16 minute read

Data transfusion

By sharing structural model data with the detailer early and often in the design phase Fitzpatrick Engineering was able to compress the construction schedule on Octapharma’s new blood plasma facility by eight weeks

When Octapharma deter- struction documents. The construction manually from 2D drawings.” This meant mined that centralising its team, and ultimately the fabricator’s that the earlier the detailing started the storage and lab processing detailer, must then recreate its own 3D less design information there was to would save the company data from our 2D documents and do so in transfer electronically, and the more data $1 million per month, accelerating the con- a fraction of the time that we had to create the detailer had to recreate by hand. struction schedule of its new North the 3D models in the first place. It is an Carolina blood plasma facility was para- outdated linear process still overly reliant Sharing 3D data mount. Fitzpatrick Engineering Group on 2D drawings and a costly waste of Fitzpatrick Engineering Group used was able to compress the construction effort on every project.” RAM Structural System for structural schedule by eight weeks, by sharing accu- New construction delivery processes analysis and design, AECOsim Building rate structural model data early and often (such as design-build, integrated project Designer for modelling, and MicroStation with the detailer in the design phase. With delivery, and fast tracking) seek to speed PowerDraft for drafting. the help of tightly integrated Bentley software’s interoperdesign and analysis software Fitzpatrick Engineering implemented a better, more efficient ‘‘ With accurate data in an accessible ability made it easy for Fitzpatrick Engineering Group to collaborate. For this particuway to deliver structural steel, reduce RFIs and change orders, format, the detailer eliminated errors lar project the architect, mechanical, electrical, and and help Octapharma save $2 re-entering and recreating data plumbing firms all worked in million. Shortening the schedule ’’ Revit; the contractor worked in Navisworks; and the freezer specialist worked in AutoCAD. With $1 million per month on the line, the process, but haven’t necessarily “We shared our AECOsim model as a meeting the tight schedule was crucial on addressed the efficiency problem. “The Revit model for the design and constructhis project. Technology and BIM have traditional detailing process has simply tion teams via the Integrated Structural helped facilitate faster projects, but faster been pushed earlier into the structural Modeler (ISM),” explains Fitzpatrick. doesn’t always mean more efficient. Doug design phase,” explains Fitzpatrick. “The ISM allowed us to easily update Fitzpatrick, president of Fitzpatrick “Sometimes there is a one-time elec- models for the team members on a weekEngineering Group explains, “Even tronic hand-off of structural information; ly basis yet still leverage all the AECOsim though we work in BIM now, in 3D, most a noticeable improvement, however, any features and functionalities that make of our projects require delivery of 2D con- information after that has to be recreated our new process more efficient.”

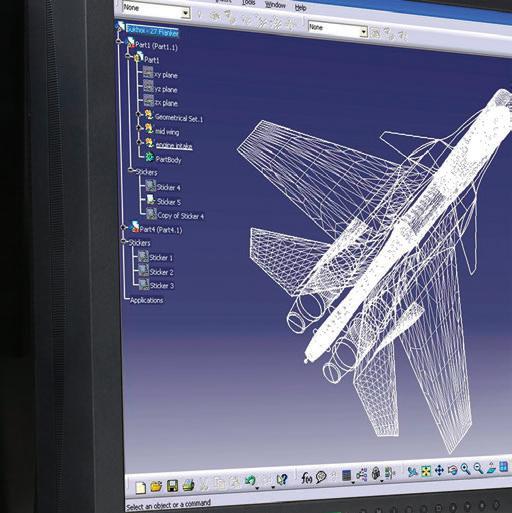

(Above) Octapharma’s state-of-the-art blood plasma facility in Westlake Business Park, Charlotte, North Carolina (Right) AECOsim Building Designer creates a complete detailer model, ready for delivery of fabrication data to the steel supplier

Fitzpatrick Engineering Group realised that keeping the steel detailer’s data in 3D as long as possible was essential. With AECOsim Building Designer’s enhanced CIS/2 export, Fitzpatrick Engineering Group could share accurate model data repeatedly with the detailer during the design phase. This ensured the detailer had the most accurate and up-to-date information and virtually eliminated the need for the detailer to recreate data from 2D documents. Fitzpatrick Engineering Group and the detailer also worked to ensure the steel fabricator’s preferences were incorporated into the model. A faster, more efficient process “The ability to share model data multiple times during the design phases of the project was the key component to meeting the demanding schedule,” noted Fitzpatrick. “The process allowed us to reduce the traditional 12- to 14-week delivery time of the fabrication package down to just six weeks. Best of all, this new process enabled by AECOsim is sustainable. It can be applied to all of our projects going forward allowing us to provide real value to our clients.”

