36 minute read

YOUR INDUSTRY

Advertisement

industry your

Giving Australian agricultural diagnostics a booster shot

f QUICK, and accurate diagnostic tools need to be available to growers and diagnosticians Australia-wide.

Anumber of Australasia’s top research institutions have joined forces to develop diagnostics tools that aim to keep pests at bay and maintain good biosecurity across plant production industries. In this article, AUSVEG’s Ian Thomas outlines the extension activities being undertaken as part of the Boosting Diagnostics for Plant Production Industries project.

Plant pests and diseases have been the burden of growers since the beginning of agriculture. The disruption to trade while diagnostic decisions are being made can be costly to businesses and trade, and reducing this timeframe will be crucial in the coming years as disease and pest pressure rises due to increased global trade and climate uncertainty.

To prevent incursions and stay on top of good biosecurity practices, modern, quick, and accurate diagnostic tools need to be available to growers and diagnosticians Australia-wide.

In 2019, a Rural R&D for Profit program entitled Boosting Diagnostic Capacity for Plant Production Industries (or Boosting Diagnostics) commenced. Led by the Grains Research and Development Corporation, Assays for identification must be developed and tested, both in the field and thelaboratory. Boosting Diagnostics seeks to increase Australia’s ability to detect, contain, and eradicate plant pests and disease outbreaks. In recent years, the development of DNA identification tools such as LAMP, qPCR, and MinION (Oxford Nanopore) make it easier than ever to identify pests and diseases on-farm, but for these tools to be effective there is a lot that must first happen. Assays for identification must be developed and tested, both in the field and the laboratory. Reference samples must be secured and categorised. Protocols need to be developed, tested, and tested again. Boosting Diagnostics supports the development of new diagnostic tools, underpinned by strong communication and extension activities to raise awareness of these tools among diagnosticians and industry. This will assist in early, rapid, and accurate detection of pests and diseases on-farm and allow swift and precise responses from industry. It is not solely about detecting the presence of pests and diseases, but also their absence. Australia is thankfully free from many pests and diseases that plague the rest of the world. This absence — and our ability to prove it — allows Australian growers access to markets all over the world. The extra capacity provided by Boosting Diagnostics will help provide strong scientific evidence that our growing regions are free from pests and diseases.

Extension and communication activities

Throughout the remainder of 2022, AUSVEG will be coordinating the extension and communications component of Boosting Diagnostics to deliver the many and varied project outcomes into the hands of those who will use them day-to-day. These activities will be delivered in two streams: the Diagnostic Stream and In-field Stream.

f SPOTTED wing drosophila larvae; a potential threat to berry and wine production.

The Diagnostics Stream will focus on delivering developed technologies, protocols and expertise to diagnosticians and lab-based personnel through relevant diagnostic events and activities. Meanwhile, the In-field Stream will focus on in-farm triage and translating the diagnostic knowledge to actionable on-farm capacity and capability. This component will target professionals working in the field, ranging from agronomists, field pathologists, biosecurity officers, state surveillance staff and growers. AUSVEG will run seven workshops in different regions across Australia, each focusing on the pests and diseases impacting each region’s industries and addressing their specific requirements. During this process, AUSVEG will increase the awareness and knowledge of selected National Priority Plant Pests (NPPPs), provide updates on project activities, and deliver updated resources to diagnostic personnel across the plant production industries.

Pest and disease targets

Boosting Diagnostics will focus on a variety of target plant pests and diseases affecting a broad range of plant industries. These include the cyst nematodes of the genus Heterodera (pests of grains and vegetables), Xanthomonas citri subsp. malvacearum (the cause of bacterial blight of cotton), and spotted wing drosophila (Drosophila suzuki; a potential threat to berry and wine production), among many others. The individual projects are broad and varied, and approach the issue from different angles. CSIRO Research Scientist Dr Mike Hodda is working to organise the complicated taxonomy of Heterodera nematodes. “We are building a collection of local and exotic species so that we can work out what is in Australia and what is not, and how to distinguish them,” Dr Hodda said. “The benefits to vegetable growers will be better recognition of cyst nematode issues; faster, cheaper and more reliable diagnostics; better management options; and enhanced market access through area freedom.” Cyst nematodes can occur in many crops but are notoriously difficult to

diagnose as symptoms of their damage are easily mistaken with nutrient deficiency or drought stress. Dr Hodda advises that growers look for damage that occurs in a lens or oval shaped area and is pointing in the direction of cultivation, as well as expanding by a few metres each year. AUSVEG will run seven workshops in different regions acrossAustralia. “The nematodes themselves are just visible to the naked eye as white, beige, or brown balls about the size of pin heads protruding from roots,” Dr Hodda explained. CSIRO is putting a call-out for samples from any vegetable growers who believe they may have cyst nematode issues in their crops.

