marlboroughwinenz.com HALF CENTURY STU MARFELL CIRCULAR WINE YOUNG WINEMAKER ISSUE NO. 346 / OCT 2023 THE OFFICIAL MAGAZINE OF MARLBOROUGH WINE

Photo: Jim Tannock

Sizable viticulture asset in the Waihopai

Readily available is 20 hectares of uncontracted fruit, nestled harmoniously in the heart of the desired Waihopai Valley Marlborough The property consists of 7 4 hectares devoted to the cultivation of the quality Sauvignon Blanc and 12 6 hectares dedicated to the production of awardwinning Pinot Noir It's a haven that beckons both wine enthusiasts and those with an appreciation for the purest expressions in the industry or perhaps a company looking to expand their evergrowing portfolio Located just minutes up the picturesque Waihopai Valley, you'll find this vineyard enjoying an enviable location It places you within an arm's reach of renowned wineries allowing you to immerse yourself in the tapestry of the region's rich winemaking culture Here, you can relish the convenience of easy access to key winemaking establishments Known for its excellent flavor profile the fruit is an opportunity to secure Sauvignon Blanc and Pinot Noir that could easily be used for quality table wine or converted to rose production which is rapidly becoming a consumers go to The site comes with a good water right and the envision to replant in consecutive years with current infrastructure having 2 5 metre rows to support the redevelopment With the potential to build on site this property offers you a blank canvas to create a rural haven and guarantees an established income to support a healthy and fruitful lifestyle in Marlborough This site has the versatility to be a grower in the Marlborough wine industry, an investors opportunity or an extension for an established wine company, this sizeable vineyard is a canvas of possibilities Our vendor is motivated to sell and is looking to step back from the tools so contact Mike Poff or Charlie Fairhall McLean for the information pack or to view this property

Deadline Sale 12pm, Thu 09 Nov 2023 33 Seymour Street, Blenheim Charlie McLean I 027 346 1671 charlie.mclean@bayleys.co.nz BE MARLBOROUGH LTD, BAYLEYS, LICENESED UNDER THE REA ACT 2008 Mike Poff I 027 665 5477 mike.poff@bayleys.co.nz BE MARLBOROUGH LTD, BAYLEYS, LICENESED UNDER THE REA ACT 2008

bayleys co nz/4135681 bayleys.co.nz

Waihopai, 470 Waihopai Valley Road

this issue...

12 Circular Economy

The Marlborough Circular Wine Group is taking a collaborative approach to waste, carbon emissions, soil health, and biodiversity. “In every session there’s someone saying, ‘we could do that’,” says facilitator Melissa Macfarlane.

18

Young Winemaker

Preparation, experience and loads of support from his ‘Matua family’ were key to Callum Haynes taking out the title of the 2023 Tonnellerie de Mercurey Marlborough Young Winemaker of the Year competition.

24

Vineyard Stalwart

Seventeen years after he arrived in Marlborough from Fiji and began his career in vineyard work, Dhirendra Swami takes huge pride in efforts that help ensure the quality of the region’s vines and wines.

Winepress October 2023 / 1 12 24 18 FEATURES Editorial -

Vantage Point - Bill Spence Wine Story - Stu Marfell Generation Y-ineBilly Brown 30 In the Pipeline Quentin Davies 32 Biosecurity WatchKerrie Hopkins 34 Industry News 36 Wine Happenings Cover:Pernod Ricard Winemakers

Zealand regenerative viticulturist

Doughty at Triplebank Vineyard

Marlborough’s Awatere Valley.

Tannock See page 15.

Sophie Preece

New

Jason

in

Photo Jim

20

◆ Over 60,000 cubic metres of storage spread over two sites.

◆ Chilled storage available during vintage for handpicked grapes.

◆ Sophisticated monitoring equipment ensures your product is kept at the optimum temperature.

◆ We could lease you a small room for your exclusive use to suit your particular temperature requirements (0 o C to + 30 o C).

◆ We store bottled wine, barrels of wine and new plants awaiting the opportune time to plant.

◆ Individual rooms available to grow new budwood.

MECHANICAL ENGINEERING WWW.PHOENIXMECHANICAL.CO.NZ 021 177 2669 Warm and Chilled Glycol Systems Design & Build Mechanical Services Heat Recovery Systems S/S Wine and Juice Lines Water Treatment and Filtration “Over 15 years experience serving the Marlborough wine industry ” PHOENIX FERTILISER SPREADING. 03 578 9590 Broadcast Bandspread Variable Rate sales@centaland.co.nz MARLBOROUGH NO TILLAGE FOR ALL YOUR REGEN VINEYARD SERVICES GROUND AERATION SPECIALISED DIRECT DRILLING CRIMP ROLLING MATT RYAN 021 865 232 PIP RYAN 0274 865 232 CALL TODAY TO DISCUSS YOUR OPTIONS PROVINCIAL COLDSTORES LIMITED Let us take care of all your controlled Temperature storage requirements: ◆ Custom controlled area ◆ Approved Transitional Facility for unloading of Imported Containers

Old Renwick Road, Blenheim Tel: 03 578 2648 Fax: 03 578 2546 www.provincialcoldstores.co.nz Gouland Road, Spring Creek. Tel: 03 570 5944 Fax: 03 570 5955 “the coolest

in Marlborough” C M Y CM MY CY CMY K PCL AD Winepress 2016.pdf 1 15/07/16 3:21 PM

place

General Manager:

Marcus Pickens 03 577 9299 or 021 831 820 marcus@winemarlborough.nz

Editor: Sophie Preece 027 308 4455 sophie@sophiepreece.co.nz

Marketing and Communications:

Sarah Linklater 021 704 733 sarah@winemarlborough.nz

Events Manager: Loren Coffey loren@winemarlborough.nz

Advocacy Manager: Nicci Armour advocacy@winemarlborough.nz

Advertising:

Joanna May advertising@winemarlborough.nz

Grape Grower Directors:

Andrew Nation nationa@gmail.com

Anna Laugesen anna@craiglochart.co.nz

Michiel Eradus michiel@eraduswines.co.nz

Nigel Sowman nigel@dogpoint.co.nz

Tracy Johnston tracy@dayvinleigh.co.nz

Wine Company Directors:

Beth Forrest beth@forrest.co.nz

Damien Yvon damien@closhenri.com

Gus Altschwager gus@akwines.net

James Macdonald james@hunters.co.nz

Jamie Marfell

Jamie.Marfell@pernod-ricard.com

Designed by: Blenheim Print Ltd 03 578 1322

Disclaimer: The views and articles that are expressed and appear in Winepress are entirely those of contributors and in no way reflect the policy of the Marlborough Winegrowers. Any advice given, implied or suggested should be considered on its merits, and no responsibility can be taken for problems arising from the use of such information.

This document is printed on an environmentally responsible paper, produced using elemental chlorine free (EFC), third party pulp from responsible sources, manufactured under the strict ISO 14001 Environmental Management System and is 100% Recyclable.

From the Editor

WRITING ABOUT Marlborough’s wine industry each month means disseminating information about soil, microbes, genetics, plant health, varieties, workforce, technology, climate, biodiversity, marketing, and exports. There’s plenty more to talk about in wine of course, including seasonal workforces, competitions, celebrations, regulations, logistics, biosecurity, and infrastructure.

But mostly I think we write about people. And that’s what I love to hear about in wine – whether it’s a scientist excited by the chemistry behind a trial, a viticulturist measuring the soil impacts of a cover crop, a winemaker passionate about growing the place of Chardonnay in the region, or senior executive planning planting days for the good of people and planet.

In this edition we have plenty of those people, from the Marlborough Young

Winemaker of the Year to a vineyard supervisor taking pride in the work he and his team do in the region’s vineyards. There’s a story on Stu Marfell, a winemaker and show judge whose watched tough Awatere Valley farmland transform to worldclass vineyards, and on a truck driver whose career in wine has been a little bit accidental.

Marlborough’s Circular Wine Group is also featured this month, celebrating the collaboration of a group of industry members, spanning small and large wine companies, determined to reduce waste and emissions while growing biodiversity and soil health.

The group is leveraging industry insights, experiences, ideas, and energy, to offer sustainability solutions for individual businesses, says Rose Family Estate winemaker Nick Entwistle. “People have different interests and scale and different ambitions. But everyone is trying to be proactive, and I don’t think you’d find many other industries where people are investing as much time and thought into it collaboratively to come up with a solution.”

SOPHIE PREECE

Winepress October 2023 / 3

"For all those subjects there’s typically an individual, team or community dedicated to doing things better for business, environment and the industry at large."

Vantage Point

More than 50 years of Sauvignon Blanc

BILL SPENCE

THE IDEA for new and different grape varieties was seeded by my brother Ross, who was studying at Fresno State University in California. In the university vineyards he found many European grape varieties that were not grown commercially in New Zealand. When he returned from the United States, and with a loan from our grandmother, land was purchased in Huapai. This land was used to grow and propagate root stock for other varieties to be grafted onto, which were sold to wineries around New Zealand, to make enough funds to be able to start a winery of our own.

In the mid-1960s, while sourcing scion wood, Ross and his wife went to the Government viticultural research centre at Te Kauwhata and found many of the new varieties he had dealt with when studying in the US. These were grafted at Huapai and then planted out in the trial vineyard at the Matua Rd block, nicknamed the fruit salad block. Unfortunately, many of these varieties had viruses, with leaf mosaic, yellow and red blotch, and leaf roll.

produced a soft semi-sweet medium-bodied wine that was popular at the time.

Unfortunately, the vines had leaf roll virus, which inhibited a viable crop, but with this small amount of

PROTECT

‘‘We knew we had a style and flavour that was exciting and different from any other white wine available in New Zealand at the time.”

Bill Spence

Photo Left to right, Ross and Bill Spence

and many other varieties we had no interest in. These clones were brought in by Frank Berrysmith, viticulturist for the Department of Agriculture, with the Sauvignon Blanc clone imported from Davis University coded TK09156.

