www.fluidpowerworld.com December 2022 Piston pump basics p. 20 A primer on pneumatic actuators p. 24 Noise-free, compact power units p. 28 A look inside IFPE education p. 39 Sustainable PAGE 34 machinery fromdesignsBauma

The Best Route to Value, Quality and Service. www.fluidpowerworld.com December 2022

We are excited to see our friends at ConExpo/IFPE 2023. We can’t wait to share new innovations on our core products that will make them work quieter and at higher pressure and speeds. We are also excited to share some groundbreaking new applications that will keep Permco at the cutting edge of the hydraulic world. So follow us to ConExpo/IFPE to learn moreit is the best route to the show! Visit us at Booth S81107 THE ROADTO CO N E XPO/IFPE2023 With Perm C O i t’ s Personal Home of the American Champ 1500 Frost Road Streetsboro, OH 44241 Contact us now for a Permco distributor near you. permco.com | (800) 626-2801

tompkinsind.com 800-255-1008 ALWAYS ADAPTING. SELF-RENEWING, FLAME-RESISTENT PROTECTION.

With StrideLinx remote access you can securely connect with remote systems in an instant, troubleshooting and correcting issues without the hassles, delays and costs of traveling.

StrideLinx VPN routers provide 10GB of FREE monthly bandwidth to securely monitor, program and/or troubleshoot your remote systems. Optional services are available to maximize your remote access capabilities, including:

• Cloud-based Data Logging - Unlimited cloud data storage for up to 7 years with active subscription

• Cloud Notify/Alarming - provides customized “alarm” email and push notifications when control limits are exceeded on HMI / PLC devices connected to the StrideLinx VPN router

• White Labeling allows users to re-brand the platform, mobile app and hardware

Don’t let a simple support call become a costly site visit Research, price, buy at: www.automationdirect.com/stridelinx

StrideLinx VPN Routers starting at $385.00 (SE-SL3001)

Linx the #1 value in automation Order Today, Ships Fast! * See our Web site for details and restrictions. © Copyright 2022 AutomationDirect, Cumming, GA USA. All rights reserved. 1-800-633-0405

Mary C. Gannon • Editor-in-Chief

The future is sustainable and it’s here to stay

Last month, organizers for CONEXPOCON/AGG and IFPE announced that a key focus of the 2023 events will be on next levels of sustainability in construction, highlighting the many aspects of the shows designed to ensure a sustainable future. This is a reflection of an industry moving towards a sustainable future.

First up are manufacturers that plan to highlight their electric, autonomous, or digital technologies, such as Volvo Construction, Caterpillar, Skyjack, and many others, who will be introducing electric-powered, emission-free machinery at the event.

If the machines and technologies highlighted at bauma in October are any indication, reducing emissions while remaining powerful are keys to the future. I expect we will see many of the same machines launched at bauma on the CONEXPO-CON/AGG lots. We’ve highlighted a few of those on page 34, with a look at Liebherr’s Hydrogen-powered excavator, Komatsu and Proterra’s battery powered excavator, and more. It is important to note that in many of these larger machines, the hydraulic systems remain the same because you can’t beat the power density provided by hydraulics in heavy-duty operation.

Additionally, many of the education programs offered on the IFPE and CONEXPO-

CON/AGG side will be geared towards sustainability. Here’s a look at some of the IFPE sessions — and be sure to turn to our pre-IFPE coverage on page 38 to see more indepth looks at some of the IFPE sessions and also what’s new in Las Vegas since 2020.

• Efficiency in hydraulic systems,

• Efficiency in pneumatic systems,

• An integrated electrohydraulic unit for fluid power applications,

• What can you do to make your machine more efficient,

• Advancing autonomy from operator assist to driverless vehicles,

• Electrification of vehicle powertrains, and

• Reducing energy consumption in fluid power systems.

Additionally, CONEXPO-CON/AGG has given sustainability its own education track in its seminar offerings, now with 13 sessions dedicated to the topic. They tackle subjects like reducing the carbon footprint of concrete, getting and managing electric construction equipment, asphalt and concrete recycling, carbon neutrality, and a “Sustainability 101” session.

Show organizers are promoting several initiatives less relevant to the engineer but still part of their move to a more sustainable show. For example, they have partnered with the Arbor Day Foundation, and are working toward planting 130,000 trees in

forests of greatest need, one for every show registrant. Exhibitors and attendees can contribute to the Arbor Day Foundation’s funds. Each dollar contributed will result in one tree being planted in a forest in need.

And finally, CONEXPO-CON/AGG and IFPE are committed to reducing the environmental impact of the show. This includes partnering with vendors dedicated to sustainable practices and reducing waste, helping exhibitors choose more sustainable options, and measuring its total 2023 environmental impact to identify future improvements.

Show organizers say that registration for 2023 is outpacing all previous shows in attendee registration. To continue this momentum, they have extended a special registration code to our readers to January 6, 2023. By registering with the code PR30, you can save 30% off registration.

I hope to meet many old and new friends in March at IFPE. Be sure to mark down our booth number, SL80022 and stop by to say hello. And stay tuned for our February issue, which will include our complete IFPE coverage. FPW

Mary C. Gannon •

-Chief mgannon@wtwhmedia.com On Twitter @FPW_marygannon

Editor-in

FLUIDLINES

2 FLUID POWER WORLD 12 • 2022 www.fluidpowerworld.com

ALWAYS YOUR BEST PERFORMANCE

Tank mounted return filter. Working pressure up to 116 PSI, flow rates up to 236 GPM.

In-line high pressure filter. Working pressure up to 6090 PSI bar, flow rates up to 79 GPM.

Filling caps and air breathers with 10 µm filter element. Flow rate up to 422 GPM. Replaceable filter element.

PASSION TO PERFORM

Visual oil level indicators available with 3”, 5” and 10” mounting sizes, to monitor the level of oil in the tank.

www.mpfiltriusa.com

(215) 529-1300

sales@mpfiltriusa.com

FMM 050-150

TAP 114

LVA

Paul J. Heney • VP, Editorial Director

FMM 050-150

TAP 114

LVA

Paul J. Heney • VP, Editorial Director

Seeing some old names — anew

At the recent Danfoss Distributor Meeting in Orlando, I caught up with Eric Alström, the company’s President. Danfoss is a bit more than a year removed from the purchase of Eaton’s hydraulic business, and Alström told me that the merger’s gone better than one may have imagined.

“As of January 1st [2022], everybody knew who they were reporting to. And remember, we went from a regional P&L structure in Eaton to our global product line structure in Danfoss. So, it’s a big change for many Eaton team members. And we also had financial transparency as of January 1st, which is, of course, really important. So basically, we have been operating as one company since then,” he said. “However, there are some things that take longer, like the IT backbone and CRM systems. We have one ERP now in Danfoss that we’re rolling out. And Eaton will, of course, also be brought onto the same ERP system — and that takes a little bit longer. So that is a journey, but nothing that’s stopping us from doing regular work and being together as one company.”

I also asked Alström about the return of beloved fluid power industry names. For example, on the event’s tradeshow floor, I regularly saw the Vickers name — one that takes me back to my first days in the industry in the early 1990s.

Alström said that, leading up to the acquisition, they did some exploration and asked innocent questions of partners, including about brand strength. It became very evident that in the industry, Vickers was still a strong brand — and the only reason that it had been diminished was lack of investment.

“So now we are investing in Vickers,” he said. “We are investing in all of the fluid conveyance brands. Anecdotally, on day two of coming together as a new company, on August 3rd, I got an email from a distribution partner that started with, ‘My brother and I have had our fluid conveyance company since 1972. We’re a proud distributor of Aeroquip products. Please don’t do what Eaton tried and put Danfoss in the front. Nobody ever bought an Eaton Aeroquip hose. Everybody was buying an Aeroquip hose.’ That just resonated very strongly with me. We confirmed that these brands are really strong. Let’s nurture them. Let’s come up with new products and innovations so that people see that they’re alive again.”

Alström concluded by saying that Danfoss is putting the brands in the foreground and promoting them as, “By Danfoss.” So, they’ll be Boston by Danfoss and Aeroquip by Danfoss. The goal, he said, will be to invest in and breathe life back into those legacy brands that are still industry favorites to so many. FPW

Paul J. Heney VP, Editorial Director pheney@wtwhmedia.com On Twitter @wtwh_paulheney

FROM THE FIELD 4 FLUID POWER WORLD 12 • 2022 www.fluidpowerworld.com

FEATURES

PNEUMATICS

An introduction to pneumatic actuators Learn what are the key considerations for selecting the right pneumatic actuator for your unique application.

INDUSTRIAL HYDRAULICS

Refrigerator-sized hydraulic power units that don’t make a peep Technology advancements enable smaller, quieter, and more energy-efficient hydraulic power units that save space and reduce the total cost of ownership.

MOBILE MACHINERY ROUNDUP

Sustainable machinery designs top Bauma innovations While many compact machines boast all-electric systems, several prototype designs feature alternative options to power larger, heavier-duty equipment.

IFPE EDUCATION

Efficient fluid maintenance is core to sustainability

IFPE conference programming will take in-depth looks at fluid cleanliness and life to ensure sustainable, efficient systems.

IFPE TRAVEL

The new Las Vegas is ready for IFPE A lot has changed in the Nevada desert since the last show took place in March 2020 — here’s what to expect for 2023 visitors.

24

28

34

39

44

6 FLUID POWER WORLD 12 • 2022

DECEMBER

2022

Contents | vol 9 no 7 | fluidpowerworld.com • 12 • 2022 ON THE COVER Mobile machinery makers launched many innovative, sustainable designs at Bauma, including the R 9XX H2 excavator which is powered by Liebherr’s hydrogen engine. | Courtesy of Liebherr Machines Bulle SA asbpe.org SILVER NATIONAL AWARD asbpe.org SILVER REGIONAL AWARD DEPARTMENTS 02 FluidLines 04 From The Field 08 Troubleshooting Challenge 10 Association Watch 12 Design Notes 20 Fundamentals 22 Energy Efficiency 59 Products 63 Component Focus 64 Ad Index

EDITORIAL

VP, Editorial Director Paul J. Heney pheney@wtwhmedia.com @wtwh_paulheney

Editor-in-Chief Mary Gannon mgannon@wtwhmedia.com @dw_marygannon

Technology Editor Ken Korane kkorane@wtwhmedia.com @fpw_kenkorane

Senior Editor Rachael Pasini rpasini@wtwhmedia.com

Associate Editor Heather Hall hhall@wtwhmedia.com @wtwh_heathhall

Contributing Editor Josh Cosford @FluidPowerTips

Contributing Editor Carl Dyke @carlindustry

Contributing Writer Robert Sheaf rjsheaf@cfc-solar.com

PRINT PRODUCTION

VP, Creative Services Mark Rook mrook@wtwhmedia.com @wtwh_graphics

Senior Art Director Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

Senior Graphic Designer Allison Washko awashko@wtwhmedia.com @wtwh_allison

Graphic Designer Mariel Evans mevans@wtwhmedia.com @wtwh_mariel

Director, Audience Development Bruce Sprague bsprague@wtwhmedia.com

VIDEO SERVICES

Video Manager Bradley Voyten bvoyten@wtwhmedia.com @bv10wtwh

Videographer Garrett McCa erty gmccafferty@wtwhmedia.com

Videographer Kara Singleton ksingleton@wtwhmedia.com

Media, LLC 1111 Superior Ave., Suite 2600, Cleveland, OH 44114

888.543.2447 • Fax: 888.543.2447

MARKETING

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com @wtwh_taylor

Digital Production/ Marketing Designer Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Webinar Manager Matt Boblett mboblett@wtwhmedia.com

Webinar Coordinator Halle Kirsh hkirsh@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

IN-PERSON EVENTS Events Manager Jen Osborne jkolasky@wtwhmedia.com @wtwh_jen

ONLINE DEVELOPMENT & PRODUCTION

Web Development Manager B. David Miyares dmiyares@wtwhmedia.com @wtwh_webdave

Senior Digital Media Manager Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer Melissa Annand mannand@wtwhmedia.com

Software Engineer David Bozentka dbozentka@wtwhmedia.com

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Nicole Lender nlender@wtwhmedia.com

Digital Production Specialist Elise Ondak eondak@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com

VP, Strategic Initiatives Jay Hopper jhopper@wtwhmedia.com

Webinar Coordinator Kim Dorsey kdorsey@wtwhmedia.com www.nfpa.com

Events Manager Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist Olivia Zemanek ozemanek@wtwhmedia.com

FINANCE

Controller Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist

Jamila Milton jmilton@wtwhmedia.com

SALES Ryan Ashdown 216-316-6691 rashdown@wtwhmedia.com

Jami Brownlee 224.760.1055 jbrownlee@wtwhmedia.com

Mary Ann Cooke 781.710.4659 mcooke@wtwhmedia.com

Jim Powers 312.925.7793 jpowers@wtwhmedia.com @jpowers_media

Courtney Nagle 440.523.1685 cseel@wtwhmedia.com @wtwh_CSeel

submitted advertising and editorial information. Noncommissioned articles and news releases cannot be acknowledged. Unsolicited materials cannot be returned nor will this organization assume responsibility for their care.

FLUID POWER WORLD does not endorse any products, programs or services of advertisers or editorial contributors. Copyright© 2022 by WTWH Media, LLC. No part of this publication may be reproduced in any form or by any means, electronic or mechanical, or by recording, or by any information storage or retrieval system, without written permission from the publisher.

SUBSCRIPTION RATES: Free and controlled circulation to qualified subscribers. Non-qualified persons may subscribe at the following rates: U.S. and possessions: 1 year: $125; 2 years: $200; 3 years: $275; Canadian and foreign, 1 year: $195; only US funds are accepted. Single copies $15 each. Subscriptions are prepaid, and check or money orders only.

SUBSCRIBER SERVICES: To order a subscription please visit our web site at www.fluidpowerworld.com

FLUID POWER WORLD (ISSN 2375-3641) is published seven times a year: in February, April, June, July, August, October, and December by WTWH Media, LLC; 1111 Superior Ave., Suite 2600, Cleveland, Ohio 44114. Periodicals postage paid at Cleveland, OH & additional mailing offices.

POSTMASTER: Send address changes to: Fluid Power World, 1111 Superior Ave., Suite 2600, Cleveland, OH 44114

DECEMBER 2022 • vol 9 no 7 • www.fluidpowerworld.com Don’t compromise! Use MAIN Manufacturing Products, Inc. as your source for hydraulic flanges Dependable - 60 yrs service Informed - members of SAE & NFPA tech committees Quick - Thousands in stock specials can be 3-4 days MAIN Manufacturing Products, Inc. Grand Blanc, MI USA 800.521.7918 Info@MainMfg.com MAINMfg.com SAE 4-bolt, JIS, DIN, ISO standard & special adapters Socket and Butt weld, NPTF BSPT, ORB, BSPP, 6149, etc. Materials: Carbon, 304L, 316L, duplex, Cu-NI, ductile, alum. etc. In-line, el, tee, F, blind, cross, reducing, flange heads Made in USA tompkinsind.com 800-255-1008 ALWAYS ADAPTING. SELF-RENEWING, FLAME-RESISTENT PROTECTION. 2011- 2020 FLUID POWER WORLD does not pass judgment on subjects of controversy nor enter into dispute with or between any individuals or organizations. FLUID POWER WORLD is also an independent forum for the expression of opinions relevant to industry issues. Letters to the editor and by-lined articles express the views of the author and not necessarily of the publisher or the publication. Every effort is made to provide accurate information; however, publisher assumes no responsibility for accuracy of

2013- 2017 2014- 2016 2014 Winner

12 • 2022 FLUID POWER WORLD 7

WTWH

Ph:

Robert Sheaf • Founder/CEO of CFC Industrial Training

The circuit shown here is used to open and close the cage doors on a zoo enclosure. The staff would start the hydraulic system when they needed to open and close the gates. They then would shut it down when all the gates were closed.

After having trouble opening one of the larger cage doors, they spent time making sure there wasn’t a mechanical obstruction and that the gate wheels rotated freely. A local repair shop told them to increase the pressure on the electric motor-driven pump, but it would not go any higher. They tried increasing the setting on the relief valve and it also would not increase the pressure.

They tried to start the gas engine stand-by system but could not get that up and running, either. They also noticed the oil temperature kept climbing the longer they allowed the power unit to run.

Can you identify what was the problem? We welcome responses of all kinds directly to Robert Sheaf at rjsheaf@cfc-solar.com or to mgannon@ wtwhmedia.com. The solution will be provided next month, in conjunction with our February 2023 issue. FPW

Pressure problems on a multi-circuit system Solution to system overheating on drum pusher system

After finding the circuit drawing on the drum pusher system which was overheating, the service technician found that the unloader valve was stuck in the shifted position and both filter elements were missing. To solve the problem, both filter indicator switches were disconnected at the terminal strip to keep the machine from shutting down.

8 FLUID POWER WORLD 12 • 2022 www.fluidpowerworld.com

TROUBLESHOOTING CHALLENGE

FPW EM P I P I P I SOL. 1B SOL. 2A SOL. 3A SOL. 3B SOL. 4A SOL. 4B UNLOADER 4 - BANK MANIFOLD LOCATED UNDER MAIN FRAME DOOR LOCKS CONVEYOR PUSHER Circuit

EM Gage A Sol. 1A Sol. 1B 3000 PSI Set Max Compensator to 2700 PSI Set Load Sense to 300 PSI Gage C Gage B

7

Low Pressure Suction Valves

ISO 9001 Certified

Medium - High Pressure Valves

Ball Valves

Subsea & Gas Valves

Check Valves

Flow Control Valves

Needle Valves

Flanges & Adapters

Bar & Custom Manifolds

Specialty Valves

Flow Control Needle Valves

Tank Accessories

Pressure Gauges & Snubbers

SSW Power Unit Systems

Transfer Pumps

Industries Served:

• Oil & Gas

Check Valves Bar & Custom Manifolds

SAE Port Flanges

• Industrial Hydraulics

• Mining

• Forestry

• Chemical & General Processing Plants

• Medical

• Aerospace

• Factories

• Mobile Equipment

• Defense

SSW Power Unit System

• Machine Tool

• Testing Equipment

• Ocean Depth Technology

• Automotive

• Food Processing

• Agriculture

• Industrial

• Aviation

• Petrochemical

• Marine

• Subsea

Made In America

DELAWARE MANUFACTURING INDUSTRIES CORPORATION Solutions

Pressure

Under

800.248.DMIC (3642) • WWW.DMIC.COM • SALES@DMIC.COM

Edited by Mary C. Gannon • Editor-in-Chief

IFPS launches online instructor-led certifi cation review training

The IFPS announced that it has officially launched an online instructor lead Hydraulic Specialist Certification Review Training course.

