43 minute read

F/LIST

©Embraer

The new sustainable products do not mean compromising on quality and will meet the same exacting standards of current F/LIST products. Carbon fibre can be used as it reduces operating costs due to its light weight nature.

Advertisement

Sustainability has become a watchword for the future of Business Aviation with the aerospace industry collectively navigating a pathway to a carbon neutral future by 2050. It is a bold ambition with discussions around sustainability dominated by talk of electric, hydrogen and hybrid propulsion programs, as well as sustainable aviation fuel (SAF) which is available now, although supply is still limited.

In the cabin sustainability is already making its presence felt. OEMs and owners have started to question in detail how products are made and processed, which is positioning sustainability as part of the competitive landscape. The availability of sustainable options is influencing purchasing decisions and the need to offer attractive, compliant, competitively priced interiors that do not compromise on quality, is now critical. Anticipating and responding to these needs is Austria-based F/LIST. The third-generation family company is combining years of heritage, knowledge and craftsmanship with contemporary technology, new materials, and cross-industry knowledge sharing, to satisfy the increased demand for lightweight, high-performing, eco-friendly concepts.

Visionary Perspective

perspective leading a dynamic team to make the seemingly impossible possible. The eclectic mix of experts include carbon fiber technology professionals from the F1 sector, jewellery designers and architects, amongst others.

“To enhance the passenger experience and disrupt the interiors sector we need to dream a little bit and change the status quo, ” Prince says as she explains how her colleagues collaborate to define novel, environmentally friendly concepts that will add inherent value to the customer experience, and the asset itself.

“We are ambassadors for cabin sustainability, and we can only ensure success by introducing new thinking around the subject. If we give our customers intriguing, stylish, yet functional materials we believe it will encourage them to think sustainability-first when it comes to creating a cabin interior. We must convey that sustainability does not mean compromise in the cabin. ”

F/LIST is already marketing decorative surfaces made from rattan, and textiles produced from agricultural byproducts, and Prince believes there is a world of opportunities. “Our incredible new product portfolio will surprise and delight with its superior quality, design potential and elegant beauty as we provide the opportunity to turn design fiction into design fact. ”

F/LIST embraces external industry experience and the innovators act as a conduit between aviation and a whole new set of suppliers. Prince’s team regularly liaises with start-ups devising impressive next-generation eco-materials, but that don’t have the experience of, or voice in, the aviation industry. Luxury brands are also benefitting from the opportunities provided to have their high-end products redirected from the catwalk to the cabin. “We keep an open mind, examining every opportunity, but the screening process is intense. We must make sure materials are fire retardant and durable, that they are relevant and practical to work with, and that we can modify and repurpose it for the aerospace sector. We then develop unique, attractive components that broaden cabin design options. It is a long iterative process, involves an element of failure, yet stimulates amazing results.”

Previously Unseen Materials

The enhanced F/LIST portfolio will introduce previously unseen materials to operators, OEMs and completion centers, and demonstrate that sustainable materials can perform as well, if not better than existing products, last as long, and are breathtakingly stunning. “Our customers are going to be astounded as we extend the parameters of cabin design,” Prince says. “Business Aviation travellers are surrounded by our products in the cabin, which supports engagement with sustainability. The cabin interior will inspire debate and discussion amongst peers, and most importantly influence their environmental mindset in the skies.”

Offering the best natural materials to the aerospace industry has always been fundamental to F/LIST. “We are going back to basics. As our understanding of, and passion for natural products expands, we are creating innovative bio-based materials by applying bionic design to create smart structures that support loads and forces exactly where necessary,” she continues. “We are integrating plant fibers instead of synthetic fibers, as well as incorporating byproducts and materials from biorefineries. The results are strong, yet light components, that form cabin frameworks.”

For F/LIST sustainability extends beyond the product. It is applied across the complete value chain. From fair and responsibly managed raw material sourcing to the use of solar and renewable energy, to supporting sustainable circular economies, F/LIST seeks to optimize the value delivered to the customer, while simultaneously minimizing resource consumption. This perspective leads to game-changing business models that encompass extended reuse, repair, and refurbishment, and reinforces the sustainability message. Even the buildings are sustainably managed. The Thomasberg, Austria, headquarters is river cooled, the production plant is heated with renewable energy and intelligent LED lighting brings light to the interiors.

“Our mission is to manufacture tangible and pragmatic innovations that support the sustainability narrative. If customers approach us with one idea, and we can transform it into a sustainable concept, that really motivates us,” Prince summarizes. “Our goal is to sustainably create eco-friendly products that meet and exceed customer expectations, last longer and can be recycled at the end of life.”

More information from http://f-list.at

©F/LIST

Mélanie Prince, Head of Innovation at F/LIST

Editor’s NOTE

Matt Harris

Matt Harris is commissioning editor for AvBuyer. He is an experienced General and Business Aviation journalist and has edited a variety of titles across the last two decades. These include AvBuyer, BizJet Advisor and GA Buyer Europe.

https://www.linkedin.com/in/ matthew-harris-avbuyer/

Don’t Compromise on Maintenance!

Everyone’s been talking about the pre-owned market lately. Whether it’s the speed at which desirable business jets and turboprops sell, the increases in average asking prices, or the sudden resurgence of interest in various older models (given the lack of newer inventory on the market), we are without doubt navigating some abnormal times.

Some of today’s market situation was created by charter and fractional ownership fleet operators needing to bolster their fleets to cater for a surge in demand emanating from the Covid pandemic when many traditional airline passengers turned to private aviation as a safer travel solution.

And having liked what they saw, many of those first-time business aircraft users became first-time business aircraft owners, further draining the inventory pool.

With the market balance now firmly tipped in favor of sellers, some are even insisting their desperate buyers forego a pre-purchase inspection, accepting their aircraft in an ‘as-is’ condition.

A very real danger exists that inexperience, desperation, or a giddy combination of both could lead at least some to experience ‘buyer’s regret’ when the realities of ownership set in, and the aircraft’s full MRO needs become apparent.

Eyes Wide Open

Today’s market environment accentuates how vital it is to buy a jet with an understanding and a plan. The understanding includes knowing exactly what the maintenance condition of the aircraft is – whether it’s engines, airframe, APUs, and/or avionics are covered by an hourly maintenance plan and, if so, what is and isn’t covered when a maintenance need arises.

