SLIDES LINEAR HOW

Large, small, or no screen at all, the C-more

With the C-more headless HMI, you can display your factory floor data how and where you choose. The new CM5-RHMI has all the powerful functionality of the C-more Touch Panel HMIs, but without display size restrictions. This HDMI-enabled device works with televisions, monitors, projectors, and most any other HDMI display device or use the C-more Remote HMI mobile app and/or the embedded Web Server if you prefer no local display at all. The choice is yours!

C-more Headless HMI priced at: $599.00 (CM5-RHMI)

Features include:

• HDMI video/audio output with multiple resolutions

• Video: VGA 640x480, SD 720x480, XGA 1024x768, HD 1280x720, FHD 1920x1080

• Audio: use USB audio adapter (not included)

• Works with most HID-compatible resistive and pCap touch screen monitors

• The USB A port allows support for most industrial touch screen monitors in the market

• Multiple connections

• (2) Ethernet, (1) RS-232, (2) RS-485, (1) RS-422 ports support programming and device connections

• USB-B port for programming, monitoring, and configuration

• (4) USB-A ports for USB HID devices such as USB hub, pen drives, touch screen displays, keyboard, mouse, and bar-code scanners

The easy-to-use C-more HMI design software can be downloaded free of charge from our webstore. Get started on your project today or take it for a test drive. Download as often as you need, no license or key required.

Get your copy now at: www.go2adc.com/cmoreswcm5

• SD card slot for log files, project memory, or graphic media

• 90MB of user memory

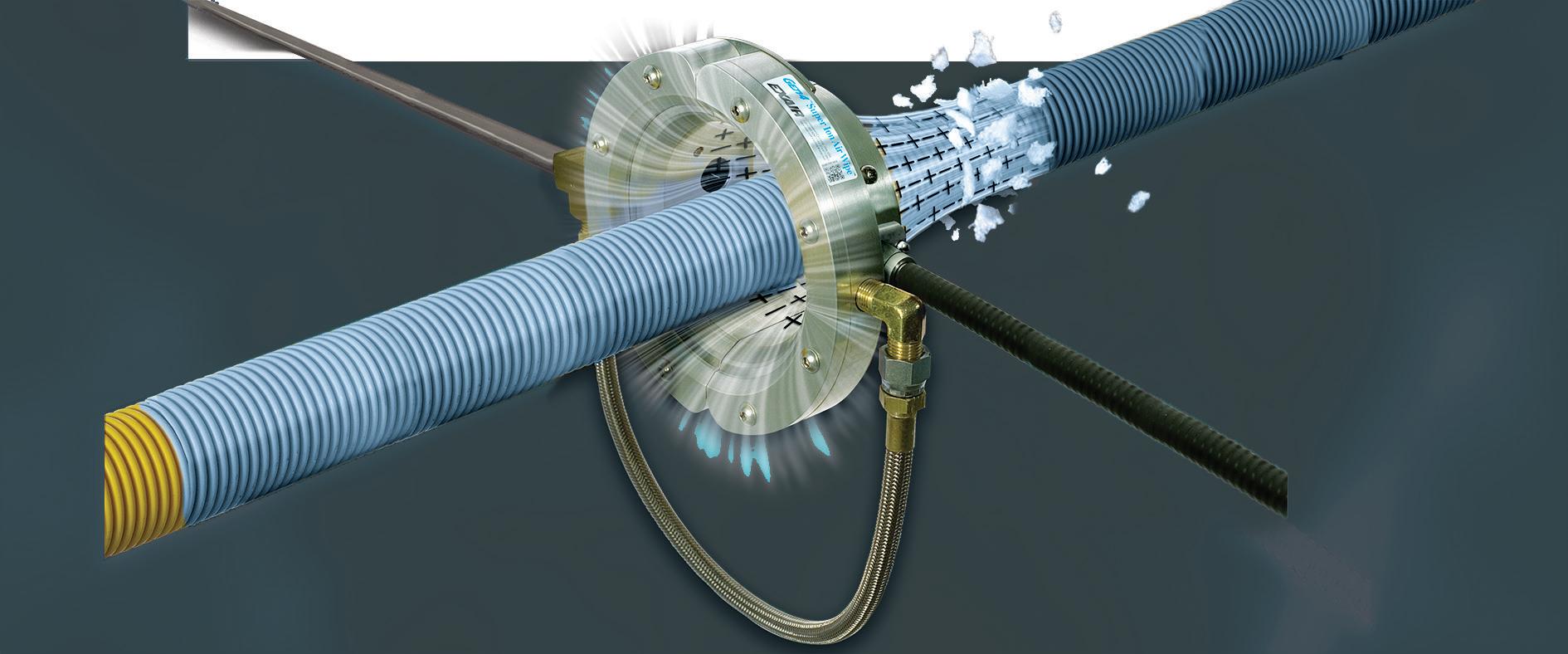

Super-Low Waving Caged Ball

LM Guide Model SPH

• ISO-Compliant Dimensions

• Flange Type and Compact Type

Super High Speed

LM Guide Model FHS

High Speed Roller Ring RT

• Superior High Speed Performance

• Easy to Install

Utility Slide Advanced Wheel Guide

• Smooth Sliding Mechanism

• Superior Contamination Protection

• Achieves the highest LM Guide speed 15m/s

• Can be used freely in horizontal, inverted and wall-mounted orientations

Over the past year, we’ve been busy working with our new sister publication Engineering.com, striving to create more meaningful content to help you in your engineering career. We’ve always brought you exceptional technical engineering content and pertinent industry news, but we’ve had feedback that you want more. Whether you’re a student looking for the best university program to apply for or what specific fields of engineering to study, a new graduate deciding on the best companies to pursue, or a mid-career professional looking to move to the next level, we want to be the go-to resource for you.

With that in mind, we’re so excited to launch the new Top Workplaces for Engineers program today. Our editorial team is partnering with the professionals at Energage, the HR technology company behind the Top Workplaces employer recognition program, to find out which companies should be at the top of your list of potential employers each year. The award will honor companies that create exceptional workplace environments for engineering professionals across a variety of industries, and we will publish the list of winners in the Spring of 2025.

This new program will celebrate organizations that prioritize a people-first workplace

culture where engineers can thrive and innovate. To be eligible, participating companies must employ at least 35 engineers or have an engineering workforce that makes up 10% or more of its total workforce. The award is based on employee feedback captured by the confidential, research-backed Energage Workplace Survey. Participating companies will be evaluated against the industry’s most robust benchmarks based on more than 18 years of culture research.

Maybe you’re currently at a company that is a fantastic place to work, and you’d like to nominate it for consideration. You can easily do so here: engineering.com/topworkplaces. The nomination timeframe runs through mid-January. But the next couple of months will breeze by with all the holiday celebrations, so make sure to nominate today.

Stay tuned for the exciting results, which will be unveiled right here, in the Spring of 2025. DW

Paul J. Heney - VP, Editorial Director pheney@wtwhmedia.com

@wtwh_paulheney

Rotor Clip Wave Springs are engineered to save space and weight by reducing spring heights up to 50%. Our experienced engineering team is ready to assist you in specifying a standard spring or developing a custom design in the material and size you require. From prototype to production, we'll provide you with the perfect spring solution for your application.

FOLLOW THE WHOLE TEAM @DESIGNWORLD

EDITORIAL

VP, Editorial Director Paul J. Heney pheney@wtwhmedia.com

Editor-in-Chief Rachael Pasini rpasini@wtwhmedia.com

Managing Editor Mike Santora msantora@wtwhmedia.com

Executive Editor Lisa Eitel leitel@wtwhmedia.com

Senior Editor Miles Budimir mbudimir@wtwhmedia.com

Senior Editor Mary Gannon mgannon@wtwhmedia.com

Associate Editor Heather Hall hhall@wtwhmedia.com

CREATIVE SERVICES

WEB DEV / DIGITAL OPERATIONS

Web Development Manager B. David Miyares dmiyares@wtwhmedia.com

Senior Digital Media Manager Patrick Curran pcurran@wtwhmedia.com

Front End Developer Melissa Annand mannand@wtwhmedia.com

Software Engineer David Bozentka dbozentka@wtwhmedia.com

DIGITAL MARKETING

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com

Digital Marketing Coordinator Meagan Konvalin mkonvalin@wtwhmedia.com

FINANCE

Controller Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist Jamila Milton jmilton@wtwhmedia.com

VIDEO SERVICES

Videographer Cole Kistler cole@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

VP, Creative Director Matthew Claney mclaney@wtwhmedia.com

Art Director Allison Washko awashko@wtwhmedia.com

Director, Audience Development Bruce Sprague bsprague@wtwhmedia.com

Webinar Coordinator Emira Wininger ewininger@wtwhmedia.com

Webinar Coordinator Dan Santarelli dsantarelli@wtwhmedia.com

EVENTS

Events Manager Jen Osborne josborne@wtwhmedia.com

Events Manager Brittany Belko bbelko@wtwhmedia.com

Event Coordinator Alexis Ferenczy aferenczy@wtwhmedia.com

Ph: 888.543.2447

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Digital Production Specialist Elise Ondak eondak@wtwhmedia.com

HUMAN RESOURCES

Vice President of Human Resources Edith Tarter etarter@wtwhmedia.com

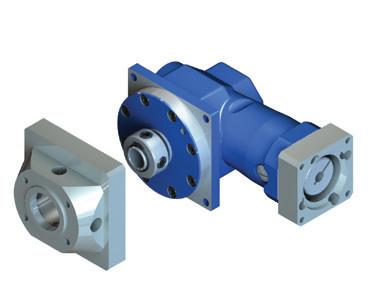

EPL-U

Inline gearbox with hollow or shaft output and custom adapter for easy mounting to linear actuators

WDS

Bellows and elastomer style distance couplings, up to 6 m long, connect actuators without additional shafts

Parallel mounting kits save space by mounting the motor parallel to the ballscrew actuator

GSL

Theta axis with zero-backlash strain wave gearbox includes output flange or thru-hole for tooling and integrated motor mount

DL-DC

Right angle Dyna-Lite gearbox with hollow output design for easy mounting to linear actuators. Includes output adapter tailored to the actuator

Simplify the process of designing and building your own Cartesian systems with GAM’s Linear Mount Products

®

Choose from a variety of inline and right angle gearboxes that connect directly to actuators, along with the necessary mounting adapters and couplings, to transform individual products into an integrated solution.