Tom Blansett, CFPAI, IFPS Technical Director, will facilitate this 12-week virtual/online training course to help candidates prepare for the Hydraulic Specialist Certification test. Classes will be held Thursdays from 10:00 AM -1:00 PM EST beginning on March 9, 2023 (skipping March 16). The registration fee includes the training and the testing fee. Three additional online pretests are also included with this workshop.

Throughout the training program, each Outcome contained within the study manual will be explained in detail. Many animated hydraulic circuit schematics are shown to aid in comprehension and understanding. All Outcome review questions will be explained along with a detailed explanation of how the answer was found. This training is limited to 15 participants. Participants can take the course only or pay for the course and the testing.

Recommended prerequisites include an engineering degree or 3-5 years of hydraulic application experience. The IFPS Fluid Power Math course (coming soon) is highly recommended prior to the start of this course.

Recommended publications for this training course:

• Hydraulic Specialist Study Manual*

• Fluid Power Reference Handbook*

• Fluid Power Math Handbook*

*Select the bundle during registration to receive a discount price on these publications. FPW

Learn more at ifps.org.

IFPS launches new series of safety posters

The International Fluid Power Society has always offered access to free safety posters from the International Hydraulic Safety Authority, but members can now access free safety posters created by the IFPS itself.

Posters are available to members only and are available for printing for free. Topics include hydraulic injection injury, lockout/tagout, cylinder pressure, eye safety, and hydraulic systems. More poster topics will be added throughout the year.

Additionally, IHSA posters are also available for download, on a variety of topics, such as hose charging, fluid spray, safety blocks, high-temperature burns, and more.

IFPS membership is required for download. Visit ifps.org to download. FPW

10 FLUID POWER WORLD 12 • 2022 www.fluidpowerworld.com

ASSOCIATION WATCH

NFPA encourages members to engage with students

The Fluid Power Action Challenge is a STEM-based competition that challenges middle school students to solve an engineering problem using fluid power. The students work in teams to design and build a fluid power mechanism and compete against other teams in a timed competition. The Fluid Power Action Challenge provides a bridge from the classroom to the community by teaching students about the technology and its applications, which creates needed visibility in the minds of tomorrow’s workforce so they can consider fluid power as a career path.

As NFPA seeks to increase the number of educated technicians and engineers in our industry, the Action Challenge aims to introduce our technology and spark interest in a fluid power educational path. With that building block established, NFPA has created workforce development pathways in several states with a high concentration of NFPA members. This program, Fast Track to Fluid Power, intends to guide students along a track that leads to careers at NFPA member companies.

Fluid power experts are encouraged to join the NFPA this spring as volunteer judges are welcomed and appreciated by teachers and event organizers.

Upcoming Fluid Power Action Challenge events with Fast Track to Fluid Power Hubs include:

• Master Pneumatic & Macomb Community College, Warren, Michigan, Workshop Day 1/18/23 and Challenge Day 3/29/23

• Price Engineering & Waukesha County Technical College, Waukesha, Wisconsin, Workshop Day: 2/3/23 and Challenge Day: 3/10/23

• Deltrol Fluid Products & Triton College, River Grove, Illinois, Workshop Day Friday 2/17/23 and Challenge Day Friday 4/28/23

Learn more about getting involved with Fluid Power Action Challenge events by emailing workforce@nfpa.com. FPW

Development of ISO Standards continues

The U.S. Technical Advisory Groups (TAGs) for contamination control (TC 131/SC 6) and connectors (TC 131/SC 4) met recently to continue the ISO standardization work in fluid power systems. More than 30 connector and filter test engineering experts attended inperson or virtually. Both NFPA and non-NFPA members, representing many fluid power-related companies, were in attendance, including Holmbury, Donaldson, Pall, Parker, Cummins, Eaton, Danfoss, Caterpillar, Mann+Hummel, and John Deere.

There are 88 published ISO standards and 17 projects in various stages of development under the direct responsibility of the contamination control and connector subcommittees. In the international arena, the U.S. TAG develops and advocates for the U.S. position in each of these standards. Here is a sample of the projects currently under development:

• TR 6049, Hydraulic fluid power —Procedures used to NIST certify the standard reference material SRM 2806x a calibrant for liquid automatic particle counters

• ISO/FDIS 23369, Filter multi-pass test under cyclic flow conditions

• ISO/DIS 12829, Hydraulic spin-on filters with finite lives — Method for verifying the rated fatigue life and the rated static burst pressure of the pressure-containing envelope.

• ISO/FDIS 1179-2:2013 — Connections for general use and fluid power — Ports and stud ends with ISO 228-1 threads with elastomeric or metal-to-metal sealing — Part 2: Heavy-duty (S series) and light-duty (L series) stud ends with elastomeric sealing (type E)

• TS/AWI 11686 – Connectors for fluid power and general use — Assembly instructions for connectors with adjustable stud ends and O-ring sealing.

• ISO 171651 (hydraulic hose lengths and requirements) – reference document 131/4/6 N 458 (U.K. experts’ matrix of hose assembly length tolerances in ISO 171651).

The next U.S. TAG to TC 131/SC 6 and TC 131/SC 4 meetings will be held in a hybrid format in the March/April timeframe. Other U.S. TAGs continue to meet virtually as needed. NFPA is looking for engineers interested in participating in standards development activities as experts in ISO/TC 131 and/or the U.S. TAG to TC 131.

If you are interested in attending and/or participating in standards development, please contact Denise Husenica at dhusenica@nfpa.com.

FPW

www.fluidpowerworld.com 12 • 2022 FLUID POWER WORLD 11

Edited by Rachael Pasini • Senior Editor

in the 2022 LEAP Awards Hydraulics innovations are recognized

The annual LEAP Awards (Leadership in Engineering Achievement Program) acknowledges innovation and engineering achievements from around the globe. Our expert independent judging panel received numerous submissions this year and selected 44 gold, silver, and bronze winners and honorable mentions across 14 categories.

This year’s Hydraulics submissions showcased a range of technologies that demonstrate the fluid power industry’s advancements. Our judges awarded gold, silver, and bronze awards to three innovative designs.

The 2022 Hydraulics category winners are:

Gold

DGD Fluid Power Cartridge Flow Transmitter (CFT)

The judges commented: “This product lands in the ‘Why didn’t I think of that?’ category. One of the major hassles in using a flow meter is installation, packaging, and footprint. Conceptually, the CFT addresses these challenges in a practical and useful way with a form factor that is easy to implement into a circuit.”

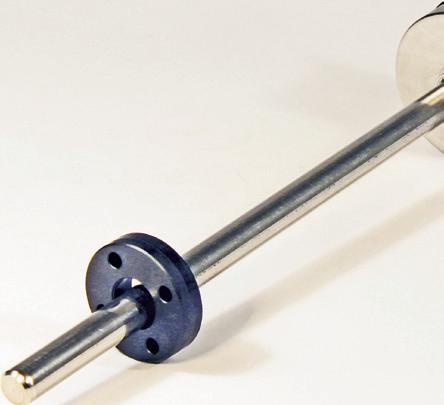

The DGD Fluid Power CFT is a turbine flow meter configured as a cartridge valve. It offers easy integration into hydraulic systems, requiring no additional hardware or connections for continuous flow monitoring of all critical hydraulic functions. It also provides real-time data for predictive maintenance and remote troubleshooting and offers turbine flow accuracy. The CFT is available in standard M42 cartridge style design and Sun Hydraulics cavity T-18A.

12 FLUID POWER WORLD 12 • 2022 www.fluidpowerworld.com DESIGN NOTES

DGD Fluid Power’s Cartridge Flow Transmitter (CFT) is a turbine flow meter configured as a cartridge valve that easily integrates into hydraulic systems.

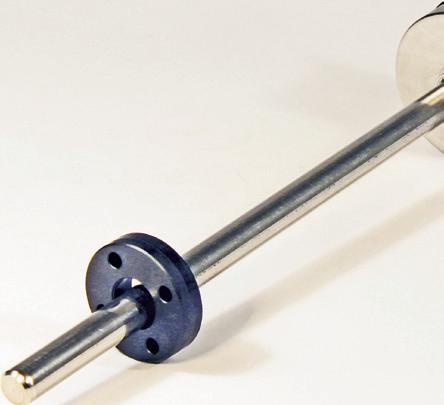

A patent is pending for the CFT, which is centered around the design of a turbine flow meter within a cartridge body. The speed of the turbine is sensed differently than existing in-line meters on the market. Existing units use a sensor positioned to sense the tips of the turbine blades passing by. Currently, the geometry necessary to do this made packaging within a cartridge body impossible. To overcome this, the CFT design uses a Hall Effect sensor to monitor the speed by sensing magnets in the turbine’s hub. This allows the sensor to be placed along the axis instead of positioned on the turbine’s circumference. This also removes the need for dynamic seals or rotating parts other than the turbine, which rides on two bearing points on the shaft and with a finite spherical point against the sensing element.

The CFT is unique because it can be designed into a hydraulic manifold. Current manifold assemblies usually require designers to disassemble in-line flow meters and reassemble the internal components inside integrated manifolds. The CFT eliminates the need to do that and makes replacement feasible as needed.

The CFT is suitable for hydraulic fluids, transmission fluids, oil-in-water emulsions,

water and glycol mixtures, and Skydrol with temperatures between -20 and 70° C. The device’s steel body has a stainless option, and the standard seal is made of synthetic rubber. The CFT four factory-configurable hydraulic flow ranges from 0.5 to 100 gpm and is pressure-resistant up to 5,000 psi, depending on the application.

Silver

Danfoss Power Solutions

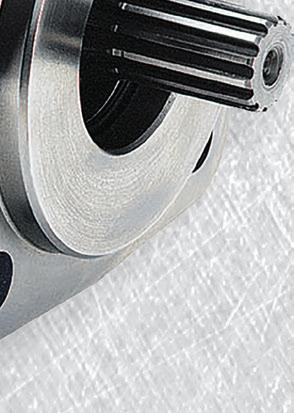

shhark low-noise gear pump

The Danfoss shhark low-noise gear pump improves operator comfort by reducing noise in the cab of off-highway machinery. Compared to standard gear pumps, the shhark pump reduces noise by up to 10 dBA. Noise generation is at lower frequencies, which operators are less sensitive to, thus improving sound quality. In addition, flow pulsation is reduced by 78%, resulting in less vibration.

The shhark pump features a patented asymmetric gear tooth profile that ensures low-noise performance, better sound quality, and higher efficiency, even after many hours of heavy-duty operation. Unlike dual-contact flank pumps, in which the low-noise performance can decline over time, shhark pumps maintain consistent low-noise performance throughout the pump’s life.

In the mobile machinery market, noise reduction is becoming as important as improving efficiency and reducing emissions. Several regulations have set 80 dBA as the maximum noise level allowed in the cab to protect operator health and comfort.

After the diesel engine and the cooling system fan drive, the hydraulic gear pump used for steering is the most significant source of noise in the cab. However, given the trend of electric and hybrid machines, along with quieter drivetrains in general, the high-frequency noise emitted by gear pumps is becoming more noticeable. A common solution to reduce sound level in the cabin is to install an end-of-line noise reduction device — such as a muffler, damper chamber, or accumulator — downstream from a standard gear pump. Usually, these components reduce the ripple pulsation only for specific frequency ranges, not for the complete frequency spectrum of the pump ripple. As a result, there’s a growing demand for a product that produces low-frequency and low-intensity noise throughout the entire frequency spectrum. This can be done only by replacing the standard gear pump with a low-noise gear pump. When used in place of standard gear pumps, the shhark pump eliminates the need for end-of-line noise reduction measures, reducing costs and saving space.

The shhark low-noise gear pump is available in displacements ranging from 6.18 to 29 cm3/rev. It has a rated pressure of up to 250 bar and an operating speed of up to 4,000 rpm. Multiple pump configurations are available, including a compact configuration, with SAE, DIN, and European standard

DGD Fluid Power dgdfluidpower.com

www.fluidpowerworld.com 12 • 2022 FLUID POWER WORLD 13

The Danfoss shhark low-noise gear pump reduces noise and vibration in off-highway machinery cabs, improving operator comfort and reducing space and costs.

mounting flanges and shafts. An integral relief valve is also available and interchangeable with all standard models.

The shhark low-noise gear pump is ideal for any cab-equipped off-highway machine, particularly tractors, wheel loaders, telehandlers, sweepers, harvesters, rollers, and electric and hybrid machines. Additional applications include indoor lift trucks, aerial platforms, material handling equipment, and others requiring low noise and high efficiency.

Danfoss Power Solutions danfoss.com

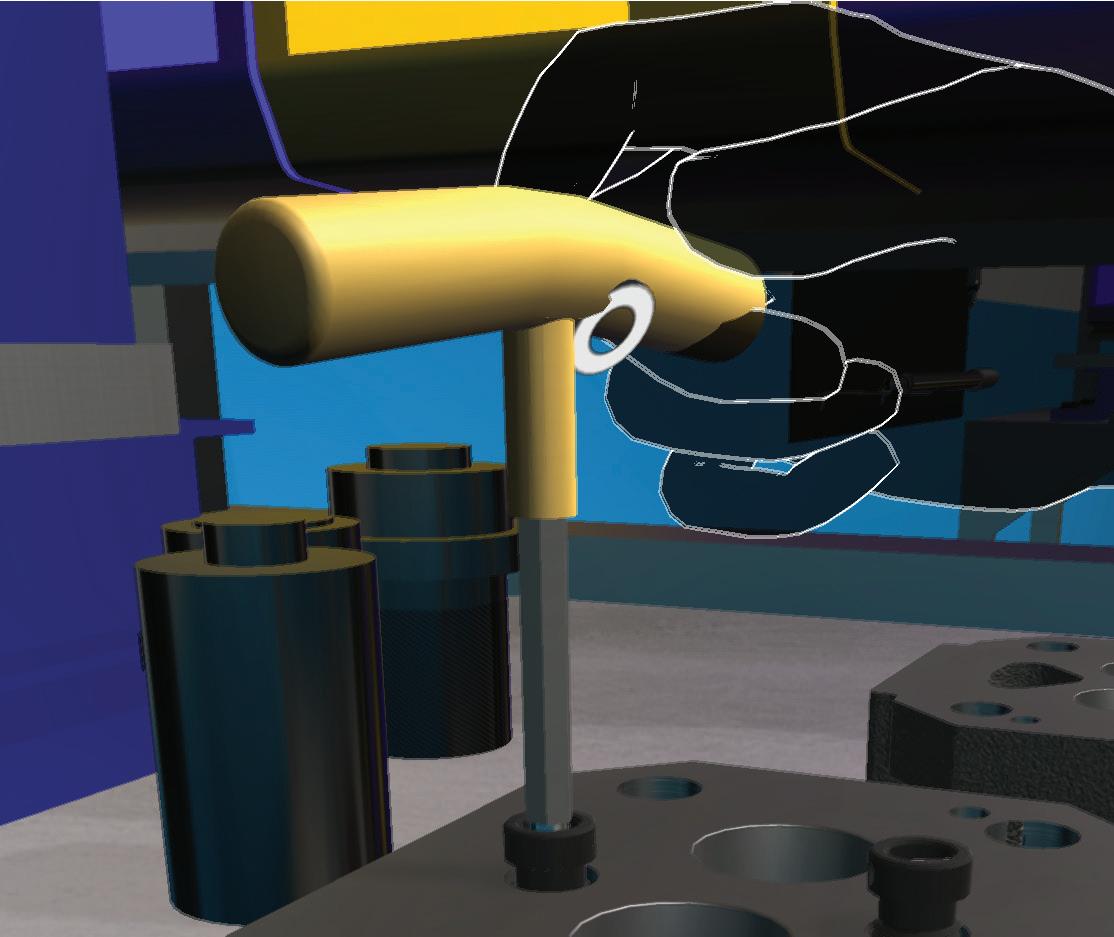

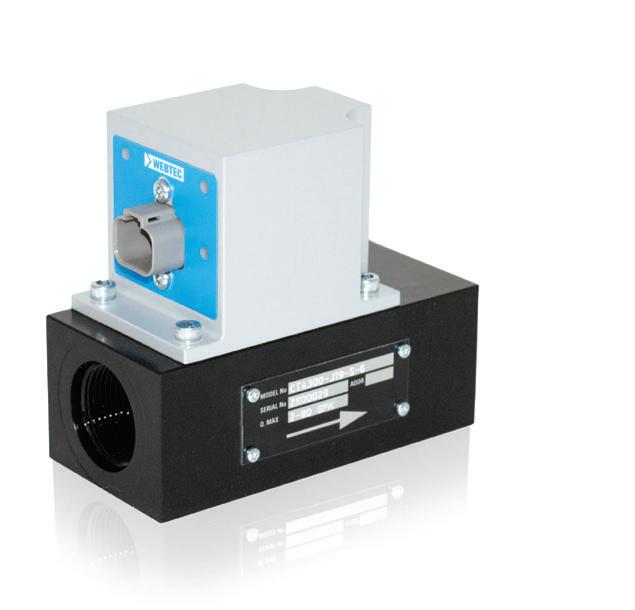

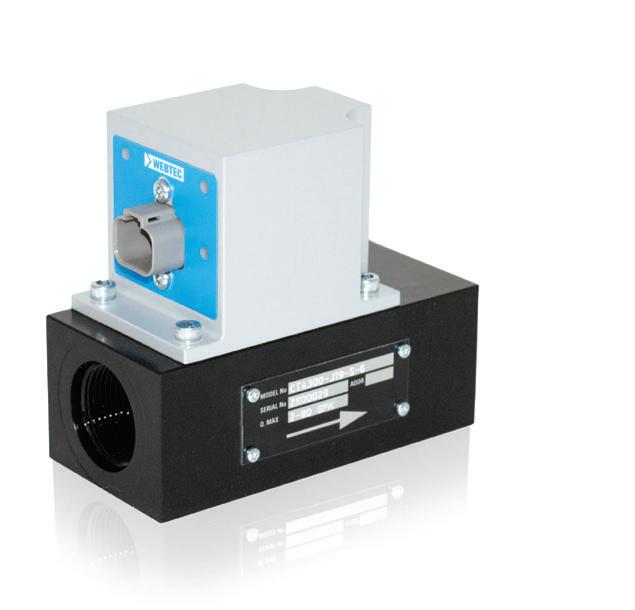

Bronze Webtec RFS200 Run-time Meter

Webtec’s RFS200 run-time meter is ideal for recording the time that construction or agricultural equipment is operational, apportioning the use of shared hydraulic tools between many users, or accurately monitoring the service interval of attachments. It ensures that maintenance can be conducted on a time-used basis, rather than machine hours, allowing for more astute and costeffective management of hydraulic system health.