“To submit samples, growers should collect a handful of affected roots into one plastic bag, and a few hundred grams of surrounding soil into another bag, label them both with your name, location, and the crop, and keep them cool.”

Further tools

Each Boosting Diagnostics sub-project is a small piece of a larger puzzle.

Dr Andrew Weeks from Cesar Australia is developing diagnostic tools that use environmental DNA (eDNA) to identify pests without needing direct insect collection. eDNA is left behind in frass; that is, excrement from the eDNA is left behind in frass of various pests, or on feeding sights. digestive system of various pests, or on feeding sights. It can be used to help identify pest species presence — even when they may not be found. “The eDNA diagnostic tools, sampling approaches and factsheets developed through this project will enable more rapid identification of some high priority plant pests, allowing more effective management intervention to be undertaken to prevent or limit incursions or outbreaks,” Dr Weeks said. “The project will assess the feasibility of moving the technology into the field. We envisage the technology could be rolled out in some form within the next two-tothree years.” As each one falls into place, the picture of what improved diagnostics and better biosecurity looks like for Australia’s vegetable growing sector will begin to take shape.

MORE INFORMATION

Any vegetable growers who would like to submit samples to the CSIRO’s nematode project can contact Dr Mike Hodda on (02) 6246 4371 or email

mike.hodda@csiro.au

For further details about the Boosting Diagnostics project, please contact AUSVEG Project Officer Madeleine Quirk on (03) 9882 0277 or email

madeleine.quirk@ausveg.com.au

This project is supported by the Grains Research and Development Corporation through funding from the Australian Government Department of Agriculture, Water, and the Environment — as part of its Rural R&D for Profit program — and the Cotton Research and Development Corporation, Hort Innovation, Wine Australia, Sugar Research Australia, and Forest and Wood Products Australia.

INDUSTRY COLLABORATION

The Boosting Diagnostics for Plant Production Industries project is a partnership between the Grains Research and Development Corporation; Cotton Research and Development Corporation; Horticulture Innovation Australia Ltd; Wine Australia; Sugar Research Australia Ltd; Forest and Wood Products Australia Ltd; AgriFutures Australia; Commonwealth Scientific and Industrial Research Organisation (CSIRO); Minister for Primary Industries and Regional Development (SARDI); Western Australian Agricultural Authority; Department of Jobs Precincts and Regions (VIC); Department of Agriculture and Fisheries (QLD); Department of Primary Industries (NSW); Department of Primary Industry and Resources (NT); Biosecurity Tasmania; Plant Health Australia; Plant and Food Research; AUSVEG Ltd; Cesar Pty Ltd; and Bio-Protection Research Centre.

RAF Hydraulic Control Valves Leading Edge Valve Technology

RAF Hydraulic Control Valves

The valve range offers the following features and benefits:

Pressure Control: Increased uniformity across your field, regardless of pressure fluctuations.

Remote Control: Activate remotely via electric, hydraulic or pneumatic signal.

System Protection: Protects pumps, filters and pipeline from pressure and flow surges.

Level Control: Maintain water level in tanks and reservoirs.

RIVULIS

Shining a light on careers in Australian horticulture

BY AUSVEG

AUSVEG has launched the Grow Your Career

in Horticulture video

series, which highlights the diverse range of careers in the Australian horticulture industry. AUSVEG Communications Officer Sophie Burge reports.

The Grow Your Career in Horticulture series features video interviews with employees from nut, fruit and vegetable businesses across Australia to gain an understanding of those vital ‘behindthe-scenes’ roles in the industry. These videos show the daily tasks, responsibilities, and pathways of current employees on Australian farms. AUSVEG National Public Affairs Manager Tyson Cattle said that the series is designed to highlight the technical and skilled opportunities that are available on fruit and vegetable farms across Australia. “The horticulture sector is a large, developed and diverse industry that employs a wide range of skilled people. While much of the media attention is focused on harvest labour within the sector, it is often forgotten that the industry requires a range of skillsets to manage and operate their farm business,” Mr Cattle said. “The horticulture industry has many opportunities for workers to upskill and access on the job training further their career in horticulture. While there are many harvesting opportunities on the Harvest Trail, there is also a range of other essential roles to be found on farm and production line.”

Showcasing opportunities

Many of the roles highlighted in the video series are in the highest demand in businesses across the horticulture sector and align with the approved 31 occupations under the Horticulture Industry Labour Agreement — supporting growers to sponsor skilled and semi-skilled workers from overseas to fill these critical occupations.

