portfolio Vanessa Shimada

contents

03 01 02 03 04 05 06 07

Cheer Flower Farm Domino Aquaponics Factory In-Situ Concrete Housing

Green Link

What

The

The C Chair The Musical Playground

Experimental Glass Lamp

What Cheer Flower Farm

Rhode Island School of Design

Integrated Building Systems

Team: Jamie Dunlap and Anthony Kershaw

Revit, AutoCad, Rhinoceros, VRay, Illustrator, Photoshop

We were tasked to transform the What Cheer Flower Farm in Olneyville, Providence RI. Beyond expanding the flower farming space, the project included a new building with spaces for processing, events, administration and for a Floral Academy.

We we assigned a central circulation system and timber structural system to be included in our design. The project incorporates a greenhouse as part of the enclosure. Since the soil of the site is contaminated from previous activity, the facade expands the planting space with close proximity to the classrooms of the Floral Academy.

The project acts as a welcoming host to both those enrolled in its program and those simply visiting. The materiality and shape of the building allows it to fit in with the surrounding context while looking inviting to visitors.

04

05

The building sits in the Northeast corner of the site and it opens up to the rest of the site where most of the flower farming happens.

06

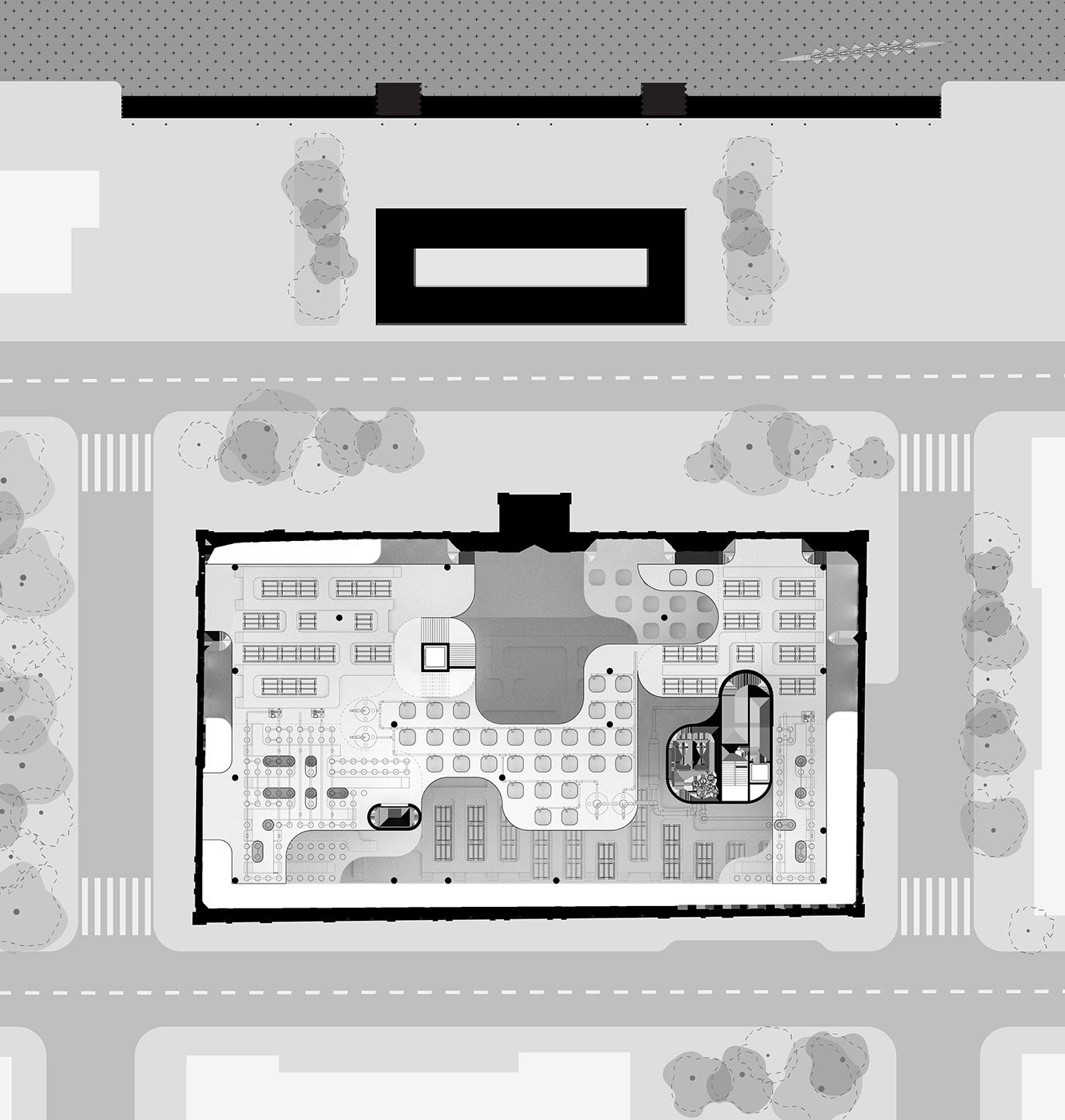

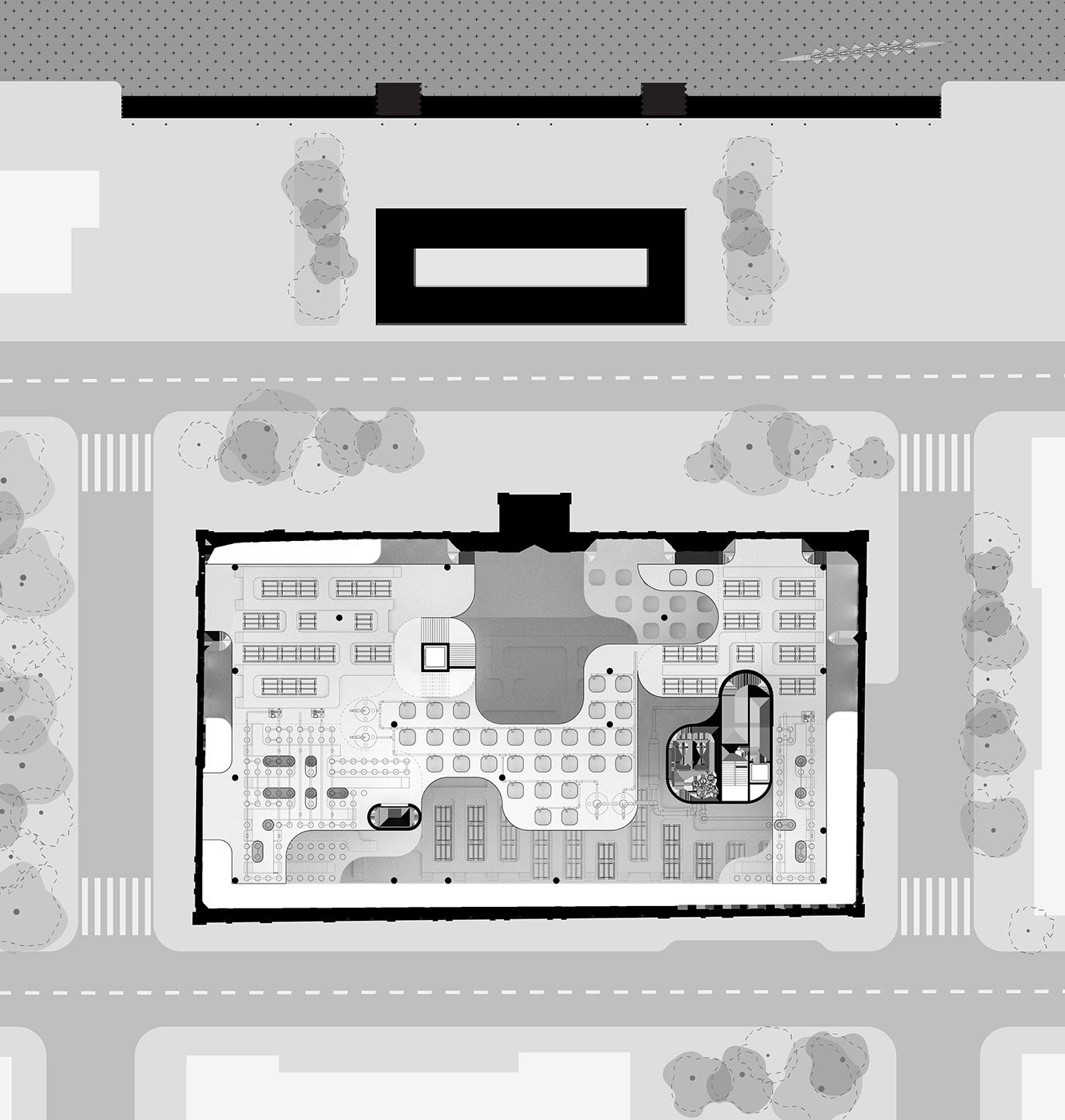

Ground Floor Plan

The courtyard and the open space in the ground floor provide space for community events. The timber structure is organized in a 20’x20’ grid, with 12”x12” thick columns.

07 01 02 03 04 05 06 07 04.5 07.5 08 09 10 A B C D E F 61’ 41’ 57’ 33’ 43'-0 7/8" 66'-11 1/8" 74'-1 3/4" 184'-1 5/8" 44'-1 5/8" 60' 20' 150'-11 1/8" 13'-2 1/2" 60' 40'-0 1/4" 103'-9" 184'-1 5/8" 104'-1 5/8" UP UP refuse 400 sf compost 400 sf stem processing (double height) 3,000 sf storage 3,000 sf lobby 1,500 sf reception 400 sf meeting 400 sf utility 200 sf utility 200 sf 68.6’

Translucent cover for seed starting

Black Water JugThermal Mass

Cross Tensioning

Framing

Uncovered shelving for plants needing direct sunlightcertain vegetables catering to the cafe

PV

Third

Perforated Metal Flooring

08

T.O.

Floor Slab 24’ - 0” T.O. Roof Slab 36’ - 0”

Wall R Value:

2 x

Wood

Double Pane Window R: 7.0

34.79

6 Light

Framing

2” Window

Brick

Brick Shelf

Light-Steel

Single-Pane Glass R: 3.0

Frame

Tie

7-Ply Cross Laminated Timber Semitransparent

3/4” Plywood SheathingR: 0.93 Air

Jamb Sash Gas Fill Low-E Coating Sill Spacer Stop Stool 2 x 6 Wood Frame 24” O.C. 10-M24 Bolt Glu-lam

Steel

Continuous Rigid Insulation- Mineral Wool R:10 Mineral Wool Insulation R: 22.66 3/4” Gypsum Board R: 22.66 Reclaimed Brick Sheathing R: 0.525

Space

Structure

Plate

Weather Barrier

Fan

In the facade around the courtyard facing South, the enclosure includes a double skin facade that acts as a greenhouse. The greenhouse expands the farming space and it allows for farming opportunities in the colder months. It has its own structural and circulation systems.

09

Facade Components

10

The greenhouse has its own structural and circulation systems that complements the rest of the building and provides openness and visual connection to the courtyard and the rest of the site.