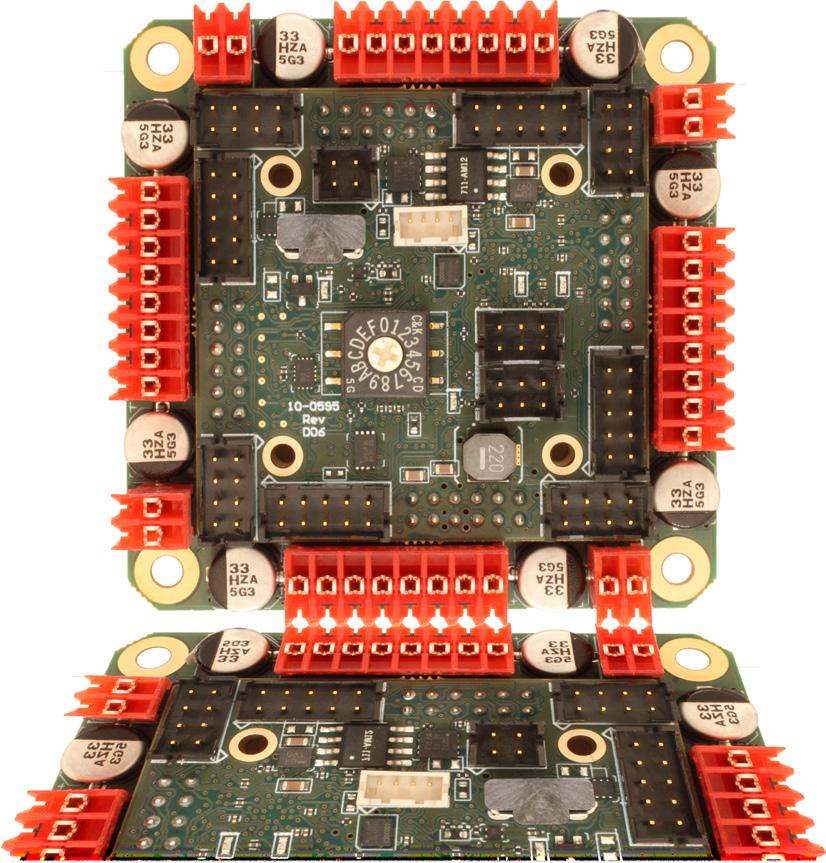

Wire bonding is a critical process in semiconductor production. Extremely fine wires 15 to 75 μm in diameter create tiny electrical connections between a semiconductor chip and other components. The distances between the bond wires are often less than 100 μm, and any deviation can lead to connection errors. Austria-based F&S Bondtec uses IDS Imaging Development Systems industrial cameras in its wire bonder machines to precisely determine wire positions and for quality assurance.

With manual devices, operators must manually approach each bond position before making the corresponding connections. Semiautomatic wire bonder machines position the wire after the first bond to create a wire bridge. Fully automatic machines use a structure recognition system to determine the chip position and create the wire bridge. In this case, operators only change the wire or tool on the bonder occasionally and perform loading and unloading.

F&S Bondtec uses image processing with IDS industrial cameras for various production tasks, especially in its 56i series semiautomatic machines and 86 series automatic wire bonders. Its wire bonds connect previously placed microchips or other components with different contact points on printed circuit boards.

For each bonding process, parameters such as ultrasonic amplitude, force, time, or the movement sequence for setting up the bonding bridges must be programmed in advance. The camera’s image feed is also used when creating these programs. For example, operators can drag a wire in the live image, change its position, and adjust the axes.

The company uses between one and seven IDS cameras per system. The uEye XCP models are 29 x 29 x 17 mm with a C-mount and completely enclosed die-cast zinc housing. Their screw-type USB micro-B connection and compatibility with the Vision Standard (U3V/GenICam) simplify integration. F&S Bondtec also uses tiny uEye CP cameras with extensive pixel preprocessing. These can also be used for multi-camera systems with their internal 120 MB image memory for buffering image sequences.

On the software side, the company uses a specially developed image recognition library that supports position-pixel mapping, greyscale recognition, and edge detection. It also uses the free IDS peak software development kit, which includes all the programming interfaces and software tools required to operate and program the cameras. DW

IDS Imaging Development Systems www.ids-imaging.us

Pulsed Field Ablation (PFA) is a cutting-edge medical technique primarily for treating cardiac arrhythmias. It uses an electroporation mechanism to target and send short, highvoltage electrical pulses to heart tissue. PFA devices vary in design but typically include specialized catheters and generator systems to deliver the pulsed electric fields.

Lemo’s new Redel 2P High Voltage connectors deliver 5 kV isolation between contacts in either a 26- or 34-pin configuration within a compact Ø18 mm design. These connectors are suitable for the latest generations of cardiac mapping and PFA medical devices and applications requiring compact and high-performance interconnect solutions. Features and benefits include:

• High contact density: With exceptional contact density, the connector ensures precise signal integrity and consistent high-voltage performance for advanced medical applications.

• Durability: It includes Lemo’s push-pull latching system and is built for a lifespan exceeding 5,000 mating cycles.

• User safety: The connector is compliant with IEC 60601 and sterilizable for patient and operator safety. DW MEDICAL MOLDED CABLE ASSEMBLIES

Innovative Interconnect solutions from BAYCABLE can transform the way our customers deliver care. Turn design challenges into next-generation, market-leading medical devices with our extensive manufacturing capabilities and engineering expertise.

Industry expertise:

• Robotic surgery system cable assemblies

• Video cable assemblies

Turn your design challenges into next-generation, marketleading medical devices with our extensive manufacturing capabilities and engineering expertise. We have facilities in Fremont, CA and Santa Ana Sonora Mexico.

• Patient monitoring cable assemblies

• Single use cable assemblies

• Sensor probe cable assemblies

Highlights:

• ISO 13485:2016 and ISO 9001:2015 certification in our Fremont, CA and Mexico facilities

• Highly trained technicians and trainers certified to IPC/WHMA-A-620D

• Custom molded cable assemblies and strain reliefs

• 100% final product electrical testing

• Fine wire termination capabilities

• Laser stripping, laser marking, and ultrasonic welding capabilities

Realize your vision with Festo’s approach to smart automation. Partner with Festo today.

Industry Leadership

Superior Quality Products

Global Training & Support

South Korea is famous for its service and delivery robots, yet complex indoor environments challenge their applicability in office settings. Earlier this year, Hyundai Motor Company and Kia Corporation released a new DAL-e Delivery robot with improved performance based on its December 2022 design. The new robot is more efficient and reliable for food, beverage, and parcel dispatch services, ensuring prompt goods delivery.

To enhance driving stability, the robot is designed in a square column with rounded corners with the center of gravity at the bottom. The sensors are discreetly integrated, and the sophisticated metal-like design lends a sleek aesthetic.

DAL-e Delivery is based on four Plug and Drive (PnD) modules, a mobility solution that combines a motor with steering, suspension, braking systems, and environmental recognition sensors. With free-moving PnD modules and autonomous driving technology, it can speed up to 1.2 m/sec, recognize obstacles, and navigate congested areas. The robot's enhanced suspension provides a steady ride over bumps in the floor to ensure stable delivery. DW

Hyundai Motor Company www.hyundai.com

WHITTET-HIGGINS manufactures quality oriented, stocks abundantly and delivers quickly the best quality and largest array of adjustable, heavy thrust bearing, and torque load carrying retaining devices for bearing, power transmission and other industrial assemblies; and specialized tools for their careful assembly.

Visit our website–whittet-higgins.com–to peruse the many possibilities to improve your assemblies. Much technical detail delineated as well as 2D and 3D CAD models for engineering assistance. Call your local or a good distributor.

EDITED BY MIKE SANTORA

FarmWise is an AgTech company using computer vision and artificial intelligence to revolutionize farming operations. Their flagship product, the Vulcan precision weeding implement, is designed to optimize weed control management on vegetable farms in California, which have been slow to automate due to the complex and versatile nature of specialty crop farming. By combining new technology with custom-built components, FarmWise enhances efficiency, increases crop yields, and addresses labor shortages with a high-accuracy and fully mechanized process to remove weeds.

The Vulcan intra-row weeding implement is FarmWise's answer to the challenges posed by weed competition in vegetable farms. Weeds can adversely impact crop yield by competing for essential resources such

as water, light, and nutrients. Traditional cultivation methods, combined with hand weeding, are labor intensive and costly, especially in regions like California, where labor shortages and rising wages are prevalent.

FarmWise's Vulcan Automated Weeding System is a pull-behind solution focused on in-season weed control management. The system leverages computer vision and artificial intelligence to address three key challenges associated with weed removal: precision, labor, and herbicides. Traditional cultivation is imprecise. It either leaves some weeds or only partially remove weeds in between rows of plants. Such cultivators are also cumbersome and error-prone due to a lack of automation and precision control that can lead to mistakes such as crop kills.

Hand weeding is more precise, but it requires time-consuming, physically challenging, and repetitive manual labor that is also expensive for producers.

Chemically suppressing weeds has been the most common, efficient, and cost-effective method for controlling weeds in row crops. Using herbicides is becoming less attractive for two major reasons: a shortage of herbicides on the market and the environmental call for farmers to use more sustainable weed control methods.