Buyers should also be going into a purchase with their eyes wide open, and with a firm grasp of what they need the aircraft to do (both from a crew and passenger perspective).

Given that today’s picked-over market is laced with older pedigree aircraft, if an aircraft’s systems are near to obsolescence, or don’t provide the necessary capability, prospective buyers should know what it will cost to upgrade them.

And where differences exists between a buyer’s ideal for the aircraft and its existing capabilities and equipage, buyers need to be able to operate with any compromise for as long as it takes to find a suitable slot at their preferred MRO provider to upgrade. Supply chain issues and high demand on MRO facilities continue to put a strain on schedules.

All these factors and more are why various articles in this MRO special edition center on the need for you to plan and understand your MRO requirements.

In this MRO Special Edition

For example, it’s important to keep on budget with your business jet upgrade, and three leading industry experts offer tips for how to do so, while sharing some of the common ‘budget-busters’ to avoid.

Chris Kjelgaard delves into gaining a fuller understanding of the costs and processes of an engine overhaul, reducing the chance of an expensive shock, while Dave Higdon discusses some strategies for avoiding unnecessary overhaul disruption – whether planning ahead to book the desired MRO slot or thinking about your ongoing flying needs with alternative lift or loaner engines.

Hourly maintenance programs offer assurance and predictability to owners and operators – but it’s important to make sure you understand the levels of coverage. Gerrard Cowan asks some of the program providers how owners can achieve flexibility in their programs without becoming exposed to expensive maintenance risks.

We also consider some of the upgrade elements of private jet ownership. For example, if you’re purchased an older pre-owned jet, or the cabin of your existing aircraft is feeling a little dated, what are some of the top cabin electronics upgrades you can make to bring new jet capability to your passengers? Brian Wilson discusses.

Or, if you’re looking at the flight deck with a view to upgrading, how do you balance the cost versus value of any potential retrofit? Ken Elliott highlights the ways true value can be defined in the cockpit.

And Chris Kjelgaard identifies the seven factors that could drive your next cabin refurbishment project, discussing them with some of the industry’s seasoned refurbishment professionals.

One of several things the Business Aviation industry does extremely well is to provide ever-greater levels of service to owners and operators, as is borne out by Pratt & Whitney’s recent service offering enhancements, featured in this special edition, and highlighted by Rolls-Royce in their interview with AvBuyer, again published here.

So, whether you’re new to aircraft ownership, or you’re a seasoned business aircraft owner/operator, the AvBuyer team trusts you’ll find this MRO Special Industry Guide useful, packed full of actionable intelligence for making the most of your aircraft’s next MRO shop visit. Enjoy!

MRO Special Industry Guide Contents

4

Editor’s Note: Don't Compromise on Maintenance!

8

Keep on Budget with Your Business Jet Upgrade

14

Pratt & Whitney Enhances Service Offerings

16

Engine Overhaul: Understanding the Costs & Processes

22

Engine Overhaul: Tips to Avoid Unnecessary Disruption

28

Hourly Maintenance Programs: Getting Value for Money

34

Rolls-Royce: Striving for Engine Support Perfection

40

Cabin Electronics: New Jet Functionality for Older Planes

Don’t forget to read our regular content in the front section of this issue.

46

Measuring ‘Cost’ versus ‘Value’ of a Flight Panel Retrofit

52

Seven Factors Driving Your Next Cabin Refurburbishment

Sponsored Content

2 F/LIST 27 GE OnPoint 37 Sponsored Announcements from TAE and C&L

EDITORIAL Commissioning Editor Matthew Harris +44 (0) 20 8939 7722 editorial@avbuyer.com

Editorial Contributor (USA Office) Dave Higdon dave@avbuyer.com

ADVERTISING Steve Champness Publisher Americas +1 770 769 5872 steve@avbuyer.com

Lise Margin Account Manager +1 703 818 1024 lise@avbuyer.com

Maria Brabec Account Manager EMEA & APAC Aircraft & Services Sales +420 604 224 828 maria@avbuyer.com

STUDIO/PRODUCTION Helen Cavalli Mark Williams +44 (0) 20 8939 7726 helen@avbuyer.com mark@avbuyer.com

CIRCULATION Sue Brennan +44 (0) 20 8255 4000 Freephone from USA: +1 855 425 7638 sue@avbuyer.com

AVBUYER.COM Michas Rapf michas@avbuyer.com

Emma Davey emma@avbuyer.com

MANAGING DIRECTOR John Brennan +44 (0) 20 8255 4229 john@avbuyer.com

USA OFFICE 1210 West 11th Street, Wichita, KS 67203-3517

EUROPEAN OFFICE AvBuyer House, 34A High Street, Thames Ditton, Surrey KT7 0RY, UK +44 (0)20 8255 4000 Freephone from USA: +1 855 425 7638

PRINTED BY

Fry Communications, Inc. 800 West Church Road, Mechanicsburg, PA 17055

Keep on Budget with Your Business Jet Upgrade

When planning to upgrade your business jet, is there ever a legitimate reason to exceed the budget? What are the pitfalls to avoid blowing an upgrade budget? Matt Harris asks for the insights of some leading industry insiders…

As anybody who has previously upgraded a business jet would testify, the numerous options available for getting the look, feel and functionality of the aircraft exactly as you’d want it are dizzying.

With choice comes a lot of opportunity for original upgrade budgets to grow – sometimes exponentially beyond what was projected.

Aircraft owners planning upgrades need to keep a strong focus, take a disciplined approach to the overall upgrade project, and should be prepared to build a cushion into their budget to allow for an element of expansion on the original project.

By working well ahead of the upgrade with a trusted MRO center, owners and operators will be able to discuss the popular and most effective solutions available for their cabins and cockpits that enhance not only their current mission needs, but future needs too. The Benefit of Expert Input

“It’s less about going over budget, and more about the owner getting exactly what they need or want in the end,” argues Phil Stearns, Director of Sales & Marketing for Stevens Aerospace & Defense Systems, who adds that the initial budget for an upgrade is “just the starting conversation” and should include plenty of room for change before the project begins.

In fact, owners have more chance of seeing their budget

PHOTO COURTESY OF STEVENS AEROSPACE

swell significantly when they decide to perform an upgrade at the last minute, notes André Ebach, Head of Maintenance for Aero-Dienst.

