for staff safety.

DOW PAPR training was provided by EHS Consultants, Malissa Mayer-Diaz and Belinda Rivera, and Sr. Safety Specialist, Nikki Ward

PPE training for Healthcare staff was provided by EHS Consultants, JeT Newton and Belinda Rivera

SERVICE HIGHLIGHTS N95 REPROCESSING

Due to global PPE shortages during the pandemic, UTMB was proactive in working to conserve the supplies on campus to ensure an adequate supply of N95 filtering facepiece respirators (FFRs) were available to Healthcare personnel (HCP). UTMB Healthcare Leadership reached out to the EHS Biosafety Program and Galveston National Laboratory (GNL) to assist with researching potential decontamination methods that would be suitable for the reuse of N95 FFRs for HCP. Collaboratively, the team set out to test and validate two different decontamination methods: moist heat and vapor-phase hydrogen peroxide. The team successfully demonstrated by using stringent testing that, after multiple decontamination cycles, the N95 FFRs met acceptable Reprocessed 15,113 N95s with current 80% return rate performance standards. The decontamination systems were validated using both biological and chemical indicators, filtration efficiency, breathability, form fit testing, and strap integrity testing for each respirator model. The following N95 models were tested separately for each decontamination method: 3M 1805, 3M 1870/1870+, 3M 1860/1860S, Prestige Ameritech RP88020. For each study, the N95 FFRs were subjected to multiple decontamination cycles (of a single method) and then assessed to determine the decontamination point of failure. The validation studies concluded that the folded style FFRs (3M 1805, 3M 1870/1870+) can withstand moist-heat decontamination for several decontamination cycles. Overall, all N95 models tolerated vapor-phase hydrogen peroxide decontamination. The N95 reprocessing program was a collaborative multidisciplinary effort across the UTMB Enterprise. The reprocessing program was a collaborative effort amongst the UTMB Healthcare, Research, Environmental Health and Safety, and support services.

Nikki Ward, Sr. Safety Specialist, and EHS Consultants, Corrie Ntiforo and Malissa Mayer-Diaz, reprocessing used N95 masks

Drying reprocessed N95 masks

SERVICE HIGHLIGHTS MEDICAL WASTE ASSESSMENT & DISPOSAL MEDICAL WASTE

Anticipating regulatory requirements enhances the quality of facility management decisions. This experience not only had monetary value but affords experience for a more well-rounded professional staff. This value added service incorporated engineering controls, design, and formal DOT destruction testing to reduce the cost of medical waste processing.

The Environmental Protection Management Team worked jointly with Healthcare and Research Departments to provide for a safer and more cost-effective method to dispose of medical and red-bag research waste. In partnership with the BOF Utilities and Property Services, EPM developed a medical waste metrics dashboard and wrote a proposal for medical waste improvements for executive leadership.

Meagan Thibodaux Sr. Safety Specialist

Medical Waste Storage

EPM picking up used N95 masks from the campuses/ clinics and transporting to GNL for reprocessing

