14 minute read

Installing USBs in BizJets: An Unexpected Challenge

Looking to ensure your cellphone, iPad and laptop stay fullycharged aboard your business jet? Then you’ll need to install USB ports. Before you do, though, there’s a bit for you to consider. Chris Kjelgaard speaks with Duncan Aviation and Garmin…

Aircraft owners choosing to install rapid-charging USB ports at each passenger seat are creating a trend that has important implications for aircraft electrical power-generation requirements — both in itself, and in what it could presage for future aircraft power needs as new technologies make their way into the cabin.

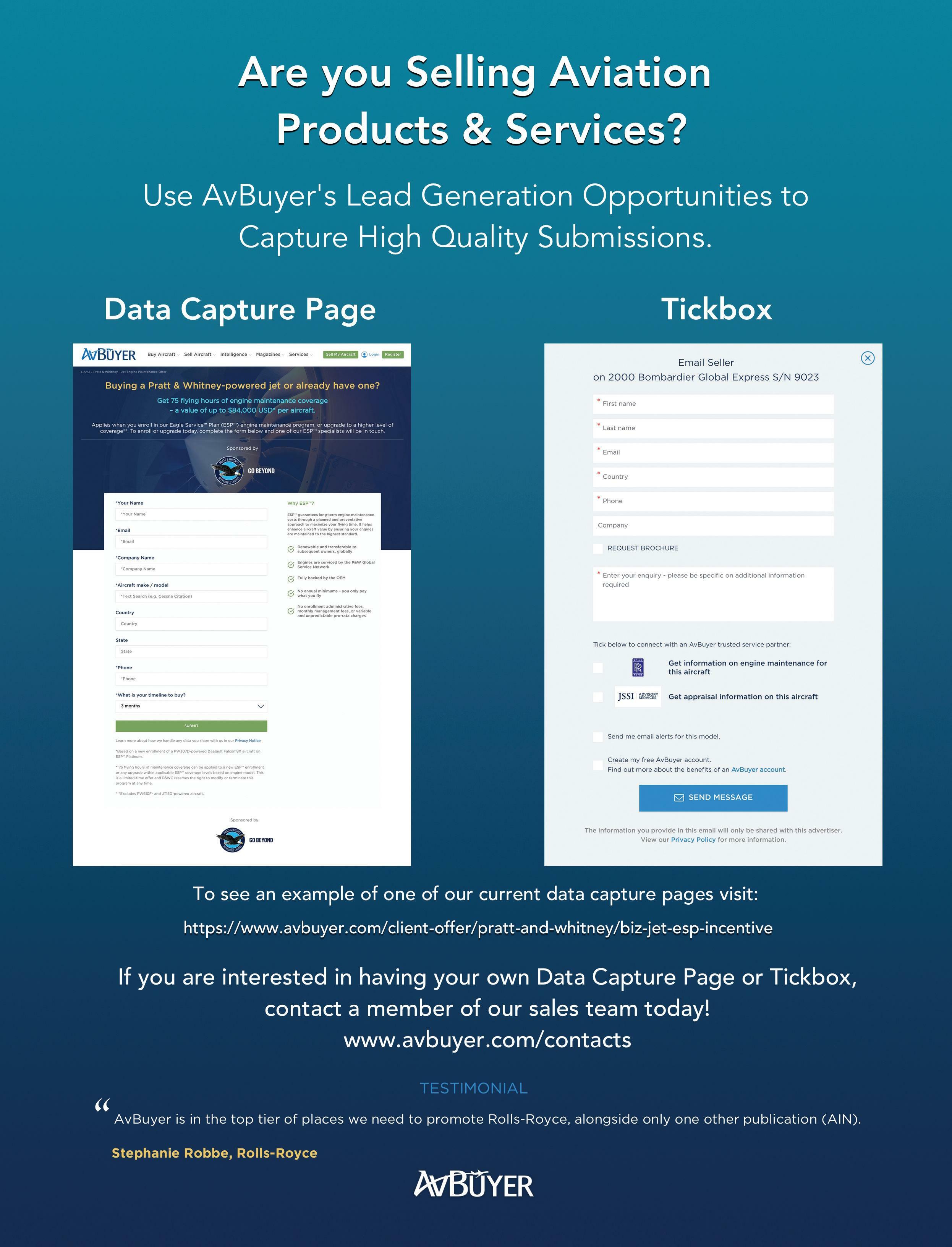

Advertisement

One of the most noticeable trends in Business Aircraft cabin refurbishment today is for owners to ask MRO providers to install rapid-charging USB ports at every passenger seat in the aircraft, to allow passengers to use their personal electronic devices in flight and keep the devices fully charged.