11

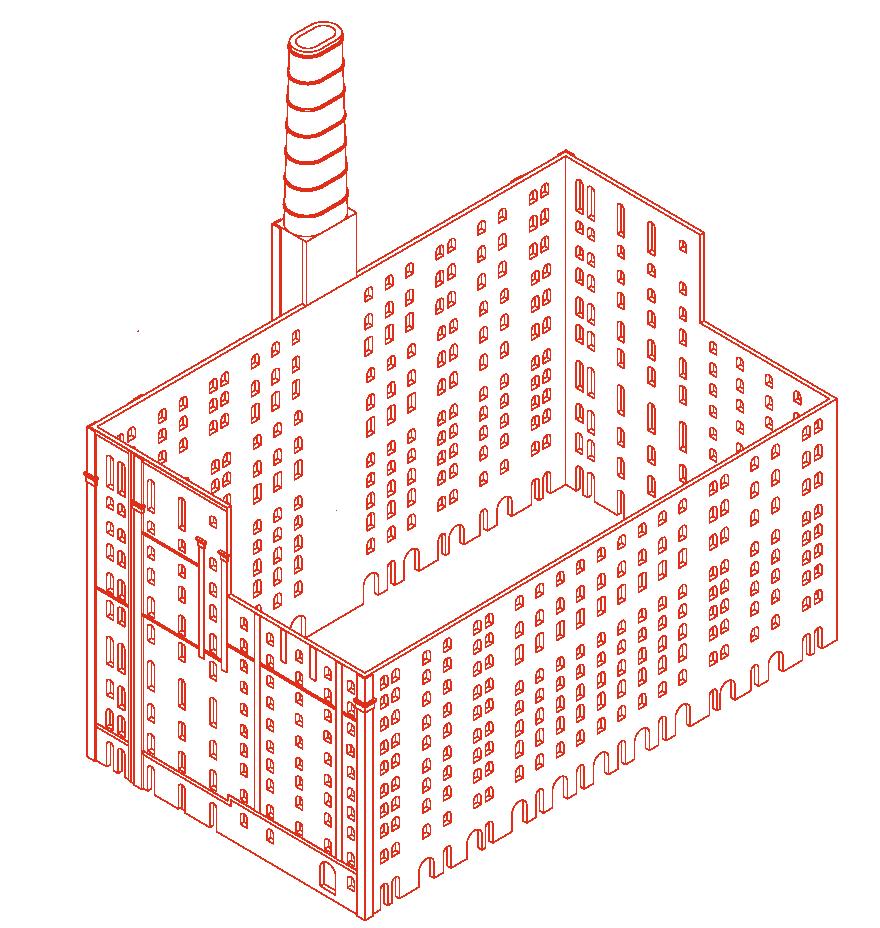

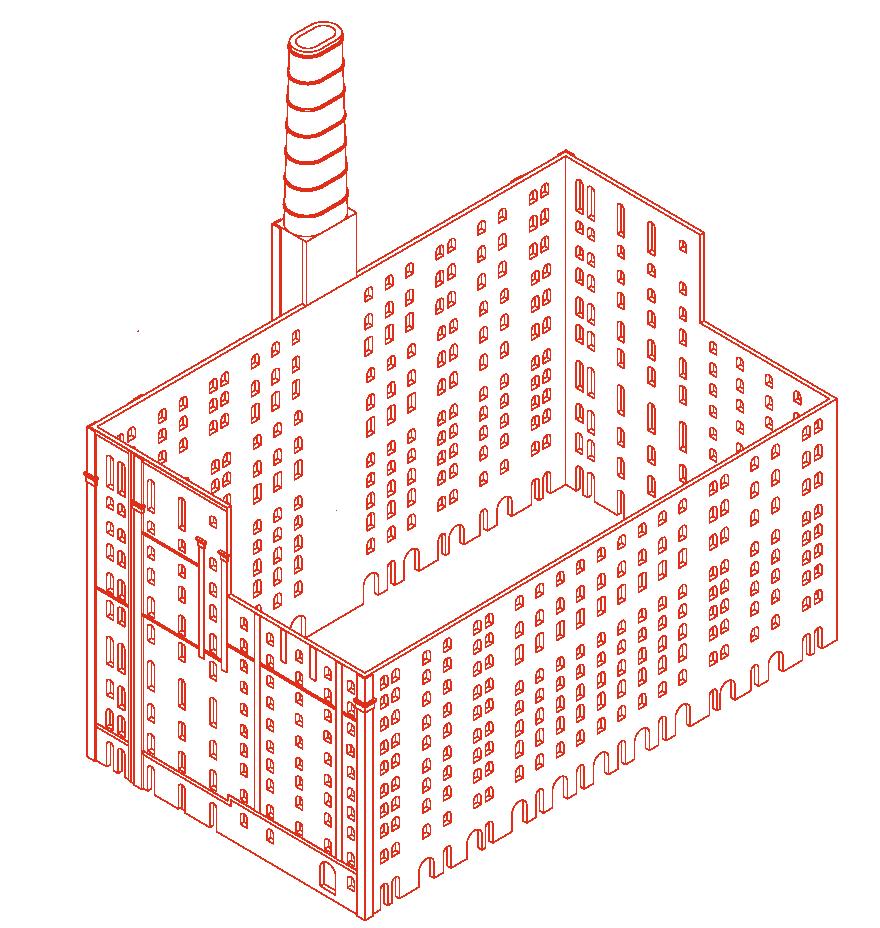

Domino Aquaponics Factory

Rhode Island School of Design

Studio Super-Absorbed

Team: Yuqi Tang, Yizhou (Viola) Tan

Rhinoceros, VRay, Pix2Pix, Dall-e, Illustrator, Photoshop

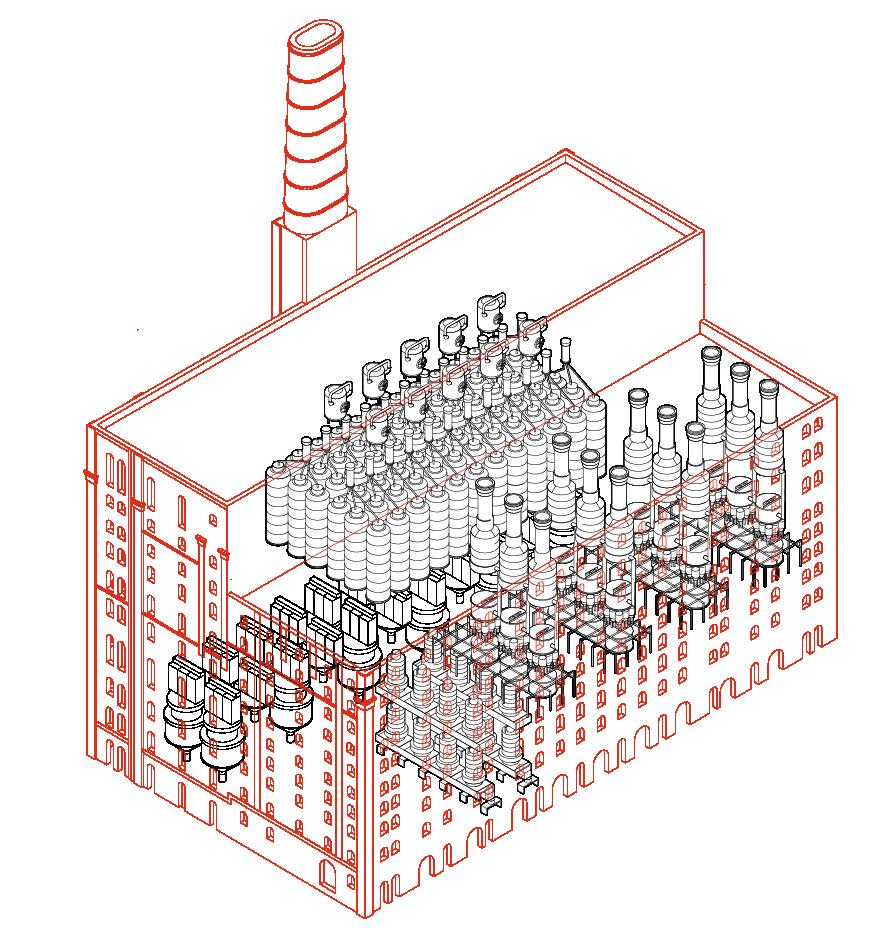

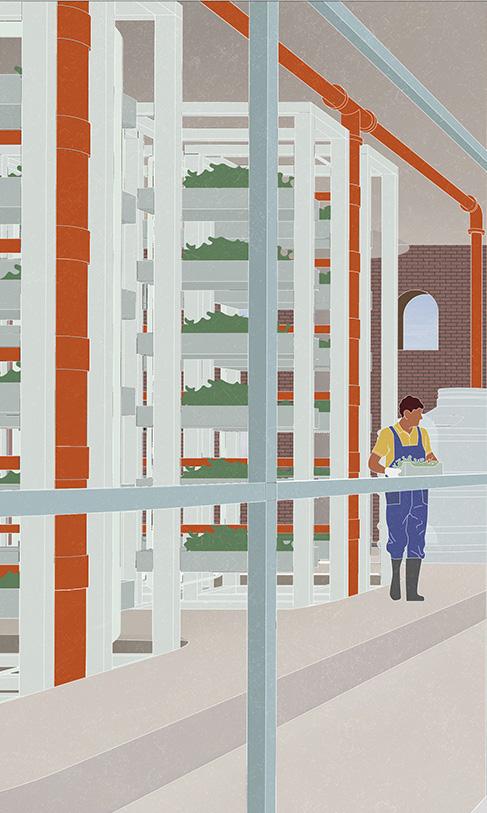

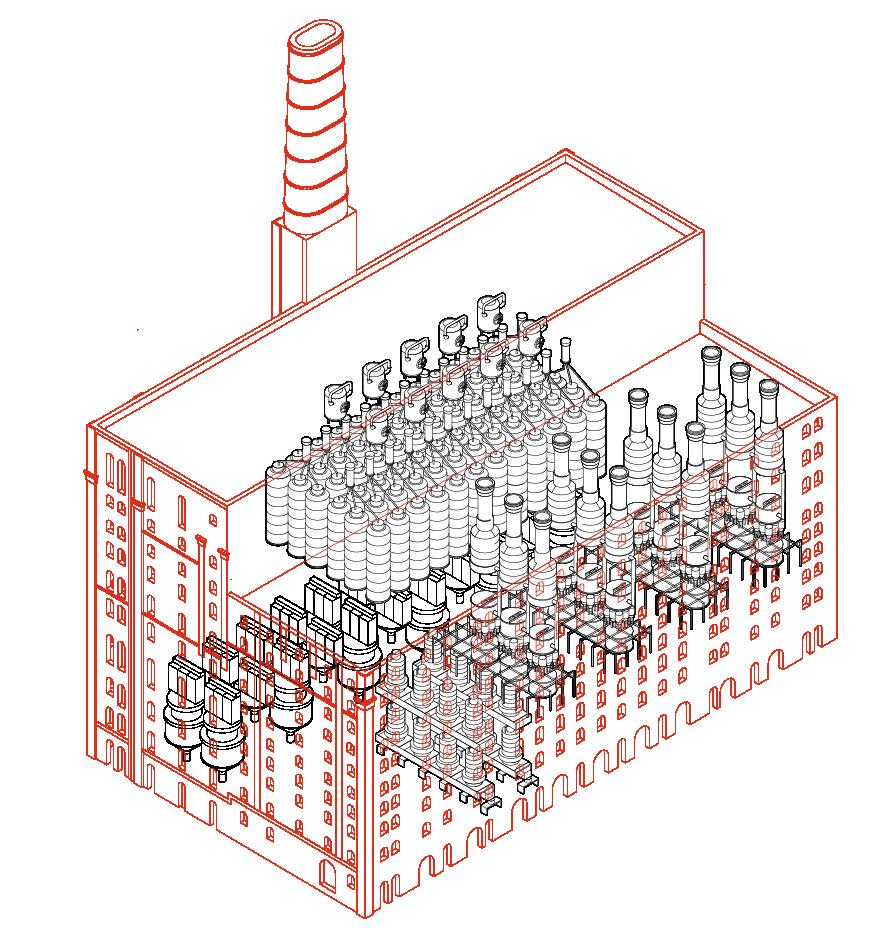

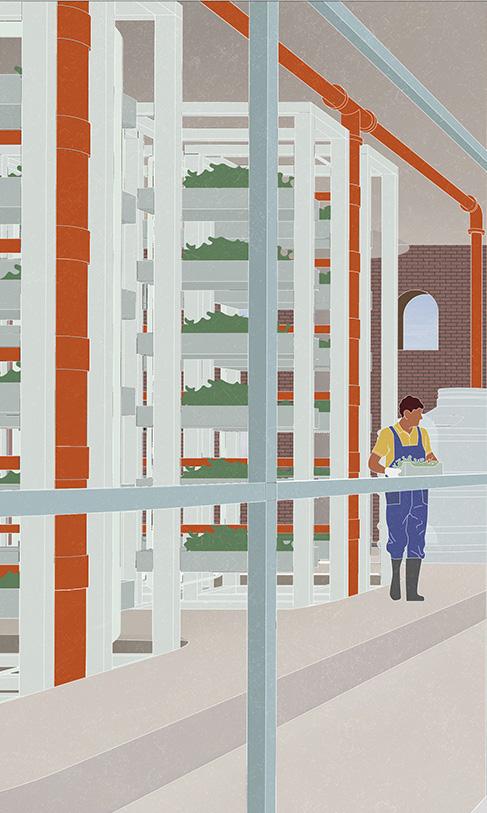

We were tasked with imagining how architecture can absorb machine functions and turn them into physical elements, while acknowledging the value of industrial heritage and computational processes. The Domino Aquaponics Factory acts as a machine for aquaponics production. Aquaponics is a food production system that combines aquaculture (growing aquatic animals) and hydroponics (growing plants without soil). It fits in the larger urban system by supporting the community through providing healthy food options year round, providing vocational training, and supporting the community and local gardens with composting services.

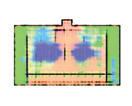

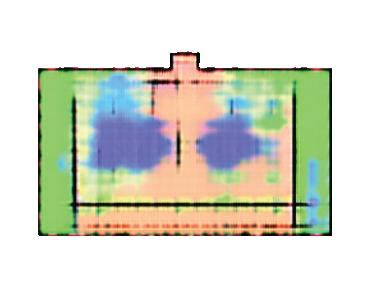

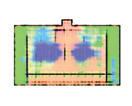

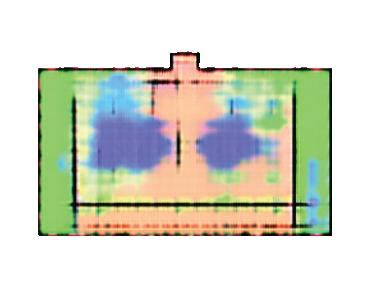

Machine Learning (AI) was one of the main driving factors in our design process. A generative adversarial network (GAN,) called pix2pix, was used to arrange the program partition in plans and produce diagrammatic sections. The program arrangement training results were then arranged in 6 floors that align with the facade. The section training results were organized in a grid and then used to regulate the columns placement