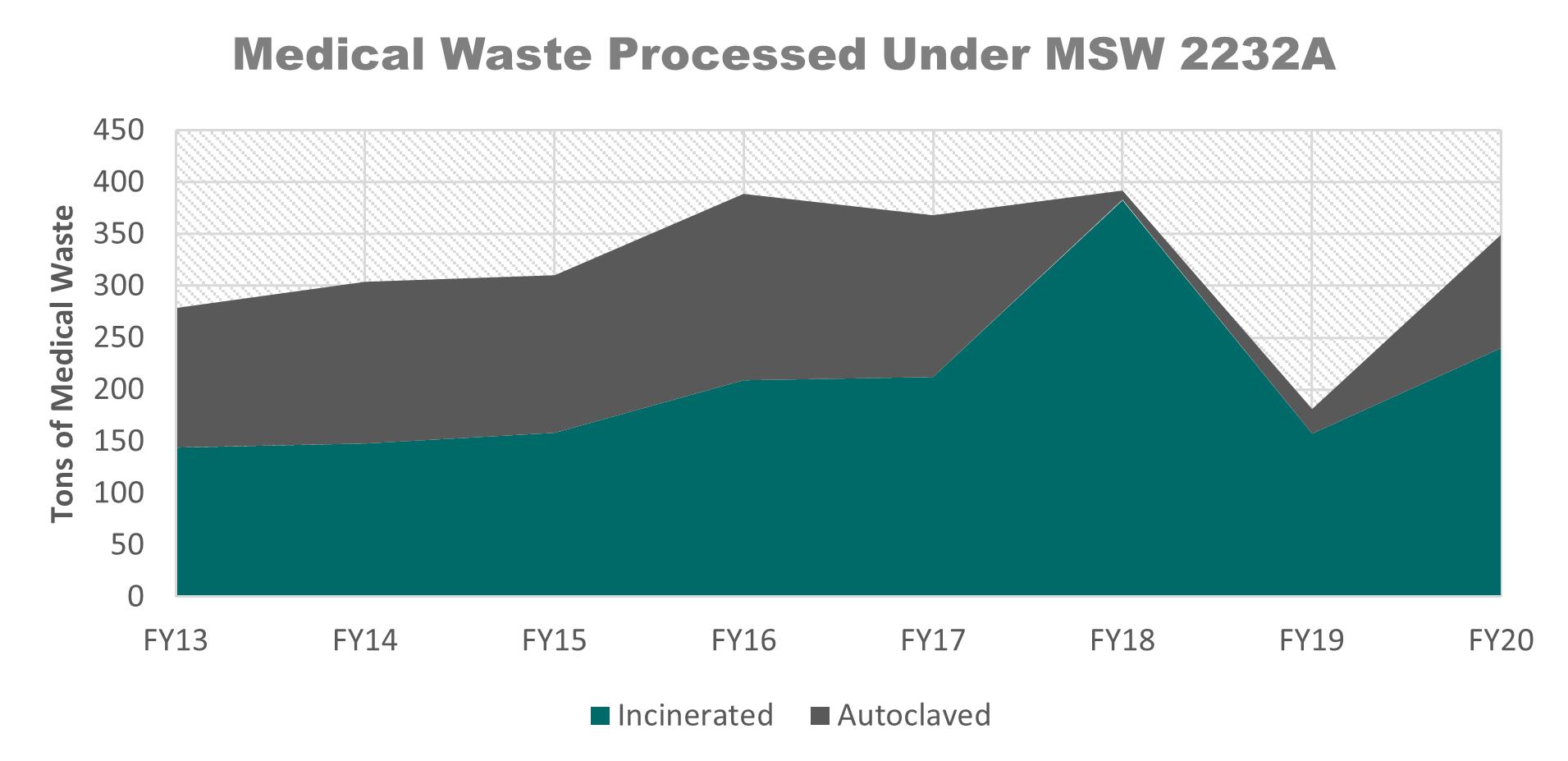

Trending of medical waste processed at UTMB Galveston Campus through incineration or autoclaving under the TCEQ Municipal Solid Waste Registration #2232A

SERVICE HIGHLIGHTS BIOLOGICAL SHIPPING

Biological Shipping Trends FY20

BSP oversees packaging, labeling, and documentation for biological materials shipments as well as, all international biological materials and Federally regulated select agents shipped from our campus. BSP works closely with the Office of Technology Transfer to provide support for shipping of biological material to collaborators and institutions around the world.

UTMB and the Galveston National Laboratory (GNL) was one of the first laboratories to receive patient sera and to isolate the virus for internal research and subsequent sharing through the World Reference Center for Emerging Viruses and Arboviruses (WRCEVA).

As of August 31, 2020, BSP has sent 237 shipments of SARs-CoV-2 virus and RNA, and one of the world’s first infectious clones all over the United States and the world.