“Growers’ preference is always to employ locals first where possible, when they have the right skills and attitude,” Mr Cattle said. “These videos aim to showcase the many varied career opportunities for local workers in the exciting $15 billion Australian horticulture industry to entice people to give the industry a go. “Many people we interviewed for these videos did not intend Highlighting the diverse range of careers in the Australian horticulture industry. on a career in horticulture, but discovered a passion for it after working on the farm. They have each come from various backgrounds and landed in horticulture through different avenues by transferring key skills from seemingly unrelated courses and past careers to start successful careers in horticulture. “A job in horticulture can be the start of a lifelong, satisfying career with plenty of opportunities for upward growth. Putting food on the table for millions of families in Australia and abroad makes it a worthwhile and fulfilling career.”

INTRODUCING JORDAN KLEESH

At a glance

NAR NAR GOON

NAME JORDAN KLEESH AGE 25 JOB PRODUCTION ASSISTANT/ SALES AT RED GEM POTATOES LOCATION NAR NAR GOON, (GIPPSLAND) VICTORIA

As a Production Assistant at Red Gem Potatoes, Jordan Kleesh works primarily in the processing facility in Nar Nar Goon, Victoria. Jordan oversees the product movement throughout the day, and works with various teams in the facility coordinating the processes and market orders.

He helps to load and unload trucks, check the packaging line and pick orders — while ensuring proper food handling, quality and safety standards are met. Red Gem grows and supplies brushed and washed varieties of potatoes to major retailers around Australia. The business is based in Nar Nar Goon, but it also has farms operating in Hillston in the Riverina region of New South Wales and Mount Gambier in South Australia. Trials of sweet potato and onions are also underway through joint venture crops in Gippsland. Red Gem grows more than 15 potato and onion varieties annually on 1,000 acres (400 hectares) of land around Australia. AUSVEG caught up with Jordan for the ‘Grow Your Career in Horticulture’ series.

Jordan, can you please tell us about your role at Red Gem Potatoes and what it involves? At Red Gem, we grow brown onions and several potato varieties including Kipfler, Nicola, Mozart, Royal Blue and Crème Royale. In addition, we manage many farms to help support our volumes to our customers, which are very important to this business — from our biggest customers such as Coles & Hello Fresh to smaller ones located locally and interstate.

I work on the packing side of the business. After we receive the freshly harvested potatoes into our packhouse, we prepare and package them, so they are ready to be sent out to our customers quite quickly — they are in and out on the same day if necessary. My day-to-day duties include loading and unloading trucks, picking orders, running the line and machines, as well as other general factory and forklift duties. In our packing shed, we have two different potato lines: the brush line and the wash line.

The waste or defective potatoes are rejected for other markets — utilising waste and having less of it is very important to the business. The washed side is a little more involved, as the potatoes must go through a washing plant to be washed before they come through the lines to get packaged. It’s a simple process but at the same time, there's a lot behind it that you've got to do to get it right. We are very lucky to have been the first company to utilise x-ray vision technology to help us with sizing and grading our brushed potatoes. With this, we have achieved a quality no one else can do in the industry!

What does a typical day look like for you? My day typically starts with a production team meeting early in the morning to outline and organise what the goal is to achieve for that day. This involves determining what our orders are for that day and the day after and making sure we have got enough product coming in for us to package to then send out again. From there, we set up the lines where we prepare the pallets and do whatever else is needed to unload the potatoes from the truck. Throughout the day once the team arrives, we begin the process of packaging, which involves things like keeping track of timelines, moving pallets around, moving people around and making sure the lines are operating correctly and are not overflowing. My day also involves looking at quality assurance, where I check the product to ensure it meets the customer’s specifications and requirements. To do this, I pick up a bag off the production line and tip it out before I hold or cut up potatoes to ensure they do not have any internal defects and weigh correctly.

Can you please tell us about your journey into horticulture? When I was 16, I began working at Red Gem as a casual employee, where I would fold crates and help with packing and other general factory duties. After a year, I left to try something else. While I was at school, I was studying sports science and then I came back to work at Red Gem for a year and a half where I did inventory, quality assurance and more general factory duties and light forklift duties. From there, I left to do my carpentry apprenticeship that I had finished just as the COVID-19 pandemic started. The COVID situation impacted my carpentry career, but luckily enough — as a result from my prior work experiences at Red Gem — I was able to find work again with the team doing casual forklift driving. What began as casual work ended up being full-time work again, and I found the opportunity to progress through the business to where I am today.

