3 minute read

CO-ROBOT

Co-Robot System

Designsprojekt with Wöhner

Advertisement

Currently control cabinets are made of metal. The basic structure consists of a frame, which is covered with sheet metal. The products are usually placed on a mounting plate. The cabinet is always mounted in the factory in Rödental. When transporting from the production site to the place of destination, therefore, especially air is transported.

Research &Branding

Wöhner GmbH & Co. KG is an electrical engineering company that manufactures and sells products for the distribution and control of electrical energy. Wöhner presented itself innovatively from the beginning and was one of the first companies to replace porcelain as an insulating material with plastic.

Wöhner products are always integrated with innovation and sold to switchgear manufacturers and to the electrical trades. The aim of this design project is to use the innovative perspective to research the future usage scenario for electric cupboards.

Handwerk Industrialisierung Autonomous Urban-scale computing

Sicherheit

Service

Informationsträger

Kommunikation

From product provider to solution provider. In the electronics industry, pure product competence and services are decisive for the market. In the design project for the future scenario, the four key words are important, namely security, service, information carriers, communication

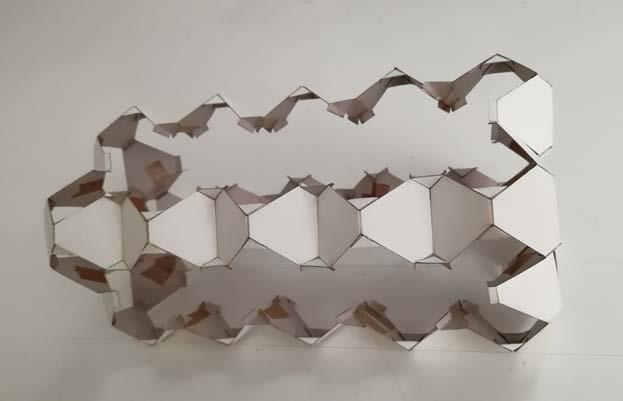

12 Ideen &Form-Research

Based on the directions of mathematical fractal, the ideas with the grid system have been further developed. In the rectangular grid system, the cell has been separated from each matching cell by the new rectangles with the bearings in the center. With the development we finally got the pattern, so that it can be developed into a 3-dimensional shape.

In order to realize the automation, the first idea with centralization structure, which consists of triangular modules, is raised, and thus cooling function and power distribution are integrated. The modular structure simplifies the traditional logistic and package system.

Design &Entwicklung

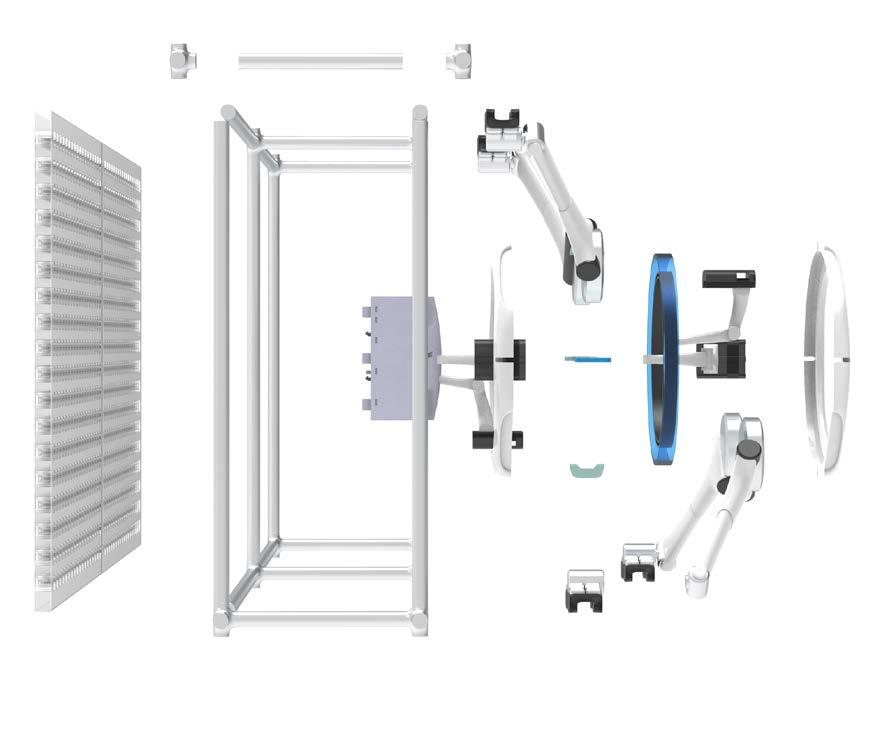

After researching the lattice system and fractal, the basic knowledge of modularity and automation is deeply understood. After careful consideration, the end development of the control cabinet came out with higher performance and lower costs. It consists of two parts: the shelf system and the robot system. The shelf system provides the workstations for the robot, which can climb on the surface of the shelf thanks to the four 3-dimensionally movable legs.

