HEIGHT SAFETY BOOK

The history of work at height is a testament to the people who put their lives on the line every day. Unsafe methods, carelessness, poor equipment... It’s no surprise accidents involving height were (and still are) the biggest cause of death in the workplace. Determined to make a difference we set off on a mission to save lives and change the face of an industry.

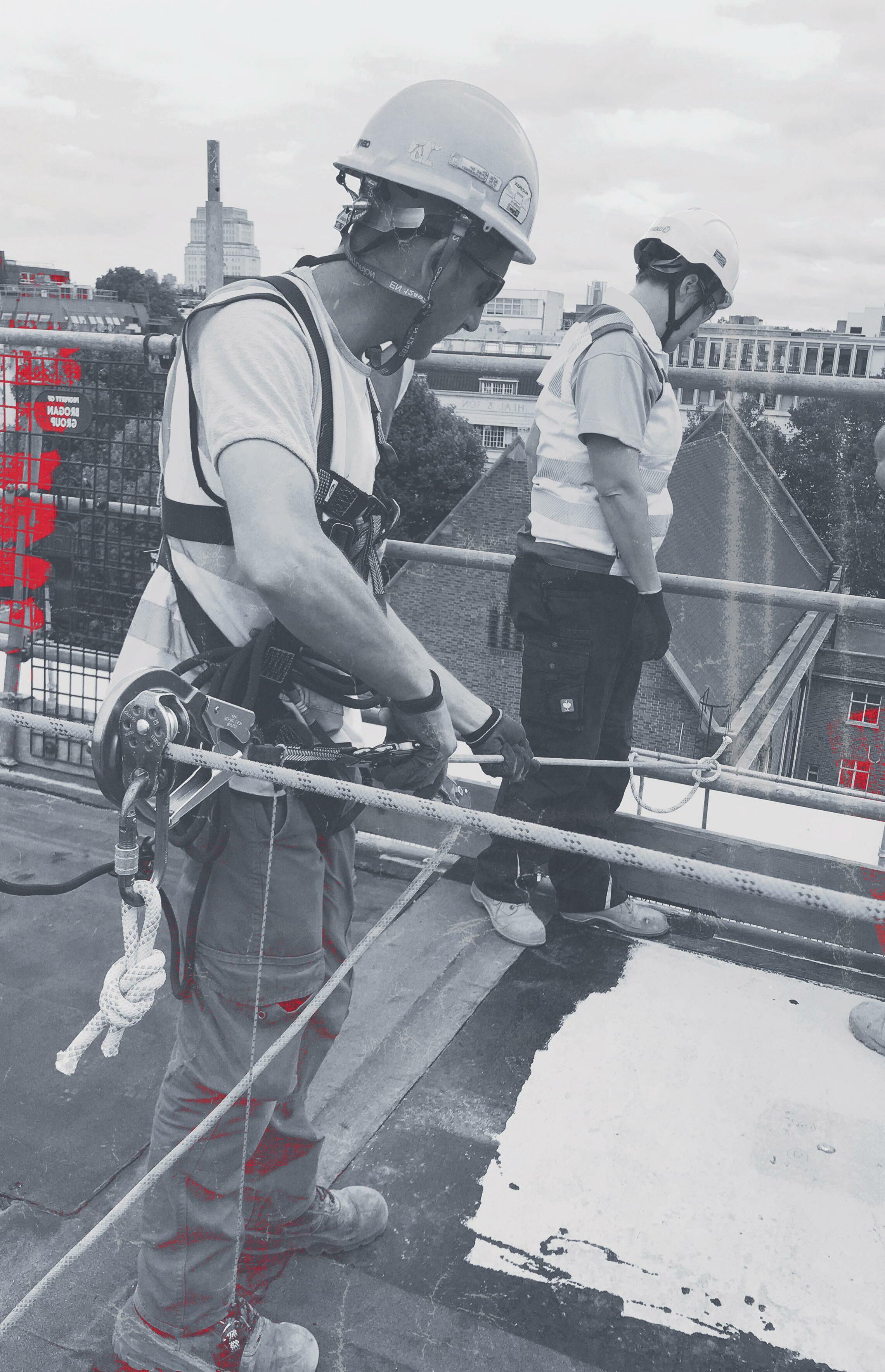

Fast forward over a decade and we’re still working tirelessly in the fight against gravity. We’ve come a long way since the early days and gained an incredible team of experts in work at height, access solutions and product design who continue to innovate and deliver hand-crafted high-end height safety equipment and training courses to individuals and international giants alike, all from our headquarters in Hertfordshire. Now part of the Enfield Safety family, Leading Edge is more than a company. It’s an ethos. A symbol of integrity, ingenuity and excellence. That’s why thousands of people all over the world choose us for their height safety training and equipment every year. Come and be part of the journey.

As a UK based height safety training provider and manufacturer, Leading Edge supplies only services and equipment that fully comply with the standards, regulations and claims made relating to those products and services. Monitored through our BSIF membership, maintained through our ISO accredited standards and backed up by supplier qualification schemes... all combining to underpin an industry leading product range.

Being a training provider and safety product manufacturer helps us to understand the relationship between workers, work methods, equipment suitability and performance in ways other companies can’t. Whatever height access challenge you face, we draw from a wide range of technical expertise to help you find the very best access solutions.

At Leading Edge we’re more than a product manufacturer. First and foremost we’re a specialist height safety company. That means we design word-class safety-critical height safety equipment solutions. If you or your employees work at height here’s a few reasons you’ll love Leading Edge products.

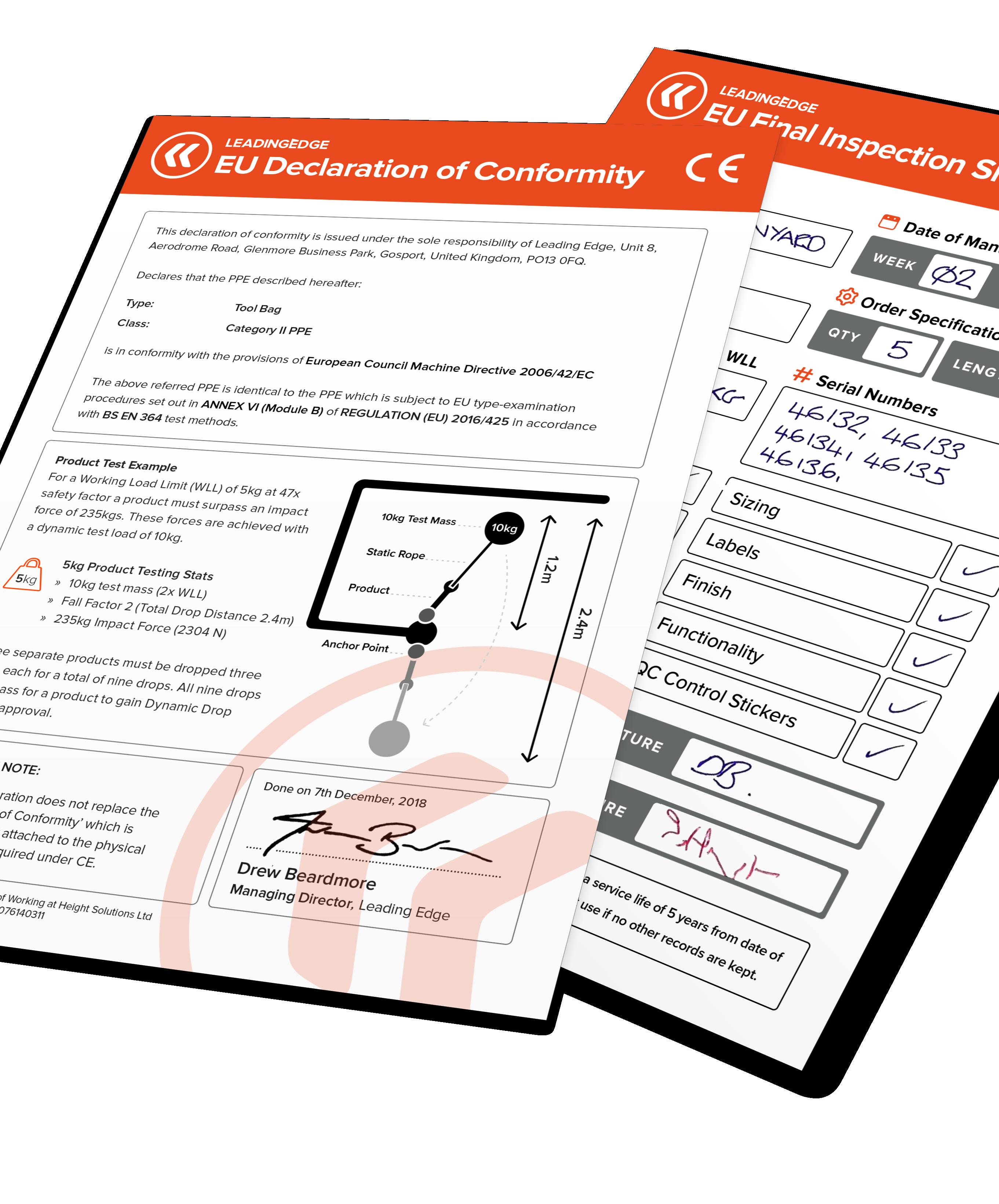

All Leading Edge products are in conformity with the provisions of REGULATION (EU) 2016/425

Engineered with Safe Working Loads that exceed minimum requirements.

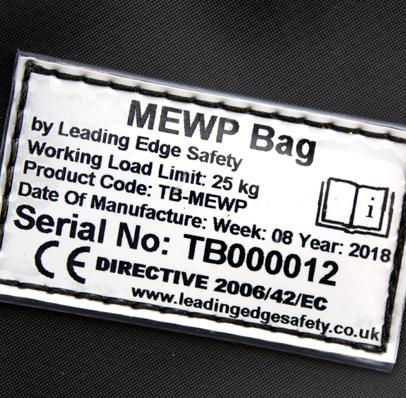

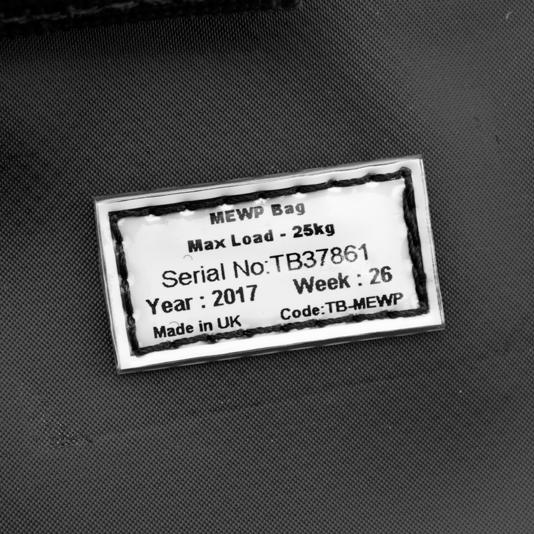

Every item serialised and logged – for complete traceability of your equipment.

All items come certified with a ‘EU Declaration of Conformity’.

It would be simple to outsource production but to make things right we knew we had to make them ourselves. So we took the harder path. We built our own factory. Hired our own team. Took responsibility for every step from the moment raw materials land until your order leaves. Any products that are made outside of the factory are to a specific design brief and rigorously inspected. It wasn’t easy, but the net result is a level of workmanship and reliability we feel proud to put our name on.

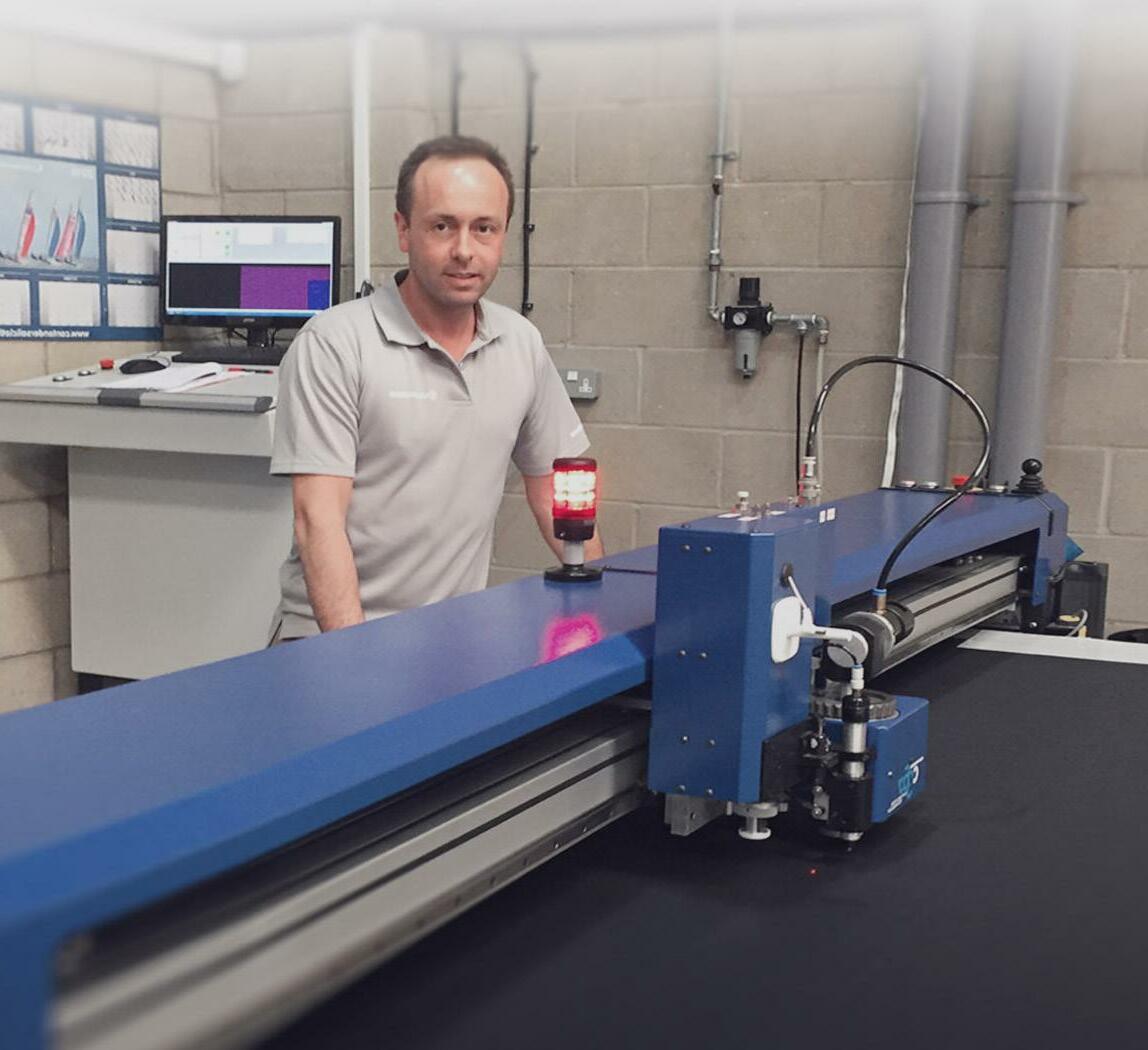

Nothing is faster or more accurate than a CNC table for preparing intricate material pieces. That’s why we nest and laser cut the fabric component. It means our sewing team have perfect base materials to work from every time — and it raises the overall quality of our products!

Prepped with laser sharp precision.

Our sewing team are the heart and soul of production at Leading Edge. From the UK we sourced the best talent we could find. Their hard work, attention to detail and teamwork make it possible for us to consistently deliver the highest standards in safety-critical manufacturing.

Many of our products feature high quality non-fabric materials and metal components. It’s all painstakingly constructed by hand. That might be more work for us, but in the end every item gets a level of care that eliminates fail-rates associated with automated production.