What are some common misconceptions about careers in horticulture? There is a whole lot more to horticulture and a lot of people don’t realise that until they actually start working in it. About four months into working at Red Gem again, I had the opportunity to visit the Hillston farm in New South Wales, where I saw and learnt the entire process of planting. This included the overall groundwork that prepares a crop before planting, such as soil conditioning. It was witnessing the planting process and the factory side of things — which are not as simple as people would think — that ignited my interest in horticulture. The whole process is not just as simple as putting a potato into a bag. We have got so much to organise such as inventory, quality control, the factory side of things, logistics and forklifts — plus the various office roles for the business side of things. I’ve learnt the inventory side, the quality control side, and now sales. If you’re prepared to learn, there are numerous opportunities to grow your career in horticulture. Another common misconception about working in the industry is that there is only seasonal work, which is not the case. There are plenty of packing sheds that operate all year round because the potatoes come in from numerous different places around Australia and not every farm does harvest at the same time. The potato industry is always growing and harvesting, and there’s always work.

Why do you do what you do? I love my job as every day is different. One day I could be working on the factory floor or in sales or be up at the farm for a week helping that team, to then come back to the packing shed. If you’ve got the dedication to the industry, I find it tends to give back to you because employers notice and reward effort. In my situation, Red Gem has provided the opportunity for me to move forward in the business, which is fantastic. From my experience, it’s never too late to get into horticulture. I’m 25 and although I was in and out of the industry at the start, I’m glad I returned. It’s also a good feeling to see the product you’re producing end up on somebody else’s plate. At the end of the day, I get to watch the process from start to finish. When you go into the shop, there's no better feeling than when you look at a bag or the tag, and you see that tag has gone through your hands before landing in the local shopping centre. Overall, working for a company with a great heritage gives me the comfort and belief that we can achieve great things every day.

INTRODUCING OLIVIA DE LA MARE

At a glance

COBBITTY

NAME OLIVIA DE LA MARE

AGE 21

FORMER

ROLE

INTEGRATED PEST MANAGEMENT (IPM) OFFICER AT GREEN CAMEL ORGANIC PRODUCE

PRODUCE/ GROWING METHOD

GREENHOUSE GROWERS OF ORGANICALLY CERTIFIED TOMATOES, MINI SNACKING CUCUMBERS, AS WELL AS PREMIUM BARRAMUNDI IN STATE-OF-THE-ART HIGH-TECH GLASSHOUSES LOCATION COBBITTY, NEW SOUTH WALES

As an Integrated Pest Management (IPM) Officer, Olivia De La Mare was responsible for controlling plant diseases and pests using a non-conventional approach.

Olivia worked in the high-tech glasshouses at Green Camel Organic Produce, helping produce organic tomatoes and cucumbers. At its New South Wales operation, Green Camel delivers an organic- and pesticide-free product range that is offered in the major Australian food retailers. IPM is vital for this type of operation and involves strategic releasing of beneficial insects to naturally control pests along with organic spray applications. It relies heavily on strict biosecurity to prevent pest incursions. Regular and thorough monitoring of plants and planning ahead of time controls pests in a timely manner. The benefit of IPM is that it reduces the reliance on harsh residual-systemic chemicals to control a disease or pest. Instead, an integrated and layered approach is used to prevent, identify and control pests before reaching an economic threshold. It looks closely at the lifecycle of each pest and uses natural predators and systems to prevent and eradicate problems. Green Camel operates 2.4 hectares of glasshouses and an integrated barramundi farm, producing 600,000kg Truss tomatoes, 300,000kg snacking tomatoes, 190,000kg of baby cucumbers and 35,000kg of live barramundi. These sites use Green Camel’s food production system to grow organically certified tomatoes and cucumbers, as well as premium live barramundi. Green Camel’s goal is to make organic and pesticide-free produce consumption mainstream in Australia by delivering high quality commercially feasible products.

Its key partner, Perfection Fresh, is one of the leading growers and marketers of produce in Australia, possessing excellent relationships with the major retailers and access to a wholesale channel. Perfection Fresh supplies supermarkets including Woolworths, Coles, Aldi and Costco, independent retailers, fast food chains and an expanding number of export markets. AUSVEG spoke to Olivia as part of the ‘Grow Your Career in Horticulture’ series. Since then, Olivia has departed Green Camel and is now completing her Bachelor of Agricultural Science at Charles Stuart University in Wagga Wagga.

Olivia, can you please describe your role at Green Camel Organic Produce and what it involved? My role in Integrated Pest Management (IPM) involved a lot of different ways of controlling plant pests and diseases within our high-tech glasshouses, rather than the conventional methods using chemical sprays. My job involved a lot of monitoring for pests, watching numbers, as well as doing organic sprays and releasing beneficial bugs to control the pests that we do have in our crops. The beneficial bugs came to us packaged either on cards, in vials or in bottles from our suppliers. From there, we released the bugs into the crop where — as predators — they ate or laid eggs to destroy or control the pest that we had in the crop. We also had a variety of sticky traps installed in and around the crop that revealed if we have pests, such as white fly or thrips. I also did trap counts and controlled all of the sprays to make sure the spray patterns are applied correctly.