One of the major challenges FarmWise faced was developing a system capable of adapting to the wide variety of crops, bed spacings, row spacings, and soil morphologies found on vegetable farms. Compared to corn farming in the Midwest, which has undergone significant automation, vegetable farming in California remains labor intensive due to its complexity.

To meet this need, FarmWise leveraged advances in deep learning and precision control software to develop Vulcan, which features a

PBC Linear slides are a key component of FarmWise's Vulcan intra-row weeding implement. The slides provide precise height adjustment for the weeding tool, ensuring that the tool is always at the correct level to remove weeds without damaging crops.

perception module combined with an actuator to perform consistent intraand inter-row weeding at row level across a diverse portfolio of crops.

The weeder module has two translation axes, including a hydraulic z-axis actuator, allowing it to move up to a dozen inches or so vertically. A feeler wheel arrangement locates the weeder module relative to the crop surface and informs it of changes in the bed's topology.

To achieve greater flexibility and reach in the z-axis, FarmWise specified UGA Low Profile Uni-Guide with a custom-positioned hand brake from PBC Linear. Up to 18 of these slides, located at the back of the implement, add a few inches of vertical travel. This addition extends bed capabilities and accommodates varying soil types. The slides offer a robust and customizable solution to adjust the system's height, enabling it to cater to various farm configurations and terrains.

The low-profile design of the slides was vital to reduce the

cantilever length of the weeder module, mitigating the risk of transport shock during field-to-field movement.

The role of computer vision and artificial intelligence Central to the Vulcan precision weeding implement's success is the computer vision and artificial intelligence technology in the FarmWise Intelligent Plant System (IPS) Scanner. The IPS Scanner integrates lighting with the camera sensor via a custom LED board. This package enables the capturing of consistent, high-resolution images at a high frame-per-second rate. The data immediately flows through the IPS pipeline, detecting and localizing each plant in real time.

Sophisticated detection models were developed by gathering a vast number of images and annotating them to accurately distinguish between individual crops and weeds. Using these detection models, the system determines the position of

With Interpower you don’t have to stress about power cords. Interpower North American and international cords and cord sets provide the correct AC power for country-specific customers to safely connect to the mains power. Interpower manufactures state-of-the-art electrical cord sets for global markets with 1-week U.S. lead times.

Interpower cords and components are manufactured in accordance with Interpower’s product quality plan: hipot testing, continuity testing, and ground testing with inspections after each stage of the manufacturing process. When it comes to raw materials, we don’t cut corners.

Toll-Free Phone: (800) 662-2290

E-mail: info@interpower.com

Business Hours: 7 a.m.–5 p.m. CST

« Abuse Resistant Belts work where others fail.

« Super Strong Joints are virtually unbreakable.

« High Tension Belts move heavier loads.

« HEHT black belts double capacity.

« Low cost, highly efficient, elastic flat belts.

Line-shaft Spools

l High precision. Reasonable

l Easy to install. Zero downtime.

Using PBC Linear slides on the Vulcan intrarow weeding implement system was a major advance in weed control technology. The slides provide the precision and robustness needed to automate the weeding process while minimizing the risk of crop damage.

crops and the location of every crop stem and makes precise decisions on blade openings and adjustments. As the system traverses the field, it makes micro adjustments to ensure the highest quality weed removal. The actuation engine, controlled by the software, opens and closes the weeding blades as needed to clean the intra-row, or in between the crops located on the same line. In addition to the weeding blades that are connected to the actuator, the precision weeding implement includes a set of top knives that simultaneously clean the inter-row surface area between the rows of crops.

FarmWise's Vulcan intra-row weeding implement, powered by computer vision, artificial intelligence, and custom PBC Linear slides, represents a significant step forward in precision agriculture. By providing a tailored solution to weed control management, the system optimizes yield potential, reduces labor costs, and minimizes the need for harmful herbicides. DW

EDITED BY MIKE SANTORA

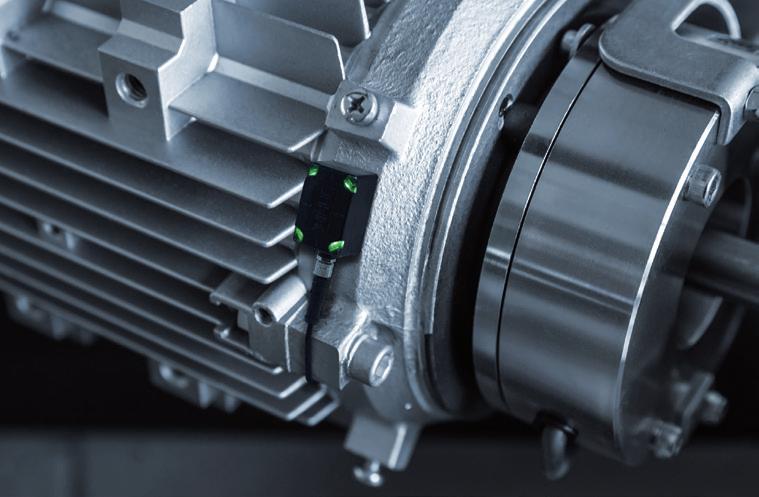

According to PwC, 70% of CEOs worldwide believe Generative AI (GenAI) will significantly transform the way their companies create, deliver, and capture value. That includes manufacturers, who can use the systems to spot equipment failures and minimize downtime. Here, Chris Johnson of SMB Bearings emphasizes how industrial bearings equipped with sensors can support GenAI by providing real-time data and insights.

GenAI is a remarkable form of Artificial Intelligence with the unprecedented ability to produce an array of data types including images, videos, audio, text, and 3D models. Put simply, GenAI can delve into existing data, deciphering patterns, and leveraging this knowledge to generate entirely new outputs.

Its capabilities extend far beyond mere replication, as it crafts highly realistic and intricate content that mirrors human creativity, thus positioning itself as an invaluable tool across various industries, such as gaming, entertainment, and product design.

GenAI, which generates new, original content like text or images using patterns learned from data, also has immense potential in manufacturing which will also help drive the growth predicted in PwC’s report. For manufacturers, the technology can predict equipment failures and minimize downtime, significantly enhancing operational efficiency.

As such, GenAI could be a vital tool in Maintenance 4.0. These sensors can monitor parameters such as temperature and vibration, detecting potential issues before they escalate. This proactive

monitoring not only enhances equipment performance and reduces downtime but also optimizes production processes. Moreover, the data collected can train GenAI algorithms, enabling continuous improvement over time.

Smart bearings, integrated with sensors, have been used in automotive anti-lock braking systems (ABS) for years and are now being increasingly adopted in various industries. The rise of the Industrial Internet of Things (IIoT) allows manufacturers to remotely monitor processes and convert physical machine actions into digital signals.

In this Industry 4.0 landscape, the performance of bearings remains vital to the efficient operation of plant machinery. Replacing a single bearing is far more cost-effective than replacing an entire motor, making the choice of smart bearings an economically sound decision.

The benefits of smart bearings, particularly for predictive maintenance, are substantial. IIoT-enabled smart bearings can self-diagnose potential faults and failures through sensor data

Interpower North American and international cords and cord sets provide the correct AC power to allow country-specific customers to safely connect to their mains power without reconfiguration. Interpower manufactures stateof-the-art electrical cord sets for global markets with 1-week U.S. manufacturing lead times.

Interpower cords and components are manufactured in accordance with Interpower’s product quality plan: hipot testing, continuity testing, and ground testing with inspections after each stage of the manufacturing process. Cords are also rigorously tested at Interpower’s testing facility in Ames, Iowa.

Toll-Free Phone: (800) 662-2290

E-mail: info@interpower.com

Business Hours:

For manufacturers, GenAI technology can predict equipment failures and minimize downtime, significantly enhancing operational efficiency.

embedded within the bearing housing. Examples include wheel hub bearings with built-in sensors for ABS brakes, or bearings with sensors that collect data on temperature, vibration, and speed from multiple bearings, transmitting this information to an industrial control system.

Real-time monitoring of speed, pressure, force, temperature, and vibration can yield critical data, enhancing the overall predictive maintenance strategy.

However, it's essential to analyze smart bearing data alongside other critical asset data for a comprehensive operational overview. Proper use of smart bearings can extend their service life, reduce energy consumption, and predict early equipment failures.

Component manufacturers are increasingly incorporating smart bearings, and bearing manufacturers are partnering with IIoT innovators to

offer extended cloud-based predictive maintenance services for various industrial machines. This integration can also lower training costs, as lessexperienced operators can achieve desired performance levels more rapidly.

While it’s impossible to predict every detail, the advantages of smart bearings with predictive maintenance capabilities are clear. Their use is expected to grow significantly in sectors like aerospace, defense, wind turbines, railways, and automotive.

Let's consider an automotive manufacturing plant. Within the plant, there's a robotic assembly line responsible for fitting components into vehicles. Each robot arm is equipped with various bearings to ensure smooth movement and precise positioning of components.

Now, these bearings are not ordinary; they are smart bearings

embedded with sensors capable of monitoring parameters such as temperature, vibration, and load distribution in real-time. This data is continuously fed into a centralized AI system powered by GenAI algorithms.

As the assembly line operates, the GenAI system analyzes the data streaming from the smart bearings. It detects subtle changes in vibration patterns or temperature fluctuations that might indicate early signs of bearing wear or potential faults.

Here's where GenAI shines: based on historical data and patterns learned from thousands of similar scenarios, it predicts the likelihood of a bearing failure within a specific timeframe. For instance, if the vibration patterns deviate beyond a certain threshold or if the temperature exceeds optimal levels, the GenAI system can forecast that a bearing is likely to fail within the next few days.