The design is based on Webtec’s Reverse Flow Indicator (RFI) technology and is repackaged and enhanced to provide the desired timing functionality.

The RFS200 run-time meter is activated by the passage of hydraulic fluid and allows precise monitoring of system usage. In comparison, other products typically rely on hydraulic pressure to operate the timing function. When an attachment is removed from the machine, the hydraulic fluid is invariably isolated in the pipework. As the environment warms, the trapped fluid expands, the pressure rises, and the counter is activated. Webtec’s solution is immune to this phenomenon.

Webtec used its Make it Blue process to create the RFS200. Make it Blue is a four-step process defined as Begin, Listen, Upgrade, and Engineer, in which the Webtec team works with the customer to understand their requirements before moving on to the next stage. Customers were instrumental and established initial requirements that Webtec adjusted during development to ensure the device met customer needs within budget. FPW

Webtec webtec.com

Webtec’s RFS200 run-time meter allows precise monitoring of system usage to ensure that maintenance can be conducted on a time-used basis.

14 FLUID POWER WORLD 12 • 2022 DESIGN NOTES Simplified hose configuration, less hose and adapters combine to reduce repairs and downtime, cutting the overall cost of hydraulics. 1-763-784-5531 www.SuperSwivels.com No Kinks No Hose Twisting Full Flow Quality Products Made In The U.S.A. Patent No. 5547233 Fax: 1-763-784-7423 Email: sales@superswivels.com Available In BSPP Hydraulic Live Swivels Inline & 90° Heavy Duty Ball Bearing Design • Also In 304 & 440 Stainless Steel • Rated To 10,000 P.S.I. • Heat Treated • Custom Design & Sizes Available • Rebuildable Ball Bearing Design • Full Flow —Low Pressure Drop • Superior Quality Alloy Steel • Side Load Resistant Sw i tc h Y o u r S w i v ®le S w i t c h Y o u r S w i v ®le

DESIGN NOTES

Edited by Rachael Pasini • Senior Editor

monitoring and predictive maintenance Pneumatics devices that improve

Pneumatics products continue to evolve as technology advances. This year’s LEAP Awards judges evaluated a range of devices that help machine builders simplify communication, improve real-time data and analytics, and digitally transform their systems. Two notable products stood out and received recognition.

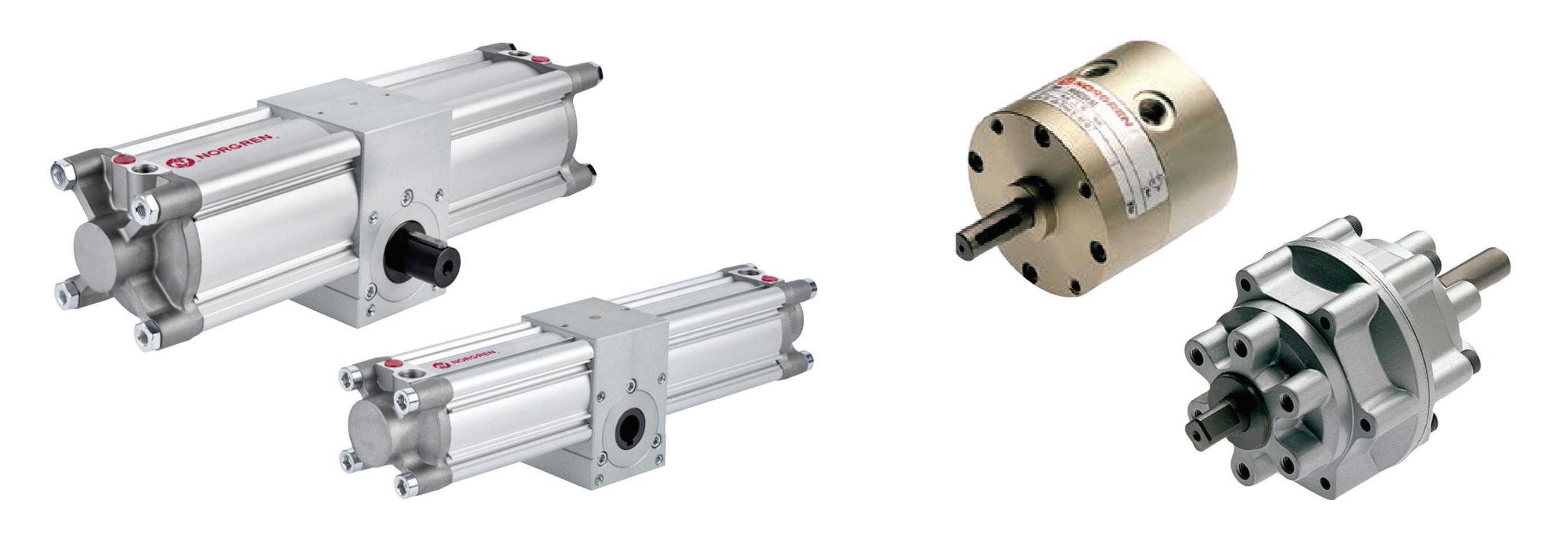

The 2022 Pneumatics category winners are: Gold Norgren

Excelon Plus Integrated Electronic Pressure Sensor (IEPS)

The judges commented: “Love the space savings, and the addition of the pressure sensor is an excellent idea.”

The Excelon Plus IEPS represents the latest generation of pneumatic air preparation equipment with its fully integrated design. It improves monitoring through an easy-toread 1.44-in. color TFT display and IO-Link functionality.

The visual display changes color based on pressure levels for optimal system performance. It provides secondary pressure readings when the system is at or above the pressure setting (green), when the secondary pressure is below the setting (red), and when there is a system fault (yellow).

The IO-Link mode operates via the PLC/ automation system and provides real-time process data to alert operators of issues, such as leaks, clogged filters, or pressure setting adjustments. This helps operators take corrective actions immediately rather than during the next scheduled maintenance.

Pressure sensor calibrations can be adjusted for offset and span correction, while built-in diagnostics, self-testing, and fault reporting present an accurate measure of

gauge status. In addition to IO-Link mode, the IEPS features near-field communication (NFC) for additional read/write functionality of attributes and settings.

The new design evolved from bolton type pressure sensor designs. Bolt-on pressure sensors extend the footprint of the assembly, are prone to mechanical damage, and can require additional installation time. With a compact, lightweight design, the IEPS maximizes machine real estate and protects against corrosion with micro fog and oil fog lubrication. It can achieve up to 98% of water extraction and features a flush-fitting integrated gauge to reduce damage. It also has a unique, double-safety bowl lock, so the bowl cannot be removed when the sensor is in use.

The IEPS conforms to standard environmental tests for temperature, humidity (ETSI 300 019-2-3), and shock and vibration (BS EN 60068-2-6), and the sensor can withstand 1.5 times overpressure without compromising accuracy. It has electrical protection against overvoltage, reverse polarity, and short circuits on signal lines. An electrophoretic coating protects it from water in the airline.

Norgren’s IEPS is a standard option for

Excelon Plus 84 regulators, filter/regulators, combo units, or a standalone pressure sensor unit. The Q84G standalone module can be installed as a standard digital pressure switch or a pressure transducer with IO-Link. The R84G pressure regulator and B84G general-purpose filter/regulator have a push-to-lock adjusting knob with a built-in tamper-resistant feature.

Adjustable settings for all units include setpoint, tolerance, hysteresis, pressure units, temperature units, screen orientation, digital output type (NPN, PNP, Push-Pull), and digital output state (Normally High, Normally Low). Various accessories, such as gauges, porting blocks, adapters, padlocks, and mounting brackets, are also available.

The Excelon Plus IEPS can be used in various applications, including material handling, machine tools, metal forming, materials (glass, rubber, wood, and plastics), packaging, printing, paper, and electronics. The IEPS is an option for machine builders looking to align with Industry 4.0 and digitally futureproof their systems. FPW

www.fluidpowerworld.com 12 • 2022 FLUID POWER WORLD 15

norgren.com

Norgren

Norgren’s Excelon Plus IEPS is a digital option for regulators, filter/ regulators, combo units, or as a standalone pressure sensor unit.

DESIGN NOTES

Silver Emerson AV/AES Valve System with integrated OPC UA

Emerson’s Aventics series Advanced Valve (AV) valve system with Advanced Electronic System (AES) Profinet and Ethernet/IP is the first valve system with preinstalled Open Platform Communications United Architecture (OPC UA) functionality. Key protocols, such as OPC UA, embedded in technologies enable device monitoring and machine connectivity when sending data from a valve system to an upper system. The AES helps users solve interoperability challenges, access data more efficiently, and improve productivity and efficiency by integrating a digital twin.

The AV/AES valve system simplifies communication by allowing direct access to valve system data and analytics without going through a gateway. No gateway is

needed unless deeper analysis or local dashboards are required. This can result in cost savings since receiving analytics from a valve system without OPC UA is more complex and expensive.

The system also provides easy integration for new or existing applications and machines. Simplified connectivity to edge computing and cloud systems makes the AES flexible and provides easy access to data and analytics without changing the PLC. Instead of dealing with bits and bytes, the product’s structure includes self-describing and tagging.

The AV/AES Valve System includes a digital twin of devices, which is the starting point for the digital twin of a machine. The digital twin with OPC UA provides actual

data via valves, analog signals, and digital signals, in addition to system info and a digital nameplate. Digital twin add-ons can include additional analytics, such as valve switching counters, time measurements, and sensor statistics.

OPC UA functionality also expands the valve system’s capabilities, making it easier for industries such as automotive, food and beverage, packaging, and pulp and paper to digitally transform. The AV/AES valve system can be used for any pneumatics application that uses data for analytics or predictive maintenance. FPW

© 2022 SPIR STAR www.spirstar.com | 281.664.7800 | Toll Free: 800.890.7827 extensive selection | technical expertise | outstanding quality | personal service

Emerson emerson.com

Emerson’s AV/AES Valve System simplifies communication, integration, and connectivity.

DESIGN

Edited by

Edited by

More LEAP winners recognized for innovative achievements

the LEAP Awards recognizes fluid power innovations across many categories, including Sensors and Switches and Motion Control.

Festo wins silver for Sensors and Switches Festo took home a silver medal in the Sensors and Switches category for its SDBT-MSX proximity switch. The Sensors and Switches category covers equipment feedback devices, such as mechanical switches and photoelectric, proximity, reel, and hall-effect sensors. Submissions also included pressure, speed, temperature, and vibration sensing devices, vision systems, and edge devices.

Festo’s SDBT-MSX is the first programmable proximity switch with an automatic switching point setting. With an initial detection range of 20 mm, the SDBT-MSX is easy to install and commission, especially in applications where mounting is difficult. The switch is ideal for all standard applications, including factory automation, the electronics industry, and small parts handling.

Installing an SDBT-MSX requires only two steps. First, the user fits the switch in the approximate end stop position within the 20 mm detection range marked on the sensor. Then, the user connects the cable to the controller (PLC). No power supply is needed during installation.

During initial operation, the proximity switch detects the end position of the piston stroke and automatically learns and remembers the switching point. This is an industry first for a solid-state positioning switch.

reduce the variety of sensor types needed to

The SDBT-MSX fits in all drives with a T-slot. It pairs best with Festo drives, such as the DSBC cylinder, ADN and ADN-S compact cylinders, and DGST mini-slide. Such pairings give users access to the switch’s full capabilities.

Festo festo.com

power efficiency requirements and could tolerate high-shock loading. The actuators

www.fluidpowerworld.com 12 • 2022 FLUID POWER WORLD 17

Festo’s SDBT-MSX proximity switch is easy to install and includes an automatic switching point setting.

Kyntronics supplied 18 SMART ElectroHydraulic Actuators to the legs of an Autonomous Field Supply Vehicle.

Quality Precision Performance Reliability

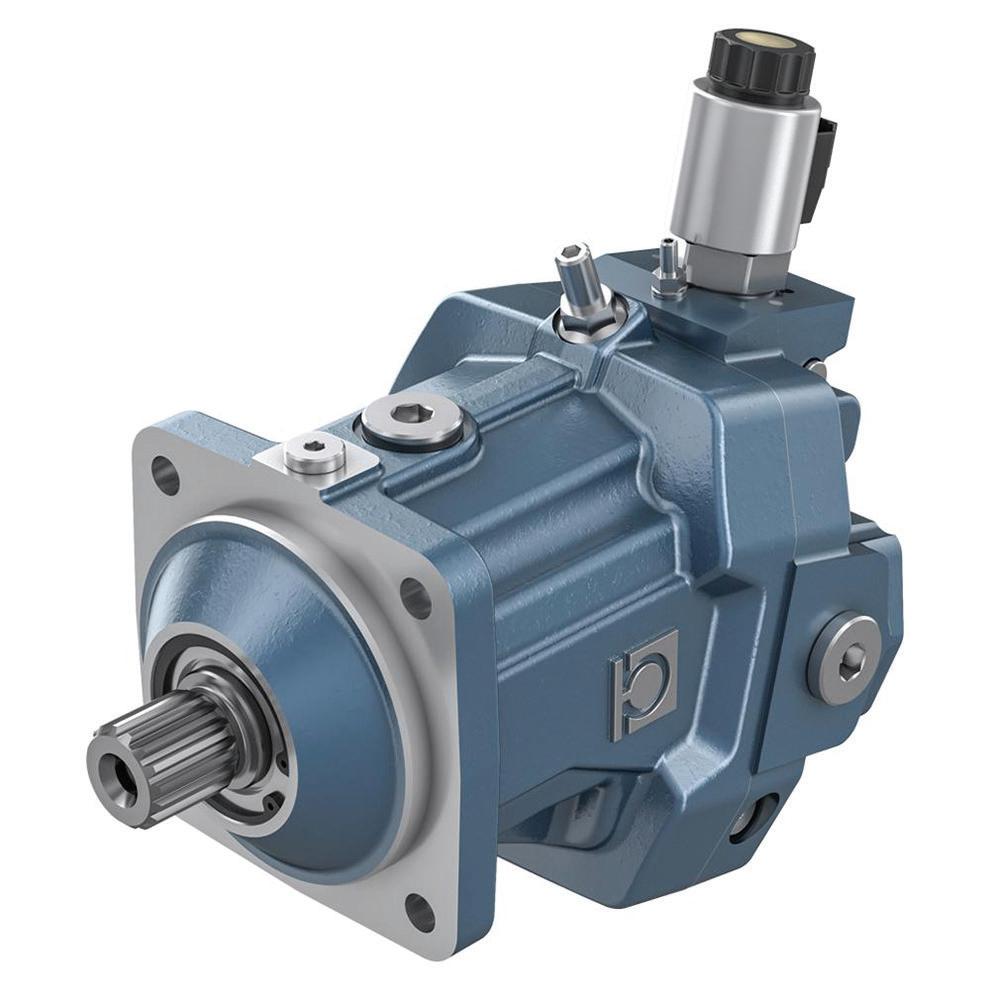

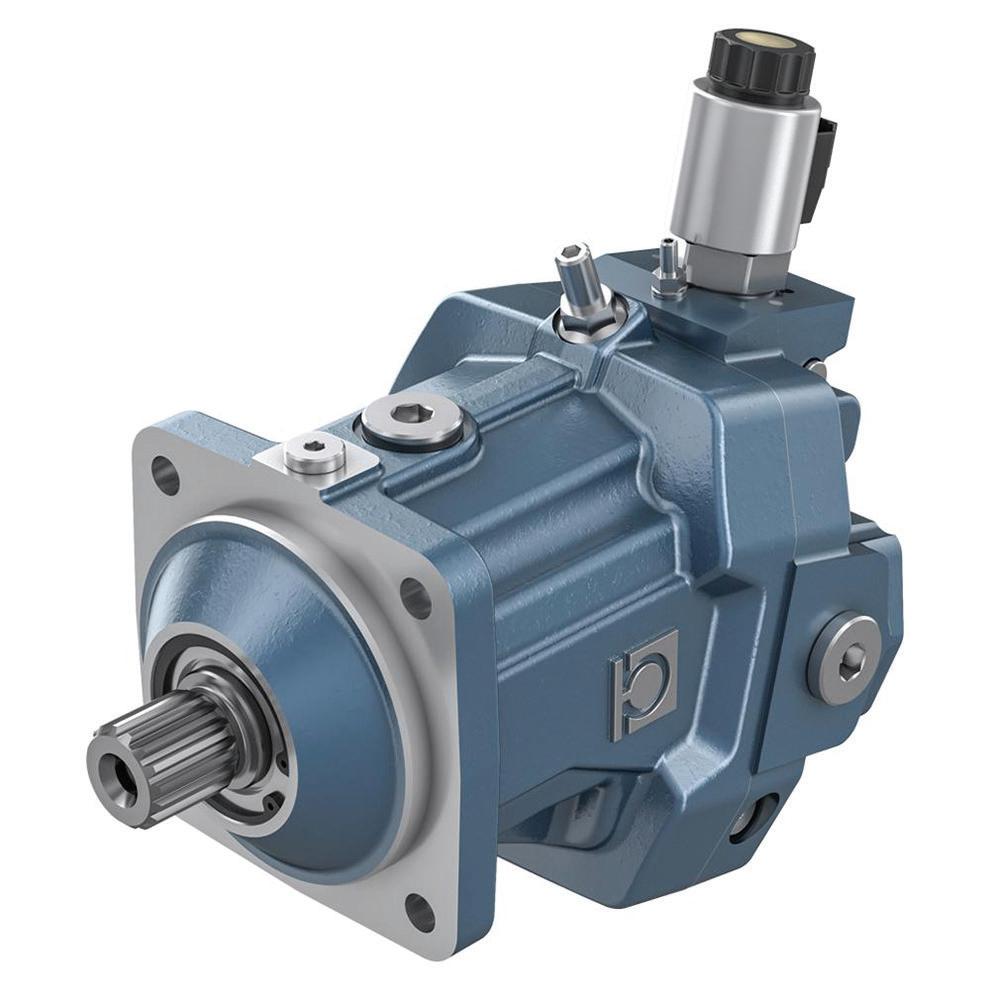

Kawasaki is a world-leader in pump efficiency and performance. Inside our range of products you’ll find some of the most efficient axial piston pumps available on the market today. Our engineers understand our customers’ needs, each pump has been designed to deliver high performance across a diverse range of applications.

allowed the vehicle to control pitch and roll angles and body height during the vehicle’s walking cycle. In addition, the AFSV was developed for autonomous behaviors, including recovery gait, putting the body on the ground, leveling the body independently of the terrain, and using an autopilot system.