This was the break we wanted, as it showed no viruses. We grafted this clone and planted three and a half hectares at our Waimauku vineyard. This clone showed more varietal characteristics as well as producing a commercial crop, so ticked all the boxes we were looking for.

We found setting up Matua a costly exercise. After purchasing tanks, pumps and all the machinery you need to start a winery, we were quickly running out of money and mortgaged to the hilt. Ross had left Villa to work full time in the company, and I was working for Nathan Liquor division during the day and would help Ross weekends and nights at the winery.

The property we were renting was getting surrounded with subdivisions, and we were being squeezed out. At this stage we had to make the decision to get partners or to sell. I explained our situation to old family friends, the Margan family, and Noel Margan said he would purchase 50% of the company for his two children, Maureen and Ian, with the remaining 50% split between Ross and I, with the provision neither family would own any more than 50% for the first 20 years of the partnership’s existence. The deal was sealed with a handshake and that is exactly what happened. This enabled us to purchase and build our Waimauku vineyard and winery.

Trying to sell Sauvignon Blanc to the trade proved to be a little harder than we anticipated, even though we had received accolades from wine societies and wine appreciation groups. Varieties such as Cabernet Sauvignon, Chardonnay and Riesling were known, but not Sauvignon Blanc. When trying to get customers to stock Sauvignon Blanc, many thought it was a White Cabernet Sauvignon.

While visiting New Zealand, Robert Mondavi came to our winery and I explained the plight of trying to sell our new-found variety. He said he had had the same problem in the US, so suggested we do what he did and call it ‘Fume Blanc’. He created this name because of the smoky haze

which hangs over the Loire Valley after harvest, where Sauvignon Blanc is grown in France. We took his advice and renamed it in 1977-78.

Two years on, the name Fume Blanc became confusing also, as many Australian produces were calling any white wine that had been in oak casks Fume. Sauvignon Blanc had established a small but growing place in the market by this stage, so we reverted back to labelling the wine Sauvignon Blanc. We kept spreading the word on this new dynamic wine experience — we knew we had a style and flavour that was exciting and different from any other white wine available in New Zealand at the time.

Many other New Zealand and overseas wineries started to be interested in Sauvignon Blanc, the first being Peter Hubscher, the winemaker for Montana. He sent Wayne Thomas, Montana’s viticulturist, to purchase cuttings from our Waimauku property to be planted in their new venture in Marlborough. Corban’s, Hunters and the Giesen families showed interest in planting Sauvignon Blanc in their respective areas and cuttings were supplied to them as well. In 1980, Montana Sauvignon Blanc from Marlborough exploded on the market, both locally and internationally. The wine style was so much more intense in asparagus and gooseberry – different from the softer styles coming out of the North Island – and this unique style changed the face of the market. Later David Hohnen, of Cloudy Bay, made the New Zealand wine brand a force on the international market, creating demand throughout the world for New Zealand Sauvignon Blanc.

Many of the early plantings of Sauvignon Blanc in Marlborough were of the clone TK09156, often called the ‘Spence clone’. This intense style of wine is due to Marlborough’s cool temperate climate, together with the stony, boney, lean soils of the region, blended with passionate growers and winemakers.

Every person who has worked for the Spence brothers, and Matua, should take a bow, as it was them who helped Ross and I fulfil our vision to make this new unique style of Sauvignon Blanc world famous.

Long May it last.

Winepress October 2023 / 5 EDUCATE Sprayer Calibration Mini Sprayer workshops Patternator consultations New Sprayer inductions GrowSafe approved decal Spray coverage monitoring Services We are a Blenheim business Ensure chemical is applied evenly and at the correct rate Reduce chemical waste, saving $$$ Meet quality assurance schemes Decreased risk of crop damage/disease Reduced risk of costly mid-season breakdowns. Further your commitment to sustainability practices Benefits W H A T S N E W ? Sprayer Testing NZ continues to invest in the latest technologies to ensure the accuracy of applying chemicals. We offer an independent, honest and professional service. Introducing The Patternator as recently demonstrated at the local Spray days The Patternator analyzes the vertical spray distribution from sprayers in vineyards Sprayer Testing NZ will consult with you to establish the best sprayer setup. Our customers usually rebook throughout the season to adjust their sprayer to ensure maximum coverage Book now on 027 267 9384 or email us sprayertestingnz@gmail.com to find out more. www.sprayertesting.co.nz

Table 1: Blenheim Weather Data – September 2023

Temperature

The mean temperature of 12.1°C was 0.9°C above the long-term average (LTA) temperature for September (1986-2022). The average daily maximum temperature of 16.5°C was 0.3°C above the LTA. The average daily minimum temperature of 7.7°C was 1.7°C above the LTA. The warmest day was 20 September, which recorded a maximum air temperature of 21.2°C. The coldest day was 2 September, which recorded an air minimum temperature of 1.9°C and grass minimum temperature of –1.7°C.

1GDD’s Max/Min are calculated from absolute daily maximum and minimum temperatures

2GDD’s Mean are calculated from average hourly temperatures

Table 2: Weekly weather data during September 2023

The first week of September recorded very close to average temperatures. The second week was 1.1°C above average and the third week recorded a mean temperature 3.4°C above average, which is a massive departure from normal. The mean temperature during the third week of the month of 14.6°C was only slightly lower than the November LTA mean of 14.9°C. The cold temperatures in the final 9 days of September came as a bit of a shock after such a warm third week.

6 / Winepress October 2023

Sep Sep 2023 Sep Period Sep 2023 compared to LTA of LTA 2022 LTA GDD’s for month – Max/Min1 68.3 121% 56.6 (1996-2022) 64.5 GDD’s for month – Mean2 77.9 113% 69.1 (1996-2022) 64.4 Growing Degree Days Total Jul – Sep 23 – Max/Min 77.6 89% 87.5 (1996-2022) 126.2 Jul - Sep 23 – Mean 133.6 102% 131.5 (1996-2022) 156.5 Mean Maximum (°C) 16.5 +0.3°C 16.2 (1986-2022) 16.1 Mean Minimum (°C) 7.7 +1.7°C 6.0 (1986-2022) 7.1 Mean Temp (°C) 12.1 +0.9°C 11.2 (1986-2022) 11.6 Ground Frosts (<= -1.0°C) 3 1.8 less 4.8 (1986-2022) 6 Air Frosts (0.0°C) 0 0.8 less 0.8 (1986-2022) 1 Sunshine hours 178.0 91% 196.1 (1986-2022) 195.4 Sunshine hours – lowest 129.6 1989 Sunshine hours – highest 260.3 2020 Sunshine hours total – 2023 1726.0 97% 1787.4 (1986-2022) 1737.8 Rainfall (mm) 48.2 92% 52.5 (1986-2022) 38.6 Rainfall (mm) – lowest 3.0 1951 Rainfall (mm) – highest 191.5 1943 Rainfall total (mm) – 2023 392.8 80% 489.5 (1986-2022) 692.4 Evapotranspiration – mm 74.5 102% 72.8 (1996-2022) 68.3 Avg. Daily Wind-run (km) 259.7 95% 273.9 (1996-2022) 212.1 Mean soil temp – 10cm 10.9 +1.6°C 9.3 (1986-2022) 10.2 Mean soil temp – 30cm 11.4 +0.6°C 10.8 (1986-2022) 11.5

Mean Mean Mean Ground Air Rainfall Sunshine Wind-run (°C) Max (°C) Min (°C) Frosts Frosts (mm) (hours) (km) 1st - 7th 11.3 (+0.1) 16.2 (=) 6.3 (+0.3) 3 0 3.2 37.2 200.1 8th - 14th 12.3 (+1.1) 17.6 (+1.4) 7.1 (+1.1) 0 0 12.2 55.1 293.1 15th - 21st 14.6 (+3.4) 19.5 (+3.3) 9.8 (+3.8) 0 0 0.8 56.7 389.4 22nd - 28th 10.7 (-0.5) 13.1 (-3.1) 8.4 (2.4) 0 0 32.0 14.4 149.0 29th – 30th (2 days) 10.2 (-1.0) 15.7 (-0.5) 4.7 (-1.3) 0 0 0.0 14.6 285.0 1st – 30th Sep 12.1 16.5 7.7 3 0 48.2 178.0 259.7 2023 (+0.9) (+0.3) (+1.7) (1.8 less) (0.8 less) (92%) (91%) (95%) Sep LTA 11.2 16.2 6.0 4.8 0.8 52.5 196.1 273.9 (1986 – 2022)

LTA – Long Term Average

Frosts

Three ground frosts were recorded in September on the first three days of the month. No air frosts were recorded during September.

Sunshine

September recorded 178 hours sunshine, 91% of the LTA. However, the first three weeks of September recorded above average sunshine hours. The final 9 days of the month were very overcast associated with rainfall.

Rainfall

September recorded 48.2 mm rain, 92% of the LTA. The first three weeks of the month recorded only 16.2 mm rain and at that stage it looked as if Blenheim was headed for its fourth month in a row with low rainfall. June (22 mm), July (24 mm) and August (24.2 mm) all recorded close to a third of their LTA rainfall. Fortunately, 32 mm rain was recorded between 22 and 30 September. The 9-month rainfall total from January to September 2023 was 392.8 mm, 80% of the LTA.

Wind

Average daily wind-run for Blenheim during September 2023 was 259.7 km, 95% of the LTA of 273.9 km.

Nine days during September exceeded the LTA daily wind-run total of 273.9 km. The windiest day of the month in Blenheim was 17 September, with 678 km wind-run. This is the highest daily wind-run total for Blenheim in the past 10 years. The most recent higher daily total is 711 km windrun recorded on 10 September 2013. The average wind speed on 17 September was 28.25 km/hr, compared to average September wind speed of 11.4 km/hr. The maximum windspeed (wind gust) during September was 86 km/hr recorded at 1.28 pm on 17 September. This is the strongest wind gust since 14 October 2013, which recorded a gust of 86.7 km/hr.

According to the Beaufort wind force scale a wind speed of 86 km/hr is classified as a ‘Strong Gale’ and is able to cause “slight structural damage - chimney pots and slates removed. (Not too many of those left these days). The Beaufort scale was developed in 1805.