The blurred fuzziness in the training results allowed for organic floor plates that respond to the site context and assembly cycle of the factory while still maintaining the openness that draws the public in and allows it to function like a machine.

12

13

14

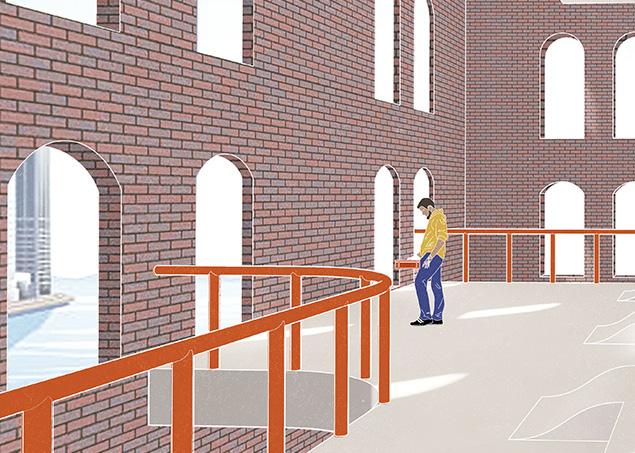

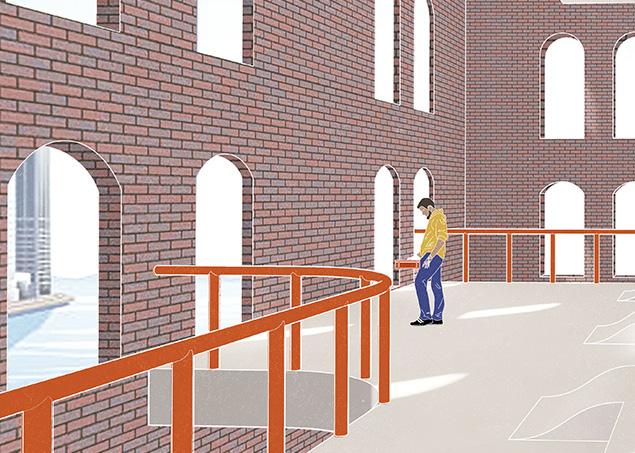

Before: Domino Sugar Refinery

During: Brick Shell

After: Domino Aquaponics Factory

15

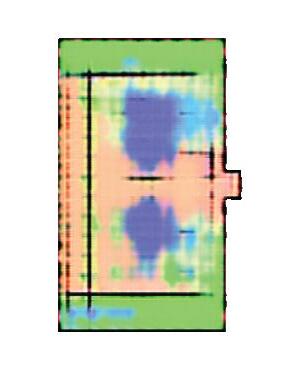

16 PIX2PIX PIX2PIX PIX2PIX PIX2PIX

2a. Public/Private Partition

2b. Production Area

1. Overall Program Partition

Processing Plants Fish Public Area Footprint Entry Apertures Ground Greenery Building Water Site Context Program Partition Public/Private Partition Program Partition Building Footprint Building Sections Floor Slabs Existing Aquaponics Factory Plans Urban Light Industry Building Plans Hand-Drawn Sections Aquaponics Factory Plans Dataset Dataset Dataset Dataset Public Area

3. Section

AI Process

Section

AquaponicsProgramPartition Public/PrivatePartition AI Interpretation

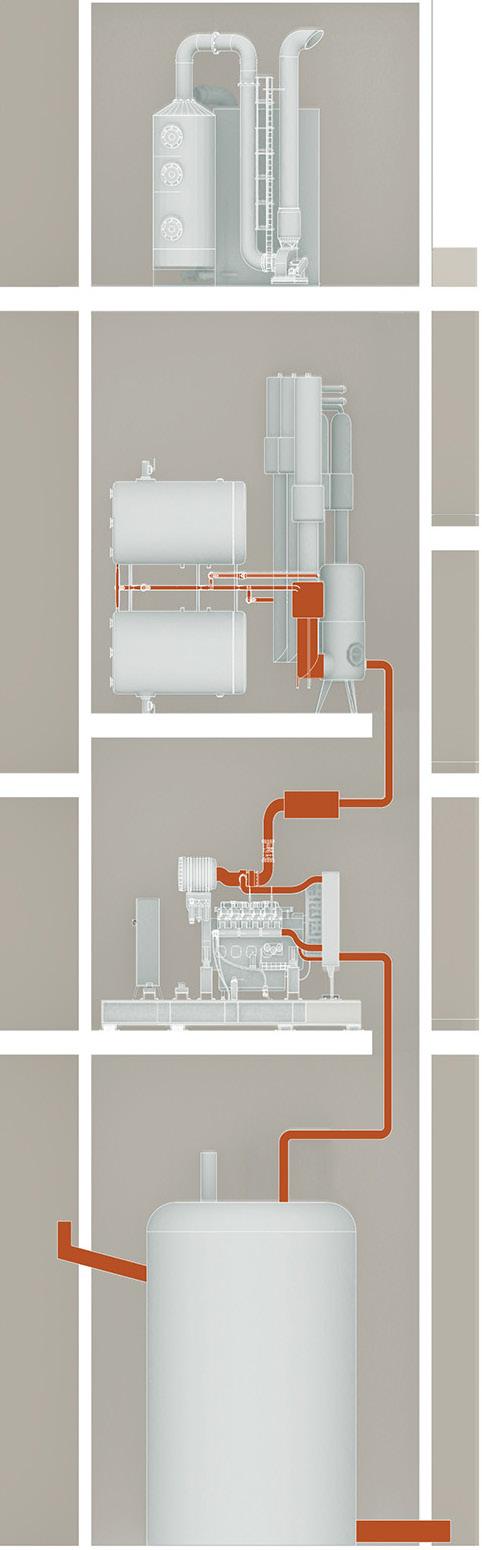

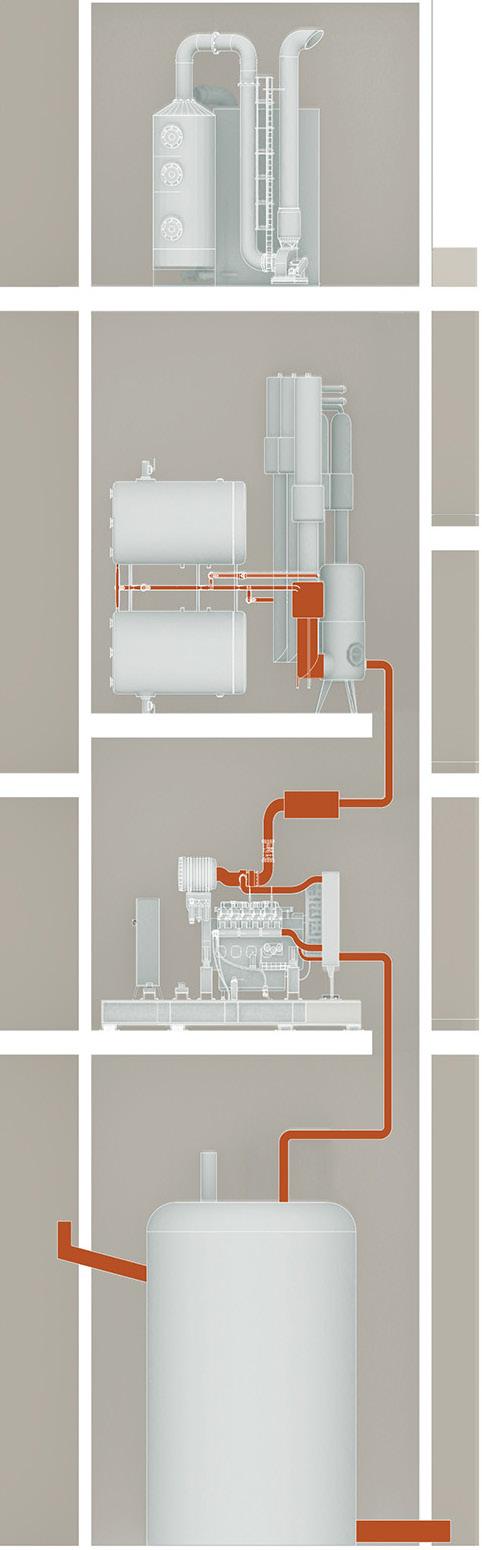

Germination

A temperature, environment

Public Market Space

Grow Trays

A vertical carousel system for harvesting. Used for growing fruit and bulb vegetables.