With accurate data in an accessible format, the detailer eliminated errors re-entering and recreating data. As a result, Fitzpatrick Engineering Group needed about one-third less time to review the fabrication package. “Because we can now reliably send accurate data, the menial task of checking lengths, section sizes, cambers, steel grades, and so on has virtually been eliminated. We can now focus our attention on the more unique aspects of our design,” explained Fitzpatrick.

“The ISM and IFC export have been key enablers in sharing our model data,” noted Fitzpatrick. “They allow us to work in a robust Bentley analysis and design environment yet still provide useful information for other members of the design and construction team.” The link between RAM Structural System and AECOsim Building Designer also helped shorten the time needed to prepare construction documents. “With AECOsim we are able to produce accurate drawings quickly at any phase of the project. This speed and accuracy would not have been possible without AECOsim,” said Fitzpatrick.

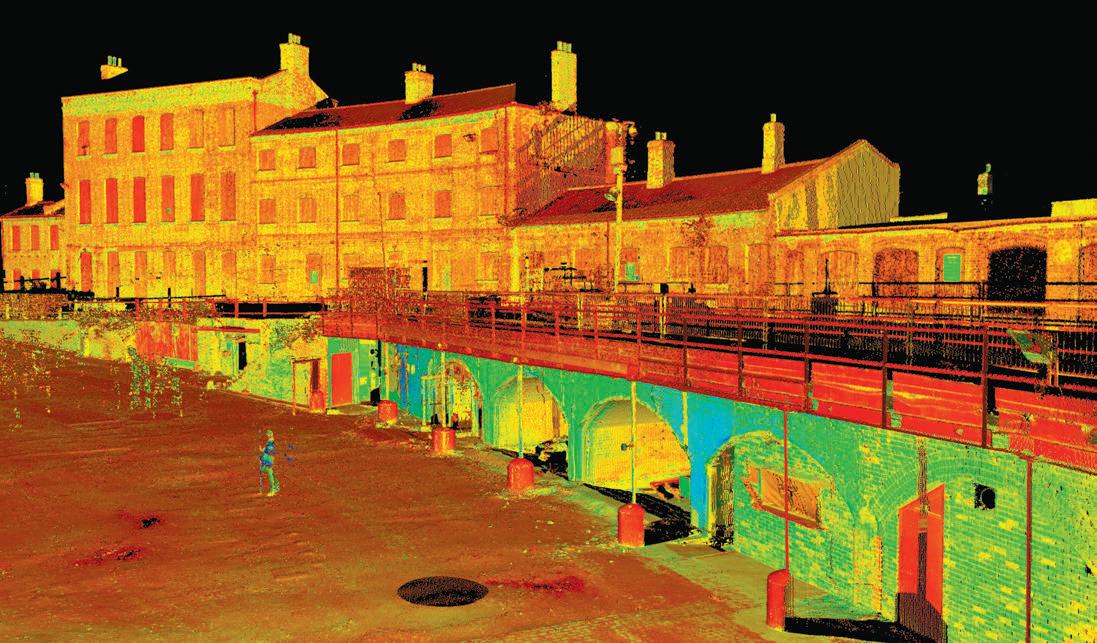

Point cloud of Kings Cross site

Heritage and BIM

Working on heritage buildings poses major issues – how to bring the existing structure into the 3D BIM process and the requirement to record and retain many architectural features. Plowman Craven explains how it overcame these challenges with the regeneration of Kings Cross in London

Many in the AEC arena will see new buildings as the main application for Building Information Modelling (BIM) but a considerable percentage of projects are refurbishments or part developments of existing buildings, many are listed.

Heritage buildings pose two major issues — how do you bring the existing structure into the 3D BIM process and the requirement to record and retain many architectural features.

