4 minute read

We support joint training partnerships with industry

Ready to LEARN.

Advertisement

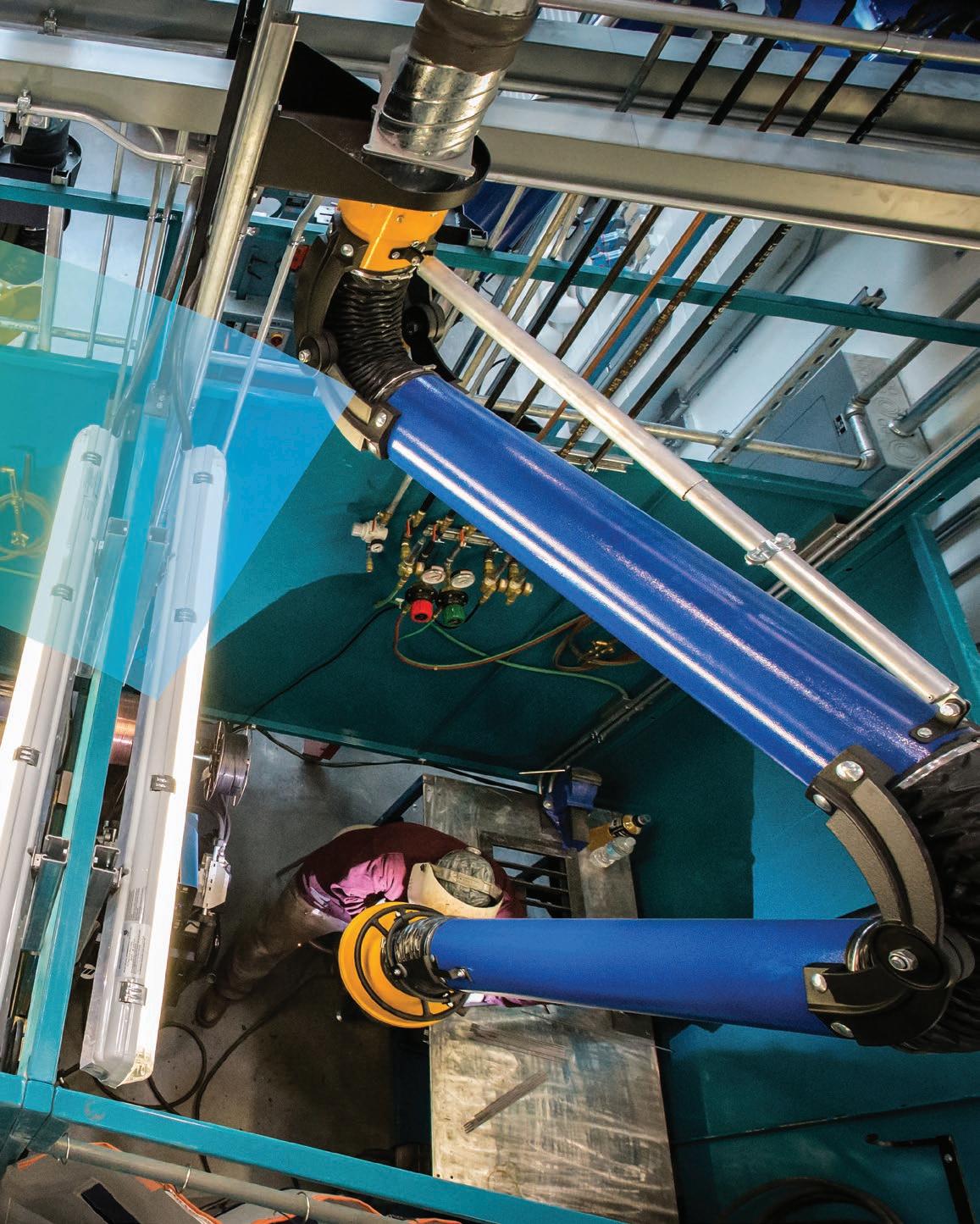

The Welding shop in Lethbridge College’s new Trades, Technologies and Innovation Facility has 60 welding booths where apprentices learn a variety of different welding processes to prepare for careers. Before the new building opened in 2017, students would learn the operations at various booths; these state-of-the-art multi-process booths allow students to remain in place as they practise any of the different processes. The welding student shown here is practising skills with the Shielded Metal Arc Welding process, one of several welding and cutting processes students learn in their second year. Welding students also can benefit from working with a “virtual welder” – one that allows them to practise a particular technique over and over again, such as maintaining even pressure or a correct angle. “Our virtual welder simulates the real welding experience and requires real welding procedures – the sounds, the lights, the sparks,” says Dave Heins (Agriculture Mechanics 1992), an instructor in the Welding apprentice program. “Your body will learn after you’ve practised enough. You can look at the weld and the wire and get a very accurate sense of your work.” The goal, welding instructors say, is to have the students learn to react exactly the same way each time.

READY FOR WHAT HAPPENS NEXT

Our new Trades, Technologies and Innovation Facility (TIFF) positions Lethbridge College as the institution for trades training in southern Alberta by bringing together students, faculty and industry to create a vibrant, responsive learning environment.

The facility is the single most important capital investment for trades and technologies in southern Alberta in over 50 years. It’s also the largest construction project in the college’s history. It has increased our capacity to train the next generation of skilled tradespeople and engineering and design technologists. And it’s revolutionized our curriculum, bringing together students, faculty and industry partners in a modern, environmentally-sensitive space that features:

• modern labs, apprentice shops, tool rooms, classrooms, meeting rooms and offices • more than 200 solar tubes to provide natural light to the workshops and classrooms and to reduce energy costs • 60 welding booths set up for students to learn five different welding processes • rooms housing wind turbine components to train on • a multi-purpose lab that provides students with learning opportunities for fluid mechanics and surveying applications • a dedicated 3D printing room • collaborative spaces to incubate the great ideas of tomorrow

ALL ABOUT TTIF