“Getting in contact and working with the maintenance facility at an early stage in the process is very important for proper planning, and for building a reliable budget for the upgrade,” he says.

Another benefit of involving the MRO shop in the process early is that it will help owners ensure that the upgrade is approved by the aircraft manufacturer, as well as the local aviation authority. “National airworthiness authorities require systems to be approved by the manufacturer and will require their consent in the form of an STC (Supplemental Type Certificate),” says Vince Goncalves, Regional VP Africa, ExecuJet MRO Services.

“STCs have been carefully designed by the STC holder in conjunction with the aircraft manufacturer, and they require the appropriate expertise for integration into the aircraft’s systems.”

Over the years, Ebach has seen many customers choose to perform an upgrade simply because they’ve seen it on another jet. “It is always better for the aircraft owner when their modifications and upgrade decisions are tailored to their own needs and aircraft,” he says, not just copied from another aircraft.

Stearns notes that while owners may have an initial budget in mind, once they explore their needs with the MRO shop, based on how they use the aircraft, additional or alternative upgrade items can make sense, justifying an increase on what was originally budgeted.

“It could be that a Large Jet cabin configuration isn’t working as well as it could for the owner on transatlantic flights,” he highlights. “A slight reconfiguration – such as adding a bed, couch, or a redesign of the galley – could fix that.

“Or perhaps, with the growing number of cell phones and laptops being used by passengers today, the addition of USB and other charging ports make perfect sense.”

Ultimately, budget should be weighed against enhanced productivity or comfort. Not everything is driven by functionality, though. Sometimes personal preference can be important in planning an appropriate upgrade budget.

For example, corporate owners may place high importance on corporate identity, conveyed through color scheme or logos, both inside and outside of the aircraft. And private owners might want to reflect some of their favorite things in the cabin, like the seat design of their sports car, or a design element from a vacation home, Stearns suggests. At that point, costs will inevitably increase.

“If the owner can put a value on the ‘wow-factor’, they can usually justify increasing their budget,” he argues. As already mentioned, though, there’s a far

higher chance of hitting the ‘wowfactor’ with proper planning, far in advance of any proposed upgrade project’s start date.

Budget Upgrade? Avoid These Temptations…

While there are some legitimate reasons for aircraft upgrade budgets to increase, there are some common temptations aircraft owners experience that will result in unnecessary additional expense if they’re not carefully avoided.

First, avoid selecting an MRO center for the upgrade based on the cheapest quote. Ebach suggests selecting a provider you trust, ultimately. Goncalves agrees. “Aircraft owners and operators shouldn’t be tempted or influenced by the ‘best price’, which could lead to a mismatch between the end-result and your expectations.

“If there’s a large difference between proposals from MRO providers, then there’s usually a very good reason for this, and it needs to be queried first,” he suggests.

“Next, avoid buying upgrade items based on brand or clever features,” Ebach warns, adding that it can be tempting to pay for a specific upgrade item “simply because it’s state-of-the-art”. Such an approach could lead to owners over-paying for functionality they don’t ultimately need or incurring unanticipated additional work to integrate it with the airplane’s existing systems.

Nor should upgrade options be overlooked because they are a different brand to what the owner has been used to in the past, he adds.

Ultimately, customers should be guided through the whole project by their trusted MRO center to identify the best upgrade for their needs. “With such a large number of options available on the retrofit market, it is easy to get lost,” Ebach warns. “But an experienced MRO shop will be able to walk its customers through the project, and filter through the vast array of choices to find the right ones.”

PHOTO COURTESY OF AERO-DIENST

Hidden Additional Costs

Clarity is also essential to managing budgets, and there are areas of an aircraft upgrade that owners should be very clear about – but often aren’t – such as the hidden extras of an upgrade or modification.

“Don’t be led by the bottomline price,” Goncalves says. “Work through the upgrade proposals line by line when making comparisons between what each shop is offering. When there is a discrepancy, ask why, and don’t accept vague answers.”

Does the price include the cost of equipment, but exclude installation costs? “Someone has to perform the work, including the removal of the existing system and installation of the new equipment,” Ebach adds. “Then there’s the cost of engineering, hangar space, costs of compliance with the relevant aviation regulations (e.g., burn testing). Are these included?”

“When receiving a proposal make sure that any item quoted ‘Price to be Determined’ gets discussed early on,” Goncalves says.

Stearns notes that the price for

paint stripes and colors have risen dramatically lately. “Custom paints, metallics, and extravagant designs are generally not in the base price” when owners are looking for a baseline budget for an upgrade.

“Be very clear with the paint shop and designer what you want upfront so that all costs of a paint refurbishment are budgeted for.”

And then there are the factors that the aircraft owner/operator is responsible for in their budget. “For example, in the case of charter operators there’s the lost income from charter flights owing to an extended period of downtime,” Ebach illustrates. “This is a hidden cost that can easily be overlooked.”

Depending on the type of upgrade or modification, significant work could be required to gain access to the necessary area, including removal of the interior. “In addition to the extensive man-hours incurred, this can sometimes result in unexpected discoveries, such as corrosion,” Ebach notes. “Is there a contingency in the budget for such unforeseen surprises?”

Other hidden costs can occur later because of penny-pinching in the near term. “From a strictly aircraft-protection standpoint, it’s important to understand that the paint’s primary responsibility is to protect the aircraft,” Stearns illustrates. “The secondary function is to look good.”

If the paint on an aircraft is peeling or cracked, the surface below will be at risk of corrosion, which can be an expensive fix further down the line. “It’s necessary for aircraft owners to budget for regular, inexpensive, visual inspections and repairs of such areas sooner, rather than later,” Stearns emphasizes. The upgrade could be a good opportunity to do so.

PHOTO COURTESY OF STEVENS AEROSPACE

Tips for a Budget-Oriented Upgrade

Keeping the budget in hand when it comes to upgrading your business jet ultimately requires planning, planning, and more planning, according to Ebach.

“We’ve seen many upgrade projects move through our hangars over the decades, and, without exception, the most successful are the customers who get in contact with us early,” he emphasizes.

Successful upgrades start with seeking the MRO center’s expertise and input into the project, proceeding with renderings, technical descriptions, engineering, removal of old equipment, installation of new, and, of course, aftermarket support, “with as few ‘budget shocks’ as possible along the way,” he concludes.

