The surprising benefits

‘Autism spectrum disorder (ASD) is a general term that defines a complex group of neurological conditions characterized by varying degrees of deficits in social-emotional reciprocity, nonverbal communication in social interactions, and in developing, maintaining, and understanding social relationships’ (Suha Hussein). Few of us are unaware of the struggles of children with ASD both in the education system and in the family dynamic.

So it is quite good to know that creative activities like pottery could help with these issues.

As a retired teacher and mother of four children with autistic tendencies I have long known the benefits of tactile activities on aiding focus, attention and calming sensory issues. Now it seems there is the research behind creative activities which supports this experience. For those struggling with the behaviour of children in the classroom, at home with ongoing sensory issues, pottery seems to help in a variety of ways.

‘Pottery’ is a broad term which includes hand-building sculptures with clay, throwing clay on a motorised wheel, and using techniques such as carving, pressing, rolling, wedging, coiling and decorating. One teacher Alice Darlington designed specific clay-based lessons for those with autism to assist intellectual development and communication skills. According to her, pottery activities: ‘significantly boosts the confidence of the participants, it generates a sense a curiosity among the students as they begin to ask questions, and the inclusive nature of workshops… improves the social interaction as they get to communicate and work with others’ (Autism 360.com).Whilst these comments could equally apply to any artistic activity, Professional Potter Blake Zucker explains just why clay is so special.

‘

My pottery is made on a pottery wheel; the spinning movement is soothing. While pulling up the clay there’s a manipulative force and creative energy that allows me a sense of freedom. Clay has a forgiving quality that’s appreciated, with a flexibility that most materials don’t offer. Wedging clay is a pure physical movement and fierce energy; this is satisfying in itself’

Blake very specifically describes the way in which working with clay assists focus, regulation of emotions and communication:

‘Thinking of what I will be making, I slap the clay on the wheel. While centring the clay I give thoughts to what I will be making. When I’m unable to sort out my feelings and thoughts my work can express emotions help me move forward and bring a balance in life. Many times my works are a profound voice when I have difficulty speaking.’(Autism is art)

Pottery is therapy also for the anxiety which often manifests in Autism. According to Elizabeth Kvarnstrom it is a powerful artistic avenue which deeply benefits people suffering from mental health issues. This is because it combines the primal experience of touch (clay, tools) with emotional and creative engagement. In this way she believes it activates our natural resilience, in a sense grounding the self.

The arts are often overlooked as non essential learning or activities, but in reality they are closely aligned to cognition, visual and spatial awareness, fine motor skills and resilience. Art allows those with autism to express themselves through images when they struggle to communicate. As visual thinkers those with ASD can use the concrete materials for self expression, imagination and self-soothing. When conversation is stressful, interactions with clay is a useful tool to communicate what the individual is thinking or feeling and still remain included in the class.

Most of all those with ASD can benefit from emotional regulation by engaging in thoughtful, deliberate activity; ‘Pottery incorporates physical movement and tactile sensation with meditative practice. Pottery creation can be deeply relaxing and provide solace from troubling thought patterns and behaviours’ (Bridges to recovery)

Many people have discovered the therapeutic benefits of pottery without perhaps knowing exactly why. These studies contribute much in our understanding of viable interventions for those struggling with ASD.

Blake Zucker: Why making Ceramic Pottery is my Preferred Art Form | The Art of Autism (the-art-of-autism.com)The Impact of Art on Autism - Autism Care Today (act-today.org)

Pottery May Improve Autistic Intellectual Abilities | Autismag (autism360.com)

Pottery Therapy in Mental Health Treatment - Bridges to Recovery

Why make your own glazes?

• They create a unique glossy finish to your pottery

• It doesn’t involve toxic chemicals on your pottery or in your kiln

• You can use materials from around home

• Is usually cheaper

What is glaze made from?