Tell us about your journey into horticulture? I started in agriculture at a very young age because my whole family was involved in it. As I got older, I started studying agriculture in high school. By age 16 or 17 (when I got into year 11 and 12), I started studying a Certificate II in Agriculture, in a class called primary industries. When I left high school, I was looking for jobs in agriculture and an opportunity to harvest in a high-tech glasshouse came up at Green Camel. So, I came in and had look around the Cobbitty site and they hired me on the spot. I worked in harvest for a few months before progressing into the IPM space. Every single one of us are given the opportunity to progress into different roles. In my case, I moved from harvesting into IPM. When I first started working at Green Camel, I had no experience in horticulture. I was very much animal-based, but I came into horticulture with an open mind. As I began working and started asking questions, new opportunities started opening up.

Why do you like working in horticulture? I really love working in nature and especially in organic horticulture, you are watching how nature fights nature within our beneficial bugs, and with our natural pesticides. I worked with about 50 people in the crop in Green Camel, who were a mix of crops workers, growers, IPM and so on and so forth.

What was it like working in IPM at the beginning? When I started in IPM, I did a lot of on-the-job training. For my role, I found there actually were not any specific courses that I could take, so I learned everything working on the ground. I learnt how to identify bugs, pests, and diseases, and anything else that might be different in the crop. A big part of this job was always learning. You were always looking for something new and different, and how to identify and control it.

What advice do you have for someone considering a career in horticulture IPM? Getting into horticulture does not really require that much prior training. A lot of training is done on-site and in its own unique way for each individual site, because everything changes so dramatically. A few things that you can get that might help you along are chemical certificates so that you can handle any sort of chemicals, and forklift licences, which are commonly used on-site. As soon as I started working in horticulture, I was obsessed. I started working in fruit growing and became obsessed with house plants at home. So, a work-life balance for me never really works because it is my life. It is such a beautiful environment to work in. Working with plants all the time is great for your mental health. What are some common misconceptions about careers in horticulture? A big misconception about working in horticulture is that it is very labour-intensive where people think you are just picking or weeding, and that you do not really see anything from the crop. However, it is a lot more involved than that. Yes, we had crop workers who were twisting, de-suckering, and taking care of the plants — but in my role, I got to see every stage of the plant. Rather than just coming in, picking a few things and leaving again, you got invested in the crop. Another misconception in horticulture is that the days are always long and always hard work. There are a lot of opportunities out there in the horticulture industry where you can have a great work-life balance. I worked from 6.30am until 2.30pm each day, so my afternoons were completely free and for me it was like that all season. Horticulture is something that you can see directly affects the world. It is designed to feed people. You are feeding the masses, and you never really realise it until you see the amount of fruit that comes off the crop. What I did in IPM is at the very start of the train. It was making sure that those plants are healthy and ready to produce fruit. There is always a need for people in horticulture. If it is something that you want to do, you just go for it. Get in the crops, work hard, and ask questions — and so many opportunities will open up for you.

MORE INFORMATION

For more information about the Grow Your Career in Horticulture series, please visit

ausveg.com.au/grow-your-career

The Grow Your Career in Horticulture series is funded by the Federal Department of Education, Skills and Employment through the Harvest Trail Services Industry Collaboration Trial.

f THE changes state that workers on farms must be paid a minimum of $20.63 for full time and $25.41 per hour for casual employees.

Piece rate requirements

BENJAMIN HAMILTON ADMINISTRATION, MARKETING & SALES, VEGETABLESWA

As of April 28, 2022, your legal obligation is to guarantee your employees a minimum pay rate under the Horticulture Award.

Last November, the Fair Work Commission determined that a minimum floor price would be set for workers paid a piece rate. The changes state that workers on farms must be paid a minimum of $20.63 for full-time and $25.41 per hour for casual employees. The determination also requires that the piece rate must allow for the average competent worker to earn the equivalent of at least 15% above the minimum hourly rate for the employee’s classification.

The changes implemented on April 28 will act as a safety net for all horticultural workers and guarantee workers are paid according to the minimum wage. There have been concerns that these changes might limit productivity, as they have traditionally prompted workers to work faster for more pay.

vegetablesWA Human Resources and Industrial Relations consultant Stephen Farrell has been working on providing contract templates for employers. Growers would benefit from implementing New changes to the Horticulture Award implemented on April 28, 2022. policies and procedures to meet industry standards, and the templates can be downloaded from the vegetablesWA website. Additionally, these contracts are available to download from the Fair Work Ombudsman website.