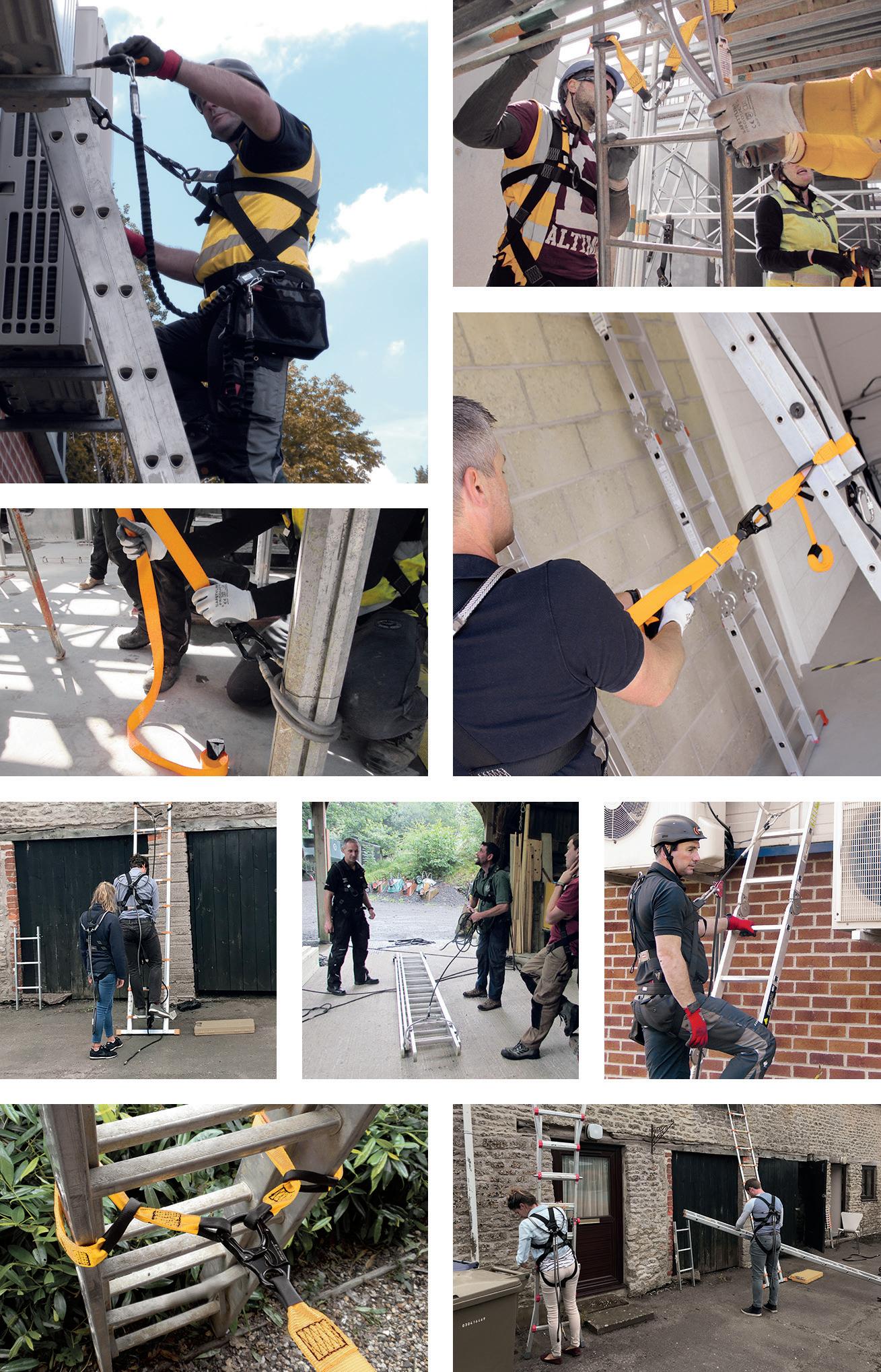

We don’t just deliver a course. We work together to find the right work methods and equipment to take your team to the edge — based entirely on your personal needs and access requirements.

Sit a course at our offices in Hertfordshire or book us on-site and we’ll come to you with all the necessary equipment to deliver training. From Lands End to John O’Groats we can get you trained, wherever you are!

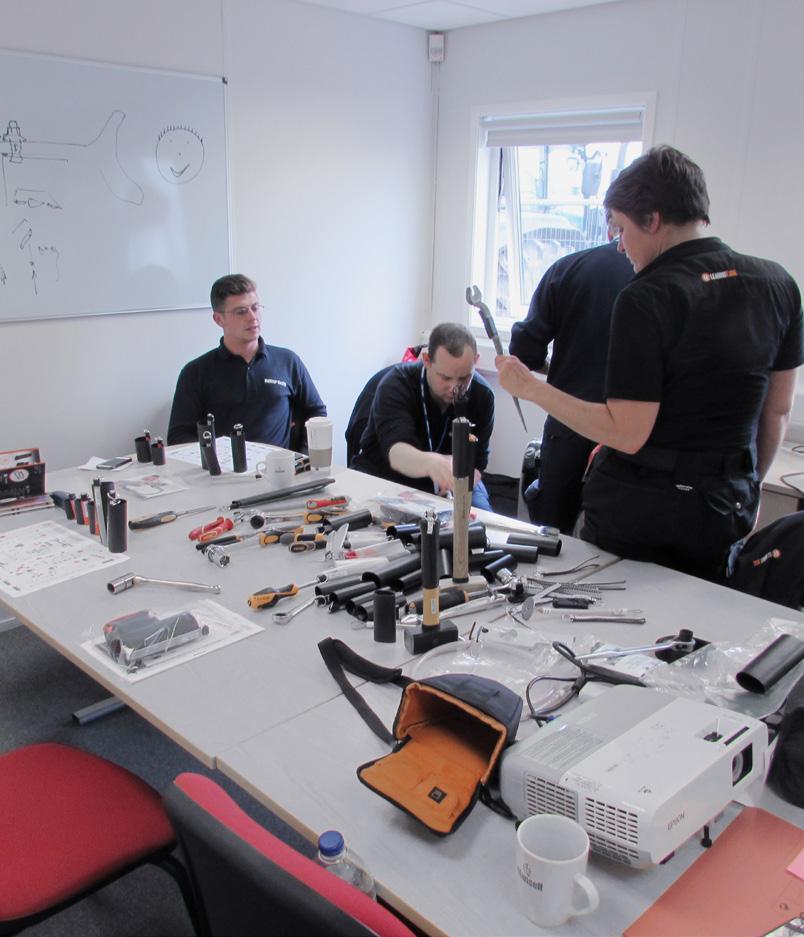

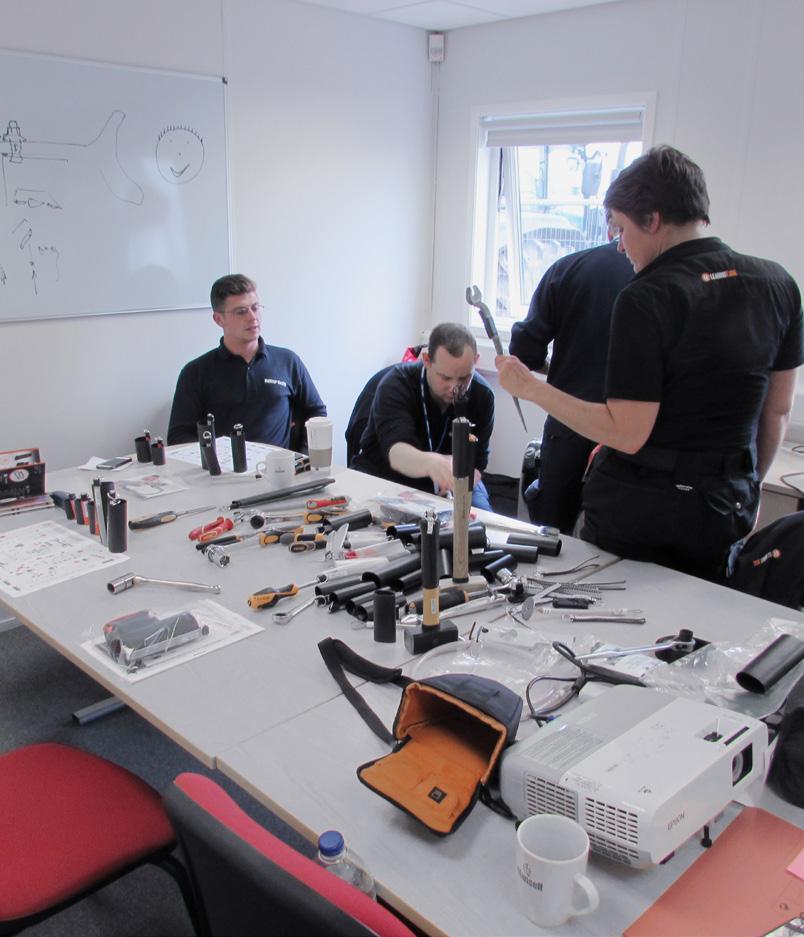

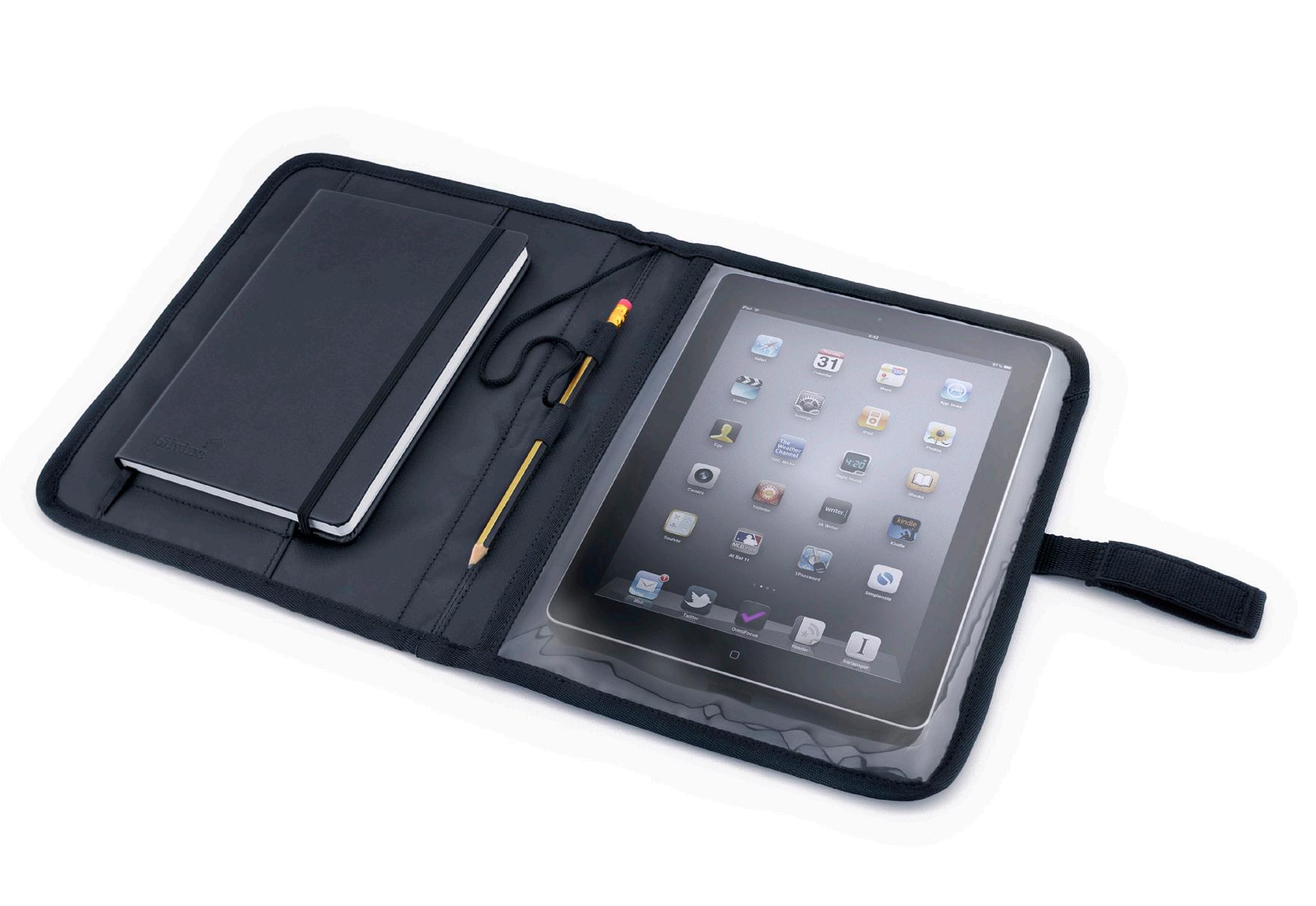

We bring our own projector, screen, laptop, props and bags full of equipment to deliver lessons. We just need somewhere to teach. So if you’re booking a course on your site the only thing we need is a training room and practice location that can hold the appropriate number of people.

Thousands of people choose Leading Edge training every year. And it’s not just because relevant all relevant government bodies and industry recognise our courses. But it helps to know you’ll be awarded with license IDs and certificates you can rely on to prove your competence.

After your training you need to prove your competency. To do that you’ll sit a detailed multiple-choice exam that shows us you’ve absorbed everything you’ve been taught. The test papers are taken back to HQ and independently marked by a third party — and that’s how we guarantee your certification meets the necessary legal requirements.

The best time to make mistakes is when your instructor is there to identify and correct them. That’s why we have the safety net of a practical assessment after your theory exam. Your instructor will observe you setting up and using your equipment and show you where you’re going wrong. So, once we leave you’ll have no doubts about your ability to use height access systems safely.

“I thought I knew all about working at height but I have learnt a lot more today.”

Work at height principles apply to everyone. But we all work in different ways. So, Leading Edge courses are flexible. Choose a Trade Sphere when you book your Working At Height course and we’ll customise it with information, imagery, equipment and exercises that relate directly to your specific trade or application.

Gain a height access solution for any general industry that requires protection from edge exposure in the workplace. This includes, but is not limited to, theatre, marine, public building access, industrial units, manufacturing and infrastructure services etc. The course typically provides a wide skill-set to work in many situations, however if you have a specific general industry trade not covered by our spheres, have a word with our instructors. We’ll help you find a bespoke solution and customise the course to suit your personal needs.

Leading Edge Work is a generalist sphere suited to construction workers exposed to a variety of edges, or those with multiple job roles requiring a broad knowledge of height safety principles and practices. While we aim to cover an assortment of working at height techniques to access multiple edges across horizontal and vertical planes, the course is also highly adaptable. So if you have a construction trade not covered by other spheres pick this one and our instructors will tailor the course around your specific height access requirements.

Whether you’re operating roof machinery and cranes, traversing gantries and walkways or climbing racking, working at height in factories and warehouses exposes you to a wide range of fall hazards. To cover your bases we’ll give you the broad skill set to solve the variety of height access challenges you face on a daily basis. By the end of the course you’ll be confident in your ability to set up and operate appropriate equipment for the prevention of slips, trips, falls and pendulum in the factory and warehouse environment while climbing.

Learn how to access and traverse a spectrum of machines and plants including cranes, diggers, excavators and dozers. As a plant and machinery operator working close to the ground poses specific challenges, as many work at height protection systems require a minimum fall distance to engage. To solve this you’ll learn how to utilise two systems in unison; a primary fall restraint system backed up with a secondary pendulum prevention system. The combination maintains mobility while ensuring ultimate fall safety at any height with plants and machinery.

Get the skills to work on all types of flat and pitched roofs. Whether they be glass atrium’s, new builds, asphalt, membrane, concrete, profiled metal or tiled, you’ll learn how to use existing roof systems, select anchorage locations and adopt temporary measures when permanent ones are unavailable. You’ll also discover restraint and adjustable restraint systems to gain safe access to one or multiple edges and learn a variety of more advanced techniques such as the use of lifelines and Mansafe Systems for increased mobility and intermediate attachments for multi-user support on roof edges.