Kyntronics provided three configurations of actuators based on the force and speed requirements of the specific leg joints — the coxa, femur, and tibia joints. The actuators were integrated with RMD’s gait engine control software, which uses position and force feedback from the actuators to control the vehicle’s legs and body.

The coxa actuator was responsible for rotating the leg around its vertical axis (analogous to the hip joint). A linkage was used to transform the 6-in. stroke of the actuator into 180° of rotation.

The femur actuator was installed on the leg and on its side to reduce the vehicle’s overall thickness. By installing the femur actuator inside the coxa structure, RMD reduced the inertia of the leg, improving walking performance.

The tibia actuator was installed in the last active leg joint. The tarsus joint, attached to the foot, was driven by a bellcrank mechanism that kept the foot perpendicular to the ground without requiring active control. A position sensor was mounted on the side of each actuator to provide rod position feedback. Position sensor data was used to calculate the overall pose of the leg. The force in each cylinder was also monitored to ensure that the loads on the legs were maintained within safe limits.

Kyntronics SMART Electro-Hydraulic Actuators installed on these three critical leg joints delivered the force density and durability of a hydraulic solution while being energy-efficient and eliminating leak risks inherent with hydraulics. Additionally, the valving inside the Kyntronics actuator allowed the actuators to hold a static load without consuming any power. FPW

18 FLUID POWER WORLD 12 • 2022

Kyntronics kyntronics.com DESIGN NOTES Kawasaki Precision Machinery (U.S.A.) Inc. • Grand Rapids, MI • www.kpm-usa.com • 616.975.3100

K3VLS Open Circuit Piston Pump • 50, 65, 85, 105 and 150cc displacements • 280 bar continuous pressure rating • 350 bar peak pressure rating • Load sensing, torque limiting, power shift and electronic displacement controls ASSEMBLED IN THE U.S.A. SAE Keyed Shafts Available Connect with thousands of engineering design professionals online.

THINK? WHAT DO YOU

By Josh Cosford • Contributing Editor

By Josh Cosford • Contributing Editor

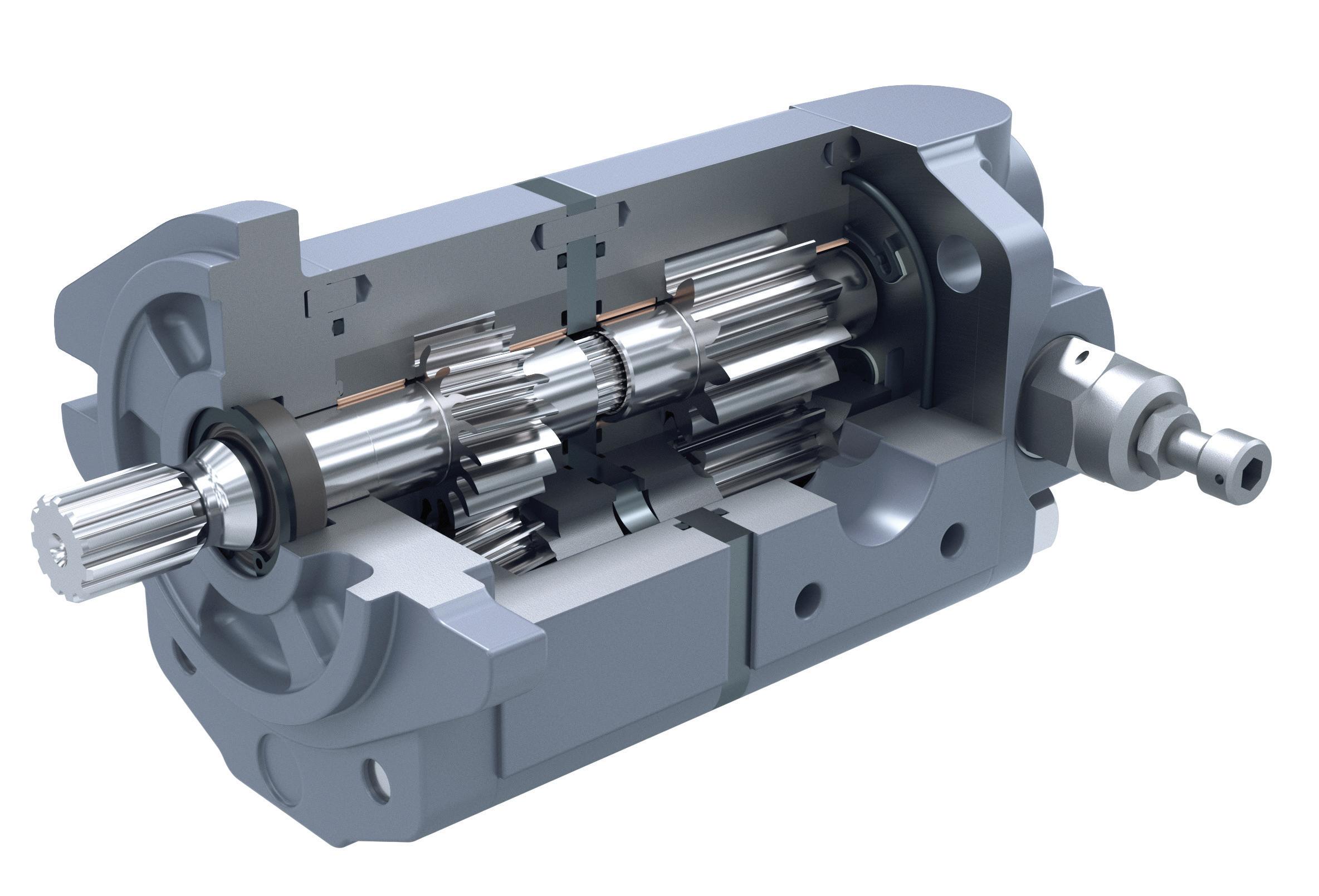

Piston pump technology ensures power and effi ciency

Axial-piston styles

The fixed-displacement piston pump offers designers a relatively inexpensive entry point to the piston pump. They provide reliable, high-pressure fixed flow for open-circuit hydraulic systems with no fancy controls. However, the control options available to piston pumps offer many clever tactics to control your hydraulic system, from pressure compensation to electrohydraulic proportional control with onboard pressure transducers.

or decrease displacement as required by the compensator as directed by the control piston. As a result, the control piston moves in the same axial plane as the rotating shaft, serving up a compact and powerful package.

Bent-axis piston technology

A hydraulic pump is literally the heartbeat of your hydraulic system. If you’re new to hydraulics, you’d be surprised at how many ways you can push fluid under pressure. The rotating and/or reciprocating of gears, vanes or pistons offer a designer constrained by any performance or budget envelope the options to best suit any application, especially since each of the primary pump construction styles offers unique options within each series.

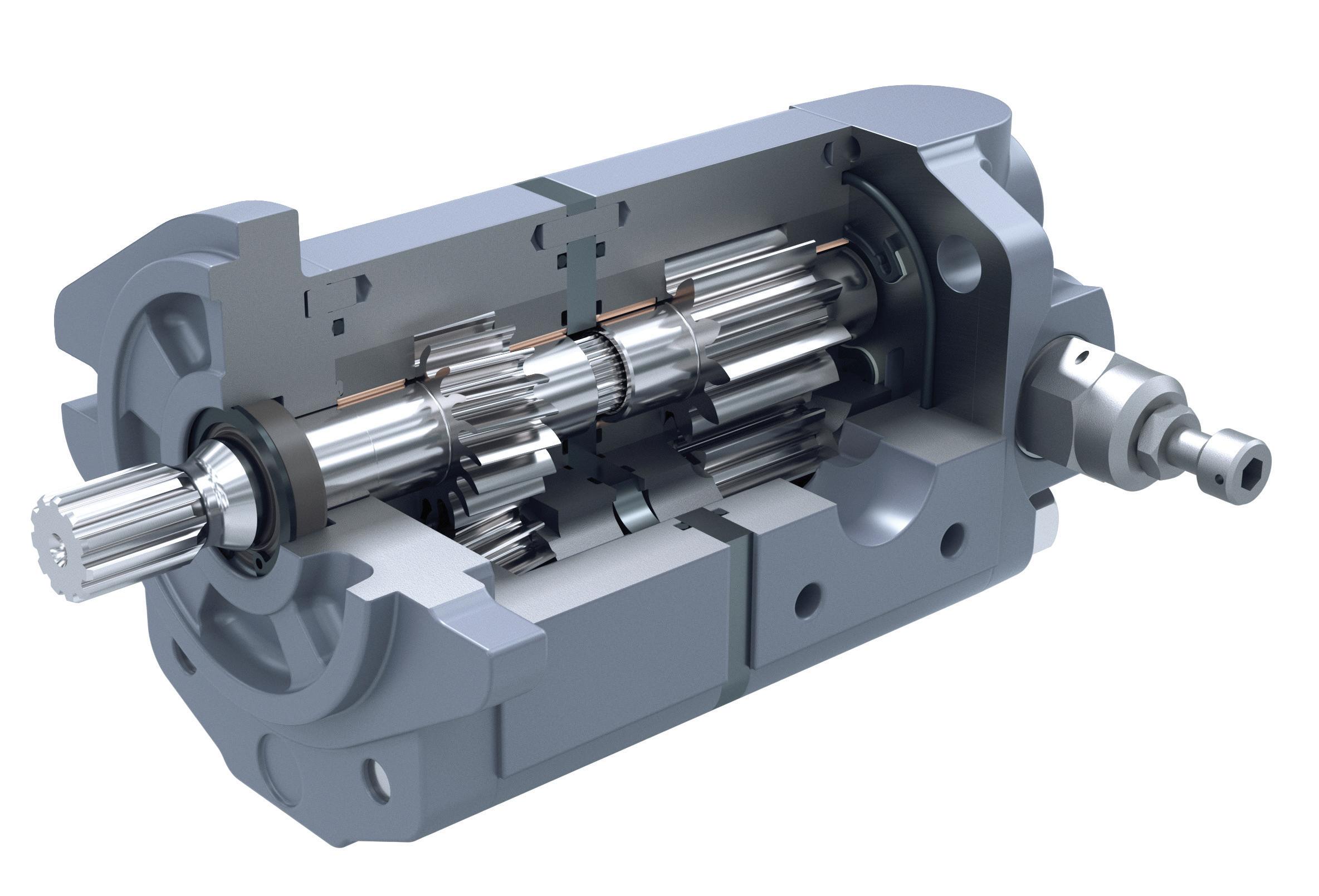

Piston pump technology exclusively employs axially or radially reciprocating pistons relative to the input shaft. Fixed and variable displacement pumps are offered in all three primary construction variations — axial swashplate, bent-axis and radial. For both axial and bent-axis piston pumps, you will notice their pistons reciprocate in parallel as the rotating group orbits the shaft. Radial piston pumps look more like old wartime engines from aircraft, with their pistons reciprocating perpendicular to the input shaft. Although the most complicated design, piston pumps enjoy power and efficiency not possible in gear or vane pumps.

A pressure compensator is a relief valve for the control piston of the variable-displacement pump. The compensator is a very low flow component that essentially controls the swashplate angle to modify displacement in such a way as to maintain a set pressure. Any downstream flow demand lowers pressure drop at the pump, causing the pump to increase flow to maintain pressure. So long as downstream flow demand does not exceed the pump’s maximum flow rate, the pump can compensate and remain at full pressure. However, any flow exceeding its maximum rating will be subject to the downstream actuators’ load pressure. Manufacturers offer various forms of displacement and pressure control. For example, load sensing control allows the pump to read downstream load pressure signals to reduce flow during off-demand periods and at reduced pressure equal to a few hundred psi higher than the highest load. A step further, you’ll find horsepower limiting (sometimes called torque or power limiting), which provides the machine maximum flow and pressure so long as the total demand is less than the prime mover’s capacity. Should a machine, such as an excavator, demand higher flow and pressure than the engine can supply, such as when multiple high-pressure actuators are simultaneously activated, the pump will automatically restrict flow to reduce the total power required.

Regardless of compensator type, each variation achieves its result by varying only the swashplate angle. For axial piston pumps, the swashplate pivots to increase