With this predictive insight, the manufacturing plant can take

The benefits of smart bearings, particularly for predictive maintenance, are substantial. IIoT-enabled smart bearings can self-diagnose potential faults and failures through sensor data embedded within the bearing housing.

proactive measures to prevent unplanned downtime. The GenAI system automatically generates maintenance alerts, scheduling a preventive maintenance task to replace the affected bearing before it fails. Maintenance technicians receive these alerts well in advance, allowing them to plan the maintenance activity during scheduled downtime, minimizing disruption to production schedules.

Furthermore, the data collected from these smart bearings doesn't just stop at predicting failures. It also feeds into the GenAI system's continuous learning loop. By analyzing patterns of bearing performance and failure across various operating conditions, the AI algorithms become more adept at fine-tuning their predictive capabilities over time. This iterative learning process enhances the accuracy of future predictions, ultimately optimizing maintenance schedules and maximizing equipment uptime.

In this way, bearings with smart sensors support GenAI by providing realtime data insights that enable predictive maintenance strategies. By harnessing the power of AI-driven predictive analytics, manufacturers can proactively address equipment issues, optimize maintenance schedules, and ultimately drive efficiency and productivity in their operations.

By leveraging affordable sensors, manufacturers can ensure that critical machine components play a vital role in preventing equipment failure. In this new era, industrial bearings are more essential than ever, driving the GenAI revolution forward. DW

The proliferation of edge devices that employ artificial intelligence (AI) and machine learning (ML) presents designers with a growing array of challenges, including overcoming performance limitations, supporting connectivity, and ensuring security, all while minimizing power consumption.

Balancing the need to maximize performance while minimizing power consumption can be especially difficult. Using a multi-core microcontroller unit (MCU) is a must.

Using an MCU that has an integrated neural network (NN) processing unit (NPU) can be a key consideration.

The MCU should have a dualcore architecture to support high performance, on-chip accelerators, connectivity, security features, and various analog and digital peripherals for sensing, control, and humanmachine interfaces (HMI). For enhanced flexibility, the NPU needs to support a variety of NN architectures, including convolutional NNs (CNNs),

recurrent NNs (RNNs), and deep learning models like temporal convolutional networks (TCNs), transformer networks, and more.

Finding an MCU with all those features is great. Finding one supported with an open-source library like TensorFlow for ML and AI development is even better.

FIGURE 1: In addition to dual Arm Cortex cores and a neural processing accelerator, the MCX N series MCUs offer a wide range of capabilities. (Image source: NXP)

This article reviews the features of the MCX N Series MCUs from NXP Semiconductors and how they address the performance needs of edge device developers, including the capabilities of the integrated NPUs. It presents available evaluation kits and development boards, looks at the possibility of embedding a watermark in an ML model to protect ownership, and reviews the use of TensorFlow and TensorFlow Lite.

NXP’s MCX N industrial and IoT (IIoT) MCUs feature dual Arm Cortex-M33 cores operating up to 150 MHz and are well-suited for Edge AI computing applications. They’re designed for the high performance and low power consumption needed on the edge.

These MCUs feature an NPU for ML acceleration. When running typical ML models, the NPU delivers up to 42x faster performance than a standard computer processing unit (CPU) core.

The NPU, coupled with the dual-core architecture, means more processing is done in less time. That allows the system to spend more time in sleep mode, reducing overall power consumption. The low-power cache further reduces power consumption.

The MCX N series MCUs have a comprehensive security subsystem that includes secured boot, crypto accelerators, temper detection, and more to safeguard over-the-air communications. These MCUs also include various interfaces for system integration, analog functions, timers, and motor control blocks (Figure 1).

The MCX N MCUs are offered in two groups that differ based on the integrated peripherals. N94x devices like the MCXN946VDFT have a wider set of analog and motor control peripherals, while the MCX N54x devices like the MCXN546VDFT include a high-speed USB with a PHY to secure digital (SD) and smart card interfaces. Common features of these MCUs that make them especially suited for edge AI applications include:

• Dual Arm Cortex-M33 150 MHz with 618 CoreMark (4.12 CoreMark/ MHz) for each core.

• Primary: Arm 32-bit Cortex-M33 CPU with TrustZone, MPU, FPU, SIMD, ETM and CTI

• Secondary: Arm 32-bit Cortex-M33 CPU

• 4.8 GOPs edge AI/ML acceleration with NPU

• Platform security with EdgeLock Secure Enclave, Core Profile

• Operating temperature range of -40 °C to +125°C

• Low power operation down to 57 µA/MHz active current, 6 µA in power-down mode with RTC enabled and 512 KB SRAM retention, and 2 µA in deep power-down mode with RTC active and 32 KB SRAM

NPU acceleration

The key to MCX N94x and MCX N54x performance in edge ML applications is the integrated NPU. The eIQ Neutron NPU is built using a highly scalable architecture that supports flexible ML acceleration. It delivers up to 40x faster ML throughput than a standard computer processing unit (CPU) core.

Fast throughput is especially important in edge devices. It enables the device to spend less time awake, reducing overall power consumption and extending battery life. The eIQ Neutron NPU is scalable from 32 Ops/cycle to over 10,000 Ops/ cycle, delivering as much speed and computing power as needed. It’s not just fast; it’s flexible and can support most types of NNs, including CNN,

RNN, TCN, transformer networks, and more.

The eIQ Neutron N1-16 NPU in the MCX N94x MCUs can execute 4.8 G (Giga operations per second) INT8 operations (150 MHz * 4 * 4 * 2) per second using its four compute pipes, and each compute pipe contains 4 INT8 Multiply-Accumulate (MAC) blocks for a total of 16 MAC blocks. Some of the Neutron N1-16 NPU functional blocks and software tools include (Figure 2):

• Dedicated controller core

• In-line dequantization, activation, and pooling

• Integrated tiny caching that reduces power consumption and reliance on system memory speed

• Weight decompression engine

• Multi-dimensional DMA for input and output formats, including striding, batching, interleaving, and concatenating

• Programmability through eIQ ML SW development environment and eIQ-supported runtime inference engines

• The MCUXpresso Software Development Kit (MCUXpresso SDK) provides a comprehensive software package with a preintegrated TensorFlow Lite for Microcontrollers (TFLM), including the Neutron library.

EVKs and dev boards

Evaluation kits (EVKs) and development boards (dev boards) are available for the MCX N94 and N54 MCUs. At the start of a project, developers can use the MCX-N5XXEVK, EVK for MCX N54 devices and the MCX-N9XX-EVK EVK for MCX N94 devices to compare performance and application suitability and begin development.

For example, the MCX-N9XX-EVK includes an MCX N94X MCU with a 64-Mbit external serial flash, FXLS8964AF accelerometer, P3T1755DP temperature sensor, visible light sensor, onboard CAN PHY, Ethernet PHY, secure digital high capacity (SDHC) circuit, onboard MCU-link debug probe circuit with energy monitoring, and more. The board is compatible with the Arduino and FRDM ecosystems, as well as Mikroe click boards.

Designers can also use the FRDMMCXN947, a scalable dev board optimized to speed prototype development using the MCX N94 and N54 MCUs. This dev board includes headers for access to I/Os on the MCU, serial interfaces, external flash memory, and an on-board MCU-link debugger. NXP also offers expansion boards and code examples for various applications through the MCUXpresso Developer Experience.

eIQ ML IDE and watermarks

EVKs and dev boards are important tools for designers. Once the MCU selection has been made and development started, an SDK and integrated development environment (IDE) are needed. The NXP eIQ ML IDE is a software development environment for ML algorithms on MCX-N MCUs.

eIQ ML software includes an ML workflow tool called eIQ Toolkit, along with inference engines, neural network compilers, and optimized libraries for the eIQ Neutron NPU. The eIQ Toolkit uses an intuitive graphical user interface (GUI).

With the Toolkit, developers can quickly create, debug, optimize, and export ML models. They can also import models and datasets from various sources, including TensorFlow frameworks. The output seamlessly feeds into TensorFlow Lite, TensorFlow Lite Micro, and other platforms.

The Toolkit also supports watermarking ML models to strengthen ownership claims. ML models and data sets represent substantial investments, and establishing clear ownership can be an important consideration. To help strengthen developers’ ownership position, NXP has added a method within the eIQ Toolkit ML Software Enablement environment for embedding a watermark in a model.

TensorFlow is an open-source software library for building, training, and deploying machine learning

models and inference on deep neural networks. TensorFlow development is compatible with Python APIs, Java, JavaScript, C++, and other languages. TensorFlow is typically used for model training and inference on devices. TensorFlow Lite is optimized for inference on resource-constrained devices.

TensorFlow Lite is a subset of TensorFlow designed for powerrestricted applications like edge and mobile devices. Developers can create, train, and modify ML models in TensorFlow and then convert them to a smaller, more efficient format using TensorFlow Lite. But there are some caveats.

The ML operators used in a model can be important considerations. Not all are equally easy to convert to TensorFlow Lite. A limited number of operations are included in the conversion tool. TensorFlow also supports custom operators (Figure 4). The conversion tool enables

designers to add operators, which adds a layer of complexity and can inadvertently limit deployment options.

TensorFlow Lite models require less memory, and their relative simplicity results in minimal latency for real-time operation on the edge. In addition, edge inference using TensorFlow Lite does not rely on a wireless connection and enables devices to be widely deployed without considering the availability of an Internet connection.

No further training occurs after a model is deployed on an edge or mobile device using TensorFlow Lite. That makes TensorFlow Lite models well-suited for focused, task-oriented applications. Additional training can occur using TensorFlow in the Cloud with the new model downloaded to edge devices.