“Authorized service centers are more likely to already have OEM approvals/STCs for the systems you’re upgrading, saving time and cost,” Goncalves adds. “Be sure to request the contact details of the STC holder or system OEM to discuss your upgrade with them, too.

“OEMs place their reputation in the hands of your local service providers’ abilities and will guide you as best as they can,” to ensure your upgrade budget is well spent.

“Moreover, service providers who have OEM approvals undergo regular audits, and tend to have the necessary infrastructure, experience and equipment to complete your upgrade successfully.” ■ More information from: Aero-Dienst: www.aero-dienst.com ExecuJet: www.execujet.com/en Stevens Aerospace: www.stevensaerospace.com

MATT HARRIS is commissioning editor for AvBuyer. He is an

experienced General and Business Aviation journalist and has edited a variety of titles across the last two decades. These include AvBuyer, BizJet Advisor and GA Buyer Europe.

https://www.linkedin.com/in/matthew-harris-avbuyer/

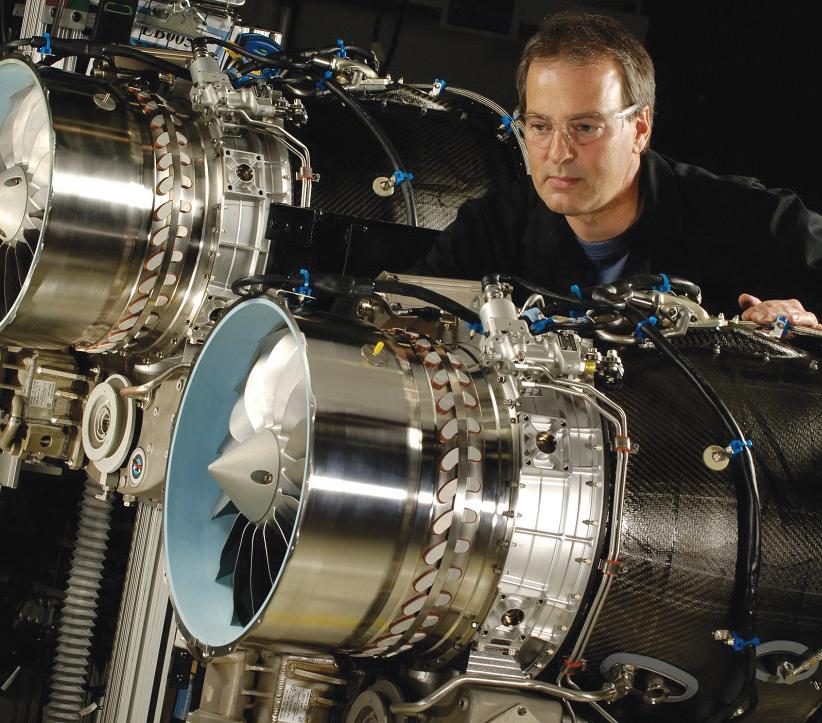

Pratt & Whitney Enhances Service Offerings

Among the companies making the headlines at the recent EBACE was Pratt & Whitney Canada with a trio of announcements highlighting enhancements to its products and services for customers in Business and General Aviation…

Never one to miss an opportunity to grow the support services it offers to operators, Pratt & Whitney Canada has expanded the portfolio of its P&WCSMART maintenance, repair and overhaul (MRO) solutions.

P&WC Extends P&WCSMART into Turbofan Market

Since Pratt & Whitney launched the P&WCSMART portfolio in 2014 it has grown to more than 30 different offerings for PT6A and P&WCpowered helicopters and regional aircraft. But this latest program expansion takes the service into the business jet market for the first time, for Cessna Citation Mustang owners and operators.

Specifically, the new P&WCSMART solution is a flat-rate ‘zero time since overhaul’ (0-TSO) engine exchange for PW615F-A engines.

This is part of the company’s effort to provide flexible, cost-effective solutions for major engine maintenance, which support the full engine lifecycle, with flat-rate overhaul options, overhaul alternatives, and more, according to one company spokesperson.

The new P&WCSMART offering enables Citation Mustang customers to exchange their existing PW615F-A engine with a freshly overhauled PW615F-A engine for a “very attractive price”, Pratt & Whitney says.

With this option, customers avoid having to rent an engine and the corresponding removal and installation, reducing downtime to just a few days – the time necessary to install the 0-TSO exchange engine(s).

“P&WCSMART solutions provide competitive flat rates and capped costs for major engine maintenance, eliminating price variables and uncertainty,” Irene Makris, Vice President, Customer Service, Pratt & Whitney Canada, commented. Video Series to Support PT6E67XP Operators

Furthermore, having announced the expansion of its PT6 E-Series engine family in April, Pratt & Whitney Canada has launched a new video series about the PT6E-67XP to “help customers fully benefit from the PT6E67XP engine experience - including digital connectivity, built-in intelligence and powerful diagnostic/prognostic capabilities”.

The PT6E-67XP engine powers the Pilatus PC-12 NGX (which entered service in 2020), and the Video Series comprises three parts, showcasing different aspects of the PT6E-67XP engine user experience.

“This video series will help customers new to the PT6E-67XP engine to take full advantage of its state-of-the-art technology,” says Nicholas Kanellias, Vice President, General Aviation, Pratt & Whitney Canada.

Part 1 - Simplifying the Flying Experience with Intuitive Controls: The PT6E-67XP features a dualchannel integrated electronic propeller and engine control system — the first of its kind in the General Aviation turboprop market.

The result is a more intuitive way of flying that reduces pilot workload. The first video in the series demonstrates how the digitally enabled single lever simplifies engine operation and allows for true precision-controlled auto-throttle.

Part 2 - Supporting Troubleshooting with World-Class Service: The PT6E67XP is digitally connected through its Data Collection and Transmission Unit (DCTU), which wirelessly transmits full-flight engine data shortly after landing and shutdown.

The data is reviewed and analysed by dedicated experts of Pratt & Whitney Canada’s Proactive Services team, who will then contact the Director of Maintenance directly to provide updates, and, if needed, recommend preventive actions, such as proactively swapping-out parts. The second part in the series provides an overview of troubleshooting support.

Part 3 - Facilitating Maintenance with Digital Connectivity: Part three looks at digital connectivity. Available for download on the Apple iOS App Store, the DCTU app was developed to communicate with DCTU hardware

on PT6 E-Series engines using wireless connectivity, for the purpose of performing maintenance actions.