A project that Plowman Craven has been involved with for over a decade is the urban regeneration of Kings Cross, a large mix of new build and listed buildings. A project in which the King’s Cross Central Limited Partnership (KCCLP) wanted to

About the author

Peter Folwell is a director at Plowman Craven with responsibility for survey deliverables within the BIM environment. He is involved in Survey4BIM and a founder of BIMnet.

embrace 3D delivery and more importantly have a BIM approach on a site that had over 20 historic buildings.

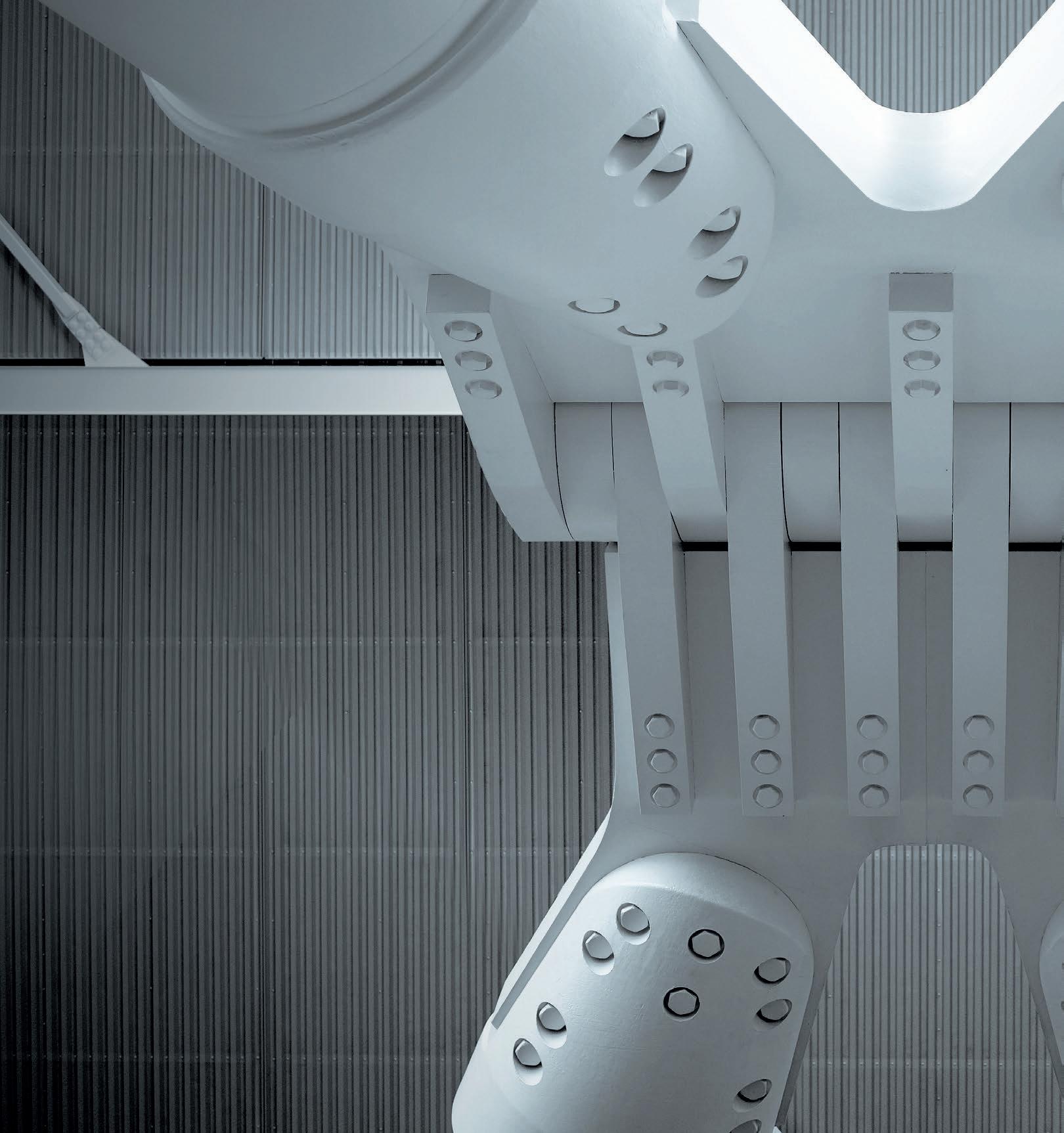

People travelling into London from around the world will be fully aware of the regeneration that has happened around King’s Cross and St Pancras. It has become a destination rather than a place to pass through, whether you are interested in iconic structures such as the St Pancras Renaissance Hotel or the spectacular western concourse ceiling, designed by John McAslan and partners, or a Harry potter fan wanting your photo taken on platform 9 ¾.