These installations are often accompanied by similar installations of USB rapid-charging ports on the flight decks of the aircraft, as owners and pilots replace traditional flight bags with lightweight, easy-to-use, easy-to-access tablet devices.

Moreover, aircraft owners usually want installations of dual ports, rather than single ports, at each seat and pilot position, according to Duncan Aviation’s Avionics Sales Representative Adrian Chene.

Also notable, according to Bill Stone, Senior Manager for Aviation Business Development at Garmin International (a leading manufacturer of aviation-grade USB charging ports), is that owners usually choose to have the most powerful USB rapid-charging ports installed, rather than the less powerful ports that the manufacturers also offer.

The desire to install dual USB ports at every passenger seat is a natural one for owners when passengers in Business Aircraft cabins increasingly are consuming personally selected video, graphic and audio content by means of their PEDs, rather than everyone watching or listening to the same video or audio content at the same time, on bulkhead monitors and whole-cabin sound systems.

USB ports at each seat not only provide each passenger with individually tailored entertainment and communications, but also the major convenience of keeping each passenger’s PED batteries topped up to allow immediate use when the passengers disembark from the aircraft.

However, there is a cost associated with the increased individuality and convenience that USB ports at each seat provide.

The direct cost of installing certificated aviation-grade dual USB rapid-charging ports at each seat is not major in terms of the notoriously expensive business of buying and installing aircraft equipment. But neither is it insignificant…

Such units — which, unlike ordinary consumer USB ports have hardened, specially tested electronic circuits to ensure they do not create radio interference with flight deck avionics and radios, and are designed specifically for use in aviation environments — are priced at around $300 each. And they require installation, at a price, by an MRO provider which knows what it is doing.

Just as importantly, there’s also an indirect cost associated with installing USB ports — one to which many owners may not have given much thought, but which could be a concern, particularly for owners wishing to retrofit older Business Aircraft with USB data feeds and rapid-charging capability. That cost is the increased electrical power requirement demanded of the starter-generators associated with each engine, to produce the sizable amounts of power that dual USB rapid chargers need.

Stone and Chene note that the additional peak USB-port electrical power requirement, plus the existing electricalpower requirements for the aircraft’s other flight deck, control, systems and cabin functions, must lie well within the specified electrical power-generation capability for which the aircraft is type-certificated.

Simply put, to provide a sufficient margin of control and safety in any foreseeable operational situation, type certification rules for any aircraft require the maximum potential consumption of electrical power by all the aircraft’s systems to be no more than 80 percent of the aircraft’s certificated electrical power-generation capability, according to Stone.

That said, Chene notes different aircraft manufacturers have different methods for calculating the peak electrical loads and requirements on their aircraft, which in practice might stretch the 80 percent limit by a few percent.

The arithmetic by which the maximum power requirement for the aircraft’s USB ports is derived is simple. As an example, Chene posits a retrofit with dual USB rapidcharging ports at all 12 passenger seats and the two pilot seats in a Dassault Falcon 900EX, which (like all other modern Falcon models) is designed largely to use DC electrical power rather than AC power.

When charging personal devices, aviation dual USB rapid-chargers can draw peak electrical input loads of 60 watts or more per port. (Garmin’s GSB 15 dual-port USB Type A units draw a maximum of 68W per port, while each of the two ports in Mid Continent Instruments’ TA360, another widely used aviation dual USB rapid-charger, draws a maximum of 60W.)

Stone notes that such peak input loads last only for very brief periods, because the device being charged controls the level of power draw and can only handle the peak input power level for a short time, reducing the draw quickly from that level as its battery becomes more fully charged.

But Chene points out the overriding factor in calculating the aircraft’s total electrical-power requirement is that the aircraft’s type-certification rules require that, no matter how unlikely it would be for everyone on the aircraft to be charging devices through two ports at the same time, the starter-generators must be able to provide (say) 68W x two (USB ports per seat) x 14 seats, for a total of 1.904kW.

At the same time, the aircraft’s starter-generators must also provide enough power for all the aircraft’s other electrical requirements.