Basic ash glaze- historically used in Chinese, Japanese& Korean pottery

Made from simply wood ash, clay in approx. half and half proportions with water added. Specific woods produce slightly different effects when burnt into ash and included in this recipe; likewise the type of clay ie: fire, powdered porcelain, stoneware

Salt glaze: salt is introduced into the kiln at high temperatures ie 12000 to create a pitting effect. The salt reacts with the silica mineral in the clay to form a glossy,

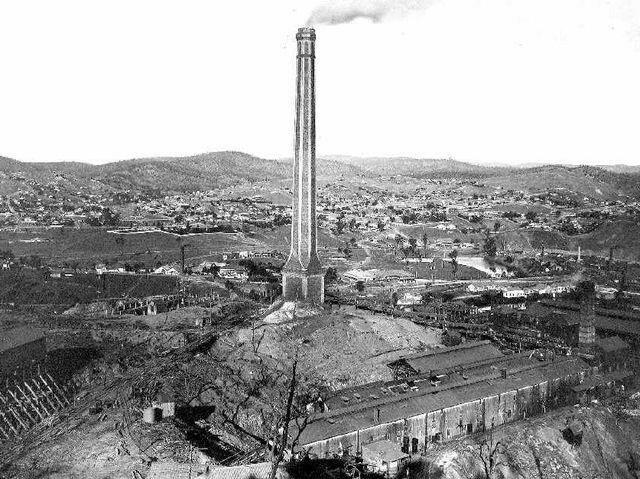

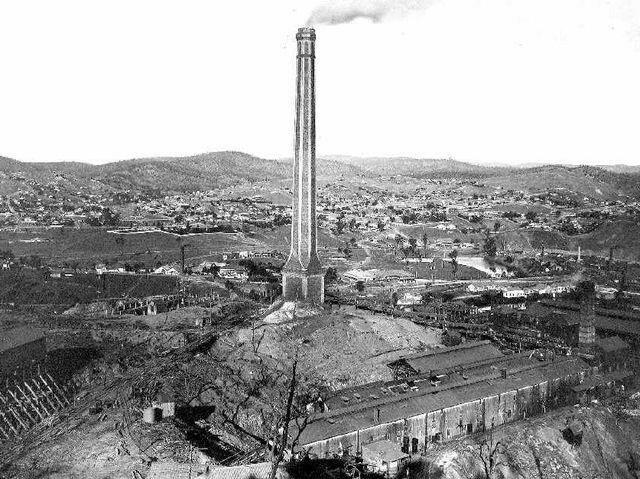

Henry Crissman’s Mobile Anagama Kiln

In our first edition of ‘wild pottery’ I described my research journey into the Anagama Kiln.

I had come across extremely talented and skilled ceramicist Henry Crissman in NY who had designed and created the mobile Anagama Kiln based on the Japanese Anagama design.

I was excited to finally find the blueprint to this kiln and even more excited when the arts co-ordinator of a nearby township wrote a letter of support for the building of such a kiln which would support their arts community as well as mine.

Of course, despite a background in DIY I would baulk at such a project which involves welding and archway engineering. So I turned to the very skilful Men’s Shed in Mount Morgan, who were a little overwhelmed at the scale of the build. Needless to say they have offered to construct the inside wooden skeleton should I pursue the project. A more interesting point was made that this trailer would be very heavy and how was I going to tow it? I also wondered how I would go about getting it registered for road use…

In the meantime I have successfully fired up my mud daub wind tunnel kiln to 830 degrees and with a few alterations feel I could make it up to bisque fire. I have also managed to make this without spending a single dollar on materials (or labour!) I just using the oil drum I had, the modified washing machine tub that had been welded into a smoker, with legs and hinged door. This shell was insulated with raw clay, rocks and clods of earth dug from my designated concrete slab area. A chimney was inserted into the drum lid and covered in another 2 inch layer of insulation. So far I have fired the artworks from the workshop with great results, on an internal rack half way up the structure.

.

Raw clay

Location

10cm under surface of ground in a seam 1 metre thick

Hillside

Filtered & wedged clay Fired clay bisque

yellow dense clay sticky when wet

On surface appeared as rock, next to riverbed

Cemetery

Grey brown hard lumps

Cracked road – breaks off in chunks

Car Lyn red clay near brickworks

chocolate crumbled clay that is soft when wet

In garden while excavating

I put a call out locally for anyone who think they have clay to contact me. Here is what we discovered….

