2 minute read

HYDROGEN GAS READY BACKUP POWER FOR SITE IN CALIFORNIA

Siemens Energy has supplied 4 x 2MW hydrogen-ready generators for an industrial client based in Ontario, a city in southwestern San Bernardino County in the U.S. state of California. The customer’s site is roughly 35 miles (56 km) east of downtown Los Angeles and 23 miles (37 km) west of downtown San Bernardino, the county seat.

Ontario is located in the western part of the Inland Empire metropolitan area, it lies just east of Los Angeles County and is part of the Greater Los Angeles Area. As of the 2020 Census, the city had a population of 175,265 people.

The city is home to the Ontario International Airport, which is the 15th-busiest airport in the United States by cargo carried. Ontario handles the mass of freight traffic between the ports of Los Angeles and Long Beach and the rest of the country.

SIEMEN’s manufacturing client in Ontario now operates a facility which can rely on electrical power from an 8 MW ‘carbon neutral’, peak mitigation, backup power system offering demand response, an operating reserve and fully-financed engine solution. SIEMENS is also involved in another similar 6 MW and 10 MW solution being built for the same customer.

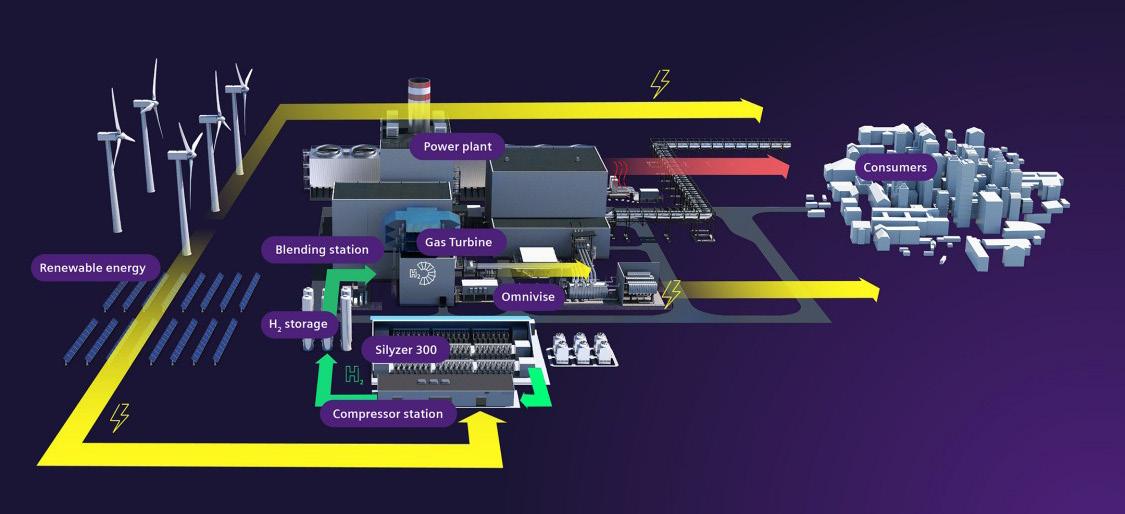

Looking at hydrogen’s potential Siemens Energy has effectively combined its unique portfolio of gas and steam turbines, electrolyzers, and heat pumps, and turning it into a unique optimised power plant solution with one operating system.

Siemens’ hydrogen power plant includes an H2-fired gas turbine (e.g. SGT5-9000HL, SGT-800, or SGT-400), electrolyzers with H2 compression and storage, and an Omnivise fleet management system to integrate all components including renewable energy sources feeding electricity into the electrolyzer.

According to the company, combining the full re-electrification of hydrogen with heat generation can significantly increase the overall efficiency of the hydrogen power plant solution.

This option includes a heat pump for heat recovery and a thermal storage system as buffer.

The heat pump captures waste heat from the electrolysis process and increases its temperature to feed either directly into a district heating network, or temporarily store it in a thermal energy storage system as a buffer before feeding it into the heat network.

A spokesman commented: “Our hydrogen power plants reduce CO2 emissions, which helps our customers to achieve their decarbonization goals. Siemens Energy integrates the different components into one plant solution. Renewable energy is used to produce hydrogen when it is abundantly available,” he explains.

“The power plant re-electrifies the energy when renewables cannot meet the demand. The Omnivise control system optimises supply and demand between the different elements of the solution.”

What H2 will mean for clean energy production

Today, the world produces 75 million tons of hydrogen each year. Most of it is generated from fossil fuels, mainly natural gas and coal.

This accounts for 6% of the global natural gas consumption, 2% of the global coal consumption, and results in 830 million tons of carbon-dioxide being released every year – almost as much as Germany’s annual CO2 emissions. Producing all of this hydrogen with green energy will help to substantially reduce emissions. The future market for this tiny molecule is huge.

Siemens Gamesa and Siemens Energy are joining forces to kickstart a new era of offshore green hydrogen production that will power a cleaner future.

Together, they are developing an innovative solution which fully integrates an electrolyzer into an offshore wind turbine as a single synchronised system to directly produce green hydrogen.

Siemens Gamesa is adapting the world’s most powerful turbine, the SG14222 DD offshore wind turbine, to integrate an electrolysis system seamlessly into its operation.

Siemens Gamesa’s modular approach ensures a scalable offshore wind-tohydrogen solution. Siemens Energy is developing a new electrolysis product which meets the needs of the harsh maritime offshore environment and is in perfect sync with the wind turbine.

The developments will serve as a test bed for making large-scale, cost-efficient hydrogen production a reality and will prove the feasibility of reliable, effective implementation of modular offshore windto-hydrogen systems. Siemens Gamesa and Siemens Energy will target a total investment of approximately EUR 120 million over the next five years in the Ongoing development of this innovative solution, with a full-scale offshore demonstration expected to be achieved by 2025-2026. www.siemensgamesa.