Petrochemical and refinery work means accessing complex structures such as chimney stacks, pipe racks, steel frames, vessels, tanks, walkways, gantry’s and fixed ladders. You’ll learn how to assess your level of edge exposure, identify and select appropriate anchorage points and employ fall protection systems to gain access to these structures, utilising both front and rear connections on twopoint harnesses for maximum mobility across horizontal and vertical planes. Everything you need to conduct work at height in the Petrochem/refinery industry.

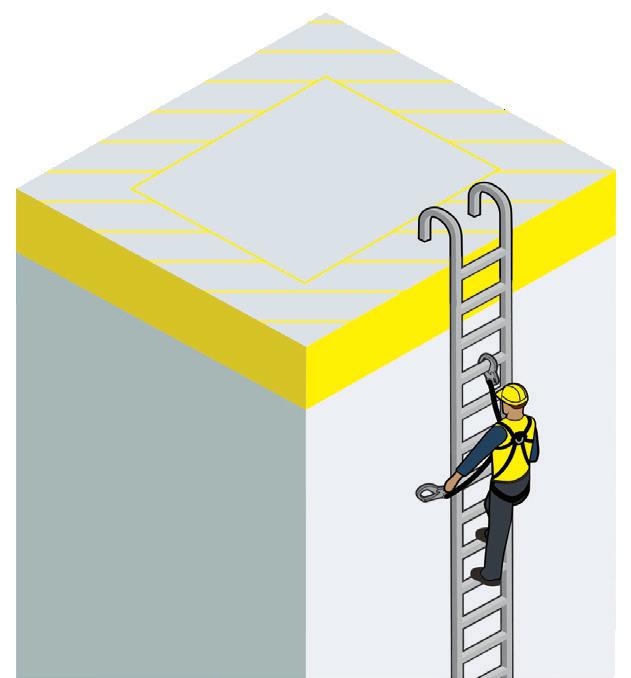

Working with industrial ladders creates two distinct hazards: users falling from ladders and ladders slipping away from underneath users themselves. Thankfully the technology and work methods exist to stop this happening. You’ll learn how to gain safe short duration access using industrial ladders, adjustable restraint systems and stabilisers to prevent slips, moving or falling. Finally you’ll explore positioning aids for hands free work in fixed and variable locations along the side of a building for total ladder safety.

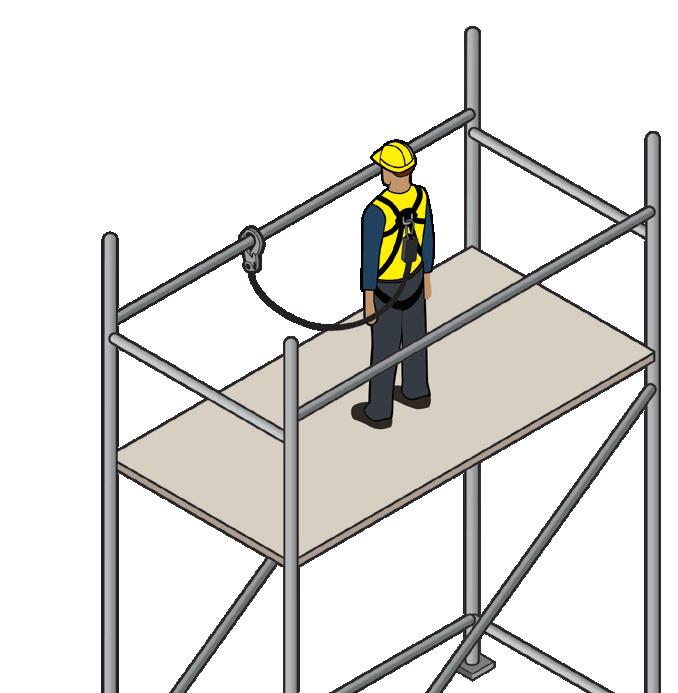

As a scaffolder it’s not enough to throw on a harness and hope for the best. It needs to be worn correctly in conjunction with the right fall protection systems. The problem is it’s easy to use the wrong lanyards — you feel safe but if you’re working below the minimum required fall distance, you’ll hit the floor before protection engages. To keep you safe you’ll discover how to use fall arrest and fall restraint systems relative to your working height, and learn how to use adjustable lanyards correctly in twin configuration for 100% tie-off whilst manoeuvring on a scaffold.

As a facade worker you need access to large leading edges for the installation of cladding, glazing. To do this you’ll learn how to select and use suitable anchorage locations and devices, and cleverly employ multiple adjustable restraint systems to give you localised or total perimeter edge access. We’ll also show you how to safely access hard-to-reach corners and support multiple operatives across a wide working area by adopting specialised practices like lifeline bending and intermediate attachments.

Concrete structures pose two particular height safety challenges: multiple open edges around progressively expanding decking, and infill exposure between table forms. The good news is there are several access solutions available to you. Whether working with Alsipercha, lifelines or inertia reels, we’ll show you how to safely utilise rebar for anchorage points and employ any of these three protection systems to access and complete your concrete frame work safely, efficiently and with personal confidence.

Work at height in demolition is highly unpredictable. Structural integrity is uncertain and strip-outs expose you to fall hazards from removed walls, floors and partial deconstruction. To gain safe access in challenging and constantly changing environments you’ll learn how to scan your work area for safe anchor points, make use of bracing, doorways and windows, and adopt temporary height access solutions such as Man Anchors when a fixed structure is unfit to use. Think on your feet, adapt and prevent the risk of accidents at height on a demolition site.

Precast puts you at permanent risk of a fall from straddling gaps and working with progressively extending leading edges while installing planks and floor panels. To stay safe we’ll show you how to identify and set-up suitable anchorage and give you the equipment and methods you need to work around intricate edges as the build takes place. We’ll also explore more advanced techniques required to access precast elements such as stairwells to give you a complete skill set required for the precast industry.

“We’re amazed how much we learnt. We’re already booking management courses.”

Theory is the first step on the road to competency in height safety. There’s a lot to learn: legislation, control measures, equipment performance and work methods — the list goes on. Sound daunting? We understand. That’s why we’ve broken down everything you need to know into digestible modules. They’re easier to absorb, so if certain topics concern you more than others we can adapt to keep information relevant and be as deep or as brief as you need.

Foundations lays the groundwork for your training. We’ll discuss course objectives and prime you with essential background knowledge on the subject of height safety, covering the basics of why we need it, the devastating effects falls have on individuals, families and businesses and your general legal responsibilities and duties. By exploring historical references, statistics and legislation we’ll paint — in real terms — a picture of where we are today, how far we’ve come and how far we still have to go to make the work place a safe place.

As a manager or employer you have strict legal responsibility to keep your workforce safe at height. But while the WAH Regulations and British Standard exist for everyone’s benefit, extensive jargon-filled documents are daunting and difficult for non-legal professionals to understand. Thankfully we do all the heavy lifting to pull out the clauses that are relevant to you and explain them one-by-one in layman’s terms, helping you understand how to comply with the law and prevent unknowingly exposing yourselves and your team to the possibility of future legal repercussions.

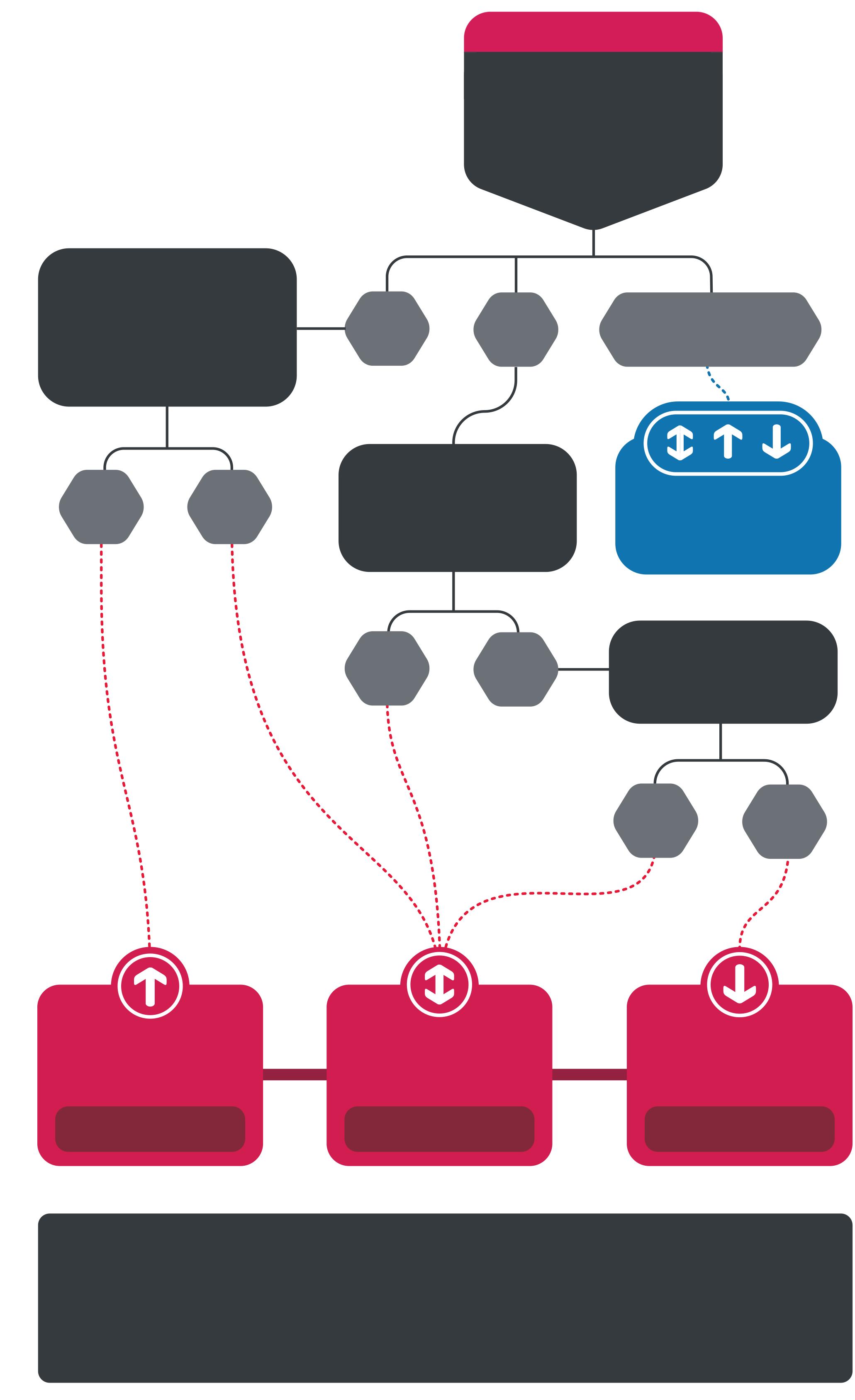

To have a meaningful discussion about height safety we need a clear picture of the terminology and work methods fundamental to all work at height. They fall into three distinct categories: Fall Arrest, Work Positioning and Fall Restraint. In DEP we break down and deliver detailed definitions of all three methods, demystifying what they mean, how they function, the equipment that comprise them and the various ways in which they can be utilised in a height access solution.

Before work at height can begin each task must be assessed for risk and appropriate safety measures should be placed where needed. To do this we’ll utilize the Hierarchy of Control Measures, which outlines a step-bystep procedure to guide your height access provisions. We’ll start at the top with the safest possible procedure (avoiding the need to work at height all-together) and move down the hierarchy with progressively hazardous scenarios, giving you the knowledge to conduct your own future assessments using HCM.

Throw it over your shoulders, clip it together, fasten the leg straps and you’re good to go, right? Be under no illusions, a damaged or incorrectly worn harness can lead to death, or if you’re truly unlucky, extreme testicular trauma and rectal damage! To prevent such a nauseating fate we’ll take you back to basics, familiarise you with different types of height safety harnesses and their various purposes, teach you how to perform pre-use inspections and then get down to the nuts and bolts of how to don and adjust. At the end of the module each of you will be provided with your own harness to practice with, which will then be assessed by the instructor to make sure the whole team is competent and confident before moving on.

Once you have an understanding of fall arrest and restraint methods we take a deeper look at intermediate devices, which work together between your anchor point and harness to form a height safety system. These include inertia reels, lanyards, lifelines, connectors and anchorage. We walk you through each device, demonstrating how they function, how you use them, what their limitations and performance capabilities are, and the practices and work methods that enable you to use them correctly in applications.

Anchorage is the first and arguably the most important link in the height safety chain. The challenge is knowing what constitutes a safe anchorage point and how to select the right anchorage device to connect out of a myriad of different options and configurations. To help you understand we’ll start by exploring permanent anchor points comprising of fixed structures in your environment and move on to temporary solutions. Finally we’ll talk in depth about available anchorage devices and analyse their specific uses, configurations, ratings and certification to give you the theoretical knowledge to identify and set up suitable anchorage for your height safety system.

While we should do all we can to prevent falls, using arrest and adjustable restraint systems mean the risk of a fall still exists. We need to be prepared to conduct a swift height rescue should one occur. In height rescue 101 we’ll examine the physical effects of suspension intolerance and re-flow syndrome on the human body and demystify the law, revealing exactly what you are required to plan and make provisions for. We’ll then introduce you to the 3 main methods of height rescue—lowering, raising and combined—to gain an overview of how they operate, their requirements of use and their pros and cons for the recovery of conscious and unconscious fall casualties.

Working at height puts your life in the hands of your equipment, so it’s in your interest to make sure your kit is fit for use. To ensure safety we’ll teach you the importance of frequent kit inspection and outline the basic principles of product and service life. We’ll then explore both the causes and visual indicators of degradation on a variety of different products, helping you keep your kit in good condition by handling, storing and transporting it appropriately and identifying damage when conducting daily pre-use inspections.

Formal equipment inspection is a requirement that must be conducted by a competent person on a 6-monthly basis. To understand your legal responsibilities we’ll introduce you to the inspections process for a full range of PPE and demonstrate how to record the relevant paperwork. At the end of the module is a practical exercise in which groups complete a harness inspection test, giv ing them the confidence to conduct daily pre-use checks.

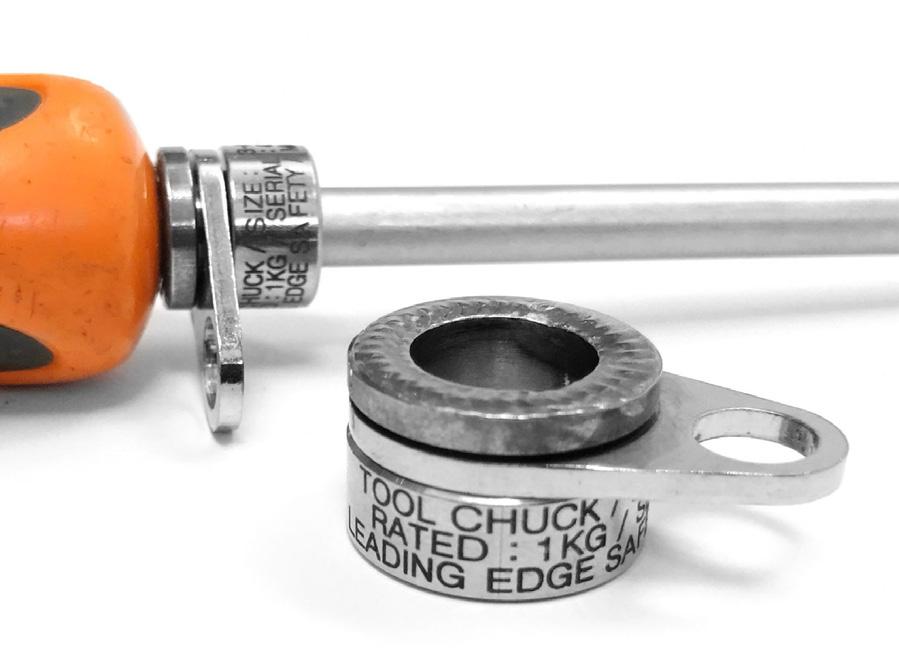

Dropped objects are a serious risk, and not just to people, to anything below a work area where hand-held equipment can fall. In Dropped Objects we have a frank discussion about the problems associated with untethered tools, cover some mind-blowing physics about the impact force even the tiniest objects can generate, and lay down the law regarding individual and company liability resulting from injury. Finally we explore some tool tethering solutions available to you today so you can secure your tools at height.