Maximum wind gusts under New Zealand’s climatic conditions occur over a very short time interval. In order to capture the maximum wind gusts, wind speed at the Blenheim weather station is recorded every three seconds. Although New Zealand does not experience hurricanes (cyclones, typhoons) some coastal areas can occasionally record hurricane force wind gusts; i.e. very short duration wind gusts in excess of 118 km/hr. In an actual hurricane the wind gusts are experienced over a prolonged period of time and do much more damage over a widespread area, than a very short, high speed wind gust in a very confined area in New Zealand.

Soil Moisture

Shallow soil moisture (5-35 cm) on 1 September was 33.6%. With only 16.2 mm rain during the first three weeks of September the shallow soil moisture slowly dropped to 30.6% by 21 September. During the subsequent 7 days there were 32 mm of rain so that by 30 September the soil moisture had risen to 37.7%. However, without significant rain in October we should expect the shallow soil moisture to drop substantially. LTA soil moisture on 1 October is 36.3% and on 31 October is 27.5%, an 8.8% reduction. However, it is not uncommon for shallow soil moisture to drop by 12 to 13% when rainfall is low during October, e.g., October 2022 recorded only 16.8 mm rain and shallow soil moisture dropped from 36.1% on 1 October to 22.4% on 31 October 2022.

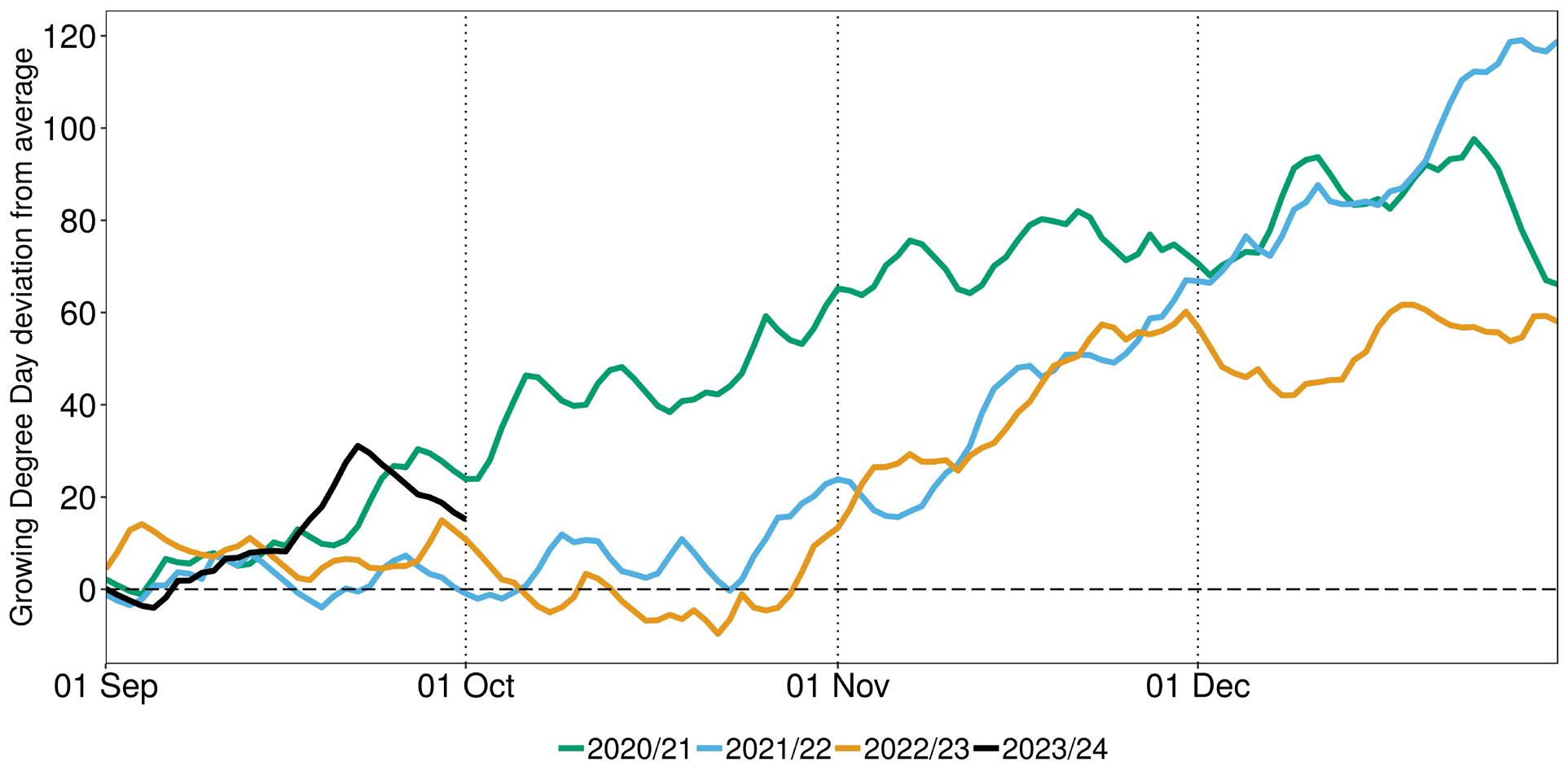

New Growing Season and Growing Degree Days

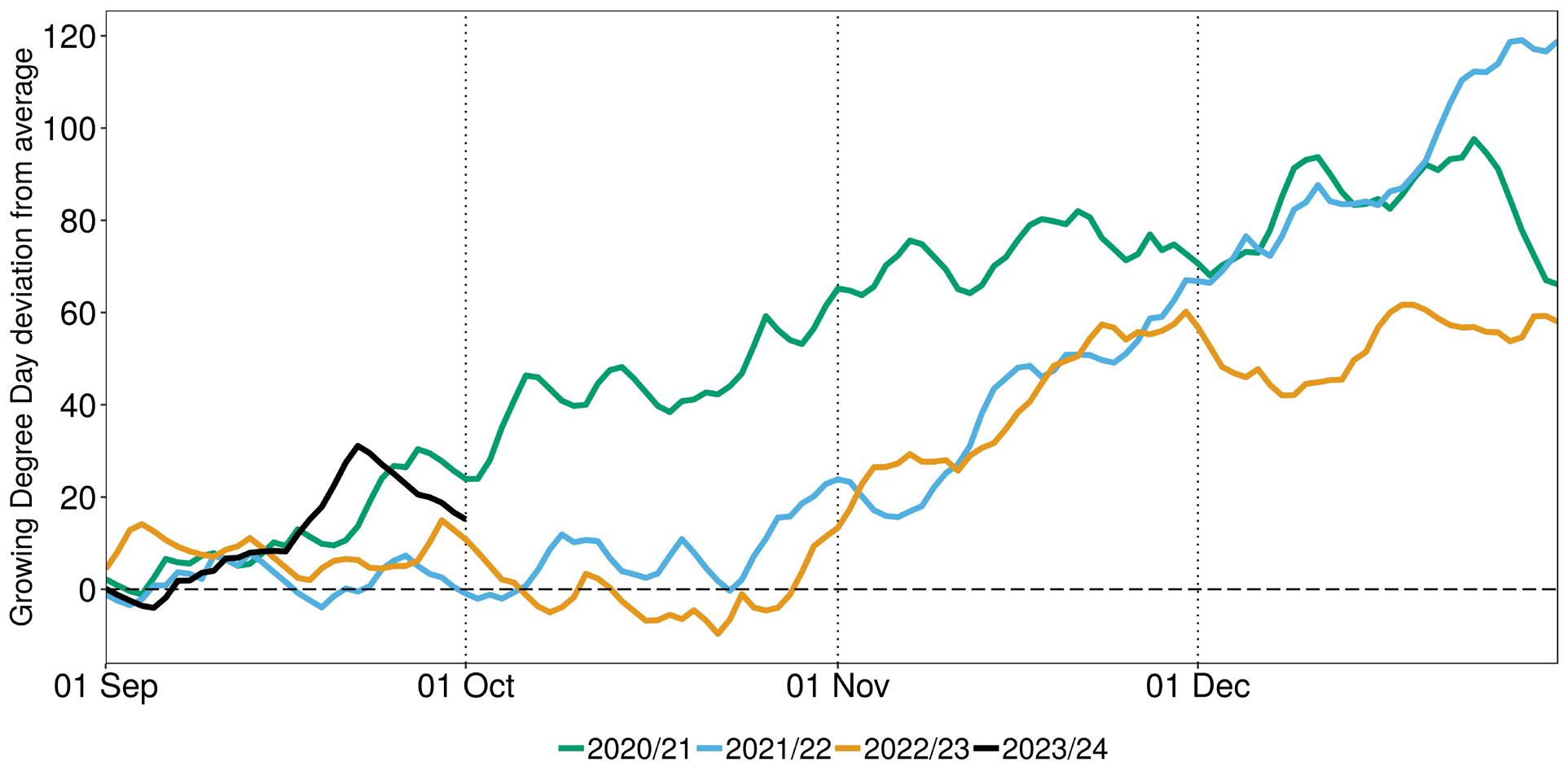

We were anticipating that the 2023-24 growing season would get off to a later start in September 2023 compared to recent years, due to the very cool temperatures in August 2023. Figure 1 presents the deviation in growing degree days from the long-term average, for the current season during September 2023 and for the previous three seasons from September to December.

The black line for the start of the 2023-24 season reflects the very warm temperatures in the second and third weeks of September. The GDD line rose very sharply and reached a higher point than in any season since 2005-06. These warm temperatures meant that budburst of grapes in the lower Awatere and central Wairau plains was earlier than we had originally anticipated. However, the very cool temperatures in the final 9-days of September meant that much of the gain in GDDs above the LTA that had occurred was very quickly lost. These cool temperatures put the brakes on the initial surge in budburst that occurred as a result of the warm temperatures.

Where will the GDD line head over the next 3-months?

