5 minute read

Fleet Renewal Contributed by Murray Palmer, PRM

Fleet Renewal Engine Overhaul Supplemental Inspections (Cessna) Contributed by Murray Palmer, PRM

Good Aircraft Maintenance will keep our fleet flying for many years to come.

Advertisement

Long term planning is vital when it comes to fleet maintenance. The VFC’s maintenance department has been actively proceeding down a path which will continue to keep our fleet flying safely. Safe dispatchability is "JOB ONE" for the maintenance department. As our aircraft ages and the hours accumulate on the individual aircraft, it only stands to reason that maintenance costs and down time will increase. Ways in which we can mitigate those expenses are to increase the inspections intervals and to overhaul the different components on the aircraft before they become a concern.

This past October, the Club sent Allan Girard, one of our licensed Aircraft Maintenance Engineers (AME), on a training program to the Lycoming College of Technology in

Williamsport, PA. The purpose of this investment was to ensure that we have an AME trained in the correct techniques required to allow the VFC to overhaul the Lycoming engines in our fleet of Cessna 172s, as well as the engines on our aging Piper Seminole. We are all very proud of Al’s attention to detail during the training program, as he attained a high class standing at the completion and arrived back home with a certificate allowing him to overhaul engines on site.

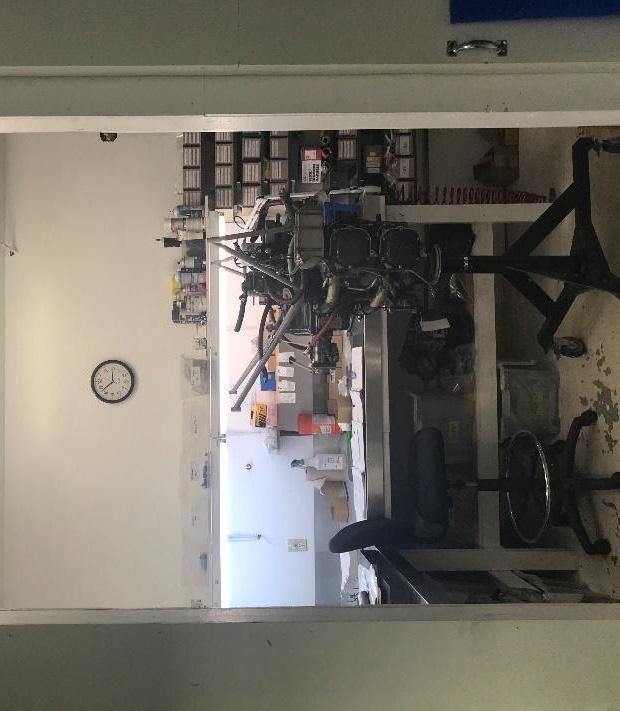

During Al’s absence from the club while on course, a renovation of the maintenance shop was undertaken, and an engine overhaul shop was created to isolate the overhaul procedures from the rest of the maintenance facility. Many thanks to Darrell Fournier for once again sharing his many talents (this time as a home renovator) to help advance the Club’s interests in building this new shop addition!

Upon Al’s return from the training course, he immediately set out to complete the requirements of the new shop, making sure that everything necessary was completed prior to accepting the first engine for overhaul.

Naturally, there were the expected delays and issues experienced as any new venture is undertaken, but in no time, there was an engine being disassembled and inspected. A long list of required parts were researched by Rebecca Adler, our stores person, and soon being shipped to the Club for Al to apply in the overhaul.

There were certain engine components for which the VFC did not yet have the capabilities to inspect and certify. Consequently, we had to send these parts for inspection and certification, as a mandatory requirement to proceed with the overhaul. The VFC has now invested in acquiring the skills and equipment necessary to complete

all aspects of the rebuild/overhaul processes, thereby further reducing expenses. Griffin Victor, a certified AME, has attended a portion of the courses required for him to be able to certify our non-destructive testing (NDT) requirements, and will complete further training over the next few weeks.

Al worked diligently to overhaul the first engine. Going forward, the Club is planning to overhaul each of the Cessna engines, and continue with trend monitoring of the overhauls, assuring a reliable, safe power source for the entire VFC fleet.

Of note, the overhaul is not completed until the engine is test run. A stand to do engine runs was required, and the old VFC service truck (that was not road worthy any more) was transformed into a firstclass mobile test stand.

There is a requirement by the engine manufacturer, as well as Transport Canada, to do test runs on overhauled engines prior to installation in an airframe. These test runs are designed to search out any flaws or deficiencies that may show up such as oil leaks and the like. All aspects of operation of the engine are monitored through out the runs such as oil pressure, oil temperature, fuel pressure, cylinder head temperature, exhaust gas temperature, engine

RPMs, manifold pressure, and all other vital parameters are recorded and filed, making sure that each and every one of the set standards are met or exceeded.

The testing of the first overhauled engine began with an initial start up which was extremely anti-climatic after the weeks of anticipation during the build up phase. “Will it start, will it run rough, will it leak oil, will it leak gas” …all valid questions prior to hearing the fist bark of the newly overhauled engine. The start-up was flawless, with only a small puff of smoke (burning off the excess oil used in lubricating the parts on installation), after which it ran extremely smooth.

A test run was completed and then an initial break in run was completed. The weather the day of the test run was typical of the west coast, cool and damp. The test club propeller that we had made up was very effective and moved a lot of air as is evident from the picture.

All in all, the testing ran according to plan with no surprises. Congratulations Al…good job!!!

The intent of the club is to overhaul all of the engines in the fleet, and when there are new innovations suggested for the power plants, the club will be able to incorporate them.

Other plans in the works to create a safe and reliable fleet of training and rental aircraft is to increase the intensity of the inspection program, so as to include better scrutiny of areas not normally inspected as regularly as our Phase inspections call for. Incorporating these inspections into our system has brought to light issues that have now been addressed, while providing the AME team with a substantially better understanding of the condition of each aircraft in our fleet. These inspections are inclusive to the complete fleet of single engine aircraft approved by Cessna as well as Transport Canada.

The Club has also undertaken the responsibility of having all of the fixed pitch propellers overhauled, and all existing service bulletins complied with. Progress has been made, and we will be completing the entire fleet with in the next few weeks.

The existing maintenance staff at the VFC has the qualifications and experience to carry out complete airframe restorations, major and minor repairs, installation of Supplemental Type Certificated components as well as cosmetic enhancement. They are proud of their work, and pleased to be able to ensure that all VFC members are provided with a safe and reliable fleet of aircraft.