1 minute read

Introducing WineGuard™

Automated Handling Solutions (AHS) and Advanced Material Processing (AMP), material handling and processing platform companies consisting of Spiroflow and Cablevey Conveyors from AHS, together with Kason Corporation and Marion Process Solutions from AMP, have launched a new test facility in central Germany. The site is designed to service the whole of Europe and will enable customers to fully benefit from these unique partnerships and their integrated product portfolios.

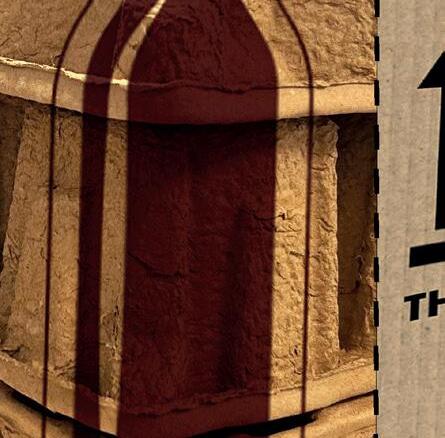

WineGuard™ is the new and secure way to send your bottled beverages through the post/courier system. Protect your glass bottles in transit with WineGuard Allpack’s range of bottled beverages transit packaging solutions.

The 1000 sqm premises is conveniently located close to Frankfurt Airport and offers customers the opportunity to experience the full range of products from all four businesses, including Spiroflow’s T6 Bulk Bag Discharger, T3 Bulk Bag Discharger, 4” AMC Conveyor, 3” AMC Conveyor, a full range of Flexible Screw Conveyors, Low Profile Bulk Bag Filler, CTE Filler, and SMART 4 Bin; Cablevey’s 6” Cablevey conveyor with wash down Clean in Place; Kason Corporation’s M1 CENTRI-SIFTER, Multi Deck Sieve, 24” VIBRO-BED Drying system - Fluid Bed Dryer, VIBROSCREEN, and Lumpbreaker; and to complete the offering, Marion Process Solutions’ M0 Mixer.

Manufactured using fully recycled materials and being fully recyclable, our pulp fitment ranges fit into specially designed cartons that can securely hold multiple bottled beverages, providing functional, affordable transit packaging protection.

The test center also includes a spare parts and service hub, in addition to a powder lab, where customer materials can

Pulp fitments and corresponding carton sizes available for the following amounts of bottles -

• x3

• x6

• x12 be evaluated before conducting bulk testing. Here, material characteristics such as bulk density, moisture content, and angle of repose can be identified to determine material flowability. The site is equipped with full dust extraction.

“This new facility offers a comprehensive selection of our products to customers in Europe and beyond,” said testing & facility manager, Emmanuel Ricohermoso III, Dr.-Ing.

“For us, it’s all about offering ease of access to our capabilities and expertise, as well as the opportunity to see how these technologies can be used to optimise material handling and processing systems.”

Tom Finnegan, Sales Director Europe for AMP and AHS, added:

“Adding to our portfolio of testing facilities globally, the center represents an important step change in our ability to service our existing blue chip multinational customers and new European based customers quickly to meet needs and requirements across Europe. Being centrally located means that we are well-placed to offer local sales and service support and assist with general customer enquiries.”

An official opening of the test facility took place on the 12 July. To arrange a trial at the new location, please visithttps://amp-ahs.com/test-facilities/#contact