NIWA are predicting a 45% chance of above average, 40% chance of average and only 15% chance of below average temperatures for Marlborough over the whole 3-month period from October to December 2023. The likely direction of the GDD deviation line from October to December 2023 is uphill, as has been the case in almost every season over the past ten to fifteen years. It has been a long time since Marlborough has experienced a season with consistently cooler than average temperatures. However, the high chance of average to above average temperatures doesn’t mean that we won’t get periods when the temperature is below average, as is shown on the GDD lines over the past three seasons.

Winepress October 2023 / 7

Normalized Growing degree days for Blenheim: days above (+) or below (-) the long-term average for the period 1 September to 31 December

1 September to 31 December

8 / Winepress October 2023

Rob Agnew Plant & Food Research – Marlborough Research Centre

Figure 1: Normalized Growing degree days for Blenheim: days above (+) or below (-) the long-term average for the period

Rob Agnew Plant & Food Research / Marlborough Research Centre

Figure 1:

BAC 2896 Optimised two-way systemic activity, delivered by a class leading formulation. • Optimised formulation gives unparalleled penetration • Unrivaled and proven efficacy • Proven crop safety • Soft on key beneficials Movento 100SC - for results you can trust. Movento 100SC is registered pursuant to the ACVM Act 1997, No. P8434 and approved pursuant to the HSNO Act 1996, No. HSR100545. Movento® is a registered trademark of the Bayer Group. © Bayer Crop Science 2023. You can’t afford second best. We’re with you in the field cropscience.bayer.co.nz

50 years

BY 2010, as the global financial crisis bit, Marlborough grape growers were lucky to get $1,200 per tonne, which was half of what they have achieved two years earlier. A year later, things started to pick up a little. The Brancott Heritage Centre tasting room and restaurant opened on ‘Rob’s Knob’, although it was soon followed by the closure of the magnificent facility at Riverlands, open for less than a decade.

Also in 2011, Blenheim based FMR Group launched a sprayer that captured and recycled vineyard spray, cutting drift and reducing chemical use by about 30%. By 2012, VinLink was operating at Riverlands, offering contract winemaking services overseen by former Grove Mill winemaker Dave Pearce.

Marlborough was rocked in July 2013 by an earthquake sequence which crumpled winery tanks. Various innovations emerged to reduce quake risks, which helped when the even bigger Kaikōura earthquake struck in 2016.

Also in 2013, Ormond Nurseries replanted rootstock to meet demand after 90% was pulled out in 2008. Marisco Vineyards began planting the first of 800 hectares at Waihopai Valley’s Leefield Station.

In 2014, a thousand more Recognised Seasonal Employer (RSE) scheme workers were allowed into New Zealand, the Marlborough District Council issued three resource consents and 12 building consents for wineries, and WineWorks began building Marlborough’s largest building –10,000 square metres for wine storage – at Riverlands.

In 2015, Gerry Gregg (Mr Montana) who’d started with the company in 1976 and performed a variety of roles for differing owners, retired. The Young Winemaker of the Year competition was launched, and Marlborough Lines bought an 80% stake in Yealands, by then New Zealand’s sixth largest wine exporter, for $89m.

2015 also saw Dr Mike Trought made a Fellow of New Zealand Winegrowers, recognising three decades of wine research.

In 2016 harvesters started to be used to shake vines before harvest, reducing disease risk and botrytis. The Bottling Company opened at Riverlands to service the needs of the growing wine industry.

In 2017 came a probe into various companies’ employment practices and treatment of RSE workers. MDC prosecuted five companies and individuals for grape marc leaching into waterways.

In 2018, Seresin winery was sold to Ben Glover and Rhyan Wardman who renamed it The Coterie. The Southern Valleys Irrigation Scheme shut off in early February 2019 due to dry conditions, and some vineyards trucked in water. Hortus began building a multimillion-dollar expansion at its seasonal worker complex on Blenheim’s outskirts.

In February 2020, the Bragato Research Institute Research Winery was opened on the Nelson Marlborough Institute of Technology Blenheim campus. A month later, the wine industry was dealing with closed borders, severe staff shortages, freight disruptions and staff pressures as Covid-19 began impacting on Marlborough and the rest of the world.

CELEBRATE Celebrate Your Christmas Function with Us! Tailor-made tours to suit your team Enquire today: groups@marlboroughtourcompany co nz

Winepress cover after the 2016 Kaikoura earthquake, as wineries worked to replace damaged tanks.

Photo Jim Tannock

This year Marlborough celebrates 50 years of wine. BRENDON BURNS reviews the decade 2010-2020, which began in a slump but quickly recovered.

A cooperative venture with returns for all BRENDON BURNS

More than a decade after a grape growers’ cooperative began in Marlborough, it continues to help lift returns, says one of its founders. Ross Flowerday says the 2008 global financial crisis flattened grape prices in the region, but also kickstarted the grower-owned Marlborough Grape Growers Cooperative (MGGC). “We are there for the good of the industry. Without the co-op, the industry wouldn’t be what it is today.”

MGGC grew from Marlborough Grape Producers (MGP), which was established by three growers in 2001, after they became frustrated by the terms offered by major wine companies. MGP started producing Sauvignon Blanc for the open market and for The Wine Group (TWG), which is second only to Gallo in American sales. As demand grew, MGP turned to other growers they knew for supply, including marine electrician Dave Smith. By 2008, grape prices had crashed from around $2,500 a tonne for Sauvignon Blanc to around $1,200. Low prices continued for some years, while demand from TWG began exceeding what MGP could supply, and some MGP growers began discussing ways to boost numbers. An invite went out and 27 growers attended a meeting in June 2012. The following month 43 growers came along and agreement was reached to form a cooperative. An interim company was formed as a cooperative took longer to establish. As well as offering a higher price per tonne than the regional average, the cooperative did not have a tonnage cap, says Ross. “Wine companies would say, right, we’ll pick this amount of fruit and then you can’t sell the rest anywhere else either. It was like a sheep farmer only being allowed to grow three-legged sheep.”

He became the cooperative’s first chair, followed by Dave Smith, then current chair Ben McLauchlan. Winemaker Drew Ellis, who’d been MGP’s winemaker, joined the new organisation as its sole employee. Now it has five full-time staff, while many co-op members also come on board at vintage.

The initial vintage in 2013 saw 5,147 tonnes of Sauvignon Blanc grapes supplied to TWG, from the inaugural 43 growers. Last vintage 12,708 tonnes were supplied by 75 members. TWG pays for processing into wine at VinLink and takes two thirds of production – shipped as finished wine – for bottling and marketing in the US under its Cupcake brand, priced at around US$10 (NZ$17), as well as more premium brands. MGGC chief executive Mike Brown says the balance of fruit is made into bespoke blends, chiefly for Australian, UK and German markets, and is the biggest selling New Zealand Sauvignon Blanc in Germany. While there’s no cap on growers, they are expected to produce quality fruit at the level a vineyard can sustain. Mike says MGGC harvests when fruit is at optimal ripeness, which can make growers anxious but is appreciated by customers.

Last year, it launched a joint venture project with Cloudy Bay founder David Hohnen and his business partner to produce a super-premium Sauvignon Blanc. Marlborough Heartland launched in Sainsbury’s UK supermarkets earlier this year at £12.50 ($26) a bottle. “It’s the pioneer returning and working with mostly smaller scale growers who are the 'real heartland' of Marlborough,” Mike says.

The wine is a ‘game changer’, as the co-op moves to add branded wines to its successful business model as a producer of bespoke supply, he adds. Well-known Māori winemaker Steve Bird has just made a Pinot Gris and Rosé with MGGC fruit for the US market, representing a new varietal offering. Last October the co-op marked ten years since it was first incorporated as a company. Mike Brown says returns to its growers remain 10% ahead of the district average.

Agriculture and Viticulture Machinery Sales & Service Specialists

New Zealand agent for Netwizz and Olinet netting applicators. Slim, standard and hydraulic mast models available.

Winepress October 2023 / 11 GROW

Jeremy Watts 021 446 225 | jeremy@agrivit.co.nz Service: Keiron Hebberd 027 572 8787 | keiron@agrivit.co.nz Parts: Warrick Meiklejohn 03 572 8787 |warrick@agrivit.co.nz 29 High Street, Renwick 7204, Marlborough | 03 572 8787 | info@agrivit.co.nz | www.agrivit.co.nz

Sales:

Circular Wine

Reduce, reuse, recycle, regenerate

THERE’S UNLIKELY to be a centralised silver bullet that resolves Marlborough’s waste challenges, says Rose Family Estate winemaker Nick Entwistle. But a new Marlborough Circular Wine Group is leveraging industry insights, experiences, ideas and energy, to offer sustainability solutions for individual businesses.

“People have different interests and scale and different ambitions,” says Nick. “But everyone is trying to be proactive, and I don’t think you’d find many other industries where people are investing as much time and thought into it collaboratively to come up with a solution.”

Pernod Ricard Winemakers New Zealand sustainability manager Tracey Marshall (see page 15) says the group is working to grow sustainability and circularity in the Marlborough wine industry, by looking at challenges such as waste, carbon emissions, soil health, and biodiversity. The group’s open discussions on issues facing all wine companies are energising, she says. “There are some really solid actions coming out of it.”

Marlborough Circular Wine emerged from a series of industry workshops in Spring 2022, focused

12 / Winepress October 2023 EDUCATE

SOPHIE PREECE

Wither Hills’ Rarangi wetland

“The gold is where we share those learnings around the table.”

Melissa Macfarlane

Tapping into the potential of grape marc

A new research project aims to transform grape marc from the New Zealand wine industry into high value products. Food additives, chemicals for specialised applications, and paper products with fire-retardant and antimicrobial properties are among potential outcomes of the $9.8 million project, led by the University of Auckland.

Professor Paul Kilmartin, an expert in wine chemistry, will lead the research programme, which was awarded funding by the Ministry of Business, Innovation and Employment’s Endeavour Fund. “Our research team holds several patents and has developed leading-edge technological approaches that will be applied to grape marc components,” Paul and his colleagues said in a funding application.

Besides Waipapa Taumata Rau, University of Auckland scientists, the team includes researchers from AUT, crown research institute Scion and the University of Canterbury.