18

Germination Lab

temperature, oxygen and moisture-controlled environment for the seed germination process.

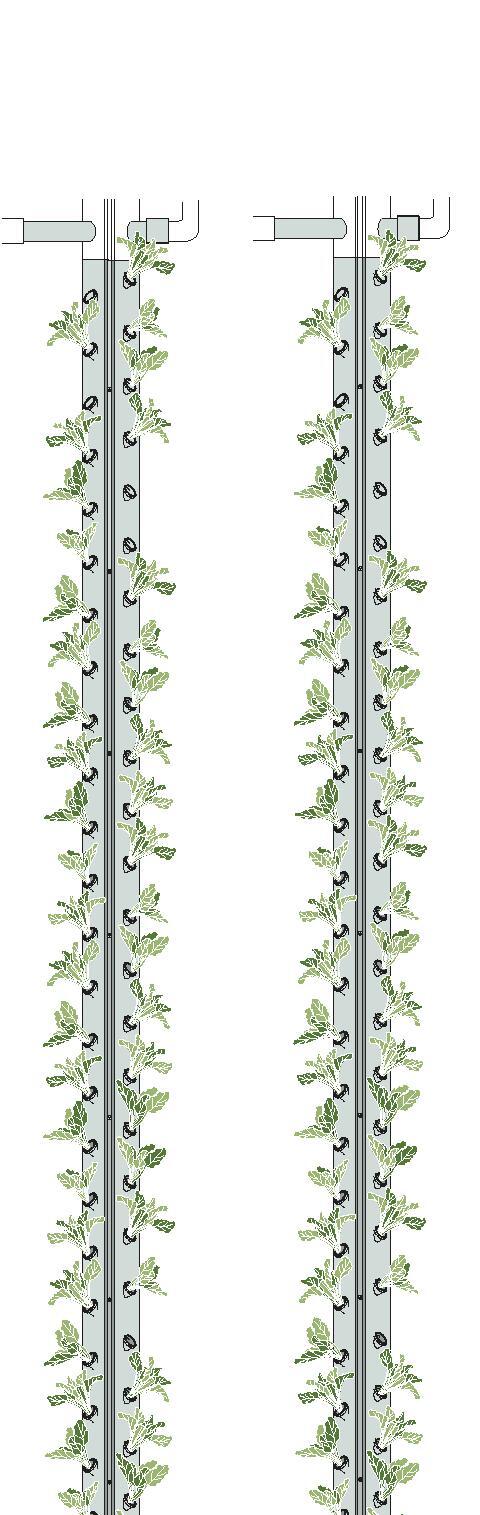

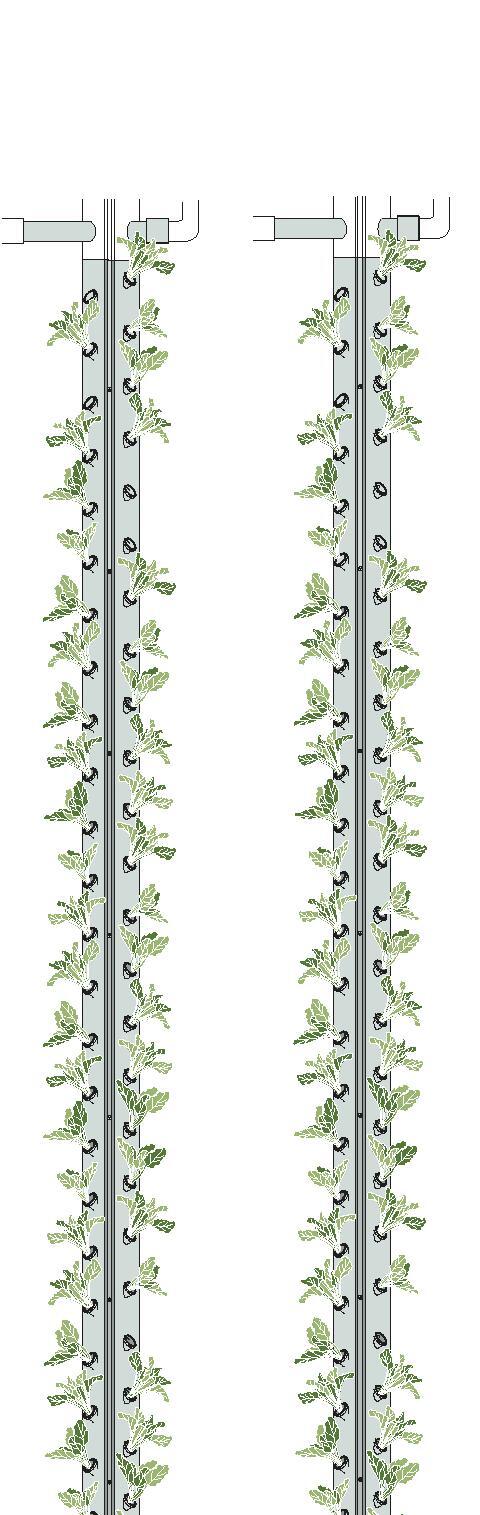

Vertical Farming Towers

Perforations along pipes to house crops. Used for growing leafy vegetables.

Machines

Combustion generator, bio filter, anaerobic digester and compost.

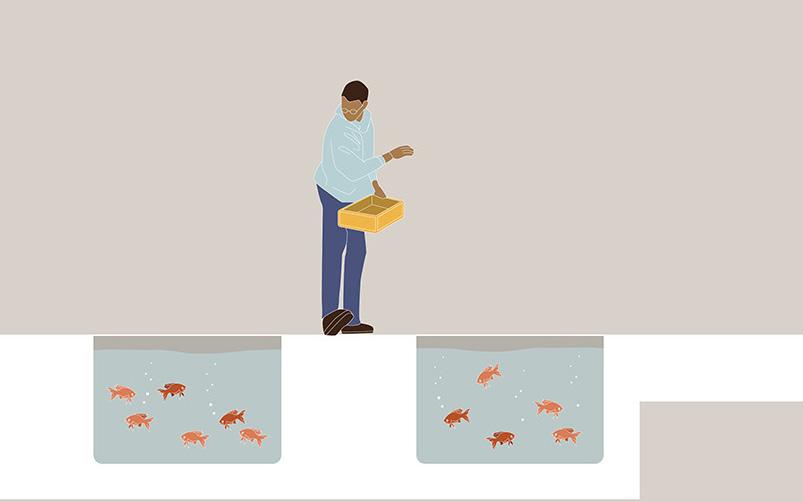

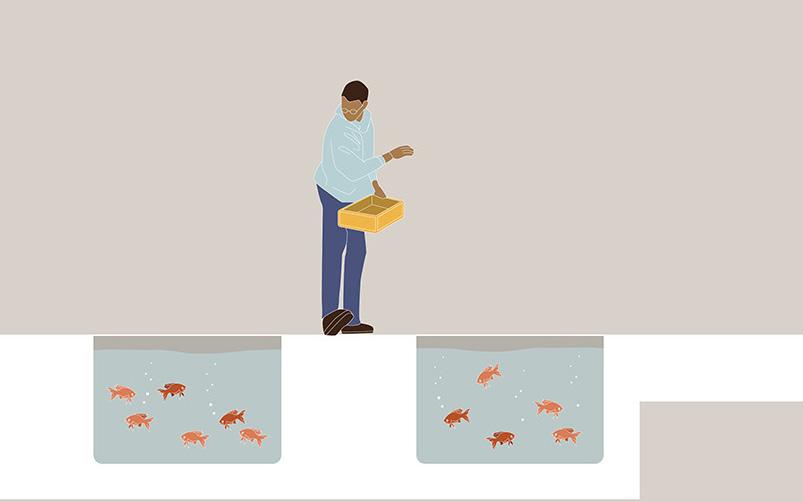

Aquaponics Fish Tanks

Connection to facade

Aquaponics Fish Tanks

Connection to facade

In-Situ Concrete Housing

University of Minnesota Studio To Build A Home Team: Faith Scamehorn Rhinoceros, Illustrator, Photoshop

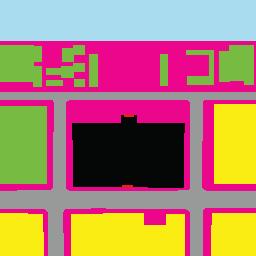

The Minneapolis 2040 Comprehensive Plan is a ambitious plan that addresses issues related to housing, climate change, racial inequality, public health and transit. Policy 35 of the Minneapolis 2040 Plan encourages, “Innovative Housing Types and creative housing programs (that) help meet existing and future housing needs.”

In response to that, we were tasked to develop ‘prototype’ houses that challenge the existing housing typologies and uses the opportunities and constraints of an assigned material system: in-situ concrete. We worked with different scales and throughout the semester we designed an accessory dwelling unit, a multifamily triplex and a mixed use cluster development. Each project taking inspiration from the previous one.