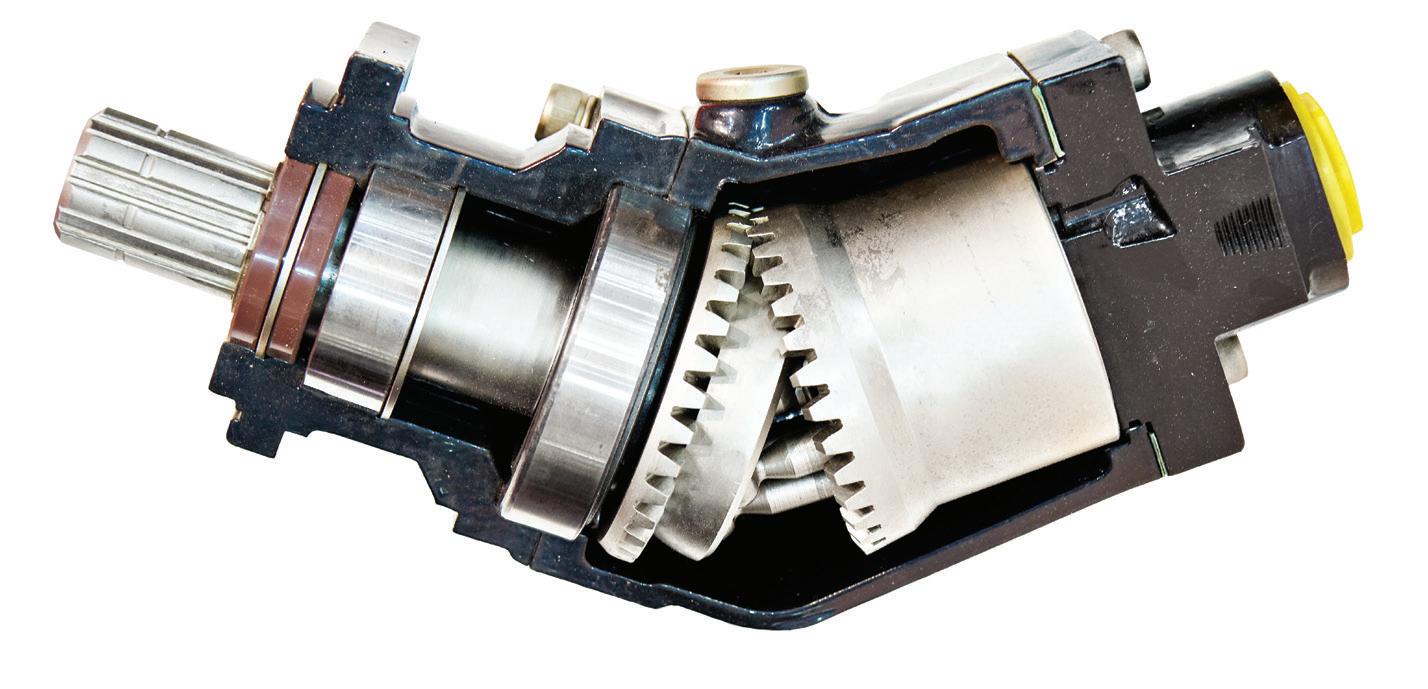

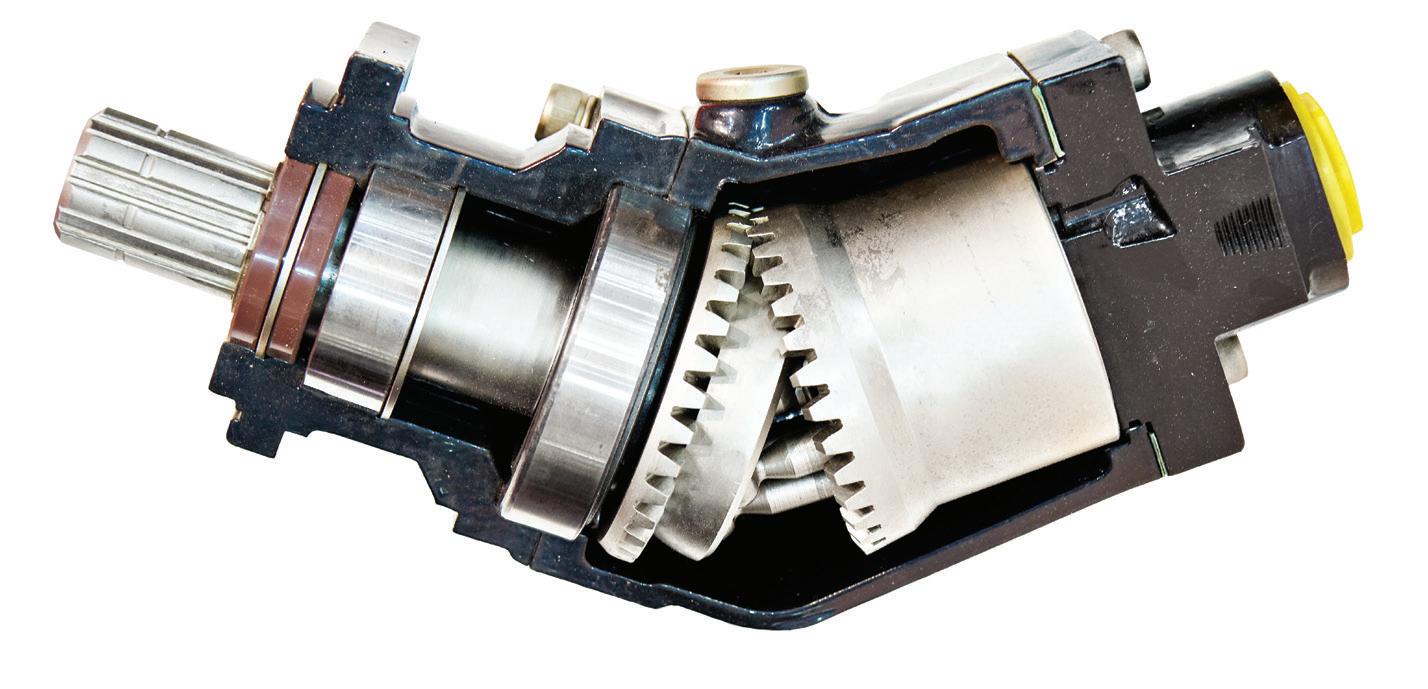

Although axial piston pumps are easily the most popular, other piston pump designs are offered with variable displacement. You may be aware of the bent-axis piston motor (Figure 1), which is famous for its high power and high-speed reputation. Its shaft and bearing assembly rotate at a taper relative to an axial piston motor. Despite their high-pressure design, the bent-axis configuration offers 25% higher rotational speed than straight-axis motors, and their bearing design is better suited to pulley or gear-driven applications. The force vector from a gear or pulley must oppose the bent direction of the motor (Figure 2), much like your arm pulling against a surgical band from underfoot to do bicep curls.

The tapered, oversized roller bearings inside a bent-axis piston motor provide superior side load protection to resist the steeply angled rotating group side load. For example, a swashplate on an axial piston motor may allow a maximum of 15-22° angle, while the bent axis piston motor

The radial force applied to a bent axis piston motor must originate from the opposite direction of the bend. This opposing orientation balances the forces created by the pistons pushing against the rotating group on an angle.

20 FLUID POWER WORLD 12 • 2022 www.fluidpowerworld.com

FUNDAMENTALS

Bent axis variable displacement axial piston motors.

1 2

| Courtesy of Bondioli & Pavesi

φopt = 45º φopt = 45º

1 “Clockwise” rotation, pressure at port B

2 “Counter-clockwise” rotation, pressure at port A

operates at 40° or more. This extreme angle allows the motor to achieve high displacement in a small package, resulting in a high radial load on the input shaft. Resisting these side loads requires the heavy-duty tapered bearings like those you see in Figure 3 and explains the necessity to pull from the opposing direction as the motor angle.

The same benefits of the bent-axis piston motor apply to its pump kin. Superior power density, high-speed operation and high resistance to radial load make these the top choice for mobile hydraulic designs driven directly by diesel or gas engines. In addition, their inherently robust design makes them the top choice for gear or pulley-driven pump applications (as long as the installation recommendations are adhered to). Although the tapered roller bearings provide high side-load resistance, because the bearings are loaded to remove excessive clearances, excessive wear may occur. As a result, you’re more likely to replace the bearings on a bent-axis piston pump than in other designs.

You may be surprised to know that variabledisplacement bent-axis piston motors are offered by manufacturers. Unfortunately, their appearance doesn’t seem to offer any place to mount any useful swashplate angling device. Their construction varies significantly from a swashplate variable-displacement pump, where instead of varying swashplate angle, the entire lens plate slides up and down inside the port plate.

A stroke piston opposed by a bias spring and control piston works much the same as in an axial piston pump. The compensator receives a pilot signal from the pressure port to balance the pressure drop at the pump’s outlet, varying the angle of the rotating group as required to maintain pressure.

The leading manufacturers of piston pumps offer most, if not all, control options for

their bent-axis piston pumps. Basic pressure compensation with no other function often goes by pressure cut-off in product literature (or pressure override). The basic pressure cutoff control simply observes outlet pressure and adjusts the swashplate angle to alter flow rate, thereby maintaining a set pressure drop. So long as system demand is less than maximum flow, the outlet pressure remains at compensator set pressure. However, should demand rise above maximum pump flow, your circuit is at the mercy of the path of least resistance.

To be honest, selecting a pressurecompensated bent-axis piston pump for anything other than high-speed belt or pulley driven applications is an expensive bit of overkill. The control devices of variable-displacement bentaxis piston pumps are often quite advanced; you can expect various advanced controls such as horsepower limiting, hydraulic proportional control or even electro proportional control. I’m aware of one particular manufacturer that offers no less than seven kinds of horsepower-limiting controllers for one pump!

Proportional pump control uses proportional pressure-reducing valves in place of standard pressure compensators. For example, imagine a bent-axis piston pump where the spring offset stroke piston fights against spring pressure by infinitely varying the pressure inside the control side of the piston. Precise pressure observed by downstream transducers offers a closed-circuit feedback loop for the machine controller to adjust the proportional valve setting to match the desired outlet pressure. Some pumps may even take it a step further to include a linear transducer to provide precise displacement feedback, guaranteeing your circuit precise output flow and pressure despite fluctuations from the load, temperature, or viscosity.

With so many pump options on the market, do we really need so many advanced options for a single pump style? My vote is yes because the bent-axis piston pump offers unique advantages over other designs.

| Courtesy of Adobe Stock

The variety of control options available ensures that your system, no matter how complex, has the pump design you need. FPW

www.fluidpowerworld.com 12 • 2022 FLUID POWER WORLD 21

CFCINDUSTRIALTRAINING.com 7042 Fairfield Business Drive Fairfield, Ohio 45014 +1 513.874.3225 info@cfcindustrialtraining.com UPSKILL YOUR WORKFORCE! ONSITE AND CERTIFICATION FOR: TRAINING CFC provides direct, Industry and/or Machine-specific training to companies the world over. Electrical Techs & Engineers Hydraulic Techs & Engineers Pneumatic Techs & Engineers Our Hands-On Training Equipment is mobilized directly to your facility with Certified Instructors traveling on-site. This turnkey approach includes all books, materials, equipment, and travel arrangements. We have the capability to upskill your entire workforce NOW! Multicraft Techs & Engineers

Cross section of bent-axis piston pump highlights the bearings used to resist side loading.

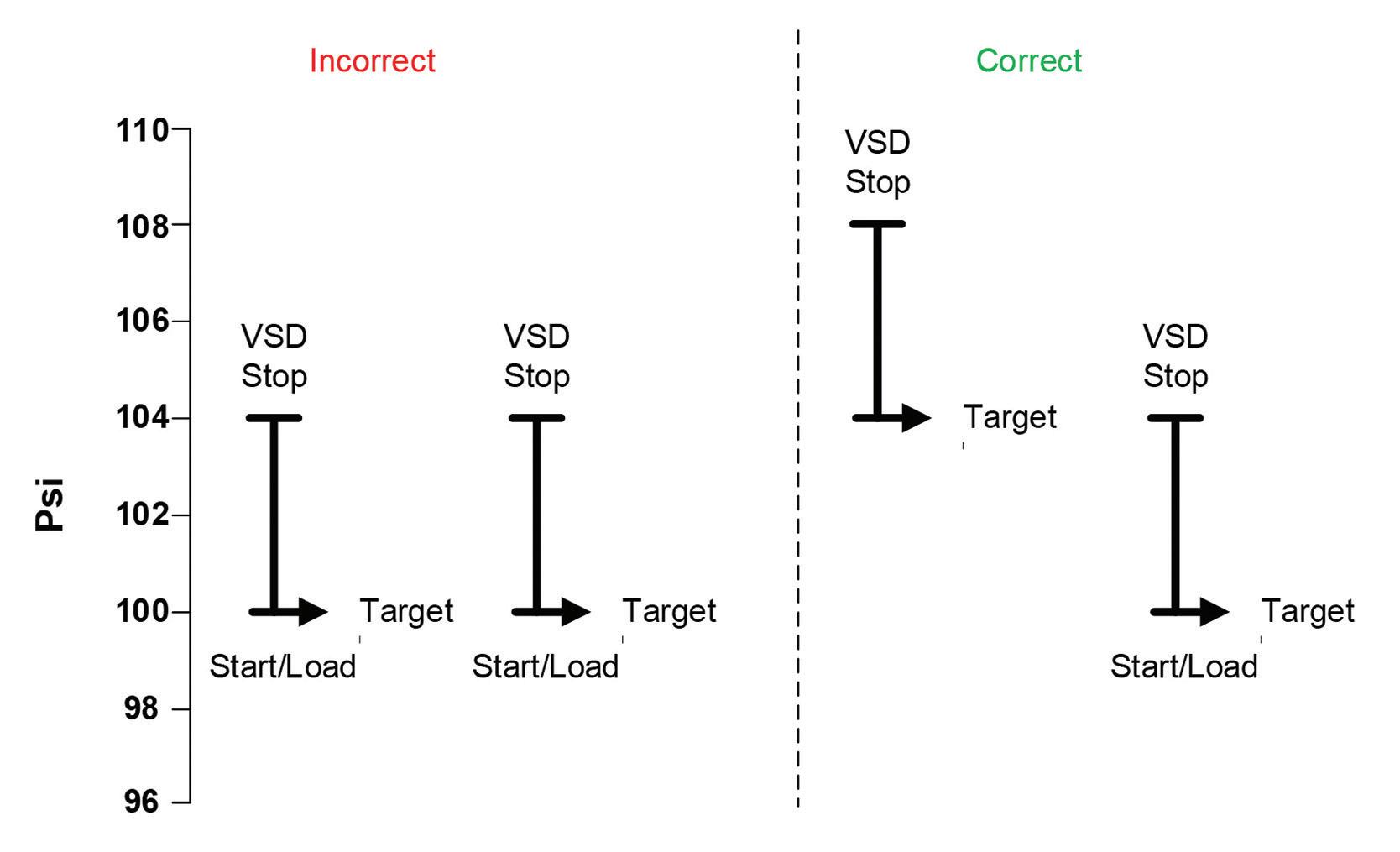

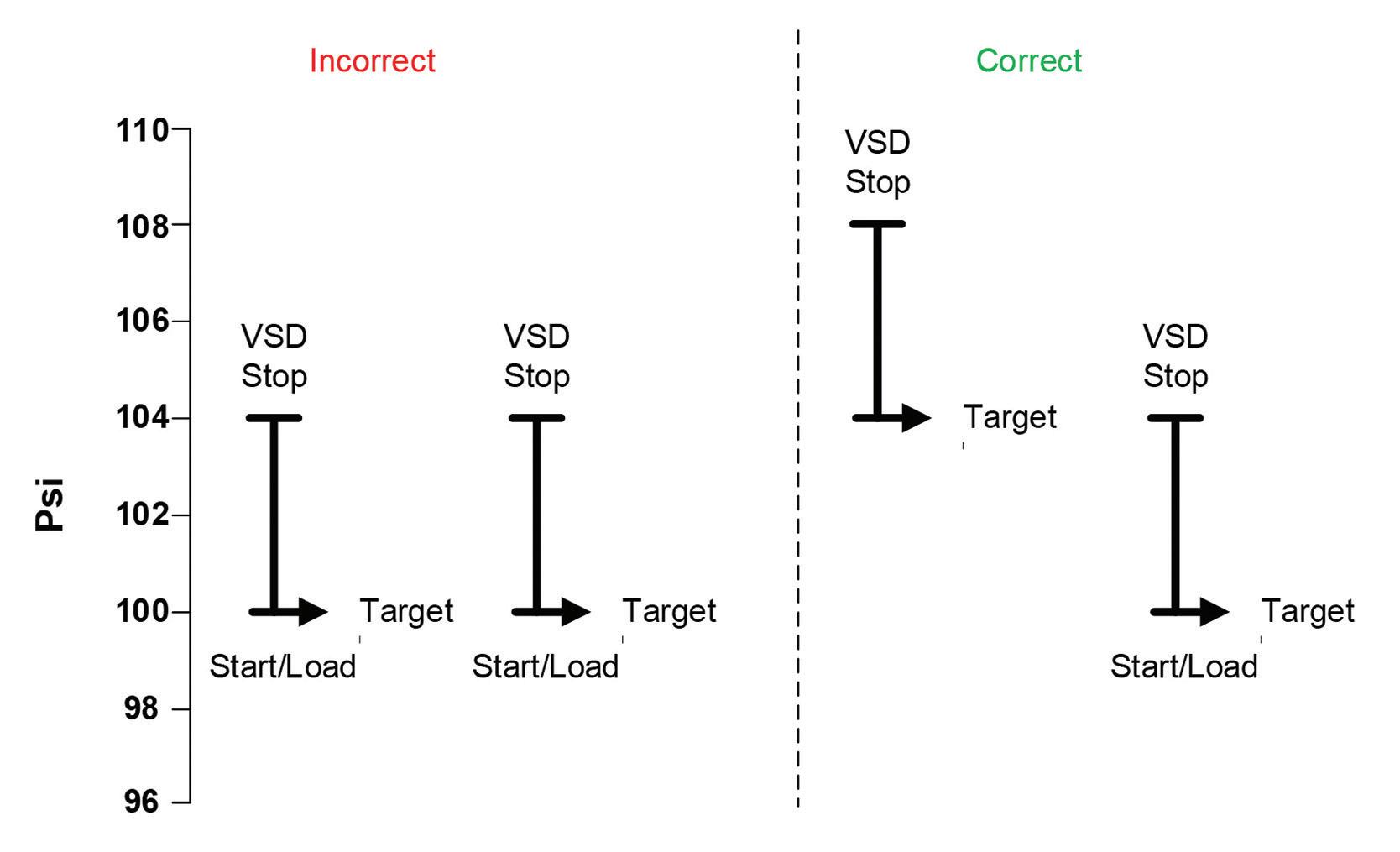

Are two VSD compressors a problem?

Question: I’m a compressor salesperson. Lately, the large building tenders we’ve seen have been spec’d for two variable speed screw compressors to run together sharing the load. This would make sense to me if one was a 100% backup and they never ran together, but that does not seem to be the case. Everything I’ve ever learned about multiple compressor systems indicates that two variable speed units running together will cause issues.

At the time of our quote, there was no way to get back to the actual decision maker and if we quoted any other configuration, it would be up to the contractor to sell it … and we know that isn’t going to happen …

Clearly, we need to do a better job of getting with the local engineering firms so we can be doing the spec’ing, but I’m just wondering about your thoughts on this situation that we’ve kind of been forced into.

Answer: Yes, any compressed air system really needs only one properly sized VSD, but it drives maintenance guys crazy if one compressor gets all the hours — while the other gets minimal run time, which needs to be the case with a mix of VSD and fixedspeed compressors.

So, the result is often the purchase of two or more VSDs. It is possible to run efficiently with two variable compressors, but the settings need to be adjusted so the control points are stacked. This way, you don’t have two VSDs running together at part load, which can happen (for example two units running at 25% instead of one at 50%). VSDs running at low speeds are inefficient and can cause internal condensation problems and high oil carryover.

But, even with this, the compressor with the highest setpoint will get the

majority of hours. Some manufacturers have two sets of pressure setpoints that can be programmed into the compressor controllers, and even set on time schedules. This can be used to easily to swap settings, and still maintain compressor coordination, if operators want to change which compressor is in the lead position.

I’m unsure what can be done about the poor specifications, I can only hope your tender writers are reading this. FPW

It is poor practice to run two VSD compressors sharing the load. This leads to inefficient operation where both are running in an inefficient part of their control bands. Stacking the pressure settings solves this problem.