The programme will be “an example of how to create substantial new high-value product revenue streams for New Zealand companies while eliminating a primary industry waste stream as part of our future circular economy,” the funding application says.

Paul’s background in wine chemistry includes setting up the University’s postgraduate Wine Science programme in 2003, which is now located at the Goldwater Wine Science Centre on Waiheke Island.

Winepress October 2023 / 13 GROW

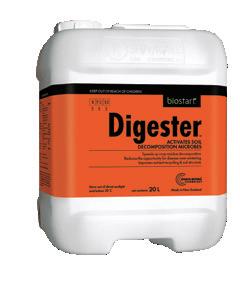

on vintage waste challenges for the 2023 vintage. Wine Marlborough advocacy manager Nicci Armour says the series ended with a speed dating session, where there was a clear desire to go beyond the requirements of Sustainable Winegrowing New Zealand (SWNZ), share best practice, and think about longer term issues, while also tackling immediate challenges. “What came through from ongoing discussions was that while people benefitted from sharing immediate challenges – and it was helpful to inform us and allow council to understand how they could support – there was also a very strong desire to talk about the long-term sustainability picture for the Marlborough wine industry. And to share available resources and work together on that.”The group already has a plethora of potential projects lined up or under way, targeting immediate challenges like lees in vintage 2024, along with longer-term opportunities around the likes of grape marc, packaging, biodiversity and soil health. “There seems to be three tranches to what the group is doing,” Nicci says. “One is supporting our immediate problems and challenges with respect to environmental waste. Then there are big long-term, chunky challenges and where they fit into the picture that we want to create for our sustainability story for the Marlborough wine industry. The third is around giving back to the community.” That might include wine industry planting days, or taking “guardianship” of a reserve area to protect and build its biodiversity, Nicci says.

Melissa Macfarlane been engaged by Marlborough District Council (MDC) to facilitate the steering group’s establishment under the Smart + Connected platform, which brings industry and community groups together to better address challenges and opportunities.

Some of the waste challenges being faced by wine companies seem “so big” and people don’t know where to start, Melissa says. The group allows those who are exploring prototypes and testing to share their experiences, so others can determine what might work for them.

“Everyone is taking a slightly different angle to different problems,” she adds. “Testing and prototyping is great –that’s how we are going to learn and build to bigger solutions ultimately. But the gold is where we share those learnings around the table.”

In October a group of 35 industry members visited Delegat winery to learn about trials using a decanter to reduce lees waste, in an example of that “gold”, says Melissa, also excited by the learnings from Geo Bag trials at Rose Family Estate. “In every session there’s someone saying, ‘we could do that’. So it’s levelling up the whole industry.”

Part of the steering group’s success to date has been in breaking down problems into “more manageable chunks” – such as thinking about grape marc in terms of storage, transport and reuse – rather than as an insurmountable whole, Melissa says. They’re also looking at future opportunities, such as biochar, “and sparking these very

Amp-up your spray application

14 / Winepress October 2023 GROW

Maximise coverage, efficiencies and savings Talk to your local merchant to find out more. Du-Wett® delivers superior spreading using less water. That saves time, labour, and fuel. And because Du-Wett optimises efficacy, you get the most out of every cent you spend on your spray programme. Approved pursuant to the HSNO Act 1996, Approval Code HSR002503 Exempt from ACVM. Du-Wett is a registered trademark. UPL-LTD.COM

Circular route in regenerative road map

SOPHIE PREECE

New Zealand’s primary producers have long worked to protect the soil and environment, says Pernod Ricard Winemakers New Zealand sustainability manager Tracey Marshall. “It is New Zealand doing what New Zealand does, which is finding ways to improve positive outcomes for people, business, communities and the environment.”

The company launched a 60-hectare regenerative viticulture trial in Marlborough three years ago, including cover crops, reduced inputs, and soil monitoring to ascertain outcomes for vines, wine, soils, and the wider vineyard ecology. Successful aspects such as subsurface irrigation are progressively being taken into the company’s other vineyards, with the wider view to grow an understanding of regenerative viticulture in New Zealand. Protecting soils and waterways, preserving biodiversity, reducing inputs, supporting yield, and ensuring quality are all principles in regenerative viticulture, and are well understood in New Zealand, Tracey says. “New Zealand has always been part of that continuous improvement in sustainability, and this is just another name for it really.”

The trial includes the development of a Regenerative Viticulture Index – a tool to measure progress and benchmark impacts on soil, inputs, yields and profitability, says Tracey. “Taking the key regenerative principles and applying a scoring system against them.” The company has also created a dedicated regenerative viticulturist role, with Jason Doughty bringing more than 20 years of viticultural expertise. Jason says Pernod Ricard Winemakers understands that the quality of its wines is impacted by nature. “We see regenerative viticulture as a cornerstone of our sustainable practices, which over time will help us continue to improve our vines, soils, and terroirs.”

Tracey, who has an agricultural science background, is “digging deeper” into the soil science side of regenerative viticulture. Starting with the business case for cover crops and how they interact with soil carbon, for example, has been invigorating, she says. “Yield and profitability is an important part of that approach as well. How can we grow to the quality and crop levels we require while reducing inputs such as machine passes, water, fertilisers, and so on?” Viticulture has different imperatives to agriculture, particularly when it comes to plant vigour, which is not necessarily advantageous when growing grapes, she adds. “There’s certainly a space for New Zealand viticulture to define what regenerative is in the context of grape growing. And that context might still look different around the world.”

In 2019 Pernod Ricard Winemakers launched its 2030 Sustainability and Responsibility Roadmap, with targets around biodiversity, waste minimisation,

circularity, carbon emissions reduction, and soil health, along with social imperatives. Those goals began at global group level, and are then applied to each country, including timelines for goals and actions, Tracey says, noting there’s now an emphasis on turning targets into runs on the board.

Different winemaking regions face different levels of challenge in each of the four pillars of the roadmap. “In New Zealand, soils in our wine regions are lower risk of having poor soil condition in comparison to some other countries,” Tracey says. “And when it comes to soil carbon, we are not starting from a low baseline. So, we are looking at how we can use the practices and principles to improve the function of that soil.” That might mean planting cover crops with the ability to improve soil compaction issues and ensure better infiltration of nutrients and water, and greater resilience as a result. “It’s about finding what we need in our context.”

If soil is an easier target from a New Zealand standpoint, then emissions reductions is a tougher one, given the distance from export markets. Pernod Ricard Winemakers has taken strides to reduce carbon emissions, focusing on reducing waste and inputs including water and fuel, as well as introducing more renewable electricity and lightweight packaging. But the decarbonisation of the transport industry and glass production to get Scope 3 emissions down are key, she says. “There are things we can influence and change, and then there are other players who need to deploy their own carbon reduction plans and there is a lot happening in that space, which is really positive.” Tracey is part of Marlborough’s Circular Wine group (see page 12) and brings insights from Pernod Ricard Winemakers global operations and New Zealand projects to that collaboration, while learning how others have grown circularity. “Like always, the wine industry is very open to sharing and solving problems together,” she says. “It’s one of the things I love about this industry.”

Winepress October 2023 / 15 PROTECT

Jason Doughty.

Photo Jim Tannock

smart minds to go away and think of different ideas”. It’s about celebrating quick wins on the way to bigger outcomes, she adds. “As an example, with lees it’s about working with council in the short term to make sure the testing parameters are understood and achievable. Longer term, once dewatered, what can we do with the remainder?”

Circularity is based on a lot of r’s, starting with reduce, reuse and recycle, with a goal to tackle waste as early in the value chain as possible. That could mean sharing machinery instead of everyone owning their own, and addressing> plastics, packaging, and fuel consumption, Melissa says. “There’s definitely something for everyone.” Then there’s the focus on regenerating nature and renewable energy, along with the ultimate goal of a resilient ecosystem, “so lots of rs”.

MDC economic development officer Mark Unwin says some ideas will find “a natural home” outside the steering group at a later date. “It’s not necessarily to say, ‘hey you have to solve that problem and solve it now’, and that’s what success is like. Some of it is about introducing people and connections they make.” Nor does every trial need to succeed for the process to be valuable, he adds, noting that previous Smart + Connected projects have benefitted from shared thinking, even when some potential solutions prove unsatisfactory. “Where a solution doesn’t work but you’ve come to that conclusion quicker through collaboration then you have saved time and money and you can move on to new projects. “

Nick Entwistle was involved in discussions around a centralised solution to grape marc in 2014, facilitated by the MDC and participating wine companies. Now he believes waste solutions need to be more bespoke, given the diversity of operations. “I think the realisation now is that there’s not going to be one large, centralised industry solution for any of these problems.”

New Zealand Winegrowers has a target for the industry to achieve zero waste to landfill by 2050, and Rose Family Estate has set its own target of 2030. That’s a big focus for the company and in early September they undertook a waste audit, which included consulting recyclers such as Future Post (see page 17) to assess what it could and could not recycle. “Now we have a catalogue of what we can send to people… and it’s all of our job to either no longer purchase the things we cannot get rid of, or seek out someone that can recycle them for us.”

Nick says the company’s focus on its sustainability strategy (“we spend a lot of time thinking about it”) is partly a reflection of the new generation coming through at Rose Family Estate, and in Marlborough in general. “We can all see that unless we tackle some of those issues, we will not be able to continue doing what we are doing.”

16 / Winepress October 2023 PROTECT

Looking to the future

The new Future Post factory in Blenheim will produce up to 500 posts a day from waste plastic when at full capacity, with many of them vineyard posts. A single 22kg plastic post contains the equivalent of 281 milk bottles and 1,257 bread bags, and the posts themselves can be ‘rerecycled’ if required.

Future Post National Sales Account Manager

Diana Jamieson says the factory is also recycling a huge amount of vineyard and winery waste plastic, with driplines, drums, buckets, pallet wrap and pallets all diverted from landfill to make posts. In the case of companies like Marisco and Cloudy Bay, which are dropping off waste plastic and putting in Future Posts, there’s a neatly closed loop, she says. “It’s a great circularity story.”

