10 minute read

Progress on the Wendover, Stover and Shrewsbury & Newport canals

Progress on the “S&N”

More progress on the Shrewsbury & Newport Canals Trust’s current major project to reinstate the East Basin at Wappenshall Junction

Shrewsbury & Newport Canals

The “Great Wall of Wappenshall” [the retaining wall of the east basin at the Wappenhall Junction where the Shrewsbury and Newport canals meet] was finally completed by Shrewsbury & Newport Canals Trust volunteers at the end of June and a “Topping out” barbecue was had to celebrate this milestone in our restoration plan. We then set about completing more of the basin base slabs. With 92 to cast in total, this will also be somewhat of a marathon task. As I type this we will have completed 36 of them.

Cement shortages have delayed progress, but we are now managing to get 4 or 5 done each week. We have dispensed with the concrete pump as it was getting expensive. We have now switched to a mix on site arrangement where the concrete is discharged into a 3-tonne swivel dumper and delivered to the waiting “spazzlers” to spread it. Once roughly spread, it is purged of any air pockets using a petrol driven vibrating poker. Then it is finally tamped and expansion slot laths are inserted 20mm deep around the edges. These are smothered in mould oil to ensure they can be easily removed once the concrete has set.

Our team of volunteers has now become quite proficient in using this method 3and 10-12m of concrete can be completed in about 2½ hours. The only problem we have encountered is that in the extreme heat, the curing concrete needed to be kept wet to stop it from cracking. So spraying with water for the following 24 hours became necessary. Night shift anyone?

The other major task has been to backfill the retaining wall up to towpath level. Each 150mm of soil has had to be compacted using a whacker-plate. This has proved to be very hard work, as many passes have been required along the 46m length of the wall. We are now about 400mm from the top of the wall. Another 2 or 3 weekends should see it finished. Bernie Jones

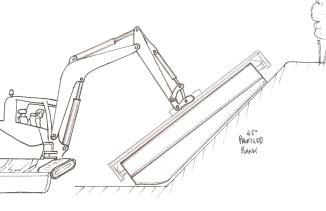

Opposite: SNCT volunteers completing a slab by tamping it down. The guys with spades are removing any excess concrete to the next slab. Above: Here are a team of “spazzlers” spreading the concrete over the reinforcing mesh that is supported on spacer rings that are on the polythene liner. Right: SNCT’s JCB excavator is putting soil behind the retaining wall. This is then spread with shovels and rakes, then whacker-plated at every 150mm depth. We had to attach a rope to the whacker plate to pull it over the wet soil. Extremely good free exercise if anyone feels like joining us!

Pictures by SNCT

Progress Wendover Arm

The Wendover Arm Trust are continuing with the next length of channel excavation and re-lining, and have invented ‘The Bentomatic’

Grand Union Wendover Arm

For the June working party it was dry and sunny, with all with all work completed just before we had 70mm or rain in two days! The weather was with us for once!

The pipe capping/roadway has continued at a pace during the good weather. We now have 245 metres of capping completed from Bridge 4 towards Tringford (work is proceeding from the far end of the dry section back towards the GU Main Line). During the recent works the second “lamp hole” (a shaft to allow inpection of the flow in the pipe, 2m below) into the pipeline was reached. As can be seen in the picture, the lamp hole is close to the towpath because of the glazed clay piping being laid in a series of straight lines on the curving canal. The next section of pipe goes off at a different angle to “graze” the offside apex of the next bend to the right. The lamp hole pipe was cut down below bed level and covered with a concrete slab before the normal pipe capping concrete was installed. Pipe capping: an explanation The Wendover Arm was built primarily as a feeder to bring in water from springs near Wendover to feed the Tring summit of the canal’s main line – but it suffered from long-term leakage problems as a result of the porous chalky soil it passed through, and this led to its eventual demise as a navigation, and to the worst section being drained many years ago. That’s the length that’s now being restored: it has an 18-inch glazed clay pipe installed underneath, buried in the canal bed, to carry a feed to allow water from Wendover to still reach the pumping station at Tring (and from there to the Grand Union main line) after the canal had been drained. Due to the age of the pipe (which is now abandoned and blocked), as part of the channel restoration and waterproofing work, protective measures must be taken to avoid damage to the new lining system if the pipe ever collapses under the restored canal. Therefore the pipe is being uncovered, a section at a time, and a concrete ‘raft’ or capping is being installed on top of it to provide that protection.