Corrie Ntiforo EHS Consultant

Morgan Gerami Systems Analyst I

Relationships Count As the COVID-19 Healthcare Emergency (HCE) developed and UTMB adapted in response, EHS was tasked early on to assist in evaluating which spaces on campus would be both appropriate and safe for patient use. Several strategies were evaluated such as moving existing, non-COVID-19 patients into newly identified surge spaces, modifying larger areas such as the field house gym into an infirmary and also provide for some additional clinician sleep rooms for the extended shifts onsite. EHS met with Healthcare leadership, reviewed proposed changes and then started expedited discussions with the Texas State Fire Marshal. Within hours, we identified reasonable modifications of identified, contiguous spaces for these potential surge spaces. A written memorandum was also obtained to memorialize the discussion and logic behind the effort.

Changing Spaces Some changes included changing rooms into sleep rooms by a simple addition of smoke detectors and fire alarm strobes, planning for conversion of unused spaces and planning to convert non-healthcare spaces that once were used as healthcare. EHS was able to add several, fully compliant sleep rooms for clinicians in just a day or 2 – the other spaces were never called upon, however a significant pandemic surgeplan is now in-hand. Other areas, that were once used for healthcare but have not been for some time were identified, evaluated for good clinical workflow and support and then reviewed for safety compliance. Plans of action for conversion were developed. Areas identified were/are in various buildings within the Galveston campus Healthcare Core. All areas met Texas State Fire Marshal requirements upon execution of the plan.

League City South Tower Another repose to the surge demand crisis was the expedited delivery of the League City South Tower project. The expansion of the League City Campus hospital comes at a fortunate time, though the expansion of the pandemic came several months before the projected completion of the South Tower Project. It makes sense to expedite the completion as much as possible. The team was asked to expedite the project by 2 months, which in construction terms is “… not practicable”. The team embraced the challenge and succeeded, however as extraordinary times require extraordinary efforts from extraordinary people. The teams changed work/reporting protocols, put in the extra effort and the longer hours to ensure that work was completed. Other on-going efforts were put on hold and additional personnel resources were devoted to quality inspections, delivery coordination and final inspections. Additionally, old work-flows and protocols were dropped in favor of efficient direct-working relationships. The results were very time effective and ended up in the delivery of a Joint Commission-ready facility. The South Tower was delivered as requested in preparation for surge needs. Routine Facility Assessments As facilities were modified in response to the HCE, there was a distinct need to control access into the vulnerable facilities at UTMB. Control of personnel traffic into the facilities was severely curtailed for infection control purposes. These changes can have an effect on proper fire safety exiting from the building, however so EHS once again worked proactively with user groups and the UTMB Campus Police department to develop a safe solution that met the needs of the institution. Additionally, EHS maintained a higher vigil on these spaces, as well as the temporary tents by performing routine safety inspections to ensure conditions did not deteriorate.

SERVICE HIGHLIGHTS

EHS PHOTOS

10.

2.

4.

7.

9.

5. 11.

12.

Photos:

1. Training on PAPR assembly, donning, and doffing 2. JeT Newton training on PAPR assembly, donning, and doffing 3. Jim Stone training on PAPR assembly, donning, and doffing 4. EPM staff: Jordan Sweet and Meagan Thibodaux 5. EPM bulking hazardous chemical waste 6. EOC tours training nurses on controlled substance disposal 7. EPM preparing medical waste boxes for DOT testing standard 8. Lunch donated to EHS staff re:COVID-19 9. Triage tents at League City Campus 10. EHS Holiday Potluck & Pumpkin Carving Winners: Fire & Life Safety Team 11. BSP team ready and prepared 12. EPM team at the EHS Retreat at League City Campus (LCC) 13. EHS staff, in groups, working on projects during the EHS Retreat at LCC 14. Jack Tarpley, AVP, judging a team building project, while three (3) of the

EHS Program Directors await the winning team entry (De’Anne Meeh,

Sophie Brocard, and Chuck Carlisle) during the EHS Retreat at LCC

13. 14.

Satellite image of Hurricane Laura, category 4, August 26, 2020 Photo: Public Domain - the U.S. National Oceanic and Atmospheric Administration (NOAA)