MORE INFORMATION

This article has been compiled from information on the Fair Work Ombudsman Horticulture Award. For more information, visit the Fair Work Ombudsman:

horticulture.fairwork.gov.au

Food Ladder

a program helping educate kids about horticulture

f TYPE 2 Diabetes is 10 times higher among Australian Indigenous children than anywhere else in the world.

Food Ladder is a not-for-profit organisation tackling the food security crisis in Australia.

BY FOOD LADDER

Food Ladder is a not-for-profit organisation with a 12-year track record tackling the food security crisis in Australia where the availability, variety and quality of fresh and nutritious food is poorer in remote Aboriginal communities than in major cities.

Healthy food is typically unaffordable in remote locations, resulting in healthy food habits deteriorating, high rates of chronic disease, poor educational engagement and retention rates, and poor employment and participation rates in vocational training. Food Ladder actions its mission with a two-pronged approach. Firstly, the expansion and commercialisation of the Katherine Food Ladder, which proves that a centralised, locally-owned food growing and distribution social enterprise provides a better-quality product, employment and health outcomes, as well as a continuous supply of locally-grown fresh and affordable produce to remote communities in the Northern Territory.

f FOOD Ladder provides fresh vegetables but also creates behavioural change and social cohesion in healthy eating practices.

f ROSELLA bush food. Secondly, the rollout of Food Ladder Systems designed for remote schools across Australia.

The greenhouse and hydroponic growing system has been tailored to each 8–10-week term as it takes students along the six-week journey from sowing the seeds to harvest and then closing the loop by cooking, and consuming the fresh vegetables. The school systems produce up to 1,500 plants per year, engaging children in the joy of plant cultivation and healthy eating.

f A centralised, locally-owned food growing and distribution social enterprise provides a continuous supply of locally-grown fresh and affordable produce to remote communities in the Northern Territory.

f THE Food Ladder Online Learning Platform houses over 140 educational resources.

f THE Food Ladder Online Learning Platform is working with over 100 schools and has access to over 36,000 students across Australia.

Type 2 Diabetes has no cure but is preventable with a healthy diet. It is 10 times higher among Australian Indigenous children than anywhere else in the world and we are committed to reversing this.

Food Ladder Online Platform

The Food Ladder Online Learning Platform houses over 140 educational resources, including STEM-aligned school curriculum, recipes, horticultural resources, paddock to plate programs, and is working with over 100 schools and has access to over 36,000 students across Australia.

Outcomes

• Pre-vocational and vocational training • Programs and pathways to employment • Food Ladder Online Platform resources • Social and emotional wellbeing • Increased learning from disengaged students, students with learning and behavioural issues • Sustainable Indigenous employment outcomes • Social enterprise development • Increase in nutrition and health awareness • Sustainability education • Community pride and achievement.

Through our online platform, emphasis has been placed on the collection and aggregation of data, to monitor the impact Food Ladder is having in remote communities, not only through fresh vegetable consumption but also on the behavioural change and Multi-faceted positive impacts in remote communities in the Northern Territory. social cohesion in healthy eating practices. Real-time, site-specific data allows us to demonstrate to funders and supporters the multi-faceted positive impacts we are having in communities.

MORE INFORMATION

For more information check out the Food Ladder website foodladder.org

BAM Act applies to all pests, diseases and weeds.

f THE BAM Act plays an important role in building trust in the integrity of WA produced food and agricultural products.

Let’s talk

AMinisterial review of Western Australia’s Biosecurity and Agriculture Management Act 2007 (BAM Act) is opening the doors for a real conversation about the future of biosecurity and agriculture management in WA.

From mid-June, there will be a number of opportunities to have a say about the BAM Act and how it can support the best outcomes for WA. If you have an interest in biosecurity or food integrity, now is the time to step forward.

The BAM Act provides a legislative framework not just for biosecurity and agriculture. It provides a foundation for safeguarding WA’s environment, economy and communities.

On paper, the sections of the BAM Act relate to biosecurity, the use of agricultural and veterinary chemicals, ensuring quality and safe agricultural products, and biosecurity funding mechanisms. In reality, the BAM Act influences our everyday lives. The BAM Act plays an important role in building trust in the integrity of WA-produced food and agricultural products. The quality and safety standards, and traceability and sustainability requirements set out under the Act, sustain WA’s brand as a reliable supplier of products that are superior and safe, and free from pests, diseases and chemical residues. They ensure that consumers and markets know where and how our food and products have been produced. Importantly, the biosecurity provisions of the BAM Act don’t just apply to agriculture, but also to fishing, pearling, forestry and aquaculture. In fact, the BAM Act applies to all pests, diseases and weeds, regardless of their nature and what aspect of life they threaten (except human health). It protects the plants and animals that sustain our primary industries, and also safeguards our landscapes, waterways, ecosystems and biodiversity, and our safety, outdoor lifestyle and sense of community. The review is a statutory requirement, and this is the first time the BAM Act has been reviewed. So far, it has served us well, but there are new challenges with

f A growing number of pests and diseases are making their way across WA’s borders.

