4 minute read

Global Engagement

Providing a wealth of extra- and co-curricular activities for students to gain hands-on experiences in cities, towns, and neighborhoods around the corner and around the world.

MArkerS And MileStoneS

2010 Students and faculty establish Engineers for International Development (EfID) to connect engineering students with existing needs for simple infrastructure improvement in developing countries and begin work in Nicaraguan village

2015 EfID chapter wins Second Place in the 2015 National Council of Examiners for Engineering and Surveying Award competition for connecting professional practice and education

2015 Bioengineering students travel to Guatemala to repair hospital equipment

Engineering Students Fix Equipment in Guatemalan Hospitals

The Roosevelt and San Juan de Dios Hospitals in Guatemala have no shortage of medical equipment. What the hospitals need, however, are trained and qualifed people who can repair or maintain the equipment.

To help solve this dilemma, fve Volgenau School of Engineering students partnered with Engineering World Health to travel to Guatemala and ofer their assistance. The team spent three weeks at Guatemalan hospitals troubleshooting, repairing, and, if necessary, disposing of donated medical devices and supplies. Some devices were as simple as an electric fan, others as complicated as an autoclave.

The team made the city of Antigua its home for the month, dividing accommodations between two large homestays on the edge of town. Antigua is known for its beautiful architecture and panoramic views of three volcanoes, but this team wasn't there to sightsee. They had important work to do. In the frst week, the students jumped right into intensive Spanish lessons and their work at the hospitals. "The hardest aspect of this trip was communication," says bioengineering major Caitlin Johnson. "It was difcult to communicate to the maintenance department how they should maintain the equipment or how to repair easy fxes by themselves. This required a lot of close work with the technicians at the hospital, all of whom had very little English."

The students were also surprised at the sheer number of donations the hospital received.

"The hospitals have so many donations from other countries sitting around the hospital, or outside in the ‘graveyard'—a fenced-in area reserved for medical devices—that they can't or don't know how to use," says Johnson. "The amount of equipment is staggering."

The equipment is donated for many diferent reasons— charity, age limits, or recalls. Some machines are broken, some are incompatible with the local power rating, some are missing parts and some have instructions only in English. Without technicians who understand the machinery or maintain it, the equipment is useless.

The teams repaired hospital beds and fxed kitchen equipment. They devised work-around solutions for dialysis machines and bottle warmers, overcoming not only the language barriers but also a lack of tools to solve technical challenges. For instance, they had to use adjustable wrenches for repairs when they actually needed a set of socket wrenches.

The group's favorite fx came after troubleshooting an electrostatic unit for days and repairing several more obvious issues. Finally, they discovered a fried cockroach creating a carbon bridge that shorted out part of the circuit. After they brushed of the remains of the barbecued insect, the unit went back in service.

The students agreed the best moments were also the most rewarding.

"Every single time I put a machine back in service, I would see a doctor's face light up with gratitude,” said bioengineering student Mohamed Ali. "Even if they didn't know a single English word, their gestures would say it all."

In all, the team was able to repair:

• 3 fully electronic hospital beds • 3 manual/electronic hospital beds • 1 liquid warmer • 1 infant scale • 1 ECG printer • 7 vital signs monitors • 5 cords and power supplies for the monitors • 1 industrial oven • 1 tortilla machine • 1 bread slicer • 1 floor fan

A version of this story by Martha Bushong appeared in Mason News.

Mason engineering student Mohamed Ali works to repair a baby bottle warmer at Roosevelt Hospital in Guatemala. (Courtesy photo)

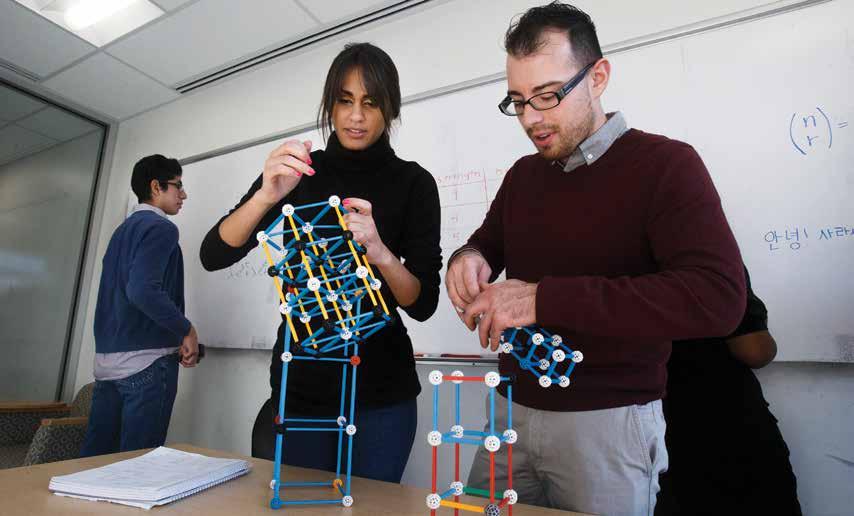

George Mason University students went to South Korea to work with students from Pohang University of Science and Technology (Postech) to collaborate on innovative approaches for designing products. Mason students on the multidisciplinary team ranged in major from engineering to biology.

West Meets East at Postech University in Korea

A group of six George Mason University students with majors in engineering, biology, math, and graphic design took part in a winter intensive class during the frst two weeks of January at the Postech University in Korea.

The class, supported by Mason’s Ofce of Student Creative Activities and Research (OSCAR) and led by Professor Padmanabhan Seshaiyer (from the Department of Mathematical Sciences, and director of the STEM Accelerator Program) and Associate Professor Nathalia Peixoto (from the Department of Electrical and Computer Engineering), also included six Korean students. Peixoto and Seshaiyer taught workshops on Design Thinking, Innovation, Creativity, and Entrepreneurship (DICE) at Postech, the leading Korean university in science and engineering. During the workshops, American students were paired with Korean students and each day they participated in hands-on activities, teamwork endeavors, and projects that required contributions from all team members. The fnal projects were based on a product design for a health care problem. Innovative solutions proposed by the teams will be submitted to undergraduate design competitions. The American group stayed at the Postech dormitories and ate at the student cafeterias every day, immersing themselves in Korean student life.

"I think the American students profted from the international experience and had the opportunity to observe how the educational system there works," says Peixoto.

A version of this story by Martha Bushong appeared on the Volgenau School website.