What is really impressive though is the exemplar 67 acre site owned by the KCCLP adjacent to the two main transport hubs. It is the largest mixed use development in single ownership to be developed in central London for over 150 years.

An inaccessible area of London that consisted of disused buildings, railway sidings, warehouses and contaminated land that has now been transformed into a vibrant new quarter of offices, homes, community facilities, schools, a world-re-

nowned university plus shops, restaurants and cultural venues. One of the real unique features of this development, and as mentioned above, it has a large number of historic buildings set alongside new build and public spaces.

KCCLP, as the major developer and asset manager, from the beginning were very progressive in their approach to requiring complete data sets, improved collaboration between people involved in developing and managing their assets and the application of BIM.

One of the key elements was to have an up to date master set of 3D geo-spatial information, including management of the primary survey control, which could be utilised and supplied to relevant parties thus reducing the need for repeat or unnecessary additional surveys.

The complexity of the site meant it was critical that all aspects were tied to a recognised grid and datum including correlation with underground utility information and below ground infrastructure such as rail and underground tunnels.

The historic buildings on the site posed a specific conundrum — how do you get these complex and varied buildings into the 3D design world? We would be dealing with large structures such as the transit sheds through to the irregular shaped Gas Holders. 3D laser scanning technology has been used as a surveying tool for a considerable number of years and in the early days of this project, the data, although collected in 3D, was delivered to the architects and engineers as 2D drawings. There were a number of factors which drove this at the time: Stakeholder ability or familiarity working with ‘as built’ parametric models. . Software capabilities to deal with ‘point cloud’ (laser scanning data output) and models simultaneously. Limited understanding of ‘point cloud’ data and the ability to handle large data sets. As the awareness of the benefits of BIM grew, software and hardware development increased, there became a greater understanding of the tools available and their application.

The first building to be delivered as a ‘BIM ready’ 3D Revit model was the Midlands Good Shed, built in 1850 by the Great Northern Railway, and now sensitively being restored to house a new Waitrose store and cookery school, plus an events and cultural space for the Guardian Media Group.

This survey model provided the basis of a fully federated model, hosted by BIMXtra, and included new steelwork elements added by Arup, 3D models from the architect Bennetts Associates, steelwork fabricator Bourne Steel, main contractor Kier, and M&E consultant Hoare Lea. With the number of stakeholders involved in the project, each with different requirements, it was important from the outset to fully understand and make sure that the survey model met expectations. Key considerations included: Collaboration with each team to understand specific requirements — As there was no recognised profes-

SCOTLAND BUILD 2015

Digital Construction Week will showcase and explore the digital technologies and processes changing the face of the architecture, engineering, and construction industry from design all the way through to operation.

Whether you’ve been exploring BIM adoption, experimenting with emerging smart technologies or investigating advances in manufacturing and materials, you’ll have witnessed the impact of digital technologies and the changes taking place in the AECO world.

Join over 5,000 industry professionals at the Digital Construction Show on the 21st & 22nd for our free seminar series and features, network with peers, and meet some of the most innovative suppliers in the AECO industry.

Meet with leading industry fi gures and government at our Westminster Reception. Showcase your work and expertise at The Digital Construction Awards. Take part in our DCW Fringe Event Series.

Digital Construction Week is the event series for the entire built environment throughout design, construction, engineering, management, and operation.