Primarily used by technicians, the DCTU app makes it easy to view a host of parameters, events, exceedances and faults, retrieve diagnostics data, monitor the engine’s health status, perform live diagnostics, and test transmissions or change engine modules using barcode scanning, among other actions. Part three of the series demonstrates how.

Carbon Offset Service Rolled-out to GA Customers

And finally, having rolled-out its Carbon Offset Service initially to Eagle Service Plan (ESP)-enrolled business jet customers, before expanding it to helicopter and regional operators, Pratt & Whitney Canada has now further extended the service into General Aviation.

European fractional owner JetFly has signed up its entire fleet of PT6A and PT6 E-Series powered Pilatus aircraft that are enrolled in the ESP maintenance program to the Carbon Offset Service, which enables operators to contribute to greater environmental sustainability by offsetting the carbon footprint of their aircraft in a simple, costeffective manner.

P&WC’s Carbon Offset Service enables operators to contribute to greater environmental sustainability.

The operator’s aircraft’s emissions are estimated, and compensated, through the sourcing of carbon offset credits from South Pole (a globally recognized provider of environmentally sustainable solutions), and the Carbon Offset Service supports initiatives that benefit the environment and local communities by creating economic opportunities, such as clean water access, renewable energy, and forest conservation projects.

“JetFly’s decision to register these engines in our Carbon Offset Service underscores the importance of expanding to our General Aviation customer base, the largest market segment for the company,” Irene Makris, vice president, Customer Service, Pratt & Whitney Canada highlights.

“Environmental responsibility is important for JetFly and for our customers,” adds Cédric Lescop, Chief Executive Officer, JetFly. “It also fits within our sustainability goals, and this is one of the reasons why we also fly PT6A and PT6 ESeries powered aircraft – they are reliable and fuel-efficient engines.”

“Pratt & Whitney has a longstanding commitment to offering environmentally responsible products and solutions to its customers,” Makris concludes. ■

More information from www.pwc.ca For the PT6E-67XP Video Series, visit: https://www.pwc.ca/en/airtimeblog/articles/expert-talk/new-videos -showcase-pt6e-67xp-features

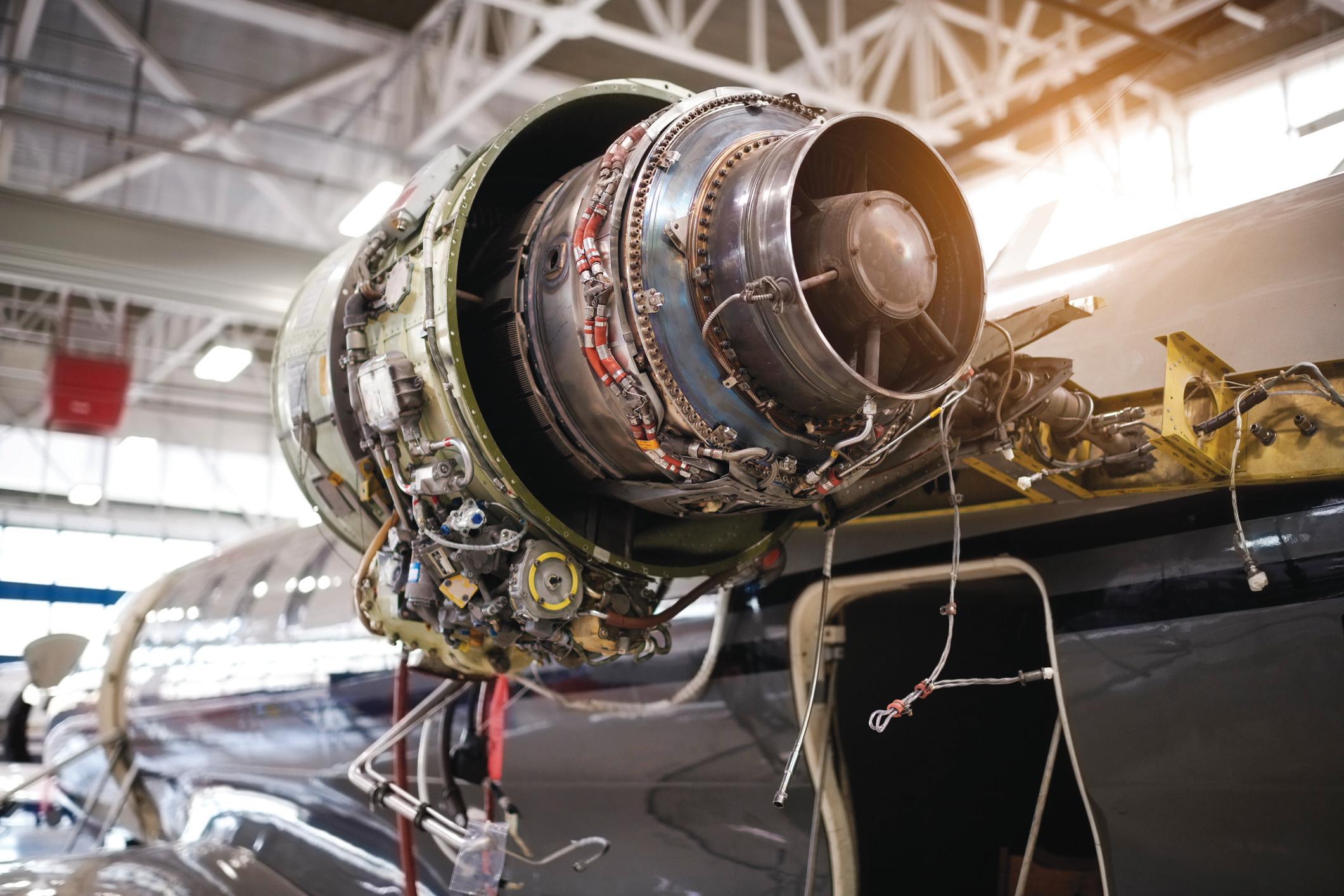

Engine Overhaul: Understanding the Costs & Processes

Any mistaken assumptions by an aircraft owner about an overhaul can add even more cost to an alreadyexpensive process. But what homework should owners do before the overhaul begins? Chris Kjelgaard finds out…

It is all too easy for a Business Aircraft owner to not fully comprehend the extent of the repair and replacement work that might be required during a scheduled engine overhaul. It’s even easier to underestimate how much work might be required when an engine must undergo a shop visit for unscheduled maintenance after a fault is detected, or a part fails.

