8 minute read

Taking stock reimagining the production line

BAKERY, CEREALS & GRAINS

Taking stock

Reimagining the production line

Sam Schachna, CEO of Roma Foods, shares lessons learned and how he’s rethinking the world of work with SafetyCulture. Here’s a look back — and a lens on what’s next.

COVID has sparked a renaissance in the local food manufacturing sector, and companies like my own are fortunate to be riding this wave. Operating for nearly seven decades and exporting to over 70 countries worldwide, Roma Foods is an Australian, family-owned manufacturer on a mission to create great food for healthier living. Despite the upheaval caused by COVID-19, the pandemic has in fact accelerated opportunities for Australian food manufacturers. As consumers increasingly demand locally made, allergenfriendly and plant-based foods, we’ve had to take our operations to another level.

The future is very bright for local companies — especially if you are able to double down with the right tech, teams and operational approach.

The Australian food manufacturing sector was well prepared leading into the pandemic due to the Good Manufacturing Practices that are embedded within the industry. Nevertheless, COVID has highlighted several priorities and accelerated several trends in the food manufacturing sector. Something that insulated Roma Foods against major COVID disruption was our existing focus on local, robust supply chains. The industry will face continued supply chain disruption from both COVID and global influences. It is therefore critical to purchase locally wherever possible and build strong relationships to enhance the overall resilience of the sector.

Roma Foods is proud of its strong relationships with local suppliers based on years of collaboration. As an industry, we need to invest in the depth and capability of local supply chains — from farm to plate — to ensure that we are always in a position to provide food security to all in our community.

Investing in smart operations

not an even playing field for local manufacturers, as Australia does not have the scale or local market size to compare to global multinationals. To thrive in the local industry, it is critical to compete where local is a competitive advantage and to invest in skills and infrastructure to improve efficiency and innovation.

With ever-changing government regulations and market dynamics, COVID led to us adopting a new mindset of ‘measured urgency’, proving that we can do better, more quickly and effectively. To achieve this, Roma defined a new business strategy to meet the needs of the ever-growing health shopper, launching over 40 new products into the health and mainstream aisles and adopting new technology improvements such as digitising workflows to empower our journey of growth and innovation while ensuring we prioritise safe people, safe product and safe data. We’ve invested in tech solutions like iAuditor by SafetyCulture that can help staff perform checks, report issues and collect onthe-ground data in minutes. It hasn’t just unlocked the ability for us to achieve the step-change growth that we’re driving for, but has also allowed us to do it in a manner that is safe, agile and ambitious, always looking for avenues for growth.

Always have one eye on growth

Being alive to opportunity and taking calculated risks is key to survival. This is especially so in a time where there is so much uncertainty. Through COVID we scaled up to respond to increased demand in the short term and kept one eye on growth, launching new brands into new markets. Our community relies on us and it’s something we take very seriously.

A key tenet of an expansion mindset is investing in human and capital infrastructure. Our vision is to have a Roma Foods product in every family’s pantry. By investing in our people, brands and capability, we are getting closer to achieving our vision every day.

Fibre analysis

The Gerhardt FIBRETHERM fibre analysis automates the time-consuming and labour-intensive digestion and filtration processes for determining the various fibre fractions in grains, cereals and feedstuffs. It fully complies with the standard methods specified by Weender and van Soest. The system enables the simultaneous processing of up to 12 samples, which can reduce energy and chemical consumption, and the laboratory time taken compared to the standard manual method. The analysis system automatically controls and monitors all of the boiling, washing and filtration processes within a single self-contained system and users have no direct contact with any chemicals to ensure maximum safety and productivity in the lab.

The method is based on the FibreBag technology developed by C. Gerhardt. This filtration technology can avoid the common problems associated with the classic filtration method using frits and filter beds, and it simplifies the handling and digestion of samples to help ensure fast, consistent and precise results.