TO EXHIBIT OR ATTEND GO TO: www.digitalconstructionweek.com

INDUSTRY PARTNERS SPONSORS

MEDIA PARTNERS IMAGE: HEATHROW T5 DETAIL , LARS PLOUGMANN

CHARITY PARTNER

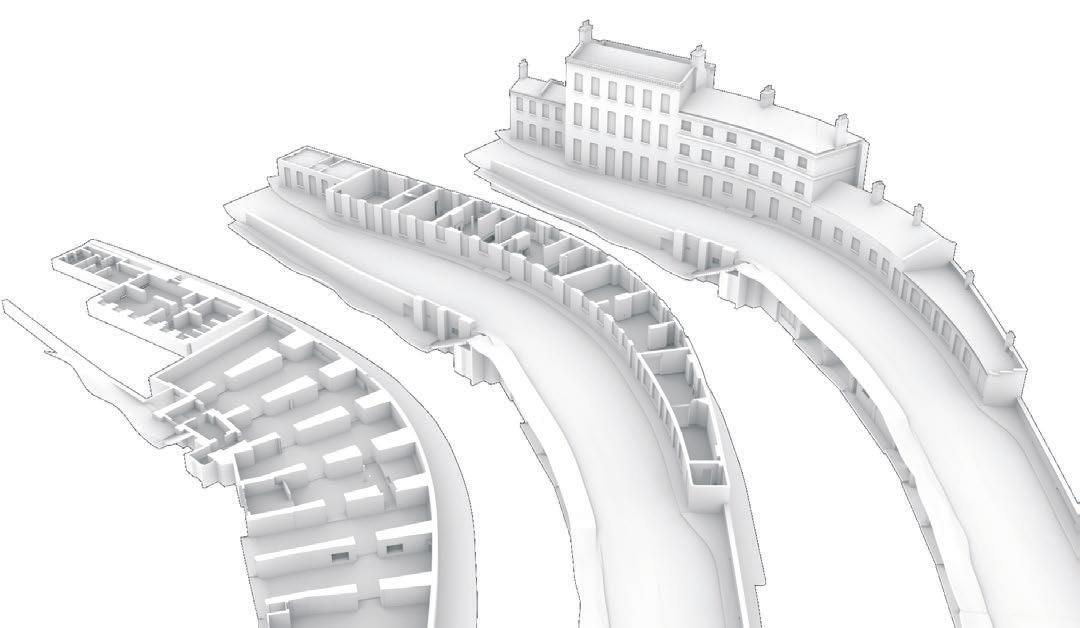

Revit model of the Fish and Coal Building on Regent’s Canal at King’s Cross. The building will be used by the Jamie Oliver Group

sional body specification we developed our own 3D BIM Survey Specification which was used to establish the level of detail required, family structure and delivery method. Model sizes and understanding capabilities of stakeholders in handling ‘point cloud’ data — With buildings of this nature structural features are not always orthogonal and will have deformities such as warping, bowing or leaning. To model every one of these deformities made the models too large and also works at the limits of Revit capabilities as it is primarily a design tool. Lateral and vertical deviation parameters were incorporated to record the maximum deviation of the model element from the point cloud. View filters could then be used to indicate components which are outside of tolerance. This then enabled the user to bring in the point cloud data for this feature and understand in greater detail the surface variations. Structure of the model could be phased and additional information added as the project progressed. In specific circumstances there may be consideration of complex architectural features to be recorded — Intricate modelling of these features may be required. These would be modelled in other more appropriate softwares and brought into the Revit model as families, non-modifiable, as to not make the model overly heavy. The Midlands Good Shed project is near completion and many of the lessons learnt have been incorporated into the other schemes such as the Fish and Coals Building, to be used by the Jamie Oliver Group, and Coal Drops Yard, a new retail destination. These have been fully 3D laser scanned and ‘BIM Ready’ models produced for the design and engineering teams.

Bam Construction, which won the project to refurbish the Fish & Coals, has fully adopted a BIM approach and utilised the models to co-ordinate designs, service clash detection and onsite verification. In relation to data collection and model delivery key considerations such as: IFC file size challenges. Level of detail requirements. Capabilities of dealing with point cloud sizes. . Technology compatibility were continually reviewed and addressed with all stakeholders. Pure restoration has been a major consideration for KCCLP, the developers, and in 2011 Gasholders No. 8, together with 10, 11 and 12, built in the 1850s, were dismantled by a team comprising Arup, Bell Phillips Architects, Shepley Engineers and BAM Nuttal.

Before the dismantling every structural element was recorded utilising 3D laser scanning technology and modelled.

Due to the shape and intricacies of the gas holders this was the only technique that really could meet the tolerance and timeframe requirements.

It took two years to complete the restoration of Gas holder No 8, rebuilt and placed on the new site next to Regents Canal.