• Construction ran from April 2014 to August 2017. • The total construction cost was $77 million. • Construction used 31 per cent of regional materials and 22 per cent of recycled materials. • Over 80 per cent of construction waste was diverted from the landfill. • The facility prioritizes space for student learning: o 72 per cent of the square footage is dedicated to shops, labs and related support. o 14 per cent of the square footage is dedicated to lecture, classroom and seminar space.

$ 10M

NEARLY $10 Million dollars WERE raised in our Possibilities are Endless Campaign, THAT went toward the new Trades, Technologies and Innovation Facility

168,812

The Trades, Technologies and Innovation Facility provides 168,812 sq. ft. of state-of-the-art facilities for students in a variety of skilled trades and technologies programs

READY TO TEACH THE NEXT GENERATION

When the builders and industry leaders of southern Alberta saw a shortage of skilled plumbers in the region, they looked to Lethbridge College. And Lethbridge College responded to their need – creating a new Plumbing Apprenticeship program.

In 2019, the apprentices in the first cohort of the fouryear program walked across the stage to receive their diplomas – as well as their “tickets” ensuring they had the skills, knowledge and experience needed to succeed in this growing field.

From Lethbridge College’s earliest days, the institution has been responding to the needs of the community, providing outstanding educational experiences close to home. And this important work couldn’t be done without the dedicated and skilled teaching that happens each day in the classrooms, labs and shops across campus. Students and apprentices benefit when they learn from instructors who are experienced in the fields they teach. From automotives to welding to wind turbine technicians, our instructors know their subjects extraordinarily well – because they’ve done the work themselves.

The entire campus community and our 40,000+ alumni are grateful for their work. Thanks to their instructors, our grads are ready for what happens next. They know it matters most.

HERE FROM THE BEGINNING Mechanics and Welding programs were some of the first programs to start at Lethbridge College in 1957.

1957

What happens next matters most.

TRADES PROGRAMS AT LETHBRIDGE COLLEGE

• Agricultural and Heavy Equipment Technician • Automotive Service Technician • Automotive Systems • Baker • Carpenter • Cook • Culinary Careers • Electrician • Heavy Equipment Technician • Parts Technician • Plumber • Welder • Wind Turbine Technician

lethbridgecollege.ca/trades

Want to learn more about the skilled trades at Lethbridge College? We’d love to hear from you.

Centre for Trades tradeslc@lethbridgecollege.ca 403.320.3411 lethbridgecollege.ca/trades

403.320.3202 3000 College Drive S. Lethbridge, AB T1K 1L6

lethbridgecollege.ca