For many the thought of conducting a risk assessment seems laborious and over-demanding, but it needn’t be difficult and if done properly will make all the difference. A good risk assessment protects employees and employers. To get you started we dive right in and show you how to easily identify hazards, consider who might be harmed, evaluate risks and record and implement your findings into a pain-free risk assessment.

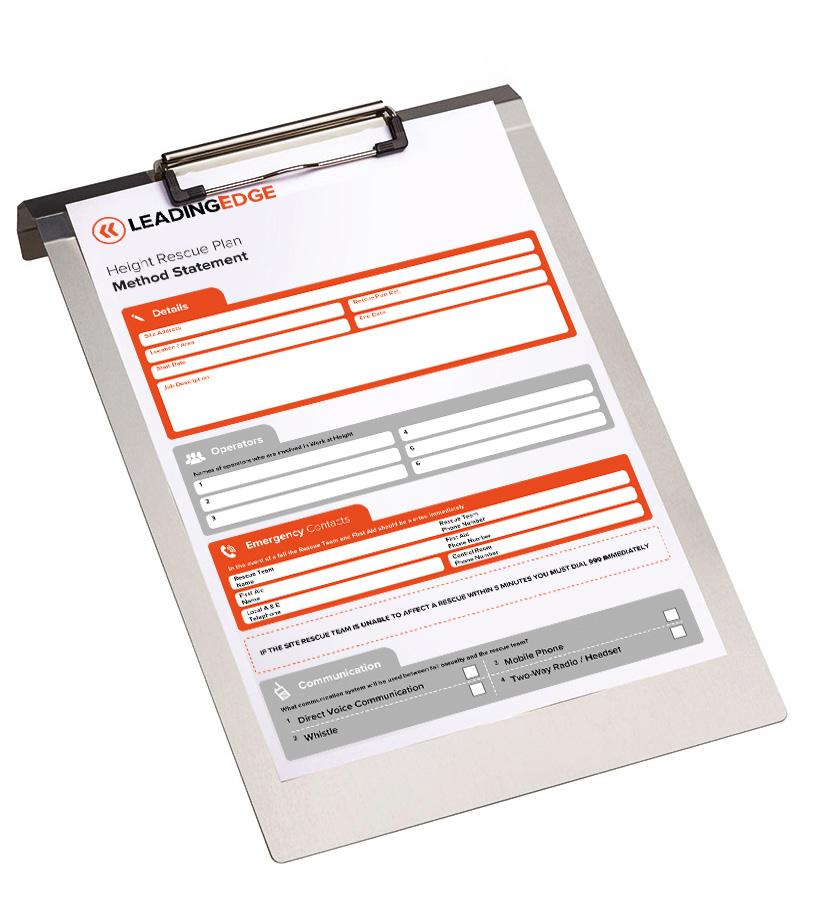

Those responsible for planning work at height are legally required to provide a method statement, a document explaining the way tasks should be completed. It outlines in detail the hazards involved and provides a guide on how to complete the job safely. With examples, we’ll walk you through the process of creating a strong, simple and effective method statement that communicates risks and necessary precautions to all those involved in work at height, whilst avoiding the pitfall of ambiguities or generalisations that could lead to confusion.

You’ve sat through the all modules, now it’s time to put it all together! Using the knowledge gained throughout the course we give you several mock scenarios and challenge you in teams to conduct visual risk assessments, decide upon suitable anchorage locations and select equipment for work at height. In an informal discussion each group will then explain and debate their decision making process to demonstrate their ability to plan for a variety of work activities.

“Leading Edge deliver training in a vibrant way. The content is enlightening.”

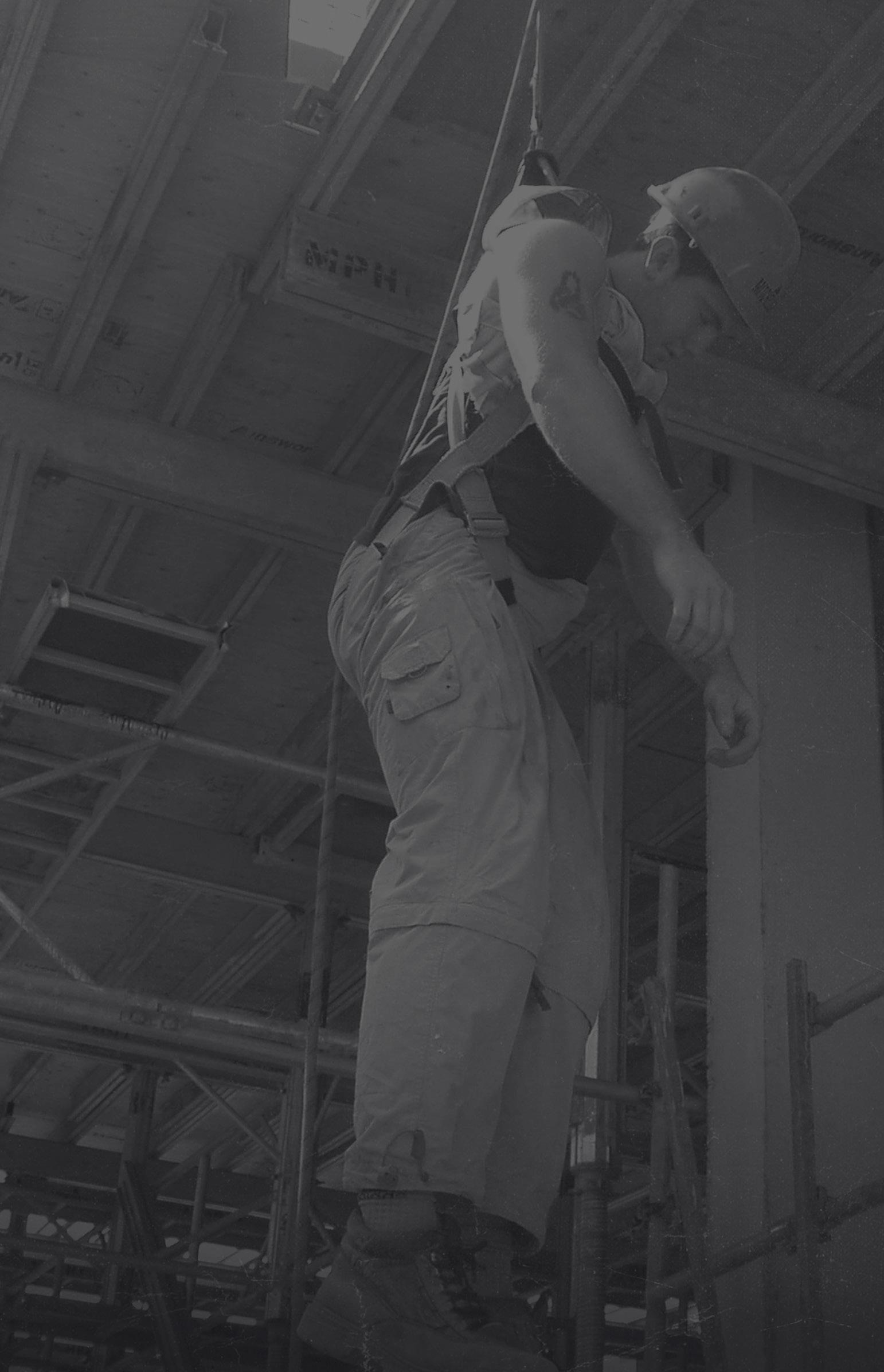

It’s not enough to know theory. You have to do it in the real world. That’s where Leading Edge courses really shine. There are many ways to work, so after exploring your access solutions we’ll get hands-on in a live scenario where you’ll physically practise setting up and using your equipment.

The theory is complete. It’s time to put our harnesses on and get outside for the practical session. But before we do we will conduct a quick recap of the information learned in the harness training theory module to double-check everyone has remembered how to correctly fit and adjust their harness before going any further.

Anchorage forms the foundation of any working at height solution, so mistakes made here make all subsequent safety efforts worthless. But how do we know which device to use and where to place it relative to our work area and the leading edge? What wrapping method should we employ and how do different configurations affect load capacity? These are some of the questions we’ll answer, so by the end of Phase 2 you’ll know how to select and operate anchorage devices suitable to your work area.

Fall arrest blocks give you increased mobility straight out of the box. The trade-off is they allow you to enter into a fall. However, if you do go over an edge the fall arrest block quickly engages it’s breaks to halt the motion and (hence the title) arrest the fall. Because this work method permits falling it requires particular caution when checking, placing and anchoring to prevent misuse and avoid pendulum whilst being aware of minimum height restrictions. We’ll demystify strict rules and practises so you can gain the benefit of fall arrest blocks in various situations depending on your activities and level of exposure.

Higher up in the height safety hierarchy is restraint. This method offers the same level of access as fall arrest blocks but is considered a safer and more desirable style of work because the rope ‘restrains’ your proximity to an edge.

Restraint Systems are extremely versatile, allowing for both front and rear connection in several configurations across horizontal, vertical and pitched planes.

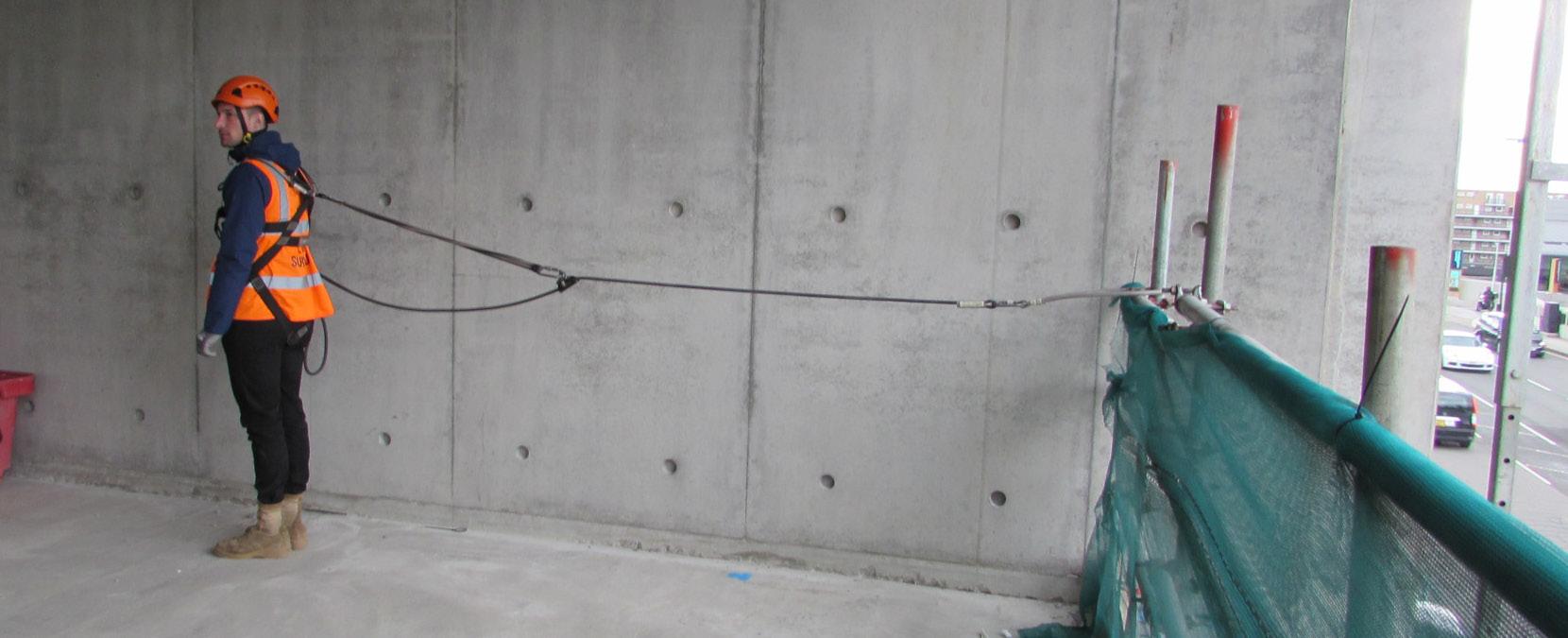

In phase 5 we’ll combine the best of both worlds by introducing lifelines. Lifelines prevent pendulum and provide greater access when working over large areas as the added use of a pulley allows you to safely traverse the edge along which the lifeline is set. You’ll learn how to deploy, position and tension a lifeline, operate it using front and rear attachment across horizontal planes, and explore more advanced techniques such as lifeline bending for multiple edge access and intermediate attachments to support multiple simultaneous users.

Lifeline

Lifeline

Lanyards are the most extensively used piece of equipment in the height safety arsenal. It’s no surprise given their versatility. You will discover all the different kinds of lanyard to achieve a range of access from simple fixed locations to climbing and the traversal of complex structures. This is your chance to reaffirm lessons learnt during theory modules and practice connecting to harnesses and anchorage while gaining the invaluable ability to select the right lanyards for your applications. We’ll continuously verify your competency along the way!

“All trained operatives were able to work with confidence and competence.”

It’s the powerful combination of both theory modules and practical exercises, tailored to your trade and delivered by directly employed expert instructors that distinguishes Leading Edge. We present a simple yet truly comprehensive height safety solution with engaging courses catering for all levels of your company, from operatives up to management.

Learn basic safety principles, don a harness and gain competence operating your height safety equipment during a half day of theory and practical exercises — the most efficient package for teams who are required to work at height with limited exposure.

This course is aimed at beginners to working at height. For example a volunteer or person that requires a skill update or refresher training. Every course is tailored to your unique working at height requirements.

Learn about different types of full body harnesses and discover what they are for, how they are used and the effect falling in one has on the body. Each of you will be given a harness to don under the guidance and assessment of the instructors. Your whole team will feel confident inspecting, wearing and adjusting harnesses safely for work at height.

A series of group practical exercises test your new height safety skills in a live scenario where you’ll set up anchorage and practice using fallarrest, restraint and lifeline systems in a variety of configurations required for your job.

Master the equipment, methods and practices that keep you safe at height when working at the edge. We not only help you discover a personalised height access solution but tailor your course to suit your trade, ensuring your whole team gain complete theoretical and practical safety skills that have direct association to your daily activities.

Working at height is more than just wearing a harness. It’s about fully understanding the risks, anchorage selection, equipment mechanics, usage and best practices. This course gives you the all the knowledge, awareness and practical skills that empower you to work safely at height.

The course begins by establishing a general awareness of the dangers of working at height and takes you on a journey through the methods, practices and equipment that together form your height access solution. We’ll discuss what restraint, fall-arrest and work positioning mean and get you fully trained in the use of height safety harnesses, adjustable restraint and intermediate devices such as inertia reels, lanyards, lifelines, connectors and anchorage. You’ll then explore the fatal effects of suspension intolerance, take a brief look at rescue, discover how to perform pre-use equipment inspections and test-drive the latest tethering solutions for preventing dropped tools.

There are lots of ways to work at height. Understanding what equipment to use for different applications based on your access, scope of work and exposure is essential for your safety. You’ll master how to select and use the right equipment for any job you do at height.

The course concludes with a group practical session that tests your new skills in a live scenario where you’ll set up anchorage and practice using fall-arrest, restraint and lifeline systems in a variety of configurations required for your job at height, all under the watchful eye of your instructors.