Ron Marshall • Contributing Editor ENERGY EFFICIENCY

22 FLUID POWER WORLD 12 • 2022 www.fluidpowerworld.com

Contributing to Your Success STAUFF Corporation 201.444.7800 STAUFF Canada Ltd. 416.282.4608 stauffusa.com We offer thousands of critical components designed to help our customers operate more efficiently. Look to STAUFF for Quick Couplings, Clamps, Hydraulic Filters, Test Points and many other components to keep machines—big and small—moving you forward. Contributing to Your Success

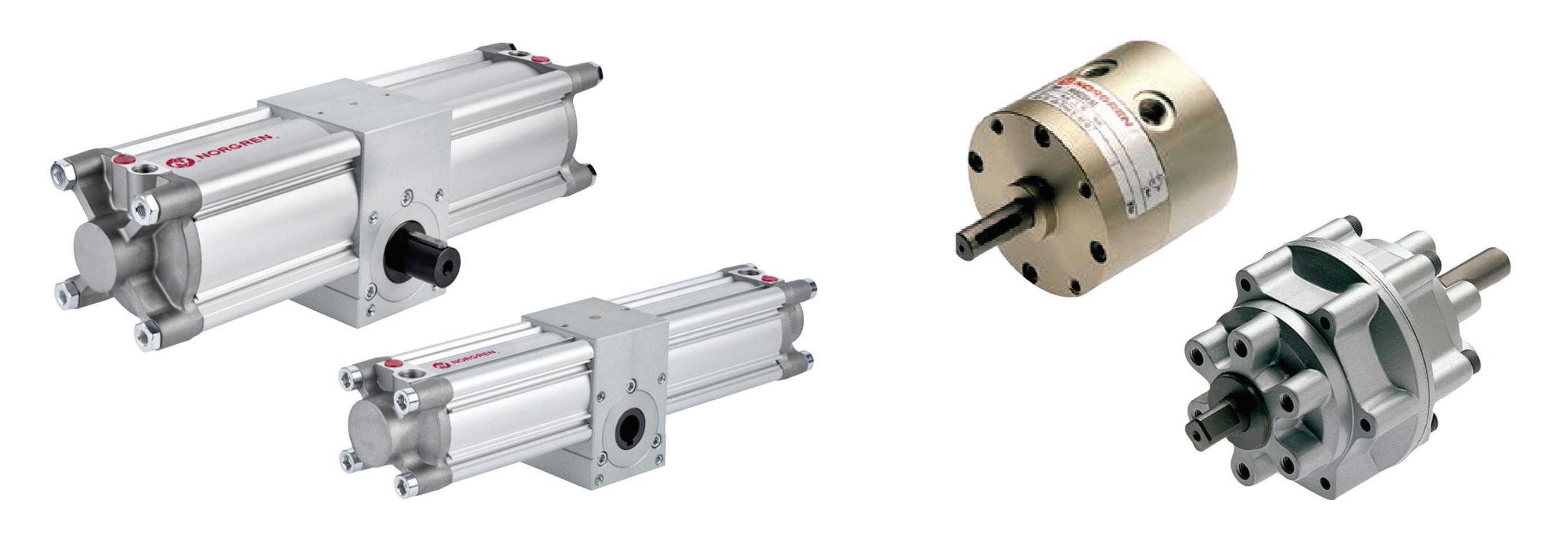

An introduction to

pneumatic actuators

By Dietmar Grün, Product Manager, Motion Control, Actuator, Norgren

By Dietmar Grün, Product Manager, Motion Control, Actuator, Norgren

24 FLUID POWER WORLD 12 • 2022 www.fluidpowerworld.com PNEUMATICS

Pneumatic systems harness the energy generated by the controlled release of compressed air to power and move tools and machinery used in the engineering, manufacturing, construction, medical, and amusement industries and are especially prevalent in industrial automation and food, beverage, and pharmaceutical manufacturing applications. Pneumatic systems use air compressors to reduce the volume of air in the system, which increase its pressure and then pass that pressurized air through one or more filters and lengths of pneumatic tubing, where it’s controlled by valves, until it reaches a pneumatic actuator. The actuator produces the linear or rotary motion and force required to power the end process, such as a pushing, lifting, gripping, punching, or vacuum device.

Pneumatic actuators provide alternatives to electric actuators and motors and are typically used to power devices that handle relatively small, lightweight loads since pneumatic systems produce less force than hydraulic systems. But that doesn’t make these systems any less vital to the many industries they’re employed in. In fact, due to a combination of the relatively low cost required to maintain pneumatic systems and engineering advancements including corrosion-resistant seals that help prevent leaks, the application range for pneumatic systems is now comparable to that of the electric automated systems also used to handle smaller loads.

www.fluidpowerworld.com 12 • 2022 FLUID POWER WORLD 25

Learn what are the key considerations for selecting the right pneumatic actuator for your unique application.

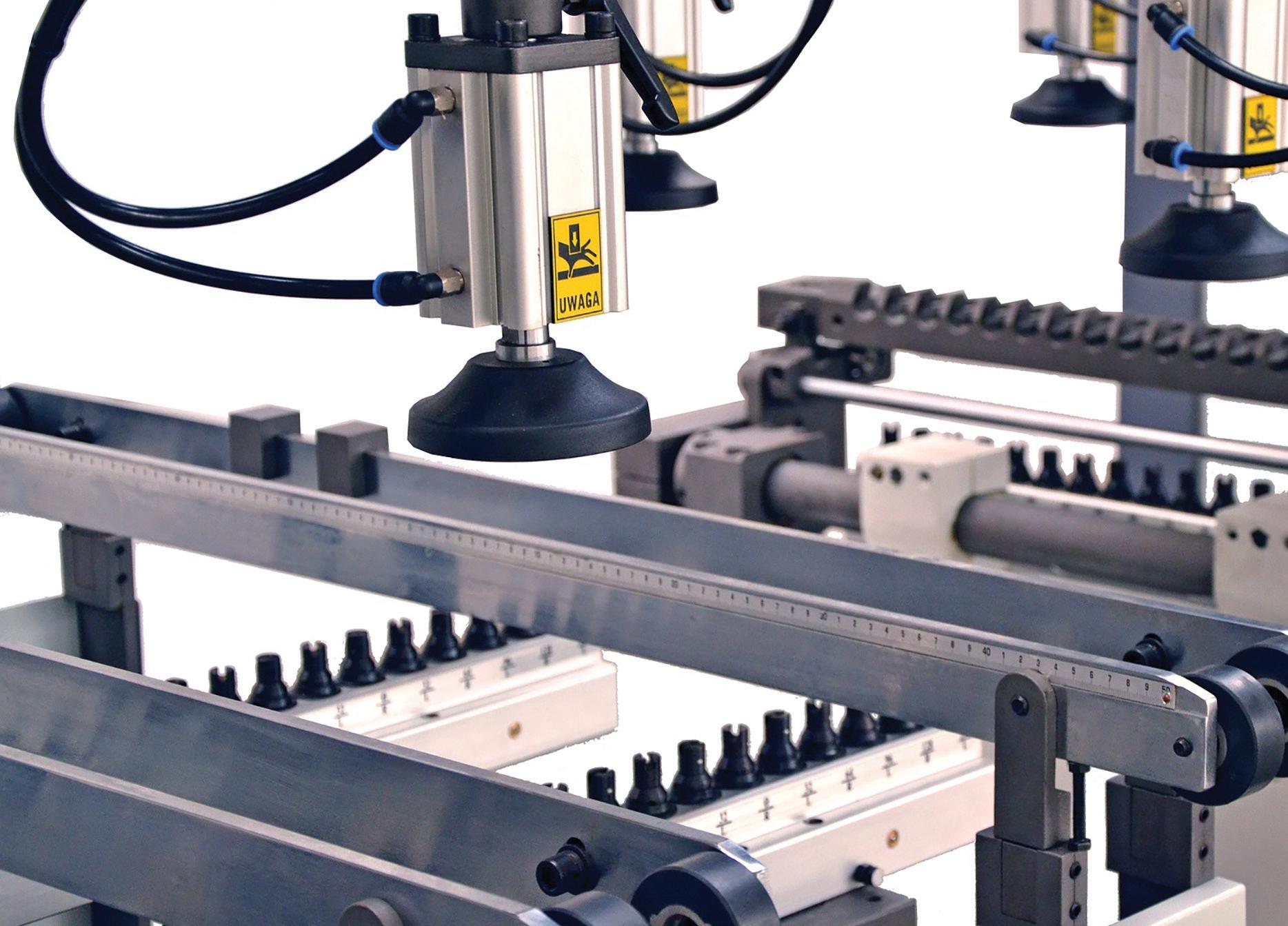

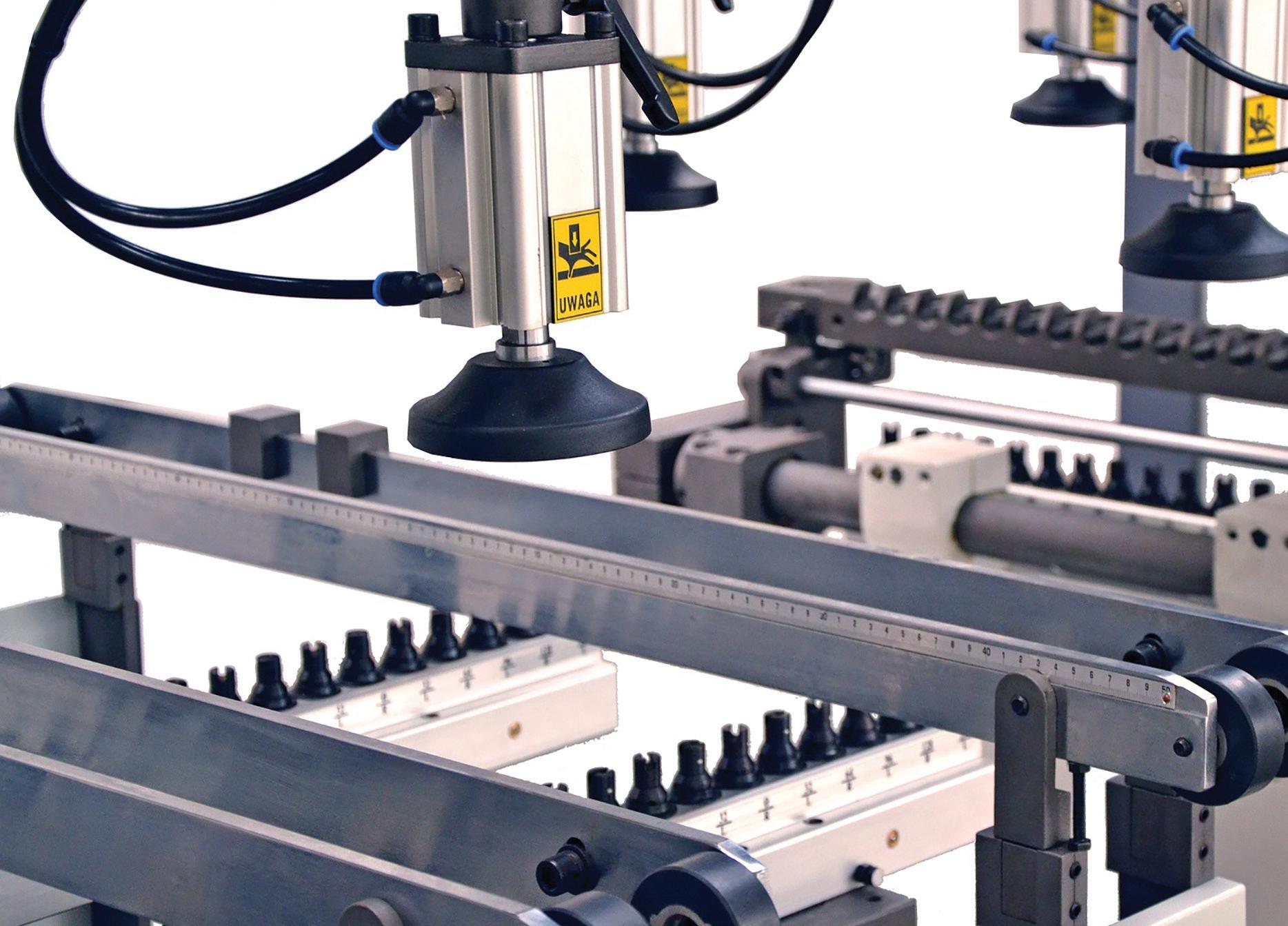

Industrial automation applications often employ material handling solutions like pick and place equipment. The automated process pictured here features pneumatic actuators equipped with vacuum cups that can grip and move delicate items like glass.

Pneumatic actuators

Pneumatic actuators, also known as pneumatic cylinders, are the business end of a pneumatics system. When compressed air is forced into an actuator, it moves the piston housed within it and generates the linear or rotary motion and force required for the end device attached to the piston — such as a pushing, lifting, gripping, punching, or vacuum mechanism — to do its work. Pneumatic actuators are lightweight, require little maintenance, can be used in challenging environments exposed to extreme temperatures and corrosive materials and are widely available in National Fluid Power Association (NFPA-) and ISO-compliant models for international compatibility. Their bore, or their inner diameter,

determines their output force, and the larger the bore, the greater the force. They do produce less force and operate at slower speeds than hydraulic or electric actuators, but they remain a popular, cost-effective alternative to those technologies.

The key components of a pneumatic actuator include an end cap, a piston, a piston rod, a cylinder barrel, a wiper seal, and a cushion sleeve and seal. In a simple circuit, a singleacting pneumatic actuator can be operated by a button. When the button is pressed, the

compressed air moves the piston rod outward to generate the required linear or rotary motion and force needed to operate the end device, like an arm that moves a load along a linear path, a gripper that picks and places a component, or a vacuum cup used to handle glass.

Types of pneumatic actuators

Several types of single- and double-acting pneumatic actuators are engineered to suit many different applications.

Single-acting pneumatic actuators have a single air-entry port and push the piston in a single direction. The piston is returned to its original position by a spring. They have a limited stroke length, which makes them ideally suited for slower moving operations, and they use less air than double-acting actuators, which helps increase efficiency and reduce operating costs.

Double-acting pneumatic actuators have two air-entry ports, which enables them to execute both an instroke and an outstroke and move the piston back and forth without the use of a spring.

Tie-rod actuators are the most prevalent actuator design in the pneumatics industry and are widely used in heavy-duty

and high-temperature industrial automation applications.

Square or rectangular end caps are secured to the barrel by threaded tie rods and nuts. They are equipped with static seals to prevent air leakage and are available in standard, compact, and lightweight variations. They are also available with profile barrels — which feature concealed tie rods, enable direct assembly for flush-mounted switches, and offer a cleaner appearance — and round barrels, which feature exposed tie rods, are available in a wide variety of configuration and mounting options, and can easily be adapted to solve difficult actuation challenges.

Welded actuators are lighter and more compact than the standard tie-rod configuration and, as such, are widely used in lighter duty and lower force applications including mobile equipment. Instead of tie rods, these pneumatic actuators feature barrels welded directly to the end caps and ports welded to the barrel. Their front rod glands are generally bolted or threaded into the cylinder barrel to allow the piston rod assembly and rod seals to be removed for service and they typically come with fixed or buffer cushions, although some models offer adjustable cushioning upgrades.

PNEUMATICS 26 FLUID POWER WORLD 12 • 2022 www.fluidpowerworld.com

Norgren ’ s ISOLine actuators conform to the latest ISO 15552 standard and are available in both profile (front) and tie-rod options (back) as well as in ISO-6432-compliant versions optimized for highly corrosive environments. They also feature Norgren ’ s Adaptive Cushioning System and are in stock at Allied.

Norgren offers rotary actuators in rack and pinion (left) and rotary vane variants (right).

Compact actuators are designed for applications where space is at a premium and are available in a variety of options. Norgren, for example, offers compact pneumatic tie-rod, welded, and clamp actuators.

Clamp actuators are used to hold a workpiece in place while work is being done. They combine a standard pneumatic actuator with a clamp and a toggle mechanism and are often designed to exhibit robust resistance to weld splatter to ensure long lifetime performance.

Valve actuators generate linear or rotary motion to open and close valves. These pneumatic actuators are compatible with a variety of valves, including ball and butterfly valves.

Rotary actuators produce a reciprocating angular or turning motion that enables an oscillating stoke motion through a defined angle. These pneumatic actuators are available in rack and pinion, rotary vane, and helical options; feature simple, durable designs that reduce maintenance requirements; and typically deliver relatively high force (torque) for their size. Rotary vane actuators are small, selfcontained, double-acting actuators that take up less space than rack and pinion actuators but deliver lower torque. Rack and pinion actuators offer greater torque but can require a larger footprint to achieve certain angular motions.

Rodless actuators, unlike other pneumatic actuators, don’t have a piston rod that extends

outside of the cylinder body. Instead, these pneumatic actuators contain the movement they produce within the length of their cylinder body, which, also unlike piston rod cylinders, allows them to support the load during movement.

Key considerations for selection

Several key considerations can help you choose the right type of pneumatic actuator with the right physical and electrical characteristics for your unique application.

Type of motion: Pneumatic actuators can generate linear or rotary motion.

Single-acting or double-acting: Pneumatic actuators come in single-acting, springreturn, and double-acting, pneumatic-return variations, and selections will depend on the amount of force and accuracy required, as well as the size of the job.

Pressure and flow requirements: Remember, the larger the cylinder bore, the greater the force. Pneumatic actuators are widely available with bore sizes extending from 8 to 320 mm.

Operating environment: Several manufacturers offer pneumatic actuators designed to deliver robust, long-lifetime performance in environments exposed to hazards including extreme temperatures, corrosive materials, and dirt and dust.

Special features: If you’re looking to save energy, ensure that the actuator is right-sized and appropriate for the operation at hand and consider using an IVAC product. FPW

Allied Electronics | www.alliedelec.com

Norgren | www.norgren.com

12 • 2022 FLUID POWER WORLD

Norgren ’ s welded Roundline actuators are available in single- and double-acting versions with bore sizes spanning 8 to 63 mm and switch brackets that enable both standard M/50 reed switches and solid-state switches to be mounted on the outside of the barrel. They are also available in space-saving, corrosionresistant stainless steel, high-temperature, nonrotating, guided, double-ended piston rod and ISO6432-compliant versions and are in stock at Allied.