Misunderstandings on the part of aircraft owners can easily happen when too much is taken for granted regarding their engine maintenance plan coverage, or an over-reliance on maintenance tracking software for information on engine status exists.

Preparatory homework is required, allowing the owner to review their assumptions before the engine enters the shop for maintenance, scheduled or otherwise.

“We find operators are typically unfamiliar with many factors surrounding major maintenance events like overhauls,” says Joe Capra, Senior Commercial Director, Pratt & Whitney Turbofans for StandardAero Business Aviation. But if the owner realizes that, as with most things ‘information is power’…it is easy for the owner to prevent themselves being surprised.

“Those who take the time to visit the facility where their engines will undergo the maintenance benefit from meeting the technical team, learning the process, reviewing choices regarding parts, cost and supplemental support, and understanding anticipated turnaround-times for their event,” he adds.

“Our OEM-authorized engine service centers have technical experts with experience from overhauling or repairing hundreds of engines and will provide all the tips and suggestions to navigate the process,” Capra assures.

“This includes establishing a budget, or in the example of pre-paid maintenance plans, a review of what is and isn’t covered.”

Engine Maintenance Plan Familiarization

COURTESY OF STANDARDAERO

To prevent expensive misunderstandings, it’s particularly important for owners to know exactly what they are buying when either they contract for new engine maintenance plans for their aircraft or buy an aircraft with engine maintenance coverage already in place, according to Sean Lynch, Program Coordinator for Engine Assurance Program (EAP).

“Before you buy the aircraft [with an engine maintenance program supposedly already attached], you need to make sure the program is fully transferable and paid-up, or you’ll end up in a fight with the seller over the bill or lose the engine coverage,” Lynch warns.

As Capra indicates, it is vital for aircraft owners in possession of prepaid engine maintenance plans to know exactly what their plans cover. For instance, several engine OEMs — and at least one well-known independent pre-paid plan provider — offer different levels of maintenance coverage, each being priced to suit different owners’ budgets. The different levels offered by any given provider don’t all offer the same coverage.

For example, cheaper monthly plans often don’t provide engine rentals when the engines covered under the plan are in the shop for maintenance. Nor do they cover the costs of shipping those engines to and from the maintenance shop. And they’re less likely to provide engine condition trend monitoring or cover the replacement of Life Limited Parts (LLPs), or routine line maintenance.

Indeed, some plans only cover engine maintenance following a catastrophic part failure.

On the other hand, comprehensive programs — offered optionally by some engine OEMs and as the only choice by others — cover just about every cost incurred when an engine enters the shop for scheduled or unscheduled maintenance, including short-term engine rentals, transport costs, and even (in some cases) charters of an alternative aircraft.

Those few maintenance-related cost items not covered by some of the comprehensive plans are either left out to provide a little wiggle room for plan cost savings at the owner’s option — the providers offering even more comprehensive coverage to owners willing to pay the full amounts — or are excluded because they can only arise owing to negligence on the aircraft owner’s part.

Over-reliance on Maintenance Tracking Software

For engines not covered by pre-paid maintenance programs, another misunderstanding that can mislead owners on each engine’s part life and condition is for them to place too much faith in the information provided by the maintenance tracking software program used for the engine.

“If the engine is not on a program, you need to familiarize yourself with the [aircraft’s maintenance] logbooks, because with engine maintenance tracking programs the data is only as good as what has been inputted,” notes Lynch.

“You need to verify [from the detailed information on completed maintenance tasks] in the logbooks that the engine status matches up with what the tracking program says.”

Capra agrees. “We think maintenance tracking software

programs and databases are excellent for tracking when maintenance is required,” he says. “We do, however, strongly believe that looking through the logbooks and understanding what the total run time has been on noncycle or hour-life items helps to understand whether these items will have a higher susceptibility for replacement during the next maintenance event.

“An example might be the total time since installation of a set of turbine blades,” Capra highlights. “Were they installed new or used at the last major shop event? Or were they original to new manufacture and reinstalled at the last hot section inspection?”

The logbook information is critical to understanding the history of what was accomplished on the engine, he explains, and it shouldn’t be taken for granted that maintenance time-tracking software alone provides these insights.

Know your Life-Limited Parts

From a maintenance-cost viewpoint, it is critical for aircraft owners to know how much life any given Life-Limited Part (LLP) has, both before and after full overhaul or major mid-term inspection, according to Lynch. LLPs (such as fuel control units, turbine disks and even individual turbine blades) are enormously expensive to replace.

The cost of having to do so can be ruinous for an owner who has relied entirely on what the maintenance tracking software says regarding engine life, but suddenly finds during a major scheduled inspection conferring, say, another 1,000 hours of engine time until the next full overhaul, that the engine contains LLPs which only have 100 hours of running life remaining.

This happened in one specific example Lynch encountered, of a Gulfstream G100 whose engines were covered under a plan which neither included the cost of LLP replacement nor the cost of renting replacement engines while the recently inspected engines were inducted again for LLP replacement.

Another even more extreme example Lynch cites from his personal experience is that of a critical part failing in an engine which had emerged from a mid-point inspection (MPI) only a few months earlier. Unknown to the owner, the engine contained a part which had been installed eight years earlier during a compressor zone inspection and was years out of warranty.

The failure of that part when the engine was still fresh out of its MPI led to the engine having to be removed from the aircraft and inducted for unscheduled maintenance, at a total cost of $240k. Luckily for the owner, the engine was fully covered under an EAP comprehensive program.

In some cases (not those cited above) the additional engine maintenance costs resulting from a misunderstanding over remaining part life can be so high that they exceed the actual market value of the aircraft in good condition. This effectively renders the aircraft immediately obsolete, fit only to be scrapped except possibly for a little price recovery available from some non-limited engine parts which may be resaleable.

That said, Capra reckons most owners are aware of how expensive misunderstandings regarding remaining LLP life can be and pay particular attention to knowing just what the LLP ‘green time’ situation is in their engines.

“In major maintenance events, where access to life limited parts is performed, we make owners and buyers aware of any short hour/cycle situations and offer the decision to replace these items with new or used parts with sufficient time remaining to suit their operational requirements.”