Managing work at height requires an advanced skill set covering a wide range of legal and moral responsibilities. To achieve this we enable you to identify potential hazards, complete effective risk assessments and method statements, get you fully up to date with the latest equipment and work methods and teach you all the skills you need to be manage work successfully.

A big part of being a manager means ensuring your team has the right equipment for their tasks. We’ll explore the function and use of various types of height safety equipment at an advanced level, giving you full proficiency in the selection and utilisation of harnesses, intermediate devices and anchorage that together form your employees height access solutions.

Discover the effects of falling on the human body and get all the guidance information and product knowledge you need to begin making necessary height rescue provisions for work at height. You’ll be able to select and place appropriate recovery systems for any work at height and fulfil your risk assessment requirements — an essential skill for any managerial role.

Learn how to store and maintain your equipment and discover how to perform weekly kit inspections on a full range of PPE. We also reveal strategies that safeguard against the repercussion of not controlling equipment in-line with requirements.

In a final group exercise you’ll demonstrate your competency as a manager by risk assessing and selecting appropriate work methods and equipment for several mock work at height scenarios. As a qualified WAH appointed person you can issue ‘permit to work’ (PTW) for all working at height activities.

The Leading Edge license card management system gives you the power to take disciplinary action by removing the corners of a license if the card holder commits an act of misconduct. A Leading Edge card with all 4 corners removed is considered invalid and requires the operative to be retrained before continuing work.

With health and safety on the rise in the workplace, ladder use has declined in favour of ‘safer’ alternatives. The trade-off is these alternatives are often costly, time consuming and prohibitive. But by utilising height safety equipment and stabilising techniques you’ll discover that ladders are a genuinely safe and incredibly convenient method of gaining short duration temporary access.

Unlike your average ladder course Leading Edge provides a hybrid of essential working at height techniques (harnesses training, restraint systems, anchorage devices) and a solid theoretical and practical understanding of all aspects of ladder use including hazard awareness, legislation, kit inspection, positioning, stabilising and climbing to giving a complete solution for you need to work safely with ladders.

Understanding what equipment to use for short duration ladder work based on your access, scope of work and exposure to risk is essential for safety with ladders. You’ll master how to select and use the appropriate height safety equipment and ladder stabilising gear to create a safe temporary system of work.

The course concludes with a group practical session that tests your new skills in a live scenario where you’ll set up your combined ladder and height safety equipment in a variety of configurations, under the watchful eye of a professional instructor.

To be safe when working at height is more than just climbing a ladder. It’s about fully understanding the risks, PPE selection and mechanics, stabilisation, ladder usage and best practices. This course gives you all the knowledge, awareness and practical skills to create a short duration, temporary work access solution.

We provide our own projector, screen, laptop, props, ladders and bags full of equipment to deliver theory lessons. We just need somewhere to teach. So, if you’re booking a course on your site, don’t forget to arrange a training room that can hold the appropriate number of people.

Discover how to examine and detect mechanical or material faults in your equipment, allowing you to confidently re-certify or decommission any type of Working at Height PPE throughout service life. You’ll also learn how to record and maintain your findings in a self-directed inspection log that saves you time, money and provides essential protection for both employees and employers.

The course follows best practises in line with British Standards BSEN365:2004, BS8437:2005 & A1:20012.

Theory ( 2 Hours )

Practical ( 2 Hours )

Formally inspect a selection of 50+ PPE items and record your findings in an assessed inspection log

This is an individual practical assessment, where you will formally inspect a selection of 50+ PPE items and record your findings. To increase your product exposure, this is followed by a group discussion on reasons for pass and failure of the many PPE items, so that you are competent to act as the appointed person for formal kit inspection within your company.

The nature of this course requires a huge amount of equipment to learn about and examine. We bring everything you need. So there’s no need to worry about sourcing any PPE yourself.

You won’t just be learning how to assess a wide array of materials and components. You’ll perform real inspections on a huge assortment of over 50 real PPE items in various conditions that we bring to your course. There’s simply no better way to master the inspection process.

The theory phase equips you with essential knowledge of inspection legislation and the factors that effect product and service life. We then teach you everything you need to begin creating and maintaining formal 6-monthly equipment inspection logs.

After finishing this course you’ll be able to formally control and maintain your companies PPE as a licensed appointed person. From here you can continue to competently perform formal kit inspections on a full range height safety equipment in-line with the British standards and best practices

It only takes five minutes for the onset of suspension intolerance to change a life forever. Venous pooling, orthostatic intolerance, vascular shock — learn how these devastating conditions affect a fall casualty. We’ll study the science and look at some eye-opening statistics to reveal why a rescue plan is essential for protecting people who work at height.

Explore 3 different recovery systems, discover their suitability and effectiveness for various recovery scenarios and get in depth practical training in the system/s of your choice. We’ll also look a the process and frequency of equipment inspection as well as anchorage considerations you will commonly encounter in the field.

By conducting repeated self and assisted recoveries — in vertical and horizontal rigged positions with a variety of fall protection equipment — you’ll gain total confidence recovering a fall casualty with your chosen rescue system/s. And to test you can act under pressure we’ll do a 5-minute rescue challenge to compete for the fastest, safest recovery.

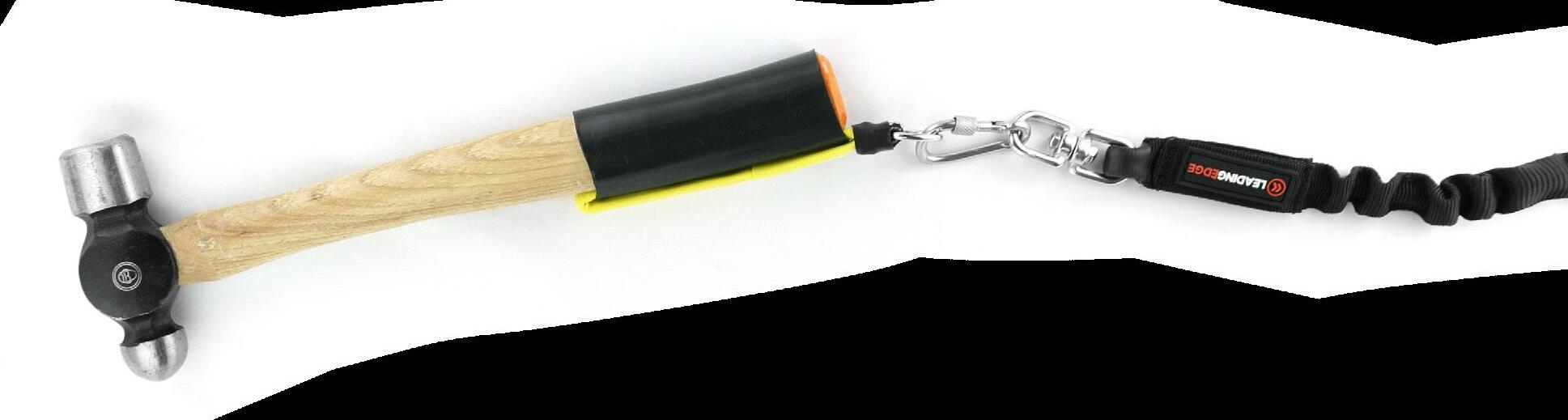

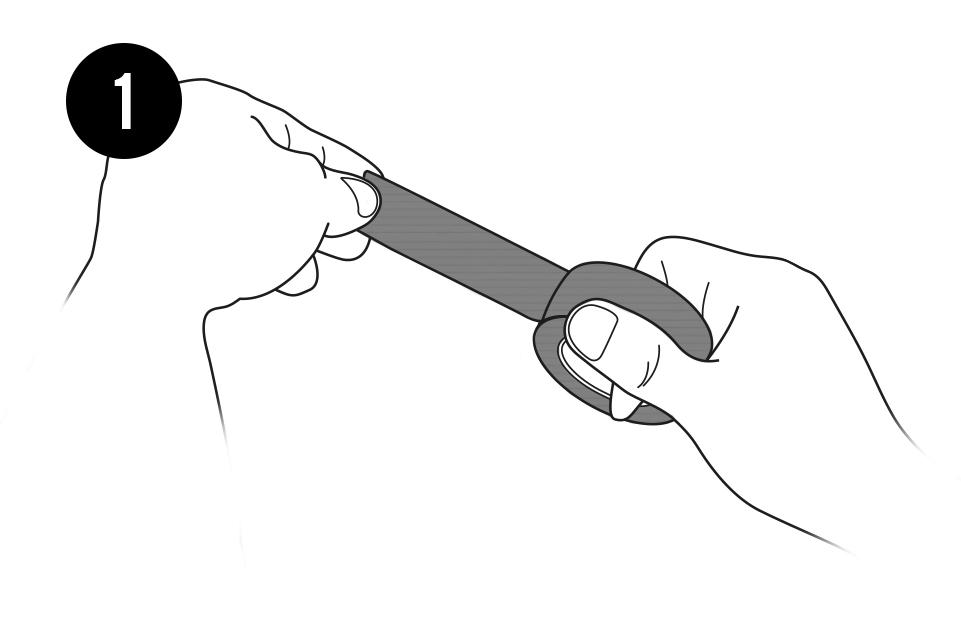

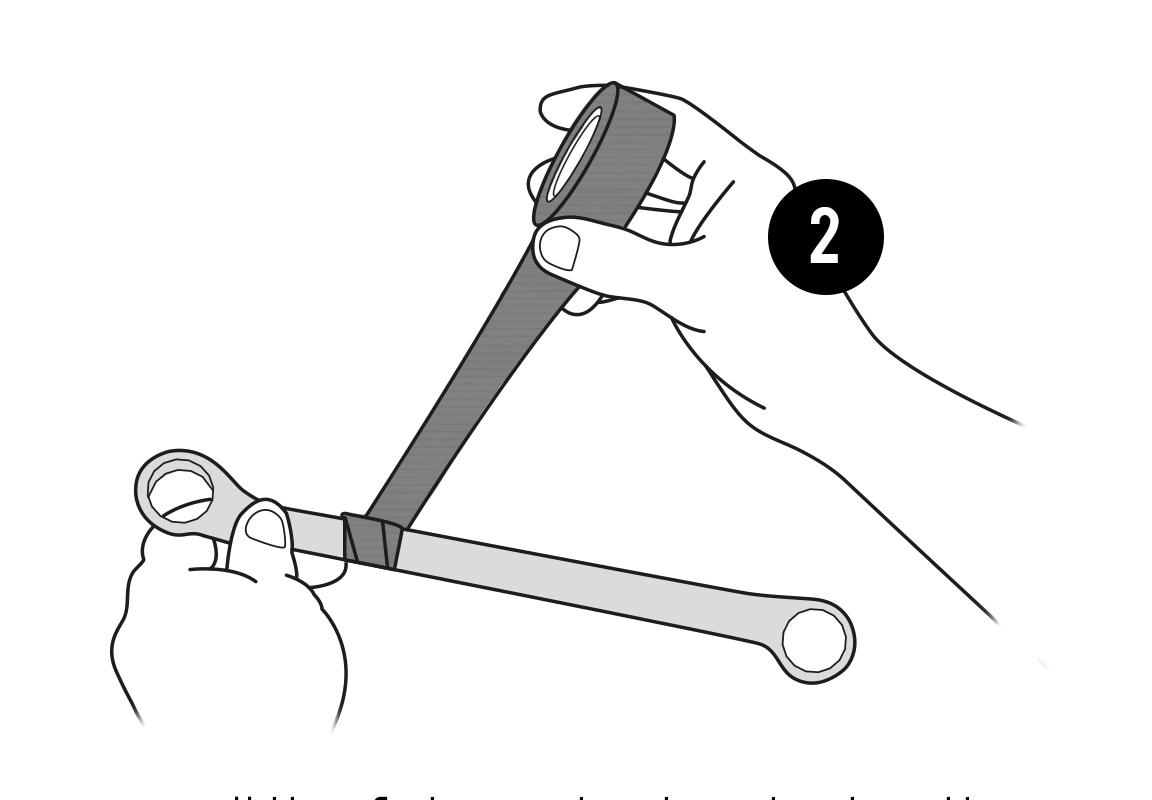

After covering statistics and legislation that help you understand why tethering is so important, you’ll not only discover what testing methods to look for when buying tethers, but learn how to safely transport and store your tethered tooling. You’ll also learn classifications of different tool types and the options available for tethering them, giving you the skills to select and apply the correct tethers to your own tools.

The real benefit of this course is getting to physically practice selecting and applying a wide range of tethers to different types of tooling. We’ll also show you how to use the Leading Edge tethering roadmap to help you find a complete tethering solution.

Correctly tethering a tool takes more than tying a piece of string around the handle. It’s about fully understanding the risks, configuration and selection, equipment mechanics, usage and best practices. This course gives you the knowledge, awareness and practical skills to create a safe environment for tools and materials at height.

We believe your employees tool drop prevention skills should be proven just like any other height safety course. That’s why every trainee must sit a multi-choice examination to demonstrate their competence to use tools safely at height.

We provide our own projector, screen, laptop, the latest tool safety products, and a bag full of tethering equipment and tools to deliver the practical and theory lessons. We just need somewhere to teach. So if you’re booking a course on your site, don’t forget to arrange a training room that can hold the appropriate number of people.

You might not think an extra strap under the arms would make much difference. But our testing showed they not only increase overall strength and make a big difference to the comfort, they also stop the harness riding up and elongating in the event of a fall, making it impossible to fall out.

The load capacity of our harnesses goes all the way up to 21½ stone! They’re proven to be 100% safe – even for heavier harness users.

note: user weight should also allow for clothing and PPE

With a rescue step you’re fully protected from the dangers of hanging in a harness after a fall. It sits conveniently on your shoulder with a pull-cord, which when activated releases an adjustable system loop. Standing on this loop alleviates pressure and allows normal blood flow through your legs, giving you vital extra time to be recovered.

Tails make it easier to attach your harness to a fall-protection system. They extend the rear anchor point with a low-stretch high-strength Dyneema lanyard, which means you no longer have to reach between your shoulders to connect. Our tails are tested for high impact edge abrasion, feature reinforced eyelets and are rated to 26kN. When used in conjunction with inertia reels, they reduce the likelihood of the cable and hook coming into contact with the edge.

Leading Edge harnesses offer a choice of 1 or 2 points of anchorage attachment (front & rear). With 2-point harnesses, you have the option of either Soft Loops or D-Rings placed on the chest of your harness offering greater flexability in working.

Leading Edge harnesses come in three sizes, catering for people of all body shapes. To find a good fit, compare your chest measurement to the size ranges below. Keep in mind elasticated webbing harnesses are much more flexible with their sizing.

Check for minor cuts or abrasions on the webbing body. This type of damage can cause failure of the webbing during a fall. If anything looks suspicious, inform your manager and find a different harness.

A 1mm cut on the selvedge edge is enough to cause catastrophic failure with dynamic impact caused via a fall.

All harnesses are designed to dissipate impact forces into the largest muscle group: the thigh muscles. If worn loosely, the harness straps will ride up and transfer this harmful force into the base of the spine. Equally, there is a chance that you can fall out of the side of a loose harness. Wearing your harness correctly is vital for your safety!

Make sure your rear dorsal D-Ring is positioned correctly between your shoulder blades. It should never sit lower down your back. This would result in possible severe lower back trauma in the event of a fall.

Thread the metal buckles situated on your chest and leg straps, placing the male buckle through the female buckle to secure. They should sit flush against each other forming a solid link.

Adjust and Pull the ends of the loose straps to remove any slack. The ideal tension for both the chest and leg straps is ‘two fingers tight’ – i.e. when you can fit two fingers between your body and the harness strap. Loose webbing causes harmful localised impact trauma.

Make sure at least one plastic slider on each strap is pushed tightly against it’s buckle. This ‘locking off’ prevents the webbing slipping through the buckle during a fall – otherwise you risk either falling out of your harness or (given enough free fall) incurring damage.