(Image

NXP’s MCX N Series MCUs support designers’ needs for high performance and low power consumption in edge AI/ML devices. The integrated NPU is a key element that supports ML on the edge. In addition, NXP offers EVKs, dev boards, and ML tools to speed the development process, including TensorFlow Lite models that need less memory and are optimized for lowlatency edge operation. DW

robots, designed to operate in close interaction with humans, rely heavily on smooth and controlled joint and limb motion. This makes the selection of the motors that power the axes of motion critical. Alongside high torque density and responsiveness, efficiency to enable long battery life is key, and reliability is also important. Achieving freedom of movement requires integrating numerous axes of motion, which is best accomplished by working closely with an expert in this field.

In education and therapy applications, humanoid robots are used to assist hands-on learning and development across a range of subjects and requirements. In the study of engineering, students can develop skills in programming, while in health and therapy settings, patients can receive rehabilitative care through humanoid robot interaction.

Humanoid robots can be equipped with a 'brain' tailored to their specific tasks, supported by targeted programming and artificial intelligence. Despite this customization, they share a common human-like form, including

Torque-dense and efficient motors are essential in developing humanoid robots. And brushed dc motors are answering the call.

hands or grippers. While sensors and tools can be added for physical modularity, the motor skill requirements for humanoid robots remain broadly similar across various tasks.

For robot developers, the general universality in physical motion enables a single humanoid design to be used as a basis for multiple applications. However, to achieve this scale of movement and utility for widespread tasks, humanoid robots typically need to optimize 20 or more degrees of freedom. Accordingly, the operational performance of the actuators that power these axes of motion is crucial.

Portescap, which designs and manufactures miniature motors, recently specified a motion solution for an existing humanoid robot design. The robot manufacturer needed compatibility with their existing drives and controls but wanted to increase torque density and reduce mass. This would be central to improving the robot’s precision by optimizing control of movement, increasing responsiveness, and reducing inertia.

The robot developer also wanted to extend battery lifetime, so the motors needed to have high efficiency. With

more than 20 motors per unit, and robots used across a diverse array of environments, reliability was also a priority. The relatively high number of motors per robot, combined with the purchasing demands of the end- user markets, meant that the need to balance cost with value was also important.

The engineering team determined that the characteristics of a brushed dc motor would best fulfil the requirements. Providing simplicity of control, this motor design would ensure integration with the humanoid’s existing architecture. While achieving the cost-point required by the OEM, the inherent characteristics of a brushed dc motor would be wellmatched to a humanoid’s close human interaction, where the advantages of high torque at low speed would enable fine control.

Why brushed dc motors? They offer a number of features that are useful in robotic applications. Here’s an overview of brushed dc motor design, and in particular the advantages of coreless dc motors.

A typical brushed dc motor consists of an outer stator, typically made

of either a permanent magnet or electromagnetic windings, and an inner rotor made of iron laminations with coil windings. A segmented commutator and brushes control the sequence in which the rotor windings are energized, to produce continuous rotation.

Coreless dc motors do away with the laminated iron core in the rotor. Instead, the rotor windings are wound in a skewed, or honeycomb, fashion to form a self-supporting hollow cylinder or “basket.” Because there is no iron core to support the windings, they are often held together with epoxy. The stator is made of a rare-earth magnets, such as neodymium, AlNiCo (aluminum-nickelcobalt), or SmCo (samarium-cobalt), and sits inside the coreless rotor.

The brushes used in coreless dc motors can be made of precious metal or graphite. Precious metal brushes (silver, gold, platinum, or palladium) are paired with precious metal commutators. This design has low contact resistance and is often used in low-current applications. When sintered metal graphite brushes are used, the commutator is made of copper. The copper-graphite combination is more suitable for applications requiring higher power and higher current.

The construction of coreless dc motors provides several advantages over traditional, iron core dc motors. First, the elimination of iron significantly reduces the mass and inertia of the rotor, so very rapid acceleration and deceleration rates are possible. And no iron also means no iron losses, giving coreless designs significantly higher efficiencies (up to 90 percent) than traditional dc motors. The coreless design also reduces winding inductance, so sparking between the brushes and commutator is reduced, increasing motor life and reducing electromagnetic interference (EMI).

Motor cogging, which is an issue in traditional dc motors due to the magnetic interaction of the permanent magnets and the iron laminations, is also eliminated, since there are no laminations in the ironless design. And in turn, torque ripple is extremely low, which provides smooth motor rotation with minimal vibration and noise.

TOP: Coreless dc motors like the Portescap Athlonix range can increase dynamism and efficiency.

BOTTOM: Coreless dc motors have a rotor that is hollow and selfsupporting, which reduces mass and inertia. Portescap

Because these motors are often used for highly dynamic movements (high acceleration and deceleration), the coils in the rotor must be able to withstand high torque and dissipate significant heat generated by peak currents. Because there’s no iron core to act as a heat sink, the motor housing often contains ports to facilitate forced air cooling.

The compact design of coreless dc motors lends itself to applications that require a high power-to-size ratio, with motor sizes typically in the range of 6 to 75 mm, although sizes down to 1 mm are available, and power ratings of generally 250 W or less. Coreless designs are an especially good solution for battery-powered devices because they draw extremely low current at noload conditions.

Coreless dc motors are used extensively in medical applications, including prosthetics, small pumps (such as insulin pumps), laboratory equipment, and X-ray machines. Their ability to handle fast, dynamic moves also make them ideal for use in robotic applications.

Portescap specified a 16DCT Athlonix motor, based around a coreless design. This saves significant weight compared to incorporating a traditional iron core and enables greater responsivity and smoother motion thanks to reduced inertia. Neodymium magnets also increase torque density by achieving a stronger magnetic field, enhancing the interaction with the motor windings.

The coreless design was also specified to increase efficiency and reduce energy consumption by removing the effects of hysteresis and eddy current losses associated with a conventional iron core dc motor. Precious metal commutation

also enhances efficiency by reducing resistance and minimizing the voltage drop across the brush-commutator interface.

The optimized ironless construction of the motors allowed cooler operation and improved power density. Motor inductances were adjusted to match drive requirements, ensuring optimal speed and torque characteristics.

To further minimize weight, the engineers customized the windings with lightweight, self-supporting coils. Combined with the coreless design and neodymium magnets, these advantages achieved up to an 8 % reduction in motor diameter while delivering the necessary torque.

To further increase durability, as well as improve torque transfer, the engineers also integrated the pinion gear into the motor shaft. This approach would optimize alignment and enhance control at each axis, minimizing play, which would also reduce mechanical wear.

Thanks to the collaboration between the robotic and motion engineering teams, the developer was able to achieve the targeted size and weight as well as the required motion profile for each axis. DW

Each axis on this multi-stage setup includes a drive and linear-guide type specific to its stroke and dynamics requirements. vidiot • Adobe Stock

LISA EITEL EXECUTIVE EDITOR

There are many ways to build linear systems for motion in the X, Y, and/ or Z directions — also called Cartesian coordinates. Industry terms for these systems depend on how the axes are assembled, where the load is positioned, and (to some extent) the type of use for which the system was designed. In many industrial applications, Cartesian and gantry-style robots are prevalent … but in precision applications, XY tables are often the better choice due to their compact rigid structure and very high travel and positioning accuracies.

Cartesian systems consist of two or three axes — X-Y or X-Z or X-Y-Z. They often incorporate an end effector with a rotational component for orienting the load or workpiece, but they always provide linear motion in at least two of the three Cartesian coordinates.

Cartesian systems can include two axes (X and Y) or three axes (X, Y, and Z). When a Cartesian system is used, the load is usually cantilevered from the outermost axis (Y or Z). For example, in an X-Y gantry the load is mounted to the Y axis either to the end of the axis or at a distance from the axis … creating a moment arm on the Y axis. This can

limit load capacity, particularly when the outermost axis has a very long stroke, creating a large moment on the lower, supporting axes. They’re used in a wide range of applications with maximum strokes on each axis typically one meter or less. The most common of these applications include pick-and-place, dispensing, and assembly.

To address the issue of outer axes causing a moment load on the inner axes, gantry systems use two X axes, and in some cases, two Y and two Z axes.

Gantries almost always have three axes — X, Y and Z. The load on a gantry

Some laser-cutting operations require large-scale split-bridge systems with exacting accuracy requirements.

system is located within the gantry’s footprint and the gantry is mounted over the working area. However, for parts that cannot be handled from above, gantries can be configured to work from below.

Gantry systems are used in applications with long strokes (greater than one meter) and can transport very heavy payloads that are not suitable for a cantilevered design. One of the most common uses for gantry systems is overhead transport, such as moving large automotive components from one station to another in an assembly operation.

XY tables are like XY Cartesian systems in that they have two axes (X and Y, as their name implies) mounted on top of each other, and typically have strokes of one meter or less. But the key difference between XY Cartesian systems and XY tables

lies in how the load is positioned.

Instead of being cantilevered, as in a Cartesian system, the load on an XY table is almost always centered on the Y axis, with no significant moment created on the Y axis by the load.

This is where the principle of how the system is used helps distinguish between the various types of multi-axis systems. XY tables generally work only within their own footprint, meaning the load does not extend beyond the Y axis. This makes them best suited for applications where a load needs to be positioned in the horizontal plane (X-Y).

A typical example is a semiconductor wafer being positioned for inspection, or a part being positioned for a machining operation to take place.

Designs called open-frame or open aperture have a clear opening through the center of the table. This allows them

to be used in applications where light or objects need to pass through, such as back-lit inspection applications and insertion processes.

Because XY tables are primarily used for very high precision applications, the guideway of choice is crossed roller slides, which provide extremely smooth and flat travel. Drive mechanisms are typically ballscrew or linear motor, although very fine pitch lead screws are also common.

Positioning stages and rotary tables are leading the migration to integrated designs in motion applications. Just consider how fiber optic, test and measurement, and semiconductor applications such as assembly setups all use precision stages and tables to boost throughput and quality. More specifically, the manufacture of flat-

panel displays has spurred ever-larger motion-stage formats with linear-motor actuation and air-bearing load carrying. Elsewhere, belt-driven stages satisfy the need for long strokes but avoid ballscrew support challenges and the cost of linear motors.