Pictures by WAT

Pipe capping being laid and Whilst excavating the bed for the capping we are going (below) a section completed below the coal tar lining (added late on in the canal’s working life to try to waterproof it) and the original excavation level when the canal was originally built. The local strata are very hard primaeval chalk and, even with modern diesel-powered excavators, this is difficult work! We can imagine the original navvies digging through this by hand: it must have been slow and tiring. Later, when the pipeline was installed, the steam powered excavator probably struggled to get to 2m down as well! Luckily the pipeline excavation shows us where the pipeline is buried. Swing bridge brickwork restoration: Work on the old swing bridge walls has been continued. The foundations for a curved wall have now been built up with heritage bricks to form a “lead in” from the 45-degree banks to the width between the swing bridge walls. This must be robustly built to withstand boating “errors” for many years to come! The first of several Memorial Benches was “planted” on the offside bank near to Whitehouses. Bentomatic: We are still developing a new method for laying the Bentomat (waterproof bentonite clay lining material) by use of an excavator. This uses a fabricated steel structure so that a Bentomat roll can be lifted and manipulated with an excavator. The framework has been designed, stress proven by analysis and built by a specialist Company. Special welding techniques were used to guarantee the joint strength required. A roll of Bentomat weighs around 1 tonne so a 13 tonne Excavator is required to avoid tipping over. After initial trials, some adjustments have been made, and it is hoped more trials can commence in July.

This equipment has been nicknamed ‘The Bentomatic’ in honour of Wallace and Gromit. When in use the reliance on manually handling of the Bentomat and the subsequent difficulties involved will be much eliminated. We will also not have to spend time and energy cutting the large Bentomat roll into smaller pieces to aid handling.

Historical refuse Tip: This is the short section of infilled channel just past the current limit of navigation at Tringford, where the unexpected discovery of contaminated fill (basically old domestic refuse with a lead content) has pushed up the expected cost of re-excavating it very significantly. Following on from some intensive work clearing the area (including the Bentomat cutting slab) and obtaining several technical proposals from hazardous material removal specialists, we are now in the process of further analysing the material in page 29

the tip. This has been done after we were given advice by one of the potential contractors, and it may mean that we can reduce the cost of removal of the infill if we can show that the material is less hazardous than previously thought. The results were expected to be available towards the end of July.

Wanted: An Archivist to sort out and help store hundreds of pictures on our cloud-based archive. We have many historical pictures that need to be stored for multiple access users. Once Impression of ‘The Bentomatic’ at work we have a viable storage and description procedure, extra help will be provided to get the pictures into the cloud. Tony Bardwell , Wendover Arm Trust Operations Director

Repairs to the old swingbridge wall while (below) the adjacent lead-in brick walls take shape

Progress Stover Canal

Next it’s down to South Devon, where the Stover Canal Trust are reproducing a historic wharfside crane from an oak tree and a black-and-white photo

Stover Canal

The volunteers of the Stover Canal Trust have been progressing the construction of a replica of the crane which was used at the Ventiford Basin terminus to load granite brought down from Haytor on Dartmoor onto the barges. We had just one black and white photograph to work from and much research was done to ensure the original was followed as closely as possible.

A suitable oak tree was sourced in north Devon and it was transported to a local sawmill to be fashioned into shape. The pieces were then taken to our compound near the canal (but unfortunately some 1½ miles from the basin) where it was skilfully finished, with the jib and supporting strut being fitted to the main shaft.

On 2 August the pieces were taken to the basin along the Stover Way cyclepath and assembed on-site. Some metalwork remains to be added to show the gearing used on the original and an unvelling is planned for mid-September. The whole Basin restoration, involving landscaping, planting, seating and an information board, is expected to be completed by Spring 2022.

We are grateful to the contributions which local contractors have made to the crane construction, many of them have worked at ‘cost’ rates or less!

Rob Harris Trustee, Stover Canal Trust

The Stover Canal Ventiford Basin crane Above: The only surviving photograph of the original crane. Opposite upper: a suitable oak tree for the main shaft, sourced in North Devon, is fashioned into shape at a local sawmill. Opposite lower: The strut and jib are fitted to the main shaft

Pictures by Stover Canal Trust

Stover Canal Length: 1¾ miles Locks: 5 Date closed: 1943

The Stover Canal, built between 1790 and 1792, was a short waterway running inland up the Teign valley in south Devon. From a junction with the River Teign above the head of the estuary at Newton Abbot it climbed via five locks (the bottom two built as a staircase pair) to a terminus at Ventiford. It was built to take barges up to 56ft long, but some of the locks were double this length, to take two barges at once. The barges carried ball clay from local clay pits down the Teign estuary to Teignmouth; from there it was carried onward by coastal shipping for use in ceramic trades. From 1820 the canal also served the granite quarries on Dartmoor via the Haytor Granite Tramway (with stone ‘rails’) until the quarries closed in 1858. After that the upper end of the canal fell into disuse, but the lower part continued to carry clay until 1937. It was closed in 1943.

Dartmoor Haytor Granite TramwayVentiford

Stover canal Teignmouth Newton Teign estuary Abbot R. Teign Site of crane: Ventiford Basin Graving Dock Lock: restored

Teigngrace Lock Graving Dock Lock Teignbridge Lock Jetty Marsh Locks

The Stover Canal Ventiford Basin crane (continued) Top: erecting the main shaft. Above: Attaching the strut and jib to the main shaft. Right: the crane erected and awaiting final metalwork.