Another bit of good news for owners is that “manufacturers’ warranty terms, and conditions and elements of maintenance plan cost coverage, are well understood by OEM-approved engine MRO facilities,” according to Capra. “These programs can change from time to time, so involving the prepaid maintenance plan provider and the MRO is very beneficial to understanding plan coverage.”

Involve Experts When Purchasing an Aircraft

Lynch recommends that, when aircraft engines are not covered by pre-paid maintenance plans and decisions need to be made regarding purchasing those aircraft or sending their engines for maintenance, owners avail themselves of the expertise of an experienced technical inspector or A&P mechanic who is highly familiar with the engine

Engage the power of TAE Aerospace

For over 30 years, TAE Aerospace has been supporting TPE331 engine operators worldwide with first-class maintenance, repair and overhaul services.

Commercial and military operators have come to rely on TAE Aerospace to maximise the performance of their TPE331 engines and minimise the impact on aircraft availability during routine and unplanned maintenance events. With Honeywell Authorized Service Centres across the globe, we are one of the world’s largest TPE331 engine service providers covering engines, LRU components, fuel controls and engine component repairs. With multiple Airworthiness Approvals from around the world, OEM correlated dynamometer test cells and prop stands for pre- and post-maintenance testing, vibration analysis and performance runs, we make sure you get the best from your TPE331. We deliver customer value by offering a high-quality service at a price that will reduce your maintenance cost. Contact one of our experienced team today. North America John M +1 (602) 881 1600 Mario M +1 (706) 993 0898 Bruce P +1 (208) 229 8340 Kurt M +1 (480) 376 4550 South America George M +1 (954) 673 6492 Europe and Africa Tomas P +420 725 908 515

Benefits of using an Authorized Honeywell Service Centre

• Access to 100% guaranteed OEM certified parts • Reduced downtime due to parts availability and guaranteed stock levels • Access to OEM support and warranties • TAE Aerospace technicians have access to the latest Honeywell technical documentation and training • Unparalleled global experience • Cost efficiencies through access to approved dealer discounts

type involved.

StandardAero reckons that owners will get the same level of expert advice from high-quality engine maintenance providers when the owners contract them for the engine work required.

“It really depends on how comfortable the owner or buyer is with making those decisions,” suggests Capra. “We recommend they find a qualified service provider that can answer their questions and is an organization they can trust.

“Reputable, OEM-authorized shops are designated by the OEMs and are FAA-approved to do this, meaning that the owner/buyer’s aircraft will not only meet our high regulatory standards, but also the OEM requirements for service.”

Today’s overheated used aircraft market is contributing to owner misunderstandings regarding engine maintenance costs — even more so given that supply-chain issues are affecting the prompt availability of parts, and the resulting cost of obtaining them quickly.

“The market is dynamic, and parts have become 20-30 percent more expensive in the last six months,” says Lynch, noting that the issue is affecting the prices of a variety of parts produced by different engine manufacturers for different engine types.

How ‘Sunshine Parts’ & Improper Storage Impact Maintenance Costs

Replacement of LLPs during unscheduled maintenance is a particularly onerous burden for aircraft owners. A single turbine blade can costs as much as $3,500, and when there are 72 of them on a single highpressure turbine blade stage, the cost of replacing that stage and its turbine disk can run to $300k or more, Lynch highlights.

This type of eventuality raises another issue for aircraft owners — that of ‘sunshine parts’, LLPs and other parts which Lynch says may well be functioning completely normally and within operational parameters in an engine, but which airworthiness authorities require to be inspected for wear and tear every time the engine is opened up for unscheduled maintenance.

Should the mechanics working on the engine find any wear at all in any sunshine parts, airworthiness regulations require that they be replaced immediately with unworn parts — even if the replaced parts are still working and “are not the driving cause of the unscheduled maintenance event”, notes Capra.

This can have a major effect on engine maintenance costs and overhaul decisions. “They can be difficult to predict,” Capra says. Wear in sunshine parts is “largely dependent on total time since the last major maintenance event, the total run time, and operating environment. All are factors that can create engine wear”.

Improper preservation of the engines on stored aircraft is an important issue which can create huge cost and maintenance headaches for unwary, or naïve, aircraft buyers, adds Lynch.

The engines of stored aircraft are supposed to be run once a month, so the engines remain within the technical and regulatory condition requirements imposed by the maintenance manual. Engines not run for 60 days are subject to additional engine maintenance protocols.

A key requirement for anyone storing an aircraft over longer periods is to remove all oil from its engines. This is to ensure that any water entering the engine, for whatever reason, cannot bead up on the engine’s main bearing, Lynch explains. Should all oil not be removed from the stored engine and water beading occurs, this can cause corrosion in the main bearing.

Thus, any engine in long-term storage which contains oil must undergo a maintenance bearing inspection before the engine can be operated. Effectively this means the engine must be disassembled and undergo a full overhaul, he says.

If you’re buying a stored aircraft, “your best protection is to be on a fully covered engine program,” says Lynch. “Or else you should fully understand what program you’re on and deduct the value of what it doesn’t cover from the purchase price” for the aircraft.

“If it’s not on an engine program, when you’re buying the aircraft you need a really expert mechanic who knows the engine and an expert technical inspector.”

Thus, any engines that are no longer being run on a monthly basis, and have

More than 20,000 aircraft parts in stock.

If you’re having difficulty finding a specific Astra, Citation, Falcon, Hawker or Phenom part, chances are we have it! Check out our huge inventory to fulfill your parts needs and reduce your aircraft's operating costs. All of our parts are available for immediate sale, exchange or to rent. • Engines • Pumps • Engine Inlets • Valves • Actuators • Landing Gear • Thrust Reversers • Servos • Windscreens • Flight Controls • Wheels and Brakes • Avionics Visit jetspares.com to see the inventory of parts available or call (214) 350-0107.

• Cowlings • Cabin Interior Parts • Air Cycle Machines • Antennas • Engine QEC Parts • Leading Edge Devices

Always Doing Our Part

not adhered to a long-term preservation requirement, must undergo a comprehensive bearing inspection before the engine can be operated. Effectively, this means the engine must undergo a full disassembly — which could turn into an overhaul, he says.

If you’re buying a stored aircraft, “your best protection is to be on a fully covered engine program,” says Lynch. “Or else you should fully understand what program you’re on and deduct the value of what it doesn’t cover from the purchase price” for the aircraft.