Another growth industry using positioning stages is additive manufacturing. Here, ever-improving materials and layup techniques demand new stages at all performance levels. Many basic maker-level machines use stages with synchronous belt-driven axes.

More demanding applications (such as research and prototyping, medical, and small-batch manufacturing) commonly use positioning stages with motor-driven ballscrews to coordinate motion. In the same way, medical and life-research applications make use of ultra-precision stages that deliver performance motion profiles impossible

a decade ago. Here, piezomotors, miniature linear supports, and coarseand-fine tandem actuators are increasingly common options.

Pre-engineered positioning stages dominate packaging, as this industry often forces integrators to satisfy design schedules that bar design and set up of multi-axis functions in house.

Likewise, the machine-tool industry is making more use of custom-built positioning stages—in laser-cutting and similar machines, for example. These and the stages for CNC applications are increasingly customized to specific motion tasks. That helps them deliver on dynamic parameters at lower cost and without the hassle of reformatting or retrofitting stock setups.

Enabling this newer approach are proliferating software tools that let OEMs and end users manipulate initial design iterations within virtual environments that have accurate

models of real-world stage components.

Assembly is different. Here, semicustom Cartesian stages excel for pickand-place and inspection via machine vision. More typical in these setups are traditional rotary motors paired with rotary-to-linear devices (ballscrews, for example) and controllers that compensate for system dynamics to get accuracy to a few micrometers or better.

Automotive applications widely vary. For example, the large scale of sheet metal and body-assembly tasks present unique challenges that, in some cases, only overhead stages (or those with rack-and-pinion sets) satisfy.

At the opposite end of the spectrum, stages that carry inspection instrumentation to detect part features on a nanometer scale often take the form of direct-drive axis assemblies driven by a precision controller that even corrects for environmental fluctuations. DW

XY tables have very little cantilevered loading on either axis.

XY tables have very little cantilevered loading on either axis.

The base of a Cartesian robot is typically supported along its whole length.

POWER TRANSMISSION-PART CONVEYING

Lifetime Warranty Against Manufacturing Defects

LINE SHAFT CONVEYOR BELTS - Original Equipment and Connectable

CUSTOM MADE IN INCH, METRIC and O-RING SIZES

• Round, Flat and Connectable Polyurethane Belts

• Very Clean Operation

• Eliminates Tensioning Devices

• Exceptional Abrasion Resistance

Gantries can include two X or Y axes — but the defining feature is two X bases.

The base of a Cartesian robot is typically supported along its whole length.

Gantries can include two X or Y axes — but the defining feature is two X bases.

The drives, linear guides, and arrangement of axes influence how much error a given machine exhibits.

Linear errors include positioning accuracy and repeatability, which are most affected by the drive mechanism (screw, rack and pinion, or linear motor, for example) as well as system tuning. In contrast, the angular errors of roll, pitch, and yaw (as well as Abbé angular errors amplified by distance) are most affected by the assembly kinematics, inaccuracies in the linear guides, and poorly machined mounting surfaces.

Planar errors (measured by straightness and flatness) occur as deviations from an ideal reference plane. Straightness defines the extent of motion along the Y axis as the system travels along the X axis. Similarly, flatness defines the extent of motion along Z as the system travels along the X axis. Here the reference is the axis of travel (typically X) so there are only two types of planar errors involving motion along the remaining two axes. In multi-axis systems, planar errors in one axis affect adjacent axes — especially when stacked.

As shown above, the base (X) axis of a Cartesian robot is supported along its entire length, but the Y or Z axis is cantilevered. A gantry configuration can include two Y or two Z axes for additional load capacity and stiffness. However, the defining feature of a gantry is its two base (X) axes. Unlike Cartesian systems involving cantilevered loads, XY tables have very little cantilevered loading on either axis.

• Materials tear, jam or curl

• Webs and films cling to themselves

• Electronic sensors fail, making false readings

• Hazardous sparks or shocks occur

• Product clings to itself, rollers and machine beds

• Dust attraction ruins surface finishes

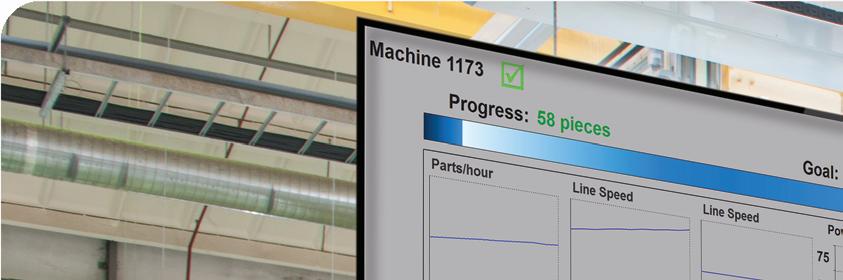

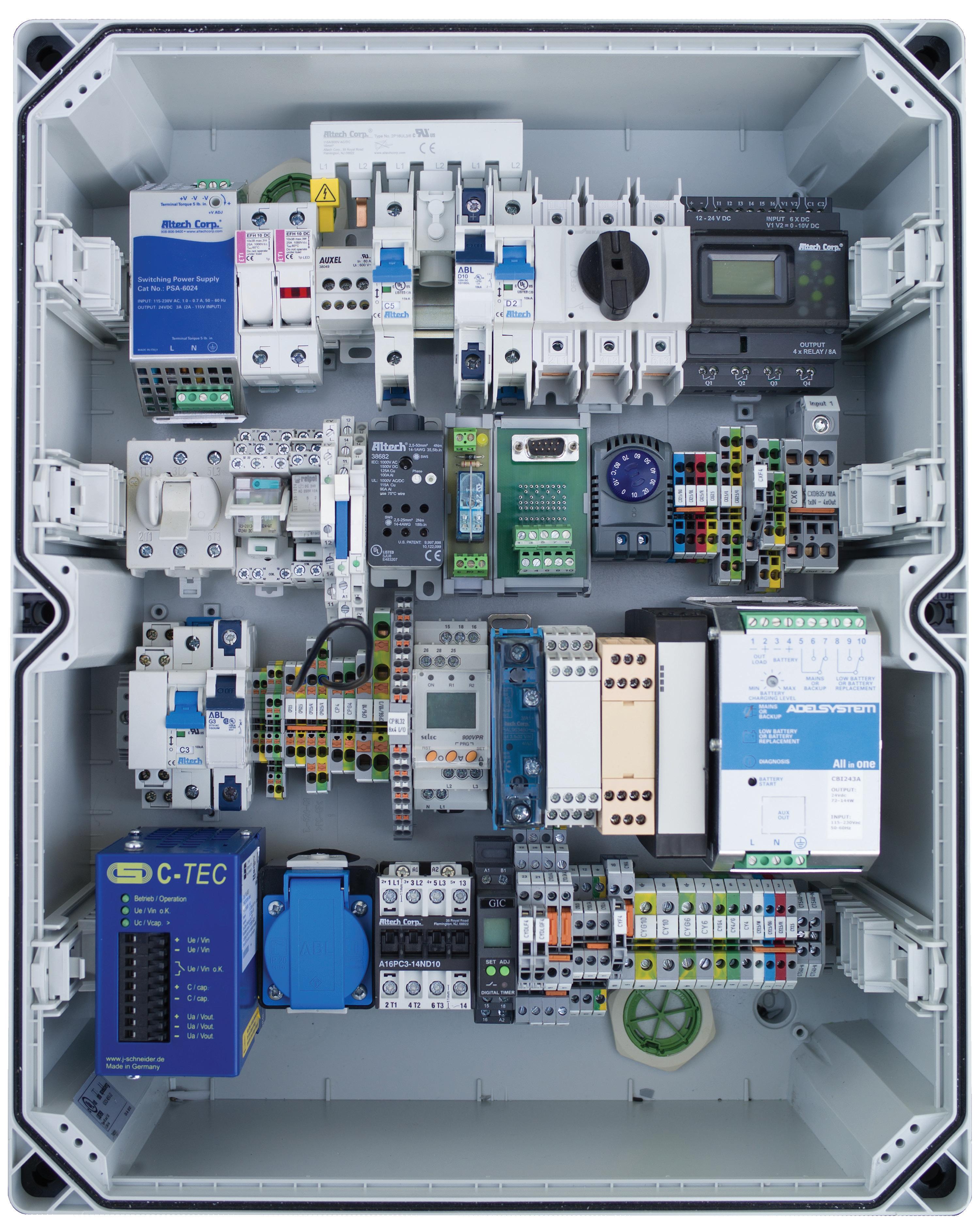

This article is sponsored by Turck USA. In this Voices interview, Design World interviewed Aurelio Banda, President and CEO, Turck USA on how connectivity, smart devices, and data-driven decisionmaking are transforming industry.

By Kristin Lewotsky

Design World: What inspired you to focus on automation as a career?

Aurelio Banda: My interest in automation was sparked by the transformative capabilities of the technology. Electrical and mechanical engineering were key to the success of a lot of companies, so to prepare for my career in this space, I focused on control systems, robotics, and general industrial automation, with a vision of streamlining processes, reducing downtime, and improving productivity.

DW: What are the most significant developments in the automation space over the past decade?

AB: Connectivity and data-driven decision-making have had a transformative effect across a lot of industrial processes, improving process efficiency and manufacturing flow. Industrial Internet of Things (IIoT) plays a key role supporting frameworks found in the modern smart factory. Cloud-based systems have revolutionized how automation systems exchange data, in the production environment and across the organization, because the shared data delivers meaningful insights and supports real-time decision making.

DW: How should companies overcome their automation challenges?