22

Triplex

Cluster Housing

ADU

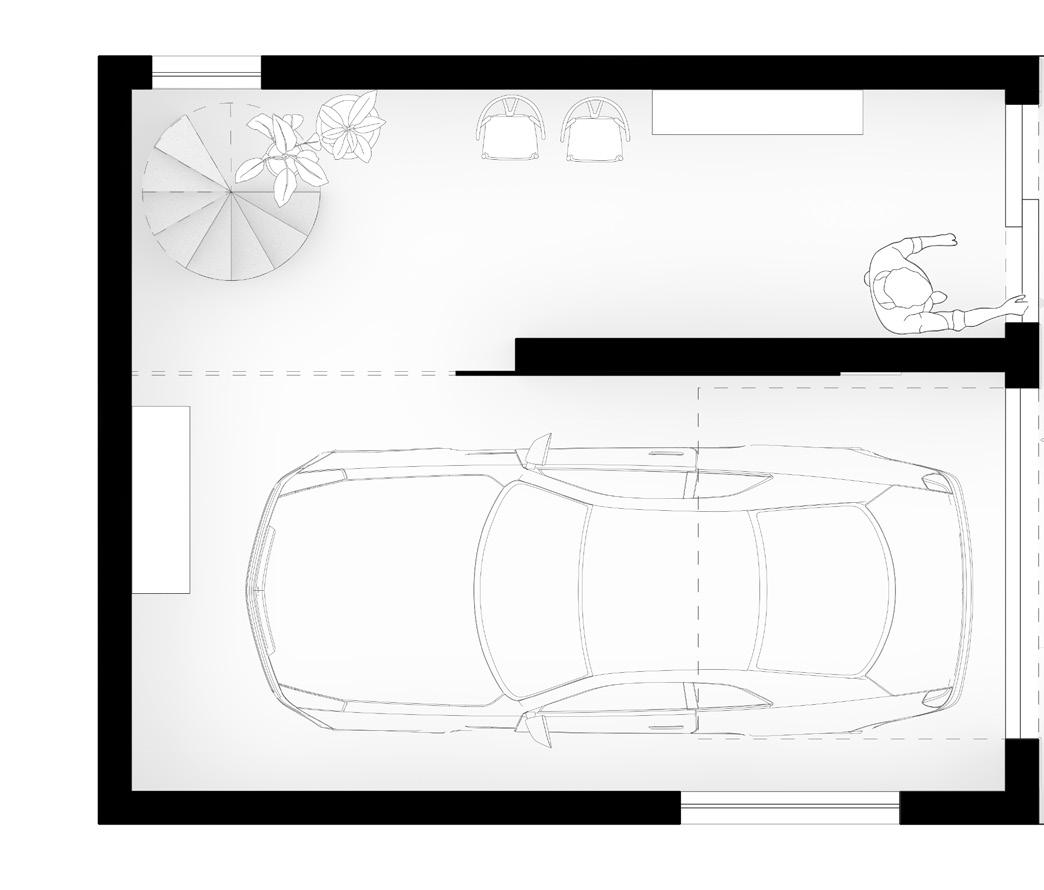

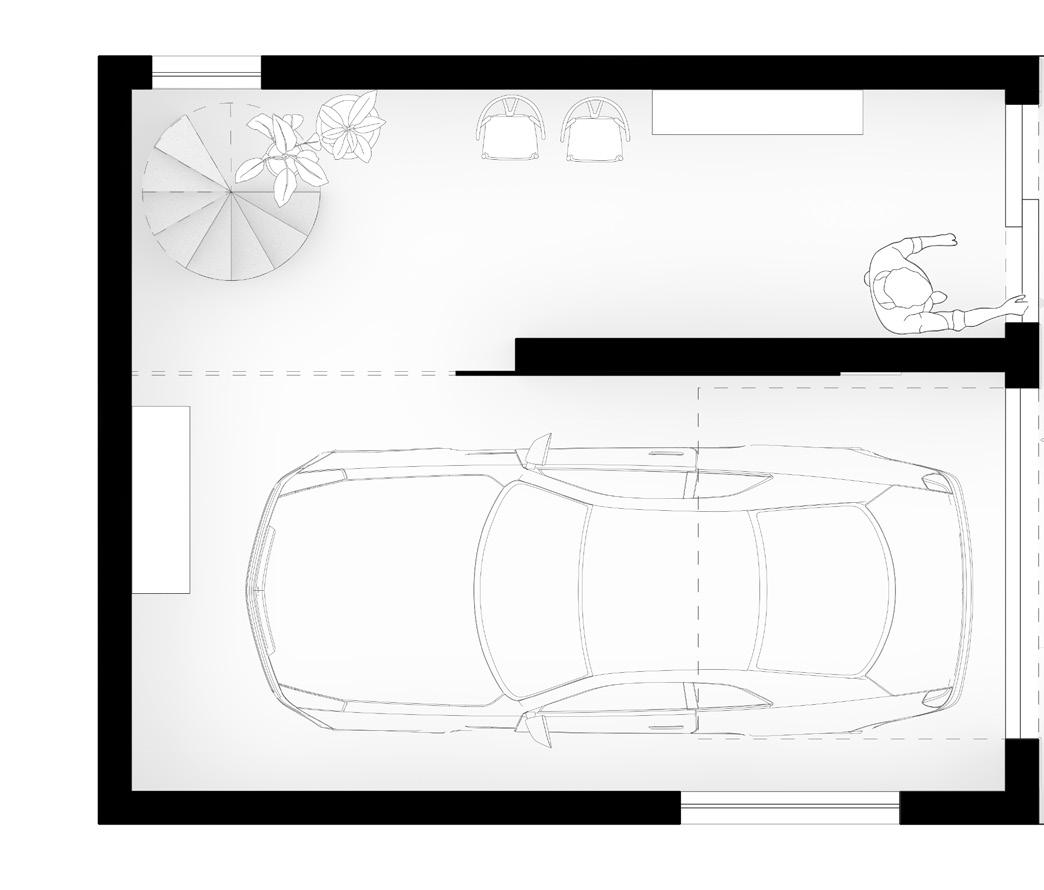

In-Situ ADU

This accessory dwelling unit uses stepped levels to establish spatial unity and visual interconnectedness, that creates an intimate and balanced interior to contrast with the stark concrete and harsh geometric exterior. Insitu concrete allows the structure to look monolithic. The small scale and sunken relationship with the ground makes the building approachable and allows it to fit into its surrounding context.

The capabilities of in situ concrete construction are highlighted in the design of the spiral staircase, stepped levels, large window opening, concrete furniture and various finishes that celebrate natural light.