“If it’s not on an engine program, when you’re buying the aircraft, you need an expert mechanic who knows the engine, and an expert technical inspector.”

In Summary…

The best way for aircraft owners and buyers to avoid making mistakes regarding the scheduling, downtime and costs of engine overhauls is to “start planning major maintenance early”, Capra summarizes. “Three to six months in advance of required maintenance is recommended. Engine leasing, parts availability, and lead times should be considered.

“Also, seek direct consultation from engine repair and overhaul providers to help establish a budget,” he concludes. “The sooner operators speak with a technical expert, the more informed they will be regarding their options in handling their maintenance events.” ■

More information from Engine Assurance Program: www.eap.aero StandardAero: https://standardaero.com

CHRIS KJELGAARD has been an aviation

journalist for 40 years, and has covered a vast array of industry areas during that time. He has served as editor of ten print and online titles and written extensively on many aspects of aviation.

Big on cost and complexity, the engine overhaul can seem an overwhelming event, ideally kept on the periphery as a ‘future event’. Dave Higdon shares tips, highlighting how confronting, and planning, the overhaul long in advance will remove uncertainty and disruption to your flight ops.

Business jet owners and operators have a multitude of factors that come into play when the time approaches for them to choose the best MRO center to overhaul their airplane.

From the basics of how experienced the shop is in working with your airplane’s powerplant, to whether they’re an approved maintenance center for the engine manufacturer, to what other customers say who have had overhauls done by the same shop – there’s lots to take on board.

Further matters of price, guarantees, location, availability of slots at the time they’re required, and the type of overhaul that’s required will also come into play as owners/operators consider the right shop for the job.

And the decisions don’t stop with the selection of the overhaul center. Owners and operators need to work out how an intensive, lengthy period of downtime will be navigated with the least disruption to their operations.

The good news is, with proper management of your jet, you will see the overhaul coming years ahead of time, assuming you purchased your aircraft with plenty of time remaining on the engines.

But regardless of the engine’s Time Before Overhaul, it's never too early to start planning for the moment the aircraft needs some TLC.

Where to Begin

The first item on your planning list should be to research and select a vendor who’s able to perform the work when the time arrives. That vendor should be capable of coordinating the other elements of the work package, including:

• Engine removal and reinstallation • Shipping (where required) • Test runs and acceptance flights.

Ensuring your overhaul partner is fully capable of coordinating the whole project, you will have peace of mind that you have a partner who knows the plan and can follow its progress closely.

Next, timing is everything. It’s logical to schedule major engine maintenance events, whether overhauls or hotsection inspections, for periods of low demand for the aircraft. So, you’ll need to analyze the data available to your flight department to know when those are likely to be.

When a major engine event is due, the ideal would be to schedule it at the same time as the airplane’s annual inspection. Of course, this approach assumes you can afford to dispense of the company airplane for the duration of the inspection/overhaul.

Avoid Operational Disruption During an Overhaul

If it seems impossible to be without lift for the period the overhaul is projected to take, it would be a wise decision to consider some of the following options, checking with your engine maintenance program provider (where applicable) to see which costs are covered on your engine plan…

Supplemental lift is one option, whether ad hoc charter, or jet cards (if you anticipate needing more than 25 hours of charter time during the downtime). Perhaps a short-term wet lease is viable if intensive usage is anticipated.

Alternatively, it could make sense to loan some powerplants while your own are being overhauled. This effectively ensures you continue to fly your own jet while only the powerplants remain at the MRO center for the duration of the overhaul. The only time the airplane would be out of action would be to have the engines uninstalled/loaners installed, and then swapped again at the end of the process.

As mentioned, it may be that the cost of supplemental lift of engine loaners are covered by your engine maintenance program (assuming you’re enrolled on one). Therefore, a part of the planning process would be to speak to your program provider to learn exactly what’s covered and what isn’t.

Note: The benefits of a professionally managed engine maintenance program can help ease the load on an operator on every level, depending on the details of the program they’re enrolled with.

Support can vary from a full, turnkey process that’s completely managed by the program provider, to more limited service covering the overhaul or inspection itself, but not the removal and re-installation of the engines, for example.

The message is clear. Use the time leading up to your overhaul wisely. Don’t wait for things to fall into place. Understand every element of the process, and the events and needs surrounding it. That is a sure-fire way to avoid any unnecessary disruption to your operations. ■

DAVE HIGDON is a highly respected aviation journalist who

has covered all aspects of civil aviation over the past 40 years. Based in Wichita, he has several thousand flight hours, and has piloted pretty much everything from foot-launched wings to combat jets.

Contact him via Dave@avbuyer.com

Operational data returns insights for improved reliability

The last few years have seen a step change in aircraft connectivity and the ability to pull massive amounts of real-time inflight engine and aircraft data. As the focus shifts from connectivity to monitoring and predictive maintenance, GE’s OnPoint is positioned to translate that operational data into tangible value in the form of proactive anticipation of problems, minimized downtime, reduced overall lifecycle costs through better planned maintenance schedules, improved fuel burn and ultimately increased residual value of the aircraft. It’s a known fact that engines need servicing over time to ensure their safe performance, but even normal functioning engines can see anomalies that may require corrections to ensure long-term safe operations. In the past, a service bulletin would be issued that might include fleet-wide aircraft downtime to inspect and if required replace hardware – a time and resource consuming resolution. With today’s analytics, more scenarios like this can instead be handled with surgical precision. Parameters such as temperatures, pressures and flow rates are carefully tracked throughout the engine and aircraft, and analytics can identify a concerning condition without the need for physical inspection, allowing a majority of the fleet to continue operations uninterrupted without unnecessary maintenance activity. Diagnostics and prognostics such as these allow engines to be on-condition, prolonging the need for engine overhaul and optimizing maintenance costs. Modern engines have over 80 sensors, and interface with airframe sensors and controls forming a complete diagnostics package. Diagnostics should be recognized as more than simply monitoring for a parameter shift. Rather, it’s an array of parameters monitoring the sensors as a prognostic system in order to predict performance changes over time. Additionally, monitoring and predictive maintenance is further strengthened from a running log and history of the thousands of engine performance characteristics and calculations at any one time.

By leveraging monitoring and prognostics in partnership with GE, then owners, directors of maintenance and even financers all can realize the many benefits of data that is specifically monitored, captured, and analyzed. Together, by using these insights, the industry can take a major step forward in overall operational optimization.