Bio-Strategy Pty Ltd

www.bio-strategy.com

Long-cut pasta packaging system

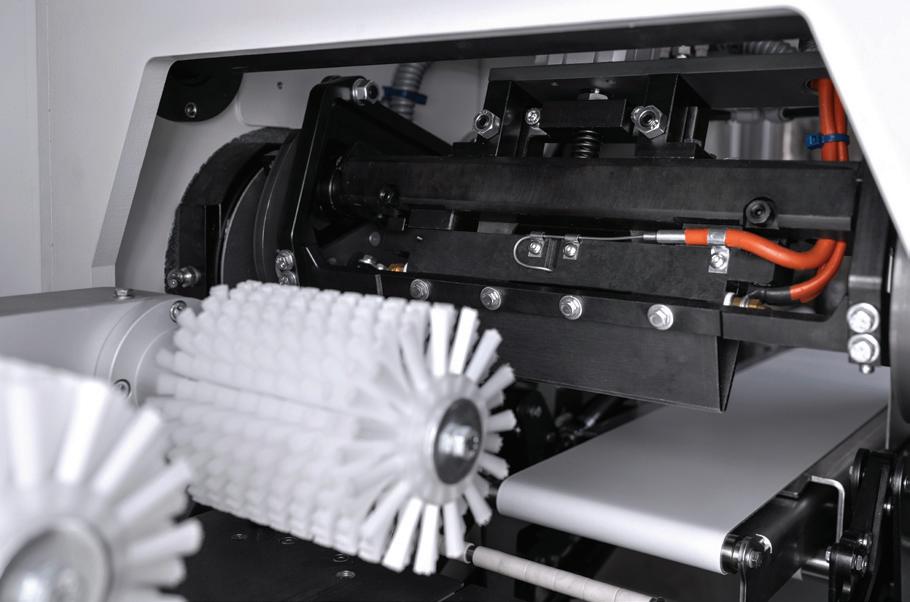

GEA has re-engineered the H-Packer SO Plus for long-cut pasta packaging by integrating a faster technologically advanced system, comprising a double dosing unit and a continuous motion packaging machine. The system is designed to enable pasta manufacturers to increase product flow, minimise product loss, simplify line control, and ensure smooth filling in the packaging process.

The modified version is equipped with a second weighing hopper and artificial intelligence. A new electronic architecture based on the Siemens PLC provides centralised system control and a customisable operator interface.

The LC-Doser DDW dosing unit of the system has been redesigned to optimise product flow to the horizontal packaging machines for flat and rough shapes and to reduce product breakages.

The system features LED lighting for quick visibility of possible malfunctions in the process and a protective device equipped with coded sensors to achieve a high safety standard. Moreover, thanks to a motorised reel holder, the machine can work not only with conventional plastic films but also with paper films.

The machine is completed by a renewed patented stripper-gripper system.

GEA Australia

www.gea.com

Allergen-free legume flours

Müller’s Mühle Business Solution has released its SMART Pulses Pro range of legume flours. The natural flour concentrates obtained by air separation are allergen-free, clean label and high in protein, making them suitable for the production of texturates for plant-based meat alternatives.

The key feature of the flour is the high protein content, which is increased to up to 65% through the air separation process.

Made exclusively from legumes such as yellow pea and fava bean, the flours are also allergen-free and clean label.

Müller’s Mühle

www.muellers-muehle-b2b.de/en

BAKERY, CEREALS & GRAINS Health bar maker enhances food safety and line efficiencies

Based in Canada, Luxme International has supplied a SANILux Tubular Chain Conveyor with automated clean-in-place technology to nutrition bar manufacturer TruFood, enhancing food safety and increasing line efficiency.

In 2019, increased customer demand prompted the US-based manufacturer to embark on an expansion project to boost its manufacturing capabilities. High on the list for improvement was the company’s ingredient delivery system — a multi-step manual process that required significant time and labour to prepare and transfer fine and coarse ingredient powders and inclusions such as chocolate chunks, soy crisps and cookie pieces to the mixer. It not only required an automated ingredient transfer solution that would increase yield and improve line efficiency, but it also needed to ensure food safety by reducing the risk of allergen cross-contamination between changeovers for different product ranges.

Following discussions with several equipment manufacturers, TruFood decided on the SANILux Tubular Chain Conveyor from Luxme. “As well as efficiently transferring screened and weighed powders and inclusions to the mixer, the ability of the SANILux to reduce the time required for a sanitary changeover and remove all allergens from the conveying system were ultimately behind our decision to partner with Luxme,” said Mike Berko, Project Engineer, TruFood. “Their willingness to work within our constrained space requirements also impressed us.”

Avoiding allergen cross-contamination

As a producer of nutrition bars with a wide range of certifications and claims — including kosher, non-GMO, organic, halal, glutenfree, fair trade and sugar-free — TruFood takes its commitment to avoiding allergen cross-contamination seriously.

The manufacturer faced a variety of challenges when seeking to upgrade its operation. “We work with mid-sized emerging brands as well as established consumer packaged goods (CPG) companies commercialising new product platforms,” Berko explained. “With this comes additional complexity, requiring sophisticated systems to protect and propel their brands. To better support these partners, we not only required more flexible and consistent operations, but also easier, more efficient changeovers and sanitation protocols. Sanitary design and ease of cleaning are forefront in our minds when evaluating any new solution.” To meet these requirements, Luxme specified its SANILux Tubular Chain Conveyor technology. An enclosed, self-cleaning system, it is designed to protect ingredients from atmospheric, airborne contaminants and other bacterial elements. The automated CIP technology is designed to ensure the conveyor is fully sanitised in just 60 minutes, and is validated with allergen swab testing.

“The SANILux can go from dry to dry, fully allergen sanitised, in just one hour — about 10% of the time it took us previously when the process was manual,” Berko said. “As well as improving food safety, this has translated into an uplift in our production capacity as changeover of the delivery system is achieved in a fraction of the time required on our other production lines, minimising downtime. By removing a manual process, it has also resulted in labour savings.”

The conveyor itself comprises a fixed drive and tension assembly, which automatically tensions the chain continuously during the process and regulates it according to friction, product flow and variation in atmospheric/product temperature.

Capable of 300, 500 or 1100 ft3/h capacities, the system is suited for the automatic conveying of all types of food, at any stage of receiving, processing and packaging.

The system has been running successfully at TruFood’s manufacturing facility since it was installed in May 2020.

In addition to fulfilling the sanitary requirements, it has also delivered improvements such as gentler product handling, reduced ingredient fines, automated and repeatable process and waste minimisation with the sealed conveying solution.