Diana says there’s plenty of demand for posts not treated with chromated copper arsenate, and for a product “with increased durability through harvest”, which motivated the company to build its Marlborough factory to support the original Waiuku facility.

Kerry Hammond, viticultural operations manager at Sheridan Contracting, recently completed a 25-hectare development using Future Posts at Starborough in Seddon, and is about to complete another for Saint Clair Family Estate. He says a major motivation for him is the $55 spent replacing every broken wooden post, including installation, as well as the need to dispose of treated posts in landfill or carefully stockpile on site.

With older blocks he is seeing up to 4% breakage in a season, “and it is getting to be quite a big cost,” he says. “There’s a lifetime guarantee with Future Posts, so we are hoping we can avoid that in the future.” The closed loop concept appeals as well, especially given the amount of old dripline he has been able to recycle through the Future Post factory when doing vineyard redevelopments. With close to 200ha of redevelopment this season alone, that’s a lot of waste plastic diverted from landfill, he says.

Apart from recycled waste plastics, UV Carbon Black is the only additive in the posts, for UV stability. Testing performed under extreme heat and UV light has shown Future Posts to be solid, dense and UV stabilised right through with Carbon Black, Diana says. Meanwhile, spectral analysis soil sampling for microplastics undertaken recently by Massey University from a Future Post fence that had been in the ground for five years, as well as soil taken 25 metres away in the middle of paddock, and away from the posts, showed no indication of micro-plastics surrounding the close proximity sample.

Winepress October 2023 / 17 GROW Repairs - call 24/7 Maintenance & Service Hire Chiller Solutions Design & Installation 1 Freswick St, Blenheim | www martella co nz Email: office@martella.co.nz Phone: 27/4 - 03 578 0030 REFRIGERATION & AIR CONDITIONING Your local specialists for over 40 years • Commercial & Industrial Electricians • Automation & Control systems • Winery Upgrades • Winery Design & Build 24/7 EMERGENCY CALL OUT Phone: 0274 497 689 Email: admin@electratech.co.nz Website: www.electratech.co.nz

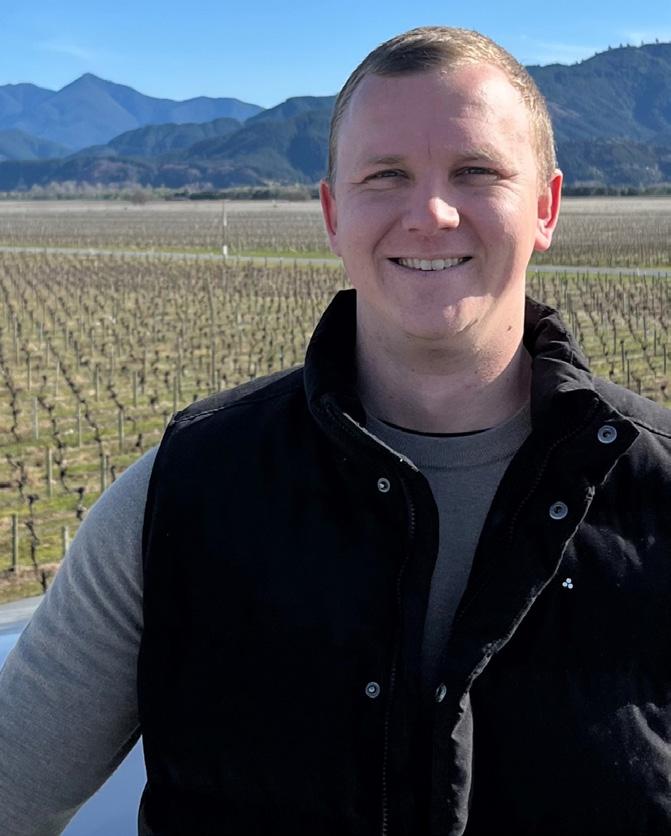

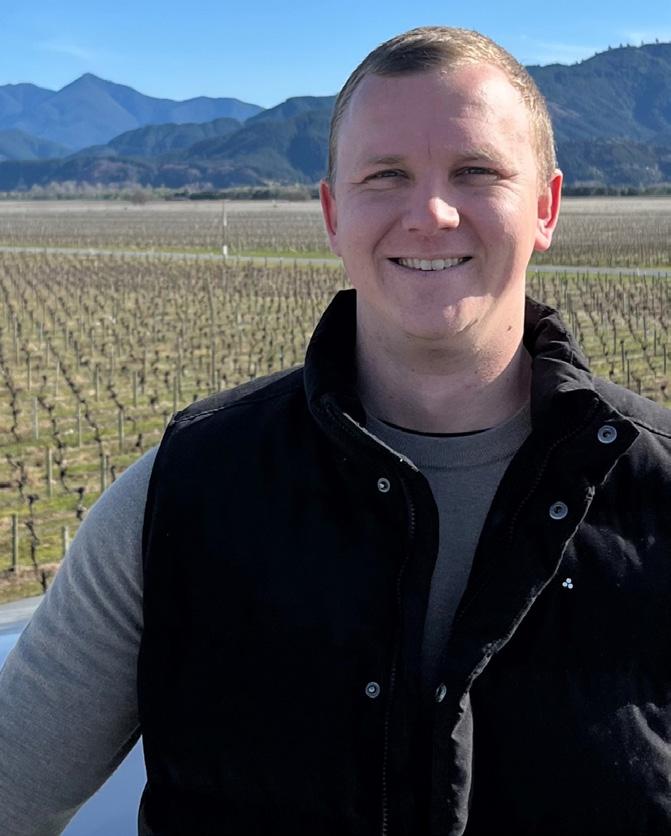

Callum Haynes

Marlborough’s top young winemaker

PREPARATION, EXPERIENCE and loads of support from his ‘Matua family’ were key to taking out the title of the Marlborough Young Winemaker of the Year competition, says the 2023 winner. Matua winemaker Callum Haynes was crowned Tonnellerie de Mercurey Marlborough Young Winemaker of the Year at the awards dinner at Te Pūkenga NMIT last month, after a grueling day against some stiff competition.

The day started at 8am and contestants were tested on many aspects of wine production, including a cellar challenge, laboratory tests, blending, fault finding, blind tasting, marketing, wine knowledge and wine judging. The toughest challenge of the day was delivering a speech to about 180 people at the awards dinner, Callum says, “over the moon” to be named the winner on the night.

“It was such a great day, surrounded by great people. One of the best things is being exposed to this new network of people who can mentor and assist you on your winemaking journey; a whole bunch of helpful and wonderful contacts you can reach out to with questions or for advice.”

The 29-year-old, who also competed in the 2021 competition, says the previous experience helped boost his confidence and gave him a sense of direction when preparing for this year’s event. “I knew going in what to expect and I knew from the judge’s feedback last time the areas I needed to improve on – mainly the lab. So, when I got accepted into the competition this year I went straight to the lab and spent a week there, talking to the lab technicians, asking questions, doing aspirations and all the other things I knew I’d be tested on.”

Callum grew up in Christchurch and had no experience in viticulture before he embarked on his wine journey, aged 17. With an interest in chemistry, German, and beer, he thought about studying brewing. But after a vineyard lunch with his parents, opted for a Bachelor of Viticulture and Oenology at Lincoln University instead. After the first year, Callum was hooked. “You get this one shot every year to make the best wine you can with what nature gives you, and that wine really is an expression of the year and the region

that can’t be reproduced, you never get two the same.”

After graduating, Callum picked up work through Delegat’s two-year graduation winemaker programme in Marlborough, before taking some time off to travel to some of the great winemaking regions in the world in Australia, Germany, France, Eastern Europe, and Argentina.

After travelling and getting a feel for the different wine regions, he decided Marlborough was the ideal place to continue his winemaking career. He picked up a twomonth contract as a vintage winemaker with Matua for the 2020 vintage, which was extended for another year and eventually led to a permanent winemaker position.

The team at Matua have been “incredibly supportive” during his winemaking journey, and particularly his boss and fellow winemaker Peter Russell, who won the Marlborough Young Winemaker of the Year title in 2021.

Along with the $1000 cash prize, an educational trip, and the opportunity to be an Associate Judge at the Marlborough Wine Show, sponsored by Quay Connect, Callum will go on to represent Marlborough in the national final on October 31 in Waipara. “I’m very excited to knuckle down and represent the region,” he says. “I’m immensely proud of Marlborough and hope to do the region proud at

18 / Winepress October 2023 CELEBRATE

PICKFORD

KAT

“I’m immensely proud of Marlborough and hope to do the region proud at the national competition.”

Callum Haynes

A new level of Botrytis and Powdery Mildew control, with one-drum simplicity. MIRAVIS® Prime fungicide combines the power of ADEPIDYN® technology, with proven fludioxonil to deliver: Scan for more information, visit www.syngenta.co.nz or talk to your local distributor. For export wine PHIs consult your winery or refer to the latest New Zealand Winegrowers Vineyard Spray Schedule. ® MIRAVIS Prime and ADEPIDYN are registered trademarks of a Syngenta Group Company. Registered pursuant to the ACVM Act 1997, No. P9724. Always read the label completely before use. © Syngenta 2023 AD110923

for

• Powerful and long-lasting control of botrytis and powdery mildew in grapes; • Two modes of action for botrytis resistance management;

Excellent rainfastness.

Actively protects

longer

•

Wine Story

GROWING UP on the edge of Marlborough’s east coast, where the Awatere River meets the Pacific Ocean, Stu Marfell saw tinder dry summers burn the landscape brown.

Nearly four decades on, Foley Wine’s chief Marlborough winemaker is surrounded by lush green vines, in a valley transformed by wine. “I guess I have been lucky to grow up in this history. It’s been a massive shift and I have been right in the thick of it.” Stu was the fifth generation on his family’s sheep and beef farm, where lambing was done early, before north-westerly winds put paid to summer pasture. When neighbouring farmers Pete and Anna Vavasour put in irrigation from the Awatere River in the 1980s, then took an audacious punt in planting a vineyard, the farming community was “fascinated”.