AB: Turck has a comprehensive technology portfolio ranging from sensors to distributed I/O to connectivity solutions, and our cloud offerings can help alleviate pain points for our end customers. These systems support greater flexibility in automated equipment, faster integration

times, and improved data transparency. Most of all, these solutions help simplify machine design and manufacturing, because the complexity can still be very daunting at times.

DW: How can connectivity help OEMs build better machines faster and boost overall equipment effectiveness (OEE) for end-users?

AB: Connectivity delivers more effective communication between devices on the factory floor, which leads to faster and more reliable machine operation. If you're a machine designer, you can develop a framework with a strong foundational platform that you can build off of using connectivity and fieldbuses to stack up solutions faster and more efficiently. You can make a machine smarter, more adaptable, and more capable.

Connectivity is also simplifying integration. As you add more intelligence or make data transfer easier, it has to be done consistently and reliably, but also simply, in order to make troubleshooting easier. If we can design an automation solution to more quickly identify the cause of a fault, that improves our OEE.

DW: There has been much talk over the past decade about Industry 4.0 but adoption has lagged predictions. What are you seeing now?

AB: The classic OEM model of designing a platform and leveraging it across multiple production series is economically sound, but we’re dealing with a lot of changes in market demand. Machine builders have to design smart equipment with the ability to

modify or do changeovers at a faster rate, because end-users need to quickly adapt to changing customer demands.

OEM’s are embracing this new design approach because they want to develop a long-term competitive advantage. To design a platform that will let them grow and create customer value, they need a machine design with a scalable architecture able to address future demands. This means sensors, intelligence, and connectivity.

DW: In terms of the big picture – the industry, technology, the economy –what gets you excited?

AB: I see the potential for automation to solve critical global challenges like the pace of market changes, the labor gap, and the uncertainty of global supply chains. Turck USA is in its 50th year, and seeing our solutions contribute to making industry more efficient and sustainable and connected gets me excited about the future of the company and our role in creating a better world. DW

To learn more about how Turck connectivity, sensor, and controls offerings can benefit your next design, reach out to us at (800) 544-7769 or visit us on the web at www.turck.us.

Editor’s note: This interview has been edited for length and clarity. A previous version appears on wtwh.me/voicesturck

Michelle Froese • Editor

In late 2021, a vulnerability in an electric vehicle (EV) charging app revealed the full names, addresses, and charge histories of more than 140,000 UK users. Last year, Shell patched a weakness in one database that could have led to a similar fate, exposing millions of charging logs across its EV charging network. Fortunately, the energy company caught the vulnerability in time. But not all charging providers will be as lucky unless security measures become standardized and impenetrable.

Several researchers from different organizations have purposely compromised EV-related subsystems or infrastructure over the last few years to expose vulnerabilities in the technology. The conclusion: millions of smart EV charger units are susceptible to account hijacking.

“I think cybersecurity is extremely important and has not been discussed enough in the EV and charging industries,” shares Joachim Lohse, CEO of Ampcontrol, an AI-powered charging management software and payment platform. “Everyone wants to talk about the next great feature, and security is simply a far less ‘exciting’ topic.”

But it’s a critical one if we’re to advance EV adoption. Although the market for electric vehicles is expanding, it’s at a slower pace than many predicted, and experts agree that establishing reliable public charging infrastructure is the key to mass adoption. In this case, reliability must cover charger availability, as well as data protection.

EV charging stations are complex from a security standpoint due to their network connectivity, interfaces, and integration with various systems, including vehicles, power grids, and payment processors. They’re also easily accessible to the public, putting them at risk for various security attacks.

“From my perspective, there are two main aspects to cybersecurity at EV charging sites: protection against attacks that aim to bring a charging network down and protection of drivers' personal information,” says Lohse. “Charging station hardware always communicates with the Internet, which means it needs protection similar to websites, business software systems, and other electronic devices.”

The good news is the risk to drivers’ data, such as their credit card information, tends to be lower because these terminals or mobile apps (such as the Apple App Store) are typically subjected to greater encryption and audits.

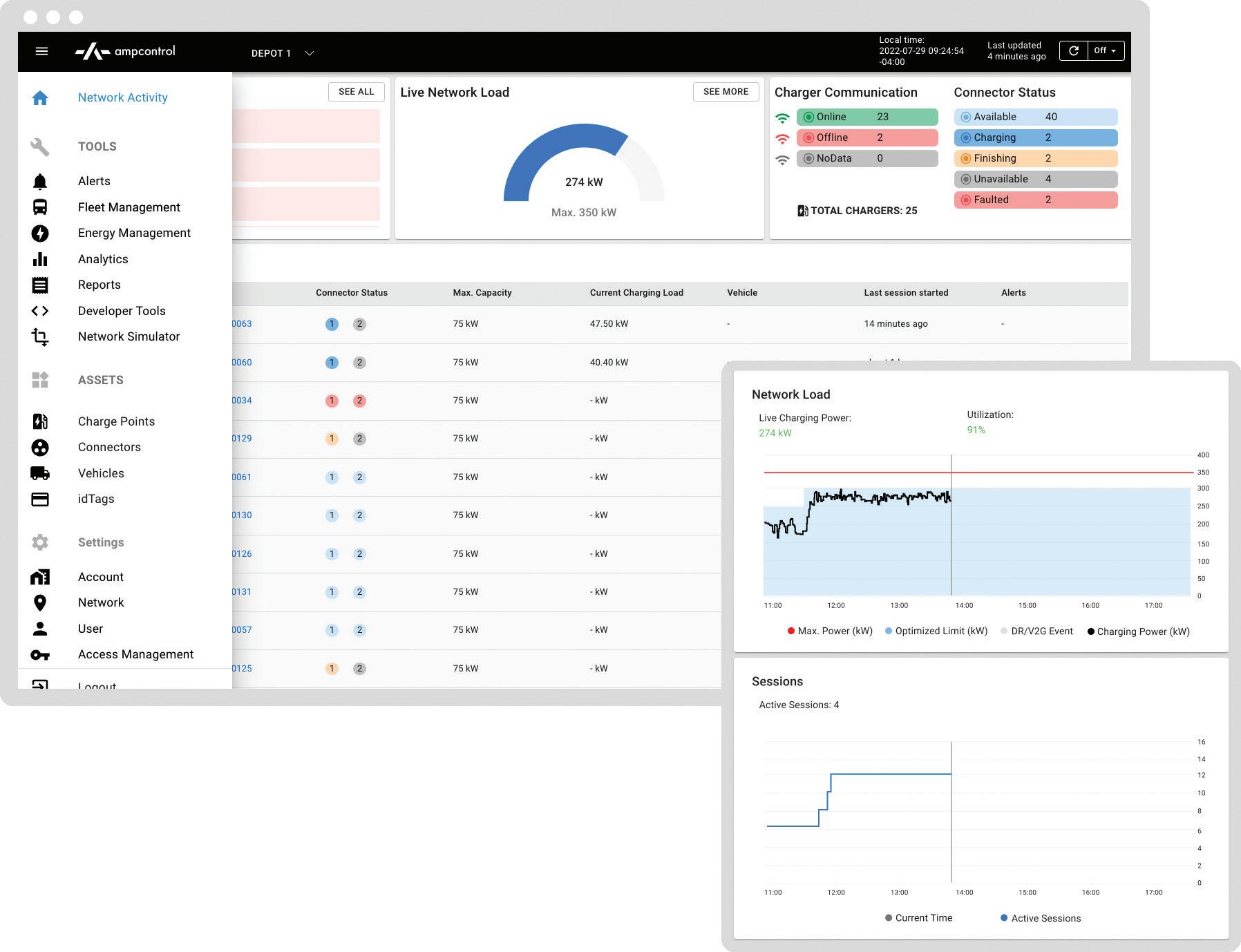

Figure 1. EV charging management software can reduce energy costs, increase charger uptime, and track vehicles. This dashboard displays live site activity, site load, as well as the charger and connector status.

The bigger concern, according to Lohse, is the poor protection of charging station data, which can make it easy for outsiders to interrupt entire charging networks.

“Unfortunately, we see ignorance. Companies are alerted to a security threat but ignore it since no one will audit their system,” he says.

“Companies must follow basic due diligence when connecting EV charging stations.”

Charging systems have several components, including the EV charger

4-WAY

hardware, communication devices (such as routers), and software that typically runs on the Cloud (Figure 1). One might think the fastest way to hijack data is through the Cloud but, again, it tends to be much better protected than the other components.

“Where we see companies cutting corners is when the chargers connect to the software. Charging stations use WebSocket to exchange data between the charger and the cloud software. Similar to web applications, this communication goes through the Internet,” Lohse explains.

for E-Mobility Applications

We partner with OEMs and system suppliers to design and produce custom solenoids, valves, and valve systems for current and emerging mobility architectures.

+ Multiple in/multiple out

+ Coolant control/switching

+ Proportional control

+ Diaphragm, spool, & pilotoperated

+ Valve systems and manifolds

Some of the core protections used in common applications (such as apps, websites, etc.) across the IT industry include:

1. Encryption (TLS 1.3)

Authentication (password protection, secrets, or highest security profile) Security protocols (HTTPS, WSS)

“Essentially, if companies exchange data between their EV chargers and software without these basic protections, they risk hackers accessing or interacting with the applications,” says Lohse. For example, they can start connecting a large number of virtual charger bots to the network and overload the servers.”

This may paint a dark picture, but as charging stations scale and potentially become one of the biggest energy consumers in the grid, they also become a risk for utilities.

CONTACT US WITH YOUR CHALLENGE.

+ Magnetics for axial flux motors

+ Customized sensor integration & feedback

“Just imagine a scenario where thousands of EVs are charging in a region, and a hacker can suddenly and simultaneously interrupt the charging stations... this would drop power quickly and unexpectedly. And the utility would need to react extremely fast to avoid wider outages.”