a growing number of pests and diseases making their way across WA’s borders, driven by factors such as increased movements and climate change. The review provides a timely opportunity to deal with the increasing pressures on WA’s biosecurity system, as well as the increasing expectations around food integrity. It is also a good time to have a conversation about shared responsibility for biosecurity and the quality and safety of agricultural products. This is a guiding principle of the BAM Act. Protecting WA is only possible with the ownership and active participation of all stakeholders, who are broader than just producers and Government.

f THE biosecurity provisions of the BAM Act don’t just apply to agriculture, but also to fishing, pearling, forestry and aquaculture.

We also want to hear from industries associated with freight, seeds, stock feed, fertilisers and chemicals, as well as Indigenous organisations, environmental groups, veterinarians, product distributors, the general public, landholders, and even tourists and travellers.

With so much at stake, there needs to be an honest conversation about the capability of the BAM Act to respond to our changing world.

The new technologies and ways of thinking at our doorstep means there is plenty to talk about. An independent six-member panel, led by Kaylene Gulich, Chief Executive Officer of the WA Treasury Corporation, is conducting the review. All panel members are highly qualified and experienced leaders in their fields, and well placed to ensure our biosecurity and agriculture management legislative framework gets the attention it deserves.

The review will involve three stages of engagement. Stage 1 will be a six-week open consultation, which will provide the foundation for Stage 2 conversations around the issues raised. Stage 3 engagement will be based on any proposed recommendations. This comprehensive and extensive review process will enable the Review Panel to reach as many people as possible, to be sure recommendations are well-informed and meaningful.

The review will involve three stages of engagement. MORE INFORMATION Visit yoursay.dpird.wa.gov.au for further details on how to participate, including the first stage consultation dates. Department of

Primary Industries and Regional Development

Bartle Frere Bananas

site and environmental issues

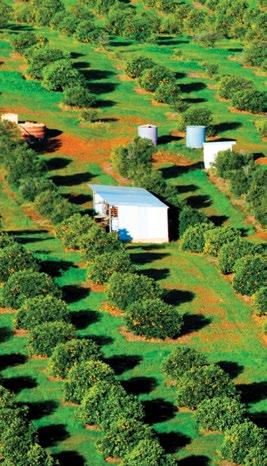

f BARTLE Frere Bananas is a 100ha family owned and operated plantation in Boogan, Queensland.

BY APPLIED HORTICULTURAL RESEARCH

There is a growing desire from farmers and consumers for their produce to be grown using more efficient and environmentally friendly onfarm practices. A key step in achieving this goal is to find new and innovative ways to deliver real-time field data into the hands of farmers, allowing them to make best decisions for their crop.

Bartle Frere Bananas is a 100ha family-owned-and-operated, Freshcare Environmental certified plantation in Boogan, Queensland. There is increasing pressure on the banana industry in Queensland to manage phosphorus and limit inorganic nitrogen loads, which are notoriously difficult to measure and model. Runoff from the farm drains to the Moresby River, which is 30km from the Great Barrier Reef.

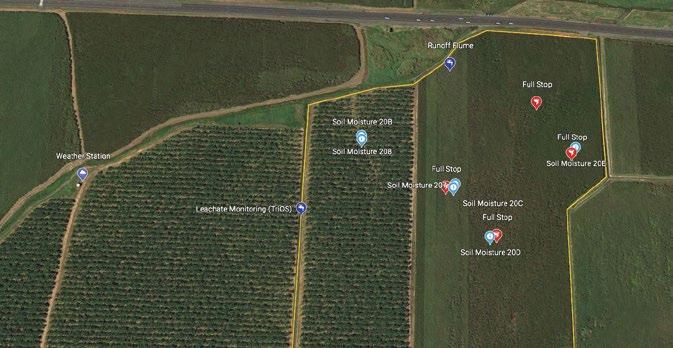

f BARTLE Frere map.

Bartle Frere Bananas converted a sugar cane block to bananas in 2019, providing an ideal location for the pilot project. The block was built up to provide industry leading drainage, with a vegetated drain designed to absorb nutrients and retain soil. Gavin Devaney won the 2021 ABGC Future Farming Award for his contribution to the Banana BMP and the broader industry.

Australian Banana Growers’ Council

and Freshcare are supporting the project by exploring ways in which these new technologies can be used to automatically collect and provide evidence for certification audits for Freshcare ENV. This will significantly reduce barriers to Best Management Practice adoption for Australian farmers.