Our black elasticated harnesses have a number of major benefits over standard harnesses – ideal if you work in your harness day in, day out.

Our premium black elasticated harness webbing has a subtle flex that moves and stretches with you as you work. It makes a huge difference and encourages proper fitting due to the increased level of comfort. We recommend it if your job requires you to wear a harness for long periods of time.

We make most of our harnesses by hand in our own UK factory to maintain the highest levels of safety and quality.

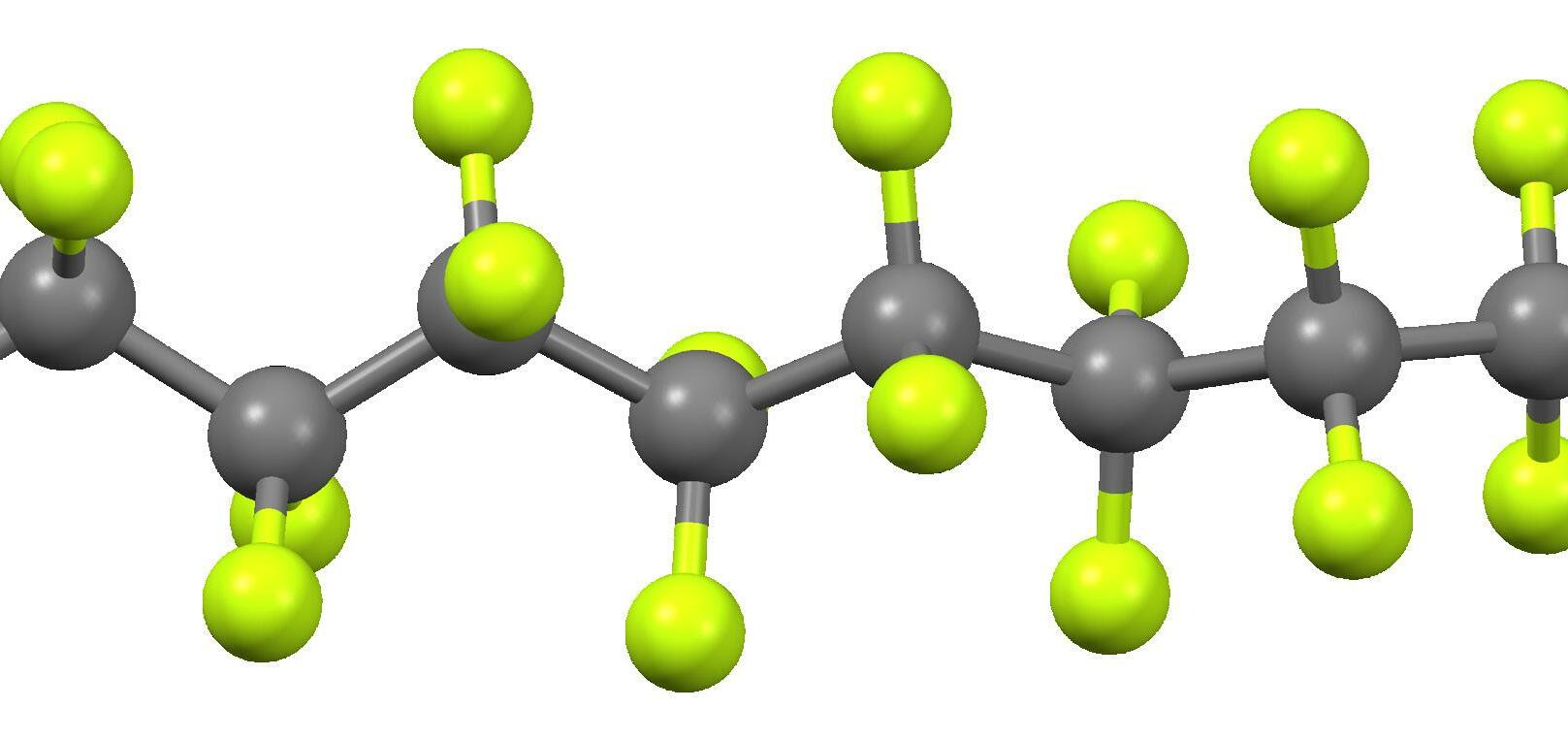

When you invest in a harness, service life matters. By coating the harness material with Teflon (a synthetic fluoropolymer) they instantly gain resistance to UV, heat and chemicals whilst also becoming waterproof with low friction. In simple terms, it provides a protective shield that greatly increases durability.

Protective case contains information tag to record annual inspections.

Elastic webbing for work positioning.

Easy-to-use aluminium alloy bent D-Rings.

Elastic webbing for work positioning.

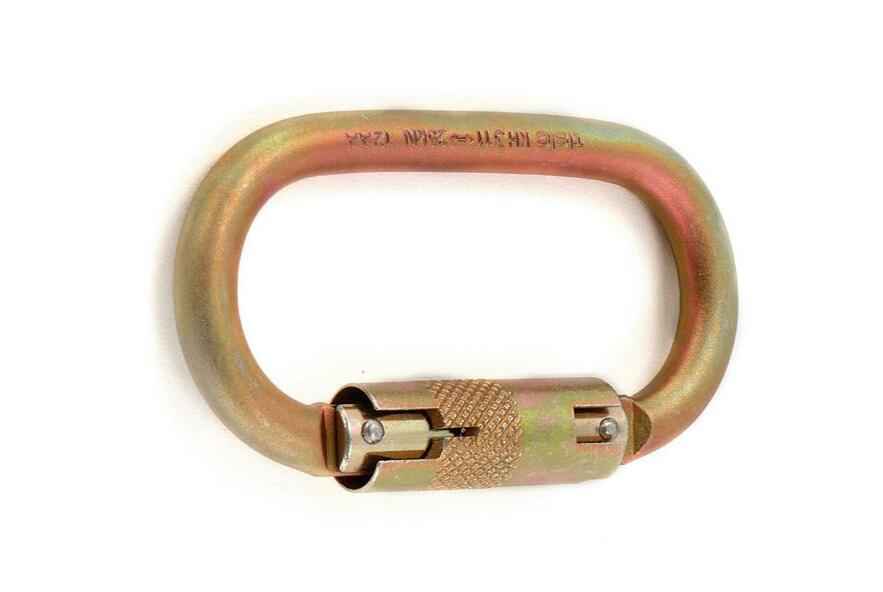

Lanyards are the most extensively used piece of equipment in the height safety arsenal. It’s no surprise given their versatility in working lengths up to a maximum of 2m. There are 5 different kinds of lanyards used to achieve a range of safe access from simple fixed restraint lanyards for static locations up to adjustable twin lanyards for climbing and traversal of complex structures. Lanyard are fully covered by our working at height courses, where you’ll learn the theory around selection, suitability and practical use of your lanyard. This gives you the ability to confidently and competently select and use the right lanyard for the right application.

Allow users to work within a limited proximity of an open edge in restraint. Each lanyard can be varied in length from 1m-2m to suit the needs of the job or working at height situation for maximum flexibility depending on anchorage location, height of user and proximity to the hazard.

Allow users the ability to work in restraint, but with the freedom to continuously adjust their system length to work within the proximately of an open edge or edges. Adjustable lanyards have a built in fall arrest backup safety system and can be purchased in any adjustable lengths to suit the needs of your job.

Fall arrest lanyards reduce the impact of a fall via a shock-absorber within the system. They can potentially open up to 1.75m in a fall factor 2 scenario. These lanyards come in lengths up to a maximum of 2m. They should only be used with sufficient height clearance.

Allow users to stay continuously tied off when climbing or moving between anchor points. Twin lanyards come in various forms and types of materials to suit the needs of the job or working at height situation but ensure 100% tie off.

Allow users to work in restraint with restricted access to the open edge, due to the lanyard being a fixed distance suitable for that situation or individual’s needs. Fixed lanyards can be purchased in any individual length form 0.5m-2m in a range of materials to suit the needs of the job or working at height situation.

Adding a dyneema tail to your harness extends the attachment point on the rear dorsal plate away from the hard-to-reach area between your shoulder blades. This makes it incredibly easy to hook up to your inertial reel or adjustable fall restraint system (Edge), whilst visually verifying a safe connection.

Tails are made from Dyneema – part of the Kevlar family of advanced narrow fibres. They are extremely strong, abrasion resistant, lightweight and flexible. As a result, they can be choked, wrapped or used over an edge.

Fixed rope lanyards provide a simple way to work in restraint, for environments where working in fall arrest is unsuitable or not permitted. MEWP’s are a common use case.

Using a lanyard with correct length, simply attach one end to the anchorage point inside the basket and the other to your harness. The lanyard then allows you to work up to a fall hazard but never move beyond it. This means a shock-absorber is not required. It also enables a greater scope of anchorage points.

Unlike traditional three strand twisted rope, which is stiff and vulnerable to abrasion, MEWP lanyards are made from advanced multi-braid rope with a protective outer-wear sleeve. This makes them extremely hard-wearing for daily use in harsh environments. The components are also machine sewn, which, unlike splicing or knotting techniques, maintains the lanyards load capacity.

1m LAN-FIXED-R-KK-1

1.5m LAN-FIXED-R-KK-1.5

2m LAN-FIXED-R-KK-2

1m LAN-FIXED-R-KSCAFF-1

1.5m LAN-FIXED-R-KSCAFF-1.5

2m LAN-FIXED-R-KSCAFF-2

Traditional shock-absorbers use a single internal tear-strip (to reduce impact force) combined with an additional structural loop. Leading Edge shock-absorbers utilize advanced narrow fibres to create a ‘dual-tear’ system. This features two webbing tear-strips sewn together to form it’s own structural loop. The benefit is twofold. Firstly, the energy from a fall is transferred equally between two straps instead of one. This halves the stopping distance and creates a much smoother arrest trend, making a fall feel less aggressive. Secondly, the internals compress into a much smaller space, resulting in a more compact, robust and lightweight design.

The packs will only open in an actual fall and always remain integrally connected, even if they become overloaded. This means you can safely use one as a connection link in your system without fear of it pulling open accidentally or failing.

The next-generation shock-absorbing lanyard offers several improvements in design, materials. This gives you greater protection, performance and service life thanks to the advanced abrasion-resistant multi-braid rope, sewing techniques and high quality metal components. The Leading Edge advanced-fibre shock-absorber also greatly reduces impact force and potential stopping distance, making a fall much safer and less aggressive on your body.

This type of lanyard is most commonly utilized by scaffolders but can also be used by anyone requiring limited access, with a maximum of 2m workable access between anchorage point and harness.

1m LAN-RSHOCK-KK-1

1.5m LAN-RSHOCK-KK-1.5

2m LAN-RSHOCK-KK-2

1m LAN-RSHOCK-KSCAFF-1

1.5m LAN-RSHOCK-KSCAFF-1.5

2m LAN-RSHOCK-KSCAFF-2

The next-generation climbers lanyard offers several improvements in design, materials. This gives you greater protection, performance and service life thanks to the advanced abrasion resistant multi-braid rope, sewing techniques and high quality metal components. The Leading Edge advanced fibre shock-absorber also greatly reduces impact force and potential stopping distance, making a fall much more comfortable and less jarring on your body.

When climbing horizontally or vertically the twin arms provide 100% tie-off while traversing between anchorage points by ensuring at least one lanyard is connected at all times.

» Edge-tested for high impact edge abrasion

» Advanced shock-absorber pack

» Twin lanyard arms, 100% tie-off

» Max user weight: 136kgs

» Minimum breaking load: 26kN

» CE approved

» Made in the UK

1m

LAN-TRSHOCK-KK-1

1.5m LAN-TRSHOCK-KK-1.5

2m LAN-TRSHOCK-KK-2

1m

LANTRSHOCK-KSCAFF-1

1.5m LAN-TRSHOCK-KSCAFF-1.5

2m LAN-TRSHOCK-KSCAFF-2

Shock-absorbing variable restraint lanyards have all the benefits of working in restraint (eliminating the risk of a fall, controlling working area etc.) with the additional advantage of a built in shock-absorber pack. This means the lanyard can adjust to suit required working length and be used like a normal shock-absorbing fall-arrest lanyard.

Example: a scaffolder working at low level with restricted height clearance can simply shorten the lanyard length to work in restraint, preventing them from reaching a fall hazard. At higher levels with enough height clearance, it can be fully extended to gain maximum freedom of movement while staying protected by the fall arrest shock-absorber.

» 14mm low stretch/high strength dyneema webbing

» 25mm Teflonised polyester tubular webbing outer jacket

» Edge-tested for high impact edge abrasion

» Shock absorber pack

» Max adjustment length 2m (including connectors)

» Max user weight: 136kgs

» Minimum breaking load: 26kN

» CE approved

» Made in the UK

PRO-LAN-VAR-KK-2

PRO-LAN-VAR-KSCAFF-2

Variable restraints allow you to work safely with height exposure by restricting you from reaching zones where the risk of a fall exists. They operate similarly to fixed restraints but have far greater flexibility, because the working length can be manually increased or decreased to accommodate a wider scope of applications. This saves you from requiring multiple fixed length lanyards of different lengths.

The ‘one size fits all’ approach is particularly helpful when accounting for user height variance in relation to anchorage distance and position – for example mobile elevated work platforms, railings etc.

» 14mm low stretch/high strength Dyneema webbing

» 25mm Teflonised polyester tubular webbing outer jacket

» Edge-tested for high impact edge abrasion

» Max adjustment length 2m (including connectors)

» Max user weight: 136kgs

» Minimum breaking load: 26kN

» CE approved

» Made in the UK

LAN-VAR-KK-2

LAN-VAR-KSNAP-2

LAN-VAR-KSCAFF-2

Advanced adjustable single lanyards allow continuous length adjustment to suit the application. This means you can manually set the desired working distance between the anchorage and the fall hazard, limiting your exposure of a fall.

The restraint lanyard facilitates both horizontal and vertical use and features built-in fall arrest protection should you fall, with the added safety benefit of reduced stopping distance.

» 11mm multi-braid pro-static rope

» Advanced fall arrest rope grab

» Edge-tested for high impact edge abrasion

» Max user weight: 136kgs

» Minimum breaking load: 26kN

» CE approved

» Made in the UK

Pro-Twins provide 100% tie-off while traversing between anchorage points by ensuring at least one lanyard is connected at all times. Once your point of work is reached, you can adjust and shorten each lanyard independently to achieve work-positioning or restraint without needing a belt or pole strap to hold you in position. This is made possible by the unique Dyneema webbing link that ergonomically connects two rope grabs together. Should you fall however, the lanyard has a built-in fall arrest function with the added safety benefit of a reduced stopping distance.

» 2x advanced fall arrest rope h » Edge-tested for high impact edge abrasion » Max user weight: 136kgs » Minimum breaking load: 26kN » CE approved

Made in the UK

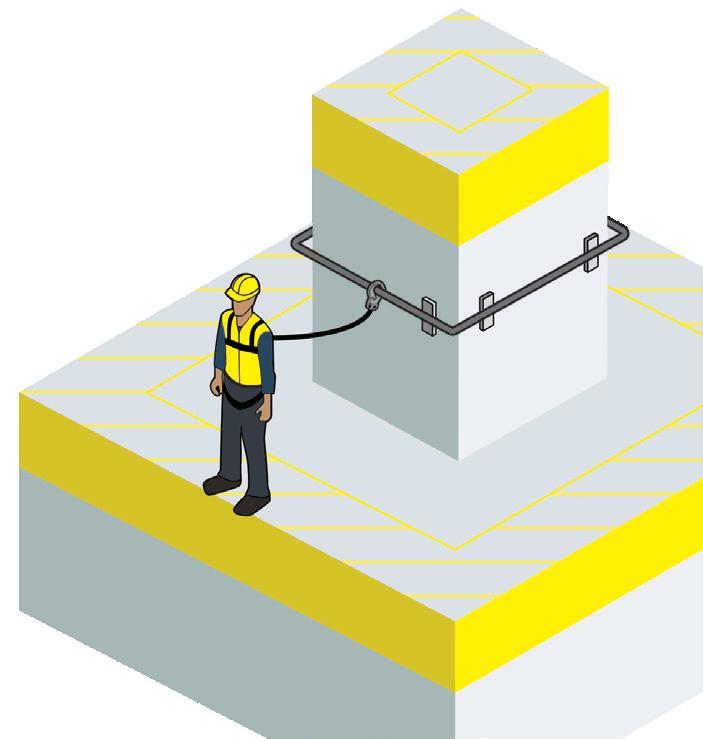

Gain a greater work area, combining fall-restraint and fall-arrest in one complete system.