24

25

26

27 -3ft 4ft 8in 5ft 10in 7ft 4in 12ft 8 in

1. Concrete

2. Insulation

3. Rebar

4. Plywood

5. Plastic formwork

6. Snap ties

1 2 3 4 3 1 5 1 2 3 1 7 1 2 3 1 3 1 2 3 1 2 5

7. Glass

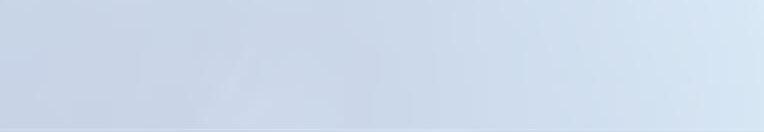

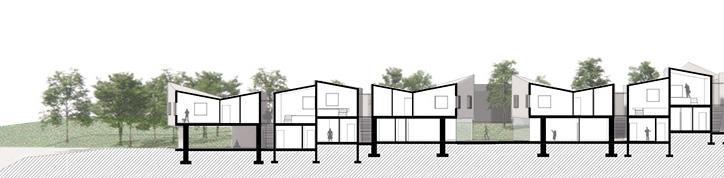

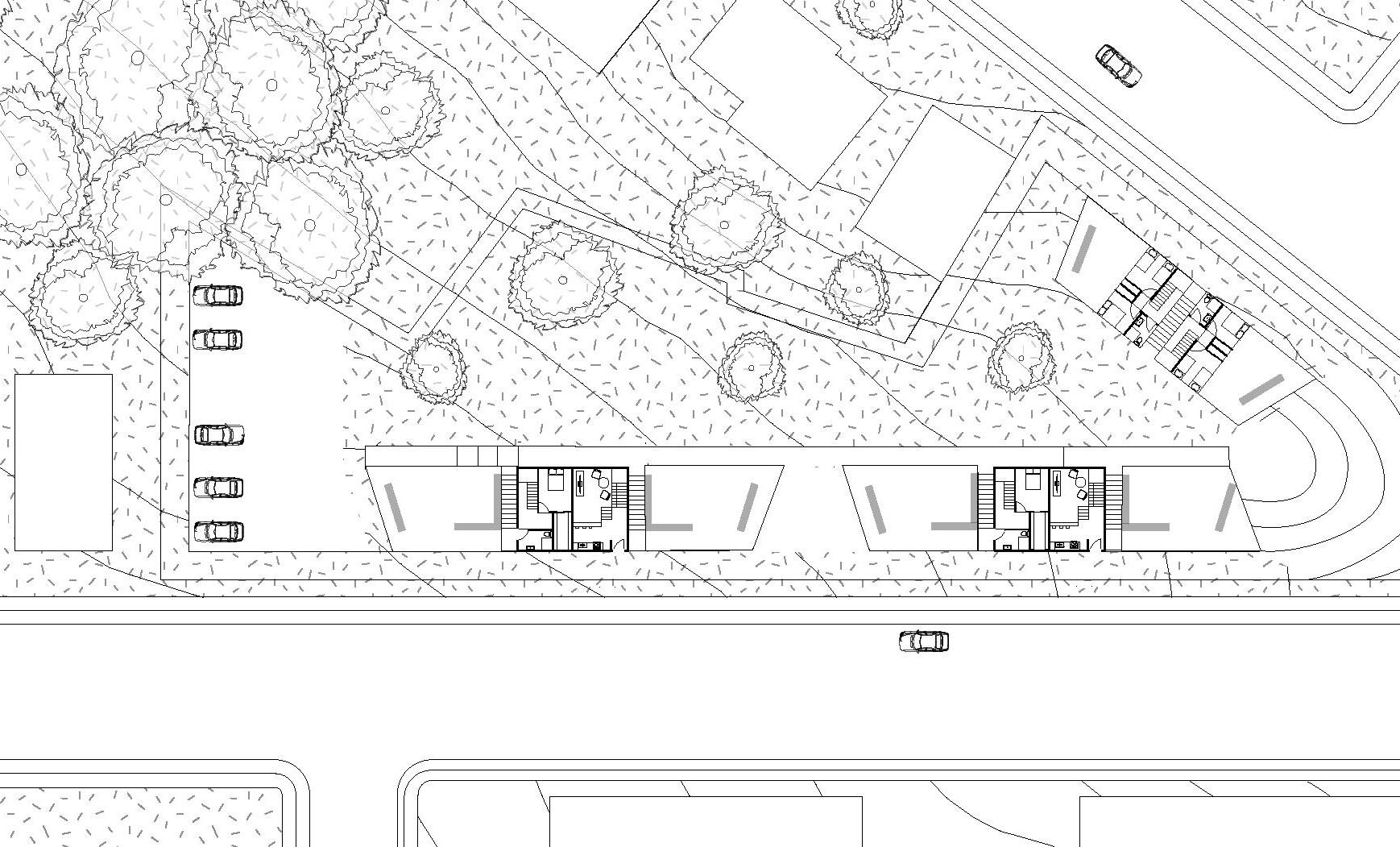

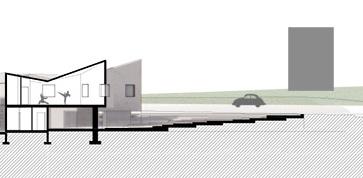

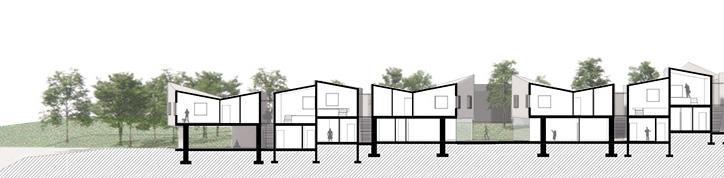

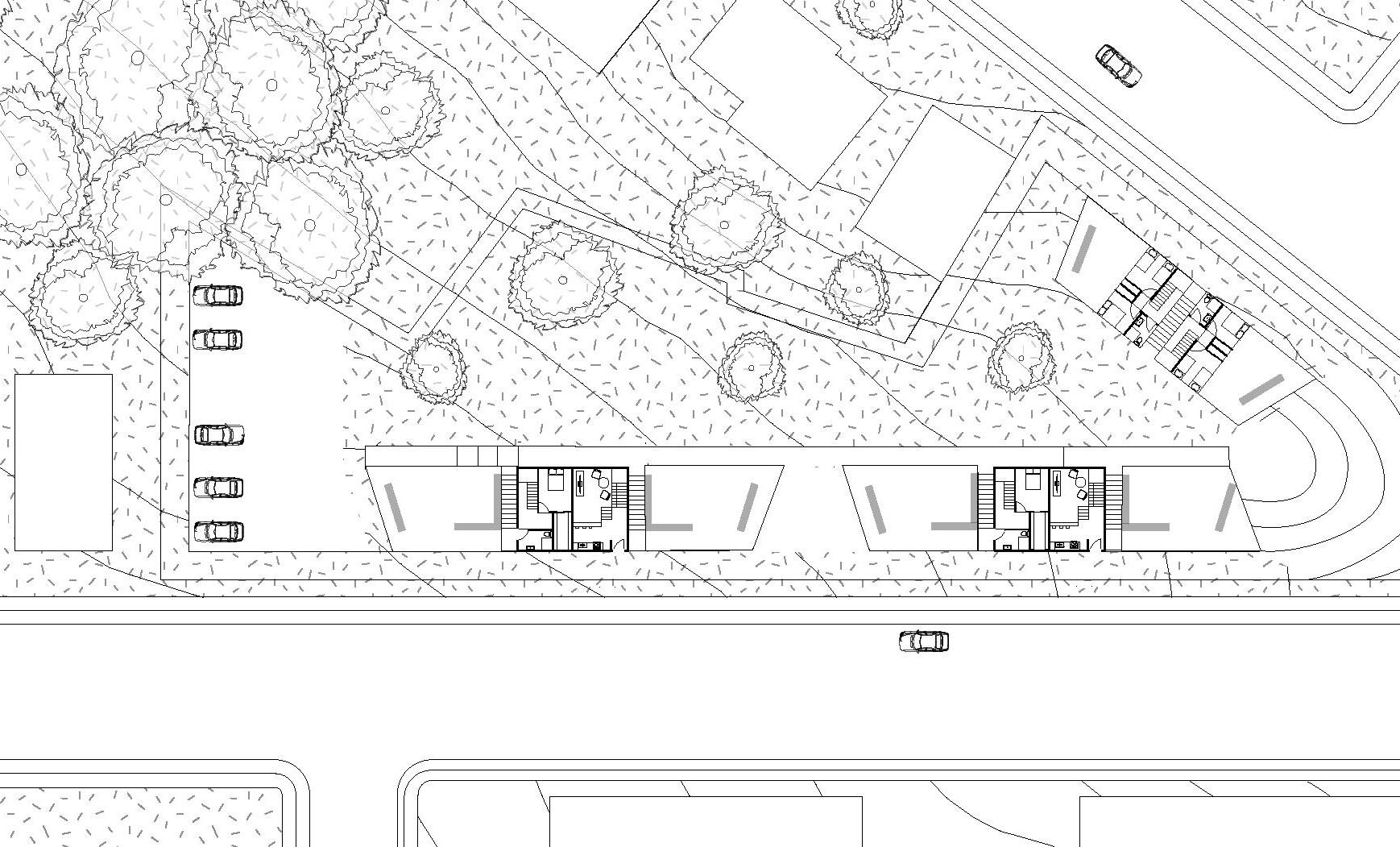

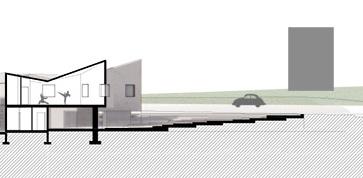

In-Situ Cluster House

The final translation of Minneapolis housing. A housing complex with 21 beds provides various types of units for a financially diverse community.

The In-Situ Cluster House uses variation and different scales for a welcoming environment. It connects to the site with its monolithic construction, and it has unique sloped roofs, stepped levels, and multiple finishes that work together to celebrate light and create an intimate experience . The complex design prioritizes the residents’ individual experiences, community development, and provides public spaces for a broader neighborhood, all while responding to the Minneapolis 2040 plan.