The Bartle Frere Bananas smart farm is a part of the Digital remote monitoring to improve horticulture’s environmental performance project funded by the National Landcare Program and Hort Innovation.

Applied Horticultural Research is developing water balance, nutrient load and growth models which will feed into a digital Control Tower.

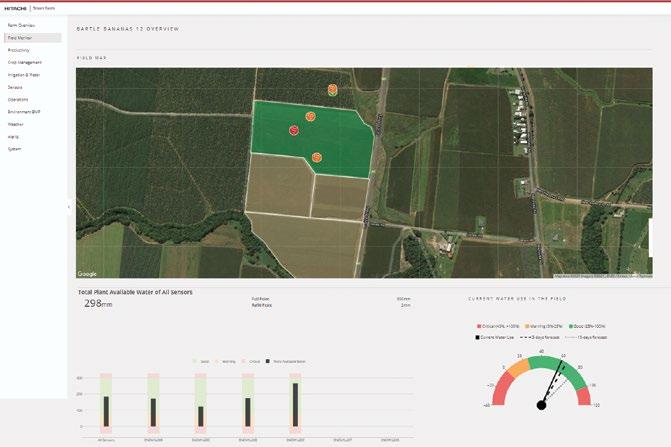

f BARTLE Control Tower. Hitachi Vantara is developing the Control Tower to holistically measure farm productivity and environmental stewardship by integrating sensor data, weather forecasts and biophysical models. The Control Tower will automate much of the Freshcare Environmental audit reports and provide decision support tools for managing nutrient runoff and leaching.

Technology

The technology installed on the pilot farm was designed to improve farm productivity, reduce costs and simplify compliance with environmental regulations. RFID bunch tracking and GPS vehicle tracking will guide farm staff directly to work areas, avoiding unnecessary trips and improving labour efficiency. Freshcare Environmental audits will be significantly automated, further improving labour efficiency and improving the accuracy of data provided in remote audits.

The technology that has been installed on the pilot banana smart farm can be seen in Table 1.

TABLE 1. TECHNOLOGY INSTALLED ON THE PILOT BANANA SMART FARM

Technology Productivity

Soil moisture to 80cm

Improved irrigation management Nitrate sensor Improved nitrogen management

Full stop wetting front detectors Improved nitrogen management Nitrate loss to environment can be minimised Nitrate runoff and leaching load manually monitored

Rated flumes Improved irrigation and nitrogen management Weather station On-site real time weather information, such as wind and rain

Smartphone and tablet Reduced time required for audit forms

Irrigation pressure transducers Vehicle Asset Tracking RFID Bunch Tracking Improved irrigation management Improved labour management Improved crop management Environmental BMP

Overwatering can be minimised Nitrate loss to environment can be minimised

Nutrient loss to environment can be minimised Overwatering can be minimised Leaching events are detected Nitrate runoff and leaching load monitored

Runoff loads can be calculated

Spray records are automatically populated

Improved accuracy of audit forms

Overwatering can be minimised Reduced interrow traffic and erosion Reduced interrow traffic and erosion Freshcare Environmental records are automated Irrigation records automated

TriOS NICO Nitrate Photometer (Innovative Sensor)

A TriOS NICO real-time nitrate photometer has been installed at Bartle Frere Bananas to measure nitrate concentration of leachate leaving the farm. The sensor will measure leachate from pre-existing sub-surface ag-pipes that drain the pilot project block. The TriOS is paired with a rated flume and real time pressure transducer to measure flow rate and total volume of leachate passing through the subsurface ag-pipe. This combination of sensors will provide a constant data stream to support Bartle Frere Bananas’ fertiliser and irrigation decisions. Additionally, it will provide a revolutionary data source for nutrient modelling and become a case study for the industry.

DECISION SUPPORT TOOLS

• Simple displays of soil moisture, evapotranspiration and plant stress data show if irrigation matches plant water use. • 7 day forecasted nutrient runoff and leaching can be used to better manage irrigation and fertiliser timing. • Growing degree day forecast, to predict a fruit maturity date using short-term and seasonal forecasts. • Simple displays of current and predicted spray conditions with guidelines on when to avoid spraying. • Interactive farm overlay of field conditions, plant health, sensors, assets, and plant health.

MORE INFORMATION

Liam Southam-Rogers, phone 0418 235 842 or email liam@ahr.com.au

Pilot smart farms have also been established in the following industries: • Avocados • Vegetables • Nursery f SOIL moisture sensors.

f GROWER Gavin Devaney with the communications node.

UPCOMING ACTIVITIES AND EVENTS

• Cassowary Coast Banana

Growers’ meeting • Continued data collection and site maintenance • Additional installation of sensors • Development of nutrient and growth models • Development of Hitachi

Control Tower • Field days and webinars • Factsheets and technology guides