Adjustable fall-restraint is a prevention system by which a person is restricted from reaching zones where the risk of a fall exists. As a system, it’s extremely versatile, allowing for both front and rear harness connection in several configurations across horizontal, vertical and pitched planes. Should it all go wrong the system has an advanced rope grab that is designed and tested to provide shock-absorbing fall arrest protection in-line within the system. The unique profile of the cam body, is engineered to allow the impact force to be absorbed and dissipated through the combination of physical contact between the multi-core rope, and the cam’s grooved shape and level of surface friction under loading.

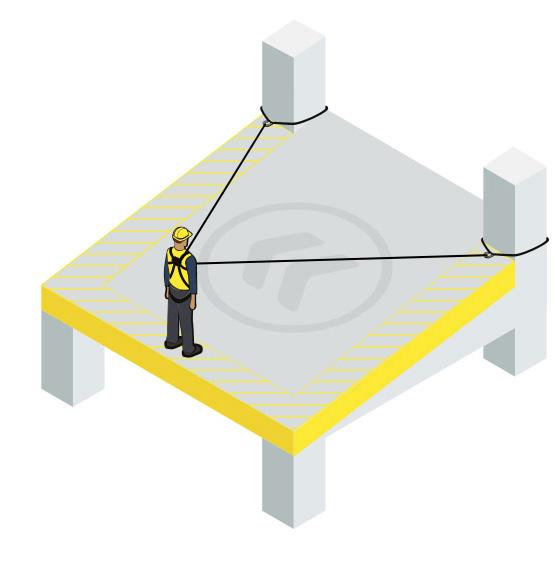

This system of work will allow users to be able to safety set up and stay in restraint when using a single adjustable rope line, anchored parallel to their working edge at ‘fall factor 2’ (foot level). This will give them access to a 2 meter working area, over one open edge.

This system of work will allow users to be able to safety set up and stay in restraint when using a single adjustable rope line, anchored at the optimum position ‘fall factor 0’ (above their head). This will give them access to a 1 meter working area, over one open edge.

This system of work will allow users to be able to safety set up and stay in restraint when working over two, three or four leading edges. Users will use two adjustable rope lines that are anchored diagonally across their working area. This will give them access to wider working areas.

This system of work will allow users to be able to safety set up and stay in restraint when using a single adjustable rope line on a pitched surface through attaching to the front of their harnesses. This will give them access to a 2 meter working area, over one open edge.

This system of work will allow users to work in restraint over a wide area. They will be able to safety set up and stay in restraint when using two adjustable rope lines, that are anchored parallel to their working edge ‘fall factor 2’ (foot level). This will give them access to wider working area, over one open edge.

This system of work will allow users to be able to safety set up and stay in restraint when using two adjustable rope lines attached to the front of their harness. This system will give users access to wider working areas, over two or three open edges.

Adjustable restraint is a prevention system by which a person is restricted from reaching zones where the risk of a fall exists. As a system, it is extremely versatile, allowing for both front and rear harness connection in several configurations across horizontal, vertical and pitched planes.

Should it all go wrong the system has an advanced rope grab that is designed and tested to provide shockabsorbing fall arrest protection in-line within the system. The unique profile of the cam body, is engineered to allow the impact force to be absorbed and dissipated through the combination of physical contact between the multi-core rope, and the cam’s grooved shape and level of surface friction under loading.

» 11mm multi-braid pro static rope

» Fall arrest cam positioning device (rope grab)

» Max user weight: 136kgs

» Minimum breaking load: 26kN » CE approved » Made in the UK » Longer lengths available on request

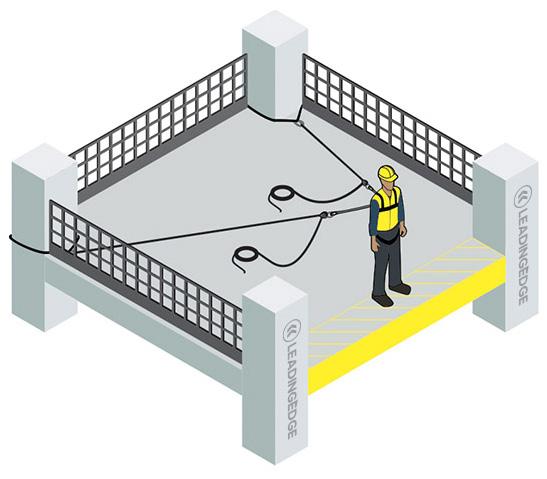

Maximise your working area and support multiple users with greater levels of protected access over larger areas of open edge exposure. When used in conjunction with adjustable fall restraint ropes, lifelines allow you to safely traverse exposed leading edges and eliminates the risk of pendulum whilst working in restraint, with fall-protection back-up for total security and peace of mind.

With training you’ll learn how to deploy, position and tension a lifeline, operate it using front and rear attachment across horizontal and pitched planes, and explore more advanced techniques such as lifeline bending for multiple edge access and intermediate attachments to support multiple simultaneous users over greater spans.

Allows a single user to remain within restraint when accessing one open edge spanning up 20 meters.

The use of a lifeline with an attached intermediate anchorage will allow two to three users to remain within restraint when accessing one open edge spanning up 20 meters.

Allows up to three users to remain within restraint when accessing one open edge spanning up 10 meters.

Bent lifelines allow a single user to safely access a corner with 2 open edge while remaining in restraint without risk of falling through pendulum.

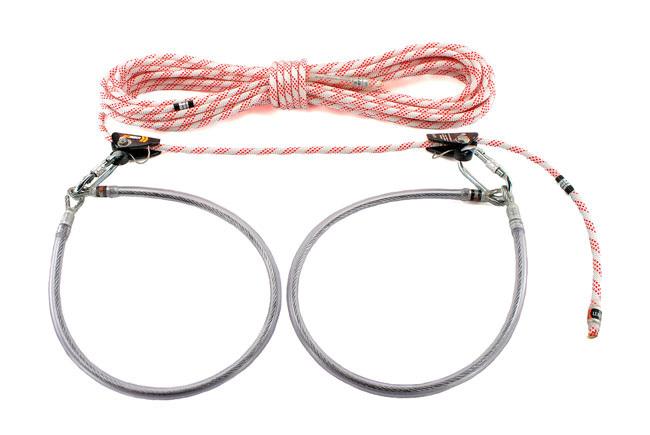

When working at height, a permanent installed horizontal lifeline is not always necessary as it’s very costly and takes too long to install. This 20m temporary lifeline system is a quick and easy to install, rigged either at foot level too above head height for maximum anchorage and rigging versatility. Allows up to 3 people to work from the system using adjustable fall restraint ropes to reach the open edge exposure.

This lifeline system has advanced rope grabs devices at both ends that provides two special functions. Firstly, they operate as rope tensioning clamps, in simple terms, the 11mm lifeline rope is pulled through the rope grabs until the line becomes tight and the slack has been removed out of the system, making ready to use. Secondly, the advanced rope devices are designed and tested to provide shock-absorbing fall arrest protection in-line within the system. The unique

profile of the cam bodies, are engineered to allow the impact force to be absorbed and dissipated through the combination of physical contact between the multicore rope, and the cam’s grooved shape and level of surface friction under loading. Hypothetically, the fall-protection back-up is only there should something go wrong, and a person falls due to miss-usage or operator error, as the primary objective is to safely work in restraint, thus no fall should occur. However, if the worst was to happen there is protection for total security and peace of mind.

This versatile temporary lifeline is easily attached via the supplied karabiners to suitable anchorages, for example: eye-bolts, omni-anchors, or fall arrest slings when fixing to beams, columns or other fixed structural points of sufficient strength.

This 20m temporary lifeline system is quick and easy to rig at either foot level or above head height for maximum anchorage versatility. It allows up to 3 people to work using adjustable fall restraint ropes or fall arrest equipment to reach the open edge exposure.

The lifeline has an in-line ratchet tensioning device that enables 1 person to quickly rig it and easily adjust the tension. This is especially useful when installing above head height.

The lifeline is made from heavy-duty hi-vis polyester webbing, which makes it hard wearing and more visible. It is supplied with 2x sewn on captive swivel snap hooks for connection to the webbing anchorage slings. This means they cannot be removed or lost. The snap hooks are also auto-locking for extra safety.

3x simple ‘O’ rings replace traditional pulleys, which are not suitable for use with webbing lifelines.

Uniquely, the lifeline comes with an in-line integrated shock absorber, protecting the lifeline from being overloaded. This special feature means the lifeline is suitable for use with adjustable fall restraint systems.

The whole kit comes complete and ready to go in its own kit bag.

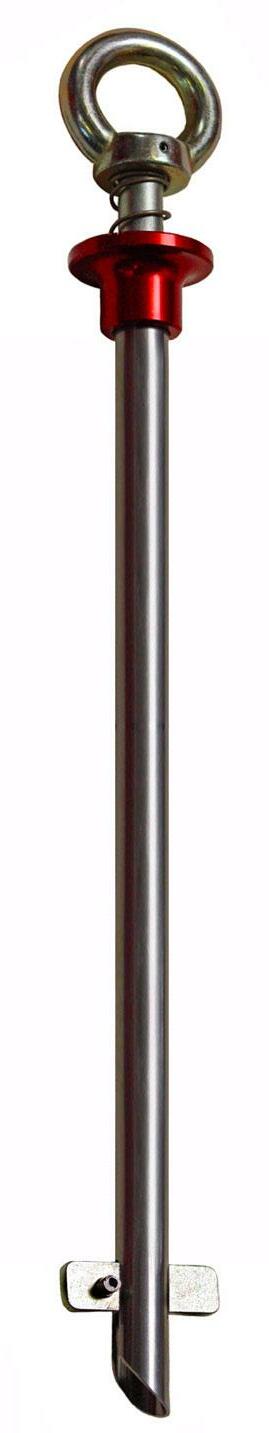

Temporary anchorage device, omni directional loading, designed to pass through holes in walls, steel work or slabs up to a maximum depth of 1000mm (depending on chosen length) with pre-drilled or formed holes of 20 to 30mm diameter, suitable for horizontal and vertical applications for fall arrest and restraint systems.

Temporary concrete anchorage device, automatic locking (release-activation) design. Configured to pass through walls or slabs up to 330mm with pre-drilled or formed holes of 20 to 28mm diameter, compressive strength of 15n/mm2 is required for fall arrest, suitable for horizontal and vertical applications.

» CE Approved

» Made in the UK

» Minimum breaking load: 26kN

330mm DYWIDAG-330

Temporary steel anchorage device, automatic locking (release-activation) design, structural steel thicknesses up to 43mm with pre-drilled holes of 20 to 28mm diameter.

» CE Approved

» Made in the UK

» Minimum breaking load: 26kN

Temporary dyneema anchorage sling, made from ultra low-stretch advanced fibre ‘dyneema’ webbing, incorporating tough tubular webbing outer jacket for greater protection, edge-tested for high impact edge abrasion, suitable for horizontal and vertical fall arrest and restraint applications.

» 14mm low stretch/high strength dyneema webbing

» 25mm teflonised polyester tubular webbing outer jacket » Can be wrapped or choked » Minimum breaking load: 26kN » CE Approved

The concrete swivel anchor rotates through 360° and the D-Ring pivots through 180° for maximum versatility. It can be reused and is ideal for permanent or portable use for horizontal lifeline systems, tie-back, staging and rigging. This anchor is supplied with a one time use Steel bolt with sleeve, which is suitable for fixing to concrete surfaces. The anchor requires a 19mm drilled hole to accommodate the sleeve, and needs a minimum hole depth of 127mm. Hole location must be 229mm away from any edge.

» Minimum breaking load: 44KN

» Attachment Eye Diameter: 57mm

» Material: Zinc Plated Steel

» Required hole diameter: 19mm

» Require hole depth: 127mm

» CE approved

The steelwork swivel anchor rotates through 360° and the D-Ring pivots through 180° for maximum versatility. It is ideal for permanent or portable use for horizontal lifeline systems, tie-back, staging and rigging. This anchor is supplied with a Steel bolt, which is suitable for use when fixing the anchor to steel surfaces. The anchor requires a 16mm drilled hole to accommodate the bolt, and needs a minimum hole depth/thickness of 6mm. Hole location must be 76mm away from any edge.

» Minimum breaking load: 44KN

» Attachment Eye Diameter: 57mm

» Material: Zinc Plated Steel

» Required hole diameter: 16mm

» Require hole depth: 6mm

approved

Door anchor is designed to install without compromising the structure in any way. There is no drilling or welding required, you simply compress the device between the vertical sides of the door or window and tighten. Designed to create a safe connecting point where it is difficult to find anchorage on the wall, pillar and joist

» 2 person anchor

» Corrosion-resistant

» Adjustable width fitting

» Reusable

» Minimum breaking load: 23kN 2-Person Anchor DBA-2

This removable anchor is designed to be mobile, quick and to simple to use. The spoon and cone design is suitable for use in concrete. It locks and removes using a hand-operated spring loaded trigger that activates a locking device. No additional tools are required. The anchor requires a 20mm drilled hole to accommodate the sleeve, and needs a minimum hole depth of 89mm. For slabs thickness’s between 13-31cm the anchor must be installed 31cm away from the edge. With slabs over 31cm the anchor can be installed 16cm from the edge.

» Suitable for vertical, horizontal or overhead use

» Spring loaded trigger that activates to engage/disengage the securing mechanism

» Reusable

»

Maximum User Weight: 136kg

» Minimum breaking load: 22kN

Useful additions to support your height safety gear.

Everything you need to work at height.

Kits are the simplest way to gain a complete safety system for any work at height activity.

Choose between a rope or webbing lifeline. Variations cover equipment for 1 , 2 or 3 people The kit includes a 1-point harness with rear D-Ring and 1m lanyard tail

Lifeline kits come with a pair of anchorage devices. The Rope Kit comes with 2m wire slings and the Webbing Kit comes with webbing sling s. You can choose to add omni-anchors

Slings can be wrapped around a structure while omni anchor are pushed through holes in the structure. Both methods create a secure anchor point.

Your lifeline kit comes with an adjustable fall restraint rope available in three standard lengths – 5m, 10m, 15m and 20m.

You may request custom lengths by speaking to a sales advisor. e.g. 3m, 12m, 50m etc.

Without proper training, operating a Lifeline Kit can be potentially dangerous. Before purchasing a kit, operatives should obtain a Working at Height certificate.

The combined systems in this kit allow you to safely traverse exposed leading edges and eliminates the risk of pendulum, whilst working in restraint. This is the safest and most desirable method of work, being at the top of individual height safety hierarchy of provision. Should it all go wrong, the combined systems have fall protection back-up for total security and peace of mind in the event of a fall.

PRO-RRL-KIT-1P-20-5-D

10m

15m

PRO-RRL-KIT-1P-20-10-D

PRO-RRL-KIT-1P-20-15-D

EN361 / EN795 / EN354 / EN362 / EN566 / EN353-2 / EN12278 1-Person Rope Restraint Lifeline Kit Add Omni Anchor OMNI350

20m Custom Kit Need something different? Fully customize this kit with alternative specifications. Custom Anchorage Type Custom Restraint Length Custom Tail Length Add or Remove Components

350mm OMNI600

600mm

1 2 3

Anchorage Points Lifeline Kits Ladder Kits

Restraint Lanyard Kits Fall-Arrest Lanyard Kits 199

The combined systems in this kit allow you to safely traverse exposed leading edges and eliminates the risk of pendulum, whilst working in restraint. This is the safest and most desirable method of work, being at the top of individual height safety hierarchy of provision. Should it all go wrong, the combined systems have fall protection back-up for total security and peace of mind in the event of a fall.