32

33

34

35

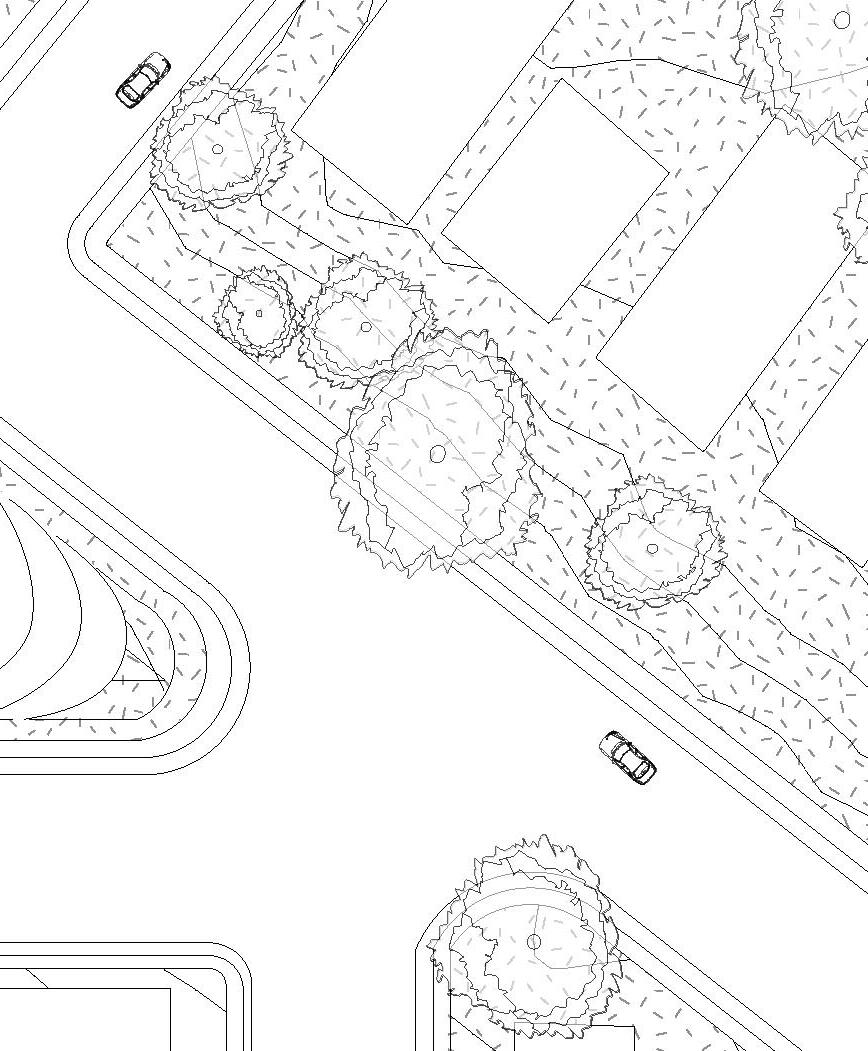

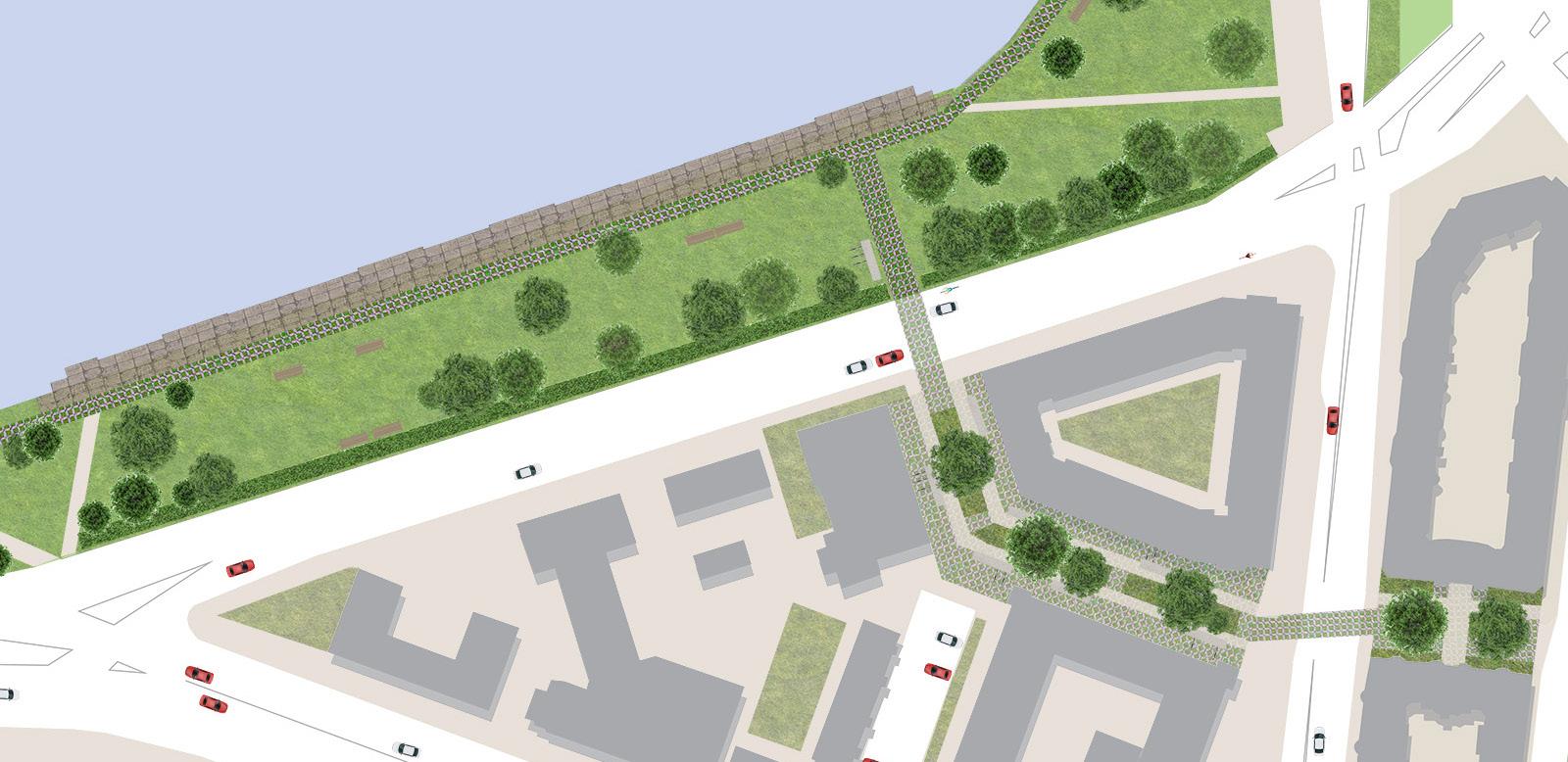

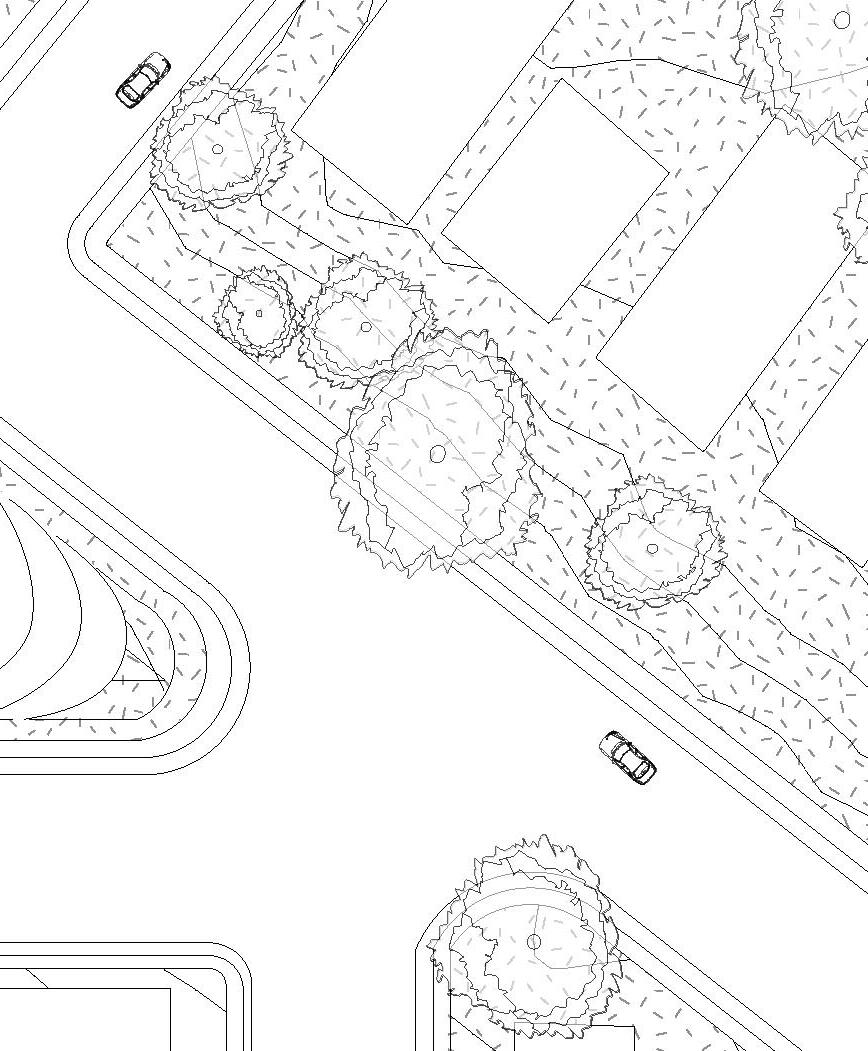

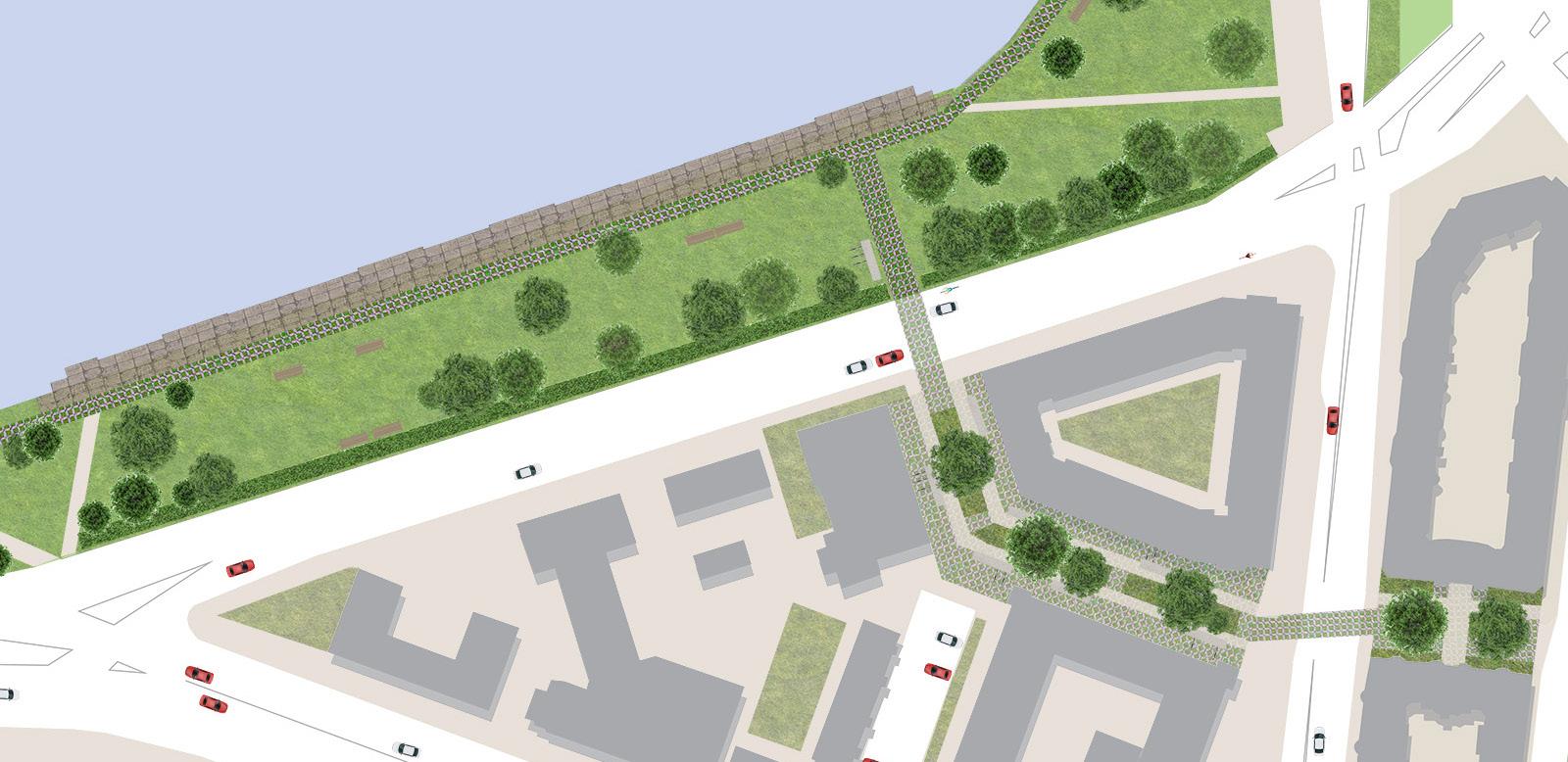

The Green Link

DIS Copenhagen Urban Design Studio

ArcGIS, Illustrator, Photoshop

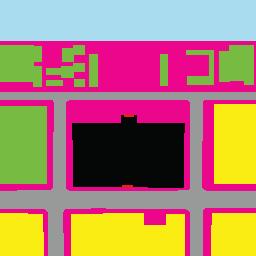

For this project, we had to design a ‘kvarterplan’ (a neighborhood plan) for the urban area around Mønten Kollegium to improve the conditions of the area. Our project had to address the question: “How can we design spaces for climate adaptation, social coherence and vibrancy?”

The Green Link is a master plan that improves the urban spatial qualities at the area surrounding the Mønten Kollegium, while also creating a link to the park and water and to the rest of the urban fabric. The final design implements a green urban and social strategy at the site, neighborhood and city scales The plan interacts with the environment through effective water management strategies, provides social green spaces to the neighborhood and provides necessary connections to the surroundings through elevated green crossings.

The site is located in a dense urban area but it is isolated from the rest of the urban fabric. It is a predominantly residential, it is surrounded by busy roads and the existing crossings are slow and out of the way. It lacks permeable spaces, therefore the site is at extremely high risk of flooding.

The Green Link adapts the environment to flooding risks and provides social interactions opportunities for the many residents and users of the area. It works at site, neighborhood and city scales.

36

37

Site Analysis

38 Residential buildings Vehicle traffic flow 20mm rainfall Old plan

39

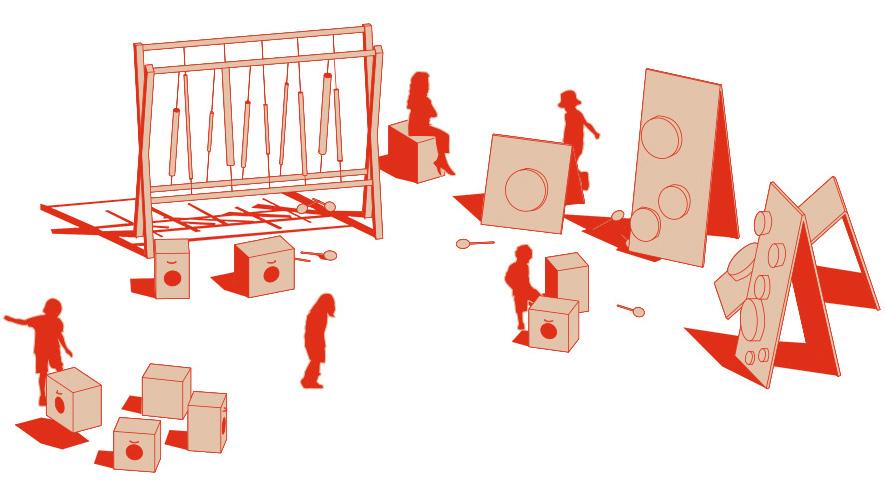

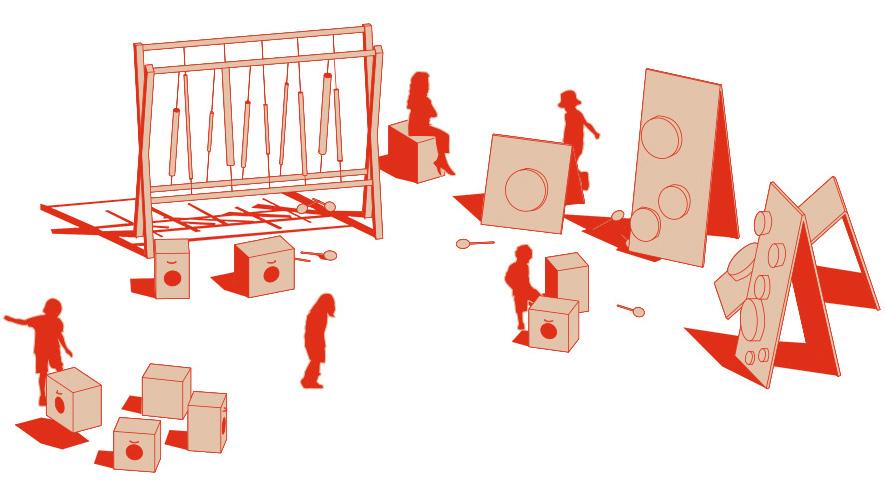

The Musical Playground

Freedom by Design

2018-2019

University of Minnesota

Client: Karner Blue Education Center

Freedom By Design is the service program of the American Institute of Architecture Students (AIAS) which uses the skills and talents of architecture students to foster accessible design through collaborative, community-based effort.

The Freedom By Design team worked with Karner Blue Education Center to create a Musical Playground. Karner Blue Education Center is a school that serves students in grades K-8 who have emotional behavioral disorders, autism spectrum disorders and developmental cognitive disabilities. Music Making has been studied to create improvements for those on the autism spectrum and with behavioral and cognitive disabilities, so the goal for this project was to have a positive impact on the children at the Karner Blue Education Center, while they play and make music.