With the camera and data chain, the robot will remain connected to the control system, allowing engineers and workers to control the status of the control cabinet behind the screen.

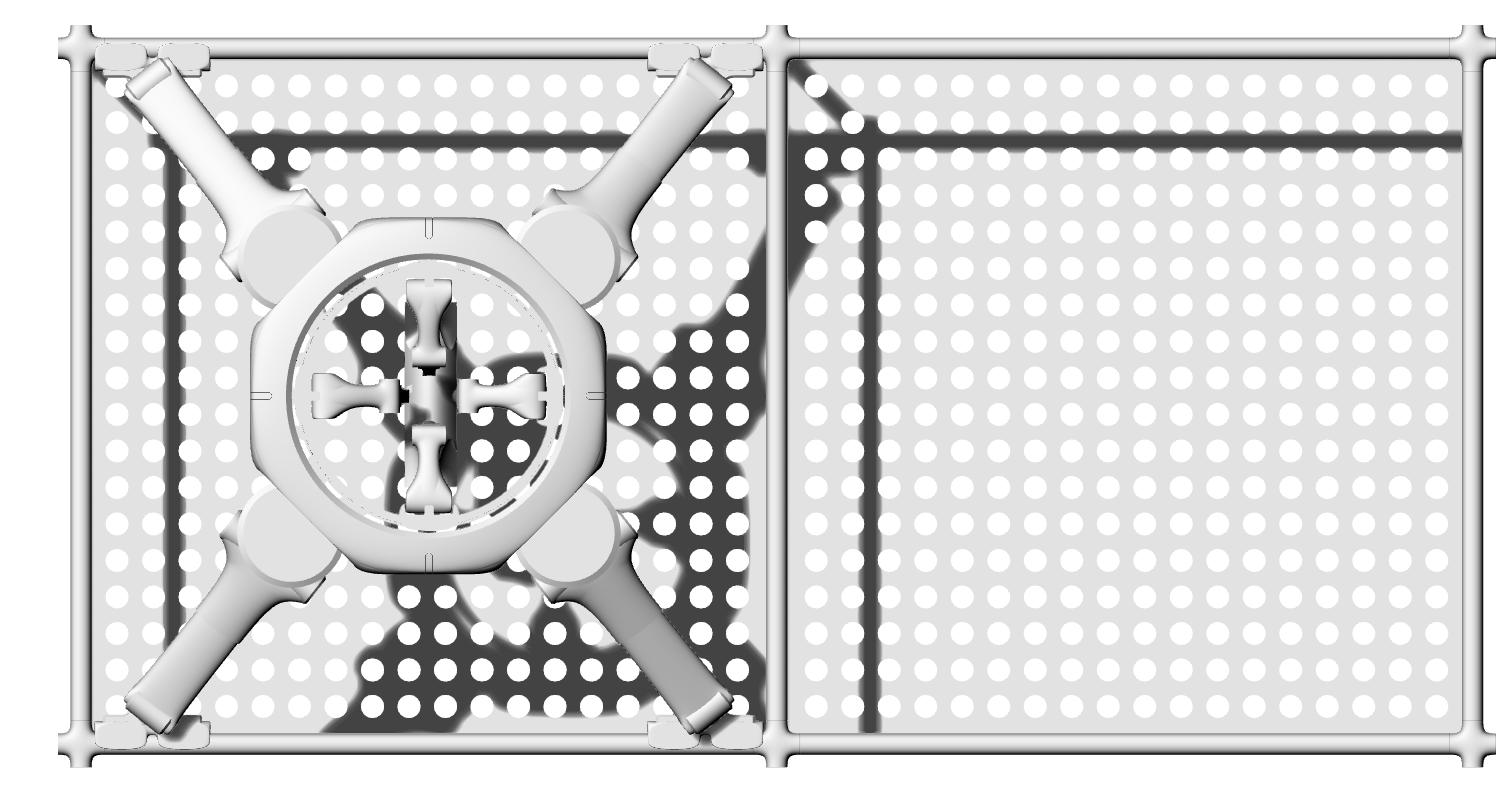

The scale of the shelving system is based on the size of the crossboard. Each cell is 600mm by 600mm with the holematrix in the background. With the help of the holematrix, with which the weight of the backboard is lighter, the shelving system can be cooled down quickly

14 Design &Entwicklung

The robot is integrated with the camera and support arms. The arms can support the component and then connect the line. In order to further develop the autoinstall system, the aesthetics and functional module of the component should be further designed. But this is not necessary for this project.

600mm

The connection of the shelving system is the focus of the design. With the auto-developing algorithm, you get the minimum surface area from the connection. This improves the structure ideally for the movement of the robot.