5 minute read

ALSUP RD’S MAVERICK X3 XRS

ARD was born from a Can-Am racer seeking to design products to help them win races and play harder on the weekends. ARD works extensively with experienced engineers, providing quality products designed with integrity and safety in mind. The owner, Mitchell Alsup, strives every day to push the limits in the UTV industry as seen in his most recent Can-Am Pro Turbo racecar. Welded, wired and assembled by Mitchell personally, he understands the importance of quality workmanship, vehicle performance, and vehicle safety. ARD is just getting started and looking forward to expanding their current footprint in the UTV/ Off-Road industry.

We caught up with Mitchell and the ARD crew to get the story behind these new turn-key builds. Rumor is that Alsup Racing Development has already sold more than a few of these cars to fellow racers, so expect to see these amazing rigs lining up during the 2021 BITD/SCORE seasons and beyond.

Advertisement

Alsup Racing Development - 2021 Can-Am X3 BITD/SCORE Pro Turbo Race Car

CHASSIS

The ARD-built 4130 Chromoly chassis is fully tig welded and engineered by Tekk Consulting, providing a safe yet competitive platform. All components are laser cut, notched and CNC bent, and etched with corresponding part numbers for ease of assembly and repair. Factory UTV UHMW skid plates keep the belly pan protected.

SUSPENSION

Alsup X3 Race cars utilize their own OEM replacement 4130 tig-welded front control arms, trailing arms and radius rods. All components utilize only the best quality hardware from Rod End Supply. An ARD 12mm radius rod conversion kit is included, allowing easy radius rod adjustment for alignment changes and axle changes. Proprietary shock tuning is handled by UTVShocks, with extensive development done for this specific platform and geometry.

AXLES

Summer Brothers Racing 300mm shafts with ARD race-prepped C/Vs

WHEELS & TIRES

ARD Can-Am racecars utilize custom 15” KMC beadlock wheels wrapped in KENDA 32x10R15 Klever X/T steel belted 8 ply tires.

DATA/ENGINE MANAGEMENT

An AIM PDM32 ECU paired with a large 10 inch display and Blink Marine 8 button keypad controls most of the engine and body control functions. An AIM-constructed wiring harness with over 20 data points is also installed, including front/rear CV temps, front diff temp, fuel pressure, fuel temp, tire pressure, CVT temp, etc. Proper data management is critical in racing environments, and ARD is striving

to use cutting-edge technology to keep their cars at the front of the pack.