At the same time, adds Lohse, charging stations will become more connected to the utility communication and grid management system.

“Although we’re still far from a true smart grid, utilities can only realistically realize such a grid when charging

networks are more secure than today,” he says. “While several layers of protection and utilities have many more certifications that will protect them, a security risk on the EV charger side could also mean a risk to overall grid stability.”

The Open Charge Alliance is one of the most prominent organizations that has developed communication protocols (called, “OCPP”) to standardize the language between hardware and software. These standards include various security aspects that cover the three protections mentioned above.

The problem is the OCPP is not an industry standard, such as the International Organization for Standardization (ISO) — which offers independent, non-governmental, international standard development. So, while some countries and states oblige EV charging networks to follow OCPP protocols, they’re not globally enforced, nor do they include a large number of certifications or audits.

“Some companies follow these protocols and have very good protection, while others don’t implement everything. It’s essential to understand that using OCPP does not necessarily mean a company’s chargers are protected. It depends on how it was implemented with the OEMs and the software company.”

According to Lose, all sides of the industry — from the OEMs to the software providers — must follow these security standards, invest in continuous improvements, and make customers aware of potential security risks. This means all industry parts must commit to exchanging data to ensure cybersecurity protections. So, for example, if a software company finds that an EV charger is running with outdated encryption, it shares this with the provider and the OEM to help them improve security (Figure 2). HTX7045C

• Low interwinding capacitance to minimize EMI and achieve high CMTI (Common Mode Transient Immunity)

• Optimized for isolated bias supplies for SiC and GaN gate drivers, such as the UCC25800-Q1 from Texas Instruments

• Ideal for automotive OBC and traction inverters in EV/HEV

3.

“The first step is really quite simple. Companies must follow basic cybersecurity principles — such as authentication, encryption, and secure protocols. They could use VPNs or more advanced role-based access control for their applications.”

A VPN is a virtual private network that encrypts Internet traffic, protecting online data. And note, these are not EV-industry inventions. Rather, they’re commonly implemented protections in nearly every tech or digital industry.

“In addition to the technical steps, we recommend investing in security at the company level. This means getting SOC 2 Type 2 certified and training staff to protect information, hardware, and more.”

SOC 2 Type 2 certification is a rigorous auditing process that evaluates and verifies a service provider’s ability to securely manage customer data, based on five trust principles: security, availability, processing integrity, confidentiality,

and privacy. It involves a thorough examination by an independent auditor, demonstrating that a company consistently meets these standards, ensuring reliable data protection and management practices.

For now, Lohse is noticing increasingly stringent requirements in the proposal process when selecting vendors, asking for certifications and details on protecting data and their future infrastructure.

“I think this is the right step,” he says. “Companies must review encryption, authentication, and other methods potential vendors use. And I expect we will see more third-party audits and certifications as the industry and networks grow. They’re expensive and take time, which is why we don’t see them too often yet. Everyone is trying to move fast, and the market is still new.”

Eventually, artificial intelligence (AI) will play a more significant role in EV charging security by detecting anomalies in charging patterns and user behaviors, potentially identifying cyber

threats in real time. The AI algorithms will also optimize charging schedules and load balancing, ensuring grid stability (Figure 3) and preventing unauthorized access to charging networks.

“In the future, AI can also help to identify possible attacks, security gaps, and such,” agrees Lohse. “For instance, we’ve already invested in R&D resources to develop tools and alerts to identify security threats better and resolve issues automatically.”

Fortunately, most hackers look for an easy hit, an unsecured system that requires little effort to breach.

“Hackers typically don’t take the complicated route,” he says. “The concern right now is that the EV charging industry is sometimes looking away or not making its best effort to ensure safe and secure infrastructure. But this can be corrected with the right intent and enforced standards that ensure a secure and reliable EV ecosystem. It’s an essential fix and a must for greater EV adoption.” EV

Michelle Froese • Editor

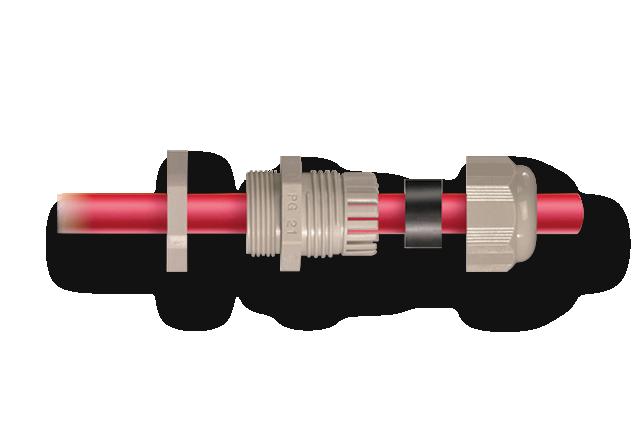

Electrical transients, often called surges, are short-duration, microsecond events. Surges are a risk to any electrical equipment, and electric vehicle (EV) charging infrastructure is no exception. Such events can interrupt, delay, or corrupt signal transmissions. More significantly, they can damage, degrade, and destroy electronic equipment.

“A surge is unlike any other power quality anomaly out there in that a fuse or a breaker cannot react fast enough to stop a microsecond transient event,” explains Jason Mies, director of Industrial Sales with Raycap, a global electrical protection and connectivity solutions manufacturer. “This means specially designed equipment called Surge Protection Devices (SPD) that react in nanoseconds are required to divert that microsecond event to the

ground and protect the downstream equipment.”

Consider the ac sine waves in Figure 1. The spikes are all transient events, which can damage or destroy equipment — immediately or over time.

“In terms of surges, we often hear about a lightning event completely damaging equipment. However, the real concern is the smaller surge events that can degrade electronics over time,” says Mies. “Let’s take an EV charger expected to perform for 10, 20, or even 30 years. Faulty power from to a switching transient could slowly degrade that charger over time, reducing its output and total life expectancy.”

EV charging infrastructure is already subject to numerous challenges, including network availability, charging speed, vehicle compatibility, O&M

concerns, and others. The reliability of the power source related to a surge event is one concern no EV driver should have to add to this list.

“If a driver pulls up to a charger and it’s out of service due to a surge event, that’s one thing that could have easily been prevented,” he says. “While equipment immunity to surges varies, it typically requires external surge protection to ensure reliability for the intended useful life. Installing surge protection in front of the charger is undoubtedly a best practice.”

Mies adds that Europe already requires surge protection in three separate locations in an EV charging site to comply with the International Electrotechnical Commission (IEC), the international standards organization for electrical, electronic, and related technologies. However, this is not yet the case in the United States. Until

it becomes standard regulation, it’s up to OEMs and installers to ensure the safest, most reliable infrastructure possible.

What’s the difference between a surge and an over-voltage event?

A power surge is a brief and sudden increase in voltage that lasts only a few microseconds. According to the Institute of Electrical and Electronics Engineers (IEEE), it’s a transient event that’s an 8×20 waveform (Figure 2). The IEEE is currently the world’s largest professional association for electronics and electrical engineering.

An over-voltage, on the other hand, occurs when the voltage exceeds the normal range for a more extended period, potentially causing overheating and damage to electrical equipment. Essentially, surges are microsecond events, whereas over-voltages are fault events that can last for seconds, minutes, or hours.

It’s important to install proper fuses and breakers to protect equipment from over-voltages and install surge protection for surges. Why? Because these devices react in nanoseconds to protect against that microsecond transient event, according to Mies.

“It could cost thousands of dollars in damaged equipment, not to mention downtime and service required, thanks to an electrical surge,” he warns. “Prevention is simple… if you want to keep your site up and running and reliable, surge protection is a very inexpensive way to eliminate many of the headaches and hazards related to surge events.”

Where should surge protection be installed in EV chargers?

Surge protection should be strategically installed to ensure comprehensive protection for the EV charging equipment and the connected vehicle. The most

significant place to protect against a lightning or utility fault event is at the power distribution panel, which feeds the charger.

“You might think the OEM or charging companies will take care of installing surge protection at the factory, but if that protection is sacrificed, it’s necessary to replace the full charger,” says Mies. “So, placing this protection in the power distribution cabinet better safeguards all the downstream charging equipment.”

The amount of exposure is also a factor, he added, as big utility lines can conduct a lot of energy, making installing SPDs at the equipment supplying power to the chargers the ideal location.

In the case of a major power event related to a downed power line or transformer damage, it’s ideal to have surge protection that’s rated to protect against fault events at that

power distribution equipment. In this case, it’s protecting the equipment and the power service.

Another threat to chargers relates to unbonded ground systems when there’s already existing power. “We call this ground potential rise,” he shares. “It happens at sites with ground systems that are not connected. If lightning strikes, it dissipates through the earth and hits and energizes the ground systems for the equipment at different levels. The power and signal conductors will try to equalize the energy between the equipment, causing damage.”

This means surge protection is required at the opposite ends of each of those lines to protect the equipment properly (Figure 3).

When evaluating surge protection for an EV charging site, consider the following:

• At the voltage protection level, size the surge protection as close to the nominal voltage of the equipment as possible. “If it’s a 480-volt device charger, it’s important to use a 480-volt rated surge protector,” says Mies. “Ensure you’re clipping that energy as close to the nominal as possible.”

• Ensure the surge protection equipment complies with the latest UL 1449 standards (see the UL site for exact ratings based on the manufacturer and product). This ensures the device has been tested properly and can handle voltage events safely.

• Avoid cheaper designs to save costs. “If the surge protector is improperly designed, then it can cause smoke and even fire at a site that’s completely avoidable. So, make sure you go online and check that UL listing,” he says. “Most reputable surge protectors are designed to handle multiple events without needing to be serviced or swapped out.”

• The most important consideration is for a surge protector to sacrifice in safe mode if it reaches end-of-life.