I recently stumbled across the Wild Clay Club worldwide and thought ’d share the beautiful creations from the variety of coloured clay found in the ‘wild’

Figure 5 Mary Kate Shire

Figure 4 Tonya Fedders

Figure

Figure 2 Andreia Pinho

Figure 3 Ms Uhlrick Brisbane

One of the challenges in using wild clay is that it does not come ready to use in a slab. The crumbled clay you might find first needs to be hydrated and then refined in some way in order to use especially on the pottery wheel.

I began hand-building with my local yellow clay after just adding water and wedging, removing rocks as I did so. I managed to build and fire this well, but found that the result often crumbled and had a rough textured finish. I did some research into refining and found some very expensive methods on one hand and very cheap options on the other.

If you have a spare $4500 you could go for the highly recommended Venco pugmill. (see image below). Sold in Australia this is for the studio potter and reports to aerate, refine and consolidate What is a pugmill you ask? Well, apparently it is a feed hopper with a motor useful in mining, farming and ceramics. It is used to blend new clay or clay scraps to create a more uniform and workable consistency. Clay is loaded into the feed hopper and the internal auger pushes the clay through the barrel through a fine screen, compressing the clay and forcing it out the nozzle. As you can see in the photo above, the clay is perfectly formed and ready for use.

On the other cheap end of the scale is hand forcing through a sieve – some even use a metal kitchen sieve My own experimentation began with some leftover flyscreen mesh I stapled to a frame. This worked very well to sieve the clay to a fine smooth result but was very labour intensive and the mesh kept stretching and eventually wearing out. My arms and hands were similarly worn out!

At the local hardware store I found a gardening sieve which was a circular plastic shape and the square holes approximately 5mm each. While it was much easier to use the result was not as effective; the sand and grit content was still too high. My next trial was with a gold-panning sieve (see image below); made of sturdy metal and circular, it was lovely to hold, sat perfectly over a bucket and removed some grit. The weave of the sieve however is not flat and the grit caught in the grooves so that it was not easy to remove. It becomes time consuming when after each drag I needed to wash out the grit. If I banged the clay through, the grit simply went into the refined clay.

A combination of these approaches will I believe work, to overlay flyscreen mesh onto the metal sieve to provide fine sieving and structural frame to prevent stretching I’d welcome feedback from anyone who has used other s

Figure 6 Venco minipubmk11

Figure 6 Venco minipubmk11

Journalists recently in Australia have exposed the ‘epidemic’ of silicosis in young tradespeople in the manufactured stone industry. Just like mesothelioma and asbestosis before it, those working with raw materials are at high risk of dust borne respiratory diseases.

What has only just come to the attention of Visual Art Teachers and home Potters is the risk inherent in clay. Despite clay being a ‘naturally’ found raw material unlike manufactured stone or asbestos sheeting, what is not commonly known is that clays are minerals composed of hydrated aluminium silicates which often contain large amounts of crystalline silica, the inhalation of which is responsible for occupational lung disease.

Like mesothelioma, chronic silicosis is also slow to develop and symptoms may not appear until years after exposure to crystalline silica. Symptoms include:

• Shortness of breath

• Persistent cough

• Fatigues

• Rapid laboured breathing

• Chest pain

• Fever

• Gradual darkening of skin

• Gradual dark shallow rifts in nails leading to cracks

What can be done to prevent inhalation in the home pottery studio?

1. Use respiratory masks and air ventilation systems when using powdered clays

2. Maintain clean environment – don’t allow dust to settle

3. Use wet down approach rather than sweeping. Use wet cloths and mops to clean area to trap the dust within the wet material

4. Avoid shaking out of towels and aprons- hose down instead

5. When burnishing, sanding or scraping greenware or bisque use respiratory masks

https://ehs.princeton.edu/.../art-theater-safety/art-safety/ceramics

ByGumersindorego-Ownwork,CCBY-SA3.0,https://commons.wikimedia.org/w/index.php?curid=17408768

What is Silicosis – Hidden Dangers of Working with Clay at Home

by Lauren Baker

| Jun 7, 2021

www.wildmountmorganclay.au

Head & Shoulders Workshop Open coil Vase Workshop

Blake Zucker

Blake Zucker

Figure 6 Venco minipubmk11

Figure 6 Venco minipubmk11