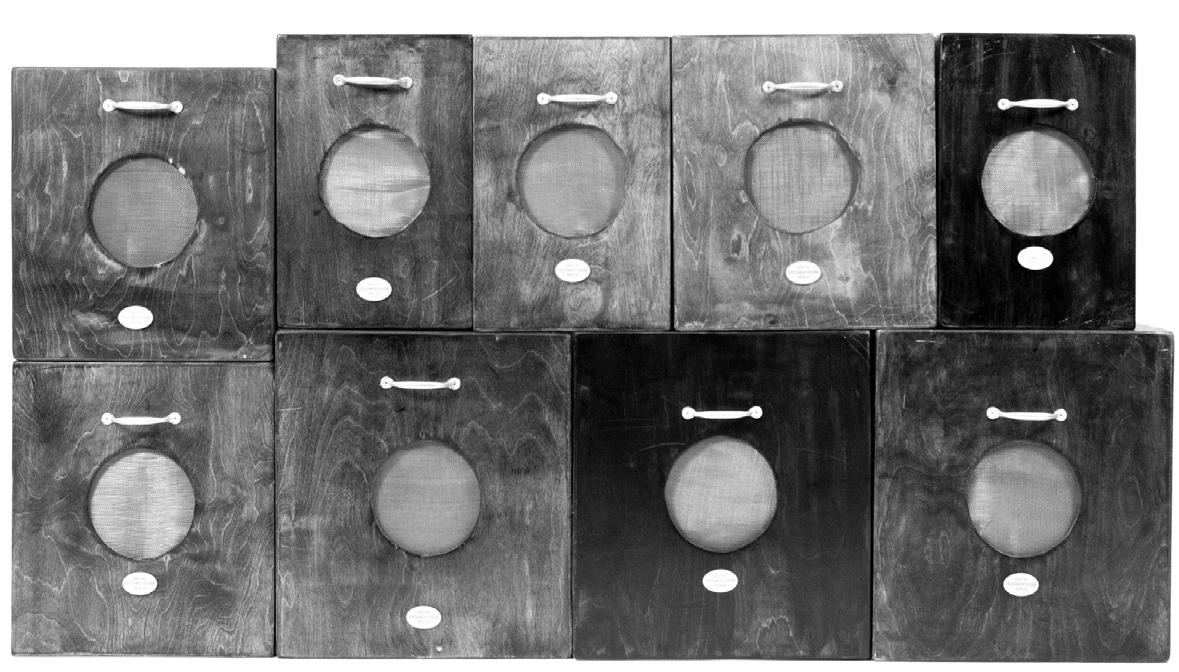

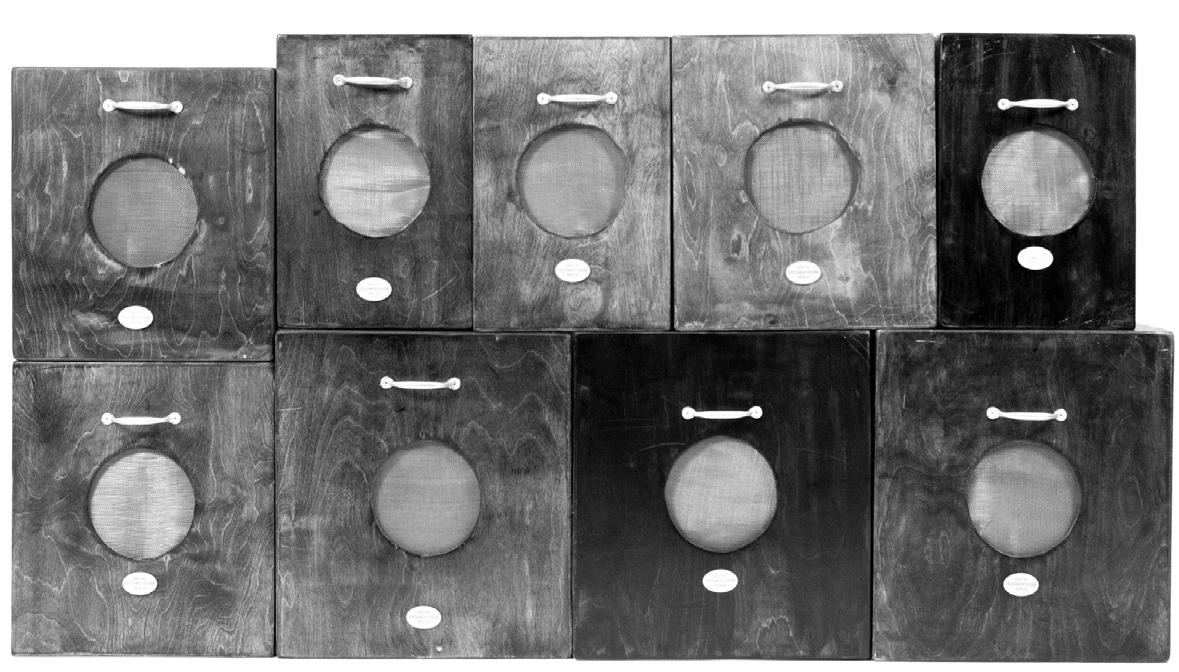

The playground is composed of three instruments. The Large Xylophone, the Drum Wall and the Cajón Drums. The instruments were designed to withstand the elements and wear-and- tear, to be safe for the use by the children and to accommodate children of all sizes from grades K-8.

42

43

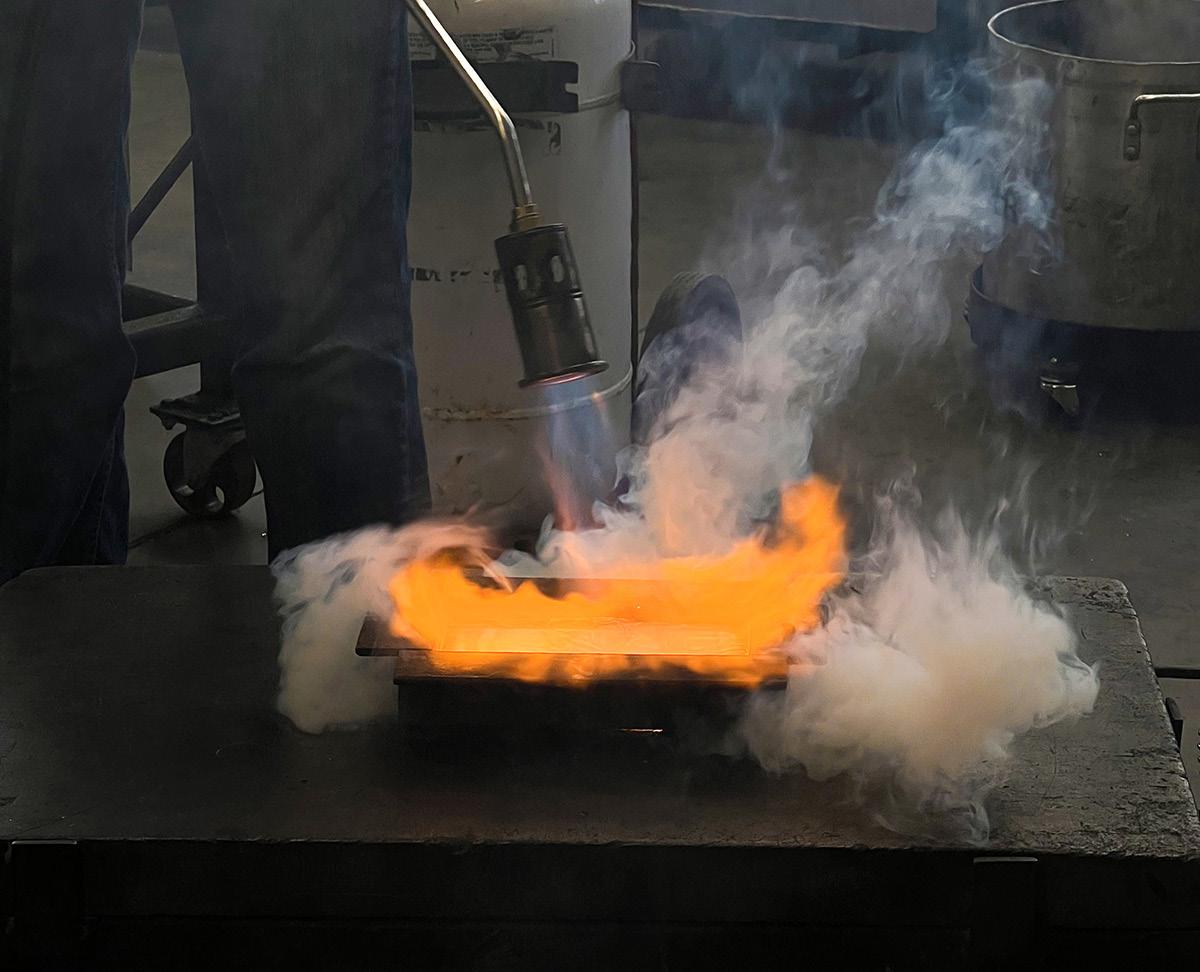

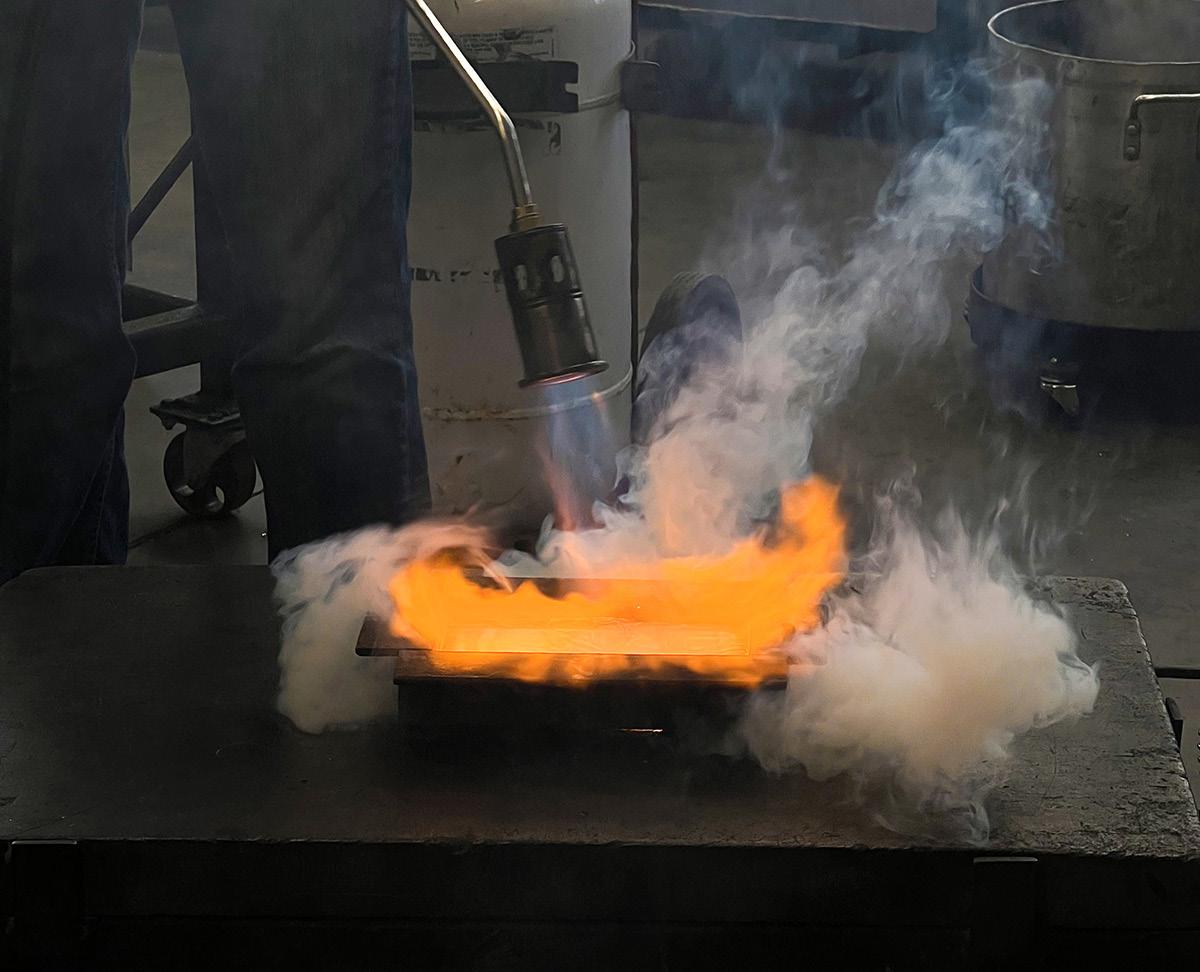

Experimental Glass Lamp

In this Glass class, I had the opportunity to learn and experiment with casting molten glass. I enjoyed exploring different materials, tools and processes to maximize the potentials of casting glass.

Experimental Glass Lamp is composed of rectangular modules of casted glass. Each piece uses a different material, tool or process that alter how the piece interacts with light.

I experimented with materials that are compatible with molten glass: copper sheets and wires, brass sheet, steel, graphite, sand, colored glass frit, wood, organic materials; with different techniques and speeds for pouring the glass, with different processes of finishing the piece: polishing, sanding and sand blasting.

44

Rhode Island School of Design Class Hot Casting

45

thank you!

Aquaponics Fish Tanks

Connection to facade

Aquaponics Fish Tanks

Connection to facade