Stu’s mother joined a team of farming wives who “jumped” at the chance to help out with the vineyards, Stu says, recalling tough times in farming and the boon of an extra income. He was 6 years old at the time, and by the age of 9 was tagging along with his brother, to pick (and eat) grapes at harvest. He’s not sure whether that was help or hindrance, but he was certainly intrigued by the new land use. “For me it was so interesting – this combination of farming and science and making this quite exotic product… From that first harvest on, I was pretty hooked.”

Summer work was split between the Marfell farm and the Vavasour vineyard until he was 15, when the latter took all his time. Stu loves that some of the Sauvignon Blanc and Chardonnay he makes today are from the vines he helped plant in the mid-1990s. “I have been learning from day one – from sticking a vine in the ground and following it through to making a wine. It’s been a really amazing opportunity.”

After boarding school in Nelson he went to Lincoln University for a Bachelor of Viticulture and Oenology, while “sneakily” working in the Vavasour vineyard and winery throughout his studies. He planned to follow graduation

with a few years of overseas vintages, but dropped in at Vavasour on his way home from final exams to catch up with winemaker Glenn Thomas. “He said ‘the assistant winemaker is moving on, are you interested?’”

So in 2003, Stu traded in his OE for an unmissable opportunity 10km down the road from his childhood home, and by 2007 he was head winemaker at Vavasour. Twenty years on, Stu is at the helm of Grove Mill and Vavasour Wines, chief judge of the Marlborough Wine Show, Sponsored by QuayConnect, and living happily at the edge of the Pacific Ocean, on land he and his wife carved off the family farm before it was sold.

Stu, who was awarded Winemaker of the Show at the New Zealand International Wine Show in 2018 and 2022, says his role has evolved a lot over the years, with the ownership change from New Zealand Wine Fund to Foley Wines in 2006, and then the acquisition of other labels, including Te Kairanga, Martinborough Vineyards, and Mt Difficulty. “I have had about 10 different jobs.”

Amid that work, judging has played a key role in his development, starting as a way to broaden his exposure. “For a while we were the only winery in the Awatere Valley

20 / Winepress October 2023 CELEBRATE

Stu Marfell’s winemaking career is integrally linked to an extraordinary transformation in the Awatere Valley. He talks to SOPHIE PREECE about his first taste of wine work, subregional expression, and the judging that helps hone his talents.

Stu Marfell

“From that first harvest on, I was pretty hooked.”

Stu Marfell

and a bit isolated, and for me getting into wine judging was a way of meeting a few more people, networking with other winemakers, and tasting a wide range of wines.”

Mentors like Raymond Chan, Michael Brajkovich and many others made a huge difference to new judges coming in, and the more Stu learned, the more he wanted to know. Judging grew his ability to critically analyse wines, both in the competition panel and back at the winery, making and blending wines. “You can pull out that analytical side of how you assess wines. It really helps.” He’s chief judge of the Marlborough Show this year, having taken over from Ben Glover, and is excited by the opportunity to help other new judges come through, “passing on knowledge I have gained from other people”.

Wine competitions are also an important way to improve a region’s wines, he says. “That’s why I think the Marlborough show is so important.” There’s a certain amount of recognition and pride in winning an award, and the ”direct feedback” can drive improvements, “and hopefully the Marlborough show does that for the region’s wine,” he says. “Over time wineries have grown Marlborough’s reputation for making exceptional wines, so we need to inspire a new generation of winemakers to keep that momentum and hold our standards high.”

This year’s show includes three subregional trophies for the Wairau Valley, Southern Valleys and Awatere Valley. “The Awatere has proven itself as a significant and important part of the wine story, as have the other valleys,” Stu says. “That’s the thing about Marlborough. It’s so diverse. In one region we have such a diversity of soil type, temperature and aspects. It’s really nice to be able to highlight that with these trophies.” It’s not about one being better than the others, he adds. “But there’s this amazing expression from each.”

Speaking from Vavasour winery, amid a landscape transformed from the one he grew up in, Stu says the credit must be paid to the pioneers of all Marlborough’s subregions. “There’s a certain amount of unknown when you go in and put a vine in the ground. It’s amazing those guys were willing to give it a go.”

Legend judges Legacy

Oz Clark, one of the world’s leading wine experts, is to join the judging panel for the Legacy segment of the Marlborough Wine Show, sponsored by QuayConnect. Oz will join chief judge Stu Marfell, shadow chief judge Ben Glover, and Stephen Wong MW in early November. The Legacy Award honours wines of pedigree and goes to the wine producer with the highest scores from three vintages within a ten-year period, with a minimum gap of two years between each vintage. The winner will be revealed at the Marlborough Wine Show Celebration – Honouring 50 Years, on November 17. marlboroughwineshow.com

THE ECO TRELLIS® ADVANTAGE

ECO TRELLIS® posts have been thoroughly tested in vineyards for more than 14 years and are very strong and durable.

In contrast CCA treated wooden vineyards posts leach contaminants into ground water and are very hard to dispose of. They’re heavy to handle, damage easily and often bend and break under pressure in the vineyard.

A recent new style of vineyard post is untested, made from alternative product sources and may not be resilient to local conditions. These posts could be performing poorly in vineyards.

Winepress October 2023 / 21 ®

ECO TRELLIS WOODEN POSTS NEW STYLE POSTS Strong and durable Yes Partially Unknown Environmentally friendly Yes No Unknown Proven in the vineyard Yes Yes Unknown History of research and testing in-field Yes Yes Unknown Lightweight and easy to install Yes Heavy Very heavy Fully recyclable Yes No Unknown Compatible with KLIMA pruning machine Yes No No Warranty provided Yes No Unknown

FURTHER INFORMATION

TUBE

sales@ecotrellis.com

FOR

ecotrellis.com FREEPHONE 0508

EMAIL

Job Hunt

Workforce survey a ‘gamechanger’

IN 2013, few people in New Zealand’s wine industry would have anticipated advertising for a drone pilot to assist with data collection or bird scaring in a vineyard. “But there’s probably a job out there now for someone to do that,” says Berakah Vineyard Management viticulturist Logie Mackenzie. “How many of those non-traditional roles are we going to need? How do we attract them to the industry?”

A National Workforce Survey sent out in September is seeking insights into wine industry workforce needs, now and into the future, and Logie says there’s plenty to consider in an ever-changing environment. In another 10 years he doesn’t expect to be seeking people who want to make wine, or run a vineyard, or drive a tractor because they grew up on a farm.

“You are going to be wanting guys who sit at a desk in the city and say, ‘this is cool; I want to learn how to grow grapes, but my main role is at a desk analysing data and making sure the artificial intelligence (AI) is doing the algorithm right, to work out how much water to put on my vines.”

Wine Marlborough advocacy manager Nicci Armour says technology is just one of the moving parts New Zealand’s wine industry employers face, with industry growth and consolidation, workforce diversity, and global labour shortages all posing immediate challenges as well as future hurdles. The survey, which she describes as a “game changer”, aims to capture all the roles and skills across all businesses in the industry, enabling forecasts of the wine industry’s future workforce.

It’s part of the Marlborough Wine Industry Workforce Steering Group strategy to help the industry prepare for future needs and adapt to existing pressures. “Change is already here,” Nicci says, noting diverse workplaces can span four generations, each with different workplace expectations. The global workforce is rapidly changing, and New Zealand – and its wine industry – are at risk of falling behind in that evolution, Nicci adds.

She’s urging wine sector businesses to respond to the survey, which will provide outputs that individual companies can use to take a future-focus. That could be particularly useful for smaller businesses without dedicated human resource experts to consider workforce needs. “The likes of growers and vineyard management businesses are so busy in the dayto-day, and not all of them are thinking about their workforce five years down the line and what they need to be doing with their people.” The level of insight, pathways and strategy wrapped around the survey analysis will help those businesses keep ahead, and support the industry in “levelling up” its talent and capability, she says.

Logie notes that technology is already playing a part in Berakah’s business, including drones, telemetry, and digital management tools that require a different skill set to that called for in the past. Into the future, robotics and AI will play an even bigger role, and the industry needs to be prepared to train and attract the skills needed to operate those tools.

Meanwhile, employers also need to keep their eye on shorter term workforce needs, with complications already afoot. As an example, Logie talks of the reduction in the number of assistant vineyard managers, as technology and consolidation allow for fewer people managing greater areas. That leaves a development gap for those who’ll ultimately fill vineyard management roles, potentially tripping the industry up as it progresses. The survey will help companies consider those challenges and prepare for the future, including in training and recruitment, and the role of data harvested by AI, for example.

“It’s important to understand how people think technology is going to end up, and what skills our workforce needs to make sure we can analyse the data and use it in a practical and efficient way to maximise our workforce, prevent burn out, and allow us to do what we need to do in the vineyards with a very restricted labour market.”

22 / Winepress October 2023 GROW

Nautilus Estate. Photo Richard Briggs

SOPHIE PREECE

Dripline Recycling Programme

Sustainably recycle your end-of-life dripline into posts for use in vineyards and farms

Purchase Rivulis industry leading dripline for your replacement programme and receive a pre-paid voucher* to recycle any brand of dripline at Future Post’s facility in Blenheim. Install 100% recycled Future Posts back on your vineyard to fully close the loop while also improving your time and cost saving measures by utilising an extremely durable, CCA free post.

To find your local dealer contact Water Supply Products: Auckland: 09 916 0094 | Christchurch: 03 348 1293 wsp@watersupply.co.nz | www.watersupply.co.nz

Future Post contact details: www.futurepost.co.nz

info@futurepost.co.nz | Head Office: 09 238 0199

DDI vineyard: Diana Jamieson 021 447 725

* Conditions apply. Please ask your local irrigation reseller for further details.