5m

Adjustable

10m

15m

PRO-WFL-KIT-1P-20-15-D

Add Omni Anchor OMNI350

PRO-WFL-KIT-1P-20-20-D 1-Person Webbing Restraint Lifeline Kit This kit comes with a medium/large size harness by default . If you require a small or extra large harness please specify when placing your order.

350mm OMNI600

600mm

1 2 3

Anchorage Points Lifeline Kits Ladder Kits

Restraint Lanyard Kits Fall-Arrest Lanyard Kits 201

The combined systems in this kit allow you to safely traverse exposed leading edges and eliminates the risk of pendulum, whilst working in restraint. This is the safest and most desirable method of work, being at the top of individual height safety hierarchy of provision. Should it all go wrong, the combined systems have fall protection back-up for total security and peace of mind in the event of a fall.

5m

Adjustable

10m

15m

PRO-RRL-KIT-2P-20-15-D

Add Omni Anchor OMNI350

PRO-RRL-KIT-2P-20-20-D 2-Person Rope Restraint Lifeline Kit This kit comes with a medium/large size harness by default . If you require a small or extra large harness please specify when placing your order.

350mm OMNI600

600mm

1 2 3

Anchorage Points Lifeline Kits Ladder Kits

Restraint Lanyard Kits Fall-Arrest Lanyard Kits 203

The combined systems in this kit allow you to safely traverse exposed leading edges and eliminates the risk of pendulum, whilst working in restraint. This is the safest and most desirable method of work, being at the top of individual height safety hierarchy of provision. Should it all go wrong, the combined systems have fall protection back-up for total security and peace of mind in the event of a fall.

5m

Adjustable

10m

15m

PRO-WFL-KIT-2P-20-15-D

Add Omni Anchor OMNI350

PRO-WFL-KIT-2P-20-20-D 2-Person Webbing Restraint Lifeline Kit This kit comes with a medium/large size harness by default . If you require a small or extra large harness please specify when placing your order.

350mm OMNI600

600mm

1 2 3

Anchorage Points Lifeline Kits Ladder Kits

Restraint Lanyard Kits Fall-Arrest Lanyard Kits 205

The combined systems in this kit allow you to safely traverse exposed leading edges and eliminates the risk of pendulum, whilst working in restraint. This is the safest and most desirable method of work, being at the top of individual height safety hierarchy of provision. Should it all go wrong, the combined systems have fall protection back-up for total security and peace of mind in the event of a fall.

5m

Adjustable

10m

15m

PRO-RRL-KIT-3P-20-15-D

Add Omni Anchor OMNI350

PRO-RRL-KIT-3P-20-20-D 3-Person Rope Restraint Lifeline Kit This kit comes with a medium/large size harness by default . If you require a small or extra large harness please specify when placing your order.

350mm OMNI600

600mm

1 2 3

Anchorage Points Lifeline Kits Ladder Kits

Restraint Lanyard Kits Fall-Arrest Lanyard Kits 207

The combined systems in this kit allow you to safely traverse exposed leading edges and eliminates the risk of pendulum, whilst working in restraint. This is the safest and most desirable method of work, being at the top of individual height safety hierarchy of provision. Should it all go wrong, the combined systems have fall protection back-up for total security and peace of mind in the event of a fall.

5m

Adjustable

10m

15m

PRO-WFL-KIT-3P-20-15-D

Add Omni Anchor OMNI350

PRO-WFL-KIT-3P-20-20-D 3-Person Rope Restraint Lifeline Kit This kit comes with a medium/large size harness by default . If you require a small or extra large harness please specify when placing your order.

350mm OMNI600

600mm

1 2 3

Anchorage Points Lifeline Kits Ladder Kits

Restraint Lanyard Kits Fall-Arrest Lanyard Kits 209

Basic level of ladder stability and mobility. Personal safety achieved only when clipped onto ladder. 1m working area of ladder stabilization.

Medium level of ladder stability and mobility. Full height safety protection with work positioning and fall arrest. 1m working area of ladder stabilization.

High level of ladder stability & mobility. Full height safety protection with work positioning and fall arrest. 10m wide working area of stabilization.

Eye-bolt goes directly into structure. Adjustable strap goes between the eye-bolt and the ladder meaning the working area is directly in front of your anchorage. Height safety protection is only achieved once clipped on to the ladder.

Eye-bolt goes directly into structure. Adjustable strap goes between the eye-bolt and the ladder, meaning the working area is directly in front of your anchorage. Height safety protection is provided from the ground up. This system allows you to work hands free, whilst being protected should you fall.

Eye-bolts can be installed up to 10m apart, allowing you to quickly and easily move the ladder across a wide working area by adjusting and re-tightening the ladder stabilizing straps. This provides maximum mobility. Height safety protection is provided from the ground up. This system also allows you to work hands free, whilst being protected should you fall.

Fall protection systems may halt a fall but remaining suspended in a harness is more dangerous than you may realise. Here’s what you need to know about height rescue after a fall incident.

For those of us who work at height fall hazards are a necessary evil. It also means we have a duty — not just to ourselves, but to others. For employers it means making the correct provisions for the workforce. For operatives it means working safely and acting quickly in an emergency. But that’s only half the story. Because our moral duties are enforced by our legal ones: the WAH Regulations 2005 and British Standard 8437.

Height rescue is here to protect your team and satisy the law

Fulfilling your legal and moral duties requires two things: training and equipment. For height rescue that means selecting appropriate recovery systems and giving workers the skills to operate them. But because training and equipment are intimately linked, we believe they should go hand in hand. So by manufacturing our own equipment and developing our courses around that equipment, Leading Edge offer the safest, simplest way to gain adequate rescue provision.

After a fall the body goes through several stages of physical distress. These are a group of conditions known as Suspension Intolerance and Reflow Syndrome. Their effects can be devastating. So much so in fact that 20% of all fall casualties are presumed dead within 10 minutes And for everyone else? Within the hour.

We’ve learnt that fatalities can occur within 10 minutes of a fall. But the truth is it only takes 5 minutes for irreversible brain damage to occur. So while it’s an testament to our emergency services that they’re able to arrive within 8 minutes of being notified, for us that’s already too late. By being prepared to act immediately you’ll not only save a life, but halt a lifetime of difficulty and hardship for the casualty and their family.

By conducting repeated self and assisted recoveries - in vertical and horizontal rigged positions with a variety of fall protection equipment - you’ll gain total confidence recovering a fall casualty with your chosen rescue system(s). And to test you can act under pressure, we’ll do a 5-minute rescue challenge to compete for the fastest, safest recovery.

We provide our own dedicated specialist rescue gear including rigging props, recovery systems and rescue dummy to deliver theory and practical lessons. We just need somewhere to teach. So, if you’re booking a course on your site, talk to us to discuss the best way to acheive your needs.

The height rescue course provides dedicated training for three types of rescue system. Together they allow the safe recovery of a fall casualty in any situation using the raising, lowering or combined raising and lowering methods. But the course is far from generic. You choose which one you want—or all three—and your training focuses comprehensively on your chosen method/s, wasting no valuable time on things you’ll never need.

When lower floors are obstructed, glazed or high-rise, the haul system allows an unconscious fall casualty to be raised back to the area from which they fell. Though highly effective, its pulling mechanism requires a minimum of five people to conduct a safe and speedy recovery.

Execute the recovery of a conscious or unconscious fall casualty by lowering them safely to the ground or a lower floor. Requiring only one person to operate makes descent a quick and easy method of rescue, however it is only suitable for applications where there are no obstructions or restrictions beneath the floor from which the casualty fell, i.e. it’s safe to lower!

The winch system combines the benefit of both haul and descent in one simple device to ensure maximum safety for all situations. The winch is n ot only easy to deploy but requires only one person to affect a speedy rescue by either lowering or raising the casualty to safety.

Learn every rescue method during 8 hours of training with 1½ hours of theory and 6 hours of practical exercises — recommended for management.

Learn your choice of Winch, Descent or Haul system during 5 hours of training with 1 hour of theory and 3½ hours of practical exercises — ideal for general operatives.

It only takes five minutes for the onset of suspension intolerance to change a life forever. Venous pooling, orthostatic intolerance, vascular shock — learn how these devastating conditions affect a fall casualty. We’ll study the science and look at some eye-opening statistics to reveal why a rescue plan is essential for protecting people who work at height.

Explore 3 different recovery systems, discover their suitability and effectiveness for various recovery scenarios and get in depth practical training in the system/s of your choice. We’ll also look a the process and frequency of equipment inspection as well as anchorage considerations you will commonly encounter in the field.

By conducting repeated self and assisted recoveries — in vertical and horizontal rigged positions with a variety of fall protection equipment — you’ll gain total confidence recovering a fall casualty with your chosen rescue system/s. And to test you can act under pressure we’ll do a 5-minute rescue challenge to compete for the fastest, safest recovery.

Lowering Systems

Lowering Systems

By utilizing the force of 5 personnel, the horizontally rigged haul system manually raises a casualty 3m in a single pull. Its multibraid pro-static rope and Dyneema is edge tested for high impact abrasion and backed up with twin haul lines to provide dual fall arrest protection. Breaking load 26kN (2.6T).

Manually lower a fall casualty to safety with the descent system. This easy-to-use device can be rigged horizontally or vertically, requires only one person to operate. It includes an automatic safety override to prevent the accidental release of a casualty while lowering.

The winch rescue system is a combined man-riding (raising and lowering) device with a PED (Personal Evacuation Device) providing an automatic, controlled descent escape function. It only requires one person to operate and can be rigged horizontally or vertically, minimising edge exposure.

Rig and deploy the speed-optimised, stabilised rescue ladder in seconds. This self-contained system requires just one person to operate, can be rigged horizontally or vertically and features a reinforced double-width design with offset, solid rungs for quick and easy climbing.

4m R-LADDER-4 12m R-LADDER-12 15m R-LADDER-15 20m R-LADDER-20

HSE’s Riddor report shows dropped

objects are one of the top three causes of fatalities in the UK workplace.

In Construction, around 500,000 workdays per year are lost due to injuries, costing the industry £659 million.

CAUSED BY FALLING OBJECTS IN UK WORKPLACES 2019-20

CAUSED BY FALLING OBJECTS IN UK WORKPLACES 2019-20

OF THOSE

WERE IN THE CONSTRUCTION INDUSTRY

Statistics show that around 30% of all dropped object incidents are related to design, technical or mechanical issues, but almost half can be attributed to human factors.

49kg of Impact Force when dropped from a height over 3 storeys (10m).

After covering statistics and legislation that help you understand why tethering is so important, you’ll not only discover what testing methods to look for when buying tethers, but learn how to safely transport and store your tethered tooling. You’ll also learn classifications of different tool types and the options available for tethering them, giving you the skills to select and apply the correct tethers to your own tools.

The real benefit of this course is getting to physically practice selecting and applying a wide range of tethers to different types of tooling. We’ll also show you how to use the Leading Edge tethering roadmap to help you find a complete tethering solution.

Correctly tethering a tool takes more than tying a piece of string around the handle. It’s about fully understanding the risks, configuration and selection, equipment mechanics, usage and best practices. This course gives you the knowledge, awareness and practical skills to create a safe environment for tools and materials at height.

We believe your employees tool drop prevention skills should be proven just like any other height safety course. That’s why every trainee must sit a multi-choice examination to demonstrate their competence to use tools safely at height.

We provide our own projector, screen, laptop, the latest tool safety products, and a bag full of tethering equipment and tools to deliver the practical and theory lessons. We just need somewhere to teach. So if you’re booking a course on your site, don’t forget to arrange a training room that can hold the appropriate number of people.

Quickly and easily convert your existing tooling for safe work at height activities.

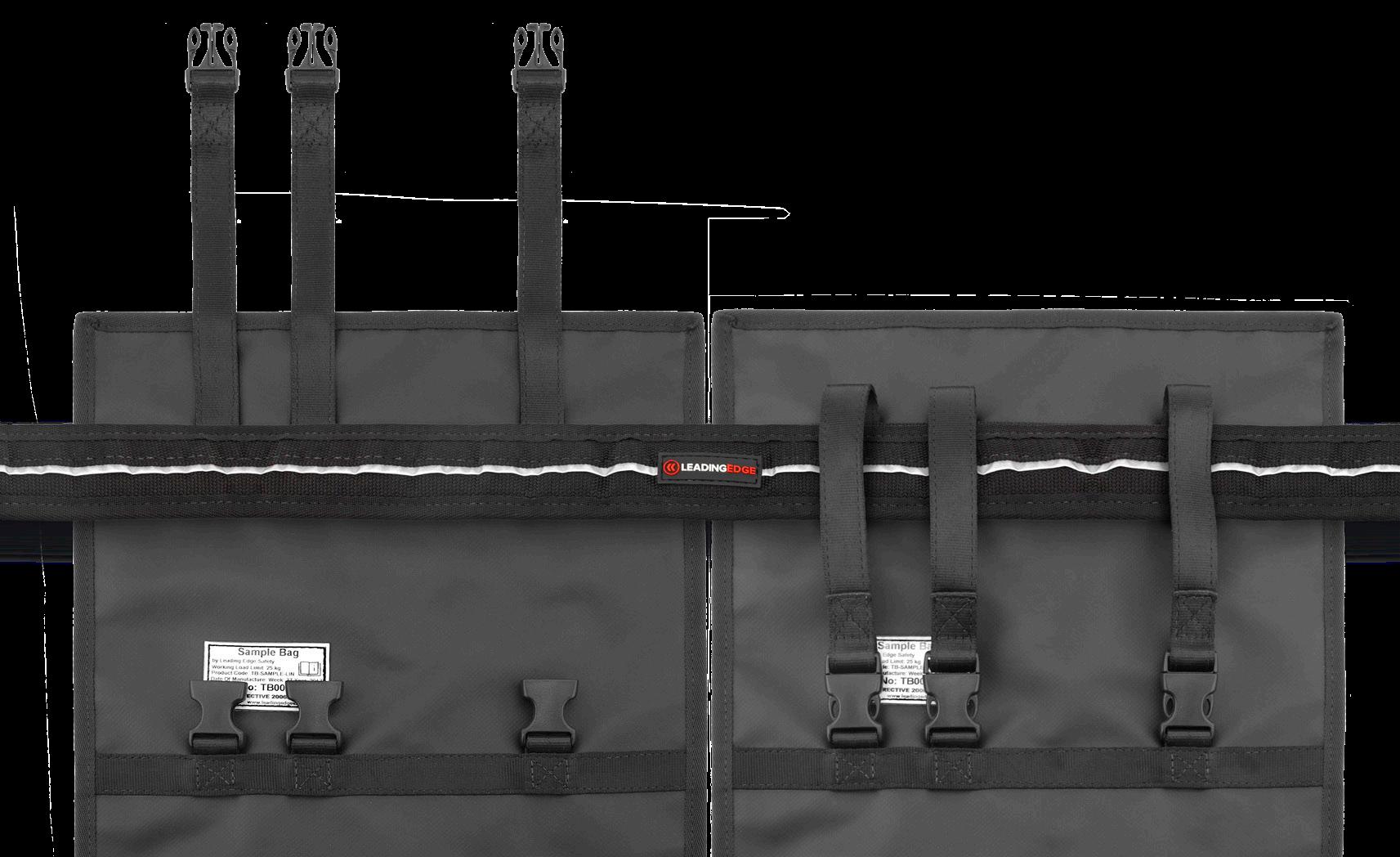

15-35mm Height Safety PRODUCTS KITS PRODUCTS