On top of that, to meet the type-certification requirement the total of the theoretical power in wattage required by all the USB ports, plus all the electrical power required by all the aircraft’s other systems, must come to no more than about 80 percent of the total electrical power-generation capability the aircraft’s starter generators provide. Replacing the Engines’ Starter Generators

A new, additional power draw of 1.9kW might not sound very important, considering that in aircraft whose startergenerators are designed to provide AC power (in other words, most older aircraft), AC inverters each consuming 1,200W-2kW of power are used to provide DC power to heat coffee pots and coffee makers, and other AC inverters on board provide power for flight deck avionics units. It was “very common” for aircraft built 20 years ago to use powerful AC inverters to provide 110V power to the cabin, according to Stone.

Now USB power is taking over. And the fact remains that supplemental type certificates (STCs) exist for various business aircraft type — particularly turboprops such as Beechcraft King Airs and possibly smaller, older business jets — to provide more powerful starter generators to replace the starter generators with which they were originally fitted.

According to Stone, early-model King Airs were fitted with two 200kW starter generators, one per engine, but over time the standard grew to 250kW starter generators. For special mission needs (many King Airs are used for government and commercial special missions), the total electrical power requirement “vastly exceeds that” 400kW or 500kW total, and STCs now exist to provide King Airs with two 400kW starter generators, says Stone.

The development of STCs for replacement starter generators resulted, at least in part, from a long-term trend from the 1960s through until relatively recently. That trend was for new and older aircraft designs alike to require more electrical power, as electronics capabilities which were developed for the consumer market increasingly found their way into aircraft cabins.

“It was the same with houses,” Stone notes. “It used to be you needed 80 Amps to power your house, and now you need 200.”

Starter Generator Replacement – How Much?

It is now “very common” for owners to have USB ports installed on flight decks and in cabins when they induct their aircraft for avionics upgrades, “for Cessna 172s and everything up from that,” Stone notes.

In every case, no matter what the aircraft type, the MRO shop has to perform an electrical load analysis to ensure that the electrical power requirement for the USB ports doesn’t tax the aircraft’s power-generation system to a level beyond that allowed by the aircraft’s type certification.

If it does, the aircraft owner must be prepared to trade off existing cabin electrical requirements against the desired USB rapid-charging capability or pay the cost of performing a starter generator replacement, downsize in scale, or forgo completely, the planned installation of USB rapid-charging ports.

When ordering a retrofit, the owner must take pains to know just how much accomplishing the relevant starter generator replacement STC will cost, particularly when the aircraft in question is older or otherwise has a relatively low residual hull value. In some, or many, cases no startergenerator replacement STC is available at all.

Indeed, Chene recently asked one Business Jet manufacturer how much its starter-generator replacement STC would cost to perform, and the OEM replied that it had never received a customer request to develop such an STC.

But where an STC is available, the cost of having the replacement starter generators installed is always expensive — and particularly significant for any owner whose aircraft is worth only a few million dollars in the first place. Chene explains that any replacement STC is “highly likely” to

Type A and Type D USB ports installed in a flight deck. Photo from Garmin. “It is now very common for owners to have USB ports installed on flight decks and in cabins when they induct their aircraft for avionics upgrades, for Cessna 172s and everything up from that...”

require replacement of the starter generator in each engine on the aircraft, not just one engine.

For all sorts of operational, safety and maintenance reasons, it would be inadvisable to replace the starter generator for one engine but not the unit for the second or third engine. That would result in the power draw from each engine being different, potentially creating an unacceptable flight-safety risk.

Should an STC for replacing the aircraft’s original starter generators be available, the owner should be prepared to receive a bill from the MRO shop for $300,000-$400,000 to cover the cost of the equipment and labor, says Chene. For the sake of gaining a few USB rapid-charging ports, such an investment could easily prove more than the owner of an aging Business Aircraft might be willing to bear.

Stone reckons the trend toward increased cabin electrical-power usage has now flattened out and he sees it basically remaining similar to those of today as updates of existing cabin electrical and electronic technologies are introduced which use the same (or less) power as today’s technologies.

He says LED cabin lighting is a good example of a modern electrical technology now becoming prevalent in Business Aircraft cabins which uses less power overall than predecessor cabin lighting systems. Future Cabin Electronics Technologies

Stone acknowledges that future electronics technologies which do use more power than today’s technologies, or which are functionally different from and additive to current cabin electronics systems, could appear in aircraft cabins — in some cases after first being introduced in the consumer electronics market. Those could change the cabin powerusage picture, he suggests.

In that respect, the widening adoption by aircraft owners of cabin USB rapid-charging ports may herald a future in which electrical power usage in the cabin grows to levels greater than those of today. Chene thinks it’s very likely that in the not-too-distant future any one, or all, of a clutch of new cabin electronics technologies could become widely used in Business Aircraft and any of them could increase the existing total cabin power requirement.

