2 minute read

Filtering rice paste for baby cereal

Rice cereal is a common first food for babies once they reach six months as it contains B vitamins, minerals and some of the nutritional value required by the infant at this time. Compared to other grains, rice cereal is also a favourable choice as it’s less likely to trigger an allergic reaction.

A food factory in China that specialises in the production of rice cereal recently sought help from Russell Finex to ensure its product met stringent food health and safety regulations.

Since the factory opened, demand for its products — including milk powders, cereals and infant formula — has increased, which has required the food manufacturer to optimise its production line.

Having never used a filtration machine in its production line, the food manufacturer trialled both the Self-Cleaning Russell Eco Filter (SCF) and Russell Filter Management System in its processing line.

The SCF has a stainless steel, reusable filter element instead of a filter bag, which is designed to eliminate the replacement and disposal costs of filter bags. The enclosed design of the SCF also protects the rice paste from airborne contamination in the environment.

To streamline production, the Russell Filter Management System was used to monitor the filtration process, minimising operator involvement. Automating this task also meant operators could focus on other tasks while eliminating the potential risk of hazardous exposure.

After a successful trial, the filter was used to filter out oversize and contamination from the rice paste before being heat treated. The filtration equipment is processing six tonnes/h, which has resulted in a significant boost in production.

Russell Finex www.russellfinex.co

Mechanical skewering machine

The MyBroch Production by French manufacturer SYSTEM B is a simple and ergonomic skewering machine suitable for butchers, food trucks, caterers, manufacturers of prepared foods and supermarkets. It is designed to be safer, faster and more precise than skewering by hand.

It is intuitive to use so no extensive training is required to operate the machine. It also involves no electrics or pneumatics, thus reducing possible downtime.

The versatile and modular machine has interchangeable moulds for fish, meat and vegetables, and various possibilities of lengths, widths and styles included in the one machine.

It is compact and fits on a benchtop, and it folds away when not in use. All parts are easily disassembled for cleaning and the machine frame can be sprayed with a water jet.

The machine is designed to improve the experience of workers involved in a labourintensive process, reduce the possibility of injury and increase efficiency.

Barnco Pty Ltd www.barnco.com.au

Durable drives for belt conveyor systems

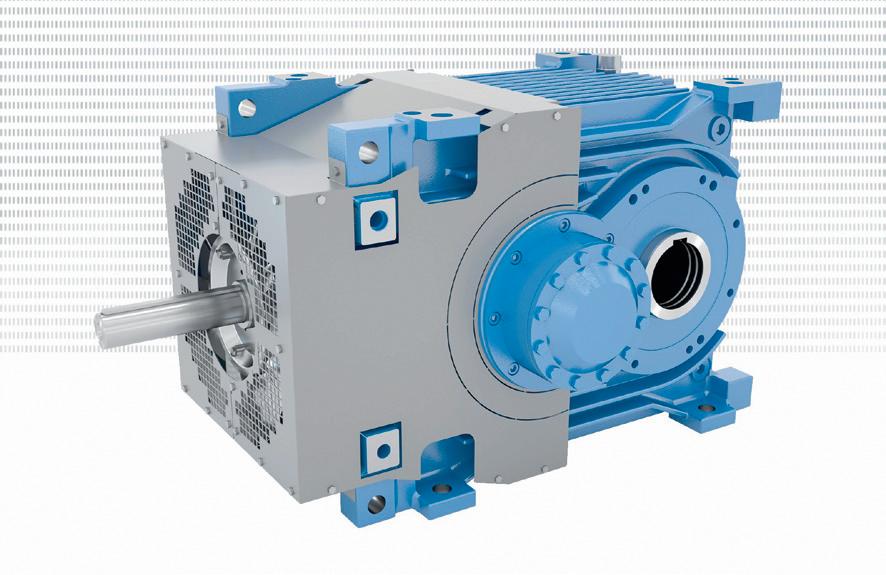

The MAXXDRIVE XT industrial gear unit from Nord Drivesystems provides output torques of 15 to 75 kNm with speed ratios from 6.3 to 22.4 and is offered in seven sizes for powers from 22 to 2100 kW.

The power and speed ranges of the two-stage right-angle gear unit have been specially designed for industries in which low speed ranges are required in combination with high powers, such as the bulk goods and mineral industries. Its robust design makes the MAXXDRIVE XT resistant to dirt and is suitable for use in rough operating conditions. A special sealing concept reduces maintenance, while large roller bearings and centre distances can increase the load capacity and service life of the components.

As standard, the industrial gear unit is equipped with a heavily ribbed UNICASE housing and an integrated axial fan. Due to the increased surface and the airflow covers, the cooling airflow is optimised and a high thermal limiting power is achieved. In many cases, additional cooling is not required.

NORD Drivesystems (Aust) Pty Ltd www.nord.com