FUEL

34 gallon Pyrotect fuel cell with quick-fill dry-break

CLUTCHES

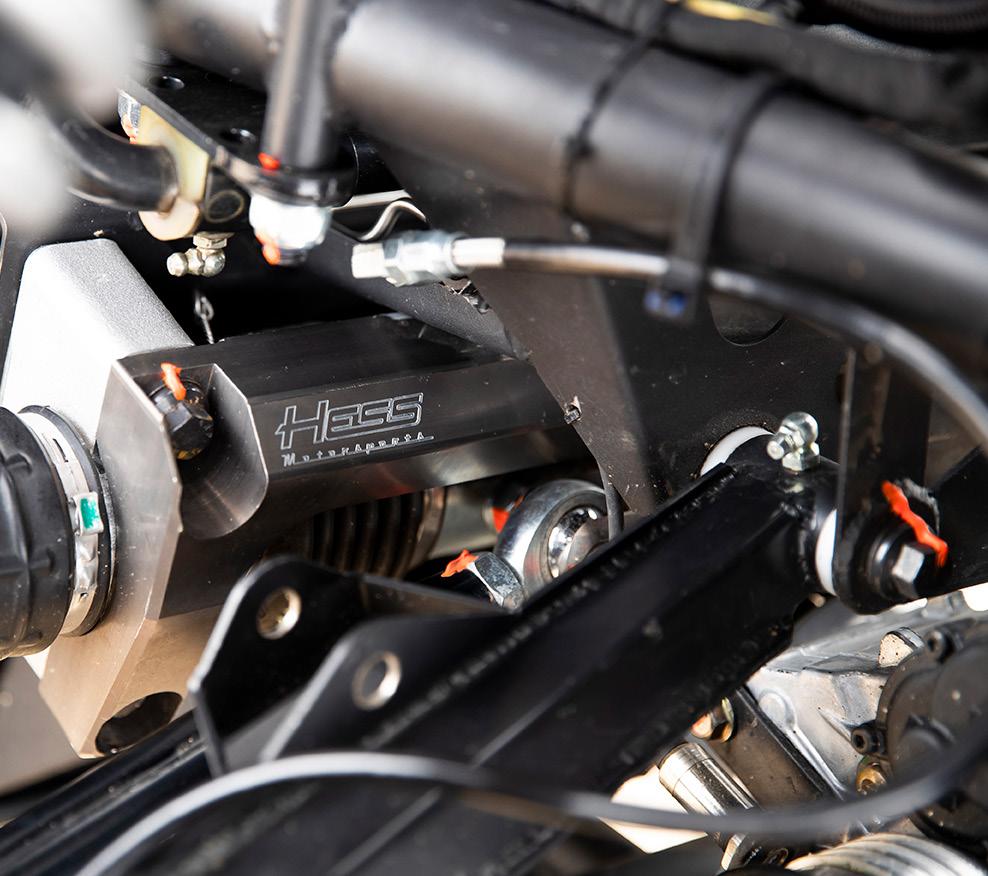

ARD uses a KWI “Float” modded clutch with extensive custom calibration and G-Boost highperformance CVT belt. KWI machines the clutches and modifies the sheave angles to provide better belt alignment, less belt chatter, lower belt temps and more horsepower throughput to the rear wheels.

ENGINE TUNING

Whalen Speed (That’s all ARD would share!)

LIGHTING

Baja Designs XL80 forward-facing driving lights, ONX6 Laser light bar, LED dome lights, LED rock lights

INTAKE

Plug and Play UMP Can-Am air filtration kit

COOLING

Oversized Triton radiator and oil cooler, mounted behind the cab with custom lines and reservoirs

JACK SYSTEM

Trayco Mickster Racejack- 3,300 lb lifting capacity with ¾” socket drive

MISCELLANEOUS

ARD Can-Am race cars are all equipped with ZRP (Zollinger Racing Products) alternator kit, tie-rod kit, wheel studs, water pump cover, oil cooler adapter plate and of course the double sheer front/rear knuckles. Extensive R&D has gone into all ZRP components to be the strongest available.

VEHICLE ASSEMBLY

ARD Turn-Key Can-am race cars are constructed in-house, from welding to wiring to plumbing. Products used during assembly have been proven over years of testing and development by the ARD staff and accompanying partners. All customers are fitted to the vehicle during the vehicle build, including steering angle, pedal adjustment, seat placement and safety harness placement. ARD turn-key race cars go through a final systems test and field test with Mitchell Alsup (owner of ARD) and Chris Blais of Blais Racing Services to ensure customers are receiving the highest quality and most competitive vehicle on the market. From data management set-up, clutch tuning, light adjustment, tire testing, and complete suspension set-up, the vehicle undergoes a true point to point field test prior to entering its first event.

CONTACT

Alsup Racing Development www.alsuprd.com 661-487-2303 info@alsuprd.com

SUBSCRIBE ONLINE FOR YOUR TO UTV OFF-ROAD MAGAZINE WWW.UTVOFFROADMAG.COM FREE DIGITAL SUBSCRIPTION!

SUBSCRIBE ONLINE AT UTVOFFROADMAG.COM AND HAVE THE LATEST ISSUE SENT DIRECTLY TO YOUR PHONE, TABLET OR COMPUTER.

A behind the scenes look at a multitime SCORE champion’s newest race rig

STORY: STAFF OF UTV OFF-ROAD MAGAZINE PHOTOS: DANIEL CURIEL & GET SOME PHOTO

WES MILLER’S BAJA 1000 WINNING POLARIS RZR XP

WES MILLER’S BAJA 1000 WINNING POLARIS RZR XP UTV OFF-ROAD MAGAZINE 51