In some cases, those technologies might mature to become less power-hungry than the older cabin electronics systems they displace — but in other cases they might just add to the cabin’s overall electrical power need. Five different technologies, each requiring as much or more electrical power than the existing system it might replace, appear particularly strong candidates for future cabin adoption, according to Chene. High-End Audio: First is the known trend of owners increasingly contracting MRO facilities to install very highend cabin audio systems in their aircraft. While the loudspeakers in such systems may be more efficient than previous-generation speakers on a watt-for-watt basis, the extremely pure sound reproduction capabilities such audio systems offer throughout the entire cabin can still require sizable amounts of electrical power to drive them. Noise Cancellation: A second, somewhat related technology that may or may not be feasible in the aircraftcabin context could be the advent of part-cabin or whole-cabin noise cancellation, to reduce the aerodynamic and engine noise that passengers in Business Aircraft cabins now experience.

Chene posits one way which possibly could be adopted to provide cabin noise cancellation could be installation of sound transducers behind the cabin wall panels, like those now used by Bongiovi Acoustic Labs to vibrate such panels to provide cabin audio content.

Instead of producing sound frequencies unilaterally, such transducers could be rigged with microphones to generate and output sound signals containing frequencies exactly

opposite to the ambient aircraft and cabin frequencies picked up by the mikes, far faster than any latency delay the human ear could detect.

In that way the transducers would work exactly like the microphones and speakers in personal noise-canceling headphones, completely flattening the sound frequencies from aerodynamic and engine noise. Bendable Flat-Panel Video Screens: A third technology Chene reckons could be introduced into Business Aircraft cabins in the fairly near term is development of large, bendable flat-panel video screens capable of wrapping around part, or all, of the fuselage cross-section.

Such screens could display camera views of the sky below, around and above the aircraft, making passengers almost feel they were traveling through the air on a magic carpet with no solid aircraft structure around them. Air Sterilization Systems: Fourth in Chene’s potential new cabin-technologies list is a cabin air sterilization system much faster-acting than the relatively new plasma ionization air-filtration system now being introduced into various business aircraft.

Instead of using hydrogen and oxygen ions derived from water to disable and kill pathogens and remove dust particles from the cabin air (as plasma ionization does), this other existing technology would instead use very narrowband ultraviolet light to destroy within a second or two any single-celled and viral organisms in the cabin air.

The UV light would be of a frequency not perceptible to the human eye, and unable to penetrate and damage human epidermal layers, but able to kill small pathogens instantly.

In an aircraft cabin, such a system would kill a virus particle emitted by someone sneezing, even before the particle could travel to the person sitting nearest the person who sneezed, says Chene. The system hasn’t yet been FAA type-certificated for aircraft use, but it is FDA-approved and could see FAA approval soon. Sensory Technology: Fifth and last in Chene’s speculative list is a sensory technology which could serve not only to control the functioning of several of the previously discussed innovations but revolutionize the jobs of flight attendants in Business Aircraft.

Chene says several aircraft OEMs are already working to develop systems that by various sensory means would be able to measure the stress responses of passengers to levels of cabin temperature, humidity, noise, light, air movement, etc. and allow flight attendants to adjust cabin levels in ways that would help to reduce passenger stress.

“The immersive [cabin] environments that we think are likely to happen are going to be power-hungry,” says Chene. And that is just a starting point for how he thinks business aircraft and the private aviation experience will evolve in the future — an evolution which could see the need for yet more electrical power being provided to the cabin.

“Vendors need to leapfrog [cabin] technologies over just transferring home entertainment to aircraft, to something a lot more inspiring,” he says. Augmented-reality technologies and technologies such as transparent OLED video panels are needed, “to inspire people and give them a sense of the lifestyle they’re enjoying” as passengers onboard business aircraft.

That sense of ease and luxury, and the relaxation, stress minimization and productivity it will help passengers achieve, will contribute greatly to the perceived, and actual, value of Business Aviation for all associated with it. ❙

More information from: Duncan Aviation: www.duncanaviation.aero Garmin: www.garmin.com

CHRIS KJELGAARD has been an aviation

journalist for 40 years and has covered a wide variety of industry areas during that time. He has served as editor of ten print and online titles and written extensively on many aspects of aviation.

MAKE MORE INFORMED CABIN UPGRADE DECISIONS with AvBUYER.com