In other locations the combination of digital photography and scanning technology has enhanced the capability to depict reality in 3D — a technique used to meet English Heritage’s requirements to show the existing true condition of the Coal Drops. This was achieved by wrapping high quality digital photography over a 3D model.

Utilising 3D digital data capture technology such as laser scanning and photogrammetry has provided the capability not only to accurately record intricate heritage features but has enabled, on a large urban regeneration project, to bring the existing environment into the BIM process. It has provided a geo-spatial platform to assist in KCCLP’s proactive application of the BIM process which is continuing right through to asset management and the ability to provide a better service to their occupiers and investors.

REAL 2015 redux

Earlier this year Autodesk held an exclusive event at Fort Mason in San Francisco’s marina area, to examine the emerging technologies and applications of what it calls ‘Reality Computing’. Now everyone can watch the talks online for free.

by Martyn Day

Nearly all design systems have moved beyond lines, circles and arcs and now provide 3D modelling, ‘intelligence’ and the capability to import geometry or point clouds from data capture devices. This merging of digital modelling and reality, combined with manufacturing advances in 3D printing is being touted as the next big leap in all design environments.

In many respects, this is the intersection of two mature market segments, the CAD world and the data capturing market. The former looks to model the real world, the latter aims to capture the real world.

The data capture market has mainly served the plant, surveying, mapping and terrestrial markets, through terrestrial or airborne laser scanning and photogrammetry and events around that technology have tended to focus on those application areas. However, new technologies, such as the rise of the UAV (unmanned aerial vehicle) market is also offering new opportunities to scan building sites to monitor progress, locate materials and compare actual vs modelled, which again works well with the industry’s migration to BIM.

Autodesk’s interest in the area of reality computing can now be seen in many of its products. AutoCAD and Revit can both work with point clouds, 123D Catch enables meshed models to be created from multiple models, Recap is a newish survey alignment tool and then there is Memento, a brand new product that can take video, pictures or point clouds, create meshes, enable editing and then 3D print the result.

At the Real 2015 event in San Francisco, it is just that idea that Autodesk wants to promote — harnessing reality capture means there are not only new ways to design but unlimited possibilities for

Reality capture in review

In participation with REAL 2015, AEC Magazine (aecmag.com) and its sister publication for product development, DEVELOP 3D (develop3d.com), produced a special report which examined the technologies and emerging uses of reality capture. It is available for free download at tinyurl.com/D3D-reports

working with real-world objects, either man-made or naturally occurring.

Autodesk has been active in applying the reality capture technology in many areas: museum curating, monitoring coral growth, capturing buildings of historical significance, surveying and city modelling. Real 2015 Possibly the first exhibition organised by a team of programmers, Real was the brainchild of Autodesk’s Reality Computing group, which wanted to pull together technology developers, researchers, artists, fabricators, product designers, educators, biologists and architects for a total cross-industry event to share and cross-pollinate ideas to build a community and start a discussion on how reality computing can solve problems that were just too hard for previous generation design tools.

The concept of the show was succinctly explained in the marketing: “From drones to autonomous cars, industrial robots to major engineering works, and game consoles to tomorrow’s mobile phones, 3D sensors are suddenly everywhere. And several decades after first grabbing headlines, VR and 3D printing are hot again, attracting billions in investment, and moving beyond early adopters to professionals. But it is the sum total, where sensing meets making, where big change is brewing.”

With over 40 industry speakers, 1,000 attendees and 30,000 sq ft of exhibition space, the ticket-only Real 2015 provided two days of great presentations from across a phenomenal range of specialisms. The great news is that all of these have just been made available for free online, on demand here: real2015.com/on-demand/

Flicking through the videos there is a veritable host of fantastic talks, from rebuilding old cars, 3D printing planes, quality, makers, digital fabrication, BIM, archeology, capturing coral reefs, environmental design to designing DNA-based cancer killing robots.

This collection of over 50 videos is like the TED of the reality capture market and well worth a browse. Real 2016 The good news is that the event is happening again, in Fort Mason, San Francisco, March 8-10, 2016. Based on the first outing, and the quality of the talks, we highly recommend this event if you want to meet the movers and shakers of the data capture world and get inspired by cutting edge applications in this quickly developing market. For notification on next year’s show, sign up at real2015.com