4 minute read

Postharvest disease management

Breaking the mould

New options for postharvest disease management

Advertisement

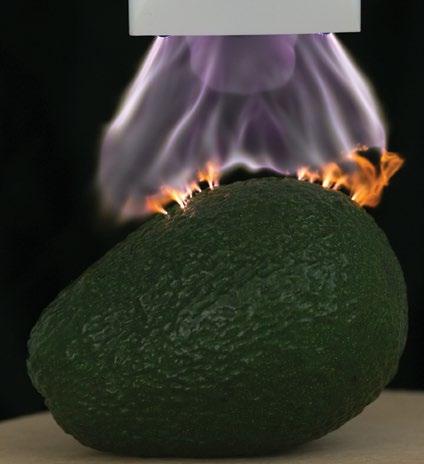

BY DR KIRSTY BAYLISS implications from a food safety PLANT SCIENTIST, MURDOCH perspective. A major advantage is that UNIVERSITY it also does not leave any chemical G lobally, 30 per cent of all food is lost or wasted. A large proportion of this is due to residues on the product. At Murdoch University, we are using cold plasma to treat the moulds that grow on fruit, vegetables and grain. To date we have trialled cold plasma for treating anthracnose (Colletotrichum pests and diseases. If we could reduce this waste by spp.) on avocados (see Figure 1), Botrytis cinerea on strawberries, blueberries and raspberries, and also 25 per cent there would be enough food available to feed reduced mould growth on truffles. We have a grain project that is focussed on reducing the fungal pathogen Fusarium 870 million people. graminearum, which is associated with the production of mycotoxins. At Murdoch University, we have Mycotoxins are secondary metabolites developed a method to treat produced by some fungi, that can postharvest pathogens and insect cause many health issues and in some pests, using the most abundant form of instances are carcinogenic. matter in the universe — plasma. One of the first activities that we Plasma is an ionised gas, and is produced naturally by lightning during a storm. Plasma technology is commonly used in television screens and neon lights and is also used in medicine and dentistry to treat wounds, so it is safe for human use. When we create plasma artificially it is at room temperature and is referred to as cold plasma. This low temperature avoids damage to the product being treated. undertake when beginning cold plasma trials is to test the impact of cold plasma on the product being treated. This includes measurements on the colour, size and weight of the product, to ensure that the plasma treatment is not phytotoxic. Once this has been demonstrated, we look at the common pathogens Cold plasma can be applied in the form of a flame or glow, air, or treated water. Cold plasma has unique antimicrobial properties that can be used to reduce infection by bacteria, fungi (moulds) and viruses. Studies have shown that bacteria such as E. coli, Listeria and Salmonella are all dramatically reduced on food products following plasma treatment. This has obvious that are associated with that product. Strawberries for example, are commonly associated with three key postharvest fungal pathogens, Botrytis cinerea, Phytophthora cactorum, and Rhizopus stolonifer. It is important to identify the main pathogens, so we can optimise the cold plasma treatment conditions for their treatment.

PHOTO © MURDOCH UNIVERSITY FIGURE 1. AVOCADO BEING TREATED WITH COLD PLASMA.

Cold plasma can be applied using different methods. We can apply it in the form of a plasma flame or glow, as shown in Figure 1. Alternatively, we can use plasma air, which is blown across the product or pumped into a package. A third option is plasma treated water, which is created by treating water with cold plasma, which draws the antimicrobial components into the water for application as a wash or spray. Treatment needs to be optimised for each product and pathogen being treated. In conjunction with the Strawberry Growers Association of WA, and the Agriculture Produce Commission, we are currently investigating the best method for application to punnets of strawberries, and will select the best treatment for larger trials.

(A)

(B)

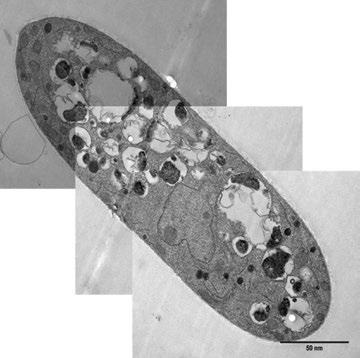

FIGURE 2. SCANNING ELECTRON MICROSCOPE IMAGE OF UNTREATED SPORES (A), AND COLD PLASMA TREATED SPORES (B). When assessing the impact of cold plasma on the pathogens, we measure changes in fungal growth and also spore germination. If the spores can’t germinate, then they are unlikely to infect and cause any damage. If they have already infected a product, then we need to be able to slow or reduce their growth and development. Scanning electron microscopy studies have shown that the cold plasma treatment destroys the structure of the spores, as shown in Figure 2, which appears to be the reason for the decrease in germination. In addition to treating fungi, our lab has also demonstrated that treatment with cold plasma can increase germination in seeds. We currently have a field trial in progress to determine if this also increases the growth and yield of the crop, or improves resistance to disease. Insects can also be treated with cold plasma, removing the need for chemical fumigation. Studies in other laboratories have shown that treatment of insects with cold plasma can interrupt metamorphosis. In conclusion, if cold plasma can be used to reduce pest and disease issues, food shelf life is increased. This also significantly reduces food waste.

ACKNOWLEDGEMENTS

We would like to acknowledge the Department of Primary Industries and Regional Development and the Agriculture Produce Commission for supporting our current projects on grain and strawberries, respectively.

MORE INFORMATION

For further information please contact Dr Kirsty Bayliss at Murdoch University. Email K.Bayliss@murdoch.edu.au or phone (08) 9360 2814.