Winepress October 2023 / 23

Vineyard Stalwart

Dedicated leader in Marlborough vines

KAT PICKFORD

DHIRENDRA SWAMI was 40 when he arrived in Marlborough on a year-long work visa with his wife Maureen in 2006. The flight from Fiji was the first time either of them had been on an aeroplane and the pair had little time to find their feet before starting work. “We arrived one day and started work at Dog Point Vineyard the next,” Dhirendra says. “We were wire lifting and bud rubbing with people on working holidays, mostly backpackers from Europe.” Seventeen years on, he takes a lot of pride in his work. “What we put into it and then it goes into award winning wines. It makes me proud of the Marlborough region.”

From day one Dhirendra felt “at home” in the vineyard. “I really enjoyed it; I love being outside and it is so beautiful in Marlborough,” he says. “I enjoyed the physical challenge, it was like being paid to exercise.” Their two children, aged 12 and 14 at the time, joined them in New Zealand a couple of weeks later and went on to finish their secondary education in Marlborough.

After a year in the vineyard, Maureen moved on to work in the aged care sector, while Dhirendra continued to hone his skills as a vineyard labourer over the next 10 years, with viticulture contract company Provine.

When Provine was bought by Vinepower in 2016, Dhirendra’s new employers recognised the value of his experience and he was promoted to vineyard supervisor, responsible for training up and monitoring staff who travel from other countries to work under the Recognised

Seasonal Employer (RSE) scheme.

“I get huge respect from the RSE boys because I have been working in the vineyards for so many years,” Dhirendra says. “With similar backgrounds and being able to speak the same language, we have an instant connection.” Last year Dhirendra took on one of four pastoral carer roles at Vinepower. He is based at the St Andrew’s vineyard accommodation in Riverlands, which houses 460 RSE staff, with the ability to grow.

The wealth of the sea to soil & plant

Ideal for use in the vineyard via drip lines or as a foliar spray, and available in any quantity from 20 to 2000 litres in a single delivery to your preferred site. www.torychannelkelp.co.nz | 027 445 3708 | sales@torychannelkelp.co.nz

GROW The vitamin and mineral content of TCKP Natural Kelp Tea analysed by Cawthron Research Institute | September 2012 Analysis Result Units Crude Protein 0 6 g/100 Aluminium 5 5 mg/kg Arsenic 2 6 mg/kg Boron 4 8 mg/kg Copper 15 mg/kg Iron 24 mg/kg Magnesium 290 mg/kg Nickel 0 66 mg/kg Phosphorus 120 mg/kg Potassium 3000 mg/kg Rubidium 1 2 mg/kg Strontium 22 mg/kg Zinc 7 0 mg/kg

Tory Channel Kelp Products' certified organic Natural Kelp Tea is a complete food for plants and soils.

“They take a lot of pride in the work that they do here for the wine industry, while being able to contribute to their family and community back home.”

Dhirendra Swami

Dhirendra Swami

The experience for vineyard staff who come to New Zealand to work via the RSE scheme these days, is completely different compared to when he first arrived, before the scheme started, Dhirendra says. “When we came to Marlborough, we had to find our own accommodation, get our own gear, enroll at the doctors and sign up at the bank ourselves. These days it’s much better. Now when people arrive, there is a whole community here to welcome them, with support and guidance to help them settle in and feel at home.”

Work in the vineyards has also changed over the past 18 years, Dhirendra says. “It was a bit tougher back then; everything was done by hand, it was 100% hand harvested at Dog Point Vineyard and the pruning and stripping was all done by hand too. Now there is machinery for stripping the vines and to do most of the harvest.”

Vakameasina

Winter is the season most favoured by RSE workers, because there is no shortage of work, with many people opting to work five and-a-half or six days a week. When they’re not working, the vineyard accommodation is a social hub, with staff catching up over a game of football, watching television, attending church services or learning new skills through the education and development programme, Vakameasina (see sidebox).

Now, as most head home after a busy winter season, they will return home armed with more skills, aspirations and fond memories of their time in Marlborough, Dhirendra says. “I can speak for the RSE boys and say they take a lot of pride in the work that they do here for the wine industry, while being able to contribute to their family and community back home.”

Vakameasina, which translates to ‘treasures we carry together’, is a free education and development programme for seasonal horticultural workers, funded by the Ministry of Foreign Affairs and Trade’s New Zealand Aid Programme. Run by Fruition Horticulture, the Vakameasina RSE Worker Training Programme aims to support people to grow their skillbase and confidence through learning pathways here in New Zealand, and support growth and learning when they return home.

Courses including small business, leadership, cooking and hospitality, computing, personal finances and plumbing, building and solar panel basics provide essential skills and the opportunity to create goals for applying that learning back home.

Winepress October 2023 / 25 GROW

Truck Stop

Murray Gibbons ready to park up

AFTER MORE than 40 years driving trucks, much of it transporting wine, Murray Gibbons is ready to hang up his keys. Murray never set out to be a truck driver, or a business owner for that matter, but when opportunity came knocking, he didn’t shy away. The only problem has been slowing down in an ever-expanding industry, he says. “I’m no businessman; just a truck driver who somehow ended up with a trucking business,” Murray says from ‘HQ’ – his tongue-in-cheek reference to the humble portacom tucked away on a corner site in Riverlands Industrial Estate, which houses operations for his company, Bulk Wine Distribution.

“I don’t know how many times I’ve tried to leave the industry, or slow down, or downsize, but I’ve failed miserably every time,” the 67-year-old says. “Somehow I ended up buying land, more trucks, wine tankers then a tanker wash.” His work has adapted to meet the needs of an ever-evolving industry. “If there’s one thing that’s constant in the wine industry, it’s change,” Murray says.

He made his start truck driving at Irvine’s Freightlines, and after purchasing his own truck and trailer contracted to what was then called Tranzlink and later became Toll Group. Nine years later he sold his truck after a car passed him on a blind corner and narrowly missed a head-on collision with an approaching vehicle. “I was sick of the mayhem on the road,” Murray says. “Then my good friend Roger Kendrick, who was doing wine carriage for the Marlborough Bottling Company [now WineWorks], asked me to help him out.” Not long after, Roger, who was a wine and mussel transport pioneer, suffered a heart attack and Murray ended up running the business for about four months while his friend recovered. “Back then he had about four tanks and three trailers and Marlborough Bottling Company only had two lines in a small building.”

It wasn’t long before things started growing very quickly to the point where Murray didn’t want to keep growing, so he got out of the Marlborough Bottling Company contract and focused on working directly with wineries instead.

By that stage Murray had bought the business from Roger, who had decided to sell due to his declining health. Sadly, Roger died in 2014 due to pancreatic cancer. After “floating around” for a while, Murray purchased an empty section on Kendrick Road (named for Roger) five or six years ago and despite his best intentions, the business has been growing steadily ever since.

Seeing a gap in the industry he also built a wine tanker wash, providing state of the art cleaning and sanitising

technology for the region’s wine transporters. With tanks ranging in size from 570 - 24,700 litres, Murray has carved out a niche for himself, with the ability to handle smaller volume wine runs as well as bulk volumes. “Back in the day you could put almost any amount of wine in a tank and drive it to the bottling line, sploshing around in the back,” he says. “Until they decided that wasn’t good for the wine.” These days they use variable capacity tanks which can hold anything from 110 – 2,000 litres, he says “Don’t ask me why it’s not good for the wine; it’s all witchcraft. I don’t want to get involved in that, as long as I can shift their wine properly – that’s all that matters.”

One of the trickiest parts of the job is accessing wineries in large trucks, Murray says. “The wine industry stops and starts with trucks, yet when they’re designing these wineries, people seem to forget about access, or don’t allow for growth, making it increasingly difficult for trucks to get in and out.”

A personal highlight has been the connections he’s made over the years. “There’s a lot of good people in the industry, really neat people and I’ve seen them change and grow over the years, shift from one winery to another and they’re always up for a laugh or a joke.”

Bulk Wine Distribution is for sale. Head to TradeMe to view the listing

26 / Winepress October 2023 CELEBRATE

KAT PICKFORD

Murray Gibbons and Meg

“I’m no businessman; just a truck driver who somehow ended up with a trucking business.”

Murray Gibbons

Small and Mighty

The most compact telehandler in the range, what it lacks in size it makes up for with power and versatility.

COMPACT P27.6

This mighty machine is great for work in vineyards. The P27.6 is ideal for scooping grape marc, fertiliser, dirt etc, and for lifting, moving equipment and working in enclosed and restricted areas such as sheds. Give the team at Power Farming Marlborough a call today!

• Tight turning radius

• Narrow width

• Low height

• 2.7 ton lifting capacity

• 6 metre reach

027 365 1617

Russell McGhie Service Manager

027 291 9576

Dave Jeffery Sales

027 362 1429 Blenheim 3535 SH 1, Riverlands | 03 573 7089 merlo nz

Bryan Simpson Parts Manager

Generation Y-ine

Thriving in the hectic business of wine

KAT PICKFORD

BILLY BROWN arrived in Marlborough almost 20 years ago to lend a hand during the vineyard development boom, and “the people” have kept him here ever since. Billy’s introduction to viticulture was lifting nets for a boutique grower in Banks Peninsula as a teenager – he loved the physicality of the job, being outdoors, and operating the vineyard machinery, so what started off as a casual job soon led to more permanent work.

In the mid-noughties Billy and a friend heard Marlborough was in the middle of a planting boom and answered the industry’s call for help to convert paddocks to vineyards. “When we arrived, there were hardly any vineyards here, mostly sheep farms. We sensed there was a great opportunity to get involved in what appeared to be a fast-growing industry.”

Billy’s friend set up a vineyard contract business and the pair had no shortage of work helping to develop vineyards and plant vines. The government-run Recognised Seasonal Employer (RSE) scheme was still two years away, and at the time contractors relied largely on European backpackers, college students and nomad Kiwis who made a living touring the country in house buses and picking up work along the way, he says. “Things were very different back then, there was next to no worker accommodation available, people would simply set up tents and camp where they could – we’ve come a long way since then.”

Since arriving in Marlborough, Billy has worked in a variety of roles in vineyard management, from developing vineyards and driving tractors to supervising contract crew. He is currently field operations manager for Vinecraft, which is based in the Awatere Valley and oversees the management of more than 2 million plants across the region.