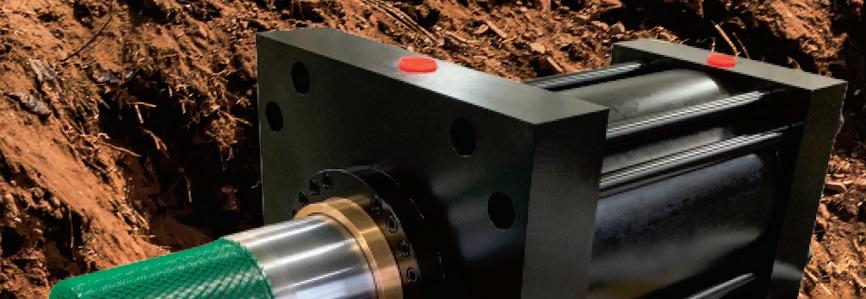

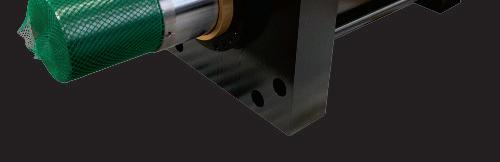

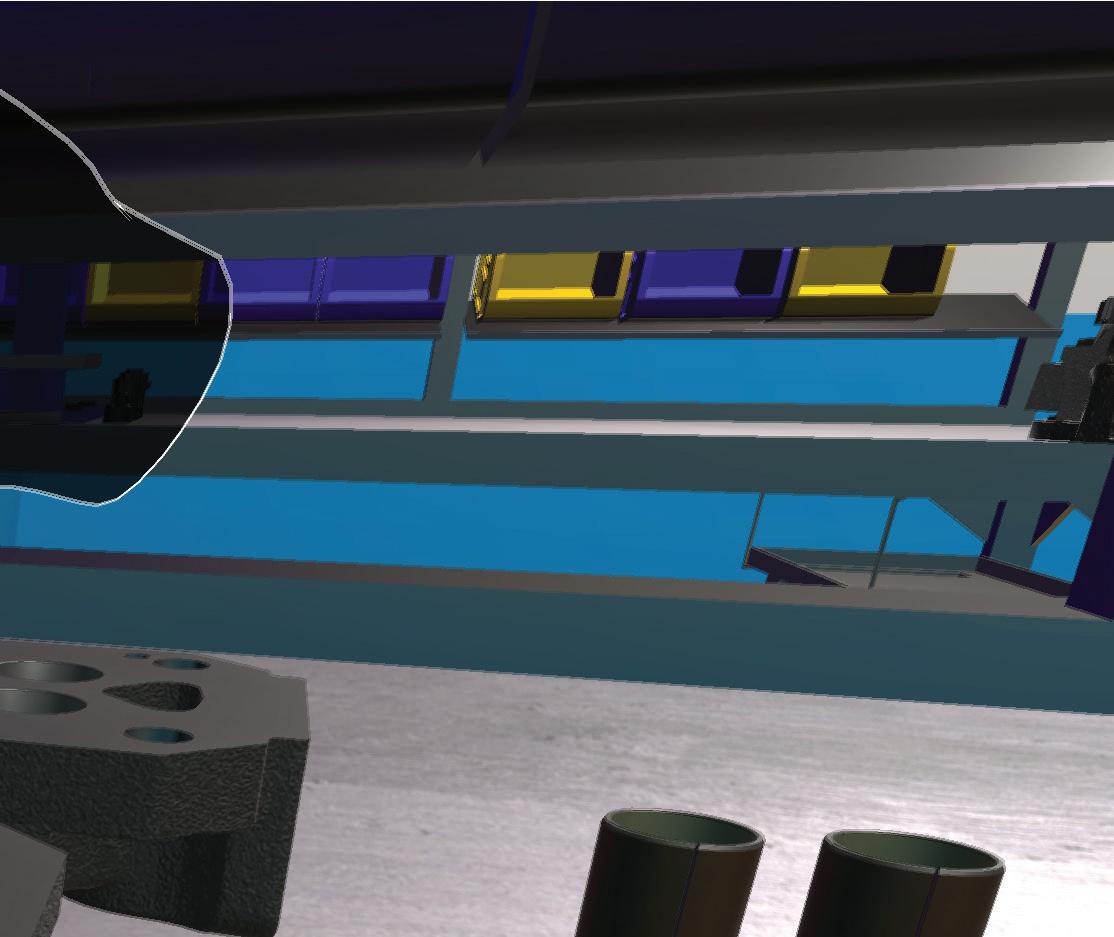

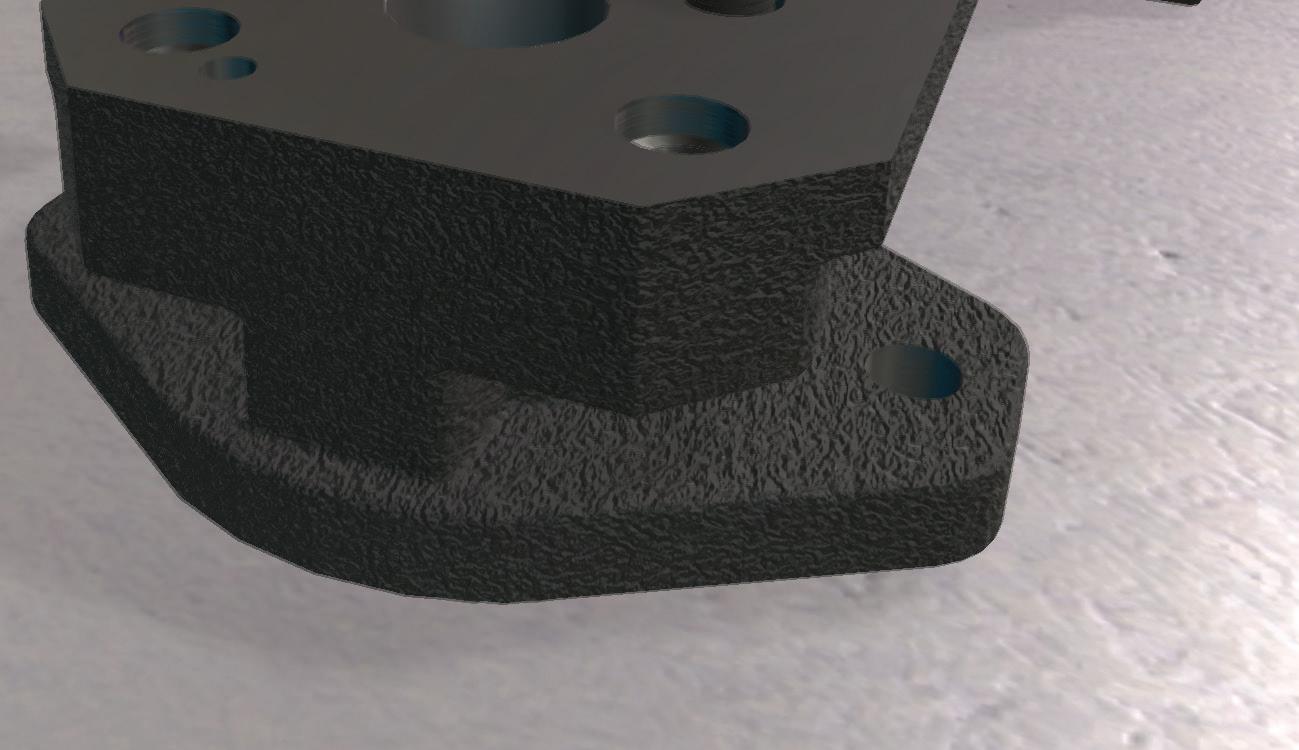

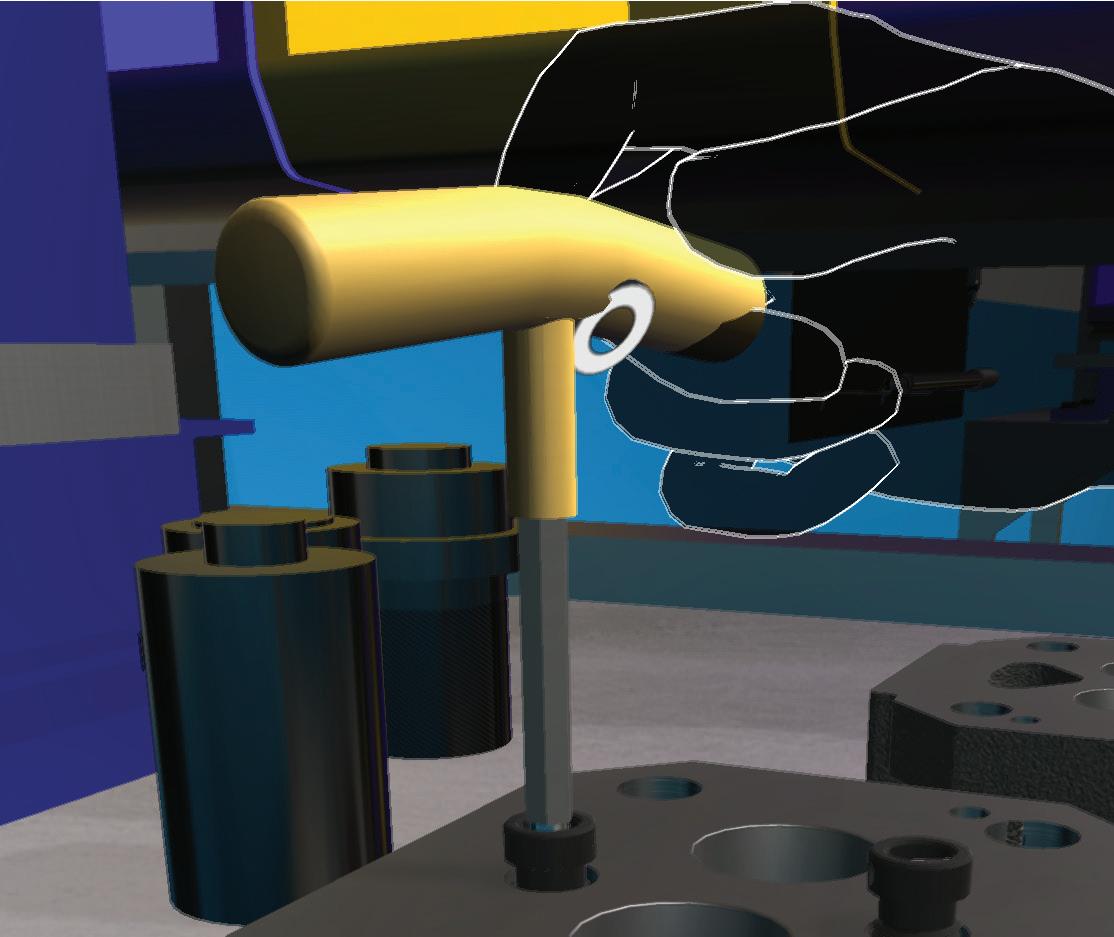

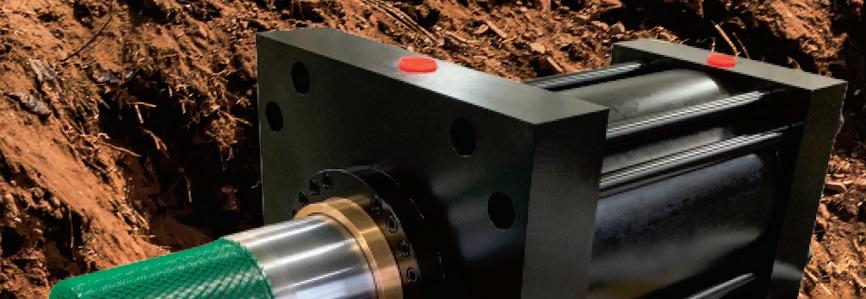

Refrigerator-sized hydraulic power units that don’t make a peep

By Rachael Pasini, Senior Editor

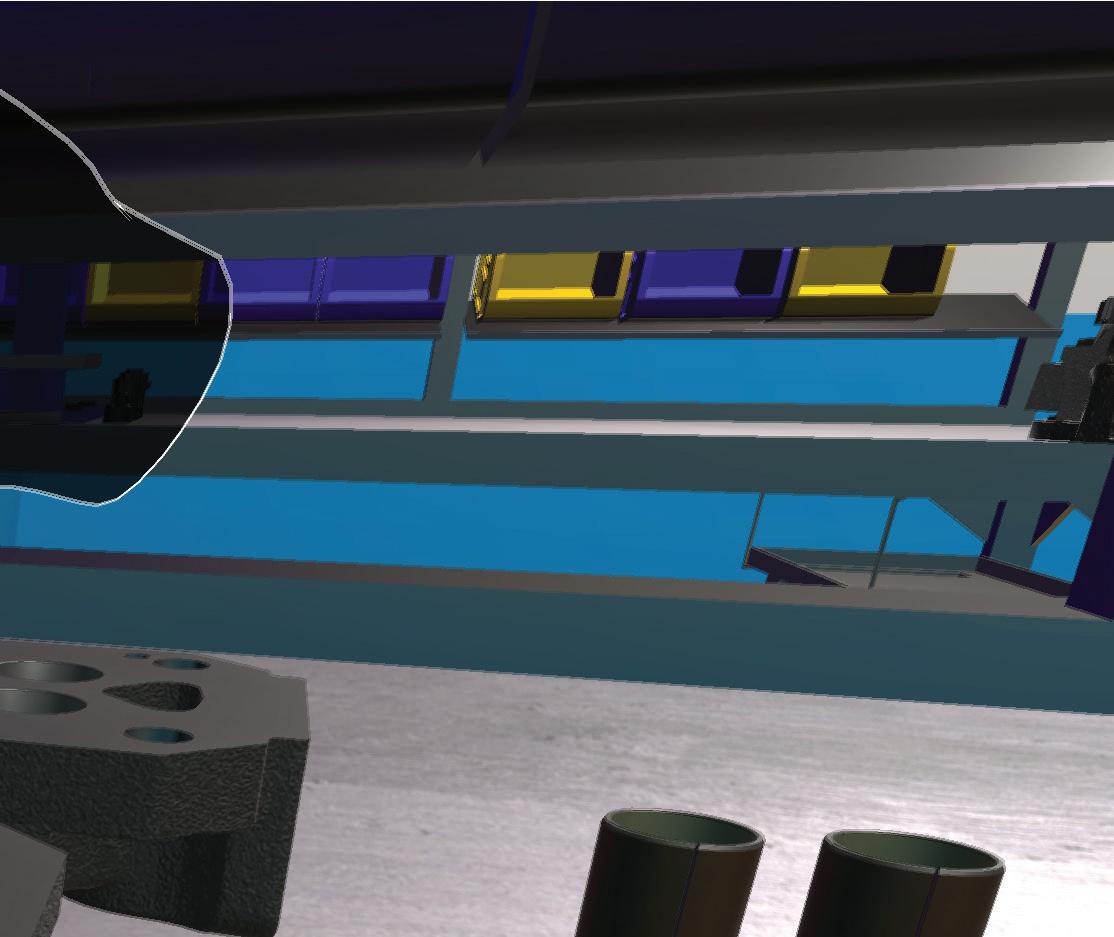

Thecommon perception of conventional hydraulic power units is that they are large, loud, and inefficient. Such claims are valid for facilities that still use power units from the 1960s and 1970s and among engineers unaware of the latest technology. However, the notion that hydraulic system designs are static in time is an outdated misconception. With the new CytroBox and CytroPac, Bosch Rexroth aims to educate machine builders on modern hydraulic power unit advancements and inspire a shift in perspectives.

The CytroBox and CytroPac defy traditional hydraulic power units with their compact, quiet, and energyefficient designs. They include small “smart” pumps and motors that only run when needed and at low torque when not in use. The smart pump and motor group reduces heat generation and makes the system run more efficiently.

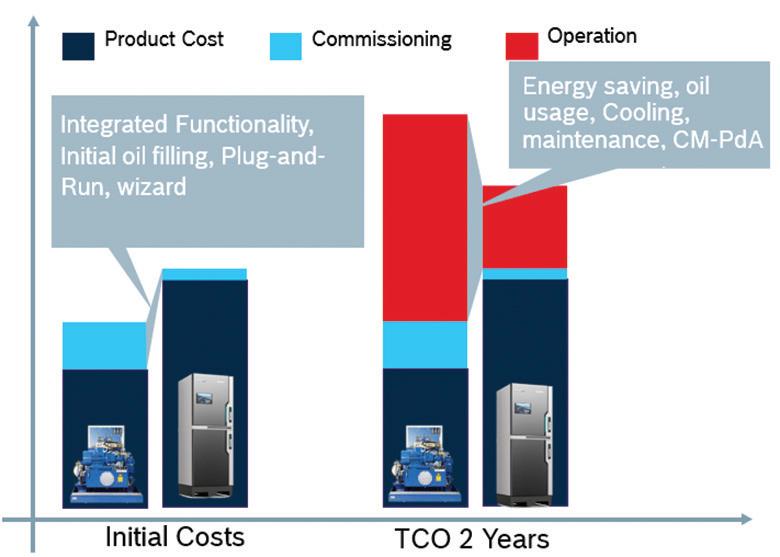

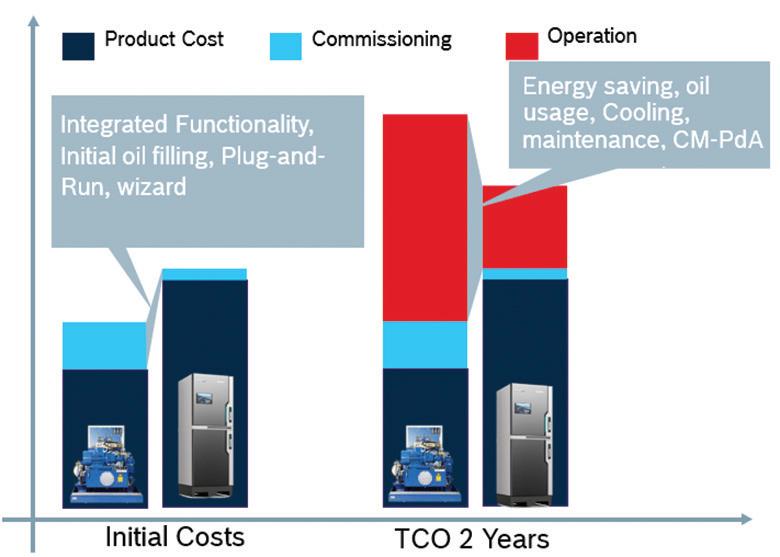

While common industry opinions may deem it difficult to work with such newer technology, modern units like the CytroBox and CytroPac require less maintenance and reduce the total cost of ownership compared to older, conventional units. Though newer technology might incur higher upfront costs, long-term cost savings related to maintenance, commissioning, and energy add up. Not to mention, the new systems are quiet and simpler to control.

Compact size without compromising power

For some applications, space is scarce, and systems require smaller footprints. Conventional hydraulic units vary in size and can be as large as Olympic swimming pools, necessitating vigilant monitoring and maintenance to cover the physical span.

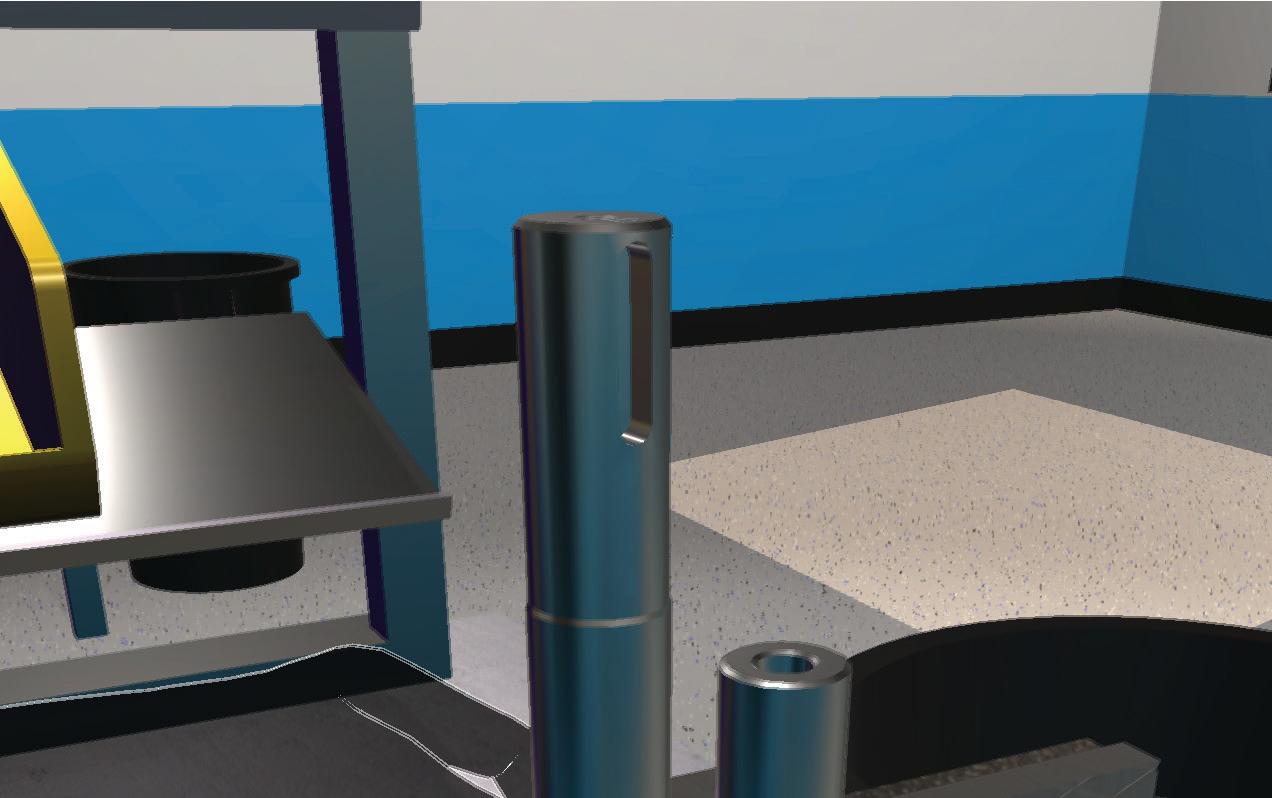

In contrast, the CytroBox looks more like a refrigerator, standing just under 8 ft high. Its maximum pressure is 315 bar, and machine designers can tie multiple tanks together to create a tandem system and increase flow. Each unit’s performance ranges from 7.5 to 30 kW and can be installed into existing production lines.

For extra space savings, the CytroPac is nearly 24 in. high with a diameter slightly greater than 14 in. The CytroPac provides up to 240 bar of pressure and a performance range of 1.5 to 4 kW. “You could probably stack six or seven CytroPac units in the corner of a plant and not take up any space,” said Tyler Stahl, application engineer and Cytro product specialist at Bosch Rexroth.

Quiet operation with visual indicators

Hydraulic units are typically loud, which causes safety hazards and requires anyone near them to wear earplugs. However, the CytroBox is so quiet that its operation can go audibly unnoticed. This means testers can sit next to the unit instead of in a different room for test applications, and operators can hold conversations without yelling at each other.

28 FLUID POWER WORLD 12 • 2022 www.fluidpowerworld.com

Technology advancements enable smaller, quieter, and more energy-efficient hydraulic power units that save space and reduce the total cost of ownership.

INDUSTRIAL HYDRAULICS

www.fluidpowerworld.com 12 • 2022 FLUID POWER WORLD 29

Modern hydraulic power units are compact, quiet, and energy efficient. Courtesy of Bosch Rexroth.

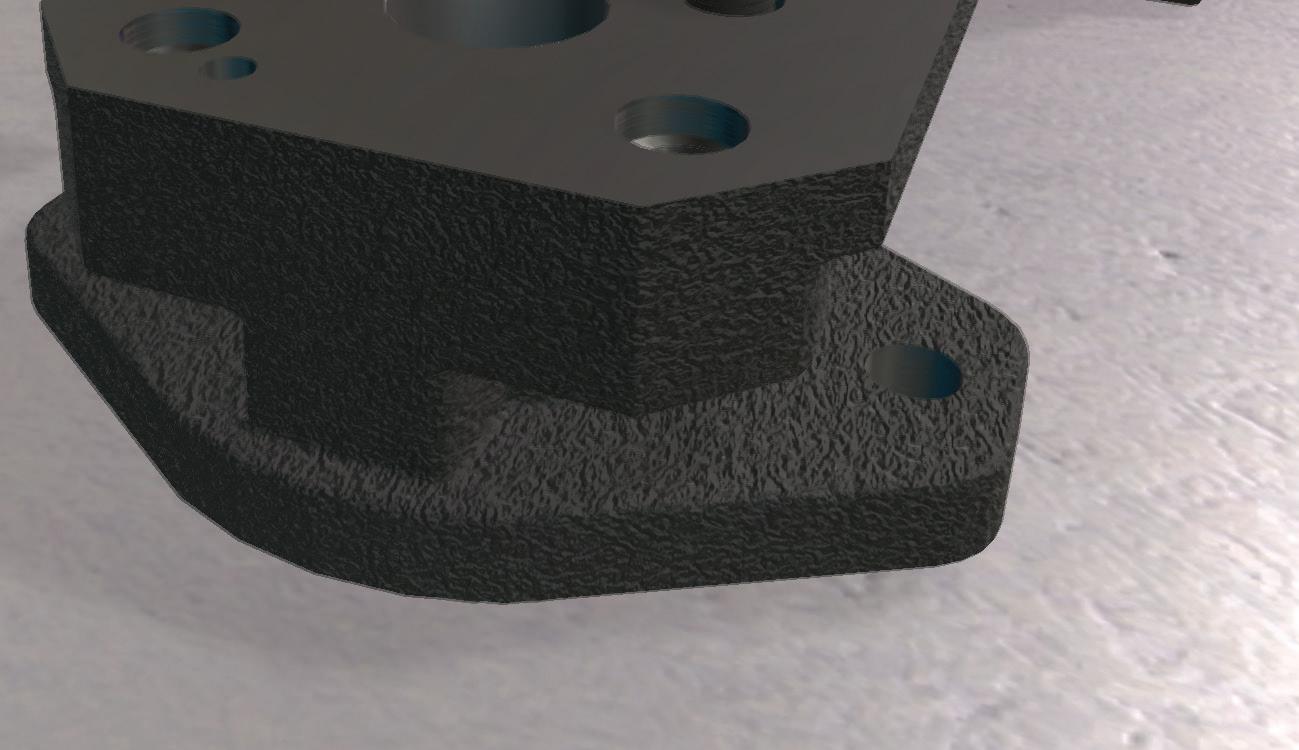

The significant noise reduction is attributed to advanced motor and pump designs and system components that help dampen noise within the box. The CytroBox uses small motors and pumps that operate at high speeds and reduce motor torque. Improved piston pump designs, quieter internal gear pumps, and reduced average motor operating speed decrease the average hydraulic system noise levels by more than 10 dB without requiring sound enclosures. Additionally, the CytroBox has a special housing that helps capture noise, and the bottom of the box is made of polymer concrete to help dampen motor vibrations.

To monitor operation, LED lights outside the CytroBox and CytroPac indicate green when the system is running, yellow when it’s stalled, and red when it’s not running. Replacing audible cues with visual indicator lights may concern those who favor more conventional systems, which often “speak” to operators and maintenance engineers through various pitched hums. However, LEDs provide discrete and immediate monitoring capability, which is common and favorable among electromechanical drives and other modern equipment.

Reducing total cost of ownership

Smart pumps provide energy e ciency

Pumps and motors in older hydraulic units constantly run at full capacity regardless of the application’s requirements. Therefore, a few decades ago, engineers developed “smart pumps” to run at variable speeds and improve energy efficiency. These pumps were designed to control flow and pressure in a system by varying the displacement (volume per revolution) as needed. Advanced

In some designs, the machine PLC must include the needed hydraulic calculations for motor speed based on both flow and pressure. However, the Bosch Rexroth version of this type of smart pump includes flow and pressure calculations in the electric drive (both VFD and servo drives), eliminating the need for complex PLC programming.

Software tools that compare hydraulic drive solutions and display the energy consumption differences allow hydraulic system

CytroPac — The Power Unit Revolution Compact — Radical New Design

calculations within the pump controller determined the flow and pressure. Widespread use of variable-speed hydraulic drives propelled improvements to this smart pump technology.

Newer versions can calculate the most efficient combination of pump displacement and motor speed based on flow demand. The smart pump electronics send a speed command directly to a motor VFD without the need for any programming in the machine PLC.

More recently, smart pump advancements include speedcontrolled fixed displacement pumps, which use efficient variable drive speed but can’t vary the pump displacement.

designers to model a machine cycle and optimize the pump and motor to achieve the highest possible energy savings.

Simplicity yields more space savings

The CytroBox is more of a valveless design that eliminates the need for proportional valves, which help control flow and pressure but can be expensive. Machine builders can still mount valves on the back of the unit if desired or needed. The CytroBox also has a built-in, sand-casted manifold that helps optimize flow and reduce pressure loss and heat emission.

Both the CytroBox and

INDUSTRIAL HYDRAULICS 30 FLUID POWER WORLD 12 • 2022 www.fluidpowerworld.com

Though the modern hydraulic power unit may have greater upfront costs, the total cost of ownership is less than conventional units Courtesy of Bosch Rexroth.

The CytroBox reduces oil consumption by 75% and noise levels to less than 75 dB. Courtesy of Bosch Rexroth.

The CytroPac is small but mighty and simpler to operate without needing complex hydraulics knowledge. Courtesy of Bosch Rexroth.

CytroPac use mineral oil HLP, which is a commonly used fluid. Being more compact, these systems use less oil, reducing the quantity facilities need to maintain. The CytroPac has a 20-L tank, and the CytroBox has a J-shaped, 150-L reservoir designed to help degas any trapped air bubbles in the fluid.

The CytroBox comes with either a 4or 10-kW cooling option. The bottom of the cabinet has a built-in heat exchanger with a kidney loop that distributes cooling water. Add-on packages and products can also be installed on top of the CytroBox to create a fully closed cooling system if a facility doesn’t have water to supply to the unit.

Industry 4.0 integration

In conventional units, machine builders manually wire the motor, pump, cooler,

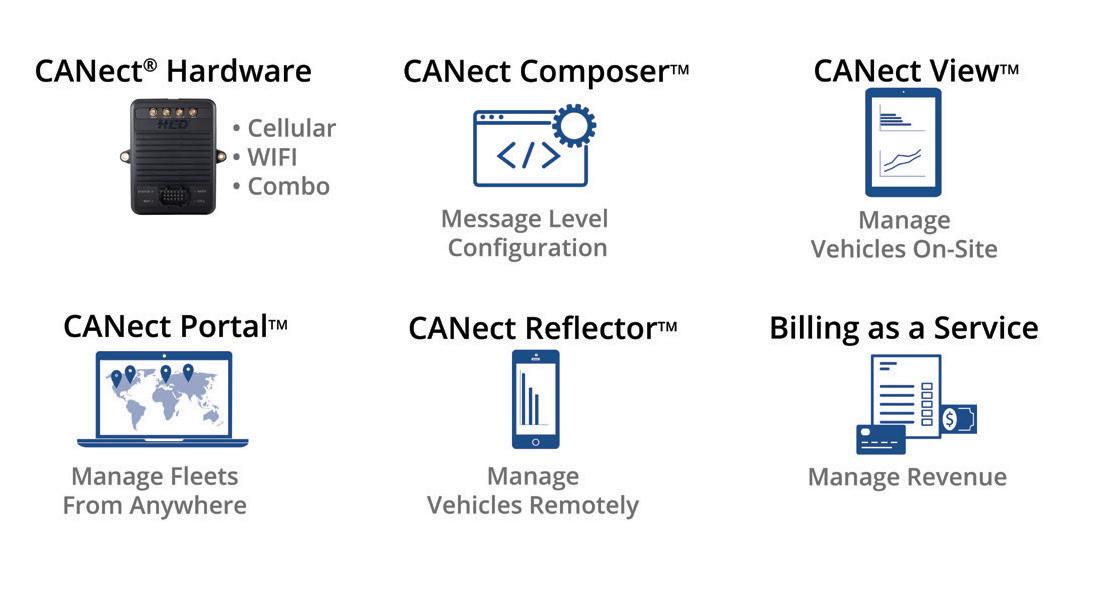

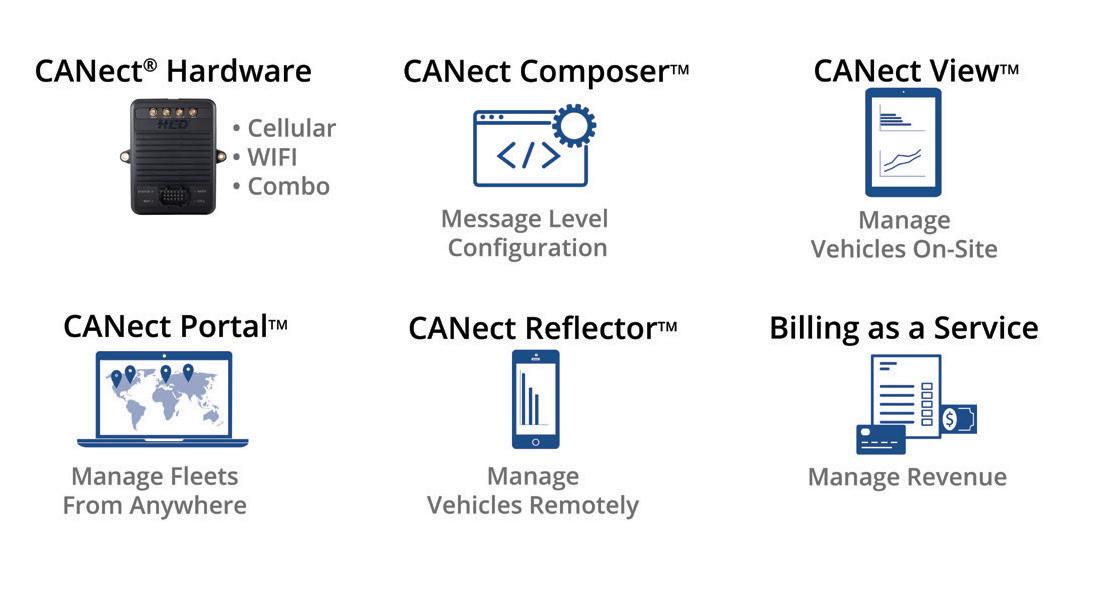

CANect® Telematics

and reservoir to an HBU control for the motor conductor, sensor analysis, and the safe torque off (STO). Comparatively, the CytroBox and CytroPac are prewired and include a multi-ethernet connection for integration with any network.

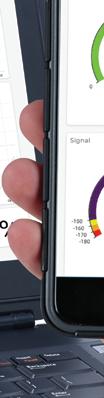

Additionally, all Cytro units include CytroConnect, a digital monitoring system that displays a unit’s operation and performance dashboard. System owners can pull up the dashboard on any desktop, laptop, tablet, or phone to locate the unit and assess operation in real time. Optional paid add-ons are available to monitor fluid cleanliness, system overheating, and other system parameters.

“There have been cases where someone logged into CytroConnect to look at a unit while the shop was down during a holiday break and noticed that the heat was rising above their

The CytroBox stands just under 8 ft high and uses a small motor and variable-speed pump to reduce energy consumption. Courtesy of Bosch Rexroth.

The CytroBox stands just under 8 ft high and uses a small motor and variable-speed pump to reduce energy consumption. Courtesy of Bosch Rexroth.

CANect® is a complete OEM telematics system designed to manage your vehicle assets.